Abstract

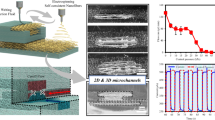

Printed transistors have a wide range of applications, but the limited resolution of printing techniques (10–30 µm) has been a barrier to utility and scalability. Printed submicrometre channel lengths have previously been achieved. However, this has required chemical processes or tedious post-processing, which limits applicability. Here we show that capillary flow printing can create submicrometre carbon nanotube thin-film transistors without chemical modification or physical manipulation after printing. We show that the approach can be used to print conducting, semiconducting and insulating inks on different types of substrate (silicon, Kapton and paper), and can be used to fabricate various thin-film transistor device architectures. The printed carbon nanotube thin-film transistors exhibit on-currents of 1.12 mA mm−1 when back gated on Si/SiO2 and 490 µA mm−1 when side gated through ion gel on Kapton. We also show that devices printed on Kapton offer mechanical bending and sweep rate resilience, illustrating the potential of these printed devices for flexible applications.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$32.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to the full article PDF.

USD 39.95

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Hegab, H., Khanna, N., Monib, N. & Salem, A. Design for sustainable additive manufacturing: a review. Sustain. Mater. Technol. 35, 576 (2023).

Harrington, E., Dhople, S., Wang, X., Choi, J. & Koester, S. Sustainability for semiconductors. Issues Sci. Technol. 39, 42–43 (2022).

Williams, N. X., Bullard, G., Brooke, N., Therien, M. J. & Franklin, A. D. Printable and recyclable carbon electronics using crystalline nanocellulose dielectrics. Nat. Electron. 4, 261–268 (2021).

Ruberti, M. The chip manufacturing industry: environmental impacts and eco-efficiency analysis. Sci. Total Environ. 858, 159873 (2023).

Lu, S., Smith, B. N., Meikle, H., Therien, M. J. & Franklin, A. D. All-carbon thin-film transistors using water-only printing. Nano Lett. 23, 2100–2106 (2023).

Street, R. A. Thin-film transistors. Adv. Mater. 21, 2007–2022 (2009).

Schnittker, K., Tursunniyaz, M. & Andrews, J. B. Recent advances in printable carbon nanotube transistors for large-area active matrices. J. Inf. Disp. 22, 193–209 (2021).

Doherty, J. L. et al. Liquid crystal displays with printed carbon-based recyclable transistor backplanes. IEEE Electron Device Lett. 45, 2427–2430 (2024).

Khan, Y. et al. A new frontier of printed electronics: flexible hybrid electronics. Adv. Mater. 32, 1905279 (2020).

Geng, D. et al. Thin-film transistors for large-area electronics. Nat. Electron. 6, 963–972 (2023).

Lu, S. et al. Flexible, print-in-place 1D-2D thin-film transistors using aerosol jet printing. ACS Nano 13, 11263–11272 (2019).

Shulaker, M. M. et al. Three-dimensional integration of nanotechnologies for computing and data storage on a single chip. Nature 547, 74–78 (2017).

Thomas, S. R., Pattanasattayavong, P. & Anthopoulos, T. D. Solution-processable metal oxide semiconductors for thin-film transistor applications. Chem. Soc. Rev. 42, 6910–6923 (2013).

Rigas, G. P. et al. Spray printing of organic semiconducting single crystals. Nat. Commun. 7, 13531 (2016).

Li, J., Naiini, M. M., Vaziri, S., Lemme, M. C. & Östling, M. Inkjet printing of MoS2. Adv. Funct. Mater. 24, 6524–6531 (2014).

Brunetti, I. et al. Inkjet-printed low-dimensional materials-based complementary electronic circuits on paper. npj 2D Mater. Appl. 5, 85 (2021).

Lu, S. & Franklin, A. D. Printed carbon nanotube thin-film transistors: progress on printable materials and the path to applications. Nanoscale 12, 23371–23390 (2020).

Lau, P. H. et al. Fully printed, high performance carbon nanotube thin-film transistors on flexible substrates. Nano Lett. 13, 3864–3869 (2013).

Franklin, A. D., Hersam, M. C. & Wong, H.-S. S. P. Carbon nanotube transistors: making electronics from molecules. Science 378, 726–732 (2022).

Zorn, N. F. & Zaumseil, J. Charge transport in semiconducting carbon nanotube networks. Appl. Phys. Rev. 8, 041318 (2021).

Zaumseil, J. Single-walled carbon nanotube networks for flexible and printed electronics. Semicond. Sci. Technol. 30, 074001 (2015).

Derby, B. Inkjet printing of functional and structural materials: fluid property requirements, feature stability, and resolution. Annu. Rev. Mater. Res. 40, 395–414 (2010).

Lohse, D. Fundamental fluid dynamics challenges in inkjet printing. Annu. Rev. Fluid Mech. 54, 349–382 (2021).

Chen, G., Gu, Y., Tsang, H., Hines, D. R. & Das, S. The effect of droplet sizes on overspray in aerosol-jet printing. Adv. Eng. Mater. 20, 1701084 (2018).

Sun, J. et al. Fully R2R-printed carbon-nanotube-based limitless length of flexible active-matrix for electrophoretic display application. Adv. Electron. Mater. 6, 1901431 (2020).

Homenick, C. M. et al. Fully printed and encapsulated SWCNT-based thin film transistors via a combination of R2R gravure and inkjet printing. ACS Appl. Mater. Interfaces 8, 27900–27910 (2016).

Grau, G., Kitsomboonloha, R. & Subramanian, V. Fabrication of a high-resolution roll for gravure printing of 2 µm features. In Proc. SPIE Organic Field-Effect Transistors XIV; and Organic Sensors and Bioelectronics VIII 9568, 95680M (SPIE, 2015).

Grau, G., Scheideler, W. J. & Subramanian, V. High-resolution gravure printed lines: proximity effects and design rules. In Proc. SPIE Printed Memory and Circuits 95690B (SPIE, 2015)

Grubb, P. M., Subbaraman, H., Park, S., Akinwande, D. & Chen, R. T. Inkjet printing of high performance transistors with micron order chemically set gaps. Sci. Rep. 7, 1202 (2017).

Noh, Y. Y., Zhao, N., Caironi, M. & Sirringhaus, H. Downscaling of self-aligned, all-printed polymer thin-film transistors. Nat. Nanotechnol. 2, 784–789 (2007).

Sele, C. W., Von Werne, T., Friend, R. H. & Sirringhaus, H. Lithography-free, self-aligned inkjet printing with sub-hundred-nanometer resolution. Adv. Mater. 17, 997–1001 (2005).

Tseng, H.-Y. Scaling of Inkjet-Printed Transistors Using Novel Printing Techniques. PhD thesis, Univ. California, Berkeley (2011).

Lee, J. H. et al. Large-scale direct patterning of aligned single-walled carbon nanotube arrays using dip-pen nanolithography. Chem. Mater. 28, 6471–6476 (2016).

Park, S., Wang, W. M. & Bao, Z. Parallel fabrication of electrode arrays on single-walled carbon nanotubes using dip-pen-nanolithography-patterned etch masks. Langmuir 26, 6853–6859 (2010).

Ding, H., Barg, S. & Derby, B. Direct 3D printing of graphene using capillary suspensions. Nanoscale 12, 11440–11447 (2020).

Leonard, B. et al. A systematic printability study of direct ink writing towards high-resolution rapid manufacturing. Int. J. Extrem. Manuf. 5, 035002 (2023).

Kowalczewski, P. et al. Novel approach to print submicron conductive lines: from the fundamental process to the laboratory printer. In 2018 International Flexible Electronics Technology Conference (IFETC) 1–4 (IEEE, 2018).

Ma, S., Dahiya, A. S. & Dahiya, R. Direct write 3D-printed interconnects for heterogenous integration of ultra thin chips. In IEEE International Conference on Flexible and Printable Sensors and Systems (FLEPS) 1–4 (IEEE, 2022).

Lewis, A. et al. Fountain pen nanochemistry: atomic force control of chrome etching. Appl. Phys. Lett. 75, 2689–2691 (1999).

Hong, M. H., Kim, K. H., Bae, J. & Jhe, W. Scanning nanolithography using a material-filled nanopipette. Appl. Phys. Lett. 77, 2604–2606 (2000).

Frisbie, C. D. et al. Self-aligned capillarity-assisted printing of high aspect ratio flexible metal conductors: optimizing ink flow, plating, and mechanical adhesion. Ind. Eng. Chem. Res. 59, 22107–22122 (2020).

Hyun, W. J. et al. Scalable, self-aligned printing of flexible graphene micro-supercapacitors. Adv. Energy Mater. 7, 1700285 (2017).

Song, D. Self-aligned capillary-assisted printing of bottom-gate electrolyte-gated transistors on plastic. ACS Appl. Electron. Mater. 2, 725–731 (2020).

Zhang, M. et al. Bio-Inspired differential capillary migration of aqueous liquid metal ink for rapid fabrication of high-precision monolayer and multilayer circuits. Adv. Funct. Mater. 33, 2215050 (2023).

Kim, K.-H. et al. Massively parallel multi-tip nanoscale writer with fluidic capabilities—Fountain Pen Nanolithography (FPN). In Proc. 4th International Symposium on MEMS and Nanotechnology 235–238 (IEEE, 2003)

Meister, A., Liley, M., Brugger, J., Pugin, R. & Heinzelmann, H. Nanodispenser for attoliter volume deposition using atomic force microscopy probes modified by focused-ion-beam milling. Appl. Phys. Lett. 85, 6260–6262 (2004).

Pascual, M. et al. All-printed SU8-perovskite DFB laser. In Proc. SPIE Advanced Fabrication Technologies for Micro/Nano Optics and Photonics XVI 124330E (SPIE, 2023).

Fabié, L. et al. Direct patterning of nanoparticles and biomolecules by liquid nanodispensing. Nanoscale 7, 4497–4504 (2015).

Kim, K. H. et al. Direct delivery and submicrometer patterning of DNA by a nanofountain probe. Adv. Mater. 20, 330–334 (2008).

Kahng, S. J. et al. Nanoink bridge-induced capillary pen printing for chemical sensors. Nanotechnology 29, 335304 (2018).

Wu, B., Ho, A., Moldovan, N. & Espinosa, H. D. Direct deposition and assembly of gold colloidal particles using a nanofountain probe. Langmuir 23, 9120–9123 (2007).

Yeshua, T. et al. Micrometer to 15 nm printing of metallic inks with fountain pen nanolithography. Small 14, 1702324 (2018).

Onoue, M., Fujita, M. & Ushijima, H. Wide area patterning of organic silane molecules by fountain-pen nanolithography. Mol. Cryst. Liq. Cryst. 505, 118/[356]–123/[361] (2009).

Fang, A., Dujardin, E. & Ondarçuhu, T. Control of droplet size in liquid nanodispensing. Nano Lett. 6, 2368–2374 (2006).

Grüter, R. R., Vörös, J. & Zambelli, T. FluidFM as a lithography tool in liquid: spatially controlled deposition of fluorescent nanoparticles. Nanoscale 5, 1097–1104 (2013).

Kang, B. et al. Fully drawn all-organic flexible transistors prepared by capillary-pen printing on flexible planar and curvilinear substrates. Adv. Electron. Mater. 1, 1500301 (2015).

Strain, K. M. et al. Direct deposition of aligned single walled carbon nanotubes by fountain pen nanolithography. Mater. Express 1, 279–284 (2011).

Yeshua, T. et al. Nanodrawing of aligned single carbon nanotubes with a nanopen. Nano Lett. 16, 1517–1522 (2016).

Xi, M. et al. High-performance thin-film transistors based on aligned carbon nanotubes for mini- and micro-LED displays. Carbon 218, 118718 (2024).

Guitton, A. et al. Capillary printing of fine structures on flexible and hybrid substrates. In IEEE International Conference on Flexible and Printable Sensors and Systems (FLEPS) 1–4 (IEEE, 2024).

Davis, E. J. & Ray, A. K. Determination of diffusion coefficients by submicron droplet evaporation. J. Chem. Phys. 67, 414–419 (1977).

Nafday, O. A., Vaughn, M. W. & Weeks, B. L. Evidence of meniscus interface transport in dip-pen nanolithography: an annular diffusion model. J. Chem. Phys. 125, 144703 (2006).

Moldovan, N., Kim, K. H. & Espinosa, H. D. A multi-ink linear array of nanofountain probes. J. Micromech. Microeng. 16, 1935 (2006).

Ye, S., Williams, N. X. & Franklin, A. D. Aerosol jet printing of SU-8 as a passivation layer against ionic solutions. J. Electron. Mater. 51, 1583–1590 (2022).

Smith, B. N. et al. Ionic dielectrics for fully printed carbon nanotube transistors: impact of composition and induced stresses. Nanoscale 14, 16845–16856 (2022).

Gabbett, C. et al. Understanding how junction resistances impact the conduction mechanism in nano-networks. Nat. Commun. 15, 4517 (2024).

Jang, H. K. et al. Electrical percolation thresholds of semiconducting single-walled carbon nanotube networks in field-effect transistors. Phys. Chem. Chem. Phys. 17, 6874–6880 (2015).

Lee, J. et al. Ion gel-gated polymer thin-film transistors: operating mechanism and characterization of gate dielectric capacitance, switching speed, and stability. J. Phys. Chem. C 113, 8972–8981 (2009).

Hyun, W.-J. et al. Printed, self-aligned side-gate organic transistors with a sub-5 µm gate–channel distance on imprinted plastic substrates. Adv. Electron. Mater. 2, 1600293 (2016).

Lee, K. H., Zhang, S., Lodge, T. P. & Frisbie, C. D. Electrical impedance of spin-coatable ion gel films. J. Phys. Chem. B 115, 3315–3321 (2011).

Robin, M. et al. Overcoming electrochemical instabilities of printed silver electrodes in all-printed ion gel gated carbon nanotube thin-film transistors. ACS Appl. Mater. Interfaces 11, 41531–41543 (2019).

Albarghouthi, F. M., Williams, N. X., Doherty, J. L., Lu, S. & Franklin, A. D. Passivation strategies for enhancing solution-gated carbon nanotube field-effect transistor biosensing performance and stability in ionic solutions. ACS Appl. Nano Mater. 5, 15865–15874 (2022).

Singh, J. P., Chu, H., Abell, J., Tripp, R. A. & Zhao, Y. Flexible and mechanical strain resistant large area SERS active substrates. Nanoscale 4, 3410–3414 (2012).

Yang, M. et al. Mechanical and environmental durability of roll-to-roll printed silver nanoparticle film using a rapid laser annealing process for flexible electronics. Microelectron. Reliab. 54, 2871–2880 (2014).

Glushko, O., Klug, A., List-Kratochvil, E. J. W. & Cordill, M. J. Monotonic and cyclic mechanical reliability of metallization lines on polymer substrates. J. Mater. Res. 32, 1760–1769 (2017).

Kim, B. J. et al. Improving mechanical fatigue resistance by optimizing the nanoporous structure of inkjet-printed Ag electrodes for flexible devices. Nanotechnology 25, 125706 (2014).

Chen, J. et al. Thin dielectric-layer-enabled low-voltage operation of fully printed flexible carbon nanotube thin-film transistors. Nanotechnology 31, 235301 (2020).

Song, D. et al. All-printed, self-aligned carbon nanotube thin-film transistors on imprinted plastic substrates. ACS Appl. Mater. Interfaces 10, 15926–15932 (2018).

Cardenas, J. A., Lu, S., Williams, N. X., Doherty, J. L. & Franklin, A. D. In-place printing of flexible electrolyte-gated carbon nanotube transistors with enhanced stability. IEEE Electron Device Lett. 42, 367–370 (2021).

Zhao, J. et al. Fabrication and electrical properties of all-printed carbon nanotube thin film transistors on flexible substrates. J. Mater. Chem. 22, 20747–20753 (2012).

Yu, M. et al. Fully printed flexible dual-gate carbon nanotube thin-film transistors with tunable ambipolar characteristics for complementary logic circuits. ACS Nano 12, 11572–11578 (2018).

Cao, X. et al. Screen printing as a scalable and low-cost approach for rigid and flexible thin-film transistors using separated carbon nanotubes. ACS Nano 8, 12769–12776 (2014).

Oh, H. et al. Inkjet-printing-based density profile engineering of single-walled carbon nanotube networks for conformable high-on/off-performance thin-film transistors. ACS Appl. Mater. Interfaces 13, 43163–43173 (2021).

Kim, J., Chen, Y., Lee, S. & Jang, J. A novel gate driver working under depletion mode oxide TFTs using low-temperature poly-Si oxide TFTs. IEEE Electron Device Lett. 42, 1619–1622 (2021).

Acknowledgements

This work was supported by the National Institutes of Health (NIH) under award number 1R01HL146849 (A.D.F.) and from the National Science Foundation under award number CMMI 2245265 (A.D.F.). B.N.S. acknowledges support from the National Science Foundation Graduate Research Fellowship under grant number 2139754. This work was performed in part at the Duke University Shared Materials Instrumentation Facility (SMIF), which is a member of the North Carolina Research Triangle Nanotechnology Network (RTNN), and is supported by the National Science Foundation (grant ECCS-1542015) as part of the National Nanotechnology Coordinated Infrastructure (NNCI). The content presented in this paper represents the views of the authors and does not necessarily represent the views of the funding organizations.

Author information

Authors and Affiliations

Contributions

B.N.S., F.M.A. and A.D.F. conceived of the study. B.N.S., F.M.A., J.L.D., X.P., Q.M., M.S. and D.B. fabricated and tested the devices. B.N.S. and F.M.A. contributed to figure design and data analysis. M.P., P.B., N.B. and A.M. contributed to AgNP ink development and print conditions for the submicrometre features. A.D.F. provided scientific guidance and supervised the project. B.N.S., F.M.A. and A.D.F. wrote the paper with revision and approval from all authors.

Corresponding author

Ethics declarations

Competing interests

M.P., P.B., N.B. and A.M. are employees of Hummink, which develops and sells the NAZCA capillary flow printer. The other authors declare no competing interests.

Peer review

Peer review information

Nature Electronics thanks Seungjun Chung, Jianwen Zhao and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data

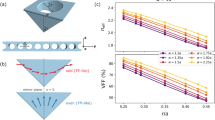

Extended Data Fig. 1 Overview of capillary flow printing.

(a) Schematic of micropipette on tuning fork with a ~ 1.5 kHz resonance frequency. (b) Representative amplitude versus frequency shift of the pipette in and out of contact with the substrate, showing a ~ 3 Hz frequency shift when in contact with the substrate. (c) Schematic highlighting the ability of pipette to deposit ink over raised topologies due to the macroresonator detecting surface topology and piezoelectric moving the pipette to account for topology changes.

Extended Data Fig. 2 Effect of CNT ink concentration on CFP CNT-TFTs.

Subthreshold curves for five bottom-contacted, back-gated CNT-TFTs (on Si/SiO2) with CNT ink concentrations of (a) 50 µg/ml, (b) 37.5 µg/ml, and (c) 25 µg/ml printed at 50 µm/s and rinsed in toluene, showing the importance of higher CNT concentrations.

Extended Data Fig. 3 CNT density analysis.

(a-c) SEM images of CNT thin films printed with CFP on silicon. Bottom images set to binary using ImageJ to determine printed CNT density, averaging 54% CNT surface coverage in channel region. (d) SEM image of CNT thin film printed on silicon showing a channel width, Wch = 15.5 µm.

Extended Data Fig. 4 Extended benchmarking data for fully printed CNT-TFTs with Ag source and drain contacts.

Benchmarking plots of (a) width-normalized on-current vs channel length, (b) width-normalized on-current vs VDS, and (c) VDS vs Lch. Data for CNT-TFTs in this figure can be found in Extended Data Table 1.

Extended Data Fig. 5 Top gating CFP CNT-TFTs through CNC.

(a) Subthreshold curves at different VDS revealing the optimal VDS for CNC is −0.5 V. (b) Subthreshold characteristics depending on gate voltage sweep rate. (c) Hysteresis characteristics depending on gate voltage sweep rate. The subthreshold curves corresponding to 20 mV/s, 47 mV/s, 60 mV/s, and 88 mV/s sweep rates are shifted by −2 V, −1 V, 1 V, and 2 V, respectively, to make variations between sweeps visible. (d) Extracted hysteresis plotted as a function of sweep rate. (e) Image of top-gated CNT-TFT through CNC, where source, drain, and channel were CFP-printed and CNC and top gate were AJP-printed for all CNC top-gated devices. (f) Profilometry of AJP-printed CNC film.

Supplementary information

Supplementary Information

Supplementary Figs. 1–7 and Table 1.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Smith, B.N., Albarghouthi, F.M., Doherty, J.L. et al. Capillary flow printing of submicrometre carbon nanotube transistors. Nat Electron 8, 1027–1037 (2025). https://doi.org/10.1038/s41928-025-01470-7

Received:

Accepted:

Published:

Version of record:

Issue date:

DOI: https://doi.org/10.1038/s41928-025-01470-7

This article is cited by

-

Breaking the submicrometre barrier of printed electronics

Nature Electronics (2025)