Abstract

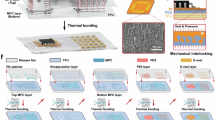

Conformal electronics are of use in the development of wearable and biointegrated devices. However, existing methods of creating such electronics can lead to a lack of mechanical robustness, are limited in their range of materials or require specialized equipment and complex procedures. Here we report a heat-shrinking method for fabricating conformal electronics in which semi-liquid metal circuits are patterned onto thermoplastic substrates and then heated to induce shrinkage around a target object. We develop a semi-liquid metal that can withstand shrinkage deformation and maintain long-term electrical stability. We also develop simulation tools to consider the effect of the thermoplastic film’s deformation on the final circuit pattern, which allows precise circuit designs to be created on the initially planar film. The resulting shape-adaptive electronics exhibit high durability, with minimal conductivity change after 5,000 bending and twisting cycles. We illustrate the potential of the method by creating circuits for de-icing model aircraft, robot tactile sensors, fruit temperature and humidity sensors, fingertip pulse sensors, and smart bandages.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$32.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to the full article PDF.

USD 39.95

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

Source data are provided with this paper. Other data that support the findings of this study are available from the corresponding authors upon reasonable request.

Code availability

The codes used in this study are provided with this paper.

References

Dai, Y. et al. Stretchable transistors and functional circuits for human-integrated electronics. Nat. Electron. 4, 17–29 (2021).

Luo, Y. et al. Learning human–environment interactions using conformal tactile textiles. Nat. Electron. 4, 193–201 (2021).

Wang, Z. et al. Conformal in-ear bioelectronics for visual and auditory brain-computer interfaces. Nat. Commun. 14, 4213 (2023).

Wang, C. et al. Monitoring of the central blood pressure waveform via a conformal ultrasonic device. Nat. Biomed. Eng 2, 687–695 (2018).

Liu, S. et al. 3D conformal fabrication of piezoceramic films. Adv. Sci. 9, 2106030 (2022).

Tan, H. et al. 3D printed electronics: processes, materials and future trends. Prog. Mater. Sci. 127, 100945 (2022).

Jo, Y. et al. Form-factor free 3D copper circuits by surface-conformal direct printing and laser writing. Adv. Funct. Mater. 30, 2004659 (2020).

Ershad, F. et al. Ultra-conformal drawn-on-skin electronics for multifunctional motion artifact-free sensing and point-of-care treatment. Nat. Commun. 11, 3823 (2020).

Ai, J. et al. Laser direct-writing lithography equipment system for rapid and µm-precision fabrication on curved surfaces with large sag heights. Opt. Express 26, 20965–20974 (2018).

Ye, D. et al. Large-scale direct-writing of aligned nanofibers for flexible electronics. Small 14, 1703521 (2018).

Jiang, Y. et al. Transient charge-driven 3D conformal printing via pulsed-plasma impingement. Proc. Natl Acad. Sci. USA 121, e2402135121 (2024).

Yi, N. et al. Fabricating functional circuits on 3D freeform surfaces via intense pulsed light-induced zinc mass transfer. Mater. Today 50, 24–34 (2021).

Zheng, B. et al. Direct freeform laser fabrication of 3D conformable electronics. Adv. Funct. Mater. 33, 2210084 (2023).

Zhao, P. et al. Transfer-printing of insoluble conducting polymer for soft 3D conformal all-organic transistors. Small 20, 2309263 (2024).

Sim, K. et al. Three-dimensional curvy electronics created using conformal additive stamp printing. Nat. Electron. 2, 471–479 (2019).

Rao, Z. et al. Microprinting on curved surfaces with sugar. Matter 6, 671–673 (2023).

Liu, J. et al. Self-healing kirigami assembly strategy for conformal electronics. Adv. Funct. Mater. 32, 2109214 (2021).

Jiang, C. et al. Patterned liquid-metal-enabled universal soft electronics (PLUS-E) for deformation sensing on 3D curved surfaces. ACS Appl. Mater. Interfaces 17, 51958–51970 (2023).

Xu, H. et al. A fully integrated, standalone stretchable device platform with in-sensor adaptive machine learning for rehabilitation. Nat. Commun. 14, 7769 (2023).

Yang, K. et al. Conformal, stretchable, breathable, wireless epidermal surface electromyography sensor system for hand gesture recognition and rehabilitation of stroke hand function. Mater. Des. 243, 113029 (2024).

Yin, L. et al. A stretchable epidermal sweat sensing platform with an integrated printed battery and electrochromic display. Nat. Electron. 5, 694–705 (2022).

Zhu, J. et al. Direct laser processing and functionalizing PI/PDMS composites for an on-demand, programmable, recyclable device platform. Adv. Mater. 36, 2400236 (2024).

Wang, S. et al. Intrinsically stretchable electronics with ultrahigh deformability to monitor dynamically moving organs. Sci. Adv. 8, eabl5511 (2022).

Wang, C. et al. Materials and structures toward soft electronics. Adv. Mater. 30, e1801368 (2018).

Ma, X. et al. Stretchable and skin-attachable electronic device for remotely controlled wearable cancer therapy. Adv. Sci. 10, 2205343 (2023).

Shi, Y. et al. Freestanding serpentine silicon strips with ultrahigh stretchability over 300% for wearable electronics. Adv. Mater. 36, 2313603 (2024).

Fan, J. A. et al. Fractal design concepts for stretchable electronics. Nat. Commun. 5, 3266 (2014).

Yin, H. et al. Structures and materials in stretchable electroluminescent devices. Adv. Mater. 34, 2106184 (2022).

Kim, T. et al. Realizing stretchable OLEDs: a hybrid platform based on rigid island arrays on a stress-relieving bilayer structure. Adv. Mater. Technol. 5, 2000494 (2020).

Xue, Z. et al. Assembly of complex 3D structures and electronics on curved surfaces. Sci. Adv. 8, 6922 (2022).

Li, H. et al. Breathable and skin-conformal electronics with hybrid integration of microfabricated multifunctional sensors and kirigami structured manofibrous substrates. Adv. Funct. Mater. 32, 2202792 (2022).

Chen, X. et al. Wrap-like transfer printing for three-dimensional curvy electronics. Sci. Adv. 9, 0357 (2023).

Koo, J. et al. A vacuum-deposited polymer dielectric for wafer-scale stretchable electronics. Nat. Electron. 6, 137–145 (2023).

Xue, Y. et al. Stretchable, ultratough, and intrinsically self-extinguishing elastomers with desirable recyclability. Adv. Sci. 10, 2207268 (2023).

Zhang, J. et al. Transparent, ultra-stretching, tough, adhesive carboxyethyl chitin/polyacrylamide hydrogel toward high-performance soft electronics. Nano-Micro Lett. 15, 8 (2022).

Hao, S. et al. Low-temperature tolerance and conformal adhesion zwitterionic hydrogels as electronic skin for strain and temperature responsiveness. Chem. Eng J. 431, 133782 (2022).

Yang, G. et al. Tunable hydrogel electronics for diagnosis of peripheral neuropathy. Adv. Mater. 36, 2308831 (2023).

Cheng, J. et al. Wet-adhesive elastomer for liquid metal-based conformal epidermal electronics. Adv. Funct. Mater. 32, 2200444 (2022).

Chen, S. et al. Liquid metal composites. Matter 2, 1446–1480 (2020).

Guo, S. et al. Flexible liquid metal coil prepared for electromagnetic energy harvesting and wireless charging. Front. Energy 13, 474–482 (2019).

Yun, I. et al. Transferable transparent electrodes of liquid metals for bifacial perovskite solar cells and heaters. Nano Energy 93, 106857 (2022).

Li, F. et al. Ultra-conformable liquid metal particle monolayer on air/water interface for substrate-free E-tattoo. npj Flex. Electron. 7, 31 (2023).

Li, Y. et al. A highly stretchable and permeable liquid metal micromesh conductor by physical deposition for epidermal electronics. ACS Appl. Mater. Interfaces 14, 13713–13721 (2022).

Ding, L. et al. In situ deposition of skin-adhesive liquid metal particles with robust wear resistance for epidermal electronics. Nano Lett. 22, 4482–4490 (2022).

Wu, H. et al. Fabrication techniques for curved electronics on arbitrary surfaces. Adv. Mater. Technol. 5, 2000093 (2020).

Choi, J. et al. Customizable, conformal, and stretchable 3D electronics via predistorted pattern generation and thermoforming. Sci. Adv. 7, eabj0694 (2021).

Xiao, Y. et al. Miniaturized flexible non-contact interface based on heat shrinkage technology. Small Methods 7, 2300316 (2023).

Meyyappan, K. et al. Gallium-based liquid-metal alloys: challenges and risk management in high-humidity environments. Adv. Eng. Mater. 26, 2400399 (2024).

Acknowledgements

We thank H. Li from Tsinghua University for her assistance in formatting the paper. This work is supported by the National Natural Science Foundation of China under grant numbers 62304150 (R.G.), 52121002 (X.H.), 62371335 (X.H.), 62371335 (H.W.) and 52301193 (H.W.).

Author information

Authors and Affiliations

Contributions

C.J. designed the different shape-adaptive electronics. C.J., W.L., Z.W., K.W., B.P., H.Z., X.L., J.L., B.Y., T.L. and X.T. participated in the preparation of different shape-adaptive electronics. C.J. performed the experiments and simulations. Q.W. wrote the code for deep learning. All photographic and diagrammatic content in the figures and Supplementary Information was created and composed by C.J., R.G. and H.W. The individual featured in Supplementary Video 8 is C.J. R.G., H.W. and X.H. conceived, designed and directed the project. R.G., H.W. and C.J. wrote the paper with input from all authors.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Electronics thanks Huanyu Cheng, Navid Hussain and Qian Zhao for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–42 and Table 1.

Supplementary Video 1

Shrinkage of the thermoplastic film during slow heating in a water bath.

Supplementary Video 2

Thermoplastic films with a Cu-EGaIn pattern shrinks onto a spherical surface.

Supplementary Video 3

Water bath heating shrinks the thermoplastic film onto different objects.

Supplementary Video 4

Hot air heating shrinks the thermoplastic film onto a metal ball.

Supplementary Video 5

Infrared video of water bath shrinkage and hot air shrinkage.

Supplementary Video 6

Demonstration of 3D electronics on different objects.

Supplementary Video 7

Infrared video recording of the heating circuit in operation on the model airplane.

Supplementary Video 8

Flight demonstration of an airplane model equipped with 3D electronics.

Supplementary Video 9

Smart bandage lights up as a warning when an external force is applied.

Supplementary Video 10

Demonstration of the robot tactile sensors.

Supplementary Code 1

CNN algorithm for object classification.

Source data

Source Data Fig. 2

Statistical source data.

Source Data Fig. 3

Statistical source data.

Source Data Fig. 4

Statistical source data.

Source Data Fig. 5

Statistical source data.

Source Data Fig. 6

Statistical source data.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jiang, C., Li, W., Wu, Q. et al. Shape-adaptive electronics based on liquid metal circuits printed on thermoplastic films. Nat Electron 9, 45–58 (2026). https://doi.org/10.1038/s41928-025-01528-6

Received:

Accepted:

Published:

Version of record:

Issue date:

DOI: https://doi.org/10.1038/s41928-025-01528-6

This article is cited by

-

Heat-shrinkable conformal electronics

Nature Reviews Materials (2026)