Abstract

Extreme high-pressure generation beyond the Earth’s central pressure is currently achieved by static compression. The high-pressure technology is a key not only for the condensed matter physics but also for the earth and planetary science to understand the interior of planets larger than the Earth such as gas/ice giants and exoplanets. On the other hand, how to determine the pressure generated is another fundamental issue. There are many kinds of pressure standards, and their mutual consistency under extreme pressure conditions is not yet known. Here we report the volumetric (density) interrelationships of seven metals (Fe, Cu, Mo, W, Re, Pt, Au) and two non-metal materials (MgO, NaCl) based on simultaneous static compression experiments up to ~430 GPa, including previously reported static compression experiments. Present results reveal the fact that even on latest pressure scales by shock-less dynamic compression studies not all of them necessarily agree within the error limit under extreme high-pressure conditions. Our internally consistent equations of state bridge various extreme pressure sciences and realize comprehensive discussions.

Similar content being viewed by others

Introduction

The crystal structure and physical properties of materials change significantly under high pressure. From the perspective of deep earth and planetary science, since the deeper part of the planetary interior is under the higher-pressure environment, the experimental technique to generate higher pressures enables us to study the interior of deeper and/or larger planets. The internal pressure of gas/ice giant planets and super-Earths far exceeds the Earth’s central pressure at which interesting phenomena are expected, such as various crystallographic phase transitions in silicate and oxides1,2,3,4, formation of new composite materials (e.g., H3O5), and metallization of hydrogen6,7,8,9 and water10, and some of them have been confirmed by static and/or dynamic compression experiments10,11. Especially the metallization of hydrogen is a very important research subject not only in planetary science but also in condensed matter physics as a room temperature superconductor. Therefore, the generation of pressure exceeding Earth’s central pressure (hereafter, extreme pressure) is a key technique for high pressure physics, although it is not easy. The maximum pressure is limited to around 300–400 GPa when we use the conventional diamond anvil cell (DAC) which is widely used as a high-pressure apparatus in static compression12. As alternative techniques, the toroidal type of DAC (t-DAC) and the double-stage DAC (ds-DAC) were developed to generate extreme pressure13,14,15,16,17,18,19,20. In most cases of static experiments, the experimental pressure is determined from an equation of state (EoS) of a standard material which is called a pressure scale. Recently some primary pressure scales (copper, platinum, gold, and iron) were reported based on dynamic compression experiments21,22,23. The shockless ramp-compression used in these studies is one of the techniques to constrain the isotherm pressure scales because the error in a thermal correction is much smaller than that in a shock compression. Therefore, the copper pressure scale21 was used as a standard to construct the international practical pressure scale for ruby (IPPS-Ruby2020)24, while the gold scale22 was used to calibrate the diamond-Raman gauge25, which is commonly used in hydrogen research.

Many primary pressure scales for various materials have been proposed based on shock experiments26,27,28, ultrasonic and/or Brillouin scattering measurements29,30,31, and ab initio calculations32. On the other hand, mutual consistency of these scales of different materials can be confirmed by the static compression experiment. Simultaneous static compression experiments of two or three materials combining with the X-ray diffraction (XRD) measurements give us information on the volume–volume (V–V) (or density–density (ρ–ρ)) relationship of the sample. The V–V data enables us to check the consistency of each EoS, and to calibrate a new EoS for a given primary scale. At pressures up to 100–250 GPa, many efforts have been made to construct an internally consistent scale through simultaneous compression for metals, oxides, alkali-halides, and noble gas33,34,35,36. However, even these internally consistent equations of state become inconsistent when extrapolated beyond the pressure range of the experiment. Even for a single material, for example magnesium oxide (MgO), large discrepancies can arise in extrapolated pressure regions (>300 GPa) due to the lack of experimental data, depending on the type of equation of state chosen37. Recently proposed pressure scales (Fe, Cu, Pt, Au) based on ramp compression21,22,23 are expected to be consistent with each other in wide pressure range reaching tera-pascal (TPa), but their consistency should be confirmed by simultaneous static compression experiments.

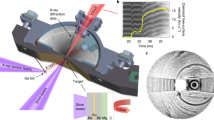

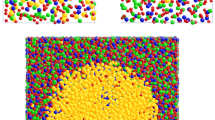

Here we report the internally consistent equations of state for Cu, Re, Pt, W, Au, Mo, Fe, MgO based on the copper scale21 and the result of static compression experiments up to about 430 GPa using t-DAC and the laser-heated DAC (LHDAC). Static extreme high-pressure experiments were conducted by using t-DAC for run #1a-#6, conventional DAC for run #1b, and the LHDAC for run #7a, #7b, and #7c. Culet size and sample combination of each run is summarized in Table 1. The scanning electron microscopic (SEM) image of a toroidal anvil is shown in Supplementary Fig. S1. In all t-DAC experiments (run #1a-#6), metal samples (reagent grade, 99.9–99.99%) in disc shape were made by a focused ion beam (FIB) system and stacked each other, and then filled in the sample chamber made on gasket as shown in Supplementary Fig. S2a-l. No pressure medium was used in t-DAC experiments. In runs #7a, #7b and #7c, the platinum was embedded in magnesium oxide, and repeatedly annealed up to ~2000 K during compression by using the laser heating optics at SPring-8, BL10XU. The lattice volume of each sample at high pressure and ambient temperature condition was measured by XRD experiments which were conducted at SPring-8 BL10XU and BL37XU (For detail, see “Methods” section). Combining with previous compression studies’ results36,38,39,40, the EoS of NaCl in B2 phase (NaCl-B2) was also calibrated. These EoSs provide the V–V relationships among these materials, and it allow various pressure scales to be compared with each other, and to assess whether discussions in condensed matter physics and earth and planetary sciences are valid in terms of pressure values.

Results

Calibration path of each EoS

All sample combinations were compressed to >300 GPa. Highest pressure of 431 GPa was achieved in run #1a (Cu + Re). Representative XRD profiles of each run at relatively low pressure and high pressure are shown in Supplementary Figs. S3 and S4, respectively. The volume data observed in this study are summarized in Supplementary Data 1 (Tables S1–S7). Each EoS was calibrated according to the calibration path as shown in Fig. 1. The copper scale21 was used as a primary scale. In addition to present results, the compression data of previous studies19,33,36,38,39,40,41,42,43,44,45,46,47,48,49 described in Fig. 1 were also used in the EoS fitting (These are also summarized in Supplementary Data 1, Table S8). The results of experiments using the ruby fluorescence method33,34,41,42,43,44 were included as data under relatively low-pressure conditions. All pressures by Ruby-scale were recalculated based on IPPS-Ruby202024. Consistency between the copper scale and IPPS-Ruby2020 can be confirmed by the compression data of Dewaele et al. 33 as shown in Supplementary Fig. S5. As described above, the EoS of NaCl in B2 phase (NaCl-B2) was also calibrated using simultaneous compression data of Pt–NaCl36,38,39, Au–NaCl36 and MgO–NaCl36. The compression data of the other combinations, W–Fe45, Pt–MgO46, NaCl–Fe47,48, MgO–Au49 by the conventional DAC, and Re–Au13 by t-DAC are also included.

The arrow from material “A” to “B” means that the EoS of “B” was calibrated using the EoS of “A” as a pressure calibrant. Pressure calibrants are also described in parentheses. For example, in the case of rhenium, Re EoS was calibrated using three kinds of data, 1st one is compression data of Cu–Re (Run #1a and #1b), the 2nd is compression data of W-Re41, and the 3rd is the data based on Ruby scale41. Used data also summarized in Supplementary Data 1, Table S8.

Generally, 3rd order Birch–Murnaghan (3BM) EoS and Rydberg–Vinet (R–V) EoS are widely used to express the pressure (\(P\))–volume (\(V\)) relationship. Higher order form of those and/or AP2 EoS model50 are also used for the higher-pressure conditions. Here we adopted the following EoS model for present experimental data.

\({V}_{0}\), \({K}_{0}\), and \({K}_{0}^{{\prime} }\) is volume, bulk modulus and its pressure derivative at zero-pressure, respectively. This model51,52 is given by a simple modification from the R–V EoS, hereafter we call this the generalized Rydberg–Stacey (R–S) EoS. The key point of this formula is that \({K}_{\infty }^{{\prime} }\) (pressure derivative of bulk modulus at infinite pressure) is included as an adjustable parameter. The R–S EoS is very useful because it behaves very similarly to the R–V, AP2 and 3BM, when \({K}_{\infty }^{{\prime} }\) = 2/3, 5/3, 3, respectively (\({K}_{\infty }^{{\prime} }\) = 2/3 is completely same as R–V model). Thus, the R–S EoS with \({K}_{\infty }^{{\prime} }\) = 5/3 can be used as an alternative to the AP2 model without using a parameter related to the Fermi gas pressure. During the fitting process, the zero-pressure volume (\({V}_{0}\)) and bulk modulus (\({K}_{0}\)) were fixed to the values in literatures except for high pressure phases (NaCl-B2 and Fe-hcp), and \({K}_{\infty }^{{\prime} }\) was fixed to 5/3 (Table 2). The reference point of NaCl B1–B2 transition based on the ultra-sonic measurement40 was adopted as a fixed point in EoS fitting. Table 2 summarizes the R–S EoS parameters of 7 metals, MgO and NaCl-B2 phase. For convenience, the copper pressure scale21 was also converted to R–S EoS model. The R–S EoS for Cu was fitted to the data up to 1.2 TPa, and the EoS agreed with the original scale21 within the pressure difference of 0.1 GPa (the volume difference of 0.005 Å3 per unit cell) up to 1.2 TPa as shown in Supplementary Fig. S5.

Compression curve of rhenium

Figure 2a shows the experimental compression data up to ~430 GPa and R–S EoS curve of rhenium based on the copper pressure scale21. The pressures of previous compression data41 based on Ruby scale and W scale were recalculated by ISSP-Ruby2020 scale and W EoS of this study, respectively, and these data were included in the Re EoS fitting.

a Blue circles and diamonds are experimental observations of this study using t-DAC (run #1a) and conventional DAC (run #1b), respectively. Pressure is based on the copper scale21. Solid curve, orange and blue dotted curves are R–S EoS of this study, R–V EoS from Anzellini et al.41, and R–V EoS from Rech et al.53, respectively. The measured errors in the lattice volume are shown in the figure. b Volume differences relative to R–S EoS model. The result for each 3BM, R–V, AP2 EoS is also plotted as green, blue broken curve and orange dash-dot curve, respectively. The other symbols and curves are the same in Fig. 2a. Here, ΔV = 0.10 Å3 per unit cell (shaded area) is corresponding to the pressure difference of 10 GPa at around 400 GPa. Source data are provided in Supplementary Data 1 (Table S1), and the pressure can be calculated by using EoS parameters in Table 2 (R–S EoS) and Supplementary Data 1, Table S10 (3BM, R–V, AP2 EoS).

The Re EoSs in R–V form reported in the previous experimental study41 and the theoretical study53 are also shown in Fig. 2a. Note that Fig. 2a is drawn for the absolute value of the volume, not relative to the zero-pressure volume. These EoSs are consistent with present result within 0.2% in volume at multi-megabar condition as shown in Fig. 2b. Interestingly, even when extrapolated to 1.5 TPa, the volume (pressure) difference between our R–S EoS and the theoretical calculation53, which examined up to 1.5 TPa, is only 0.3% in volume (1.1% in pressure).

Compression curve of iron

Figure 3a shows the compression data of iron. There are three kinds of data set based on different pressure calibration paths as shown in Fig. 1. One is the path of Cu–Re–Pt–NaCl–Fe47,48, and the 2nd is the path of Cu–W–Fe (Run #6 and Dewaele et al.45), and the 3rd is the data based on Ruby scale34,43,44. Despite the different paths of calibration (in other words, the possibility that the results of multiple error propagation may affected), they are in good agreement, with most of the data agreeing within 0.3% in volume as shown in Fig. 3b. The isothermal compression curve proposed by the ramp compression experiment23 is also consistent with present result within 0.1–0.2% in volume at Earth’s core conditions (136–364 GPa). Even when extrapolated to 1.4 TPa, the volume (pressure) difference between our R–S EoS and Smith et al.23 is only 1.1% (3.7%). This remarkable coincidence indicates that the mass-radius relation for an iron planet, which a hypothetical planet consisting of entirely iron discussed in Smith et al.23, is also supported by the copper scale21 without significant contradiction.

a Blue circles and open diamonds are experimental observations of this study using t-DAC (Run #6) and conventional DAC45 based on W scale, respectively. Open circles and squares are the compression data based on NaCl-B2 scale47,48. Crosses, pluses and asterisks are the compression data based on Ruby scale34,43,44. All pressures were recalculated by EoSs proposed in this study and ISSP-Ruby2020. Solid and dotted orange curves are R–S EoS of this study, R–V EoS from Smith et al. 23, respectively. In most cases, the error of unit cell volume for iron was not determined due to the limitations of measured peak numbers (see Methods section and Supplementary Data 1, Table S6). b Volume differences relative to R–S EoS model. Here, ΔV = 0.10 Å3 per unit cell (shaded area) is corresponding to the pressure difference of 14 GPa at around 400 GPa. Source volume data are provided in Supplementary Data 1 (Table S6) and the pressure can be calculated by using EoS parameters in Table 2.

V–V relationship between copper and rhenium

The experimental volume–volume (V–V) data of copper and rhenium are shown in Fig. 4, together with a V–V relationship (solid line in Fig. 4) between copper and rhenium. This V–V relationship is obtained using EoS parameters of both Cu and Re in Table 2. This relationship itself is independent of the pressure scale and is useful for intercomparison of equations of state. In principle, the slope of this curve is the ratio of the bulk modulus between copper and rhenium, and this information should also be an important constraint in obtaining a more reliable pressure scale.

a Blue circles and diamonds are the measured volume ratio using t-DAC (run #1a) and conventional DAC (run #1b), respectively. Pressure markers corresponding to 50–500 GPa based on the copper scale21 are shown at top of the figure. Solid curve shows V–V relation which is pressure-scale free information. Source data are provided in Supplementary Data 1 (Table S1 and S9). b Volume difference from the V–V relation curve for rhenium. Symbols are the same in (a). The measured errors in the lattice volume are shown in the figure.

EoSs and V–V relationship of nine materials

EoSs of nine materials (Fe, Cu, Mo, W, Re, Pt, Au, MgO, NaCl) are shown in Fig. 5a. The experimental data plot for each material can be found in Supplementary Fig. S6. The maximum pressure (minimum volume) observed in the experiment is indicated by the open circles for each color. These maximum pressures were reached by present study, except for gold which has been achieved by Dewaele et al.13. These EoSs are the internally consistent EoSs which have been calibrated by the copper scale21 according to the calibration path shown in Fig. 1. The internally consistent EoSs provide us the V–V relationship between these materials as shown in Fig. 5b. The volumes of each material corresponding to a given volume of copper are also summarized in Supplementary Data 1, Table S9. The experimental data on V–V plot for each run are shown in Supplementary Fig. S7. For convenience, EoSs calculation sheet is available as Supplementary Data 2.xlsx file.

a Compression curves of 9 individual materials based on R–S EoS. Open circles in each color show the maximum pressure condition measured in the static compression experiment. Solid circle on NaCl curve shows the reference point corresponding to the pressure and volume in B2 at the B1–B2 transition. All EoS parameters are summarized in Table 2. b V/V0 of each material with respect to V/V0 of copper. Pressure markers corresponding to 50–1000 GPa are shown at top of the figure. Source data of all V–V relationships are provided in Supplementary Data 1 (Table S9).

The volume deviation from the V–V curve and/or each EoS is also found in t-DAC experiments at lower pressure conditions especially. This phenomenon was also discussed by Dewaele et al.13, and it is thought to be caused by the inhomogeneous stress distribution during the rapid pressure increase in Stage II of the t-DAC experiment. Although the data of Dewaele et al.13 was used for the EoS fitting of gold, the low-pressure data below 200 GPa was excluded as mentioned in the caption of Supplementary Fig. S6. The t-DAC experiments’ data points in present study (Run #1a, #2, #3, #4, #5, #6) at relatively lower pressure were included in EoS fittings but the EoS fitting result was not affected so much by these data because \({V}_{0}\) and \({K}_{0}\) were fixed in most cases, and due to the lower data density relative to the data set from previous studies. On the other hand, at relatively higher pressure, the relative scatter of data collected in different studies under various pressurizing conditions decreases above 200 GPa in the case of Fe (Fig. 3ab). It shows that the stress distribution in the t-DAC is getting relatively homogeneous in Stage III13 of the t-DAC experiment.

It is important to evaluate the error propagation through the 2nd, 3rd … calibration shown in Fig. 1. One method is to compare data from different calibration passes, which is discussed in the Fe EoS section. The other method is to compare the present result and the V–V data obtained directly by simultaneous compression. One example is the simultaneous compression result of molybdenum and platinum54. Akahama et al.54 reported the unit cell parameters of a(Mo) = 2.6530(12) Å and a(Pt) = 3.3777(14) Å at highest pressure which originally reported as 410 GPa. According to present R–S EoSs, these values correspond to 375 ± 2 GPa and 377 ± 2 GPa, respectively, they are consistent within the error, although the pressure dropped in the present case of the copper scale calibration.

From the present V–V table, we can obtain the V–V relationship between any two materials. Especially, the combination of gold and platinum is important because these have been used as pressure reference materials in many studies to date. In this study, the EoS for gold and platinum were calibrated through independent calibration paths, but the V–V relationship between gold and platinum can also be drawn. The validity of this relationship is supported by recent direct volume simultaneous measurement results55 as shown in the Supplementary Fig. S8ab. The volume differences of gold from the V–V curve were about –0.1 Å3 per unit cell at 200–300 GPa (Supplementary Fig. S8b). It corresponds to the pressure difference of about 4–5 GPa.

Furthermore, simultaneous compression data for copper and molybdenum using t-DAC has been reported56. Supplementary Fig. S9 shows a comparison of the Mo R–S EoS in present study and the compression data from their six experiments. Here, pressure values have been recalculated by the copper scale21. There is some scatter in the data below 150 GPa, but above 150 GPa their data is in good agreement with our EoS. Note that for pressures below 150 GPa our Mo R–S EoS have adopted compression data using the ruby or MgO scale in a He pressure medium34,36.

Discussion

The intercomparison of primary scales

The comparison of primary scales based on the ramp compression experiment is shown in Fig. 6. Here the pressure difference relative to the copper scale21 (∆P) was calculated as follows. \(\Delta P=P({V}_{(P)},{{{\rm{Pt}}}}/{{{\rm{Au}}}}/{{{{\rm{Fe}}}}\; {{{\rm{EoS}}}}})-P({V}_{(P)},{{{{\rm{Cu}}}}\; {{{\rm{EoS}}}}})\), where V(P) is the volume at pressure of P which based on the copper scale, and P(VP) is the pressure at the volume of V(P) based on each EoS. For example, when the volume of Cu is V/V0 = 0.600, V/V0 = 0.694 is given for the relative volume of Pt according to the V–V relationship of present result (see Supplementary Data 1, Table S9). In this case, the pressure is 250 GPa by the Cu R–S EoS, whereas the Pt scale of ref. 22. with V/V0 = 0.694 yields 262 GPa, and ∆P becomes 12 GPa. Note that if you use the Pt R–S EoS, it gives the same pressure value as the copper scale because the V–V relationship is derived from the R–S EoS itself. Shaded areas indicate upper/lower limit of the copper and platinum scales which corresponds to 3% pressure error. Pressure difference of gold22 and iron23 scale relative to the copper scale21 is within the 3% uncertainty, although the platinum scale22 yields relatively higher pressure about ~7% at 400–500 GPa. Although the error propagated from present EoS parameter’s error (the error of \({K}_{0}^{{\prime} }\)) is a few GPa under extreme pressure condition, the fluctuation of the actual measured volume values with respect to the EoS curve corresponds to the pressure difference of 5–10 GPa (~2% in pressure) as shown in Figs. 2b and 3b. Even if considering the error of present experiments, the platinum scale seems to be higher with respect to the copper scale21 exceeding the error range. As discussed above, the simultaneous volume measurement of platinum and gold55 shows that the volumes of gold slightly smaller than present V–V relationship (Supplementary Fig. S8b). Although the difference reaches about −0.2 Å3 per unit cell (~10 GPa) at highest pressure conditions, even when taking this difference into account, it does not explain the pressure difference of >20 GPa with the platinum scale at around 400 GPa. It is possible to say that pressure scales (copper, platinum, gold, and iron) reported based on dynamic compression experiments21,22,23 agree within each error range up to 300 GPa. But above 400 GPa, the difference between platinum and the other scales is expected to be larger. The copper, gold, and iron scale are consistent within 3% error even in extrapolation to 1 TPa, but the pressure difference of platinum reached ~10%. The reason for this discrepancy for platinum is not clear here, but it may be necessary to reconsider the correction process for thermal and/or viscoelastic effects in a dynamic compression experiment of platinum.

Solid, dashed, dotted, and dash-dot curves correspond to Cu21, Fe23, Au, and Pt22, respectively. Shaded areas show ~3% error (upper and lower) of Cu and Pt scale, respectively. The pressure difference can be calculated by using the V–V relationship (Supplementary Data 1, Table S9) and EoS parameters in literatures21,22,23.

Diamond-Raman scale

Raman spectrum from diamond anvil tip is also widely used to determine the pressure in DAC experiments, and it is called the diamond-Raman scale. The advantage is that the pressure can be determined from the anvil itself, so there is no need to enclose a pressure standard material, which is often used for hydrogen experiments8,9. However, because the diamond-Raman scale has been calibrated by the EoS of a reference material, the scale also shows deviation depending on the reference material selected. Recently the new diamond-Raman scale25 calibrated by gold scale22 was proposed. Previous work of the diamond-Raman scale57,58 used platinum scale based on early shock experiment27 originally. This data was recalibrated by using the recent platinum scale22, although, there is a pressure difference between gold and platinum calibration, and the diamond-Raman scale calibrated by platinum22 yields 10–15% higher pressure than that by gold22 at around 400 GPa. This tendency is consistent with our XRD study as shown in Fig. 6.

The pressure dependency of Diamond Raman edge is expressed as follows25,57: \(P=A(\Delta \omega /{\omega }_{0})+B{\left(\Delta \omega /{\omega }_{0}\right)}^{2}\), where \({\omega }_{0}\) is the initial position of the diamond Raman spectrum edge, ∆ω is the shift of the Raman edge at the culet of the diamond anvil under a high pressure condition, A and B are the fitting parameters, respectively. Using the present R–S EoS for gold, the diamond Raman gauge can be modified as a diamond scale that conforms to the copper scale21. The pressure values25 were recalculated by the R–S EoS of gold, and fitted to the equation above, and it yields A = 491.7 ± 0.7 GPa and B = 814 ± 2 GPa (\({\omega }_{0}\) = 1332.5 cm-1 was used as a fixed value during the fitting). The modified diamond Raman scale agrees well with that of Eremets et al.25 within a few GPa, and the pressure difference is only 1 GPa at 400 GPa. Thus, the phase diagram of hydrogen proposed by Eremets et al.25 does not change so much even using the copper scale, because the R–S EoS for gold agree with the gold scale proposed by the ramp compression experiment22 within a few GPa as shown in Fig. 6.

Comparison with theoretical MgO scale

Magnesium oxide is one of the most intensively studied materials because it is the most fundamental component of rocky planets. Unified analysis using various pressure-scale-free experimental data sets, such as thermal expansion, shock compression data and sound velocity measurements for MgO, has been examined to establish the primary pressure scale using 3BM, R–V37 and AP2, Keane EoS model (Referred in Sakai et al.59). Although EoS dependence is large under extreme pressure conditions due to the limitation of high pressure data at that time37, the difference between 3BM and R–V EoS was remarkably reduced in present study as shown in Supplementary Fig. S10. In the cases of the AP2 and Keane EoS models37 considering \({K}_{\infty }^{{\prime} }\), these show good agreement to the present R–S EoS. Subsequently, the optimized scales were proposed in a similar manner for several materials using AP2 EoS model60. Their MgO scale, corrected using statically compressed data up to 250 GPa36, also shows remarkable agreement with the present R–S EoS. Furthermore, recent ab initio results up to 1 TPa61 also show very good agreement at 400–500 GPa in the case of PBEsol. It should also be noted that even at 1 TPa, the agreement is within 1%. On the other hand, the ab initio result with auxiliary-field quantum Monte Carlo (AFQMC) model yields slightly higher (~3%) pressure than the present R–S EoS at 400–500 GPa.

EoS formulae and its parameters

In this study, we adopted R–S EoS with \({K}_{\infty }^{{\prime} }\) = 5/3. According to the argument of Stacey62, \({K}_{\infty }^{{\prime} }\) = 5/3 is the thermodynamic minimum value for solids. AP2 EoS and R–S EoS with \({K}_{\infty }^{{\prime} }\) = 5/3 yield intermediate results between the 3BM and R–V models. If we adopt 3BM and R–V models to rhenium, the fitting yields \({K}_{0}^{{\prime} }\) = 4.271(8) and 4.553(8), respectively. This range corresponds to \({K}_{\infty }^{{\prime} }\) = 2/3 (R–V) ~3 (3BM). To estimate a plausible \({K}_{\infty }^{{\prime} }\), additional ab initio calculations up to 1 TPa (0 K) were performed for rhenium (see Supplementary Information, Supplementary method of the ab initio calculation section for detail). R–S EoS fitting to the ab initio calculations’ results yields \({K}_{\infty }^{{\prime} }\) = 2.60 (GGA), 2.41 (LDA), 2.62 (PBEsol), respectively. If we use \({K}_{\infty }^{{\prime} }\) = 2.62 as a fixed value with respect to the present experimental result, it yields \({K}_{0}^{{\prime} }\) = 4.274(10), which means that there is a trade-off relationship between \({K}_{0}^{{\prime} }\) and \({K}_{\infty }^{{\prime} }\), i.e., \({K}_{0}^{{\prime} }\) decreases when \({K}_{\infty }^{{\prime} }\) increases. The pressure difference between the case of \({K}_{\infty }^{{\prime} }\) = 5/3 and 2.62 is less than 0.2 % at ~400 GPa for rhenium. Compression curves and EoS parameters are summarized in Supplementary Fig. S11 and Supplementary Data 1, Table S10. Using the ab initio (PBEsol) P-V data set, we confirmed the pressure range dependency on the determination of \({K}_{\infty }^{{\prime} }\). It revealed that the P–V data from 0 to 400 GPa is not enough to determine \({K}_{\infty }^{{\prime} }\) value, the P-V data up to at least 700 GPa is needed for the \({K}_{\infty }^{{\prime} }\) value to converge to around 2.6 (see Supplementary Fig. S12 and Supplementary Data 1, Table S11). This result means that it is difficult to determine \({K}_{\infty }^{{\prime} }\) value only from static experiment data, at least for rhenium. The present study focused mainly on the EoS behavior at 200–500 GPa region and determine \({K}_{0}^{{\prime} }\) only by fixing the other parameters for the experimental data. The volume (\({V}_{0}\)) and the bulk modulus at zero pressure (\({K}_{0}\)) should be determined from the precise measurement at ambient or relatively low-pressure condition. On the other hand, the determination of \({K}_{0}^{{\prime} }\) needs the volume data at wide pressure range, and it should be discussed with \({K}_{\infty }^{{\prime} }\). The raw data at TPa regime obtained by the first-principles calculation would be of great help in estimating \({K}_{\infty }^{{\prime} }\). In future, it is desirable to determine \({K}_{\infty }^{{\prime} }\) value of each material taking account thermal effects, pressure range dependence of volume data, and its data density, etc.

Conclusion

Here we provided a preliminary reference volume–volume (V–V) data of 9 materials (Cu, Re, Pt, W, Au, Mo, Fe, MgO, and NaCl), which is very useful information for extreme pressure science in the 300–500 GPa region. The result indicates that the equations of state for copper, gold, and iron agree within 3% pressure error but only that of platinum yields relatively higher pressure about 6–8% at 300–500 GPa. The equations of state based on the copper scale show remarkable consistency with the theoretical studies for rhenium and magnesium oxide even at 1 TPa. The interrelationship between these volumes is important because it not only allows them to be compared with each other on any pressure scale but also provides an internally consistent set of scales immediately. The present 9 R–S EoSs, and IPPS-Ruby2020 scale and the modified diamond Raman gauge, are internally consistent and can bridge various extreme pressure sciences and realize comprehensive discussions. Extending the internally consistent model to silicates and oxides, H2O and H2 would help to estimate more accurate internal structure models of exoplanets.

Present t-DAC compression experiments have been conducted at ambient temperature condition. To reduce the experimental errors, it will be necessary to combine laser annealing with t-DAC experiments to mitigate the effects of non-hydrostatic pressure, but it is still a challenging technique. Furthermore, it goes without saying that direct volume measurement above 500 GPa by static compression is highly desirable to confirm the consistency of each scale as discussed above. The technique of t-DAC has a big potential to generate above 500 GPa regime, but most trials remain under 500 GPa. According to present EoS set based on the copper scale, the maximum pressure generated by previous t-DAC studies change to 60913 (Re), 47825 (Au), 435 GPa14 (Re), from the original values reported as 603, 477, 615 GPa, respectively (the last case’s big drop is mainly due to the pressure overestimation of Re EoS used in the study (for detail, see refs. 19,41,63). Even in the most successful case, only one experiment exceeded 600 GPa, and the others were limited up to ~440 GPa13. The advantage of t-DAC is that it can routinely generate ~400 GPa exceeding the Earth’s central pressure and the limit of the conventional DAC. But it seems that there is a technical barrier at around 450 GPa at which the diamond anvil breaks in most experiments. To overcome this limitation, optimization of culet size, bevel angle, tip height and flat area size is necessary, and the precision FIB machining techniques used in this study will help develop such static high-pressure generation techniques.

Methods

Diamond anvil and gasket

The toroidal anvil was processed by using a focused ion beam (FIB) system (Scios, FEI Ltd.) at Geodynamics research center (GRC), Ehime University. The anvil tip shape of each t-DAC experiment is shown in Supplementally Figure S1b. Rhenium gasket was used for all runs except for runs #7a, #7b and #7c in which tungsten gasket was used. The initial thickness of sample chamber for t-DAC experiments is approximately 12–14 μm. Conventional DACs (culet 100–300 μm) were also used for the measurements at relatively low-pressure conditions. In run #1b, glycerin was used as a pressure medium. Cu and Re disks (thickness values were 12 μm for Cu and 6 μm for Re, diameter was 24 μm for both Cu and Re, respectively) were prepared and stacked by using FIB. Sample chamber diameter was 90 μm and thickness was ~50 μm. In run #7a, #7b and #7c, platinum foil (thickness ~5 μm) was embedded in magnesium oxide which act as a thermal insulator during the laser-annealing at about 1500–2000 K. Sample chamber diameter was 1/3 of culet, and thickness was 15–40 μm. Sample configurations for all t-DAC experiments (run #1a-#6) are summarized in Supplementary Fig. S2a-l.

XRD and lattice volume measurements

XRD experiments were conducted at SPring-8 BL10XU and BL37XU. FWHM of X-ray beam was 0.7–1.0 μm (BL10XU) and 100 nm (BL37XU), respectively. X-ray wavelengths (λ = 0.4130-0.4153(4) Å) and film distance were calibrated by using ceria (CeO2) as a standard. Most of volume data of the face-centered cubic (fcc) metals (Cu, Pt, Au) were determined using 111 diffraction peak, because 111 peak is least sensitive to the non-hydrostatic effect. In the case of molybdenum, 200 peak was used in the same reason54. Some of them were determined using 2–4 peaks in which volume error was very small (see Supplementary Data 1, Tables S1–S7). Rhenium volume was determined using 3–5 peaks (100, 101, 110, and 102, 103). Tungsten volume was determined using 3–5 peaks (110, 200, 211 and 220, 210). For iron in a hexagonal-closed pack (hcp) structure phase, only two peaks (100 and 101) were used due to the limitations of measured peak numbers. Volume of magnesium oxide was determined by using 2–3 peaks. Representative XRD profiles of each run are summarized in Supplementary Figs. S3 and S4.

Stress analysis and pressure distribution

The uniaxial stress t was estimated for Pt, Au, and MgO in run #2, #4, and #7 using the gamma plot25,36,39,64 (see Supplementary Fig. S13). In the gamma plot, the stress t is expressed \(t=-3{M}_{1}/\left({M}_{0}\alpha S\right)\), here M0 and M1 are the intercept and slope of the gamma plot, α and S are the relative weight of the isostress and isostrain condition, and the elastic anisotropy parameter, respectively. We assumed α = 1 for calculation and used the elastic anisotropy parameter S of platinum65. The S of gold and magnesium oxide is estimated from the elastic stiffness constant \({C}_{{ij}}\)66,67 with using Birch extrapolation formulation36. Gamma plot at highest pressure condition in each run is also shown in Supplementary Fig. S13b–e. Although this plot of Pt in run #2 (Supplementary Fig. S13b) corresponds to relatively small t of −0.07 GPa, the data scattered relative to run #7a (Supplementary Fig. S13d). The pressure values calculated from each diffraction line 111, 200, 220, 311, 222 of Pt in run #2 are 389.2, 386.8, 384.4, 393.5, 388.0 GPa, respectively, and the average and standard deviation is 388.4 ± 3.4 GPa. The S values for molybdenum and tungsten can be estimated by using the elastic stiffness constant \({C}_{{ij}}\)68 with using Birch extrapolation formulation36, and these values are quite small above 100 GPa (10−4–10−5). Thus, the volumes of molybdenum and tungsten are not sensitive to the non-hydrostatic effect, and in other words, not suitable for the estimation of the uniaxial stress t.

Pressure distribution profiles of t-DAC (run #1a-#6) are shown in Supplementary Fig. S14. Pressure distribution was measured in 1 or 2 μm steps. The pressure fluctuations in the central 5 μm region are typically a few GPa. The pressure difference between the center tip and the surrounding flat part of t-DAC reached ~200 GPa at around 400 GPa. The pressure gradient on a convex slope reached ~45 GPa/μm in run #2 as shown in Supplementary Fig. S14b.

Data availability

The unit cell volume data for each run is summarized in Supplementary Data 1.xlsx. Data supporting the findings presented in this study are available from the corresponding author upon request.

References

Umemoto, K., Wentzcovitch, R. M. & Allen, P. B. Dissociation of MgSiO3 in the cores of gas giants and terrestrial exoplanets. Science 311, 983 (2006).

Umemoto, K. & Wentzcovitch, R. M. Prediction of an U2S3-type polymorph of Al2O3 at 3.7 Mbar. Proc. Natl Acad. Sci. USA 105, 6526–6530 (2008).

Umemoto, K. et al. Phase transitions in MgSiO3 post-perovskite in super-Earth mantles. Earth Planet. Sci. Lett. 478, 40–45 (2017).

Tsuchiya, T. & Tsuchiya, J. Prediction of a hexagonal SiO2 phase affecting stabilities of MgSiO3 and CaSiO3 at multimegabar pressures. Proc. Natl Acad. Sci. USA 108, 1252–1255 (2011).

Huang, P. et al. Stability of H3O at extreme conditions and implications for the magnetic fields of Uranus and Neptune. Proc. Natl Acad. Sci. USA 117, 5638–5643 (2020).

Eremets, M. I. & Troyan, I. A. Conductive dense hydrogen. Nat. Mater. 10, 927–931 (2011).

Eremets, M. I., Drozdov, A. P., Kong, P. P. & Wang, H. Semimetallic molecular hydrogen at pressure above 350GPa. Nat. Phys. 15, 1246–1249 (2019).

Eremets, M. I., Kong, P. P. & Drozdov, A. P. Metallization of hydrogen. Preprint at arXiv https://doi.org/10.48550/arXiv.2109.11104 (2021).

Loubeyre, P., Occelli, F. & Dumas, P. Synchrotron infrared spectroscopic evidence of the probable transition to metal hydrogen. Nature 577, 631–635 (2020).

Guarguaglini, M. et al. Laser-driven shock compression of “synthetic planetary mixtures” of water, ethanol, and ammonia. Sci. Rep. 9, 10155 (2019).

Coppari, F. Experimental evidence for a phase transition in magnesium oxide at exoplanet pressures. Nat. Geosci. 22, 926–929 (2013).

O’Bannon, E. F., Jenei, Z., Cynn, H., Lipp, M. J. & Jeffries, J. R. Contributed review: culet diameter and the achievable pressure of a diamond anvil cell: implications for the upper pressure limit of a diamond anvil cell. Rev. Sci. Instrum. 89, 111501 (2018).

Dewaele, A., Loubeyre, P., Occelli, F., Marie, O. & Mezouar, M. Toroidal diamond anvil cell for detailed measurements under extreme static pressures. Nat. Commun. 9, 2913 (2018).

Jenei, Z. et al. Single crystal toroidal diamond anvils for high pressure experiments beyond 5 megabar. Nat. Commun. 9, 3563 (2018).

Dubrovinsky, L. et al. Implementation of micro-ball nanodiamond anvils for high-pressure studies above 6 Mbar. Nat. Commun. 3, 9114 (2012).

Dubrovinsky, L. et al. The most incompressible metal osmium at static pressures above 750 gigapascals. Nature 525, 226–229 (2015).

Dubrovinskaia, N. et al. Terapascal static pressure generation with ultrahigh yield strength nanodiamond. Sci. Adv. 2, e1600341 (2016).

Sakai, T. et al. High-pressure generation using double stage micro-paired diamond anvils shaped by FIB. Rev. Sci. Inst. 86, 033905 (2015).

Sakai, T. et al. High pressure generation using double-stage diamond anvil technique: problems and equations of state of rhenium. High. Press. Res. 38, 107–119 (2018).

Sakai, T. et al. Conical support for double-stage diamond anvil apparatus. High. Press. Res. 40, 12–21 (2020).

Fratanduono, D. E. et al. Probing the solid phase of noble metal copper at terapascal conditions. Phys. Rev. Lett. 124, 015701 (2020).

Fratanduono, D. E. et al. Establishing gold and platinum standards to 1 terapascal using shockless compression. Science 372, 1063–1068 (2021).

Smith, R. F. et al. Equation of state of iron under core conditions of large rocky exoplanets. Nat. Astro 452, 452–458 (2018).

Shen, G. et al. Toward an international practical pressure scale: a proposal for an IPPS ruby gauge (IPPS-Ruby2020). High. Press. Res. 40, 299–314 (2020).

Eremets, M. I. et al. Universal diamond edge Raman scale to 0.5 terapascal and implications for the metallization of hydrogen. Nat. Commun. 4, 907 (2023).

Jamieson, J. C., Fritz, J. N. & Manghnani, M. H. Pressure measurement at high temperature in X-ray diffraction studies: gold as a primary standard. In High-Pressure Research in Geophysics. (eds S. Akimoto and M. H. Manghnani) 27–48, (Cent. for Acad. Publ, Tokyo, 1982).

Holmes, N. C., Moriarty, J. A., Gathers, G. R. & Nellis, W. J. The equation of state of platinum to 660 GPa (6.6 Mbar). J. Appl. Phys. 66, 2962–2967 (1989).

Yokoo, M. et al. Ultrahigh-pressure scales for gold and platinum at pressures up to 550 GPa. Phys. Rev. B 80, 104114 (2009).

Zha, C.-S., Mao, H.-K. & Hemley, R. J. Elasticity of MgO and a primary pressure scale to 55 GPa. Proc. Natl Acad. Sci. USA 97, 13494–13499 (2000).

Kono, Y., Irifune, T., Higo, Y., Inoue, T. & Barnhoorn, A. PVT relation of MgO derived by simultaneous elastic wave velocity and in situ X-ray measurements: a new pressure scale for the mantle transition region. Phys. Earth Planet. Inter. 183, 196–211 (2010).

Murakami, M. & Takata, N. Absolute primary pressure scale to 120 GPa: toward a pressure benchmark for Earth’s lower mantle. J. Geophys. Res. 124, 6581–6588 (2019).

Tsuchiya, T. First-principles prediction of the P-V-T equation of state of gold and the 660-km discontinuity in Earth’s mantle. J. Geophys. Res. 108, 2462 (2003).

Dewaele, A., Loubeyre, P. & Mezouar, M. Equations of state of six metals above 94 GPa. Phys. Rev. B 70, 094112 (2004).

Dewaele, A., Torrent, M., Loubeyre, P. & Mezouar, M. Compression curves of transition metals in the Mbar range: experiments and projector augmented-wave calculations. Phys. Rev. B 78, 104102 (2008).

Fei, Y. et al. Toward an internally consistent pressure scale. Proc. Natl Acad. Sci. USA 104, 9182–9186 (2007).

Dorfman, S. M., Prakapenka, V. B., Meng, Y. & Duffy, T. S. Intercomparison of pressure standards (Au, Pt, Mo, MgO, NaCl and Ne) to 2.5 Mbar. J. Geophys. Res. 117, B08210 (2012).

Tange, Y., Nishihara, Y. & Tsuchiya, T. Unified analyses for P-V-T equation of state of MgO: a solution for pressure-scale problems in high P-T experiments. J. Geophys. Res. 114, B03208 (2009).

Sata, N., Shen, G., Rivers, M. L. & Sutton, S. R. Pressure-volume equation of state of the high-pressure B2 phase of NaCl. Phys. Rev. B 65, 104114 (2002).

Sakai, T., Ohtani, E., Hirao, N. & Ohishi, Y. Equation of state of the NaCl-B2 phase up to 304 GPa. J. Appl. Phys. 109, 084912 (2011).

Matsui, M., Higo, Y., Okamoto, Y., Irifune, T. & Funakoshi, K. ‐I. Simultaneous sound velocity and density measurements of NaCl at high temperatures and pressures: application as a primary pressure standard. Am. Mineral. 97, 1670–1675 (2012).

Anzellini, A., Dewaele, A., Occelli, F., Loubeyre, P. & Mezouar, M. Equation of state of rhenium and application for ultra high pressure calibration. J. Appl. Phys. 115, 043511 (2014).

Takemura, K. & Dewaele, A. Isothermal equation of state for gold with a He-pressure medium. Phys. Rev. B 78, 104119 (2008).

Dewaele, A. et al. Mechanism of the α-ε phase transformation in iron. Phys. Rev. B 91, 174105 (2015).

Ishimatsu, N., Miyashita, D. & Kawaguchi, K. I. Strong variant selection observed in the α-ε martensitic transition of iron under quasihydrostatic compression along [111]α. Phys. Rev. B 102, 054106 (2020).

Dewaele, A. et al. Quasihydrostatic equation of state of iron above 2 Mbar. Phys. Rev. Lett. 97, 215504 (2006).

Dewaele, A., Fiquet, G., Andrault, D. & Hausermann, D. P-V-T equation of state periclase from synchrotron radiation measurements. J. Geophys. Res. 105, 2869–2877 (2000).

Sakai, T. et al. Equation of state of pure iron and Fe0.9Ni0.1 alloy up to 3 Mbar. Phys. Earth Planet. Int. 228, 114–126 (2014).

Fei, Y., Murphy, C., Shibazaki, Y., Shahar, A. & Huang, H. Thermal equation of state of hcp-iron: Constraint on the density deficit of Earth’s solid inner core. Geophys. Res. Lett. 43, 6837–6843 (2016).

Hirose, K., Sata, N., Komabayashi, T. & Ohishi, Y. Simultaneous volume measurements of Au and MgO to 140GPa and thermal equation of state of Au based on the MgO pressure scale. Phys. Earth Planet. Int. 167, 149–154 (2008).

Holzapfel, W. B. Equations of state for solids under strong compression. High Press. Res. 16, 81–126 (1998).

Stacey, F. D. High pressure equations of state and planetary interiors. Rep. Prog. Phys. 68, 341 (2005).

Stacey, F. D. & Davis, P. M. Physics of the Earth. (Cambridge Univ. Press, New York, 2008).

Rech, G. L., Zorzi, J. E. & Perottoni, C. A. Equation of state of hexagonal-close-packed rhenium in the terapascal regime. Phys. Rev. B 100, 174107 (2019).

Akahama, Y., Hirao, N., Ohishi, Y. & Singh, A. K. Equation of state of bcc-Mo by static volume compression to 410GPa. J. Appl. Phys. 116, 223504 (2014).

Zurkowski, C. C. et al. Exploring toroidal anvil profiles for larger sample volumes above 4 Mbar. Sci. Rep. 14, 11412 (2024).

Zurkowski, C. C. et al. Improving equations of state calibrations in the toroidal DAC—the case study of molybdenum. J. Appl. Phys. 136, 075901 (2024).

Akahama, Y. & Kawamura, H. Pressure calibration of diamond anvil Raman gauge to 310 GPa. J. Appl. Phys. 100, 043516 (2006).

Akahama, Y. & Kawamura, H. Pressure calibration of diamond anvil Raman gauge to 410 GPa. J. Phys. 215, 012195 (2010).

Sakai, T., Dekura, H. & Hirao, N. Experimental and theoretical thermal equations of state of MgSiO3 post-perovskite at multimegabar pressures. Sci. Rep. 6, 22652 (2016).

Sokolova, T. S., Dorogokupets, P. I. & Litasov, K. D. Self-consistent pressure scales based on the equations of state for ruby, diamond, MgO, B2–NaCl, as well as Au, Pt, and other metals to 4 Mbar and 3000 K. Russ. Geol. Geophys. 54, 181–199 (2013).

Zhang, S., Paul, R., Hu, S. X. & Morales, M. A. Toward an accurate equation of state and B1-B2 phase boundary for magnesium oxide up to terapascal pressures and electron-volt temperatures. Phys. Rev. B 107, 224109 (2023).

Stacey, F. D. The K-primed approach to high-pressure equations of state. Geophys. J. Int. 143, 621–628 (2000).

Kamada, S. et al. Elastic constants of single-crystal Pt measured up to 20 GPa based on inelastic X-ray scattering: Implication for the establishment of an equation of state. C. R. Geosci. 351, 236–242 (2019).

Singh, A. K. & Takemura, K. Measurement and analysis of nonhydrostatic lattice strain component in niobium to 145 GPa under various fluid pressure-transmitting media. J. Appl. Phys. 90, 3269–3275 (2001).

Menendez-Proupin, E. & Singh, A. K. Ab initio calculations of elastic properties of compressed Pt. Phys. Rev. B 76, 054117 (2007).

Tsuchiya, T. & Kawamura, H. Ab initio study of pressure effect on elastic properties of crystalline Au. J. Chem. Phys. 116, 2121–2124 (2002).

Karki, B. B. et al. Structure and elasticity of MgO at high pressure. Am. Mineral. 82, 51–60 (1997).

Katahara, K. W., Manghnani, M. H. & Fisher, E. S. Pressure derivatives of the elastic moduli of BCC Ti-V-Cr, Nb-Mo and Ta-W alloys. J. Phys. F 9, 773–790 (1979).

Holzapfel, W., Hartwig, M. & Sievers, W. Equations of state for Cu, Ag, and Au for wide ranges in temperature and pressure up to 500 GPa and above. J. Phys. Chem. Ref. Data 30, 515 (2001).

Daniels, W. & Smith, C. Pressure derivatives of the elastic constants of copper, silver, and gold to 10 000 bars. Phys. Rev. 111, 713 (1958).

Steinberg, D. Observations regarding the pressure dependence of the bulk modulus. J. Phys. Chem. Solids 43, 1173 (1982).

Simmons, G. & Wang, H. Single Crystal Elastic Constants and Calculated Aggregate Properties. (A Handbook MIT Press, Cambridge, MA, 1971).

Acknowledgements

We thank Yusuke Kara, Hideto Mimori, Keitaro Kuramochi and Dr. Naohisa Hirao for their assistance of XRD measurements. This work was supported by JSPS KAKENHI Grant Numbers 17H02985, 21K18155 and 20H05644. The synchrotron radiation experiments were performed at the BL10XU and BL37XU of SPring-8 with the approval of the Japan Society for the Promotion of Science [Proposal Nos. 2019A1736, 2019B1521, 2019B1528, 2020A1560, 2020A1510, 2021A1532, 2021B1549, and 2022A1566].

Author information

Authors and Affiliations

Contributions

T.S., H.K., Y.N., N.I., S.K., Y.S., O.S., K.N., and K.S. performed X-ray diffraction experiments at SPring-8. H.D. performed ab initio calculation. T.S., N.I., and H.D. contributed to the paper. T.S. wrote the paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Communications Materials thanks Guoyin Shen and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. Primary Handling Editors: Rostislav Hrubiak and Aldo Isidori. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Sakai, T., Kadobayashi, H., Nakamoto, Y. et al. The equations of state of nine materials up to 0.43 TPa for extreme pressure science. Commun Mater 6, 68 (2025). https://doi.org/10.1038/s43246-025-00792-5

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s43246-025-00792-5

This article is cited by

-

Pressure–temperature route from disordered BCC to a 2 × 2 × 2 B2 superstructure

Scientific Reports (2025)