Abstract

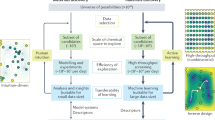

Accelerated materials discovery is critical for addressing global challenges. However, developing new laboratory workflows relies heavily on real-world experimental trials, and this can hinder scalability because of the need for numerous physical make-and-test iterations. Here we present MATTERIX, a multiscale, graphics processing unit-accelerated robotic simulation framework designed to create high-fidelity digital twins of chemistry laboratories, thus accelerating workflow development. This multiscale digital twin simulates robotic physical manipulation, powder and liquid dynamics, device functionalities, heat transfer and basic chemical reaction kinetics. This is enabled by integrating realistic physics simulation and photorealistic rendering with a modular graphics processing unit-accelerated semantics engine, which models logical states and continuous behaviors to simulate chemistry workflows across different levels of abstraction. MATTERIX streamlines the creation of digital twin environments through open-source asset libraries and interfaces, while enabling flexible workflow design via hierarchical plan definition and a modular skill library that incorporates learning-based methods. Our approach demonstrates sim-to-real transfer in robotic chemistry setups, reducing reliance on costly real-world experiments and enabling the testing of hypothetical automated workflows in silico.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$32.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to the full article PDF.

USD 39.95

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All data required to evaluate the presented conclusions are available within the Article and its Supplementary Information. All supporting data were generated using the MATTERIX code. Source data are provided with this paper.

Code availability

The code for MATTERIX is available via Zenodo at https://doi.org/10.5281/zenodo.17095671 (refs. 57,58,59,60,61,62,63) and via GitHub at https://github.com/AccelerationConsortium/Matterix.

Change history

12 January 2026

In the version of the article initially published, Kourosh Darvish’s third affiliation (Vector Institute, Toronto, Ontario, Canada) was missing and has now been added. Additionally, Hossein Darvish was incorrectly listed with two affiliations and is now listed with only one (University of Salento, Lecce, Italy). These corrections have been made to the HTML and PDF versions of the article.

References

Stein, H. S. & Gregoire, J. M. Progress and prospects for accelerating materials science with automated and autonomous workflows. Chem. Sci. 10, 9640–9649 (2019).

Tom, G. et al. Self-driving laboratories for chemistry and materials science. Chem. Rev. 124, 9633–9732 (2024).

Shiri, P. et al. Automated solubility screening platform using computer vision. iScience 24, 102176 (2021).

Coley, C. W. et al. A robotic platform for flow synthesis of organic compounds informed by AI planning. Science 365, eaax1566 (2019).

Darvish, K. et al. Organa: a robotic assistant for automated chemistry experimentation and characterization. Matter 8, 101897 (2025).

Burger, B. et al. A mobile robotic chemist. Nature 583, 237–241 (2020).

Lunt, A. M. et al. Modular, multi-robot integration of laboratories: an autonomous workflow for solid-state chemistry. Chem. Sci. 15, 2456–2463 (2024).

Li, J. et al. Autonomous discovery of optically active chiral inorganic perovskite nanocrystals through an intelligent cloud lab. Nat. Commun. 11, 2046 (2020).

Vriza, A., Chan, H. & Xu, J. Self-driving laboratory for polymer electronics. Chem. Mater. 35, 3046–3056 (2023).

Pelkie, B. et al. Democratizing self-driving labs through user-developed automation infrastructure. Preprint at ChemRxiv https://doi.org/10.26434/chemrxiv-2025-zhkrf (2025).

Mehr, S. H. M., Craven, M., Leonov, A. I., Keenan, G. & Cronin, L. A universal system for digitization and automatic execution of the chemical synthesis literature. Science 370, 101–108 (2020).

Tao, F., Zhang, H. & Zhang, C. Advancements and challenges of digital twins in industry. Nat. Comput. Sci. 4, 169–177 (2024).

Lu, Y. et al. Digital twin-driven smart manufacturing: connotation, reference model, applications and research issues. Robot. Comput. Integr. Manuf. 61, 101837 (2020).

Almeaibed, S., Al-Rubaye, S., Tsourdos, A. & Avdelidis, N. P. Digital twin analysis to promote safety and security in autonomous vehicles. IEEE Commun. Stand. Mag. 5, 40–46 (2021).

Li, Y. et al. Choose your simulator wisely: a review on open-source simulators for autonomous driving. IEEE Trans. Intell. Veh. 9, 4861–4876 (2024).

Laubenbacher, R., Mehrad, B., Shmulevich, I. & Trayanova, N. Digital twins in medicine. Nat. Comput. Sci. 4, 184–191 (2024).

Isaac Sim—robotics simulation and synthetic data generation. https://developer.nvidia.com/isaac/sim (NVIDIA Developer, 2025).

Mittal, M. et al. Orbit: a unified simulation framework for interactive robot learning environments. IEEE Robot. Autom. Lett. 8, 3740–3747 (2023).

Narang, Y. et al. Factory: fast contact for robotic assembly. In Proc. Robotics: Science and Systems Vol. 6 (2022).

Mamou, K. in Game Engine Gems 3 (ed. Lengyel, E.) 141–158 (AK Peters, 2016).

Raffin, A. et al. Stable-baselines3: reliable reinforcement learning implementations. J. Mach. Learn. Res. 22, 1–8 (2021).

Mandlekar, A. et al. What matters in learning from offline human demonstrations for robot manipulation. In Proc. 5th Conference on Robot Learning 1678–1690 (2022).

Makoviichuk, D. & Makoviychuk, V. rl-games: a high-performance framework for reinforcement learning. GitHub https://github.com/Denys88/rl_games (2021).

Rudin, N., Hoeller, D., Reist, P. & Hutter, M. Learning to walk in minutes using massively parallel deep reinforcement learning. In Proc. 5th Conference on Robot Learning Vol. 164, 91–100 (Proceedings of Machine Learning Research, 2022).

Serrano-Muñoz, A., Chrysostomou, D., Bøgh, S. & Arana-Arexolaleiba, N. skrl: modular and flexible library for reinforcement learning. J. Mach. Learn. Res. 24, 1–9 (2023).

Li, S. et al. Chemistry3d: robotic interaction benchmark for chemistry experiments. Preprint at https://arxiv.org/abs/2406.08160 (2024).

Kadokawa, Y., Hamaya, M. & Tanaka, K. Learning robotic powder weighing from simulation for laboratory automation. In Proc. 2023 IEEE/RSJ International Conference on Intelligent Robots and Systems 2932–2939 (2023).

Pizzuto, G. et al. Accelerating laboratory automation through robot skill learning for sample scraping. In Proc. 2024 IEEE 20th International Conference on Automation Science and Engineering 2103–2110 (2024).

Lopez-Guevara, T. et al. Stir to pour: efficient calibration of liquid properties for pouring actions. In Proc. 2020 IEEE/RSJ International Conference on Intelligent Robots and Systems 5351–5357 (2020).

Vescovi, R. et al. Towards a modular architecture for science factories. Digit. Discov. 2, 1980–1998 (2023).

Beeler, C. et al. Chemgymrl: a customizable interactive framework for reinforcement learning for digital chemistry. Digit. Discov. 3, 742–758 (2024).

Rihm, S. D. et al. The digital lab facility manager: automating operations of research laboratories through ‘the world avatar’. Nexus 1, 100031 (2024).

Mildenhall, B. et al. Nerf: Representing scenes as neural radiance fields for view synthesis. Commun. ACM 65, 99–106 (2021).

Zeng, A., Song, S., Lee, J., Rodriguez, A. & Funkhouser, T. Tossingbot: learning to throw arbitrary objects with residual physics. IEEE Transact. Robot. 36, 1307–1319 (2020).

Xu, Z., Wu, J., Zeng, A., Tenenbaum, J. B. & Song, S. DensePhysNet: learning dense physical object representations via multi-step dynamic interactions. In Proc. Robotics: Science and Systems (2019).

Openusd: Universal scene description v25.08 (Pixar Animation Studios and the OpenUSD community, 2025); https://openusd.org

Macklin, M. & Müller, M. Position based fluids. ACM Transact. Graph. 32, 1–12 (2013).

Sundaralingam, B. et al. Curobo: Parallelized collision-free robot motion generation. In 2023 IEEE International Conference on Robotics and Automation 8112–8119 (IEEE, 2023).

Wen, B., Yang, W., Kautz, J. & Birchfield, S. FoundationPose: unified 6D pose estimation and tracking of novel objects. In Proc. IEEE/CVF Conference on Computer Vision and Pattern Recognition 17868–17879 (2024).

Arrhenius, S. Über die dissociationswärme und den einfluss der temperatur auf den dissociationsgrad der elektrolyte. Z. Phys. Chem. 4U, 96–116 (1889).

Elsner, J. Taming the panda with python: a powerful duo for seamless robotics programming and integration. SoftwareX 24, 101532 (2023).

Johnson, M. S. & Green, W. H. A machine learning based approach to reaction rate estimation. React. Chem. Eng. 9, 1364–1380 (2024).

Black, K. et al. π0: a vision–language–action flow model for general robot control. In Proc. Robotics: Science and Systems (RSS) https://doi.org/10.15607/RSS.2025.XXI.010 (2024).

Colledanchise, M. & Ögren, P. Behavior Trees in Robotics and AI: an Introduction (CRC, 2018).

Darvish, K., Simetti, E., Mastrogiovanni, F. & Casalino, G. A hierarchical architecture for human–robot cooperation processes. IEEE Transact. Robot. 37, 567–586 (2020).

Leong, S. X. et al. Steering towards safe self-driving laboratories. Nat. Rev. Chem. 9, 707–722 (2025).

Liu, Z., Bahety, A. & Song, S. REFLECT: summarizing robot experiences for failure explanation and correction. In Proc. 7th Conference on Robot Learning 3468–3484 (2023).

Yu, W. et al. Language to rewards for robotic skill synthesis. In Proc. 7th Conference on Robot Learning 374–404 (2023).

Skreta, M. et al. Replan: robotic replanning with perception and language models. Preprint at https://arxiv.org/abs/2401.04157 (2024).

Wang, Y. et al. RoboGen: towards unleashing infinite data for automated robot learning via generative simulation. In Proc. 41st International Conference on Machine Learning 51936–51983 (2024).

Tancik, M. et al. Nerfstudio: a modular framework for neural radiance field development. In Proc. ACM SIGGRAPH 2023 Conference article 72 (2023).

Luma ai, Online platform for 3D asset creation. Luma Labs, Inc. https://lumalabs.ai/ (2025).

Buss, S. R. Introduction to Inverse Kinematics with Jacobian Transpose, Pseudoinverse and Damped Least Squares Methods. Technical report (Univ. California, San Diego, 2009).

Robot dynamics lecture notes, Lecture notes (Robotic Systems Lab, ETH Zurich, 2017).

Schulman, J., Wolski, F., Dhariwal, P., Radford, A. & Klimov, O. Proximal policy optimization algorithms. Preprint at https://arxiv.org/abs/1707.06347 (2017).

Wang, X., Chen, Y. & Zhu, W. A survey on curriculum learning. IEEE Trans. Pattern Anal. Mach. Intell. 44, 4555–4576 (2021).

Matterix Developers. ac-rad/matterix: v0.1.0. Zenodo https://doi.org/10.5281/zenodo.17095671 (2025).

Jiang, Y. et al. Autonomous biomimetic solid dispensing using a dual-arm robotic manipulator. Digit. Discov. 2, 1733–1744 (2023).

Fakhruldeen, H., Pizzuto, G., Glowacki, J. & Cooper, A. I. Archemist: autonomous robotic chemistry system architecture. In 2022 International Conference on Robotics and Automation 6013–6019 (IEEE, 2022).

Yoshikawa, N. et al. Large language models for chemistry robotics. Auton. Robots 47, 1057–1086 (2023).

Pizzuto, G., De Berardinis, J., Longley, L., Fakhruldeen, H. & Cooper, A. I. SOLIS: autonomous solubility screening using deep neural networks. In IEEE International Joint Conference on Neural Networks (2022).

Lienhard V, J. H. & Lienhard IV, J. H. A Heat Transfer Textbook 6th edn (Phlogiston, 2024).

Kerr, R. M. Rayleigh number scaling in numerical convection. J. Fluid Mech. 310, 139–179 (1996).

Acknowledgements

We thank A. Edwards for helping with code documentation and reproducibility and D. Hatcher and Y. Cao for helping with asset creation. We thank A. Yuan for his contributions to an early version of the semantic framework; A. Kuramshin, H. Kim and K. Thomas for their assistance with asset and environment generation; and M. Skreta, J. Baiand and C. Boott for their insightful discussions and feedback. A.A.G. thanks A. G. Frøseth for his generous support. A.A.G. also acknowledges the generous support of Natural Resources Canada and the Canada 150 Research Chairs program. This work was supported by the University of Toronto’s Acceleration Consortium from the Canada First Research Excellence Fund (grant no. CFREF-2022-00042), the Leverhulme Trust through the Leverhulme Research Centre for Functional Materials Design, the Engineering and Physical Sciences Research Council (EPSRC) (grant agreements EP/V026887/1 and EP/Y028759/1), the European Research Council (ERC) under the European Union’s Horizon 2020 research and innovation programme (grant agreement no. 856405), the Royal Society via a Research Professorship (grant no. RSRP/S2/232003) and the Royal Academy of Engineering under the Research Fellowship Scheme.

Author information

Authors and Affiliations

Contributions

Authors are listed alphabetically by contribution. Designed and built the core infrastructure: A.M., A.S., G.P., H.F., K.D. and M.B. Rigid assets library: A.M., A.S., B.Z., H.F., J. Chae, J. Choi, K.D., M.B., N.R. and Z.Z. Articulated asset library: A.M., A.S., J. Choi and K.D. Robot assets: A.M., A.S., K.D. and Z.Z. Full laboratory assets: A.M., A.S., J. Choi and K.D. Nested rigid assets: J. Choi and K.D. Environments: A.M., A.S., H.F., J. Chae, K.D., N.R. and Z.Z. Semantics engine: chemistry (A.S., G.T., H.H. and K.D.), device functionalities (A.S. and K.D.) and heat transfer (A.S., H.D. and K.D.). Particle system (fluids and powders): A.S., K.D., M.B. and N.R. Skill library: foundation pose (A.M., S.H. and Y.Z.), inverse kinematics solver (K.D. and M.B.), reinforcement learning (A.M., J. Chae, K.D. and M.B.), whole-body controller (K.D. and Z.Z.) and cuRobo (K.D. and Y.W.). Deployment to real setups: FR3 and OT-2 liquid handling experiment (A.W., H.F., N.R. and S.V.), liquid pouring experiment (A.M. and Y.Z.), pick-and-place experiment (A.M.) and sim-to-real deployment pipeline (A.M., H.F. and K.D.). Writing the paper draft: G.P., H.D., H.F., K.D., M.B., Y.Z. and Z.Z. Supervision: A.A.G., A.G., A.I.C., F.S., G.P., H.F., K.D. and M.B.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Computational Science thanks the anonymous reviewers for their contribution to the peer review of this work. Primary Handling Editor: Kaitlin McCardle, in collaboration with the Nature Computational Science team.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–4, Sections 1–6, Algorithm 1, asset description, chemistry laboratory simulated environments, heat transfer semantics engine example, chemistry experiment workflows and the deployment of digital twin workflows to real setup.

Source data

Source Data Fig. 4

A zip file containing the data for plotting Fig. 4l.

Source Data Fig. 5

A zip file containing data: V value for real chemistry tracking, along with the real balance data and simulation data.

Source Data Fig. 6

A zip file containing the data for the pouring analysis and the corresponding data points.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Darvish, K., Sohal, A., Mandal, A. et al. MATTERIX: toward a digital twin for robotics-assisted chemistry laboratory automation. Nat Comput Sci 6, 67–82 (2026). https://doi.org/10.1038/s43588-025-00924-4

Received:

Accepted:

Published:

Version of record:

Issue date:

DOI: https://doi.org/10.1038/s43588-025-00924-4

This article is cited by

-

Digital twins for self-driving chemistry laboratories

Nature Computational Science (2025)