Abstract

Recycling mine tailings in concrete production offers transformative potential for the resource-intensive construction sector. This review critically examines studies on utilizing tailings in cementitious and alkali-activated concrete, covering physicochemical properties, mineralogy, activation, performance, toxicity, and sustainability. It starts from fundamental characteristics and multiple utilization channels to the engineering performance and latest industrialization advancements. Our aim is to provide valuable insights and help shape a roadmap for future interdisciplinary research efforts.

Similar content being viewed by others

Introduction

The exploitation and utilization of mining resources serve as an essential foundation for economic and social progress of modern society, supplying energy, power, and raw materials for multiple industries. Minerals and metals are vital for economies of major countries with rich mineral resources such as China, Australia and Canada1,2. Tailings are residual by-products consisting of process fluids and crushed rocks that remain after the extraction of valuable metals during the mining process and the typical process is displayed in Fig. 1a. Other mine wastes generated from exploration, mining, and quarrying operations throughout the entire mining process, as shown in Fig. 1b. Although the volumes of various mine wastes generated are influenced by multiple factors, such as the selectivity of the mining method in use, the ore beneficiation process, and the ore grade3,4, the volume of tailings is typically larger than that of other waste types. The Canadian mining industry generates ~1 million tons of waste annually, of which 950,000 tons consist of tailings derived from the flotation beneficiation of ores3. In general, the tailings volume from metal ore processing is typically higher than that from non-metal ores due to relatively low grade.

a Typical mining process, modified from ref. 16; b Solid wastes generated across the different stages of mining industry, modified from ref. 4; c The hazards aroused by tailings stacking; d Incidence of diverse impact types on human health and the environment resulting from the management of waste rocks and tailings, data collected from refs. 3,247; e Distribution of tailings ponds in China and Australia, data collected from refs. 8,9; f Current main streams of reutilization of tailings.

According to Global Tailings Review5, 12.7 billion metric tons of tailings are produced annually and the number of active, inactive and closed tailings storage facilities is ~8500 worldwide, with the collective footprint exceeding 280 billion metric tons. Tailing ponds and dams are the main storage facilities of tailings wastes, which are characterized of high pollution and energy potential6, evolving to a world challenge that triggers a series of public hazards as listed in Fig. 1c. The incidence of diverse impact types on human health and the environment resulting from the management of waste rocks and tailings sourced from the beneficiation of ores are displayed in Fig. 1d. It has been reported 250 million m3 contaminated residues intruding into ecological system and 2650 human deaths were caused by 257 tailings pond accident since 19157. Since 1917, there have been 272 cases of tailings dam failures worldwide, resulting in catastrophic consequences to the resident’s lives and economy of local communities. As displayed in Fig. 1e, there are more than 14,000 and 1000 tailings ponds in China and Australia8,9, respectively. Consequently, there is an urgent call for seeking and developing safer, environment-friendly and efficient technologies towards mine waste reutilization.

Currently, the management and reutilization of tailings mainly include four streams, as displayed in Fig. 1f: (i) Secondary ore processing; (ii) Solid-backfill mining technologies such as cemented paste backfill (CPB) and cement-tailings grout; (iii) Turn into mineral fertilizer; and (iv) Solidification/Stabilization (S/S) during stockpiling such as tailings dry stacking and tailing-waste rock mixtures, yet all these methods have certain limitations and inherit drawbacks in terms of cost, universal applicability, and environmental stability10. For example, the operational cost of CPB can make up to one-fifth of the total mining expenditure and its low-strength CPB renders only for low-grade applications such as ground support11,12. The tailing dry stacking requires the modern filtration technology (i.e., power, maintenance), upstream diversion systems and surface contour management, which are associated with high capital and operational costs. In addition, the oxidations of sulfide in exposure tailings can trigger acid mine drainage, even worse inducing biotic impairment caused by toxicity from heavy metal leaching13,14. Beyond these management and reutilization streams, the use of tailings as raw materials in concrete production, which is most important construction material in modern construction, is a potential strategy, offering a more sustainable, safer solution with promising economic and application prospects to the challenge of mine waste management towards sustainable future.

Since tailings exhibit considerable variability in chemical and mineralogical composition, and some of their primary oxide constituents include silica, aluminum, iron, and calcium, certain tailings may be suitable for use as supplemental cementitious material (SCM), alkali-activated material (AAM) precursor, aggregate, and inert filler15,16,17. In addition to being directly used as ingredient materials for cement and AAM concrete production, studies have demonstrated that tailings are also viable raw materials for the manufacture of cement clinkers, concrete pigments, and lightweight aggregates18,19. With ongoing scientific advancements, recent research has increasingly focused on mechanistic studies of various tailings as components in cement and alkali-activated systems. These include fundamental investigations into enhanced reactivity through physical and chemical treatments15, leaching kinetics and reactivity of Si and Al in tailings as alkali-activated precursors20, synergistic hydration effects of tailings with other SCMs in cement systems21, the immobilization mechanisms of heavy metals and fluoride in tailings-based AAM22,23, and the impact of tailing ceramsite on the hydration kinetics of cement paste24. Nevertheless, due to the heterogeneity, lack of standardization, and complex mineralogical and chemical compositions of tailings, further understanding, advancements, and optimizations are required to enhance their efficient use in cement and AAM concrete production.

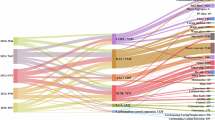

The research interest from both academia and industry is increasing in this field. Figure 2a, b shows the rapid growth of Scopus-based publications and citations related to the topic of ‘utilizing tailings as raw materials in manufacturing cement-based and alkali activated materials, namely tailing cement-based materials (tailings-CBM) and tailings alkali-activated materials (tailings-AAM)’. The literature relevant to cemented tailings backfill mixtures or cement-stabilized tailings is excluded. The number of publications is relatively balanced for tailings-CBM and tailings-AAM, especially in the recent years, highlighting their equivalent attention by researchers. As indicated in Fig. 2c, the leading types of tailings attracting research interests are iron, gold and copper tailings, aligning with the percentage distribution of various tailings reserves25. Among these articles, several review papers have focused solely on tailings-CBM25,26,27 or tailings-AAM28,29,30. In addition, these review studies primarily emphasize on activation methods, material properties and selective performances, with less attention to environmental impact, toxicological performance, and sustainability aspects. Furthermore, there is a lack of comprehensive consideration and interconnectedness of these aspects and in-depth understanding of the sustainability across various construction processes.

As the growth of this research topic gains momentum, it is imperative to continuously monitor its ongoing progression. This paper aims to bridge the aforementioned gap by offering an updated, thorough overview that encompasses both academic and non-academic advancements. It starts with fundamentals of tailings properties and activation methods, progresses into innovations in various utilization forms in production of cement and AAM concrete materials, and is followed by performance evaluations and discussions on influential factors and enhancement strategies. Additionally, it provides an in-depth evaluation of the sustainability aspects of such materials, addressing its environmental, economic, and social considerations. Finally, the repercussions, opportunities, and challenges towards large-scale practice and future research directions are discussed. This review serves as a valuable resource for academic researchers, industry experts, and decision-makers, and all other stakeholders, offering a comprehensive and up-to-date analysis of the recycling tailings in concrete materials towards a circular economy and a sustainable future.

Fundamentals of tailings

Physical, chemical, and mineralogical properties

Depending on the ore source, mineral processing, ore quality and the withering degree during storage in ponds, the physical, chemical and mineralogical properties are highly variable31. Even for the same categories, the properties fluctuate depending on different origins and boring depths32. The particle size of various tailings presents large variability, which can be categorized into three broad classifications and six subcategories, as displayed in Fig. 3a. The majority of tailings distribute in particle size range 20–300 \({\rm{\mu }}m\), classified as fine sand and powder sizes. Figure 3b compares the copper tailings with other ingredients in concrete, whose particle size distribution intersects the gap between the sand and cementitious material, rendering the microaggregate filling effect that modifies the particle packing skeleton, microstructure, strength and durability of the concrete33,34, while excessive replacement may cause adverse effect35,36,37. Fig. 3c present the macro and micro morphologies of various categories of tailings. It is shown that the majority of tailings particles typically exhibit relatively sharp edges, with a significant presence of needle-like and flaky shapes, and grooves observed on the surface. The roundness and sphericity of tailings particles are inferior to those of river sand38,39. In particle, the surface of bauxite tailings shows the hierarchical structures of round particles at nanoscale, which is probably related to the gibbsite and bohemite mineral phases, laying the foundation for their superior activating potential15. The specific gravity of tailings can vary between 2.64 and 4.29. The tailings are relatively porous and angular in microstructure with a porosity 33.1–50%, thus inheriting high water absorption rate that can reach up to 7–9% and enabling its internal curing potential. Recent study revealed that pre-wetted copper tailings powder as SCM can result improved volume stability, strength and pore structure due to internal curing effect of high performance concrete40. Bauxite tailings can be adopted as raw materials to manufacture fine LWA with high-water absorption larger than 20% for internal curing of high-strength mortars41. The pH value of tailings generally lies within the neutral and slightly alkaline region, shifting between 6.7 and 10.0 for silicon rich mines and 8.0 and 9.3 for carbonate tailings, thus heavy metals can dissolve in alkaline environments provided by tailings-CBM and tailings-AAM, uplifting the importance of environmental risk assessment. In general, chemical compositions of tailings contain significant oxides of silica, aluminum and ferric. The chemical and mineralogical compositions across the various studies are detailed in Table 1 wherein non-reactive and low-reactive mineral phases dominates the mineralogy of the tailings. Tailings materials generally consist of diverse mixtures of quartz, feldspars, carbonates, oxides, ferromagnesian minerals, and minor traces of other minerals. To sum up, physical, chemical and mineralogical properties of various tailings present the large variability, while these properties are essential in determining the efficiency and selection of pretreatment methods and the suitability of their different utilization forms in concrete, which will be detailed in following sections.

a Particle size classifications of tailings (dp denotes mean particle size), reproduced from ref. 149; b Particle size distribution of tailings relative to other main continents in concrete, adopted from ref. 33; c Representative macro-morphology and micro-morphology of various categories of tailings, source pictures adopted from refs. 8,106,174,186,248,249,250,251,252,253,254.

Activation methods

Since raw tailings possess highly stable crystalline structure and low hydraulic reactivity, the pre-treatments are often required to improve the reactivity, which particularly occurs when tailings being applied as a partial binder phase in cementitious systems. This process is commonly known as “activation”. Common activation methods include mechanical activation, thermal activation and chemical activation, displayed as in Fig. 4a–c, respectively. In certain cases, these methods were combined as depicted in Fig. 4d to achieve the optimized conditions42,43,44,45. For example, alkali fusion is a thermo-chemical compound method that effectively enhances the aluminosilicate reactivity for AAM production29,46, while the mechano-chemical method is usually adopted to manufacture binary and ternary supplemental cementitious materials to enhance the performance of cement-based materials42,43,47. In alkali fusion process, low-reactivity raw materials are blended with a solid alkali source. The mixture is subsequently heated to a temperature surpassing the melting point of the alkali source46,48. Interested readers can refer to following review papers28,29,30,49,50 for more detailed insights. While the activation susceptibility and efficiency are influenced by technical and process factors such as grinding time and method, thermal activation temperature and duration, and chemical (alkali) reagents/activators, the following points are worthy remarked: (i) Due to particle agglomeration and electrostatic effects, the positive effects of mechanical activation typically increase with grinding time, but the rate of increase gradually diminishes51,52; (ii) Excessive thermal activation may trigger recrystallization of minerals and adversely impact the reactivity; (iii) Chemical activation can be viewed as similar to engineering the original tailings, whereby the original tailings are suitably modified to meet various performance and index requirements by adding a modifying activator. It is worth noting that the choice of chemical activation depends on the nature of the original tailings and the properties of the desired activator53,54. (iv) Modifying the cementitious properties of tailings usually encompass the compound activations or the incorporation of complimentary additives based on the target properties42,55; (v) The activation efficiency of thermal and chemical activations is typically superior to that of mechanical activation. Unlike mechanical activation, which primarily facilitates particle size reduction and structural collapse, thermal and chemical activations generally induce alterations in the chemical and mineralogical compositions to varying extents48,56. Nevertheless, the exact efficiency is relied on the chemical and mineralogical properties of the raw tailings and the control of activation conditions57. For example, a study reported that the Si and Al solubility of thermally activated apatite tailings, with calcination at 1600 °C, reaches 45% and 33%, respectively, while untreated tailings are almost inert, making them unfeasible for preparing AAM58. Niu et al.59 reported that although the structure of phlogopite phase and carbonate minerals in phlogopite mica-rich mine tailings had are been partially collapsed after mechanical activation, the binding energies of Si and Al were limitedly varied. Jiao et al.56 chemically activated vanadium tailings through alkali fusion, the dissolution of Si significantly was increased from 177.1 to 1227.3 mg/L and Al was increased from 59.7 to 299.1 mg/L, respectively.

a Mechanical activation, b thermal activation, and c chemical activation, reproduced from ref. 81, d Compound activation methods, reproduced from ref. 49; e Equivalent particle size, f pozzolanic activity, and g solubility of Al and Si in alkaline environment of various tailings as a function of grinding time, data collected from refs. 45,51,60,77,97,108 (Note: Type I and type II silicate tailings are sourced differently, type I tailings are rich in magnesium, and type II tailings are rich in aluminum).

Given the large spread in properties of raw tailings, their different responsiveness to activation, as proved in Fig. 4e, g, and f, and their distant compatibility and interactivity and in various cementitious systems (i.e., unary, binary and ternary) with large diversity and complexity, it is impossible to assign a fixed activation strategy to various tailings. Activation tends to be efficient, but not always. Particle aggregation may happen due to the rise in surface energy of fine tailings particles after extended grinding, leading to decreased pozzolanic activity index as revealed in Fig. 4f60,61. The selection of activation methods requires the comprehensive considerations of their competences to performance-based criteria in terms of various utilization forms in concrete. While reactivity of most tailing seems to be improved as the grinding time, longer time is associated with higher energy chemical activation consumption. Moreover, thermal and chemical activation may induce negative environmental impacts due to toxic gases release. Therefore, the design of activation methods should compressively consider the effectiveness, cost, environmental impact, and potential for larger-scale industrialization.

Hydration and geopolymerization potentials without activation

Since the difficulty of depolymerization process is govern by mineral composition and chemical composition of the raw materials, the hydration or geopolymerization potential is heavily dependent on dissolution characteristics of Si and Al elements from precursor material in alkaline environments, especially for the tailings with low reactivity characteristic20,62. The dissolution behaviors of Si and Al in various types of tailings is influenced by their distinct mineral compositions and varying degrees of crystallinity. Notably, different mineral compositions may be presented in one category of tailings dependent on their sources. As shown in Fig. 5a, b, the dissolution behavior of tailings is analogous to amorphous aluminosilicates such as fly ash (FA), metakaolin (MK) and ground granulated blast-furnace slag (GBFS) although tailings present the decelerated dissolution kinetic20, which is recognized as a typical non-homogeneous, non-catalyzed solid-liquid reaction63. Under alkali environment, the active Si and Al elements in tailings dissolves silica-oxygen tetrahedra and aluminum-oxygen tetrahedral from the surface to produce hydration gel in CBM or geopolymer gel in AAM24,64. As displayed in Fig. 5c, more geopolymer gels are produced on the surface of tailings particles until the active Si and Al elements are completely dissolved, whereas cement and amorphous aluminosilicates are almost fully dissolved.

In terms of various categories of tailings shown in Table 1, in general, bauxite tailings with notable presence of highly soluble and thermally decomposable minerals (i.e., gibbsite, boehmite, kaolinite) and minor presence of none or low-reactive minerals (i.e., quartz and albite) should possess the superior hydration or geopolymerization potential than other categories of tailings in Table 1, which present the notable minerals of none or low-reactive minerals. The alkali dissolution and thermal decomposing potentials of different minerals will be detailed in “Activating susceptivity of aluminosilicate minerals phases in tailings”.

Activating susceptivity of aluminosilicate minerals phases in tailings

Although tailings typically are typically composed of high Al2O3 and SiO2 contents, their Al and Si dissolutions and potential hydration and geopolymerization reactivity heavily depend on the types of mineral phases containing those species. Tailings with different mineralogical features respond differently to various activation treatments. Understanding the activating susceptivity of various aluminosilicate minerals in tailings is vital for the selection of activation method. According to the relevant literature, the activating susceptivity of various aluminosilicate mineral phases towards mechanical grinding, alkalies and thermal treatment are summarized in Table 2. A study57 reported that mechanical activation did not enhance the reactivity of silica-rich tailings with high quartz content, even after significant particle size reduction. Similarly, another study65 found that the crystallinity of quartz remained nearly unchanged after mechanical grinding, supporting the low susceptibility of the quartz phase to be activated by grinding.

The activating susceptivity towards alkalies, which is associated with the alkaline solubility of Al and Si determines the potential reactivity of tailings in cementitious or alkali-activated materials. It significantly impacts the structure of the aluminosilicate framework and properties of the tailings-AAM. However, there is insufficient knowledge of how phase and structural evolution and the interactive mechanisms with a strong alkaline of various natural aluminosilicate minerals affect the kinetics of the geopolymerization reaction. The alkaline dissolution efficiency of aluminosilicate minerals in tailings is highly dependent on the chemical composition and crystallization conditions.

In terms of activating susceptivity towards thermal treatment, studies15,57 have experimentally verified that gibbsite, boehmite, kaolinite aluminosilicate minerals in tailings that are thermally decomposable whereas albite and quartz are none- or low-reactive phases. It is worth noting that optimal reactivity is not typically achieved under higher calcination temperatures but rather originates from a well-balanced amount of dissolved Al and Si. Increasing solubility in single Al or Si undesirably affects the Si/Al ratio and thus the reactivity. In addition, recrystallization of the amorphous content in the tailings may occur at elevated treatment temperatures; therefore, it is important to select the optimum treatment temperature based on the mineralogical characterization of different tailings.

Utilization forms

Numerous studies have attempted to utilize the tailings in CBM and AAM in various utilization forms as displayed in Fig. 6. The following subsections will discuss the characteristics, applicability, and potential concerns of individual utilization forms.

SCM, AAM precursor, and inert filler

The potential applicability of tailings as supplemental cementitious materials (SCM), tailings should ideally present at least one of three properties (i) Pozzolanic properties; (ii) hydraulic properties and (iii) activating properties (facilitate cement hydration by supplying CaO). Employing the CaO-SiO2-Al2O3+Fe2O3 ternary phase diagrams shown in Fig. 7a, b, different mine types can be divided into three groups. Group I is rich in calcium and inherits potential activating properties, tailings approaching this corner can behave as calcium source to direct substitute cement. Group II and Group III are both identified as either higher content of SiO2 or Al2O3+Fe2O3, while Group II holds higher CaO content. Thus, Group II possesses the potential hydraulic properties while Group III inherits potential pozzolanic properties, with SiO2 and Al2O3 are key elements in AAM production. Previous studies66,67,68,69,70,71 proposed that (N, C)-A-S-H gels tend to form in Al-rich systems, while calcium C-(A)-S-H gel is prone to form in Si-rich systems. Ca-rich tailings in blended systems for geopolymerization are beneficial in early strength development because of the formation of C-S-H gel48,72. Regardless of the gel types, excessive CaO and insufficient Al content is unfavorable for the gel formation73. Materials with higher Al content usually exhibit superior mechanical strength and thermal stability while materials with higher Si content may present better chemical resistance74,75.

a Chemical compositions of metallic tailings, data collected from refs. 17,32,81,82,97,103,104,105,106,108,109,165,224,225,226,227,228,229,230,231,232,233,234,235,236; b Chemical compositions of non-metallic tailings, data collected from refs. 17,32,81,82,97,103,104,105,106,108,109,165,224,225,226,227,228,229,230,231,232,233,234,235,236; c Pozzolanic and hydraulicity reactivity analysis, data collected from refs. 17,32,81,82,97,103,104,105,106,108,109,165,224,225,226,227,228,229,230,231,232,233,234,235,236; d Typical particle distribution of tailings suitable as SCMs, reproduced from ref. 49.

The chemical composition can primarily be used to evaluate the pozzolanic and hydraulic properties of tailings. According to European standards (EN 450-1, 2012), an alkaline solid material with a minimal sum content of Al2O3 + Fe2O3 + SiO2 higher than 70% is competent as potential pozzolanic materials and a sum minimal sum content of CaO + SiO2 higher than 50% is competent with potential hydraulic reactivity76. Notably, the content of SiO2 is essential for both pozzolanic and hydraulic properties. Figure 7c presents the pozzolanic and hydraulic reactivity analysis for different types of tailings with various chemical compositions. It seems that the majority of tailings are applicable as SCM. The coal and quartz tailings are favorable whereas phosphate tailings seem not applicable. Other types of tailings seem to be feasible, but the suitability relies on their specific chemical and mineralogical compositions. Tailings containing high silicon in the form of albite and quartz are not suitable as SCM64.

Typically, tailings on the micro-powder scale with the feature particle size D50 between 20\(\,{\rm{\mu }}{\rm{m}}\) and 400 \({\rm{\mu }}{\rm{m}}\) are suitable as SCMs as displayed in Fig. 7d, although there is a wider range of scatter in practice34,49,77,78. As per requirements of European standard (EN 450-1, 2012)79 and ASTM C61880, the content of organic materials should be limited within 5.0–6.0%. Several studies reported that coal tailings have a high loss on ignition, which might impede their applicability as SCM81,82,83. Furthermore, the high sulfide content present in sulphidic tailings, such as those from copper and lead-zinc mines, can substantially retard the hydration process, promote the formation of expansive crystalline phases, and induce decalcification of the C-S-H gel, thereby compromising the integrity of the concrete over extended durations when utilized as cement substitute84,85. For the tailings almost without pozzolanic potential, they act as inert filler in cement composites, in this case tailings may only contribute physically17,86,87.

Due to inferior aluminosilicate reactivity of tailings as shown in Fig. 8a, tailings are often supplemented with FA, MK, and GBFS as additional sources to form a blended precursor system. These amorphous aluminosilicates can generally be categorized into low/non-calcium-containing materials (i.e., FA and MK) and high calcium-containing materials (i.e., GBFS). Figure 8b presents the frequency distribution of tailings in single/blended AAM systems based on Scopus-indexed publications wherein MK that provides additional Al source accounts for slightly higher frequency than FA and GBFS due to modified silica modulus28,88. Some other industrial solid waste minerals such as volcanic glass89, low-calcium flash-furnace copper smelter slag90 and red clay brick waste91 have also been reported to make up the tailings blended system as precursors. While the reaction process and chemical transformation of AAM is significant, tailings as AAM precursors are typically subjected to pretreatments similar to tailings as SCMs in CBM92. In addition, both the incorporation of amorphous aluminosilicates and pretreatments are proven to adjust the Si/Al ratio of precursors, thereby optimizing the contribution factor of elemental structure in the geopolymerization process. The Si/Al ratio imparts a crucial impact on the various properties of AAM trough multifaceted mechanisms including polymerization process, viscosity and workability, setting time and strength development, and microstructural transformation etc.54,93,94,95,96. Since mechanical grinding allows incremental release of the increased quantities of Si an Al into alkaline medium and adjust the Si/Al ratio as documented in ref. 97, it may be feasible to control the Si/Al ratio through processing parameter such as grinding time, while there is lack of mature establishment between the Si and Al dissolution efficiency and the various tailings with heterogeneous physical, chemical and mineralogical properties.

a The dissolution efficiency of Al and Si in the alkaline media of various tailings and metakaolin, data collected from refs. 236,255; b Frequency distributions of tailings as single precursor or in blended precursors systems for AAM production in literature, reproduced from ref. 244; c Comparison on the compatibility of sulphidic tailings in OPC and AAS systems, adopted from ref. 85; d Microstructures of AAS mortars with 5% and 20% tailings, modified from ref. 85; e Microstructure of AAM mortar containing 20% copper tailings as sand replacement, adopted from ref. 110. f Indentation modulus and hardness of the interfacial transition zone in TCA and NCA concretes, adopted from ref. 111.

Although sulphidic tailings are poorly compatible with ordinary Portland cement (OPC) system as previously mentioned, the incorporation of sulphidic tailings into alkali-activated slag (AAS) system is a viable solution through function as auxiliary activator. Studies85,98 have verified that sulfur content in tailings plays the essential roles in enhancing the strength of tailings-AAS system. As displayed in Fig. 8c, the presence of SO42- in AAS promotes the generation of sulfate-rich products such as gypsum and reduces the Ca2+ concentration of pore solution, accordingly accelerating the dissolution of slag through ionic equilibrium99,100,101. The Backscattered electron (BSE) mapping results displayed in Fig. 8d revealed that S element has participated the slag hydration and intruded into the surrounding matrix due to oxide of pyrite and the reaction between sulfates and Ca2+ and Al-O tetrahedrons released from GBFS. In other word, the sulfuric tailings co-activated GBFS along with NaOH, acting as an auxiliary activator for GBFS, thus improving the microstructure and strength of AAS85.

Fine and coarse aggregates

Tailings without sufficient hydraulic reactivity and pozzolanic activity may be directly applied as aggregates in CBM and AAM. In general, the direct use of tailings as natural aggregate in CBM has stringent requirements concerning clay content, mica content, organic matter content, lightweight material content, sulfide content, and alkali content. the suitability of tailings and tailings coarse aggregate (waste rock) as fine and coarse aggregate replacements is highly dependent on their physicochemical properties such as fineness, particle size distribution, porosity, water absorption, chemical composition, etc. Zhu et al.102 noted that iron tailing sand can completely replace river sand to produce concrete with superior strength and workability if the fineness modulus of iron tailing sand meets the range of medium sand. However, due to the fineness of tailings sand compared to river/manufactured sands and their poor grain-size distribution, tailings sand may not fully satisfy the typical sand requirements in concrete103. The partial substitution of tailings sand for natural fine aggregate will alter the particle gradation and packing density inside the resultant cementitious materials, a view that is agreed upon by many researchers104,105,106. Indeed, the synergistic effect of favorable filling effect of fine tailings sand and either favorably or unfavorably altered gradation dependent on the substitution content of tailings sand will be a crucial factor affecting the various properties of the resultant composites. Zhang et al.107. noted the substitution level can reach 100% if the gradation curve and fineness modulus of tailings sand is similar to river sand. In addition, the MgO content in tailings should be less than 3% considering its expansion effect108. The quality of cement mortar or concrete is also influenced by the Cl− and SO42− contents in tailings sand109.

Despite tailings as precursors being the mainstream, there are few cases of tailings being used as aggregates in AAM92. In general, tailings with low reactive Si and Al contributions can serve as fine aggregates48. Zhang et al.110 observed tightly bonded interfacial transition zones (ITZ) with abundant gel products in tailings-AAM shown in Fig. 8e when copper tailings sand replaced 20% natural sand. They proposed that fine copper tailings sands partially participated in the geopolymerization.

In conjunction with employing tailings sand to substitute fine aggregate, tailings waste rock (TWR) can replace the natural coarse aggregate to design the full tailings concrete for sustainable development111,112. Although studies111,112 agreed the micromorphology of tailings waste rock is similar to that of manufactured rock that rich in angularity, the physical and mechanical properties of tailing coarse aggregates may vary based on the categories of tailings, the degree of damage during the exploitation process, and the degree of superficial weathering. As displayed in Fig. 8f, Lv et al.111 reported iron tailings coarse aggregate (TCA) concrete possesses superior ITZs micromechanical characteristics than natural coarse aggregate (NCA) concrete because of higher strength and increased angularity. The narrowed ITZ renders comparable mechanical strength and superior durability performance, including chloride-ion permeability, sulfate corrosion, and abrasion-erosion resistance. Due to the difference in rock feature, TWR concrete inherits a lower temperature conduction, heat conduction, and linear expansion coefficient than NCA concrete, which is suitable applied as dam concrete with minimize environment temperature-induced expansion and contraction deformation112. However, the rational selection of particles size of tailings coarse aggregate is a crucial factor in controlling the quality of tailings concrete113,114. In fact, iron sulfides such as pyrite FeS2 and pyrrhotite Fe1−xS are common minerals in mine wastes, and the properties of these iron sulfide minerals constitutes is generally the primary criteria justifying their inadequacy as construction materials because of a series of expansive and deteriorative reactions, causing tailings challenging to bond with OPC99,100,115,116. The content of sulfur compounds, particularly the presence of pyrrhotite, may raise concerns about the applicability of tailings as aggregates114,117.

Raw material of cement clinker

Owing to the similar chemical composition of CaO, SiO2, Fe2O3, and Al2O3 to that of the typical raw materials used for cement clinker production, a widen channel for the utilization of tailings is to apply them as raw clinker materials of cement18,19. The relevant studies on different types of tailings with varied chemical compositions are summarized in Table 3. It is seen that the maximum tailings content is typically controlled within 20 wt%18,19,118,119,120,121,122. Determined by specific physicochemical properties of the tailings, the applicability concerns mainly involve the interstitial fractions (aluminate and ferrite phases)123,124 and heavy metals18. To ensure suitable quality, the incorporation of tailings in OPC clinker is achieved by monitoring and adjusting multiple interdependent variables such as lime saturation factor (LSF), silica modulus (SM), alumina modulus (AM), hydraulicity modulus (HM), and mineral phase levels124. The quality of tailings-OPC clinker is influenced by processing factors such as holding time, sintering temperature and burnability. In general, the favorable formation of C3S is achieved by increasing the holding time and elevating the sintering temperature within the appropriate range, while the exact optimal parameters are dominated by the mineral phase type and content of the raw materials19,120.

Depending on the chemical compositions and trace elements, iron tailings as partial substitution of clay can produce low-heat cement and those with a low SiO2 content can produce special cement such as sulfobelite clinker and high-belite cementitious materials118,125. Tailings with high SiO2 might not be suitable for cement clinker production126. The alite and belite contents in tailings clinker and the mineral phases composition of anhydrous tailings cement are competent for Portland cement124, while the increasing ferrite phase content brought by iron tailings leads to higher tetracalcium aluminoferrite content, thus hindering the alite formation. Cheng et al.19 proposed that the higher alite content in copper tailings clinker ameliorated the hydration activity of the clinker mineral phase, which favorably reduced the amount of cement clinker. Consequently, it is important to conduct chemical and mineralogical analyses of raw tailings and tailings-clinker for the tailings cement quality control prior to the large-scale production.

Studies have demonstrated that tailings cement with excellent performance can be achieved by optimizing sintering parameters124,127. Fig. 9a summarizes the mechanical strength evolution of Portland cement with optimum tailings dosage, showing the promising results that satisfy the grade requirements and can achieve superior mechanical properties compared to OPC118,124, especially at later stage shown in Fig. 9b. This is confirmed by promoted hydration degree through deconvoluted 29Si Nuclear magnetic resonance spectroscopy (NMR) spectra118. Experimental results also indicated that Ba2+, Cr3+ and Cr6+ in tailings might enter belite during the sintering process118,124, actively enhancing the activity of C2S and promote its hydration reaction128, which was partially responsible for the strength development at later stage129. Moreover, certain heavy metal elements in tailings show fluxing and mineralization effects on the clinker preparation, thus being beneficial for the burnability of raw meal and the strength of clinker118,130. This is due to the presence of trace elements in tailings, which increase the liquid phase content and lower the eutectic temperature. As a result, the activation energy is reduced, promoting the formation and growth of C3S122,131,132,133. During the sintering process, heavy metal elements can enter the mineral phases of clinker and alter their formation, through which they are solidified in the cement clinker118,134,135. Overall, it is found that the optimal sintering of tailings during clinkerisation process holds the promising potential to improve its performance and cementitious properties that are competent to serve as Portland cement raw clinker material.

Raw material of concrete pigment

Pigment is an insoluble, finely divided solid material used to impart color and opacity. The high stability of calcined iron oxides when exposed to ambient environmental conditions makes them extensively used as pigments for paints, plastics, paper, and ceramics136. Iron oxides, which enable raw materials to generate yellow, black, red, and brown pigments, are the main oxides in inorganic pigments. The inorganic pigments are most frequently used category for pigmentation of cementitious composites137. However, their use from tailings is a relatively recent field of work. Some researchers have proposed that iron tailings demonstrate potential as pigments for the pigmentation of cementitious composites due to their chemical composition138,139,140,141. The solvent, an important component of commercial real estate paint, typically contains volatile organic compounds (VOCs), which are highly toxic and can potentially lead to occurrences of asthma and cancer142. The pigment industry is pursuing to minimize the amount of heavy metals in their composition143. The potential applications of iron tailings include their use as raw materials for pigments in building paints and cement tiles, and as SCM for pigmented cements. Iron tailings as pigment for sustainable paints alleviate the environmental impacts of building paints, since they do neither comprise the VOCs normally used as solvents or the toxic metals. This not only reduces the environmental impacts inherent to the disposal of tailings in dams, but also adds value to products141. Fontes et al.140 used iron tailings as aggregate substitutes in the fabrication of roof tiles and as a pigment. It was concluded that this material could be a qualified alternative for this purpose since iron tailings lead to homogeneous color products. In another study, the calcined iron tailings were applied as SCM to produce pigmented cements in colors other than gray. The production of pigmented cements involves less energy consumption because the calcination temperature of the iron tailings is lower than the sintering temperature of the clinker141. This option opens promising opportunities in the construction of new buildings and the reconstruction of civil infrastructures. Colored pigmented concrete possesses the advantages of conventional concrete, such as high strength, good durability, and weather resistance, making it suitable for various applications137. Although previous studies have verified the technical feasibility of using iron tailings as a pigment for sustainable construction, essential parameters such as cost, color homogeneity, abrasion resistance, durability to external exposure, and large-scale verification require further exploration.

Raw material of cold-bonded lightweight aggregate

Lightweight aggregates (LWA) provide multiple advantages in addition to being lightweight, such as toughness, fire resistance, thermal insulation, and sound absorption, with wide applications in lightweight concrete/mortar (both structural and non-structural)144. Appropriate utilization of LWA can significantly reduce the density while enhancing the workability, structural performance, and durability of concrete/mortar145. Tailings, with similar chemical compositions to clay, can be developed into a novel disposal approach as raw material for producing LWA. On the one hand, tailings are usually fine powders, and their particle size distribution is not suitable for use as aggregate without treatment. On the other hand, the sintering process, which produces high CO2 emissions in the preparation of LWA, is increasingly being restricted by laws and regulations concerning carbon emissions and environmental protection146. Researchers have shifted their focus to adopting cold granulation techniques with cementitious/alternative binders to produce synthetic aggregates from tailings powders/sands147. The typical manufacturing process for producing cold cement-bonded or alkali-activated LWA from tailings is shown in Fig. 10. In some cases, the binder materials are pre-mixed with the tailings8,148. This novel, efficient, and clean approach can achieve high utilization rates of tailings, typically exceeding 70%, thus offering substantial environmental benefits by consuming less energy and providing an extended strategy to efficiently transform tailings into valuable resources. By optimizing the input materials and process parameters, tailings-based artificial aggregates can achieve minimal water absorption, desirable particle size distribution, and physical, mechanical, and durability properties comparable to those of natural aggregates148,149,150,151,152. In a recent study153, the concrete prepared by cement-bound aggregates with 5% cement and 95% tailings satisfies the mechanical requirements of most concrete products. In addition, autoclave technology with moderately elevated temperature and steam pressure is a promising way to greatly improve the LWA properties while maintaining a high tailings utilization rate. Furthermore, the spherical shape of such aggregates tailors them for special applications such as preparing concrete for floor and road decoration, as well as pervious concrete for sponge cities8. However, research related to this subject remains nascent. It is necessary to elucidate the effects of various parameters such as the initial particle size distribution of tailings, binder materials and types, granulation process parameters, and chemical admixtures on the surface morphology, phase transformations, pelletization mechanisms, and performance of synthetic aggregates, and to reconcile the relationship between the utilization rates of tailings and product performance.

Performance evaluation

As previously discussed, the interactions between tailings and various matrix systems are complex, here fresh properties and durability are not emphasized. Figure 11 summarizes relationships between the relative compressive strength (\({f}_{{cT}}^{{\prime} }/{f}_{{cR}}^{{\prime} }\)) and tailings content in terms of their different utilization forms in AAM and CBM. It is interesting to note that when tailings are applied as a binder substitution, both the compressive strength of AAM and CBM show a similar trend, generally decreasing as the tailings content increases, as displayed in Fig. 11a, b. This trend holds true except in a few cases within a limited content range and is independent of the type of tailings. The strength reduction is mainly attributed to inherently inferior reactivity of tailings as aforementioned90,154,155, while strength enhancements are multifaceted, involving several mechanisms including physical filling, heterogeneous nucleation, improved reactivity, etc.17,156,157,158. Typically, finer tailings particles less than 75 µm with increased amorphous content and specific surface area are more beneficial in inducing these favorable effects for both CBM and AAM60. Initial phase of mechanical force activation promotes mineral breakage and component release52,60. Since the tendency of aggregation among mineral particles increases with prolonged activation, the activation duration requires to be reasonably controlled. Alternatively, implementing gentler techniques, such as kneading rather than milling, in the later stages of activation may serve as an effective optimization approach50,159. Zhang et al.160 proposed that finer tailings particles could strengthen pore structure and ITZ in CBM through the synergistic effect of pozzolanic reaction enhancement and physic filling. Han et al.161 reported the early compressive strength of cement mortars containing finer iron tailing powder were clearly lower than the parallel mortars with coarser ones, independent of the replacement levels and w/c ratios. Since iron tailings powder almost acts as an inert material in the early stage, the finer iron tailings can better cohere with the surrounding paste and effectively fill the sand-paste ITZ. Similarly, Falah et al.162 reported AAM with 10% sub-micron tailings yielded up to 4.2 times early compressive strength at same amount of alkaline activator, attributing to faster dissolution induced by finer particles. Therefore, it is essential to consider the dual nature of tailings stemming from their low reactivity, meaning that the crystalline portion behaves as microfillers while the amorphous portion participates in the reaction163.

a Binder substitution in Portland/blended CBM; b precursor in AAM; c additive in Portland/blended CBM; d fine aggregate in Portland/blended CBM; e fine aggregate in AAM; f coarse aggregate in Portland/blended CBM; g fine aggregate in special CBM; h effect of amorphous aluminosilicates and pretreatments on tailings-AAM.17,21,61,84,85,87,89,90,91,103,104,106,110,111,112,155,164,165,169,170,175,186,209,224,232,246,256,257,258,259,260,261,262,263,264,265,266,267,268,269,270,271,272,273,274,275,276,277,278. (Note: (i) Data includes early and later compressive strengths reported in literature; (ii) h is reproduced from ref. 48).

However, researchers have noted that the reactivity of various tailings are still inferior to the common binder materials (i.e., OPC cement, FA, GBFS, and MT) even subjected to activating treatments25,61,108. Johansson et al.16 ordered the performance of raw, activated and ultrafine tailings as following order: Portland cement > ultra-fine tailings > activated tailings > raw tailings. Although dense particle packing skeleton was designed according to the relevant packing models to achieve optimal filling, the compressive strength, pore structure and chloride resistance of ultra-high performance concrete containing up to 40% lead-zinc tailings were adversely affected106. In general, the optimal contents for tailings as binder substitutions are 5–20 % and 5–30%, respectively for tailings-CBM and tailings-AAM.

As displayed in Fig. 11c, the CBM shows the relative superior performance if tailings are incorporated as additives, which further highlights the adverse impact of tailings on strength development of CBM due to low reactivity. As illustrated in Fig. 11d, e, it seems that leveraging tailings as fine aggregate would not trigger a negative impact on mechanical performance in CBM and AAM, even strength enhancements were reported by many studies. The ameliorating effects are mainly physical filling and microstructural modification as aforementioned27,164. In contrast, few cases is diverged from this agreement165,166, which is probably attributed to impeded cement hydration/geopolymerization brought by heavy metals elements in tailings26,167,168. Moreover, several studies have explored the feasibility of utilizing the tailings waste rocks as full substitution to natural coarse aggregate and all results are positive as shown in Fig. 11f. In addition to ordinary Portland/blended, several attempts have utilized tailings as binder substitution in CBM prepared by special cements such as magnesium potassium phosphate cement169, magnesium phosphate cement170 and supersulfate cement21, the results are encouraging as shown in Fig. 11g, highlighting the promising potential of maximizing the benefits of tailings with low carbon cements. It has been proposed that ultra-fine iron tailings and slag exhibit a pronounced synergistic hydration effect in supersulfate cement systems due to their complementary particle size distribution and alkali dissolution characteristics, significantly improving the mechanical properties and volume stability of the hardened paste21. The effects of amorphous aluminosilicates and pretreatments on the strength development of tailings-AAM is displayed in Fig. 11h. High Ca-containing materials seem to outperform the low Ca-containing materials in tailings-AAM due to additional formation C-(A)-S-H gels and thermal and alkali fusion activations seems to outperform mechanical activations, which are aligned well with previous discussions. Overall, it is seen that tailings can be utilized in AAM and CBM through various utilization forms. In general, the appropriate content for tailings as binder substitutions is generally within 30 wt%, while the feasible content for tailings as aggregate substitutions seems to be extensive. The validity should be further supported by long-term stability such as durability and toxicity. Furthermore, future research may explore the interaction and potential synergic effects between an amorphous and crystalline portion of tailings and differentiate their contributions in CBM and AAM.

Influential factors and enhancement strategies

Multiple factors significantly affect the fresh and harden properties of tailings-CBM and tailings-AAM, such as origin, constituents, quantity, and grain size of precursor materials, water-to-binder ratio, curing regimes, free water content, and type and composition of alkaline activators171,172. Depending the utilization forms, tailings may pose opposite effects on the workability of CBM and AAM. When serving as binder substitutions, tailings powders can promote the workability by modifying the particle size distribution in binary or ternary SCMs system173. However, the workability tends to decrease due to surface texture and high water absorption of tailings sand when they replace the fine aggregate173,174. Sever studies161,175 agreed that tailings can promote early hydration and improve the pore structure of CBM at lower w/b ratios, with the strengthening effect being particularly effective in slag-blended cement systems. Despite the diverse characteristics of various influential factors, it seems that tailings content has a more dominant effect on strength development than other factors when used as binder substitutions in both CBM and AAM. In other words, factors such as alkaline concentration, curing temperature, and activation conditions cannot override the strength loss caused by increasing tailings content, as substantiated by many studies137,154,155.

Apart from activation, they are other strategies to enhance the performance of tailings-CBM and tailings-AAM. The primary one is adopting binary and ternary system, potential mechanism may involve modified particle size distribution, synergic hydration effect, microstructural amendment, and adjustment in parameters of elemental structure as previously discussed, rending better fresh, harden properties and durability160,161,176. Another strategy is incorporating various reinforcing admixtures such as nanomaterials and fiber materials to tailor the specific properties177,178,179,180, in certain cases the favorable synergistic favorable effect triggers with optimal tailings content. A study177 noted that the nitrogen-doped graphene aids the deposition of tailings and promote a stable graphene-ettringite-C-(A)-S-H gel three-dimensional structure, significantly enhancing the flexural performance of tailings-CBM. While the incorporation of nanomaterials may reduce economic efficiency, it is justifiable from the perspective of significantly enhancing performance and extending the service life of structures, thereby contributing to the overall sustainability of the material181. Another study180 noted that graphite tailings sand enhances fractural properties by promoting the distribution of steel fibers and occlusal forces between the fibers, aggregate, and cement matrix. The third strategy is to design a dense particle packing skeleton to regulate porosity34,180.

In addition, amendments in curing regimes, such as hot water-dry heat combined curing, and replacement patterns in mix design, such as the cement paste replacement method, cement mortar replacement method, and binder-aggregate concurrent replacement method, have been proven to efficiently enhance the performance of CBM34. In relation to tailings-AAM, elevating curing temperature and increasing alkali content and concentration normally revenue superior performance182,183,184. However, these modifications may diminish the environmental and economic benefits, which will be discussed in following section.

Sustainability aspects

Toxicological performance

Tailings storage facilities (TSF), as an anthropogenic pollution source, hold serious potential environmental and human health risks. Figure 12a displays heavy metal concentrations from 147 non-failed TSF sites in China, indicating there is a significant exposure risk185. Turning tailings into building materials undoubtedly addresses the fundamental cause of large environmental risks associated with stacking tailings in tailings ponds, since those contaminants are permanently immobilized/solidified in cement and geopolymer matrices through various physical and chemical actions. Extensive studies, including those on different utilization forms of tailings, have confirmed that the heavy metal leaching concentrations in tailings-CBM and tailings-AAM are typically below the regulatory levels set by various countries and regions, demonstrating that heavy metals are largely immobilized. However, the environmental leaching risk of heavy metals over time always exists, especially for tailings-CBM and tailings-AAM with high utilization rates of tailings34,108,186,187,188. Despite the variability in toxicity results in the literature, some toxic elements such as lead, cobalt, and arsenic exist at considerable levels. The toxicity tests in the literature are primarily performed at laboratory scale and for limited terms, and there is a lack of long-term toxicity assessments. Due to the complexity of interactions and immobilization forms of heavy metal ions in cementitious systems, and the multifaceted nature of the factors influencing immobilization stability, there is not yet a mature understanding of the subject189. For example, Choi et al.32 noted that heavy metal leaching decreased with increasing GBFS content in tailings-AAM with the same amount of tungsten tailings. Saedi et al.187 noted leaching was higher for tailings-CBM with activated tailing compared to that with raw tailings. In the long-term perspective, carbonation and reactions with sulfate in tailings-CBM may significantly interfere the immobilizing stability190,191. The toxicity risks of heavy metals in tailing-based building components should be carefully considered in every phase of the material’s life cycle to safeguard the individuals involved. A profound understanding of toxicological performance throughout the entire life cycle, from construction, renovation, utilization, to waste management, is vital for the large-scale deployment of tailings-CBM and tailings-AAM.

a Statistical data of heavy metal concentration of the 147 non-failed TFS sites in China, adopted from ref. 185; b Spatial distribution of tailings dam failure during 2009 to 2019, reproduced from ref. 279; c A overall sustainability assessment framework concerning environmental, economic and social aspects for a concrete construction project, reproduced from ref. 211.

Environmental sustainability

Through undertaking life cycle assessment (LCA), the explicit environmental impacts in terms of energy consumption and carbon emissions for different utilization forms of tailings in concrete have been quantified by various researchers. In comparison to tailings as aggregate substitutions, tailings as binder replacement and as cement clinker production seem to exhibit better environmental benefits. Even the emissions during the processing and discharging of tailings are assumed to be zero, Gao et al.192 suggested that substituting up to 100% tailings results in only minimal decreases in CO2 emissions. Since tailings as binder substations accompanied by strength loss, the environmental benefits may offset by additional measures to achieve the equivalent performance. Tailings activation typically results in improved performance and is paired with greater energy consumption and carbon emission, while they can be hardly quantitatively correlated. This is similar to activators of tailings-AAM, higher dosage of activators may improve the performance while increasing the environmental impact. Recent evidence suggests that enhancing the properties of tailings by activations, which increases the environmental footprint, may still offer environmental benefits with the considerations of environmental impact from activations and avoided impacts of tailings disposal as displayed in ref. 193. This is particularly the case when compared to concrete devoid of tailings, assuming equivalent mechanical performance. The tailings-CBM with preserved compressive strength at 5% cement substitution leads to carbon emission reduction of 72 kg/m3. It should also be noted that activations may also decrease the toxicological performance, the interconnectedness and relative contribution between these positive/negative effects should be comprehensively considered. Guo et al.194 noted tailings as river sand substitution favors the environmental indicator of global warming potential but other four environmental indicators, the formers are related to the energy and material conservation and the latter is ascribed to the environmental toxicity. In comparison to tailings-CBM, tailings-AAM derived from industrial waste and by-products, when used as low-carbon replacements for today’s emission-intensive materials such as OPC, typically exhibits enhanced environmental sustainability. However, variations in precursors and activators may influence these outcomes195. Activation, transportation, and alterations of properties are main factors affecting the environmental assessment.

Overall, the environmental assessments are complex. Regrettably, many studies have disregarded the impact of variations in mechanical performance on environmental performance in their analyses and not considered the product in-service or end-of-life phase196,197,198. Most LCAs are cradle-to-gate types, not encompassing a cradle-to-grave analysis that covers full life cycle of Tailings-CBM or Tailings-based building components. Therefore, additional research is required on this subject to establish a standardized framework for future LCA studies for meaningful comparisons.

Although there is no consensus for assessment of explicit environmental benefits, the environmental sustainability of turn mine tailings into concrete materials is unmistakable consider those implicit environmental benefits brought by tailings disposal concerns human heath, ecosystems and resources, such as the encapsulation of toxic substances, conservation of natural resources and risk mitigation of ecological and natural hazards triggered by tailings failure. Towards large-scale utilization of tailings concrete products, environmental performance is influenced by technology routes, secondary material market penetration, and selection of alternative products199. It is estimated recycling tailings in large-scale production of ceramic tiles and calcium sulfoaluminate (CSA) cement provides net benefits on climate change, cumulative energy demand, and resource depletion environmental indicators, saving up to around 2 Mt. CO2 eq199. The environmental benefits are more prominent for resource-based industrial city in the mining sector, another study194 demonstrates utilization of tailings reduce 200 kgCO2/t tailings and indirect carbon emission reduction is comparable to the carbon emission of annul power generation for that city. Decision makers are required to thoroughly evaluate the trade-offs between impacts on climate change and energy use, and those related to toxicity. Other implicit environmental benefits are linkage to safe and sustainable solutions for tailings disposal that indirectly impacts on other low-carbon and clean energy industries. For example, power production using renewable energy sources including solar, wind, and tidal power, necessitate the use of metals, a substantial portion of which is primarily derived from mining activities200. The fabrication and assembly of solar panels and electric vehicles also require extensive amounts of minerals to satisfy the demand for essential materials81. In the coming three decades, it is projected that the global output of mining waste, linked to critical minerals necessary for the transition to clean energy, such as copper, nickel, lithium, and manganese (primarily waste rock and tailings), will experience an exponential increase and potentially attain a volume of up to two trillion tons.

Economic sustainability

Despite the tailings-CBM and tailings-AAM themselves being value-added products, the economical sustainability is also derived from cost-effectiveness including reducing waste disposal costs and saving on raw material expenses. According to Ince et al.201, substituting 20% of tailings as a binder can achieve cost efficiency of 11% and 9.7% for cement and lime mortars, respectively. As per Lv et al.111, fully replacing tailings as coarse aggregates in two practical hydraulic engineering applications can save 8.98 × 106 USD in investment compared to conventional concrete. Similarly, Liu et al.202 reported that 100% tailings to replace river sand in UHPC reduce the both economic indicators of raw materials cost per cubic meter and cost index for unit compressive strength. When manufacturing clinker from tailings, Chen et al.19 ascertained that revenue can achieve 274.50 MUSD·a−1 based on the scenario of a 2500 t·d−1 new dry process cement clinker production line. Overall, Regardless of the utilization forms, tailings consistently exhibit strong economic cost-effectiveness, though it also dependent on mine sites location and local tailings waste management practices172.

The potential vast commercial market poised to facilitate the upgrade and transformation of pertinent industries. Mining enterprises, for instance, may derive continuous profitable revenues from turning tailings into high value-added construction materials. Concurrently, this approach will catalyze the development and manufacturing of related technologies and equipment, thereby bolstering the economic sustainability of these industries.

Additionally, digitalization is acknowledged as a facilitator for economic sustainability. It aids in the completion of material cycles by providing precise data and detailed information concerning the availability, geographical location, quantity, and quality of materials, while concurrently enhancing the efficiency of processes through improved control203,204. Digital mining technologies linked digital mine and digital twin concepts, and their related technologies such as sensor technologies, machine vision, artificial intelligence, internet of things, and distributed ledger technologies can greatly facilitate the valorization of tailings, supporting the process and production state and the whole ‘end’ product lifecycle. For example, the chemical and physical properties of tailings wastes, which is highly crucial as previously mentioned, can be supported by process monitoring and material detection (ore sorting) technologies, such as spectroscopy, machine vision, image analysis or pattern recognition205. In addition, digital platforms connect consumers and producers, allow developments of services and dematerialization, and achieve industrial symbiosis to support the economic sustainability of mine industries206.

Social sustainability

Utilization of tailings to produce concrete materials in construction industry unfolds a range of consequences for social sustainability and benefits, though this area unfortunately does not receive adequate research attention. Firstly, it is imperative to acknowledge the enhanced safety for local communities near TSFs. Tailings dams, as the leading form of TSFs presently, are regarded as dangerous sources of artificial debris flow that possess high potential energy and inferior stability. The dam failures shown in Fig. 12b pose significant threats to the economy and safety of local communities. The Córrego do Feijão Mine tailings dam failure in 2019 in Brazil, for example, resulted in the loss of 249 lives and left 21 individuals unaccounted for207. Effective disaster management of tailings dams is essential for protecting public safety and ensuring social stability, while there exists a significant imbalance between the investment made by most mining enterprises in tailings dams and the rigorous societal demands for their safety and environmental sustainability208. This incongruity is likely to trigger failures of tailings dams and result in environmental degradation. Ince209 also pointed out turning tailings to value-added products poses positive effects on the socioeconomic development of localities with closed TFSs such as Lefke-Xeros mine area in Cyprus, the employment opportunities, ecological enhancements, infrastructural developments, and the expansion of tourism associated with the relevant industries are expected to revitalize the Lefke town. From this perspective, the public tends to demonstrate high acceptance including community engagement and satisfaction to such tailings utilization since it is related to well-being and living standards of localities, thus contributing to social sustainability.

The paradigm extends to workforce dynamics, as the previously mentioned merits of turning tailings into concrete alleviate the health risks of onsite workers in TSFs with mass tailings stockpiles due to toxicity immobilization. These merits align well with the social sustainability goals set by many countries and the responsible mining framework proposed by the Responsible Mining Foundation210.

Overall sustainability assessment

The overall sustainability assessment of the case study with a series of modeled scenarios is necessary for the process optimization and decision-making of implementation of tailings-CBM and tailings-AAM construction projects. Assessing the sustainability of transforming tailings into concrete presents considerable difficulties, and there remains a lack of consensus regarding the proper methodology for executing the requisite LCA. A literature review shows that there is a lack of LCA studies integrating environmental, economic, and social issues for the sustainability assessment in the research field. As displayed in Fig. 12c, Gao et al.211 proposed a comprehensive framework to quantitatively assess the overall sustainability concerning environmental, economic, and social aspects for the comparison of tailings-CBM and tailings-AAM in construction projects, offering a more all-encompassing analysis than individual LCA. However, the indicators for each aspect and the weight of various indicators may differ depending on the practical situation of specific projects. In addition, mineral resource dissipation indicators should be accounted for in LCA to aid resource-efficient tailings utilization212. Holistic and systemic LCA helps harmonize potential and observed outcomes where multiple societal goals, values, interests, and capacities converge. These assessments consider different sizes of social groups, geographic areas, and time periods, addressing issues related to rights, justice, and equity, thus delivering a better understanding of real-world impact of the projects. The sustainability of material production and use, along with the environmental and social implications across the entire value chain, including post-consumption, are important considerations213. As shown in Fig. 13, evluating the sustainability of tailing-based sustainable concrete should across both temporal and spatial dimensions and consider the correlations among materials (including composition, processes, internal structure, and material properties), structures (such as material properties, construction, design, and structural characteristics), and infrastructures (covering structural characteristics, loads, environmental impacts, maintenance, and infrastructure properties).

Tailing-based sustainable concrete materials-structures-infrastructures and their sustainability evaluation, modified from ref. 280.

Case study-based life cycle assessment

The case study-based LCA can provide a direct insight of the environmental impact of how tailings-based concrete versus conventional concrete214. Figure 14a depicts the material metabolism diagram of copper tailings in Tongling city194. A material flow-based LCA model is was establish with the boundary of the material flow analysis system and boundary of LCA system shown in Fig. 14b, c, respectively. The environmental impact (EI) results of two scenarios, (i) Utilization of tailings to replace FA for autoclaved concrete block production; (ii) Utilization of tailings to replace river sand for concrete production, are displayed in Fig. 14d, e. The is indicated tailings-based concrete presents promising environmental benefit, as substantiated by the greatly reduction in EI categories of ADP, GWP, POCP194,198,215. However, the use of tailings also increases the ecological risk-related EI categories such as EP, FAETP, HTP and MAETP due to certain presence of toxic elements in tailings193,194. Carbon emission reduction benefit reach 199 and 39.4 kg CO2 eq, respectively for scenarios I and II. Given the fact toxic elements are immobilized/solidified in cement and geopolymer matrices, it is expected the risks can be mitigated by proper mix design and long-term toxicity validation22,23. The environmental benefits of tailings-based concrete are mainly stemmed from significantly reduction of the environmental impact and carbon emission associated with the production of conventional SCM/precursor materials.

a Copper tailing material metabolism mapping in Tongling City; b The boundary of the material flow analysis system; c The boundary of LCA system; d Environmental impact result of utilization of tailings to replace FA for autoclaved concrete block production; e Environmental impact result of utilization of tailings to replace river sand for concrete production. (ADP: Abiotic Depletion, AP: Acidification Potential, EP: Eutrophication Potential, FAETP: Freshwater Aquatic Ecotoxicity Pot., TETP: Terrestric Ecotoxicity Potential, HTP: Human Toxicity Potential, MAETP: Marine Aquatic Ecotoxicity Pot., GWP: Global Warming Potential, ODP: Ozone Layer Depletion Potential, POCP: Photochem Ozone Creation Potential).

Towards large-scale application, industrialization, and multifunctionality

While numerous research efforts have been placed to turning tailings into value-added products through various utilization forms, a considerable gap continues to persist in the application of these practices at an industrial scale. Several key challenges and bottlenecks remain to be addressed to bridge this gap. Firstly, the heterogeneity of various tailings affects activation potential and the suitability of the subsequent utilization forms, and also introduces difficulty in predicting the performance of the resultant products. The interaction and synergy between physical, chemical and mineralogical properties of tailings and different heterogeneous and cementitious systems, as well as various processing parameters require additional exploration. Secondly, while activations improve the performance of resultant products, the process is characterized by high energy and reagent consumption. In addition, discrepancies in the activating potentials of various tailings lead to activation methods that are deficient in representativeness, robustness, and consistency. Thirdly, most of the studies have screened the engineering performance of tailings-CBM and tailings-AAM in terms of chemical-mineralogical characterization, fresh and harden properties, and toxicity tests in a relatively short time frame, there is a lack of long-term durability testing and validation of up-scaled structural members. Fourthly, the presence of certain substances such as sulfide-bearing minerals, copper and hypophosphite ions raise applicability concerns, there is lack of guidelines and standards explicitly outline methodologies and regulatory requirements for suitability assessment of different utilization forms. Furthermore, the absence of adequate regulatory frameworks for waste-derived materials coupled with insufficient financial incentives constitutes significant impediments to the expanded utilization of tailings valorization over virgin building materials216. Strict regulations and market acceptance of products can sometimes hinder scalability, even in cases where the technologies are validated199. It is apparent that addressing these challenges necessitates interdisciplinary collaboration and extensive mechanistic research at multiple scales to advance our scientific insight.

Figure 15a–e displays potential applications of tailings-CBM and tailings-AAM, which include but not limited to pavement decoration, concrete paver, pigmented cement tiles, reinforced concrete beam, etc.8,140,167,217. In addition, recent studies174,218 proven that optimal content of tailings can significantly modify the essential attributes of 3D printed concrete as displayed in Fig. 15f, such as buildability, mechanical properties and durability performance. Furthermore, as displayed in Fig. 15g–i, semiconductive tailings such as iron and graphite tailings demonstrate encouraging prospects in tailoring the multifunctionality of concrete such as photocatalytic activity219, piezoresistive sensing178 and electromagnetic wave absorbing220.

a Spherical Tailings Aggregates concrete for pavement decoration, adopted from ref. 8; b Interlocking concrete paver, adopted from ref. 167; c Pigmented cement tiles, modified from ref. 140; d Geopolymer brick, adopted from ref. 281; e Reinforced concrete beam, adopted from282; f 3D printed concrete, adopted from ref. 218; g Photocatalytic property, adopted from ref. 219; h Self-sensing property, adopted from ref. 178; i Electromagnetic wave absorbing property, adopted from ref. 220.

Recent studies are exemplified in mining activity-intensive countries such as China and Australia. In China, the technological advancement in using tailings as an ingredient in the production of silicate cement, high-grade cement, and special cement is becoming increasingly mature221,222. Liaoning Shanshui Gongyuan Cement Co. LTD has implemented iron tailings as siliceous raw materials into a newly established 2,500 t/d dry-process clinker production line. This initiative allows for the annual utilization of 100,000 tons of tailings and stable manufacturing of high-grade 52.5 OPC223. A parallel successful demonstration is shown in Australia. The research group at University of Queensland, cooperated with Newcrest Mining Limited, has implemented a ‘HydroFloat flotation cells’ technology at Cadia East copper-gold mining site in New South Wales to produce tailings sand with the HydroFloat flotation cells. This technology, as shown in Fig. 16, has proven to be superior to traditional flotation methods in terms of reducing energy expenditures during milling and enhancing the recovery rates of coarse particles of gold and copper. Additionally, the HydroFloat technology has unexpectedly facilitated the recovery of coarse and silica-rich materials. Recent experimental evidences confirm that the manufactured tailings sand is suitable as alternative fine aggregate in concrete217. However, these industrial-scale practices remain at the level of primary or pre-products of concrete, the industrialization of their final tailings-CBM and tailings-AAM products for construction applications remains in its early stages and requires significant further development.