Abstract

The construction method of Khufu’s Great Pyramid remains debated. Several theories have been proposed that implicate construction-ramps and a layer-by-layer bottom-to-top growth progress. Regrettably, none provides satisfactory explanations how to lift blocks weighing up to ~60 tons and for the tremendous pace to place blocks every ~1 min. Here, a radically different proposal for the construction of the Great Pyramid is presented, where blocks were lifted using pulley-like systems fueled by sliding counterweights down sliding-ramps. One pulley-like system and three sliding-ramps are still visible today, assigned as the Antechamber, and as the Grand Gallery, Ascending Passage, and Descending Passage, respectively. The construction proposal based on analysis of the pyramid’s architecture and masonry, is physically advantageous and can explain the fast construction. The proposal offers explanations for the recently discovered voids, and for structural features such as the course height variations, the concavity and the central furrow of the pyramid faces.

Similar content being viewed by others

Introduction

When Herodotus, arguably one of the first historians, traveled to Egypt in ~450 BC, he was equally in awe of the Great Pyramid, built ~2600 BC, as any modern-day tourist. As any intellectual, he asked himself the question: how did they build the Great Pyramid? Herodotus apparently talked to locals and priests, trying to get information about the construction process. He noted in his 2nd book of the Histories series, called Euterpe, that they used machines, that the construction took 20 years, and that they finished the highest parts first1 (Citation S1). The construction duration of ~20 years matches roughly the length of Khufu’s reign, 23 years according to the Turin king list. Some modern-day Egyptologists suggested that the construction could have taken only ~10 years2,3, but the recent discovery of the Wadi El-Jarf papyri indicates that pyramid construction lasted until the very end of Khufu’s reign4,5. However, Herodotus also reported that the amount of onions and leeks provided for the workers was noted on the pyramid—it is thus unclear if Herodotus got reliable information about the pyramid construction in ~450 BC. A likely scenario is that with the decay of the Old Kingdom at the end of the 6th Dynasty and the beginning of the first intermediate period, ~2200BC6, knowledge about the construction of the Great Pyramid was lost, thus ~4200 years ago.

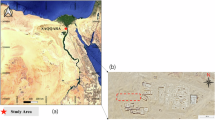

In numbers, the Great Pyramid of Giza, aka. King Khufu’s pyramid has a height, h, of ~146 m, a side width, w, of ~230 m, and thus a volume, V(total), of ~2,574,467 m3 (following V(total) = w2h/3). Most of the pyramid is built of limestone blocks. Overall, the blocks in the lowest courses (def., stone block layers as visible today on the pyramid without casing) are larger, with dimensions of about 1 m × 2.5 m × 1.5 m, and heavier, ~10 tons, than the blocks in the higher layers, with dimensions of about 1 m × 1 m × 0.5 m, and weight of ~1.3 tons7,8; though the block height distribution is much more irregular and decays in height sections8. The average block weighs ~2.5 tons, and an estimated ~2.3 million blocks were used to build the pyramid7. The total construction time can be estimated by adopting a duration of ~20 years and a ~16-h work-day, assuming an excess number of workers that could work in shifts as long as daylight was sufficient. If workers were called for state’s service during the inundation season only, ~4 months, i.e., 120 days per year, it yields ~2,304,000 min (20 × 120 × 16 × 60), while if work is considered to have advanced all year, i.e., 360 days, at identical intensity, it yields ~6,912,000 min (20 × 360 × 16 × 60) of construction time. Thus, the blocks had to be placed at a pace of 1 block per minute to 1 block every 3 min. If one were to consider a shorter, ~10 years, construction period2,3, blocks had to be placed between every 30 and 90 s. The limestone originated from a quarry just ~500 m south of the Great Pyramid7. To a lesser extent, for the casing, white Tura limestone from ~10 km across the Nile was used7. Finally, to a much lesser amount, ~3000 m3, or ~8000 tons, thus ~0.1% of the total volume, the pyramid is constituted of granite from Aswan, ~1000 km up the Nile7. It is of the Aswan granite that the King’s Chamber was built, using blocks of size up to ~8 m × ~1.5 m × ~2 m, weighing ~60 tons7,9,10.

It should however be noted, in contrast to our preconception of the pyramid structure, the inner masonry is quite chaotic. Indeed, while the exposed interior faces of the major architectural elements display millimeter-precision fittings between blocks, and the outer casing stones were equally well fitted as can be concluded from the remaining casing stones on the pyramid North face, the outer mantle was of good quality, but where the stone arrangement in previously inaccessible regions can be accessed and inspected, the masonry is found a rather random arrangement of bigger and smaller blocks interspersed by even smaller boulders and mortar8,9,11,12. The internal masonry structure can be seen when entering the pyramid through Al-Mamoun’s tunnel13, or when inspecting the large crevasse that Vyse dynamited into the south face11,12.

While excavations on the Giza plateau provided invaluable insights into the living conditions of the pyramid workers14, and the finding of logbooks of a ship crew revealed some of the organizational aspects of stone transport from Tura5, no documents from Khufu’s times were found that explain how the pyramid was built. Thus, modern-day Egyptologists ask themselves the same question as Herodotus, and propose various theories for the Great Pyramid’s construction2,3,15,16,17,18,19,20,21. The generally accepted theories rely on construction-ramps on which stone blocks mounted on sledges were pulled up the growing pyramid, constructing the pyramid rather symmetrically, layer-by-layer and bottom-to-top22, though construction based on levering has also been proposed23. The appeal of construction-ramp models is their simplicity. Construction-ramp models rely on brute-force, i.e., calling for a quasi-unlimited contingent of workforce, combined with limited engineering, i.e., building a ramp and dragging blocks up the ramp—they do not call for an unknown technical innovation. However, the use of construction-ramps, in most general terms, runs into three major problems: (i) The physics is unfavorable: There are two force components that need to be provided to pull a block up a ramp, a force to lift the block, F(lifting) = mg·sin(α), and a force to overcome the friction between block, i.e., the sledge it is on, and the ramp, F(friction) = µ(friction)·mg·cos(α); where m is the mass of the block, g is the gravity on earth, 9.8 m/s2, α is the inclination angle of the ramp, and µ(friction) is the friction coefficient of wood on mud-brick, ~0.624 (see Fig. 1c). The friction force scales with the cosine of the slope angle. The cosine function is flat for small angles; it only decreases from 1 to 0.9 for ramps ranging from 0° to 25°. In contrast, the lifting force scales with the sine of the slope angle, and the sine function increases almost linearly for small angles. Thus, the lifting force rises from 0 to 0.42 for ramps ranging from 0° to 25°. Therefore, steeper ramps demand much greater effort. This is why many ramp models propose rather flat ramps, e.g., ~10%, i.e., ~5.71°. For such a slope, the cosine is 0.995 and the sine is 0.1. Thus, to keep the lifting force low on a flat ramp, the ramp must be long, i.e., ~10 times the height it needs to reach, and the friction force remains high. (ii) The large length of ramps and absence of archeological traces: As a consequence of the ramp having to be flat, ~10%, to be operable (see point (i)), the final ramp must be ~10 times longer than the pyramid working height, thus ~1.5 km in its final state. However, for a large linear or bent ramp of that length, there is limited space on the Giza plateau, as the major limestone quarry is just ~500 m south of the Great Pyramid7, and the volume of such a ramp would be multiple times the volume of the pyramid. No archeological remains of such a ramp have been found. (iii) The slowness to operate on spiral ramps: To circumvent the problems of ramp length and volume (see point (ii)), several spiral ramp models have been proposed, where the length of the ramp is distributed by winding the ramp up the pyramid. However, it is impossible to design a 1.5 km long ramp around a pyramid with base width 230 m. Therefore, spiral ramp models usually propose steeper ramps, with even less favorable physics, and, given the decreasing side-length of the pyramid at higher height, increasing slope with increasing height. Spiral ramp models come in two flavors, where the ramp is either a mud-brick ramp built on top of the pyramid faces, i.e., external ramp15,22, or the ramp is part of the pyramid, i.e., integrated or internal ramp20,21. Necessary features of spiral ramps, in general, are that they are narrow and have corners. As a consequence, spiral ramps around the pyramid are only practicable by pulling blocks up in single file. However, in a single-file model, no work-unit can advance faster than the slowest work-unit. In addition, all spiral models (to accommodate the ~1 km length) include ~20 corners spiraling up the pyramid, where the blocks have to be rotated by 90°. In these operations, work-units are necessarily stalled, which means that all work-units behind them are also stalled. Once a corner block is rotated, the work-unit cannot move out of its position unless all blocks and corner blocks ahead have moved (Fig. S1). In other words, since there are always several blocks in corner positions stalling the entire file, and since the slowest corner block rotation plus the delay time to start moving all blocks behind it define the pace for each work-unit advancement—single-file spiral ramp models are mostly standing, and it seems highly unlikely that single-file spiral ramp models could reach the pace to place 1 block every ~1 min. In addition, most construction-ramp models do not provide solutions to how the largest and heaviest blocks were transported up the pyramid. Finally, mixed models comprising straight and spiraling ramps have been proposed18. The general problems of ramp models have been discussed18, indicating that ultimately modern-day Egyptologists might agree that the solution to how the Great Pyramid was built is yet to be found (further discussion of construction-ramp models, Text S1).

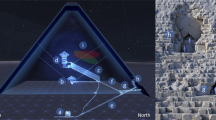

a Side-view (North–South) of the Great Pyramid with internal structures, i.e., King’s Chamber, Queen’s Chamber, Grand Gallery, Ascending Passage, Descending Passage, Horizontal Passage, Subterranean Chamber, as labeled. Recently discovered structures, i.e., Scan Pyramids’ big void (proposed, gray dashed lines) and Scan Pyramids’ north face corridor (confirmed), are also labeled. Note, Grand Gallery and Ascending Passage form a continuous sliding-ramp. Inset: Schematic of forces related to a hanging block and a block on an inclination of ~26.5° (see main text, Movie S1). b Top-view of the Great Pyramid with internal structures, i.e., King’s Chamber, Queen’s Chamber, Grand Gallery, Ascending Passage. Note that the Grand Gallery and Ascending Passage are in a continuous straight line. Note the concentration, but not superposition, of King’s Chamber, Antechamber and Queen’s Chamber close to the pyramid center. Black represents hollow spaces in a and b, granite structures of King’s Chamber and Antechamber are shown in gray. Inset: Arrangement of King’s Chamber (green), Antechamber (red) and Queen’s Chamber (blue) (drawing based on: Fig. 2 in Perring et al. The Pyramids of Gizeh, from Actual Survey and Admeasurement, London 193925 and Fig. 26 in Romer, The Great Pyramid: Ancient Egypt Revisited2). c Forces generated by a counter-weight of mass, m, in the earth’s gravitation, g, as a function of sliding-ramp slope. The Grand Gallery and Ascending Passage slope angle, ~26.5° (1 cubit over 2 cubits, 50% slope; the Descending Passage has the same slope), is indicated by the vertical dashed line, and the components of downhill-, normal- and friction-forces by the horizontal dashed lines.

Inspection of the pyramid in side- (Fig. 1a) and top- (Fig. 1b) view, reveals clustering of King’s Chamber, Queen’s Chamber, and Antechamber close to a common vertical axis, however, without superposition of these elements2,25 (Fig. 1a, b, inset). While the Queen’s Chamber is centered in the North-South axis (Fig. 1a) it is off the East-West axis center (Fig. 1b). Note, the Queen’s chamber is not considered to have been planned as a burial place for a queen, but to represent either an abandoned plan as the king’s burial chamber3, or as a serdab for the King’s Ka statue16. The Descending Passage, Ascending Passage, and Grand Gallery are parallel to the North–South axis but shifted to the East by ~7 m (Fig. 1b). The ~10.5 m long King’s Chamber, reaches the center of the East-West axis but is still largely on the East side, and substantially displaced, ~11 m, to the South of the North–South axis center (Fig. 1a, b). The clustering without superposition, combined with the absence of coherent and harmonious alignment and placement of the major architectural elements with the general pyramid geometry, indicated to me that these architectural elements likely were structurally and constructionally related—and that their locations were the result of technical compromises. If the pyramid had been built using construction ramps and layer-by-layer bottom-to-top, why would these major architectural elements not be placed in the most meaningful locations in the pyramid, e.g., the central axis? Of course, mystical reasons can be invoked, declaring that the factual placement was deliberately chosen and meaningful, but these sound like reverse-engineered answers to questions that were not appropriately addressed. In contrast, I propose that the placement of all architectural elements is the result of compromises and constraints imposed by the construction process.

Here, I propose a model of the Great Pyramid’s construction that is radically different from previous models, as it does not call for any construction-ramps on which blocks were pulled up but relies on pulley-like systems using counter-weights on sliding-ramps. In addition to the assessments of the clustering without superposition and odd positioning of the major architectural elements, the construction model proposed here evolved from the following observations: First, I recognized that the Grand Gallery had all signatures of a sliding-ramp useful for force-generation, that Grand Gallery and the Ascending Passage formed one continuous sliding-ramp with identical orientation, slope, and width, where the Ascending Passage represents a linear extension of the Grand Gallery, or inversely, that the Grand Gallery represents a linear prolongation of the Ascending Passage during construction. Second, I recognized that the Antechamber structure could be interpreted as a pulley-like system, rather than as a portcullis system, which is its general assignment. Based on these observations, I propose that the Antechamber served as a pulley-like system to lift blocks, fueled by the force generated by counter-weight sliding down the Grand Gallery and the Ascending Passage. The pulley-like system/sliding-ramp model has substantial physical advantages over construction-ramp models (Table S1). Further, the model explains the arrangement of the King’s Chamber, Queen’s Chamber, and Antechamber, and the linearity of all passages. Also, the model, extended to the entire pyramid, provides interpretations for the recently discovered voids, i.e., Scan Pyramids’ big void26 and Scan Pyramids’ north face corridor27,28, for structural oddities like the girdle masonry of the Ascending Passage, the linear arrangement of masonry blocks in the Horizontal Passage to the Queen’s Chamber8,9, as well as the concavity29, the central furrow30 and pattern of course-heights8 on the pyramid faces, the morphology of the shafts emerging from the Queen’s and King’s Chambers, etc. (Table S2). Conversely, many structural features of the pyramid provide support for the model. In summary, the model performs better than other models from a physical perspective and provides explanations for so-far unexplained structural observations, for the fast construction pace, and for how 60-ton heavy blocks could be lifted 70 m high in ~2600 BC.

Results

The Ascending Passage and the Grand Gallery were sliding-ramps for force generation

First, I noticed that the Grand Gallery (Fig. 1a), built of blocks that are inserted into the pyramid at the angle of inclination of the Grand Gallery itself9, could represent a sliding-ramp for counter-weights for force generation (Fig. 1a, inset). This had been suggested before, though in a different functional context20. Interestingly, these authors have readily provided evidence such as scratches and traces on the Grand Gallery side walls that indicate its possible use as a downward sliding-ramp for weight carrying sledges20. According to the model presented here, the South (upper) face of the Grand Gallery gives into a pulley-like system that is exposed to the South and to incoming blocks on the ground level, to lift them vertically up (see “The Antechamber was a pulley-like system”). In this context, it is important to note that the blocks of the Grand Gallery’s south wall are not intercalated with the blocks of the East and West walls, as the blocks of the North wall are20, indicating that the Grand Gallery was open on the South face until the later stages of pyramid construction. Second, the Grand Gallery and the Ascending Passage have the same direction, the same slope of ~26.5°, i.e., 1 cubit over 2 cubits, ~50% slope, and the same width8, which I recognized as manifestations that they were one and the same sliding-ramp (see “Construction of the pyramid core”). Indeed, the area that is seen today at the interface of Ascending Passage and Grand Gallery, i.e., at the foot of the Grand Gallery and the beginning of the Horizontal Passage to the Queen’s Chamber, has been described and analyzed in detail9,31, and its interpretation appears quite consensual: Large cutouts in the sidewalls allowed the insertion of beams to support a platform that would connect the central ramp of the Grand Gallery and the Ascending Passage. A ~18 cm lowering of the Grand Gallery ramp at its lower end and a protruding ledge at the Ascending Passage’s upper end are further indicators that a wooden bridge connected the two ramps9.

The physics of such a sliding-ramp (Fig. 1a, inset) with an angle, α, of ~26.5°, is described as follows: A counter-weight of mass, m, pulls downhill with a force, F(downhill) = mg·sin(α), giving 0.44mg (Fig. 1c, red line). The component of the gravitational force that is normal to the slope, i.e., the force that pushes the mass onto the ramp surface (Fig. 1a, inset), scales with the cosine of the ramp angle, F(normal) = mg·cos(α), which is 0.90·mg (Fig. 1c, dark blue line). Importantly, the normal force component is multiplied by the friction coefficient, µ(friction), to give the friction force, F(friction) = µ(friction)·mg·cos(α). The surface of the ramp is flat and smooth stone in the Grand Gallery and the Ascending Passage, and the object that was sent down the sliding-ramp was likely a wooden sledge, on which the downhill-sliding counter-weight was loaded. The friction coefficient between wood and stone, µ(friction), is between 0.2 and 0.424. Conservatively, a friction coefficient of µ(friction) = 0.2 is used here, but Hemiunu might have used a lubricant on the stone surface on which the sledge runners slid, which might have yielded an even lower friction coefficient. Anyway, the estimated friction force is F(friction) = 0.2·mg·0.90 = 0.18·mg (Fig. 1c, light blue line). Thus, in such a system, the down-sliding weight could directly lift 0.44 times its own weight, and the friction is rather low.

The Antechamber was a pulley-like system

Second, I noticed that the Antechamber, situated on a platform between the top of the Grand Gallery and the King’s Chamber and generally interpreted as a portcullis system as a last line of defense against intruders8,9,22,31, could instead represent a pulley-like system (Fig. 2). Based on earlier, detailed drawings and measurements9,31 (Fig. S2), a 3D-drawing of the structure was made (Fig. 2a, b).

a 3D-representation of the Antechamber with the different levels with individual architectural features superposed for clarity (3D-drawing based on measurements and representations from: Plate X in Piazzi Smyth, Our Inheritance in the Great Pyramid. 3rd, new and enlarged edition. London 187431, and Tavola 7 in Vito Maragioglio, L’Architettura delle Piramidi Menfite, Part IV, Roma 19659). b 3D-representation of the Antechamber with wood-logs, looking onto the South- and West-walls with the North and East walls omitted for clarity. c 3D-representation of the Antechamber with wood-logs and a hypothetical arrangement of ropes. Given the four rope-guidance grooves in the South-wall, a system of 4 parallel ropes (colored red, blue, yellow and green) is suggested. The use of 4 parallel ropes distributes the heavy weight of the blocks, up to ~60 tons, to be lifted. d Relative location of the Antechamber pulley-like system with regard to the Grand Gallery and the King’s Chamber. Note, the perfect fit of the rope(s) (red) descending from the first wood-log with an identical slope as the Grand Gallery, 26.5°, into the sliding-ramp. The ‘big step’ at the South side of the Grand Gallery (black arrow) is in the center of the North-South axis, and above the center of the Queen’s Chamber. Defining the center wood-log as the center of the pulley-like system, the center of the mechanism is ~4.87 m South of the ‘big step’ at the end of the Grand Gallery and ~3.52 m North of the King’s Chamber. Illustrating the pulley-like system in the current architectural setting may appear contradictory; however, the Grand Gallery’s upper end and the floor of the Antechamber were open until the later stage of construction. e Use of the upper slab with the boss of the Granite Leaf to stop rope movement during counter-weight reset in the Grand Gallery, when the pulley-like system was operated in gear 4. f Possible configurations of ropes in the pulley-like system: To effectively divide the pulling force by a factor of 4, in order to lift the ~60 tons heavy blocks, the pulley-like system might have been operated in gear 4 (top), while for the majority of ‘normal’ building blocks, the pulley-like system was likely operated in gear 2, where in order to lift a block by height Δh, the length l of rope to be pulled is 2·Δh, perfectly matched with a sliding-ramp with slope 1 cubit over 2 cubits (Movie S1).

The assignment of the Antechamber as a pulley-like system is likely the most challenging part of this proposal, as it represents a radical re-interpretation of a structure. Arguments putting into question the structure’s assignment as a portcullis system, and favoring its reassignment as a pulley-like system, are the following:

First, and most importantly, the Antechamber’s assignment as a portcullis system is questionable because it is non-functional unless one is to add additional blocking elements9,17,32: Indeed, the three supposed portcullis stone slabs had initially to be held at a height of ~1.1 m above the floor, the height of the two short passages on both sides of the Antechamber—to allow transport of the dead king and other goods into the chamber—before they were lowered33. However, upon lowering the slabs, space is freed up above the slabs, and robbers could climb over them, destroy or tilt away the third slab, or attack the South wall17. It appears difficult to accept that the architect who succeeded to build the Great Pyramid designed a faulty portcullis. Functional portcullis systems of different designs had been built before in Sneferu’s pyramid22. In addition to the above-mentioned flaw, the railings in the side walls that were supposed to hold the portcullis slabs in place protrude from the walls by only ~8 cm, and robbers would only have had to chisel one of them away, and the portcullis could have been angled out.

Second, a portcullis system at this level of the pyramid would arguably be useless: The pyramid had functional closure mechanisms, e.g., coverage of the entrance and the plug blocks in the Ascending Passage8, which are still unbroken. It appears therefore unreasonable that the pyramid builder had the illusion that tomb robbers that succeeded to break into the sealed pyramid, overcome the plug blocks, and make their way up to the tomb chamber, would be stopped by three stone slabs.

Third, the supposed portcullis system was difficult to maintain while the king was alive: According to general models, the portcullis granite slabs had to be mounted during pyramid construction, as the slabs should not easily be removed. This means that from the day the supposed portcullis system was built, to the day the pyramid was finalized, or a later day when the king died, the stone slabs had to be held in the up-position. Since the Antechamber is located at ~43 m height and was therefore likely completed after about half of the pyramid building time, this would represent between 5 and 10 years. The general portcullis system model comprises wood-logs inserted in the semi-circular indentations at the top of the portcullis (Fig. 2b) over which ropes were tightened to hold the slabs in place33, and to further secure the slabs, additional wood-logs would have been placed under the slabs9. These precautions, however, should not have hampered the king’s burial ceremony. Thus, the system might have gone awry at any time between its installation and burial.

Fourth, the 4 rope guidance grooves in the South-wall have each a diameter of ~10 cm (Fig. 2a, b), which seems in numbers and in suggested rope diameter an excessive design to hold portcullises. Thus, while these grooves are generally interpreted as rope guidance grooves in a portcullis system8,9,31, their number and characteristics point towards a pulley-like system that can carry the heaviest loads. However, the rope guidance grooves per se do not need to be reassigned.

Fifth, the rope guidance grooves in the south wall are ~2.65 m in height, extending by ~94 cm above the position of the wood-logs, which is nonsensical in the setting of a portcullis system, because ropes would never have passed above the wood-logs (Figs. 2c and S2).

Sixth, the three semi-circular indentations, ~39 cm in diameter, on top of the west wall are generally interpreted to support wood-logs in a portcullis system8,9,31. Their diameter appears excessive to hold single portcullis slabs. However, the semi-circular indentations as wood-log supports per se do not need to be reassigned for the interpretation of the structure as a pulley-like system. Indeed, the ensemble of the grooves in the South-wall and the semi-circular indentations in the West-wall are generally interpreted to form a system of support and guidance for ropes that are wrapped around wood-logs for holding hanging weight, in a portcullis system as generally assumed22, or in a pulley-like system as proposed here (Fig. 2c).

Seventh, the first wood-log, positioned at ~2.86 m height and ~4.17 m from the Grand Gallery, is perfectly positioned for a rope to pass over the Granite Leaf and extend down into the Grand Gallery at a ~26.5° angle, clearing the rope ~1 m above the big step of the Grand Gallery, and aligning the rope ~1.5 m above and parallel to the Grand Gallery floor (Fig. 2d).

Eighth, the assignment of the Antechamber as a pulley-like system provides a meaningful assignment for the Granite Leaf to secure the pulley-like system and to fix the other end of the ropes. Indeed, the boss on the north face of the upper part of the Granite Leaf8,31 was probably used to lever the upper part of the leaf up for the frequent exchange of ropes (Figs. 2d, and S2). Alternatively, the upper Granite Leaf may have served to squeeze the ropes between the upper and lower slabs and block the mechanism (Fig. 2e): This is the likely mechanism to stop the advance or return of the ropes, when workers had to reset the counter-weights in the Grand Gallery sliding-ramp during operation of the pulley-like system in a high gear that needed extended rope length to be pulled, as will be detailed below.

Ninth, the Antechamber is of terrible workmanship, unworthy of an architectural element. Petrie described the Antechamber masonry as rough and course and testimony to how badly the masons could work8 (Citation S2). The fact that the Antechamber masonry is so astonishingly rough and coarse8, is indicative that the structure was not an architectural element, but a working tool. However, as the Antechamber pulley-like system is deep in the heart of the pyramid and had to be operational until the later stages of construction, it could not be removed.

Tenth, despite the portcullis system being the general assignment of the structure over the last 200 years, there is—to the best of my knowledge—no consensus, how the mechanism worked, beyond that it implicated wood-logs and ropes. The structure is not directly interpretable as a portcullis system, and entire elements, e.g., the Granite Leaf with its boss or the excessively high rope guidance-grooves, remained unexplained.

Eleventh, the Antechamber is almost entirely made of granite, even the parts that would only be accessible when the system was already broken, e.g., the South-wall. The fact that the sturdiest stone was chosen for the entire structure is suggestive of it representing a working tool that needed to withstand heavy loads.

Twelfth, the Antechamber is neighbored on both sides by platforms, ~3.52 m in direction of the King’s Chamber and ~4.87 m in direction to the Grand Gallery, as measured from the central wood log, i.e., the center of the pulley-like system (Fig. 2d). These spaces, not really necessary for a portcullis system, appear well-positioned and of adequate size to space the pulley-like system from its neighboring architectural elements and to receive the newly lifted blocks to either the South or North side.

Thirteenth, further evidence in favor of the Antechamber being a pulley-like system comes from the inspection of its floor. The floor of the Antechamber was indeed a major concern regarding the feasibility of the model, as, if the Antechamber was indeed a pulley-like system, then the three wood-log-holding semi-circular indentations over which the ropes were folded must have been positioned above an open shaft (Fig. 2c, d). Inspection of photographs from the early 1900s showed that the first granite floor slab inside the Antechamber was inlaid34 (Fig. S3), and so did the later drawings9. A visit to the Great Pyramid corroborated and extended this observation. The floor is very uneven with height mismatches of ~2 cm at the interfaces between the limestone of the plateau at the end of the Grand Gallery and the first granite inlay, and the last granite inlay and the King’s Chamber floor. Indeed, all Antechamber floor slabs are inlays (Fig. S4). In summary, the floor shows that the Antechamber is an isolated element, not built in consistency with either of its neighboring architectural elements. The floor slabs being inlays was a condition for the model to be possible, as the area between Granite Leaf and rope grooves had to give into an open shaft until the later stages of pyramid core construction (Fig. 2c). Conversely, the fact that the Antechamber floor slabs are inlays between the walls and terribly uneven, provides further support for the Antechamber’s re-assignment as a pulley-like system (Table S2).

Taken together, numerous evidence indicate that the Antechamber structure is hard to be interpreted as a portcullis system, and its execution points away from an architectural element.

Importantly, not only do the rope guidance grooves extend by ~94 cm above the wood-logs, they have been extended by ~37 cm in a today visible limestone block facing the Antechamber roof31 (Fig. S2). This useless feature in the setting of a portcullis system should be noticed and put the assignment of the ensemble as a portcullis system into question (Figs. 2a–c and S2). A possible interpretation of the extended rope guidance grooves above the level of the wood-logs that held the ropes in the Antechamber structure is the following: At a later stage of pyramid construction, namely when the upper parts of the King’s Chamber were built, the Antechamber pulley-like system of the Grand Gallery was retired, and blocks were lifted by a pulley-like system of the ScanPyramids’ big void sliding-ramp directly to a higher height through the current Antechamber (see “Construction of the pyramid core”). Awaiting confirmation of ScanPyramids’ big void, its assignment as an upper sliding-ramp remains hypothetical. This may also explain why the East-wall of the Antechamber is somewhat incomplete or damaged, i.e., the semi-circular indentations are missing, and the railings have been removed (Figs. S2, S3). The flatness of the east wall top is not a problem with regard to the Antechamber pulley-like system assignment, as it is not considered that the logs rotated. The logs may have been round on one side, placed in the West-wall semi-circular indentations, fixing them laterally and may have had a flat face on the other side, placed on top of the flat East-wall, fixing them rotationally. Alternatively, when the Antechamber pulley-like system was retired, its East-wall may have been altered for easier passage of blocks and the South-wall rope guidance grooves were extended to better guide the ropes coming from ScanPyramids’ big void pulley-like system ~30 m higher up. This may explain the damage of the Antechamber South-wall with the rope guidance grooves (Fig. S5b) as the result of occasional hits by the thousands of blocks that were lifted through the Antechamber, which was then an open shaft (Table S2).

Moreover, Mariglio and Rinaldi observed that no portcullis system with slabs being lowered using logs and ropes had been built in any earlier pyramid10 (Citation S3). Thus, if we were not to look at the system from a modern-day perspective, where we are used to see falling portcullis systems, e.g., in medieval castles, then the assignment of the structure as a portcullis system should be equally or more challenging than assigning it to a pulley-like system. It is known that the Old Kingdom Egyptians used systems combining a wooden lever and a rope to lift weights, e.g., Shadoofs17, and pulling ropes over wood-logs was part of their daily use of boats. Importantly, excavations on the Giza plateau in the 1930s unearthed a tool, with dimensions ~12 cm × ~24 cm, made of granite that was interpreted as a pulley-like system35 (Fig. S6). Thus, if Hemiunu experimented with small-scale pulley-like systems, he might have translated the principle to the large scale. In contrast, a falling type of portcullis system with ropes would have represented a novel invention, and should therefore, in historical perspective, attract scrutiny. As a reminder, the former portcullis system in Sneferu’s pyramid featured a portcullis sliding laterally on an inclination, and later falling type portcullis systems, e.g., in the Pyramid of 5th Dynasty king Djedkare, did not comprise wood-logs and ropes36. As a reminder, the three plug blocks in the Ascending Passage of the Great Pyramid are, today, after ~4600 years, still unbroken. It thus appears that the assignment of the Antechamber structure as a portcullis system was based on its location in front of the King’s Chamber, modern-day intuition with preconceptions about modern portcullis systems, and lacking another apt interpretation—and has been propagated since.

In summary, I propose that the Antechamber was a pulley-like system (Fig. 2c), with 4 parallel ropes that were on one end attached to a heavily loaded wood sledge that is sent sliding down the Grand Gallery, folded twice through the gaps between the three wood-logs, and secured on the other end between the two Granite Leaf slabs or elsewhere (Fig. 2d). As noted, the first log in the Antechamber is perfectly positioned to extend into a rope that stretches down into the Grand Gallery with a ~26.5° angle (Fig. 2d). I designate the system ‘pulley-like’ because I do not think that the logs rotated in the semi-circular granite stone indentations like wheels in modern pulley systems, instead I think that the ropes slid on well-polished and lubricated wood-logs. In such a setting, the friction coefficient of rope on well-polished and lubricated wood could have been lower than that of a wood-log rotating in a semi-circular granite stone indentation. A toy model combining a ramp with slope 1 over 2, i.e., ~26.5°, with a miniature pulley-like system mimicking the structure of the Antechamber (Fig. 2b, c) readily showed that such a pulley-like system could be used to lift weights (Movie S1).

The pulley-like system could be operated in various gears for force amplification

Importantly, the physics of the pulley-like system offers advantages (Fig. 2f). There are multiple ways that the ropes could be folded over the logs, allowing the system to be operated in different gears. In order to lift the heavy blocks for the construction of the King’s Chamber, Hemiunu may have used a system similar to the one illustrated in (Fig. 2f, top), with two folds over the logs and thus 4 rope stretches connecting the pulley-like system to the mass to be lifted, which provides with the 4 parallel ropes a total of 16 rope stretches over which the total weight is distributed. The force needed to lift an object of weight, mg, is divided by the number, n, of rope stretches (not the parallel ropes) between the pulley-like system and the weight, which becomes mg/n (Fig. 2f, top). However, such a force amplification of the pulley-like system comes at a price: With an increasing number, n, of rope stretches between the weight to be lifted and the pulley-like system, the same number of rope stretches must be shortened during the lifting process. Thus, to lift a mass to height, Δh, the total length, l, of rope to be pulled is l = n·Δh. In other words, when running the pulley-like system in gear 4, Hemiunu could ‘reduce’ the weight of a block of 60 tons, e.g., one of the granite beams, to 15 tons, but for this block to be lifted ~43 m, he had to pull ~172 m of rope. To accomplish this, the model suggests that the Granite Leaf was used, lifting and lowering the upper slab with the boss, to block the movement of the ropes (Fig. 2e) while the counter-weight sledge in the Grand Gallery was reset by the workers, the ropes reattached to the counter-weight sledge, and sequentially sent down the sliding-ramp, multiple times, until the full rope length was pulled and the granite beam lifted. The toy-model readily captures the functional mechanism of the pulley-like system and showcases that using different gears (Fig. 2f) force amplification is achieved (Movie S1).

For common use, to lift the ~2 million ‘normal’ blocks, I propose Hemiunu used pulley-like systems in gear 2 with 2 rope stretches between the pulley-like system and the mass (Fig. 2f, bottom, Table S1). In such a case, to lift a block of mass, m, with weight 1·mg, needing the pulling force to lift 0.5·mg, to height Δh, a counter-weight would be sent down the sliding-ramp over the distance of length l = 2·Δh. Since, by using the pulley-like system in gear 2, the length of rope to be pulled is 2 times the height to be lifted, Hemiunu was perfectly served using sliding-ramps with slope 1 cubit over 2 cubits. I actually propose that this is the reason this slope angle was chosen for the Ascending Passage, Grand Gallery, and Descending Passage, and likely all other sliding-ramps.

Assembly and advance of the pulley-like system

As detailed below (see “Construction of the pyramid core” and “Construction of the pyramid mantle”) the pyramid grew as sliding-ramps grew and the pulley-like systems were always at the open, top end of the sliding-ramps. Therefore, in order for the pulley-like system/sliding-ramp model to be efficacious, the pulley-like system must have been relatively easily (i) assembled and (ii) advanced during pyramid construction.

The assembly of the pulley-like system may have proceeded in the following way (Fig. 3): The schematic depicts the top of any intermediate of any sliding-ramp, where a U-shaped platform with two ~2 m protruding arms on the left and right of an open shaft is built (Fig. 3a). Two outside blocks are positioned on both sides of the shaft, letting some spacing between these blocks and the shaft (Fig. 3b). Next, the granite side walls of the pulley-like system are inserted on both sides of the shaft (Fig. 3c). While the two outside blocks assure that the pulley-like system side walls do not fall outwards, the insertion of the Granite Leaf assures that the pulley-like system side walls do not fall inwards (Fig. 3d). Next, well-polished wood-logs are positioned on the pulley-like system and lubricated (Fig. 3e). Finally, ropes are folded over the wood-logs, fixed on one side to the down-sliding sledge and on the other side secured between the upper and lower slab of the granite leaf (Fig. 3f). The upper part of the Granite Leaf features a semi-circular boss on its face towards the sliding-ramp (Fig. S2), likely used to position a lever to lift the upper Granite Leaf slab to insert and secure the ropes, maybe using small granite boulders with holes, reminiscent of small 4th dynasty anchors37,38 (Fig. 3f).

a Schematic of the top of a sliding-ramp with a U-shaped shaft. The shaft structure could be created either by placing blocks in a U-shaped pattern or by corbeling the topmost blocks forward. b Placement of two blocks left and right outside the shaft. These blocks are shown rather small for better visibility of the latter stages. c Insertion of the pulley-like system side walls. The side walls are drawn symmetrically, duplicating the Antechamber West wall. d Insertion of the Granite Leaf fixes the side-walls and stabilizes the entire structure. e Addition of wood-logs (polished and lubricated) onto the semi-circular indentations. f The ropes are folded over the wood-logs and secured by lowering of the upper Granite Leaf slab, which could be levered up using the boss. Further details about the interface between sliding-ramp and pulley-like system, featuring vertical masonry at the upper end of the sliding-ramp to absorb lateral force, are given when discussing the Ascending Passage masonry, see “Construction of the pyramid core”.

The advance of the pulley-like system may have proceeded in the following way (Fig. 4): The schematic depicts any intermediate of any sliding-ramp, where the pulley-like system ropes reach to ground level or to the respective lower base level, in the case of any of the upper sliding-ramps (Fig. 4a). The base course blocks could be placed directly on each side of the pulley-like system shaft either on pyramid base level or by means of the pulley-like system of the sliding-ramp below the given sliding-ramp (Fig. 4b). The second course only needed lifting the blocks a couple of meters, and since in such a situation the ropes were long, it was likely easy to pull the blocks laterally out of axis and add them to the second course (Fig. 4c, arrow). I term this a ‘lifting cycle’ (see “Force-generation through counter-weight sliding down the sliding-ramps”). The third course is approximately in the middle of the sliding-ramp (in this schematic), and therefore building this course may be mediated by pulling blocks laterally out of axis and/or by adding them from blocks that went about half the way down the sliding-ramp (Fig. 4d, arrows). Indeed, using a pulley-like-system in gear 2, for any lifting height gain Δh, a counter-weight block had to slide down the sliding-ramp the length l = 2·Δh, and since its slope is 1 cubit over 2 cubits, the counter-block loses Δh in height. Also, in gear 2, the block to be lifted ‘weights’ 0.5 mg, while the counter-weight block sliding down the ramp generates 0.44 mg, while the friction keeps the system at rest. I term this process ‘exchange cycle’, meaning that two blocks, one being at the foot and one at the top of a sliding-ramp/pulley-like system, may both end up at half the height with minimal effort. In brief, these ‘exchange cycles’ could be interspersed with ‘common cycles’ using dedicated counter-weight blocks (see “Force-generation through counter-weight sliding down sliding-ramps”). While, for the lower courses, the lateral extraction was likely efficient, lateral extraction of blocks in the higher courses of a sliding-ramp may have been less easy because blocks hang on shorter ropes, and blocks may have been lifted in ‘common cycles’ all the way up and then laterally and downwards transferred to where the blocks were needed (Fig. 4e, f, arrows). Finally, ramp propagation reached the top course, and the pulley-like system was dismantled and reassembled (Fig. 3) on top of the new top course (Fig. 4g). The situation in Fig. 4g is reminiscent of the situation in Fig. 4a but one course higher.

a Schematic of the pulley-like system at the top of a sliding-ramp. b Blocks of the base level are added. c Blocks of low courses are added by lifting them and extracting them laterally while the blocks are hanging on the ropes (arrow). d Blocks of intermediate courses are added by either lifting and laterally extracting them and/or by extracting them from the sliding ramp (arrows). In these intermediate course settings, the height-gain of a block to be lifted and the height-loss of a counter-weight block on the sliding-ramp are about equal, opening the possibility to use a construction block as counter-weight. e and f Blocks of upper courses are likely added from blocks that have been lifted entirely and then redistributed (arrows), or maybe laterally extracted from the hanging ropes. g As an additional course is completed, the pulley-like system is moved one step up (compare g to a).

While the process of sliding-ramp growth and pulley-like system advance should have progressed quite linearly and course-by-course (Figs. 3, 4), the pyramid construction process may not have advanced that linearly. Indeed, in light of the masonry signatures in the Horizontal and Ascending Passages8,9, it seems likely that the sliding-ramps were advanced in spurts of ~10 m height, advancing the sliding-ramps on a nose-shaped protrusion (Fig. 5a, b), and then focus on pyramid construction from the given position of the pulley-like system. The largely linear forward progression of the nose-shaped protrusion naturally leads to an odd arrangement of the blocks under the sliding-ramp (Fig. 5b, arrows).

a Schematic of the top of a sliding-ramp with a pulley-like system. b The pulley-like system is advanced on a nose-like protrusion (without focus on pyramid construction), followed by an extended period of pyramid construction. The linear forward construction of the sliding-ramp can explain the cross-shaped joints in the walls underneath the ramp (arrows), as is visible today in the Horizontal Passage to the Queen’s Chamber under the Grand Gallery.

In the schematic representations (Figs. 3–5) the pulley-like system is shown reminiscent of the Antechamber structure for consistency and clarity. However, the Antechamber pulley-like system was/is likely an exceptional structure built in granite for the construction of the major architectural elements constituted of the heaviest blocks, ~60 tons, while in other locations where ‘normal’ blocks, ~2.5 tons, were lifted (see “Construction of the pyramid mantle”), likely wooden pulley-like systems were operated.

Construction of the pyramid core: Vertical shafts and vertical masonry

So far, I have detailed how the sloped passages in the pyramid may have served as sliding-ramps for force generation (Fig. 1), how the Antechamber structure may have served as a pulley-like system (Fig. 2), and how the pulley-like system and sliding-ramp may have been assembled (Fig. 3) and advanced (Figs. 4, 5) in the process of construction. However, is there any further data supporting the model? Are there signatures of sliding-ramps, pulley-like systems, their integration, or evidence for shafts in the pyramid architecture and masonry? In the pyramid as it can be visited today, obviously the vertical shaft underneath the Antechamber pulley-like system is not visible and/or accessible—it had to be filled when the pyramid core construction was completed, and the fact that the floor slabs of the Antechamber are inlays of uneven height represents evidence that the pulley-like system indeed gave into an open shaft that was later filled and covered by the currently visible granite slab inlays. The model would predict (Table S3) that if these slabs could be lifted, not far below, signatures of a shaft with heterogeneous filling should be found (Fig. 6a). In possible support, a microgravimetry survey in the King’s Chamber showed the lowest density values in the North-East corner, thus closest to the Antechamber39.

a The major vertical shaft (red) of the pyramid core construction should be in the vertical axis of the current Antechamber. It was established when the Grand Gallery sliding-ramp construction reached its top. The recently discovered ScanPyramids’ big void26, consistent with an upper sliding-ramp pulley-like system, is proposed to give into the same shaft. b At an intermediate stage of pyramid construction, a shaft (red) should have existed at the north face of the Queen’s Chamber, today manifested by a low-plateau between Queen’s Chamber and Horizontal Passage and a ~0.5 m step at ~5.5 m from the Queen’s Chamber. In this region, between Queen’s Chamber and the step, Vyse discovered sand and rubble below the floor slabs11. Microgravimetry reported low-density anomalies at the position of the proposed Queen’s Chamber shaft39, and in the North-East corner of the King’s Chamber, thus in proximity to the proposed King’s Chamber shaft39. c Masonry of the Ascending Passage (drawing based on: Tavola 5 in Vito Maragioglio, L’Architettura delle Piramidi Menfite, Part IV, Roma 19659). Ceiling, East (E-) and West (W-) walls, and floor are shaded in colors and labeled, and the girdle masonry is highlighted. d Illustration of the girdle block positions in the Ascending Passage. The shaded wheels represent the pulley-like system intermittently positioned at each girdle position during the growth of the Ascending Passage in pyramid core construction. e Masonry of the Horizontal Passage to the Queen’s Chamber (drawing based on: Tavola 6 in Vito Maragioglio, L’Architettura delle Piramidi Menfite, Part IV, Roma 19659). Masonry blocks are shown in alternating shading to highlight the horizontal and vertical alignment of the masonry with cross-shaped joints. Red arrows: The position of the vertical grooves in the Grand Gallery matches the position of the blocks in the Horizontal Passage. The blocks in the Horizontal Passage have 2 cubits length/periodicity, while the grooves in the Grand Gallery have 3 cubits lateral periodicity, i.e., \(\sqrt{1.25}\)·3 cubit periodicity along the Grand Gallery axis.

The position of the Antechamber shaft can be estimated based on the Antechamber floor slab structure and the position of North-South passage of the South ‘airshaft’ exiting from the Queen’s chamber: Accordingly, the shaft should be at least ~3.4 m long (North–South) corresponding to the dimensions and position of two granite floor inlay slabs, reaching from ~0.2 m North of the Granite Leaf to ~0.8 m South of the South-wall with the rope guidance groves9. The shaft was entirely open to the East, from where the blocks were brought to the shaft footing (see “Proposal for how the Great Pyramid of Giza was built”), and extended ~2.5 m to the West, delimited by the Queen’s Chamber South ‘airshaft’ that passes through masonry ~3 m West from its East-wall (Figs. 6a, 1b, inset). The shaft walls should have been constituted of high-quality, almost vertical masonry defined by the solid masonry that supports the King’s Chamber to the South, the Grand Gallery to the North, and likely similar sturdy masonry to the West.

According to the model, the base of the King’s Chamber was built using the Antechamber pulley-like system fueled by the Grand Gallery sliding-ramp, and the upper parts of the King’s Chamber were built using a pulley-like system fueled by the ScanPyramids’ big void sliding-ramp, where blocks were lifted through the same main shaft in a vertical axis in front of the King’s Chamber and through the Antechamber pulley-like system (Fig. 6a). Note, ScanPyramids’ big void26 is not a confirmed structure, and the prediction that it is a Grand Gallery-like sliding-ramp coupled to an Antechamber-like pulley-like system is hypothetical and should be considered as such throughout the text (Table S3).

Further evidence of a vertical shaft and subsequent heterogeneous filling has been reported from another, analogous location in the pyramid: There is a quite odd step, ~0.5 m high, located ~5.5 m North of the Queen’s Chamber in the Horizontal Passage8,9,31. The resulting low-plateau between Queen’s Chamber and step is located with regard to the Queen’s Chamber at the analogous position where the Antechamber pulley-like system is located with regard to the King’s Chamber (Fig. 6b).

In analogy, the base of the Queen’s Chamber could have been built using a pulley-like system fueled by the Ascending Passage sliding-ramp (over an extended horizontal rope), and the upper parts of the Queen’s Chamber using a pulley-like system fueled by the Grand Gallery sliding-ramp (at that stage of construction ~3/4 in length) and the Ascending Passage, where blocks were lifted through a vertical shaft in an axis in front of the Queen’s Chamber (Fig. 6b). Thus, the ~5.5 m long low-plateau between Queen’s Chamber and step is interpreted as a structural anomaly that is the structural homolog to the Antechamber with regard to the King’s Chamber—only in the case of the King’s Chamber and Antechamber a granite inlay floor has later been placed13, while this has never been done for the Queen’s Chamber and the low-plateau8. This region in the pyramid had also attracted the attention of gunpowder archeologist Howard Vyse, who ‘investigated’ and described the floor in the region between the step in the Horizontal Passage and the Queen’s Chamber as full of sand and rubble-work11 (Citation S4). This qualitative assessment has been quantitatively corroborated by microgravimetry that showed strong negative values in the first ~5 meters of the Horizontal Passage next to the Queen’s Chamber39.

Thus, it seems likely that Vyse discovered in the vertical axis in front of the Queen’s Chamber a shaft that was later filled with sand and rubble11 (Fig. 6b), which the model would predict (Table S3) to be found in the vertical axis (Fig. 6a) underneath the floor inlay slabs of the Antechamber8,9,34. For both locations, in the case of the Queen’s Chamber’s Horizontal Passage at the exact position, and in the case of the Antechamber in the close-by North-East corner of the King’s Chamber instead, microgravimetry anomalies with the lowest local survey values have been measured39. Thus, architectural analysis and physical measurements point towards the former existence of shafts related to the construction using pulley-like systems that have later been filled with crude, lower-density fill-material.

Further evidence (Table S2) for the pulley-like system/sliding-ramp model is provided by the masonry in the Ascending Passage. Indeed, the Ascending Passage features direct structural evidence for the propagation and physical integration of a pulley-like system to a sliding-ramp during pyramid construction (Fig. 4): In brief, the Ascending Passage wall masonry features blocks with joints that are perpendicular to the slope of the floor, and blocks with joints that are vertical with regard to the pyramid, termed girdles8,9,10,13 (Fig. 6c, labeled ‘nth girdle’). These girdle blocks are preceded by particularly long wall blocks on either one side that feature modifications (Fig. 6c). The girdles formed vertical boundaries when they were top of the sliding-ramp construction intermediate and were therefore suited to interface with a platform on which the pulley-like system stood (Fig. 6d, see Figs. 3–5). Naturally, these vertical girdle blocks absorb the lateral force component from the counter-weight sliding down the sliding-ramp acting on the pulley-like system. The top of the ascending passage also features sides with vertical joint/ending suggestive that it also represented a sliding-ramp intermediate (Fig. 6c, labeled ‘top girdle’). In this case, the shaft should be located next to where today the Well Shaft is located9, but the sparseness of information about the Well Shaft precludes further speculations. The upper, perfectly vertical part of the Well Shaft appears, however, to feature planned masonry and could thus be related to a pulley-like system shaft at the top of the Ascending Passage9.

In addition, Smyth described the floor of the Ascending Passage masonry as excessively hard and polished13 (Citation S5). Smyth considered that continuous application of weight and friction hardened and smoothened the floor of the Ascending Passage, which appears more plausible in light of its use as a sliding-ramp for heavily loaded sledges than human feet. The feature is of notice as robbers would never try to circumvent the plug-stones in the Ascending Passage by digging underneath, but either over them or by the side—a reasoning that the builders were naturally considering. Thus, the fact that the floor is harder and smoother than the walls and roof indicates that the floor had either been chosen to be built of harder stone to serve as a solid support or indeed had been hardened and smoothened by use.

The Grand Gallery does not comprise vertical girdle blocks; instead, it features vertical grooves cut into the wall masonry, above holes cut into benches (Fig. 6, green). The vertical groves have an average periodicity of ~1.72 m. According to the presented model, the vertical grooves were used to insert cross-beams that secured the pulley-like system, which stood on a platform in front of them, functionally akin to the girdle blocks in the Ascending Passage. Thus, the vertical grooves report about the advance of the pulley-like system as the Grand Gallery sliding-ramp grew during construction. Thus, the lateral advance of the pulley-like system at the front of the Grand Gallery sliding-ramp, as reported by the vertical grooves, can directly explain the masonry structure in the Horizontal Passage underneath, where blocks are arranged with cross-shaped joints (Fig. 6e). The Edgars described the block arrangement in the Horizontal Passage to the Queen’s Chamber, the only location in the pyramid giving direct access to study the masonry underneath a sliding-ramp, as ~20.5 m of identically 2 cubit sized blocks, 41.25 inches, i.e., ~104.8 cm, arranged with cross-shaped joints, also symmetrical with regard to the two sides of the passage34 (Citation S6); corroborated by Mariglio and Rinaldi9,10. The cross-shaped joints are astonishing, as wall construction normally implies placing blocks of an upper course laterally shifted by half the block size, so as to maximize the intercalation of blocks in a wall. Astoundingly, the lateral propagation of the blocks in the Horizontal Passage, matches the locations of the vertical grooves and thus the propagation of the pulley-like system in the Grand Gallery above (Fig. 6e, arrows, Fig. 5b). Indeed, as the pulley-like system advanced with the growing Grand Gallery sliding-ramp, blocks were added in front of the sliding-ramp, leading to the lateral and vertical alignment of blocks in the Horizontal Passage underneath (Figs. 6e, 4f, masonry in the shaft, Fig. 5b). The lateral match between these structures relates every second vertical groove in the Grand Gallery with every third block in the Horizontal Passage, resulting in this rather odd groove periodicity length of ~1.72 m (~3.35 cubit) in the Grand Gallery. The further the Grand gallery grew, the less the relationship was preserved, and after ~20.5 m, the alignment was off by ~9 cm, but in this position the Grand Gallery was already ~10 m higher than the Horizontal Passage, and the non-verticality is negligible with regard to a construction process. Thus, the Grand Gallery grooves and the masonry in the Horizontal Passage establish a vertical relationship within the masonry as would be predicted by the lateral advance of a pulley-like system at the head of a sliding-ramp during the construction process (Figs. 6e, 5b).

Summarizing, the pyramid architecture and masonry, i.e., the vertical girdles in the Ascending Passage, the hardened floor in the Ascending Passage, the vertical grooves in the Grand Gallery, the cross-shaped joints in the Horizontal Passage, the relationship between the latter two structures, the inlaid floor slabs in the Antechamber, the sand- and rubble-work fillings in the low-plateau in front of the Queen’s Chamber, to the local low-density features in the Horizontal passage and the King’s Chamber North-East corner, offer numerous signatures in support of the pulley-like system/sliding-ramp model, and how it was laterally advanced during the construction process.

Construction of the pyramid mantle: Course height-decay bins, concavity, and central furrow on the pyramid faces

There are three further phenomena, observable today on the surface of the Great Pyramid without casing, that remained largely unexplained, namely the varying height of the pyramid courses8, the concavity of the faces10,29,40, and the furrow in the pyramid faces30,40. These phenomena can directly be explained and would be expected, within the framework of the pulley-like system/sliding-ramp pyramid construction model.

So far, only the Ascending Passage and the Grand Gallery with their slope of 1 cubit over 2 cubits have been discussed as force-generation sliding-ramps—and a hypothetical sliding-ramp higher up in the pyramid core, represented by ScanPyramids’ big void—has been proposed (Figs. 1, 6). However, there is one more, today accessible, passage that shares the typical sliding-ramp characteristic: The Descending Passage (Fig. 7a, b). The Descending Passage too has a slope of 1 cubit over 2 cubits, ~26.5°8,9,31, and ‘begins’, though the term ‘ends’ appears more appropriate—as its origin is where it pierces the Giza bedrock and splits with the Ascending Passage—at the north face entrance. Thus, I propose that a pulley-like system, fueled by the Descending Passage as sliding-ramp, operated at the north face entrance lifting blocks at the pyramid periphery to build the pyramid’s mantle (Fig. 7a). Interestingly, the Descending Passage features, akin the girdles and the top in the Ascending Passage (see Fig. 6c), wall masonry towards its top with vertical borders (Fig. 7b, highlighted), potentially interfacing with a horizontally standing pulley-like system. In addition, Petrie describes the Descending Passage floor to be built of the hardest stone8 (Citation S7). The Edgards described the floor of the Descending Passage in its lower parts, roughly below the split with the Ascending Passage, as outstandingly hard and smooth, and report that a haphazardly released block spontaneously slid down the Descending Passage, gaining speed34 (Citation S8), consistent with it having served as a sliding-ramp.

a Pyramid in side-view with Descending Passage as sliding-ramp fueling a pulley-like system at the pyramid periphery. Approximate positions of the ScanPyramids’ north face corridor and a hypothetical upper pulley-like system with sliding-ramp are shown. Left: Section of course height-decay bin distribution8, with the first bin ending in course 18 matching the top of the Descending Passage9 (dashed lines). b Masonry of the Ascending Passage (drawing based on: Plate 2 in C. Piazzi Smyth, Life and work at the Great Pyramid Vol. II13). Ceiling, East (E-) and West (W-) walls, and floor are shaded in colors and labeled, and the masonry ending in a vertical joint is highlighted. c Course heights as a function of pyramid height (graph based on: Plate VIII in W.M. Flinders Petrie, The pyramids and temples of Gizeh8): The course heights are organized in course height-decay bins. Bin bases were computationally identified (asterisks). Dashed red outline: Two particularly short height-decay bins at ~69 and ~75 m height (see “Proposal for how the Great Pyramid of Giza was built”, steps 9–11). d Intermediate state of pyramid mantle construction (schematic, simplified, not drawn to scale) showing the first pulley-like system fueled by the Descending Passage, ScanPyramids’ north face corridor covered with Chevrons, and a second, upper pulley-like system. For the footings of the pulley-like systems to be accessible (the footing of the first pulley-like system is ~13 m inside the pyramid baseline), each height section must have had a straight top course, and a concave course at the base29,30. During completion, the concavity sequentially narrowed, until only an open furrow remained, allowing access to the pulley-like system footing, which was eventually closed, necessitating the coverage of the connection between pulley-like systems with a chevroned roofing27,28. e Average pyramid face concavity map based on data in ref. 29: Flat-to-concave is shown in a blue-to-red false-color scale. Note that flat and concave courses are partitioned into sections. f Central furrow of the pyramid faces: Satellite image from Google Earth, dated April 30, 2023 (right: Raw data; left: Contrast-adjusted West face). Due to the position of the sun, the central furrow is particularly well visible in the West face, but similar furrows are present on all pyramid faces (Fig. S7)30. g Sequence of completion of the pyramid mantle construction (schematic, simplified, not drawn to scale), possibly explaining concavity and central furrow of the pyramid faces: The pyramid has a more step-pyramid-like core. Sliding ramps, e.g., the Descending Passage, may have fueled pulley-like systems that stood peripherally at the edges of each ‘step’. As blocks needed to be lifted up, the uppermost sections were finished first (steps 1–5). Schematic, bottom-right, illustrates that when the sun is in specific positions, the slight concavity and central furrow of the pyramid faces can be seen by eye.

First, as mentioned earlier, overall, the pyramid courses get thinner from bottom to top of the pyramid. However, in detail the situation is much more intriguing: The course heights vary in decaying bins from bottom to top, with several courses at intermediate heights being substantially thicker than their lower neighbors, starting new course height-decay bins8 (Fig. 7c). Computational analysis, identifying courses with height differences to their lower neighbor course at least 3 times greater than the mean of their 4 neighboring (2 upwards, 2 downwards) course height differences, allowed to detect 14 course steps (15 including the 1st course) that start new course-height decay bins (Fig. 7c, asterisks). While the precise number of construction ‘bins’ on the pyramid face needs further elaboration, their occurrence and morphology are signatures of a physical process and can be explained by the presented model. The lower courses with the larger blocks within each course-height decay bin, are likely built by lifting the blocks and pulling them to the side while they hang on the ropes of the pulley-like system (see Fig. 4c), while the higher courses within each course-height decay bin may be constituted of blocks that are lifted all the way up into the pulley-like system or that have been pulled sidewise while hanging on the ropes (see Fig. 4d). In such a setting, a gradual size-decrease of the blocks should be expected with increasing height within the range of a height-decay bin, as it overall diminishes the force that the workers need to provide—and facilitates the possible lateral extraction of blocks hanging on ever shorter ropes. In agreement, the first course height-decay bin ends at 17 m height8,9, reaching the top of the Descending Passage on the north face9 (Fig. 7a, c). Based on this finding, the ~15 course height-decay bins on the surface of the pyramid are proposed to represent each the periphery (or a long-lasting intermediate) of a peripheral sliding-ramp, each with ~10 m average height (Fig. 7a, c). These sliding-ramp/pulley-like system ensembles would have been placed roughly in the center of the pyramid face, e.g., the Descending Passage, stacked on top of each other and towards the pyramid center (Fig. 7a, d). The fact that the course height-decay bins get shorter with increasing height (Fig. 7c, observe densification of asterisks with increasing height), matches the fact that the associated sliding-ramps also had to get shorter as the pyramid gets thinner towards the top. Importantly, while the course height-decay bins can be explained as manifestations of the pyramid construction process using pulley-like systems and sliding-ramps, they are unexplained by layer-by-layer and bottom-to-top construction models, unless one is to invoke that they were planned for having a stabilizing function3 in which case they are unexplainably irregular; or for mystical reasons. Thus, the intriguing, binned course height-decay pattern, especially the match of the first course height-decay bin with the top of the Descending Passage, is further evidence for the pulley-like system/sliding-ramp construction model (Fig. 7a, d).

Second, another phenomenon that remains unexplained is that the pyramid faces are not perfectly flat but slightly concave. The concavity of the pyramid faces has been described since the early 1800s8,10,30,40 (Fig. S7), corroborated by modern laser scanning and photogrammetrical analysis29. This high-resolution analysis showed that the overall concavity decreases from bottom to top of the pyramid; however—similar to the course height-decay bins—the detailed situation is more intriguing: The concavity displayed noticeable variations as a function of height on the pyramid faces29. Using the data from this survey, I calculated an average map from all sectors (Fig. 7e), and found several quality steps, i.e., abrupt changes from concave (Fig. 7d, red) to flat (Fig. 7d, blue), on the pyramid surfaces as a function of height. This data matches the construction model using the Descending Passage as sliding-ramp to fuel a pulley-like system on the pyramid surface (Fig. 7a, d): Accordingly, the Descending Passage sliding-ramp, reached its end at the pyramid main entrance with the Chevron structure, where a pulley-like system was placed (see Figs. 4, 5). Due to its working mechanism the pulley-like system lifted blocks roughly vertically up (see Fig. 4), meaning that its footing was ~13 m ‘inside’ the pyramid baseline (Fig. 7d). While the course on which the pulley like system was placed, likely course 18, was straight8,9 (Fig. 7a, d), the courses below had to maintain an overall concave shape to allow blocks to be brought to the footing of the pulley-like system (Fig. 7d). Thus, the pyramid grew with concave faces, i.e., concave height sections, which was never perfectly matched and are the reason for the minor deviations from flatness that is visible today (Fig. 7e). To build the pyramid as a whole, there should have been upper pulley-like systems (Fig. 7a, d), which should each result in one or two of the course height-decay bins (Fig. 7c) and because of their vertical working mechanism also each possibly in a concavity-section (Fig. 7e). The superposition of peripheral pulley-like systems is illustrated by the second level pulley-like system in Fig. 7d. In agreement, the recently discovered ScanPyramids’ north face corridor27,28, initially likely an open-air plateau and only later covered with chevron blocks when the faces got completed, connected the first and second pulley-like system on the pyramid periphery allowing the transfer of blocks between them and thus to higher heights. ScanPyramids’ north face corridor is ~9 m long and ~7 m set back from the pyramid face (today, though masonry analysis suggests that the chevrons extended further towards the periphery), which would thus indicate that the next upper pulley-like system was positioned ~20 m higher up (~(9 m + 7 m)·tan(52); where ~52° is the slant face angle of the pyramid) (Fig. 7a). In agreement, there is a course height-decay bin start at ~38 m height (Fig. 7a, left, Fig. 7c, asterisks). As the construction of the pyramid mantle approached completion, and blocks were added on the face layer-by-layer from the corners towards the center, the concavity of the face got narrower in each pulley-like system section, like a healing scar, until there was only a furrow left. Finally, the connection between the pulley-like systems was fully covered by chevrons—as ScanPyramids’ north face corridor today27,28—and the face could be completed.

The third so-far unexplained phenomenon is the furrow in the center of the pyramid faces30,40. Again, like the course high-decay bins and the concavity, the furrows have been described since the early 1800s40 (Fig. S7), and modern photogrammetry corroborated their existence and provided further detail30. The furrows are visible in satellite images (Fig. 7f). It has been proposed that the central furrow was the result of damage through forceful removal and tossing of casing stones and blocks from the pyramid top down the pyramid faces30. According to the model presented here, the construction went through periods where the faces were concave (Fig. 7d, e), then progressively, to complete the faces in each pulley-like system section, the concavity was narrowed, until it was only a furrow, where blocks were lifted, and laterally transferred towards the pyramid center to be delivered to the next pulley-like system. A possible sequence of the completion of the pyramid mantle construction is illustrated in Fig. 7g (note, according to the height-decay bins, there should have been more, ~15, peripheral sections than illustrated in this schematic). Sliding-ramps, e.g., the Descending Passage, may have fueled pulley-like systems that stood peripherally at the edges of each ‘step’. The pyramid would thus have had a more step-pyramid-like structure, at least in the central region of the faces. For the completion of the pyramid, blocks were lifted to the highest section, which was finished by narrowing the concave regions and closing the remaining furrow bottom-to-top. Then, this section could be retired, and the second-highest section’s scar was narrowed and closed, and so on. Since the face in each section had to close from the edges, keeping the pulley-like system functional and the horizontal corridor operatable for as long as possible, this process had to result in minor imprecisions in placing the final blocks in the center, which explains the concavity and the central furrow of the pyramid faces as can be seen today. Thus, the furrows may be manifestations of imperfect closing of these clefts, where pulley-like systems lifted blocks up. Conversely, the furrow is further evidence for the proposed model. Anecdotally, the proposed model implicating narrowing the concavity from the edges and closing the central furrow from the top section to the lowest section fits Herodotus’ account that the highest parts were finished first1 (Citation S1).

As the course height-decay bins8 (Fig. 7c), the concavity29 (Fig. 7e), and the central furrow30 (Fig. 7f), are found on all four faces, the suggestion comes naturally that the pyramid mantle was constructed on all four sides. As discussed in the introduction, considering a 16-h work-day over 20 years, the average pace to place blocks is estimated between 1 per minute and 1 every 3 min; and if a shorter construction period was considered3,22, blocks had to be placed between every 30–90 s. Thus, the proposal that peripheral pulley-like systems worked on all four faces not only matches the structural appearance of the pyramid, but can also provide an explanation for the tremendous pace of the pyramid construction (see “Proposal for how the Great Pyramid of Giza was built”).

There is more evidence in support of this proposal: Mariglio and Rinaldi inspected Vyse’s hole, the breach that Vyse dynamited into the South face, and commented that the masonry some meters beyond the well-aligned outer course was quite irregular10 (Citation S9). In addition, microgravity measurements revealed density variations within the pyramid that could be interpreted as indicating that the Great Pyramid had a step-pyramid-like inner structure41. Similarly, inspection of the breach that Sultan Al-Aziz Uthman broke into Menkaure’s pyramid north face, reveals a step-like pyramid core manifested by high-quality, almost-vertical masonry inside the pyramid42. Finally, because of their lower-quality masonry, most of the 5th Dynasty pyramids have crumbled enough to reveal that they have a step-pyramid-like core22 (Fig. S8a).