Abstract

Photodetectors, as the core devices for optical signal conversion, need to balance high efficiency, fast response, and low-cost fabrication. Perovskite, with its advantages of high carrier mobility and tunable band gaps, have become an ideal alternative to silicon-based materials. This paper systematically reviews the progress in the patterned fabrication techniques and device construction of perovskite photodetectors across various dimensional material systems. First, it introduces five mainstream patterned fabrication methods for perovskites: template-confined growth, inkjet printing, vapor deposition, seed-induced growth, and conventional photolithography. Then, the latest research on image sensors based on perovskite materials in different dimensions is discussed. Following this, the paper highlights two promising application directions with great development potential: flexible wearable devices and electrochemical vision systems. Finally, the challenges and potential solutions for the future development of patterned perovskite photodetectors are presented to guide the development of high-performance perovskite optoelectronic devices.

Similar content being viewed by others

Introduction

Photodetectors (PDs), which convert light signals into electrical signals1, are widely used in fields such as digital signal imaging2,3,4, optical communication5,6, and biomimetic systems7,8,9. Currently, silicon is commonly used for the construction of PDs10. Despite significant research advances in the use of silicon-based PDs, the materials have drawbacks such as poor light absorption11 and inadequate mechanical properties12. These drawbacks limit their ability to fully meet the rapidly evolving demands of optoelectronic devices. Perovskite is a novel material with an ABX3 structure (Fig. 1)13,14. In this structure15, A and X represent cations and anions, respectively. A is typically a monovalent organic cation or molecular group, while B is often a metal cation and X commonly denotes a halide anion16,17. A cations occupy the eight corners of an octahedron, while B cations reside at the center. X anions are located at the centers of the six faces18. This arrangement forms an octahedral structure around the B cation, with A cations residing within the octahedral voids. This configuration achieves charge neutrality within the crystal lattice19. Moreover, the structural stability of perovskite crystals is predominantly determined by the size and charge distribution of the A cation20. The unique crystal structure of perovskite materials gives them exceptional physicochemical properties, including a high carrier mobility21, high absorption coefficient22, tunable optical bandgap23,24, low defect density25, and long carrier diffusion lengths26,27. In addition, perovskite materials have a rich compositional system, and by controlling the composition of the perovskite, the material can respond to different wavelength ranges, making it suitable for constructing detectors for various wavelength ranges28,29. These outstanding properties make them highly promising for the fabrication and investigation of the performance of optoelectronic detectors30,31,32,33.

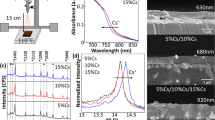

A systematic diagram from material dimensions and patterning processes to device applications. Perovskite structure. Reproduced with permission15. Copyright 2019, The Royal Society of Chemistry. Major patterning methods, including template-confined growth. Reproduced with permission54, Copyright 2021, Wiley-VCH GmbH, inkjet printing. Reproduced with permission55, Copyright 2019, WILEY-VCH Verlag GmbH & Co. KGaA. Weinheim, vapor deposition. Reproduced with permission56, Copyright 2019, American Chemical Society, seed-induced growth. Reproduced with permission57, Copyright 2018, The American Association for the Advancement of Science, as well as conventional photolithography. Reproduced with permission58 Copyright 2017, Optica Publishing Group. The dimensions of perovskite materials include zero-dimensional. Reproduced with permission59, Copyright 2019, American Chemical Society, one-dimensional. Reproduced with permission60, Copyright 2020, Tsinghua University Press and Springer-Verlag GmbH Germany, part of Springer Nature, two-dimensional. Reproduced with permission61, Copyright 2018, Royal Society of Chemistry and three-dimensional. Reproduced with permission62, Copyright 2023, The Authors. Small Science published by Wiley-VCH GmbH. Optoelectronic devices involve photodetector. Reproduced with permission64, Copyright 2023, Wiley‐VCH GmbH, integrated array. Reproduced with permission63, Copyright 2024, The Authors. Advanced Science published by Wiley-VCH GmbH, flexible wearable photodetectors. Reproduced with permission64, Copyright 2023, Wiley-VCH GmbH, as well as biomimetic electrochemical vision systems. Reproduced with permission65, Copyright 2020, The Author(s), under exclusive license to Springer Nature Limited

Building on the advancements in the application of perovskite materials in optoelectronic devices, patterning technology, as a key means of optimizing detector performance, is increasingly playing a significant role in the detector field. At this stage, achieving optical management through device structural design becomes crucial for further performance improvement34. Patterning technology is a novel approach that optimizes the performance of optoelectronic devices by constructing ordered device structures through microstructural design of the materials35. By using patterning processes to precisely control the morphology and microstructure of perovskite films, researchers can achieve localized light field enhancement and improved charge separation efficiency36,37,38, thereby enhancing the performance and stability of optoelectronic devices39,40. This technology has been preliminarily validated in fields such as flexible solar cells and PDs, offering technological support for future integration into smart wearable devices41,42,43,44. In 2003, Han et al. pioneered the patterning of perovskite materials45, by demonstrating the successful patterning of PhE-PbI4 thin films and achieving strong green emission at 525 nm. Subsequently, the development of patterning techniques for perovskite materials has received significant research interest46. Patterning technology and microstructural design techniques have also been widely used in the research on semiconductor materials and devices47. In the fabrication of optoelectronic detectors, the quality of the material patterning processes significantly impacts key performance metrics such as linear dynamic range, response speed, and resolution48. The precision of patterning processes directly determines the quality of the photosensitive material49. Perovskite-based PDs are expected to advance numerous emerging research fields, including biosensing, flexible wearables, and vision imaging50,51,52,53.

At present, many review articles focusing on patterning techniques for perovskite materials and the construction of optoelectronic detectors. Most of the existing literature concentrates on visible light optoelectronic detectors. A comprehensive review summarizing patterning techniques for both UV-Vis-NIR light and X-ray perovskite optoelectronic detectors and their applications in the optoelectronic field remains scarce. Therefore, it is warranted to conduct a timely review summarizing recent advances in their patterning techniques that bridges the gap between fabrication technologies and practical applications. This review summarizes the progress in patterning techniques of perovskite materials and their integrated application in optoelectronic devices, combining patterning processes with device construction, aiming to provide a systematic overview and reference for this field. As shown in Fig. 1, this paper first provides an in-depth analysis of the current status, advantages, and challenges of major patterning methods, including template-confined growth54, inkjet printing55, vapor deposition56, seed-induced growth57 and conventional photolithography58 from the perspective of process principles. Based on this, the key performance evaluation criteria for PDs are introduced, and the physical mechanisms by which patterned processes optimize device performance by controlling grain boundary density, charge transport pathways, and interface contact characteristics are revealed. For different dimensional perovskite systems, this paper provides a detailed review of the technological breakthroughs, structural advantages, and existing bottlenecks in the device construction of zero-dimensional59 (0D), one-dimensional60 (1D), two-dimensional61 (2D) and three-dimensional62 (3D) patterned perovskite materials63. It further introduces the exciting application prospects demonstrated by flexible wearable PDs64 based on patterned perovskites and biomimetic electrochemical vision systems65. At the end of this review, the core challenges currently faced in the field, including material environmental stability, device uniformity, and scalable fabrication, are analyzed. Solutions are proposed, such as developing new compositional systems, optimizing patterning process flows, and integrating encapsulation techniques, to provide theoretical guidance and technical roadmap references for the development of next-generation high-performance perovskite optoelectronic devices.

Methods for patterning perovskite films

Perovskite patterning techniques primarily include five categories: template-confined growth, inkjet printing, vapor deposition, seed-induced growth, and conventional photolithography. Each method has unique characteristics and achieves precise control over the growth and patterning of perovskite materials through different fabrication approaches to meet various application needs. The following sections will introduce the principles and application features of each patterning method, starting with template-confined growth.

Template-confined growth patterning

Template-confined growth typically uses a pre-selected material as a substrate, facilitating the nucleation and growth of the perovskite material within specifically patterned regions on the substrate. During fabrication, the substrate can either serve as a structural scaffold for the final product or be removed from the system, leaving only the perovskite structure. This offers a high degree of process flexibility. The following sections will introduce two classic template-confined growth approaches for perovskite patterning: template separation and structured templates.

Template-separation assisted patterning

Polystyrene microspheres, with its ease of molding and uniform size, has emerged as a widely used template-assist material. In 1996, Whitesides et al. pioneered the use of polydimethylsiloxane-fabricated microspheres (PDMS) for perovskite patterning, ushering its use in template-assisted patterning66. Luo et al. fabricated a pre-patterned polymethyl methacrylate (PMMA) micropore array template on a hydrophilic glass substrate using photolithography. Subsequently, they applied uniform pressure to hydrophobic PDMS, immersing the template completely in the perovskite precursor solution composed of methylammonium bromide (MABr) and PbBr2 dissolved in N, N-dimethylformamide (DMF), and pressing them onto the glass substrate. Under capillary action, the perovskite precursor solution entered the voids of the PMMA micropore array. As the solvent slowly evaporated, the perovskite nucleated at the edges of the pores and gradually grew. After keeping the structure at room temperature for 6 h, the PDMS was peeled off, yielding a fabricated rectangular methylammonium lead bromide (MAPbBr3) micropore plate (Fig. 2a, e)54. Luo et al. characterized the plate using scanning electron microscopy (SEM) and atomic force microscopy (AFM). They reported that over 96% of the plates exhibited a rectangular morphology, with individual plate thicknesses of ~500 nm and lengths ranging from 10 to 15 μm. The plates had an excellent photoresponse and good stability in an ambient atmosphere.

a Schematic of the fabrication of patterned MAPbBr3 single crystal arrays. Reproduced with permission54, Copyright 2021, Wiley-VCH GmbH. b Preparation protocols of the artificial template and halide perovskite photonic crystals. Reproduced with permission67, Copyright 2017, American Chemical Society. c Schematic of the preparation of MAPbBr3 perovskite nanowire (NW) arrays. Reproduced with permission73, Copyright 2017, American Chemical Society. d Schematic outline of the preparation of CsPbCl3 microdisk (MD). Reproduced with permission74, Copyright 2017, WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim. e SEM image of MAPbBr3 single crystal arrays, the scar bar is 200 µm. Reproduced with permission54, Copyright 2017, American Chemical Society. f Diagrams of the preparation of 2D inverse opal structure perovskite photonic films. Reproduced with permission75, Copyright 2016, American Chemical Society. g Low- (left), medium- (middle), and high-magnification (right) images of MAPbBr3 perovskite NW arrays. Reproduced with permission73, Copyright 2017, American Chemical Society

Plastic polystyrene is often used to make various types of molds. Tüysüz et al. used easily moldable polystyrene to fabricate polystyrene microspheres (PSMS). The authors employed centrifugation to achieve a densely packed PSMS template with monodisperse characteristics. A perovskite precursor solution, composed of 1 M methylammonium halide and 1 M lead (II) halide dissolved in dimethyl sulfoxide (DMSO), was then injected into the prepared template. Centrifugation ensured thorough contact between the microspheres and the precursor solution. Subsequent annealing followed by immersion of the resulting film in a toluene solution removed the polystyrene microspheres, yielding a patterned 3D organic-inorganic halide perovskite thin film (Fig. 2b)67. SEM image analysis showed that the polystyrene microspheres used in the fabrication were effectively removed, and the 3D structure formed by the polystyrene microsphere template was well-preserved, resulting in a honeycomb-like spatial arrangement. The patterned CH3NH3PbI3 (MAPbI3) perovskite 3D photonic crystals fabricated by template-confined growth exhibited excellent order and a distinct photonic band gap. The authors stated that the position of the photonic band gap could be controlled by adjusting the size of the polystyrene microspheres. Subsequently, Tüysüz et al. used the same fabrication method with larger PSMS to create a distributed feedback laser based on a 3D organic halide perovskite thin film. The resulting laser demonstrated good long-term stability under pulsed laser excitation at 1.6 mJ cm−2 68. It is very important to study the long-term stability of perovskites. In certain patterning processes, specific protective measures can effectively prevent perovskite from decomposing under high temperature or humid conditions. However, perovskite materials still face decomposition issues in practical applications. To better understand this phenomenon, the decomposition mechanisms of perovskites and the protective mechanisms in patterning processes that mitigate decomposition will be explored. Perovskite materials are prone to degradation under environmental conditions such as light, moisture, heat, and oxygen. These factors lead to phase transitions, hydration, decomposition, and oxidation of perovskites69. Taking CH3NH3PbI3 lead halide perovskite as an example, water vapor dissolves the perovskite, and the CH3NH3+ cations are deprotonated by H2O to form CH3NH3I. CH3NH3I then decomposes into a mixture of CH3NH2 and HI. On one hand, HI can react with O2 to generate H2O and I2, while HI itself is unstable and easily decomposes into H2 and I2. Therefore, once CH3NH3PbI3 absorbs water vapor, subsequent decomposition reactions will spontaneously occur70. In some patterning processes, byproducts generated can form a protective barrier on the surface of the perovskite film. This barrier acts similarly to encapsulation, isolating the material from moisture and oxygen in the external environment71. Patterning processes can also optimize the geometry of the patterns to regulate heat conduction and stress distribution, reducing the risk of crystal fracture or phase transitions caused by local thermal expansion72.

In addition to fabricating 3D patterned perovskites, template-assisted patterning has been widely used to create 2D and 1D patterned perovskites. Liu et al. employed soft lithography to fabricate polydimethylsiloxane rectangular groove templates. The templates had lengths ranging from 10 to 50 μm, widths of ~1 μm, and depths of about 5 μm. The groove template was then placed on a hydrophilic substrate immersed in an DMF solution containing MAX·PbX2 perovskite. After applying slight pressure to the template, the perovskite solution filled the voids within the grooves. The perovskite then nucleated at the ends of the grooves and grew rapidly along their length. After allowing the solvent to completely evaporate, the template was peeled off, leaving behind 1D patterned perovskite nanowires on the hydrophilic substrate (Fig. 2c, g)73. Figure 2c illustrates the process developed by Liu et al. for fabricating 1D patterned perovskites using a PDMS rectangular groove template. The process involved four steps: First, an DMF solution containing MAX·PbX2 perovskite was confined within the groove template to form the mold. Second, perovskite nucleated at the ends of the groove. Third, the perovskite underwent 1D growth along the walls of the groove. Fourth, after the template was separated, 1D perovskite nanowires were obtained as the final product. The length and width of individual nanowires could be controlled by adjusting the dimensions of the template.

PDMS has good processability and is widely used in microfluidic systems, sensors and other fields. Fu et al. fabricated cylindrical hole templates (CHTs) made of PDMS on a silicon substrate using photolithography. After curing, the CHTs were detached from the substrate. The diameter of the PDMS-CHTs was determined by the size of silicon cylinders arranged in a square lattice on the substrate. Similar to the patterning process used by Liu et al., they first prepared an DMF solution and then immersed the PDMS-CHTs in the solution. The silicon substrate was pre-treated with octadecyltrichlorosilane to increase its hydrophobicity. They then applied slight pressure to the PDMS-CHTs to ensure that the perovskite precursor solution fully infiltrated the voids in the CHTs. After complete solvent evaporation, the fabrication of 2D patterned perovskite MD was complete (Fig. 2d)74. The process by which Fu et al. fabricated patterned perovskite MD, as illustrated in Fig. 2d, is as follows. First, perovskite nucleated at the edges of the PDMS-CHT substrate. Second, the formed nuclei were driven to the center of the PDMS-CHT by capillary forces. Third, perovskite grew into rectangular MD. Fourth, after separating the PDMS-CHT, 2D patterned perovskite MD were obtained as the final product. Similarly, Chen et al. employed a template-assisted patterning method to fabricate 2D patterned inverse opal structure perovskite photonic films (Fig. 2f)75. The authors employed a single-layer artificial opal template, introduced densely packed PSMS with diameters ranging from 100 to 2000 nm, and then added a DMSO solution to the template while spinning the substrate to remove excess solution. They heated the substrate to 100 °C to evaporate the DMSO solution while promoting the crystallization of MAPbI3, after which they immersed the substrate in toluene to remove the PSMS.

Template-separation assisted patterning has several advantages, including ease of template fabrication, a wide variety of possible perovskite precursors, and the ability to separate the product from the template after patterning. These advantages allow reuse of the template, significantly reducing the cost and complexity of subsequent patterning operations. However, the method also has several drawbacks for practical application. For instance, when using liquid perovskite precursors, controlling the precursor flow is difficult, leading to its non-uniform contact with the template. This disadvantage can negatively impact patterning accuracy and hinder commercial viability.

Structural template-assisted patterning

In the process of fabricating patterned perovskites using various template-assisted methods, some templates do not require separation from the finished perovskite and integrate with it, remaining intact on the substrate.

Mirkin et al. fabricated an anodized aluminum oxide (AAO) template with aligned cylindrical nanopores. They applied a mixed solution of DMSO and chlorobenzene to the surface of a rotating AAO template. Then, using a syringe pump to remove any residual material from the AAO surface. During this process, the perovskite precursor solution penetrated the cylindrical pores of the AAO template under the influence of capillary and centrifugal forces. They then annealed the template, during which perovskite nucleated at the bottom of the pores and subsequently grew along the pore walls, forming 1D perovskite nanowires within the cylindrical cavities of the AAO template (Fig. 3a)76. They claimed that this method could be used to produce an array of uniform perovskite nanowires with a dispersion of less than 10% over an area exceeding 80 cm2.

a Synthesis of perovskite nanowire arrays in AAO: (I). MAPbI3 precursor solution penetrates the AAO pores, followed by spin coating and annealing (II) Sample is exposed to a DMSO/chlorobenzene solution followed by a short annealing step. Reproduced with permission76, Copyright 2016, American Chemical Society. b Layer-by-layer structure of 32 × 32 MAPbI3 NW image sensor with schematic of porous anodic AAO template assisted growth of a perpendicularly aligned, high-density MAPbI3 NW array. Reproduced with permission77, Copyright 2016, WILEY-VCH Verlag GmbH & Co. KGaA. Weinheim. c Schematics of the wetting-assisted photolithography process for a patterned MAPbI3 perovskite film. Reproduced with permission78, Copyright 2017, American Chemical Society. d Schematic of the spin-on-patterning (SoP) process of a inorganic-organic hybrid perovskite thin film. Reproduced with permission79, Copyright 2017, WILEY-VCH Verlag GmbH & Co. KGaA. Weinheim. e Schematic of the surface tension-controlled technique for the patterned fabrication of regular perovskite MP arrays. Reproduced with permission80, Copyright 2020, American Chemical Society

Similar to porous alumina, porous aluminum membranes can also serve as growth templates. Fan et al. employed a unique gas-solid-solid reaction process, utilizing a porous alumina membranes (PAM) template to fabricate 1D NW and also arranged them into a large-scale, highly ordered array (Fig. 3b)77. They initially prepared a PAM substrate using high-purity aluminum foil by a two-step anodization process, and then electrochemically deposited lead (Pb) at the bottom of the PAM channels using an alternating current method. Following this, they created a 2 μm thick standalone PAM embedded with Pb nanoclusters by etching away the aluminum substrate in a saturated HgCl2 aqueous solution. Methylammonium iodide (MAI) powder was placed at the bottom of a glass bottle, while a standalone piece of PAM/Pb was secured on a silicon substrate and positioned at the opening of the bottle. Perovskite MAPbI3 nanowires were obtained by the reaction the Pb and MAI vapor. Thanks to the excellent light-harvesting and anti-reflective properties of the fabricated perovskite nanowire array, they successfully constructed a high-performance image sensor with 1024 pixels.

Multi-template technology can also achieve patterning of perovskite materials. Hu et al. demonstrated a wetting-assisted photolithography (WAP) patterning process, claiming that this technique enabled the fabrication of pinhole-free hybrid perovskite thin films in arbitrary shapes78. As shown in Fig. 3c, they first coated a pre-cleaned glass substrate with a mixture of poly(4-butylphenyl-diphenylamine) (TPD) and chlorobenzene (CB). Using photolithography, they fabricated microstructural patterns in the photoresist layer to create the template for the WAP process, the Al2O3±x blocking layer was fabricated on the substrate. The template was spin-drop-casted by CB to duplicate the patterning of the photoresist template on the poly-TPD layer. Then the template was dipped into NaOH aqueous solution to duplicate the patterning of the photoresist template on the Al2O3±x layer. DMF was then spin-cast to remove the photoresist, exposing the hydrophobic surface of the patterned TPD film. Next, lead acetate (Pb(Ac)2) was used as the precursor, and MAI was added to DMF to spin-coat the perovskite MAPbI3 in the hydrophilic regions. Finally, the TPD layer was removed using the CB spin-casting method. The authors claimed that by carefully designing the photolithography template, pinhole-free hybrid perovskite thin films with arbitrary micro-patterns could be fabricated. A similar approach was used by Lee et al. who used a high-resolution SoP technique to fabricate silicon-based perovskite multiplexed image sensor arrays. They achieved perovskite thin film patterning with a resolution of ~1 µm by controlling the wetting/dewetting behavior of the perovskite precursor solution on pre-patterned hydrophilic/hydrophobic surfaces79. The fabrication process they described is illustrated in Fig. 3d. Initially, MAI and PbI2 were dissolved in DMSO to prepare the perovskite precursor solution. Bare substrates were cleaned sequentially with deionized water, isopropanol, acetone, and chloroform, followed by a 30-min ultraviolet/ozone treatment. After cleaning, the substrate was coated with a photoresist layer, that was microstructurally patterned using a photolithography system. Reactive ion etching was then used to remove the hydrophobic self-assembled monolayer selectively, exposing the oxide and rendering that region hydrophilic. The selective removal of the photoresist leads to the formation of regions with different surface energies on the patterned substrate surface, including hydrophilic oxide regions and hydrophobic self-assembled monolayer modified regions. The perovskite precursor solution was spin-coated to form a thin film whose thickness continuously decreased. Decrease of the film thickness during spin coating results in spontaneous dewetting of the solution on the hydrophobic region. Consequently, the solution on the hydrophobic interface migrates to the hydrophilic interface, and excess residual solution is removed from the substrate under the influence of centrifugal force. Finally, the template was thermally annealed to produce the 2D patterned perovskite thin film. The figure shows the steps the authors used in the fabrication of patterned perovskite thin films using the SoP process. They claim that the technique can be applied to various spin-coated mixed halide perovskite materials and deposition methods on different types of substrates. They also developed a matrix of multiplexed patterned perovskite photodiode arrays that had a high performance, and were ultra-thin, and flexible.

The hydrophilicity and hydrophobicity of the substrate surface can lead to differentiated material distribution on the substrate. Using this property, Wu et al. conceived a method for fabricating patterned perovskite films by evaporation-driven assembly, using hydrophilic/hydrophobic templates. They proposed a strategy termed surface tension-controlled assembly, which enables the low-cost, large-scale production of patterned perovskite films on pre-patterned substrates (Fig. 3e)80. They initially prepared the CsPbBr3 perovskite precursor by dissolving CsBr and PbBr2 in DMSO, and modified the cleaned substrates with perfluorooctyl triethoxysilane to create a hydrophobic surface before using photolithography and oxygen plasma treatment to establish periodic hydrophilic arrays on it. After spin-coating with photoresist AZ9260 and baking on a hotplate, the nonwettable substrate was covered by a designed photomask and exposed to ultraviolet (UV) light. The substrate was then immersed in acetone and ethanol to remove the photoresist, followed by plasma treatment of the non-wettable regions to create pre-patterned substrates. They then coated the patterned substrate with the perovskite precursor solution, forming an array of droplets on it, before drying, which restricted the nucleation and growth of the perovskite to the patterned hydrophilic regions. By controlling the evaporation rate of the perovskite precursor, uniformly sized 2D patterned perovskite microplate arrays were produced. They claimed that this surface tension-controlled method is applicable to substrates such as silicon wafers, glass, indium tin oxide (ITO), and SiO2.

In addition to using hydrophilic/hydrophobic templates for fabricating patterned perovskite films, peelable templates produced by photolithography and reactive ion etching are also commonly used for patterned perovskite fabrication. Zou et al. developed a method for producing patterned perovskite films using dry peeling enabled by poly-para-xylylene. They successfully fabricated multicolor patterns of red and green perovskite pixels on a single substrate81.

They first mixed CsBr, PbBr2, and phenethylammonium bromide (PEABr) in DMSO to prepare a green perovskite precursor. Poly-para-xylylene-C was then deposited on the substrate by chemical vapor deposition (CVD) to form a thin film. A two-step process was employed to spin-coat a negative photoresist NR9-3000 onto the poly-para-xylylene film, followed by baking. The poly-para-xylylene film was then etched using reactive ion etching and finally was mechanically peeled off using fine-tipped tweezers to obtain a 2D patterned perovskite film. They claimed that the peelable template process could achieve a resolution of around 4 μm for the patterned films. In addition, the poly-para-xylylene film effectively protected the perovskite, allowing for multicolor patterned perovskite films to be fabricated using multiple rounds of standard photolithography processes.

Unlike separable templates, structural templates are integrated with the patterned thin film during manufacture. In structural template-assisted patterning, the synthesis and patterning of the perovskite are performed simultaneously so that there is no need to separate them, eliminating a step that could damage the final product. The structural template-assisted patterning method offers high operational feasibility, and the patterned perovskite films produced have excellent resolution.

Inkjet printing patterning

Inkjet printing patterning involves directly ejecting the target material onto the substrate through a nozzle to fabricate patterned perovskites82. This method offers advantages such as non-contact application, no need for masks, and minimal risk of substrate contamination83, making it widely used for the patterning of perovskites on various substrates. Currently, the main inkjet printing techniques can be categorized into two types: printing with perovskite precursor inks and printing using perovskite quantum dot (QD) solution inks.

Inkjet printing patterning based on perovskite precursor inks

Early inkjet printing methods used perovskite precursors as inks to achieve the patterning of perovskite films. In this approach, the precursor is ejected from the nozzle to specific target locations on the substrate, followed by processes such as annealing to obtain a patterned perovskite. The inks used in this method have a high stability and simple formulation, and are widely used for the fabrication of various high-precision patterned perovskites.

When exploring the patterning preparation method of perovskite materials, Li et al. devised a method that involved spraying droplets of perovskite precursor onto a substrate, followed by an inkjet printing technique to fabricate patterned mixed perovskite CH3NH3PbI3 nanowires, microwires, networks, and islands (Fig. 4a, b)84. They first prepared an ink by dispersing a mixed perovskite CH3NH3PbI3 precursor in a mixture of DMF and γ-butyrolactone. They utilized a glass substrate coated with ITO, which had been patterned in advance using photolithography after cleaning with acetone, deionized water, and ultrasonic treatment. The perovskite ink was sprayed onto the substrate using an inkjet nozzle, followed by treatment to obtain patterned mixed perovskite CH3NH3PbI3 products. They characterized the products using SEM, which showed that the surface of the prepared nanowires was smooth with few defects and pinholes. Compared to nanowires, the perovskite microwires had a better coverage and uniform distribution. They also noted that when the ink was ejected onto the substrate through the nozzle, most of the solvent remained in the liquid phase due to the lower temperature (about 25 °C), the precursor has enough space to flow and time to crystallize and self-assemble, favoring the large but sporadic perovskite crystallization. As the temperature increased to 45 °C, the crystallization finished before all the solvent had evaporated, causing the ink droplets to tend to form interconnected microgrid networks. When the temperature continued to rise to 75 °C, the evaporation rate surpassed the crystallization rate, holes appeared in the patterned perovskite film, resulting in the formation of island-like structures. By changing the temperature, they were able to control the morphology of the patterned perovskite. They also fabricated a micro-line PD array composed of 5 × 5 pixels using the patterned perovskite, which was then used as an imaging sensor, which achieved clear mapping of light source signals.

a Schematics showing the process of inkjet printing on ITO substrates and a PD array consisting of 25 pixels and the electrode–gap–electrode lateral structure of a single pixel. Reproduced with permission84, Copyright 2017, American Chemical Society. b Energy level diagram and working principle of a hybrid perovskite microwire PD. Reproduced with permission84, Copyright 2017, American Chemical Society. c Diagram of the inkjet printing strategy. Reproduced with permission85, Copyright 2019, WILEY-VCH Verlag GmbH & Co. KGaA. Weinheim. d Optical images of printed perovskite QD patterns with red, green, and blue colors. Reproduced with permission85, Copyright 2019, WILEY-VCH Verlag GmbH & Co. KGaA. Weinheim. e Schematic of perovskite transformation from CsPbX3 ink to a CsPbX3 nanocrystal. The inset is the crystal structure of mixed halide perovskites. Reproduced with permission86, Copyright 2019, WILEY-VCH Verlag GmbH & Co. KGaA. Weinheim. f Schematic of the experimental setup for the electrohydrodynamic printing system. The inset shows the enlarged Taylor cone. Reproduced with permission86, Copyright 2019, WILEY-VCH Verlag GmbH & Co. KGaA. Weinheim. g Typical photoluminescence images of the electrohydrodynamic printed microscale line arrays of an apple tree and a butterfly using three-color perovskite. Reproduced with permission86, Copyright 2019, WILEY-VCH Verlag GmbH & Co. KGaA. Weinheim. h Schematic of the preparation of quasi-2D perovskite composite sheets by inkjet printing. Reproduced with permission87, Copyright 2020, WILEY-VCH Verlag GmbH & Co. KGaA. Weinheim. i Inkjet printing of the CsPbBr3/polyvinylpyrrolidone composite ink. Reproduced with permission88, Copyright 2019, American Chemical Society. j Inkjet-printed, fluorescent CsPbBr3/polyvinylpyrrolidone nanocomposite patterns with dot-constructed microarrays. Reproduced with permission88, Copyright 2019, American Chemical Society

In addition, in order to improve the photoluminescence performance of patterned perovskite QD films, Zhong et al. proposed using inkjet printing to fabricate QD films with excellent photoluminescent properties. They designed an inkjet printing strategy that involved spraying a perovskite precursor solution onto a polymer layer to create patterned perovskite QD (Fig. 4c)85. They used various polymers, including PMMA, polystyrene, polyvinyl chloride (PVC), polyvinylidene fluoride, polyvinylidene chloride, cellulose acetate, and polyacrylonitrile, to fabricate polymer films on glass substrates. The polymer powders were dissolved in DMF or DMSO to prepare polymer solutions, which were then drop-cast onto the substrates to form uniform polymer layers. Different perovskite precursor solutions were used to prepare green, blue, and red patterned inks that were sprayed onto the substrates in predetermined patterns and dried by heating to obtain patterned perovskite QD films. The patterns they produced consisted of 2D arrays of patterned perovskite MD with a single-point size of ~100 µm and a thickness of about 430 nm, successfully achieving photoluminescence in green, blue, and red with a quantum yield as high as 80%. They claimed that the single-layer colored films prepared using this strategy have simpler backlight structures and lower packaging costs compared to multilayer monochromatic films. This colored film has the potential to serve as a backlight source for liquid crystal displays, while the micro-pixel array composed of perovskite QD prepared by this strategy indicates potential applications of patterned perovskite films as micro/mini-light-emitting diode light transfer films (Fig. 4d).

To improve the quality of the patterned perovskite films produced by inkjet printing, Tang et al. developed an electrohydrodynamic (EHD) inkjet printing technique that uses a simple precursor mixing technique to prepare perovskite ink, enabling the fabrication of patterned perovskite arrays by in situ crystallization without the addition of antisolvents (Fig. 4e, f)86. They dissolved the perovskite precursor in DMSO to obtain a precursor ink, which was then placed in a glass capillary tube, and used an ITO substrate, cleaned with acetone and deionized water, as the base. Unlike previous inkjet printing methods, they applied an EHD printing approach to achieve more precise control over the application of the precursor ink. A high voltage was applied between the both sides metal-coated capillary and the grounded substrate, causing the mobile ions in the ink to accumulate at the tip of the nozzle. When the electrostatic stress overcame the surface tension of the internal liquid interface, a fine jet was ejected from the peak of the capillary cone, then the precursor ink could crystallize on the substrate at 40 °C. By controlling the driving voltage, they could regulate the droplet size, and by moving the substrate, they could accurately position the droplets, resulting in patterned perovskite films. They optimized the driving voltage and printing distance while using a small nozzle size to fabricate a high-resolution pattern of perovskite dots with a diameter of ~5 µm. Furthermore, by altering the formulation of the perovskite precursor ink, they produced blue and red perovskite micro-wires and micro-arrays (Fig. 4g), demonstrating the potential of the EHD inkjet printing approach for full-color display applications.

Li et al. also explored the use of in-situ crystallization methods to fabricate patterned perovskites. They developed a strategy for producing 2D patterned perovskites on various polymer substrates using inkjet printing to create luminescent patterns (Fig. 4h)87. They selected three polymer substrates: PVC, PMMA, and polycarbonate to demonstrate the versatility of inkjet printing for fabricating patterned perovskites. The perovskite precursor ink was prepared by adding PEABr, MABr, and PbBr2 to DMF solvent. The precursor ink was then inkjet printed onto the substrate surface, followed by annealing of the printed patterns to evaporate the solvent and form a 2D patterned perovskite array. SEM analysis of the perovskite microplate (MP) fabricated on the three different substrates. The results showed that the spots in the PMMA samples had a distinct “coffee ring” effect, indicating that the ink tended to dissolve the PMMA. In contrast, the spots on PVC and polycarbonate were much more uniform. Stability tests on the fabricated perovskites showed that the perovskite MP on the PVC substrate were the most stable in air, moisture, and light. Additionally, due to PVC’s excellent chemical resistance, the perovskite MP on it were shown to be stable in acids, alkalies, and ethanol, making them suitable for use in various extreme conditions.

Due to the involvement of solution evaporation during inkjet printing, the evaporation rate cannot be precisely controlled, leading to the inherent “coffee ring” effect that affects the uniformity of the morphology of the printed dots after drying. Liu et al. solved this problem using a method for fabricating patterned perovskites that involved adding long-chain polyvinylpyrrolidone (PVP) to the perovskite precursor ink. This additive restricts or even eliminates outward capillary flow, thereby decreasing the “coffee ring” effect during inkjet printing (Fig. 4i)88. They prepared a perovskite precursor ink by adding CsBr and PbBr2 to a DMSO solvent, and they also incorporated a PVP additive. The precursor ink was ejected onto an ITO-coated glass substrate using a nozzle. After annealing to evaporate the solvent, they obtained a microarray of crystalline perovskite nanocomposites with dot sizes ranging from ~40 to 50 µm. They conducted a series of controlled experiments to investigate the effects of the concentration of the PVP additive and fabrication temperature on the printing of the patterned perovskites and observed that at low PVP concentrations, the slow solvent evaporation rate led to the “coffee ring” effect, while at high PVP concentrations, the high viscosity of the ink hindered printing. Consequently, they selected a moderate PVP concentration (250 mg mL−1) for the perovskite precursor ink and printed at different temperatures. The results indicated that at temperatures ranging from 30 to 50 °C, the instability of droplet formation resulted in discontinuous and non-uniform dot arrays. In contrast, the morphology of the perovskite array printed at 70 °C was optimal; at this temperature, the droplet flow was uniform, and the nucleation rate increased alongside the evaporation rate, significantly suppressing the “coffee ring” effect and yielding a more uniform 2D patterned perovskite morphology. Later they employed the inkjet printing of fluorescent CsPbBr3/PVP nanocomposites to create micron-scale dot array, resulting in a fluorescent image composed of green-emitting dot spaced 200 μm apart, which exhibited uniform and bright fluorescence at a macroscopic scale (Fig. 4j).

Clearly, utilizing perovskite precursors as ink for inkjet printing offers the advantage of operational simplicity. In such processes, inks containing perovskite QD are deposited onto substrate materials, forming target patterns after solvent evaporation. The positions of the ink deposition are easily controllable, and the ink is easy to prepare. The “coffee ring” effect that may occur during the patterning operation can be reduced by altering the ink formulation.

Inkjet printing patterning based on perovskite quantum dot solutions

Another method for fabricating patterned perovskites by inkjet printing involves the direct use of perovskite QD solutions as ink. When using this technique, the additives, solvents, and ink preparation significantly influence the characteristics of the product. The main technical challenge lies in how to optimize the fabrication process by adjusting these parameters to achieve uniform morphologies and high-quality patterns of the patterned perovskite.

During the solvent evaporation step when perovskite QD ink is ejected onto the substrate through a nozzle, the “coffee ring” effect can easily occur due to uneven flow of the ink droplets, resulting in a rough surface and uneven composition of the patterned perovskite product. To address this issue, Li et al. designed a strategy that incorporated high-boiling point dodecane (DOE) and low-boiling point toluene (TOL) as additives to the CsPbBr3 perovskite QD ink. By adjusting the ratio of these additives, they aimed to control the flow of the ink droplets, thereby eliminating the “coffee ring” effect89. They dispersed the perovskite CsPbBr3 QDs in DOE and TOL and used a nozzle to spray the ink onto an ITO-coated glass substrate to fabricate patterned perovskite microarrays and microstripes. They captured fluorescent microscopy images of inks with DOE volume contents of 20, 30, 40, 60, 70, and 80%. The results showed that when using a mixed solvent of 60 vol% DOE and 40 vol% TOL, the Marangoni flow from the low surface tension (ST) region to the high ST region counteracted and nearly canceled the natural capillary flow of the liquid. In this scenario, the internal flow of the perovskite ink droplets became more uniform, resulting in a smoother surface of the patterned perovskite array after processing. The images in Fig. 5a show fluorescent micrographs of inks with different DOE volume ratios.

a Fluorescence micrographs of inks with DOE volume contents of 20, 30, 40, 60, 70, and 80% (the scale bars are all 100 μm). Reproduced with permission89, Copyright 2020, Royal Society of Chemistry. b Optical microscope and 3D confocal microscope images of the inkjet-printed QD thin films, left: binary, right: ternary. Reproduced with permission92, Copyright 2022 Wiley-VCH GmbH. c Fluorescence optical microscope image of double horses (lighting area, 44 × 28 mm2), CsPbBr3 matrix (250 pixels per inch), QDs stripe array, and a slogan of “perovskite QDs make the display more vivid” (40 × 16 mm2). Reproduced with permission92, Copyright 2022 Wiley-VCH GmbH. d Schematic of the perovskite QD color conversion film fabrication process by the inkjet-printing method using UV-curing-type ink. Reproduced with permission55, Copyright 2019, WILEY-VCH Verlag GmbH & Co. KGaA. Weinheim. e SEM images of the PEROVSKITE QD film after UV curing. Reproduced with permission55, Copyright 2019, WILEY-VCH Verlag GmbH & Co. KGaA. Weinheim. f Schematic of the film forming process using thermal-curing and UV-curing inks. Reproduced with permission55, Copyright 2019, WILEY-VCH Verlag GmbH & Co. KGaA. Weinheim

During long-term storage, perovskite QD ink is prone to aggregation, and patterned perovskite is unstable in air. To address this challenge, Peng et al. proposed a perovskite QD ink formulation that includes an octane-dodecane co-solvent (in a 4:6 volume ratio) and trace amounts of oleylamine (OAm). This ink was used to fabricate a pattern of perovskite QD by inkjet printing, followed by the development of electroluminescent matrix devices90. They claimed that the addition of trace amounts of OAm improved the dispersion of the perovskite QD in the solvent, allowing the ink to maintain a translucent dispersion and stable storage for up to 1 month. The incorporation of the octane-dodecane co-solvent effectively suppressed the uneven flow of the ink, and thereby preventing the “coffee ring” effect. The electroluminescent matrix devices fabricated using this method achieved a pixel density of 120 pixels per inch.

In addition to these binary solvent systems designed to eliminate the influence of the “coffee ring” effect, ternary solvents have also been used. The primary distinction between them lies in the different internal flow capabilities of the ink droplets during the printing, which also leads to differences in the evaporation rates of the solvents. Compared to binary solvent systems, ternary solvent systems can better balance the boiling point and surface tension of the mixed solvent. In ternary solvent systems, long-term Marangoni flow can be generated by gradient volatilization, which helps decrease perovskite aggregation and the “coffee ring” effect91.

Zeng et al. reported a method for preparing cesium lead halide (CsPbX3) perovskite QD using ternary solvent inks, which were then used to inkjet-print patterned perovskite QD films (Fig. 5b)92. They constructed a ternary solvent system by introducing lower-boiling nonane into higher-boiling naphthalene and tridecane. This ternary solvent system balanced the boiling points and surface tensions of the mixed solvents, resulting in gradient evaporation while accelerating the evaporation rate of the solvent, effectively prolonging Marangoni flow and significantly suppressing the “coffee ring” effect in the printed perovskite QD films. They reported that a solution of naphthalene/tridecane/nonane (7:2:2 volume ratio) produced a uniform 2D patterned perovskite QD film without the “coffee ring” effect. They later used the ternary solvent ink system and inkjet printing to create various large-area, rigid, and flexible luminescent patterns based on different templates (Fig. 5c).

In the process of inkjet printing patterned perovskite, methods to eliminate the “coffee ring” effect include not only the addition of additives to the ink and the use of multi-solvent systems but also the UV curing of the patterned perovskite, which is a widely used approach.

Duan et al. innovatively combined inkjet printing with UV curing to fabricate 2D patterned perovskite films (Fig. 5d)55. They devised a method to first print perovskite QD ink onto a substrate, followed by UV irradiation of the substrate for curing, to fabricate a 2D patterned perovskite color conversion layer that was characterized by optical and scanning electron microscopies. The results indicated that the average thickness of the perovskite films was ~6 µm, with a very uniform thickness and smooth surface with no fractures or discontinuities even at the boundaries of pixel regions (Fig. 5e). The films also showed no significant “coffee ring” effect. This was attributed to the use of a UV-curable acrylate resin ink, which contains only a low concentration of solvent (Fig. 5f). During film assembly, the polymer network formed by UV curing greatly suppressed the flow within the ink droplets, which produced patterned perovskite films of uniform thickness with no “coffee ring” effect. They then used the prepared perovskite films to fabricate color conversion layers, achieving bright green color conversion from blue backlight. The patterned perovskite films produced using this technique also had excellent stability with the perovskite QD remaining well dispersed in the resin after UV curing, effectively isolating them from environmental air and moisture, so that the brightness of the films maintained over 93% of their initial brightness even after 90 days.

Unlike the inkjet printing approach that uses perovskite precursors as ink, the method employing perovskite QD as ink is faced with the susceptibility of the ink to degradation, which can occur when it is ejected onto the substrate, leading to an uneven distribution. The formulation of the ink also means that there is a higher likelihood of “coffee ring” effects occurring during inkjet printing, which can significantly impact the quality of the patterned perovskite products.

Vapor deposition growth patterning

Traditional methods for fabricating patterned perovskite films, such as etching and photolithography, often require direct processing of the perovskite films, which can adversely affect the structural integrity of the perovskite itself and subsequently degrade its optical properties. To minimize the impact of the patterning process on the performance of the perovskite layer, vapor deposition growth has become a recent research focus. The core concept of vapor deposition for the fabrication of patterned perovskites is to control the experimental conditions so that the perovskite precursors are transformed into high-quality perovskite at predetermined target locations93.

A two-step vapor deposition process can pattern MAPbI3 perovskite. As shown in Fig. 6a, b, Huang et al. first immersed a silicon substrate in a octadecyltrichlorosilane (OTS) solution and then rinsed it with acetone to create a monolayer of OTS on the silicon substrate. They subsequently used photolithography and oxygen plasma treatment to selectively remove the OTS from specific locations, forming an array of microstructured hydrophilic regions. The substrate was immersed in acetone to remove the photoresist, resulting in a patterned hydrophilic/hydrophobic silicon substrate. They then deposited a dilute PbI2 aqueous solution onto an inclined silicon substrate and as the solution flowed over the surface, perovskite precursor droplets, formed in each hydrophilic region. After preheating the PbI2 nuclei on the substrate with methylammonium iodide vapor for a period, the seeded substrate was placed in a saturated PbI2 aqueous solution to promote further growth of the PbI2 nuclei. Finally, they employed methyl iodide powder as the methyl iodide source, positioned at the center of a tubular furnace, while placing the silicon substrate with the PbI2 nuclei array downstream. After several hours of treatment with argon as the carrier gas, MAPbI3 patterned perovskite arrays were formed. This gas-phase deposition method allows for the fabrication of periodically arranged perovskite arrays on wafers with a maximum diameter of 4 inches (Fig. 6c, d, e)46.

a Schematic of the procedure for preparing methylammonium lead iodide perovskite plates on a patterned substrate. Reproduced with permission46, Copyright 2015, The American Association for the Advancement of Science. b Schematic of the change in lattice structure from layer PbI2 to tetragonal perovskite after methylammonium iodide intercalation. Reproduced with permission46, Copyright 2015, The American Association for the Advancement of Science. c Dark-field optical microscope image of perovskite MP arrays. Scale bar, 200 μm. Reproduced with permission46, Copyright 2015, The American Association for the Advancement of Science. d Higher-magnification bright-field optical microscope image of perovskite MP arrays. Scale bar, 20 μm. Reproduced with permission46, Copyright 2015, The American Association for the Advancement of Science. e SEM image of perovskite arrays. Scale bar, 20 μm. Reproduced with permission46, Copyright 2015, The American Association for the Advancement of Science. f Schematic and energy diagram of CsPbBr3-GaN heterojunction. Reproduced with permission94, Copyright 2019, Royal Society of Chemistry. g Cross-section SEM image of the CsPbBr3-GaN heterojunction. The cross-section of the CsPbBr3 MP shows a uniform thickness. Scale bar: 2 μm. Reproduced with permission94, Copyright 2019, Royal Society of Chemistry. h SEM image of oriented CsPbBr3 MP with a uniform rectangular shape epitaxial on a c-wurtzite GaN/sapphire substrate. Right: EDS images of the as-gown CsPbBr3 MP. Scale bar: 20 μm. Reproduced with permission94, Copyright 2019, Royal Society of Chemistry. i Setup and corresponding crystal structure changes for the gas-solid-phase intercalation process. Reproduced with permission56, Copyright 2019, American Chemical Society. j SEM images of converted (BA)2PbI4. The scale bar is 20 μm. Reproduced with permission56, Copyright 2019, American Chemical Society. k Optical microscope image of CsPbBr3 wire networks grown on phlogopite mica. Inset is 2D fast Fourier transform of the corresponding image, showing these wires are oriented with a hexagonal symmetry. Reproduced with permission95, Copyright 2017, Royal Society of Chemistry

In addition to manufacturing 3D structured patterned perovskites, gas-phase deposition methods are also suitable for the preparation of 2D patterned perovskite film arrays. Zhang et al. proposed combining gas-phase deposition with epitaxial growth techniques to fabricate 2D patterned perovskites. They designed a method for growing highly oriented single-crystal cesium lead bromide (CsPbBr3) on a rectangular GaN/sapphire substrate (Fig. 6f)94. They employed metal-organic CVD to prepare c-plane GaN on sapphire as the substrate for perovskite growth. After cleaning the substrate with acetone, ethanol, and deionized water, they positioned it downstream in the CVD furnace while placing a mixed powder of CsBr and PbBr2 at the center of the furnace. Using argon as the carrier gas, they heated the system to facilitate the reaction, resulting in CsPbBr3 perovskite MP (Fig. 6g, h). They claimed that SEM characterization confirmed the produced CsPbBr3 MP exhibited a uniform rectangular shape, possessing orthorhombic or cubic phases, with dimensions ranging from a few micrometers to several tens of micrometers, and had a structural stability comparable to that of structures grown on mica substrates.

Some researchers have taken a novel approach by developing a two-step synthesis method that combines gas-phase and solution-based techniques for the preparation of 2D patterned perovskites. Li et al. reported a two-step method for producing 2D patterned perovskite MP and arrays, which integrates solution synthesis with gas-solid phase intercalation (Fig. 6i)56. Similar to Huang et al.46, they first prepared a patterned hydrophilic/hydrophobic silicon substrate using photolithography and then deposited a saturated PbI2 aqueous solution on it and allowed it to dry, resulting in the formation of condensed droplets of PbI2 in the hydrophilic regions. The silicon substrate with the grown PbI2 seeds was immersed in a saturated PbI2 aqueous solution and blow-dried with argon, to produce a silicon substrate with an array of PbI2 MP. Li et al. used butylammonium (BA) iodide and BA chloride powders as ammonium sources, placing them at the center of a tube furnace while positioning the silicon substrate with the grown PbI2 MP array downstream. Following this, the furnace was filled with argon and heated to 150 °C to complete the intercalation, resulting in the formation of (BA)2PbI4-xClx 2D patterned perovskite films (Fig. 6j). Images indicated that the MP retained a similar hexagonal shape after the intercalation process, while its thickness significantly increased, and the surface became rougher. Characterization of the prepared (BA)2PbI4-xClx MP using SEM, optical microscopy, and photoluminescence mapping revealed that the resulting 2D patterned perovskite array exhibited a square lattice, with individual MP distinctly hexagonal, demonstrating excellent uniformity of the final product.

One-dimensionally patterned perovskite nanowires and microwires (MWs) can also be fabricated by vapor phase epitaxy based on vapor deposition techniques. Chen et al. employed a mixture of CsX and PbX2 powders as the perovskite precursor that was placed in a chemical vapor deposition reactor, with freshly cleaved muscovite or phlogopite positioned in the middle to lower section of the reactor as the substrate for vapor-phase epitaxial growth95. By introducing argon as the carrier gas and heating the reactor to 300 °C, they achieved the synthesis of CsPbX3 perovskite nanowires. They noted that the freshly cleaved mica surfaces were smooth and free of dangling bonds, allowing for relaxed lattice matching conditions, which helps the growth of large, high-quality perovskite nanowires. They conducted optical microscopy characterization of the synthesized CsPbBr3 NW and as shown in Fig. 6k, the two samples had similar product morphologies after 2 h of CVD growth at 325 °C on p-type and m-type mica substrates. The NW were aligned parallel to the mica substrate, forming a network structure. The width of the NW was typically around 1 μm, with lengths reaching several tens of micrometers. Due to the approximately hexagonal symmetry of the mica (001) plane, the CsPbBr3 NWs grow in six directions with a 60° or 120° angle to each other, resulting in a uniform overall morphology.

The vapor deposition patterning method uses gaseous precursors, ensuring thorough interaction between the gas and the substrate during the process, which facilitates complete reaction. However, the process involves lattice insertion, which may induce crystal distortion and consequently degrade the quality of the patterned perovskite products.

Seed-induced growth patterning

Seed-induced growth is a method for fabricating patterned perovskites that uses the epitaxial growth of the target product at designated sites96, achieving both the formation of a product array and the desired material patterning.

In conventional laser patterning methods for perovskites, the direct action of the laser on the perovskite film leads to structural damage and a loss of performance while achieving the desired patterning97. Liu et al. innovatively used micro-patterned boron-nitride (BN) films to create a buffer layer, constructing a patterned high-quality perovskite array on a silicon substrate (Fig. 7a)98. They first processed the BN film using photolithography to establish growth sites, followed by the nucleation and growth of MAPbI3 perovskite using physical vapor deposition (PVD). Different shapes and thicknesses of patterned perovskite arrays can be fabricated through the design of the BN film patterns and by controlling the growth time. The BN film acts as an intermediary layer, providing epitaxial growth contact points between the silicon substrate and the perovskite layer, resulting in a perovskite microcrystalline array with good crystalline and high optical quality.

a Schematic of the process used to grow hexagonal lead halide perovskite (MAPbX3, X = Cl, Br, I) MP arrays on BN patterned films with an SEM image of the prepared MAPbX3 platelet array. Reproduced with permission98, Copyright 2016, The Authors. Published by WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim. b Schematic of the scalable growth of perovskite single-crystal films. Reproduced with permission57, Copyright 2018, The American Association for the Advancement of Science. c Schematics of the vapor-phase fabrication of CsPbBr3 MP arrays. Reproduced with permission99, Copyright 2020, WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim. d Optical images of the CsPbBr3 MP growth process. The scale bar is 50 µm. Reproduced with permission99, Copyright 2020, WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim. e Illustration of seed-assisted space-confined vapor-phase growth. Reproduced with permission100, Copyright 2021, Wiley-VCH GmbH. f Schematic of the space-confined vapor-phase-growth setup. Reproduced with permission100, Copyright 2021, Wiley-VCH GmbH

To address the problem of lattice mismatch during the patterning by vapor deposition, Gu et al. developed a novel synthesis method for cesium lead bromide (CsPbBr3) perovskite films. (Fig. 7b)57. They dissolved the perovskite precursor in DMSO to prepare a perovskite precursor ink, which was then printed to selected positions on the silicon substrate using inkjet printing. As the ink evaporated, ordered perovskite crystal seeds formed on the substrate. The substrate with the perovskite crystal seeds was then placed in a CVD tube furnace, where nitrogen gas was introduced, and the temperature was maintained at 650 °C for 15 min to achieve the epitaxial growth of the CsPbBr3. Figure 7c, d illustrates the growth process from seeds to microplate arrays. Subsequent analyses revealed that the growth sites introduced on the silicon substrate significantly lowered the crystallization barrier during perovskite growth, effectively reducing lattice mismatch and the likelihood of random nucleation. This method yielded patterned perovskites of a uniform shape and controllable size and position99.

The combined seed-induced growth and template-restricted growth method can be used to achieve patterning of CsPbI3 perovskite. Lan et al. cleaned the silicon substrate with dry nitrogen and immersed it in hexamethyldisilazane (HMDS) vapor for 30 min (Fig. 7e, f)100. After that, it was rinsed with acetone for 30 s to form a self-assembled HMDS hydrophobic monolayer on the substrate surface. A polymethyl methacrylate film was spin-coated on the substrate and square array pattern was fabricated by electron beam lithography. HMDS was selectively removed from specific locations to obtain periodic arrays of hydrophilic regions by oxygen plasma treatment. Then, polymethyl methacrylate was removed by ultrasonic cleaning in acetone for 10 min. CsI and PbI2 powders were dissolved in N, N-dimethylformamide solvent to prepare the CsPbI3 precursor solution. The seeded substrate was fabricated by dropping the precursor solution onto the pre-patterned silicon substrate and heating the substrate at 70 °C for 10 min to evaporate N, N-dimethylformamide solvent. A seeded silicon substrate covered by a piece of precleaned mica formed a space-confined reactor, which was placed at the center of a tube furnace. After purging by Argon gas for more than three times, the quartz tube was heated to 570 °C, and the growth time was set to be 5 min. The CsPbI3 microplate arrays had a smooth surface and very sharp edges, indicating their excellent crystal quality. Their research provided a new convenient and effective route to controllably grow perovskites arrays.

Seed-induced patterning can be utilized to fabricate high-quality patterned perovskites. However, the process involves many steps, including substrate preparation, inkjet printing, and epitaxial growth, which come at the cost of increased complexity and higher production expenses although achieving high-quality products.

Conventional photolithography patterning

Photolithography has advantages such as a high processing speed, high precision, and the absence of a template, making it widely used in the fabrication of patterned perovskites. Currently, common photolithography approaches include focused ion beam (FIB) lithography, electron beam lithography (EBL), laser direct writing (LDW), laser ablation, and laser modification101.

Focused ion beam lithography patterning

In the early stages, the method of using photolithography to fabricate patterned perovskites involved directly applying FIB on perovskite substrates to construct patterns by the interaction of the ion beam with the perovskite. Alias et al. reported a method for patterning methylammonium lead bromide (MAPbBr3) perovskite crystals using FIB technology (Fig. 8a)102. They applied a FIB with a Ga+ ion source to directly pattern the surface of MAPbBr3 perovskite crystals, creating binary and circular subwavelength grating (SWG) reflectors with nanometer-level precision and excellent uniformity (Fig. 8b–e). The grating thickness was ~70 nm and had a high reflectivity of about 97% at 570 nm. However, this direct ion beam process on the perovskite substrate has significant side effect: the high-energy ions used in FIB may damage the surface of perovskite crystals, and reducing the ion dose may still result in the amorphization of the crystal surface. The authors acknowledged these problems and developed a method using XeF2 and I2 gases to create an assisted environment for chemical gas-assisted focused ion beam etching in the fabrication of patterned perovskites (Fig. 8f)103. They fabricated SWG of equivalent specifications that had better absorption (>90%) across a broad spectral range (400–1100 nm), and improved the controllability of the manufacturing process while also improving etching precision and surface integrity.

a Schematic of the MAPbBr3 perovskites SWG reflector. Reproduced with permission102, Copyright 2015, AIP Publishing. SEM images of a binary SWG b normal to the surface and c at 45°. Reproduced with permission102, Copyright 2015, AIP Publishing. SEM images of a circular SWG d normal to the surface and e at 45°. Reproduced with permission102, Copyright 2015, AIP Publishing. f SEM images (top-down view and 45° tilt). Reproduced with permission103, Copyright 2015, American Chemical Society

Electron beam lithography patterning

To reduce damage to the perovskite substrate during the FIB patterning process, electron beam lithography (EBL) technology has been developed, in which the focused electron beam directly acts on the electron-sensitive photoresist covering the substrate under programmed control, creating the desired pattern in the photoresist layer. This pattern is then transferred to the perovskite substrate under the photoresist using fabrication processes mentioned earlier, such as the template method or chemical vapor deposition. After removing the photoresist, the required patterned perovskite is obtained.

Song et al. designed a top-down approach to fabricate micron and nanoscale patterned perovskite structures using EBL and inductively coupled plasma (ICP) etching on single-crystal perovskite MP (Fig. 9a, b)58. They employed ITO-coated glass substrates with the surface covered by a solution of MABrPbBr2 formed by dissolving MABr and PbBr2 in DMF. The pattern was then created in a PMMA resist using electron beam lithography and transferred to the organic metal halide perovskite by ICP etching. The resulting 2D patterned perovskite circular MD could be fitted to a radius of 7.34 µm and had a surface roughness of less than 100 nm (Fig. 9c, d). They claimed that the process not only enabled the fabrication of uniquely shaped patterned perovskites but also offered improved reproducibility. Qiu et al. recognized the significant potential of EBL in fabricating perovskite gratings. They reported a method that uses EBL to pattern the resist film and combined it with ICP etching to produce a 1D patterned perovskite periodic array (Fig. 9e)104. They fabricated color pixels with a width as small as 1.28 μm and a fixed stripe length of 3.5 μm, achieving a spatial resolution of up to 7257 dots per inch (Fig. 9f, g). They also created a sample of 530 × 610 μm2 to show a complex logo (Fig. 9h, i). They claimed that the 2D patterned perovskite structures produced using improved EBL could decrease the angular dependence of device photoluminescence (Fig. 9j).

a Top-view SEM image of an etched perovskite MD. Reproduced with permission58 Copyright 2017, Optica Publishing Group. b Fluorescence microscopy image of a perovskite MD. Reproduced with permission58 Copyright 2017, Optica Publishing Group. c Schematic of the fabricated device. A large perovskite MP is fashioned into a grating and tapered waveguide, which is on top of two silver electrodes mounted on a glass substrate. Reproduced with permission58 Copyright 2017, Optica Publishing Group. d Top-view SEM and corresponding optical image of the device. Reproduced with permission58 Copyright 2017, Optica Publishing Group. e Schematic design of pixels and in-situ color generation by mixing extrinsic structural color and intrinsic emission color on MAPbX3 perovskite gratings. Reproduced with permission104, Copyright 2018, American Chemical Society. f Microscope image of the Harbin Institute of Technology logo without photon doping. Reproduced with permission104, Copyright 2018, American Chemical Society. g The top-view SEM image of the MAPbBr3 gratings. Reproduced with permission104, Copyright 2018, American Chemical Society. h Top-view SEM image of the Harbin Institute of Technology logo. Reproduced with permission104, Copyright 2018, American Chemical Society. i Enlarged SEM image of part of the Harbin Institute of Technology logo. The inset shows the high-resolution SEM image of one pixel of the logo. Reproduced with permission104, Copyright 2018, American Chemical Society. j Microscope images of part of the university logo at different pumping densities. Reproduced with permission104, Copyright 2018, American Chemical Society

Laser direct writing patterning

Lasers have advantages such as high energy, high brightness, and good controllability, making their use for the fabrication of patterned perovskites a recent research focus105. Research has shown that when a laser is applied to perovskite precursors pre-coated on the substrate, the generated heat decreases the solubility of perovskite in the precursor, leading to the crystallization of perovskite from the precursor106.

Chou et al. proposed a method that uses the inverse dependence between perovskite solubility and temperature, reporting the use of lasers for localized heating of perovskite substrates to fabricate patterned MAPbBr3 perovskite (Fig. 10a)107. They first used a laser to deposit platinum in a predetermined cross-pattern on a glass substrate to act as a heating pad. A tunable continuous wave laser with a wavelength of 750 nm was then employed to irradiate the center of the platinum cross-pattern. The heat generated by the laser was conducted through the metal layer to the underlying MAPbBr3 perovskite, triggering its crystallization (Fig. 10b). Using this method, Chou et al. fabricated 1D patterned MAPbBr3 perovskite nanowires composed of interconnected crystals with an average size of 80 μm. They also used the nanowires to create a forked interdigital microelectrode array, which was used as a micro-PD (Fig. 10c, d).

a Schematic of the use of LDW to pattern free-form perovskite structures. Reproduced with permission107, Copyright 2016, American Chemical Society. b Time-lapse photographs showing the LDW of MAPbBr3 on a semitransparent carbon film. Reproduced with permission107, Copyright 2016, American Chemical Society. c A LDW MAPbBr3 wire drawn onto an Au interdigitated microelectrode. Reproduced with permission107, Copyright 2016, American Chemical Society. d Schematic showing the fabrication geometry for patterning on a developed and cured SU-8 photoresist microwell pattern on silicon. Reproduced with permission107, Copyright 2016, American Chemical Society. e Scheme of LDW on a perovskite nanoplate (NP)108. f Microscopic image of NP with laser patterned characters. Reproduced with permission108, Copyright 2019, American Chemical Society. g Fluorescence micrograph of patterned NP under laser excitation. Reproduced with permission108, Copyright 2019, American Chemical Society. h Schematic of the femtosecond laser writing system for sample fabrication. Reproduced with permission109, Copyright 2019, The Author(s), under exclusive license to Springer Nature Limited. i Optical images of a CsPbBr3 QD array during the erasure-recovery processes under UV light. Scale bars, 100 μm. Reproduced with permission109, Copyright 2019, The Author(s), under exclusive license to Springer Nature Limited. j Photograph (left) and enlarged optical microscope image (right) of a CsPbBr3 QD pattern. Reproduced with permission109, Copyright 2019, The Author(s), under exclusive license to Springer Nature Limited

Coincidentally, Wen et al. also explored the use of LDW for the fabrication of patterned perovskites. They reported a femtosecond LDW method for producing 2D patterned perovskite fluorescent NP (Fig. 10e)108. They employed halide-mixed formamidinium (FA) lead mixed-halide (FAPb(BrxI1-x)3) perovskite nanoparticles as the NP substrate, focusing an 800 nm wavelength femtosecond pulsed laser on their surface. The laser beam caused the decomposition of the perovskite NP surface (Fig. 10f, g). Using this approach, they fabricated 2D patterns of perovskite nanoparticles with various specifications.

LDW is commonly used for the fabrication of 3D patterned perovskite films. Dong et al. reported a scheme for fabricating 3D patterned perovskite films by employing femtosecond laser writing of perovskite QD inside transparent glass materials. This approach uses femtosecond laser interaction with a glass substrate to produce network dissociation and atomic rearrangement (Fig. 10h)109. They constructed a 3D structure of CsPbBr3 QD in an oxide glass matrix containing cesium, lead, and bromine using an 800 nm wavelength femtosecond laser. By changing the laser power density and exposure time, the laser’s effective range could be adjusted between 30 μm and 65 μm. They also investigated the effects of the laser on the already formed QDs, discovering that the green light emitted by the QDs could be eliminated by additional femtosecond laser irradiation, as shown in Fig. 10i, j, demonstrating the rewritability of CsPbBr3 QDs in a transparent medium. They also fabricated a 2D patterned perovskite array inside a 6 × 6 × 2 mm3 glass substrate, erasing and remanufacturing portions of the pattern, and constructed a 3D patterned CsPbBr3 QD perovskite film inside a 4 mm glass cube.

Laser-induced modification patterning

Researchers are investigating not only the use of laser-induced perovskite crystallization in LDW but also the interaction between lasers and perovskite ligands for patterning their surface-active layers, which is a cutting-edge area of research. Zeng et al. reported a simple and rapid patterning method based on LDW that involves laser scanning to remove the surfactant surrounding perovskite QD for patterning (Fig. 11a, b)110. Their method can be divided into three steps: spin-coating perovskite QD, laser writing, and solvent cleaning, making it a maskless and programmable approach. They first spin-coated perovskite QD onto a glass substrate, then irradiated the perovskite QD film with a focused continuous wave laser at a wavelength of 405 nm. The laser acted on the film surface under pre-programmed control to complete the patterning process. Finally, an organic solvent was used to clean the perovskite QD substrate, leaving only the perovskite QD in the laser-irradiated areas on the substrate. By performing multiple writing operations on a single substrate, larger macroscopic patterns could be created (Fig. 11c, d). Optical microscope characterization revealed that the macroscopic pattern is composed of many microscopic lines formed by laser writing (Fig. 11e, f). They employed a laser modification scheme to create a quick response code with dimensions of 100 × 100 mm2, and the pattern content could be easily recognized by QR code scanning software, demonstrating the significant potential of the LDW laser modification approach for large-area display applications (Fig. 11g, h).

a Schematic of the patterning process. Reproduced with permission110, Copyright 2017 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim. b LDW mechanism for perovskite QD patterning. Reproduced with permission110, Copyright 2017 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim. 20 mm × 20 mm Nanjing University of Science and Technology (NUST) logo (c) before and (d) after washing under UV light. Reproduced with permission110, Copyright 2017 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim. e Macroscopic grid pattern under UV light. Reproduced with permission110, Copyright 2017 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim. f Patterns composed of a microsize cross grid. Reproduced with permission110, Copyright 2017 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim. g A patterning example on a 100 × 100 mm2 substrate. Reproduced with permission110, Copyright 2017 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim. h Optical image of a QD sample after washing under UV light. Reproduced with permission110, Copyright 2017 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim