Abstract

Biopolymer core-shell microspheres play a crucial role in various biomedical applications, including drug delivery, tissue engineering, and diagnostics. These applications require microparticles with consistent, well-controlled size and precise shape fidelity. However, achieving high-throughput synthesis of size and shape-controlled core-shell biopolymer microgels remains a significant challenge. Herein, we present a one-step process for the high-throughput generation of monodisperse, luminescent, chitosan alginate core-shell microspheres by a novel manipulation of a centrifugal microfluidic device. We utilized the pH sensitivity of chitosan and the ionic gelation properties of alginate to create well-defined core-shell morphologies. To address particle merging issues and promote uniform particle size generation, we introduced an innovative pulsed mode operation in our centrifugal microfluidics device. We also incorporated fluorescent, nitrogen-functionalized graphene quantum dots into the core-shell structures, thereby rendering them useful for real-time imaging, which is necessary for diagnostic and therapeutic applications. To enhance biocompatibility, the alginate solution was supplemented with fish gelatin (FG). The resulting microspheres exhibited excellent structural integrity maintaining their core-shell structure after 15 days. Biocompatibility was demonstrated by C2C12 cell viability exceeding 88% after 15 days and by bacterial viability reaching the same percentage after 2 days. The system demonstrates considerable scalability, allowing for the consistent production of large quantities of microspheres without compromising functionality. The streamlined and efficient methodology simplifies the production process while unlocking new possibilities in targeted therapies, tissue regeneration, and diagnostics.

Similar content being viewed by others

Introduction

Microfluidics, the manipulation of fluids within microscale channels, is a rapidly advancing field offering significant advantages such as reduced reagent use, increased throughput, and enhanced control over chemical and biological processes1. At the microscale, fluid flow exhibits unique features that can be harnessed to develop devices and components with novel functionalities, particularly for biomedical research. Among numerous next-generation bio-applications, microfluidic devices hold immense promise for drug design, delivery, detection, diagnostics, therapeutics, and tissue engineering1,2. In polymerase chain reaction, microfluidics allows for rapid DNA amplification with minimal sample volumes3,4. Microfluidic systems are also widely used for efficient mixing of reagents in chemical and biological assays, where precise control over reaction conditions is essential5. With regards to biological applications, centrifugal microfluidic devices offer several additional advantages, including portability, low cost, and the ability to process large sample volumes without external pumps, making them ideal for point-of-care applications6. Centrifugal microfluidics makes use of rotational forces to manipulate small quantities of fluids through microchannels without the need for sophisticated equipment or external pumps. The key feature is using Coriolis, centrifugal and capillary forces for automated procedures in miniaturized versions. Its primary goal is to consolidate multiple laboratory processes into a single portable platform, improving efficiency and enabling a robust tool for rapid, scalable bioanalytical applications7. Such platforms enable high-throughput processing and precise fluid manipulation, facilitating biological assays and cell isolation with minimal stress8. Previous work has demonstrated the versatility of centrifugal multi-channel systems for high-throughput generation of microgels with tunable size and shape distributions9. However, issues such as intricate disc design and the need to maintain consistent flow rates continue to pose significant challenges10. Despite these hurdles, ongoing improvements continue to expand the potential of centrifugal microfluidics across various fields11.

Microparticle generation using centrifugal microfluidics is a crucial application, particularly related to drug delivery, tissue engineering and diagnostics12,13. Within various types of microparticles, core-shell microspheres—featuring an encapsulated core within a protective shell — hold particular importance for the controlled release and targeted delivery of therapeutics14. In this context, chitosan-alginate core-shell microspheres have gained attention due to their biocompatibility and biodegradability, making them suitable for a range of biomedical applications15,16. The combination of chitosan and alginate in a core-shell structure allows for tailored drug release profiles which enables drug encapsulation followed by sustained or controlled release17,18. However, current methods for fabricating core-shell microspheres often involve multiple steps, making it difficult to achieve high-throughput production while maintaining uniformity in particle size and composition19,20. This presents a major challenge in scaling up production for commercial applications. Centrifugal microfluidics offers a promising alternative, enabling the efficient and scalable generation of uniform core-shell microspheres with precise control over size and structure21,22. Agglomeration of microparticles is a serious problem encountered in nearly all processes of particle generation, and it’s commonly observed in centrifugal microfluidics devices under continuous operation at constant rotational speeds, leading to clogging, compromising reproducibility and scalability23,24. In this study, we introduce a pulsed mode operation, where controlled modulation of rotational speed prevents droplet merging at the right parameters, significantly improving microsphere separation and uniformity.

In this study, for the first time to the best of our knowledge and belief, we introduce a pulsed mode operation of a specially designed centrifugal microfluidic device that successfully addresses one of the major challenges in microparticle generation: agglomeration and merging of particles. The pulsed operation in this work was achieved through a square wave frequency modulation that induces the agitation of the continuous phase and separates the generated droplets, during which the microspheres could crosslink more homogeneously without merging into each other. This also ensures uniformity in particle size and structure and provides an additional degree of freedom for controlling the generation of particles. Since agglomeration does not take place during the generation of microspheres, without other complicated interfaces or surfactants, this process is drastically simplified and, therefore, more appropriate for various biomedical applications and industrial use.

Finally, we address another important issue related to biopolymer microspheres, achieving stable luminescence for real-time tracking and imaging. Traditionally, organic dyes and fluorescent proteins, such as fluorescein and rhodamine B, are used as labeling agents in microparticles for biological applications. However, the common use of conventional fluorescent molecules is hindered by their organic composition and susceptibility to photobleaching25,26. In this context, nitrogen-functionalized graphene quantum dots (NGQDs) present an excellent alternative, offering stable luminescence for real-time monitoring along with additional benefits such as tunable fluorescence27 and less cytotoxicity compared to other luminescent materials, such as metal-based quantum dots28. Unlike organic dyes, they do not undergo photobleaching, and nitrogen doping is reported to be useful for enhanced cellular therapy29. Here, we have successfully incorporated NGQDs as a fluorescent agent to enable bioimaging, thereby enhancing the potential for diagnostics and therapeutic applications30,31. The NGQDs encapsulated core-shell microspheres displayed excellent structural integrity and biocompatibility, achieving over 88% cell viability with C2C12 after 15 days of incubation and maintaining 88% viability for non-fluorescent E. coli after 2 days. Our approach offers significant scalability, enabling the reliable production of large batches of luminescent microspheres without sacrificing functionality.

Results

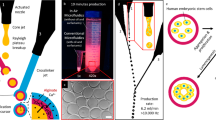

The high-throughput centrifugal microfluidic device (HTCMD) features two chambers: one for the dispersed phase (chitosan solution) and one for the continuous phase (sodium alginate solution). As shown in Fig. 1a, the HTCMD operates by spinning the device at different rotational speeds (rpm), which drives the chitosan solution through the nozzles into the continuous phase chamber containing sodium alginate, initiating the crosslinking process that forms the core-shell microspheres. The HTCMD was mounted on a servo motor connected to a microcontroller and computer to precisely control the rotational frequency over time. A schematic of the setup illustrating the components is provided in Fig. 1b. The 3D view and dimensions of the HTCMD are shown in Fig. 1c.

a(i) The working schematic shows a cross-sectional view of the HTCMD, where chitosan droplets are expelled into the alginate solution under centrifugal force, leading to the formation of chitosan core-alginate shell microspheres. a(ii) Shows a top view of the device and a(iii) shows an isometric view. b The HTCMD is mounted on a motor shaft for controlled rotation, with the motor connected to a laptop for real-time management via an Arduino interface. A strobe light, synchronized with a camera, ensures accurate frame capture during microsphere production, while the laptop controls motor speed, camera functions, and data collection

One of the recognized advantages of microfluidic devices is their high-throughput, which plays a crucial role in microgel fabrication. When particles were generated through a continuous process at a constant rotational frequency, we observed a phenomenon that is well known as solid body rotation, in which the dispenser nozzle maintained a fixed position relative to the alginate surface. Thus, the generated micro-droplets were ejected in the same place or very close to each other. Since this process relies on the ionic crosslinking properties of both the alginate and the chitosan, the calcium ions inside the chitosan solution continued to crosslink the alginate between the droplets, causing them to merge/crosslink together. This process resulted in the formation of a fiber composed of agglomerated particles, as observed in the bright-field (BF) micrographs in Fig. 2a, rather than discrete, homogeneous microspheres. This aggregation compromises the structural integrity required for applications such as cell and bacteria encapsulation. To overcome this hurdle, a novel pulsed operation method was implemented in the fabrication process of the chitosan-alginate core-shell microspheres (see Video S1). This approach involved interrupting the rotational motion at regular intervals, allowing the freshly formed microspheres enough time and space to partially complete the cross-linking process. By alternating the rotational frequencies of the process, the alginate solution moved enough for the new particles to form. This method enabled the individual microspheres to have a more uniform distribution in size and shape, as well as a more robust shell, reducing crosslinking between the formed microspheres, as shown in Fig. 2b.

a(i) The merging issue observed in continuous flow operation (image was taken during particle fabrication). a(ii) BF microscopic image where microspheres cross-link due to their proximity during formation. b(i) The solution provided by pulsed operation, where the rotational speed is varied by ± 150 rpm to allow particles to stabilize and avoid merging (image was taken during particle fabrication). b(ii) BF microscopic image of fabricated particles with pulsed operation method without merging. Scale bars represent 500 µm. c The frequencies applied for both continuous and pulsed operations. d A sequential image demonstrating the particle’s exit and the method used to calculate its volume. In the ellipsoid volume formula, a is half of the long axis, and b is half of the short axis

The selection of pulsing parameters was carefully optimized based on the interplay between chitosan solution properties, nozzle diameter, and rotational speed. If the concentration of chitosan is high, the viscosity of the solution prevents it from being ejected from the nozzle at lower rpm. At higher rotational speeds, however, droplets elongate, generating fiber-like structures and colliding with the wall of the continuous phase container, thus causing deformation and merging of ejected particles. Furthermore, the difference in rotational frequency between the maximum and minimum RPM (i.e., the amplitude of the square wave pulsed operation shown in Fig. 2c) was analyzed and optimized to achieve a balance between particle uniformity and separation. When the frequency difference is too small, the microspheres are ejected in close proximity, increasing the likelihood of merging. Conversely, if the frequency difference is too significant, a wide dispersion in droplet diameter occurs. Similarly, if the pulse duration, which corresponds to the wavelength, is too short, the motor may fail to achieve the desired rpm, resulting in droplet merging due to insufficient separation. On the other hand, if the pulse duration is too long, excessive particles are ejected per half-cycle, resulting in merging (see Fig. S1). These optimizations are critical to achieving a balance between shape fidelity and size distribution.

The rpm versus time graph for both continuous and pulsed operation at 1500 rpm can be observed in Fig. 2c. In the continuous operation, the rpm remains constant throughout the process, resulting in consistent ejection of particles with minimal separation. In contrast, the pulsed operation shows periodic drops in rpm, creating pauses in particle formation. The abrupt shifts in rotational velocity generate sufficient Euler force given in Eq. 1, causing the droplets to move and allowing enough time for partial crosslinking of the particles before new ones are produced32.

where \({\vec{F}}_{{Euler}}\) is the Euler force, \({m}_{p}\) is the mass of the particle, \(\vec{\alpha }\) is the angular acceleration (the rate of change of angular velocity) \(\vec{\alpha }=\frac{d\vec{\omega }}{{dt}}\), and \(\vec{r}\) is the position vector of the particle. As a result, precise control over particle size and shape was obtained with this novel fabrication method.

The production of core-shell microspheres in the HTCMD is driven by centrifugal force, which ejects the chitosan solution through the nozzle into the sodium alginate solution. The centrifugal force \({F}_{c}\) acting on the liquid is proportional to the mass of the droplet, the angular velocity, and the radial distance from the center of rotation33. Since only the magnitude of the centrifugal force is of interest, it can be expressed as:

where \(m\) is the droplet mass, \(\omega\) is the angular velocity, and \(r\) is the radial distance from the center of the HTCMD to the tip of the nozzle. For example, as shown in Fig. 2d, at 900 rpm, the measured droplet size was 800 µm for the long axis and 550 µm for the short axis. The volume of each droplet was calculated using the ellipsoid volume formula \({V}_{{droplet}}=\frac{4\pi}{3} {\cdot a\cdot }{b}^{2}\) where a is half of the long axis and b is half of the short axis. This resulted in a droplet volume of 0.1267 µL. At 1100 rpm, the droplet size was reduced due to increased centrifugal force, with an estimated long axis of 720 µm, a short axis of 480 µm and a corresponding droplet volume of 0.0869 µL. The number of droplets produced per second was calculated using the Hagen-Poiseuille equation for flow through a cylindrical nozzle, where the flow rate depends on the pressure difference generated by centrifugal force and the viscosity of the chitosan solution:

where the pressure difference (∆P) is derived from the centrifugal force \({F}_{c}\), which drives the liquid flow through the nozzle generating droplets, and the flow rate \(Q\) divided by the droplet volume \(V\) gives the number of particles generated, \({d}_{{nozzle}}\) is the nozzle diameter, \(\eta\) is the viscosity, and \({L}_{{nozzle}}\) is the nozzle length. Using this flow rate and the droplet volume, the number of droplets per second can be calculated for different rotational velocities. For example, the experimental data showed 34 droplets at 900 rpm and 55 droplets at 1100 rpm, which are close to the calculated values of 45 and 100 droplets, respectively. The minor discrepancies are likely due to variations in viscosity, nozzle imperfections, or droplet coalescence. The effects of rotational speed and nozzle diameter on core size and shell thickness are illustrated in the 3D plots presented in Fig. 3a, b, respectively. This demonstrates that reducing the nozzle size and increasing the rotational speed led to a decrease in core size. The smallest microspheres, while still having an AR near 1, were obtained with a nozzle diameter of 340 µm and 2000 rpm. In contrast, the shell thickness exhibited minor dependence on rotational velocity and was primarily governed by the incubation duration in the sodium alginate solution. The histograms in Fig. 3c show the distribution of core diameter and shell thickness produced with different nozzle diameters at different rpm values, showing a clear trend of the negative correlation between core diameter and rpm, reinforcing the broad distribution in shell thickness. Each group’s average and standard deviation (S.D.) are displayed in the respective distributions. A Gaussian fit was applied to visualize the distribution of data.

a 3D plot of mean core diameter in function of nozzle diameter and rpm presented by filled markers, with size indicating magnitude. b 3D plot of mean shell thickness as a function of nozzle diameter and rpm; error bars denote standard deviation, and the color scale highlights variations in core dimensions. c Histograms showing the particle distribution produced with nozzle diameters of 340 µm, 410 µm, and 480 µm at rotational speeds of 100, 1500, 2000, and 2500 rpm. The sample size for each histogram varies from 50 to 90 microspheres. All histograms were plotted with a bin width of 50 µm. (i) Combined histograms for core diameter. (ii) Combined histograms for shell thickness. \({D}_{{Nozzle}}\) = 410 µm and 480 µm at 3000 rpm resulted in fiber formation, and \({D}_{{Nozzle}}\) = 340 µm at the same rpm resulted in non-spherical samples, these cases were excluded from the analysis

To assess the mechanical and structural stability of the microspheres, degradation tests were performed using sodium citrate and EDTA with core-shell microspheres produced with and without FG. In both cases, the alginate shell rapidly dissolved in less than 1 min, leaving only the chitosan core with a final diameter of ~660 µm, compared to the initial 1400 µm of the core–shell structure (see video S2). The addition of FG did not significantly affect the degradation rate. Additionally, the microspheres were incubated in DI water and DPBS for 15 days, with no change in size. Microsphere’s mechanical tests indicated that the inclusion of FG enhanced elasticity.

This was supported by compression tests performed on calcium alginate hydrogels prepared with sodium alginate only (SA) and sodium alginate supplemented with FG (SA-FG). As shown in Supplementary Fig. S4a, the SA sample displayed a noticeable dent after compression, while the SA-FG sample retained its original shape more effectively, indicating greater deformability and resilience. These visual differences align with the mechanical results, FG-containing samples exhibited higher deformability and lower stiffness. The average Young’s modulus calculated from the linear region of the stress–strain curves was 184.1 kPa SA and 151.2 kPa for SA-FG, indicating a softer, more flexible matrix.

The correlation between core diameter and shell thickness is also shown in Supplementary Fig. S2a(i), varies across nozzles and different rpm values, without a strong consistent trend. This variability is likely due to ionic crosslinking of alginate, where the shell formation is governed more by calcium ion diffusion, which causes the SA shell to become thicker over longer incubation periods, for example at 5 minutes incubation time the shell thickness increased by 382% the initial thickness from 1 min incubation time, shown in the Supplementary Fig. S2a(ii), instead of mechanical factors such as rotational speed. In this study, all microspheres were collected manually between 1 and 2 min after fabrication. Although this introduces slight variability in incubation time, it was minimized to ensure that all samples experienced comparable gelation conditions.

Skewness and kurtosis (see “materials and methods” section) are analyses that were carried out for both core diameter and shell thickness and backed up the negative correlation between both. There are some slight deviations; for example, at higher rpm values, a greater proportion of small particles is observed, reflected by negative skewness and high kurtosis. For the shell, the skewness and kurtosis go back and forth at different parameters, and this confirms that the shell thickness is not strongly related to the nozzle diameter, or the rpm values used to produce the microspheres.

The size distribution analysis presented in Supplementary Fig. S2b reveals a negative correlation between rpm and core diameter (shown in Fig. S2b(i)), indicating that higher values for rpm lead to smaller core diameters. While a similar trend is observed for shell thickness (shown in Fig. S2b(ii)), the effect of rpm is less noticeable, having a weaker correlation, suggesting that shell formation is less dependent on rotational speed and more dependent on the ionic crosslinking from the calcium ions present in the chitosan solution.

We used both scanning electron microscopy (SEM) and BF optical microscopy to gain insight into the structural integrity and the core-shell interface of our microspheres. This provided us with a clear view of how the core material was encapsulated within the alginate shell of the microspheres. The SEM image shown in Fig. 4a illustrates a typical core-shell particle that has a spherical shape. Figure 4b reveals the core-shell interface to be distinct and well-defined. This sharp boundary defining the core from the shell confirmed that our fabrication process via the HTCMD was successful and consistent in encapsulating the core material according to design. The interface directly impacts the functionality of these microspheres for applications that require a precise release mechanism or protection of the core material. These findings were further complemented by BF microscopy shown in Fig. 4c, d, which provided a wider view of the general structure of the microspheres. The images obtained gave evidence of a homogeneous spherical geometry distribution among the microspheres; therefore, it further establishes the reliability of the HTCMD in producing microspheres with uniform size and shape, which is critical, especially when drug delivery applications are considered. Differences in the size and shape of drug-encapsulating structures can result in significant variations in release profiles, which in turn affects the efficacy of the microsphere.

a The SEM image demonstrates the high sphericity of the microspheres. b SEM cross-sectional image showing the distinct boundary between the chitosan core and alginate shell, highlighting the well-defined core-shell morphology. c BF optical micrograph of a single microsphere, illustrating its uniform shape of core and shell. d Optical micrograph of a dissected microsphere, revealing the internal core and shell structure

It is important to render the core-shell particles luminescent for real-time tracking and imaging. This is usually done by incorporating fluorescent dyes like rhodamine B or fluorescein34 However, these dyes are prone to photobleaching25. Hence, we used NGQDs, which are efficient, biocompatible emitters reported to enhance the bio-functionality of biopolymer hydrogels35. Colloidal NGQDs were prepared via standard wet chemical route36 and were mixed with chitosan in the ratio of 1% by volume in the chitosan solution and introduced in the HTCMD. A typical high-resolution transmission electron microscopy (HRTEM) image of the NGQDs is shown in Fig. 5a. The isolated islands of the QDs with identifiable lattice fringes are marked in the figure to aid visualization. The size of these quantum dots ranges between 1and 5 nm with a modal size of 2.5 nm, as shown in the size distribution histogram in Fig. 5b. The histogram was constructed from several similar TEM images. A more detailed discussion on the structural features of the NGQDs used in this study can be found in ref. 35.

a HRTEM image of the synthesized NGQDs. The regions with decipherable lattice fringes are marked as a guide to the eyes. b The size distribution histogram constructed from several TEM images. c BF (left panels) and fluorescence (right panels) optical microscopy images of the core-shell structures: (i) without NGQDs and (ii) with NGQDs encapsulation. d The UV-visible absorption characteristics of pristine NGQDs, chitosan-alginate core-shell structures and the core-shell structures with embedded NGQDs. e The PL emission from NGQDs, chitosan-alginate, NGQDs encapsulated chitosan-alginate core-shell structures. f Photographs of CS solution samples without and with NGQDs under ambient light (left) and under UV excitation (right) exhibiting intense PL from the NGQDs incorporated samples that are visible with the naked eyes. Scale bars in the optical micrographs are 500 µm

Figure 5c(i), (ii) displays the BF micrographs in the left panels and the corresponding blue fluorescence (right panels) optical micrographs of the as-fabricated microspheres. The fluorescent images were captured under a broadband (380–400 nm) UV irradiation. The images shown in Fig. 5c(i) show the control microspheres, which do not have the NGQDs. The particles, in this case, are almost undetectable on the blue channel. Whereas the microspheres depicted in Fig. 5c(ii) are clearly visible in the blue channel due to the fluorescent signal from the NGQDs. Another notable observation from the images in Fig. 5c(i), (ii) is that the size and shape of the core-shell structures remain unchanged after the incorporation of NGQDs.

The UV-visible absorption characteristics of the chitosan-alginate core-shell microspheres with and without the NGQDs and that of the bare NGQDs are shown in Fig. 5d. NGQDs display characteristic absorption behavior, with two distinct peaks:one near 346 nm and another at a higher energy in the UV region around 240 nm. Such UV–visible absorption patterns in NGQDs are well-documented37. The higher energy peak (240 nm) is most likely caused by band-to-band transitions in the carbogenic core, whereas the lower energy peak (350 nm) is probably a result of transitions involving states within the expanded bandgap. The placement of these states within the bandgap is typically influenced by edge structures and the functional groups attached to the surface of the graphene dots, which in the case of NGQDs are due to the nitrogen and amine functional groups that typically give rise to the N-states38. In contrast, the chitosan-alginate microspheres display an almost featureless absorption profile, with a peak in the deep UV region, which too is a typical characteristic of the chitosan alginate system39. We further note that the absorption profile of the NGQDs incorporated microspheres is dominated by the characteristics of chitosan-alginate and the features of NGQDs are masked due to the very low concentration of NGQDs present in the structure.

The photoluminescence (PL) emission features of the pristine NGQDs along with the emission characteristics of bare chitosan-alginate and NGQDs incorporated chitosan-alginate microspheres, under UV excitation, are shown in Fig. 5e. Here we note that, unlike the UV-vis absorption characteristics, the PL emission of the NGQDs encapsulated system is dominated by the emission features of the NGQDs. Pristine NGQDs display bright, broad-spectrum PL, peaking at around 446 nm under 350 nm excitation. In contrast, the bare core-shell microspheres exhibit weak PL with two distinct peaks at 413 nm and 444 nm under the same excitation conditions. Interestingly, the PL emission from the NGQDs incorporated system matches the peak position of the bare NGQDs, but the composite system’s PL band is noticeably narrower. Since the PL mechanism from NGQDs system is still a matter of active debate38, in this study, we refrain from exploring the possible reasons behind the observed features and the modification of PL bandwidth following their incorporation in the core-shell matrix. We concentrate only on the intense room temperature PL from the NGQDs, which is clearly visible with unaided eyes, as shown in Fig. 5f. The photographs show the core-shell microspheres with and without NGQDs under ambient light and under UV excitation, showing the intense PL from the NGQDs loaded hydrogels. We now proceed to explore the potential application of the luminescent core-shell microspheres for cell encapsulation. For cell encapsulation, as detailed in the “Materials and Methods” section, the FG was combined with sodium alginate before incorporating the C2C12 cells and the EcNF bacteria. Figure 6 presents the viability assessment of C2C12 cells and EcNF-encapsulated microspheres over their incubation period. The figure includes BF images combined with fluorescence images (live/dead and NGQDs emission assay). The BF micrographs provide a structural image of the core-shell microsphere, while the fluorescence distinguishes the live (green), dead (red), and blue (NGQDs emission). Figure 6a(i) shows fluorescence micrographs of C2C12 cells encapsulated within the microspheres incorporated with and without NGQDs during a 15-day incubation period. The left two columns display the BF microscopy images and fluorescence images loaded with NGQDs, while the right two columns display the microspheres without the addition of NGQDs. The live/dead assay confirmed that over 88% of the cells remained viable after 15 days of incubation, with minimal cell death observed in the bar plots from Fig. 6a(ii). The delicacy with which the cells are handled during the synthesis of the microspheres in our system is reflected in the high viability of the encapsulated cells.

Cell and bacterial viability analysis of NGQD-loaded core-shell microspheres. a Core-shell cell viability test over a 15-day incubation, with samples analyzed every third day. (i) The two left columns show NGQD-loaded core-shell microspheres, while the two right columns show microspheres without NGQDs. The left images include BF and fluorescence channels (blue, green, and red), while the right images show only the fluorescence channels (blue, green, and red), excluding BF. (ii) Bar plot indicating the result, which indicates that cells remained alive and viable throughout the 15-day period with over 88% viability, demonstrating the high biocompatibility of the core-shell microspheres, both with and without NGQDs. b(i) E. coli viability test conducted under the same parameters as the cell culture experiment, the two left columns correspond to NGQD-loaded core-shell microspheres, while the two right columns correspond to microspheres without NGQDs. b(ii) Bar plot of live vs. dead count for E. coli viability. c(i) EcNF encapsulation with alginate solution at higher pH (13 instead of 8.5 used in the cell experiment) and c(ii) showing the live/dead percentage for this experiment with very significant decay in viability. All scale bars: 200 µm

In contrast to the initial methodology, the impact of pH was evaluated by increasing the pH in alginate solution from 8.5 to 13 while maintaining the same parameters as the previous experiments. Supplementary Fig. S3 presents micrographs under these modified conditions showing a significant decrease in live/dead viability at day 1 of incubation time compared to the standard condition.

In Fig. 6b, we present micrographs for viability assessment of EcNF bacteria encapsulation fabricated under the same conditions used for cell encapsulation. The left two columns of Fig. 6b(i) display the BF microscopy images and fluorescence images loaded with NGQDs, while the right two columns correspond to microspheres without NGQDs. The bar plot in Fig. 6b(ii) shows the live/dead percentage of encapsulated E. coli over days 1 and 2, indicating high bacterial viability above 88% for microspheres without NGQDs and above 90% for microspheres with NGQDs.

To evaluate the impact of pH and FG, bacterial viability was assessed in the core-shell microspheres synthesized using the same parameters as the previous experiments, except for an increase in pH in the alginate solution from 8.5 to 13 and the omission of 1.5% FG without loading NGQDs. Figure 6c(i) presents micrographs under these modified conditions showing a significant decrease in live/dead viability each day compared to the standard condition.

To evaluate the influence of NGQDs on cell viability, a Student’s t-test comparing viability during each time period across all biological samples revealed no statistically significant difference between the NGQD loaded samples and the control groups (see Table S1). Additionally, a two-way ANOVA was conducted to evaluate the effects of the NGQDs and incubation time (see Table S2). While no significant interaction was observed (p = 0.925), a marginal effect of incubation time was detected (p = 0.146), suggesting a potential trend in viability changes over time. These results indicate that, under the conditions tested, NGQDs do not significantly impact the viability of C2C12 cells, reinforcing the biocompatibility and potential for bioimaging.

Discussion

The findings from this study demonstrate that the pulsed operation of the HTCMD is an efficient and scalable technique for producing biocompatible and luminescent chitosan-alginate core-shell microspheres embedded with NGQDs. By implementing pulsed operation in a high-throughput centrifugal microfluidic device, particle aggregation is effectively mitigated. This is a common challenge in continuous centrifugal fabrication via ionic crosslinking. This is an important development given that most techniques need to depend on additional steps or materials, such as oil interfaces for the prevention of agglomeration, recovery of particles, or coating40,41. One-step pulsed operation reflects the possibility of scalable manufacturing of functional microspheres, which emphasizes maintaining uniformity in the particle size and shape. Thus, this may significantly facilitate the production of microspheres and render them amenable to drug-delivery systems and tissue engineering. Additionally, functionalization with NGQDs greatly improves the microspheres’ potential for real-time bioimaging and diagnostics.

The cell viability assay showed that the encapsulated C2C12 cells maintained a very high viability of >88% and a uniform distribution inside the alginate shell throughout the 15-day incubation period, highlighting that the chitosan-alginate microspheres form a cytocompatible environment and that the presence of NGQDs did not impede cell survival, reinforcing their biocompatibility and potential use in bioimaging applications. However, unlike cells grown in 2D cultures, these encapsulated cells did not elongate. This can likely be attributed to the use of an alginate shell, whose composition lacks cell adhesion motifs, particularly arginine-glycine-aspartic acid (RGD) sequences, which are essential for integrin-mediated cell attachment42. Incorporating FG into the alginate solution has been reported to minimally modify its viscosity43 and was intended to provide a gel-like matrix with a supportive composition for cell attachment44. Additionally, maintaining an optimal pH in the cell culture environment significantly increases the viability of both cell and bacterial encapsulation. While this hydrogel combination was effective in achieving a high degree of viability, the cells did not elongate during the 15-day incubation period. Further research is needed to determine the optimal hydrogel combination to promote cell growth and differentiation. Other biopolymers, such as GelMA, could be valuable for future studies, as they have been observed to interact well with mammalian cells, providing an excellent matrix for cell adhesion45. This will be particularly relevant for tissue engineering applications aimed at developing functional tissue structures46.

Furthermore, incorporating FG into the alginate solution alters the shell’s composition, promoting effective cell encapsulation and improving bacterial viability. This multiloaded approach enables the encapsulation of biologically relevant molecules, including growth factors, nutrients, and genetic material in the core, while C2C12 cells or other cell types are retained within the alginate shell. Future research could also explore the use of other functional materials like magnetic nanoparticles and therapeutic agents, to expand their applications in medical and industrial settings. Additionally, given the potential of chitosan as a food-grade excipient, this technique may be investigated for co-encapsulating prebiotic compounds and probiotic strains, thereby providing significant advantages in functional foods and dietary supplements47.

Finally, the methodology outlined in this study significantly enhances the existing literature on the fabrication of core-shell microspheres. By integrating centrifugal microfluidics with pulsed operation, a more straightforward and resource-efficient alternative to conventional methods is provided, facilitating scalable production of functional microspheres for applications in bioimaging, targeted drug delivery, and theranostics.

The cell viability tests showed that after 15 days of incubation time, more than 88% of the cells were still alive for both the control and NGQD samples and were evenly distributed within the alginate shell. Showing that the microspheres created a biocompatible environment, and that the presence of NGQDs did not affect the survival rate overall, supporting their safe use and potential for bioimaging applications. These results were furthered backed up by the statistical analysis: Both the t-test and two-way ANOVA. In addition, the sustained viability over the incubation period shows that the microsphere’s properties maintain a stable environment for static culture, even without refreshing the media. However, unlike cells grown in 2D cultures, the encapsulated cells did not elongate as expected, suggesting the need for alternative hydrogel formulations, such as GELMA, which could enhance cellular extension and differentiation. Additionally, the encapsulation of both cells and bacteria served as proof of concept, validating the biocompatibility of the microspheres produced with this fabrication method. Future work could expand on these findings by conducting more comprehensive biological evaluations and exploring the potential of advanced hydrogel systems to optimize cell-material interactions.

Materials and methods

The HTCMD was designed to enable the scalable production of chitosan-alginate core-shell microspheres with precise control over particle size. The device consists of a 3D-printed multichannel cylindrical structure optimized for high-throughput operation. Different syringe needle diameters (480 µm, 410 µm, 340 µm, and 240 µm) were employed as microchannel dispensers for the dispersed phase (chitosan), allowing for variation in microsphere size (see Supplementary Fig. S1).

Statistical analysis

A combination of descriptive and inferential statistical methods were applied to analyze the particle size distribution and particle analysis. Histograms were used to visualize distributions, since most of the data was not normal, skewness and kurtosis were computed to address asymmetry and extreme values. The samples for each group of data (nozzle diameter vs rpm) were measured, using 50−90 measurements which is the minimum necessary to extract meaningful statistical insights while maintaining reliable trends. To check if the rpm and particle size meant bigger or smaller diameters we used Pearson correlation. Finally, we made heatmaps with color gradient to have a visual representation of the between core diameter and shell thickness and check if one influenced the other and a similar heatmap for the correlation between rpm and AR of both core and shell produced with different nozzle diameters.

The first step was to visualize the diameter of the core and shell thickness for each nozzle diameter at the different rpm values using histograms with density curves.

The aspect ratio (AR) is a key parameter for evaluating the shape and uniformity of microspheres, a perfect spherical particle has an AR of 1, while deviations indicate elongation and are calculated with the following formula:

In this study, the AR analysis shown in Supplementary Fig. S2b clearly highlights the influence of rpm on core roundness, where higher rpm values result in a less spherical core and elongated structures, however with 340 µm nozzle at 2500 rpm, the best balance between small core diameter and lower AR was found. On the other hand, the shell AR remains largely unaffected by nozzle size and rpm, likely due to the dominance of ionic crosslinking, where calcium diffusion enforces a natural spherical shape regardless of mechanical processing conditions and the core AR has minimum influence on the AR of the shell.

The asymmetry was analyzed using skewness to check if the distributions were leaning to the left or to the right using the following formula:

where \(S\) is skewness, \(E\), is the expected value, \(X\) is the data point, \(\mu\) is the mean, and \(\sigma\) is the standard deviation.

The extreme outliers were analyzed using Kurtosis which tells us whether we had too many outliers or a normal number of outliers, positive kurtosis means more extreme values and vice versa:

where \(K\) is Kurtosis, \(E\), is the expected value, \(X\) is the data, \(\mu\) is the mean, and \(\sigma\) is standard deviation.

Pearson correlation shows the relationship between rpm and microsphere size using the following formula:

where \(r\) is Pearson correlation coefficient, \({X}_{i}\) and \({Y}_{i}\) are individual datapoints for the two variables, \(\bar{X}\) and \(\bar{Y}\) are mean for \(X\) (rpm) and \(Y\) (Mean core or Mean shell, respectively). The Pearson correlation was computed separately for core diameter and shell thickness.

NGQDs

For the fabrication of NGQDs a one-step hydrothermal methodology was adapted which reportedly has high fluorescent NGQDs yield48. Citric acid 2.1 g, acquired from Sigma Aldrich, (CAS 5949-29-1) was used as the carbon source for the synthesis of NGQD; 1.8 g of ethylene diamine (CAS-107-15-3 was used as the nitrogen-doping chemical). Both were mixed in 50 mL of DI water (18.2 MΩ. cm, Millipore) and stirred for 15 min at 400 rpm until a homogenous solution was obtained. Later, this mixture was transferred into a Teflon-lined stainless-steel autoclave, sealed, and put into an oil bath preheated to 180 °C. The autoclave at this temperature was allowed to stay for 8 h to facilitate the hydrothermal reaction and obtain the desired PL properties. After that, it was allowed to cool naturally to room temperature before centrifugation at 5000 rpm for 10 min. This process was done to remove larger particles and impurities, thus purifying the colloidal NGQDs. Subsequently, the solution was placed for freeze drying. This experimental procedure always yields NGQDs with consistent yield through well-controlled nitrogen doping that showed desirable PL as evidenced by further characterization studies.

Core-shell microspheres were produced using the HTCMD, which operates on the principle of ejecting the dispersed phase into the continuous phase through centrifugal force. The biopolymer solutions were prepared as follows: Sodium alginate solution preparation: The sodium alginate salt, acquired from Sigma Aldrich (CAS 9005-38-3), was dissolved in DI water. Prior to dissolution, DI water, pH was adjusted to pH 13 by adding 1 M sodium hydroxide (NaOH, acquired from JT Baker, CAS 1310-73-2); Chitosan solution preparation: In the current work, low molecular weight chitosan, acquired from Sigma Aldrich, (CAS 9012-76-4) was dissolved at 2% w/v in 1 M hydrochloric acid (HCl, acquired from JT Baker, CAS 7647-01-0). The pH was adjusted to 5.3 with 1 M NaOH and the solution was stirred for a further 12 h to achieve the greatest dissolution of chitosan and stabilization, The solution was then filtered using a stainless-steel sieve with a #200 mesh and an aperture of 0.75 µm. to remove any undissolved chitosan remaining in the solution, before adding 0.3 M calcium chloride (CaCl2, acquired from Sigma Aldrich, CAS 10043-52-4) and mixed for an additional 2 h for complete dissolution. For monitoring pH during and after the production of microspheres, 0.02% w/v of phenol red, (CAS 143-74-8) was added into the solution as a pH indicator, having an orange pH at pH 5 and as the pH increases the color turns purple indicating crosslinked core.

Microsphere synthesis

The fabrication procedure is rather straightforward. Since the HTCMD consists of two separate chambers: a disperse phase and a continuous phase chamber, the desired hydrogels, in this case the CS solution is loaded in the disperse phase container which generates the microdroplets when rotational velocity is applied. The sodium alginate solution was loaded into the continuous phase chamber and acted as a reservoir for the ejected CS droplets forming the core-shell microspheres by ionic crosslinking. The rotational speed of the HTCMD was determined based on the nozzle diameter within the device, with an effective range of 240 µm to 480 µm and rotational speeds between 900 and 2500 rpm.

Recovery and cleaning of microspheres: After fabrication, the microspheres were recovered from the alginate solution using a 100-micron pore-size cell strainer. Microspheres not used for biological experimentation were washed with DI water, while those used in biological applications were further washed with Dulbecco’s Phosphate-Buffered Saline (DPBS, acquired from Sigma Aldrich, catalog number P3813), was used instead of normal PBS to avoid residual crosslinking from calcium and magnesium ions present in regular PBS, which is known to interfere with the alginate hydrogel matrix49.

HTCMD fabrication

The HTCMD device was designed in SOLIDWORKS and fabricated using an Anycubic Photon 3D printer with standard clear resin due to its optical transparency, which allows for visualization during the microsphere fabrication process. Printing settings, such as support structure and exposure time, were optimized to achieve the smoothest surface possible to minimize potential irregularities in the microfluidic channels. After fabrication the device was polished and covered in two layers of transparent paint, painted 24 h apart to enhance transparency.

To evaluate the mechanical properties and influence of the FG on the alginate matrix, hydrogel samples were prepared by dispensing 1 mL of 1% w/v sodium alginate solution either with or without 1.5% w/v FG into a cylindrical mold. Subsequently, 2 mL of 0.3 M CaCl2 solution was gently added to each well. The samples were incubated at room temperature for 10 min without agitation, allowing calcium ions to diffuse through the solution and form a stable hydrogel pellet. After incubation, the gels were subjected to force-distance measurements using a TA.XT Plus texture analyzer Stable Micro Systems. Each condition was tested with three independent replicates. The dimensions of the created pellets were 15.5 mm in diameter × 5 mm in thickness.

Degradation tests were conducted by incubating the freshly prepared core-shell microspheres in a 96-well plate transferred using a micropipette. Following this, the water was removed, and 100 µL of a chelating solution prepared with Sodium citrate (acquired from Sigma Aldrich CAS 6132-04-3) and EDTA (acquired from Sigma Aldrich CAS 10378-23-1) were added to the microspheres. The purpose of this solution was to target the calcium crosslinked alginate shell and initiate the dissolution. The test was performed on five microspheres per condition, and the degradation was recorded through time-lapse microscopy to monitor changes in diameter over time.

Biological experiments

All experiments were conducted in triplicate to ensure reproducibility and statistical reliability. Cell Viability Studies: For cell culture biological experiments, the solutions were prepared following the earlier discussed methodology with the following adjustments: the chitosan solution was prepared without phenol red and with DPBS instead of DI water after dilution in 1 M HCl and the pH was adjusted to 5.3 with 1 M NaOH. The 1% sodium alginate solution was mixed with 1.5% FG (acquired from Sigma Aldrich, CAS 9000-70-8) and was prepared using DPBS. The sodium alginate solution was filtered using a 0.2 µm syringe filter for sterilization, while the prepared chitosan solution was autoclaved at 100 °C for 15 min. C2C12 myoblast cells were resuspended into the alginate solution before loading the sterilized solutions into the HTCMD, and the core-shell microspheres were fabricated using the above-mentioned procedure. The recovered microspheres were washed with DPBS before incubating in culture media. The cell count for the C2C12 cells prepared for this experiment was 750,000 per mL of alginate solution. The live/dead analysis for both cell and bacteria were carried out using the LIVE/DEAD™ BacLight™ Bacterial Viability. Kit and LIVE/DEAD double staining Kit 04511-1KT-F

The C2C12 mouse myoblast cell line (ATCC, Manassas, Virginia, USA) was cultured using DMEM high glucose media (Thermo Fisher Scientific, Waltham, Massachusetts, USA) supplemented with 10% fetal bovine serum (ATCC, Manassas, Virginia, USA) and 1% antibiotic-antimycotic solution (Thermo Fisher Scientific, Waltham, Massachusetts, USA). Cultures were incubated at 37 °C in an air atmosphere of 5% CO2 and harvested from T-25 flasks using 0.25% trypsin 0.02% EDTA solution (Thermo Fisher Scientific, Waltham, Massachusetts, USA) when 80% confluence was reached. Cells were quantified with a hemocytometer, and viability was assessed by trypan blue dye exclusion. A viability of at least 95% was achieved after harvesting.

Bacterial growth studies

For bacterial culture studies, sodium alginate and chitosan solutions were prepared and sterilized using the same method described above. Microspheres were used to encapsulate non-pathogenic strains of E. coli (EcGFP and EcNF). Bacterial viability and growth over time were studied using live/dead assays and bright microscopy. The optical density measured for the bacteria was 0.2 per ml of chitosan solution. EcGFP was kindly donated by the Serna Laboratory at Tecnologico de Monterrey and was grown at 37 °C while the solution was shaken at 150 rpm in Luria Bertani broth Lennox medium (Sigma Aldrich) containing 1 µL mL−1 of chloramphenicol to retain the recombinant plasmid. Bacterial culture was centrifuged at 8000 rpm for 10 min, and the supernatant was discarded. The pellet was resuspended in a chitosan solution to perform experiments.

References

Nguyen, N.-T., Wereley, S. T. & Shaegh, S. A. M. Fundamentals and Applications of Microfluidics (Artech House, 2019).

Whitesides, G. M. The origins and the future of microfluidics. Nature 442, 368–373 (2006).

Madadelahi, M., Agarwal, R., Martinez-Chapa, S. O. & Madou, M. J. A roadmap to high-speed polymerase chain reaction (PCR): COVID-19 as a technology accelerator. Biosens. Bioelectron. 217, 115830 (2024).

Madadelahi, M. & Madou, M. J. Rational PCR reactor design in microfluidics. Micromachines 14, 1533 (2023).

Varala, S., Satish, T., Kumari, A. & Singh, A. K. Microfluidic Devices. Handbook of Biomolecules Ch. 11. https://doi.org/10.1016/B978-0-323-91684-4.00031-1 (Elsevier, 2023).

Hwu, A. T. et al. Centrifugal disc liquid reciprocation flow considerations for antibody binding to COVID antigen array during microfluidic integration. Lab Chip 22, 2695–2706 (2022).

Zhang, X., Wang, Y. & Wang, W. Recent advances in centrifugal microfluidics for point-of-care testing. Trends Anal. Chem. 158, 116768 (2023).

Yang, S. et al. Fully automated continuous centrifugal microfluidics isolates natural killer cells with high performance and minimal stress. Anal. Chem. https://doi.org/10.1021/acs.analchem.3c01075 (2023).

Li, J., Wang, Y., Cai, L., Shang, L. & Zhao, Y. High-throughput generation of microgels in centrifugal multi-channel rotating system. Chem. Eng. J 427, 130750 (2021).

Acharya, S., Chhabra, J., Mukherji, S. & Paul, D. A low-cost and portable centrifugal microfluidic platform for continuous processing of large sample volumes. AIP Adv. https://doi.org/10.1063/5.0128239 (2023).

O’Connell, K. C. & Landers, J. P. Integrated membranes within centrifugal microfluidic devices: a review. Lab Chip. https://doi.org/10.1039/d3lc00175j (2023).

Ren, C. L. Microfluidics: an enabling platform for biomedical applications (Conference Presentation). Proc. SPIE. https://doi.org/10.1117/12.2659760 (2023).

Madadelahi, M., Azimi-Boulali, J., Madou, M. & Martinez-Chapa, S. O. Characterization of fluidic-barrier-based particle generation in centrifugal microfluidics. Micromachines 13, 881 (2022).

Silva, R. Y. P. et al. Microparticles in the development and improvement of pharmaceutical formulations: an analysis of in vitro and in vivo studies. Int. J. Mol. Sci. https://doi.org/10.3390/ijms24065441 (2023).

Forigua, A. H., Dalili, A., Kirsch, R., Willerth, S. M. & Elvira, K. S. Microfluidic generation of therapeutically relevant polycaprolactone (PCL) microparticles: computational and experimental approaches. ACS Appl. Polym Mater. https://doi.org/10.1021/acsapm.2c00943 (2022).

Liu, Y. et al. The potential applications of microparticles in the diagnosis, treatment, and prognosis of lung cancer. J. Transl. Med 20, 404 (2022).

Niculescu, A.-G. & Grumezescu, A. M. Applications of chitosan-alginate-based nanoparticles—an up-to-date review. Nanomaterials 12, 186 (2022).

Suryani, A. I., Wathoni, N., Muchtaridi, M. & Joni, I. M. Targeted drug delivery system; nanoparticle-based combination of chitosan and alginate for cancer therapy: A review. Int. J. Appl. Pharm. 13, 69–76 (2021).

Zheng, Y. et al. Scalable production of biomedical microparticles via high-throughput microfluidic step emulsification. Small 19, 2206007 (2023).

Cruz-Maya, I. et al. Designing advanced drug delivery systems: core-shell alginate particles through electro-fluid dynamic atomization. Pharmaceutics 16, 193 (2024).

Badalan, M. et al. A soft landing approach for the centrifugal microgel synthesis process. Comptes Rendus. Méc. 351, 83–102 (2023).

Zhang, X. et al. Core-shell microspheres prepared using coaxial electrostatic spray for local chemotherapy of solid tumors. Pharmaceutics 16, 45 (2024).

Oliveira, M. B. & Mano, J. F. Polymer-based microparticles in tissue engineering and regenerative medicine. Biotechnol. Prog. 27, 897–912 (2011).

Madadelahi, M., Madou, M. J., Nokoorani, Y. D., Shamloo, A. & Martinez-Chapa, S. O. Fluidic barriers in droplet-based centrifugal microfluidics: generation of multiple emulsions and microspheres. Sens. Actuators B. Chem. 311, 127833 (2020).

Pandey, P. K., Rawat, K., Prasad, T. & Bohidar, H. B. Multifunctional, fluorescent DNA-derived carbon dots for biomedical applications: bioimaging, luminescent DNA hydrogels, and dopamine detection. J. Mater. Chem. B. 8, 1277–1289 (2020).

Nasrollahi, F. et al. Graphene quantum dots for fluorescent labeling of gelatin-based shear-thinning hydrogels. Adv. Nanobiomed Res. 1, 2000113 (2021).

Balakrishnan, T., Ang, W. L. & Mahmoudi, E. Enhancing photoluminescence stability of blue emissive nitrogen doped graphene quantum dots by encapsulating inside zeolitic imidazole framework-8. J. Solid State Chem. 328, 124343 (2023).

Sivakumar, K. Graphene Quantum Dots based sensor for early detection of Stroke. In Proc. Tenth International Conference on Bio Signals, Images, and Instrumentation (ICBSII) 1–3. https://doi.org/10.1109/ICBSII61384.2024.10564065 (2024).

Valimukhametova, A. R. et al. Cancer therapeutic siRNA delivery and imaging by nitrogen- and neodymium-doped graphene quantum dots. ACS Biomater. Sci. Eng. 9, 3425–3434 (2023).

Shen, J., Zhang, J., Wu, W., Banerjee, P. & Zhou, S. Biocompatible anisole-nonlinear PEG core-shell nanogels for high loading capacity, excellent stability, and controlled release of curcumin. Gels 9, 762 (2023).

Dong, Y. et al. Core-shell gel nanofiber scaffolds constructed by microfluidic spinning toward wound repair and tissue regeneration. Adv. Sci. https://doi.org/10.1002/advs.202404433 (2024).

Madadelahi, M., Acosta-Soto, L. F., Hosseini, S., Martinez-Chapa, S. O. & Madou, M. J. Mathematical modeling and computational analysis of centrifugal microfluidic platforms: a review. Lab Chip 20, 1318–1357 (2020).

Rahdar, M., Madadelahi, M. & Namazi, M. Microfiber generation on centrifugal microfluidic platforms using fluidic barriers. Chem. Eng. Process. Process Intensif. 193, 109553 (2023).

Ta, V. D., Caixeiro, S., Fernandes, F. M. & Sapienza, R. Microsphere solid-state biolasers. Adv. Opt. Mater. 5, 1601022 (2017).

Taravatfard, A. Z. et al. Nitrogen-functionalized graphene quantum dot incorporated GelMA microgels as fluorescent 3D-tissue constructs. Nanoscale 15, 16277–16286 (2023).

Qu, D. et al. Formation mechanism and optimization of highly luminescent N-doped graphene quantum dots. Sci. Rep. 4, 5294 (2014).

Tetsuka, H. Nitrogen-functionalized graphene quantum dots: a versatile platform for integrated optoelectronic devices. Chem. Rec. 20, 429–439 (2020).

Siddique, A. B., Hossain, S. M., Pramanick, A. K. & Ray, M. Excitation dependence and independence of photoluminescence in carbon dots and graphene quantum dots: insights into the mechanism of emission. Nanoscale 13, 16662–16671 (2021).

Wasikiewicz, J. M., Yoshii, F., Nagasawa, N., Wach, R. A. & Mitomo, H. Degradation of chitosan and sodium alginate by gamma radiation, sonochemical and ultraviolet methods. Radiat. Phys. Chem. 73, 287–295 (2005).

van der Kooij, R. S., Steendam, R., Frijlink, H. W. & Hinrichs, W. L. J. An overview of the production methods for core–shell microspheres for parenteral controlled drug delivery. Eur. J. Pharm. Biopharm. 170, 24–42 (2022).

Li, J. et al. Biodegradable silica-gated poly(methacrylic acid) core-shell microspheres for pH and glutathione dual-responsive drug delivery. J. Drug Deliv. Sci. Technol. 100, 106031 (2024).

Capeling, M. M. et al. Non-adhesive alginate hydrogels support growth of pluripotent stem cell-derived intestinal organoids. Stem Cell Rep 12, 381–394 (2019).

Mohseni, M., Shamloo, A., Seidi, F. & Kamrava, S. K. A review of fish-derived gelatin for tissue engineering applications. Tissue Eng. Regen. Med. 18, 799–816 (2021).

Wierzbicka, A. et al. The impact of gelatin and fish collagen on alginate hydrogel properties: a comparative study. Gels 10, 491 (2024).

Álvarez, M. M. et al. Supplementation of GelMA with minimally processed tissue promotes the formation of densely packed skeletal-muscle-like tissues. ACS Biomater. Sci. Eng. 9, 3462–3475 (2023).

Li, Y., Xiao, Y. & Liu, C. The horizon of materiobiology: a perspective on material-guided cell behaviors and tissue engineering. Chem. Rev. 117, 4376–4421 (2017).

Qu, B. & Luo, Y. Chitosan-based hydrogel beads: preparations, modifications and applications in food and agriculture sectors—a review. Int. J. Biol. Macromol. 152, 437–448 (2020).

Lu, F. et al. Highly Fluorescent Nitrogen-Doped Graphene Quantum Dots’ Synthesis and Their Applications as Fe(III) Ions Sensor. Int. J. Opt. 2019, 1–9 (2019).

Gasperini, L., Mano, J. F. & Reis, R. L. Natural-based hydrogels for tissue engineering applications. J. Funct. Biomater. 8, 48 (2017).

Acknowledgements

E.M. gratefully acknowledges the financial support of CONAHCYT (Consejo Nacional de Humanidades, Ciencias y Tecnologías, México) in the form of Graduate Program Scholarships and the support by Tecnológico de Monterrey in the form of tuition fee waiver. M.R. acknowledges the funding provided by CONAHCYT in the form of scholarship as member of the National System of Researchers (SNI 1047863) and the financial support of Federico Baur Endowed Chair in Nanotechnology (ILST002-23ID69001). M.M. acknowledges the funding provided by CONAHCYT in the form of scholarship as a member of the National System of Researchers (CVU: 969467) and the financial support of FEMSA foundation.

Author information

Authors and Affiliations

Contributions

M.M. conceived the idea of generation of core-shell microspheres using HTCMD and designed the pulsed operation. M.R. developed the idea of NGQDs encapsulation. E.M. implemented the pulsed operation, led the development of the HTCMD, performed the synthesis and characterization of microspheres, curated the data and prepared the initial draft of manuscript. E.M. also assisted in all the biological experiments and data analyses. G.T.dS. and M.M.A. conceived the biological experiments and supervised the cell viability and bacteria culture experiments. J.F.Y.dL. and R.A.G.V. performed the cell viability experiments and analyzed the results. A.C.S. and F.J.F.L. performed the bacteria culture experiments and the analysis. M.M. and M.R. revised and edited the manuscript and supervised the entire research.

Corresponding authors

Ethics declarations

Competing interests

Authors M.M., M.R., and E.M. have submitted a patent application (Application No. MX/a/2025/005747, Title: 'Pulsed operation for high throughput production of micro- and nanostructures using a centrifugal platform') covering aspects of the technology described in this work.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Macias, E., Yee-de León, J.F., Gonzalez-Vilchis, R.A. et al. One-step generation of luminescent core-shell microspheres for cell encapsulation via pulsed operation in centrifugal microfluidics. Microsyst Nanoeng 11, 166 (2025). https://doi.org/10.1038/s41378-025-01009-y

Received:

Revised:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41378-025-01009-y