Abstract

Photocatalytic conversion of CO2 into syngas is highly appealing, yet still suffers from the undesirable product yield due to the sluggish carrier transfer and the uncontrollable affinity between catalytic sites and intermediates. Here we report the fabrication of Co sites with tunable electron localization capability on two dimensional (2D) nanosheets assembled three dimensional (3D) ordered macroporous framework (3DOM-NS). The as-prepared Co-based 3DOM-NS catalysts exhibit attractive photocatalytic performances toward CO2 reduction, among which the cobalt sulfide one (3DOM Co-SNS) shows the highest syngas generation rate up to 347.3 μmol h−1 under the irradiation of visible light and delivers a remarkable catalytic activity (1150.7 μmol h−1) in a flow reaction system under natural sunlight. Mechanism studies reveal that the high electron localization of metal sites in 3DOM Co-SNS strengthens the interaction between Co and HCOO* via the orbital interactions of dyz/dxz-p and s-s, thus facilitating the cleaving process of C-O bond. Additionally, the ordered macroporous framework with nanosheet subunits elevates the transfer efficiency of photoexcited electrons, which contributes to its high activity.

Similar content being viewed by others

Introduction

The excessive consumption of fossil fuels and emission of greenhouse gas CO2 have caused rigorous environmental issues and energy crisis. Direct photochemical conversion of CO2 into value-added fuels or chemicals (e.g., CO, HCOOH, and CH3OH) by using solar energy as the driving force is considered as a promising way in terms of utilizing atmospheric CO2 while storing solar energy1,2,3. Considering the inevitable competition of hydrogen evolution reaction involved in the photocatalytic CO2 reduction, converting CO2 with H2O into syngas (i.e., the mixture of CO and H2), an indispensable raw material for Fischer-Tropsch synthesis, should be an alternative4,5,6,7.

As such, many efforts have been devoted to precise design of metal sites in order to acquire high yields of syngas, among which transition-metal sites with distinct d orbitals configuration and multiple redox states have attracted researchers’ interests. Principally speaking, the CO2-to-syngas conversion mainly involves the formation of a series of intermediates (i.e., *CO2, HCOO*, *COOH, *CO, *H; where * represents an adsorption site) via the multiple proton-coupled electron transfer (PCET) process8,9. Unfortunately, limited by the sluggish transferring efficiency of the photogenerated electrons and insufficient exposed active sites triggered by the commonly bulky nature, it is still a challenge to realize highly efficient syngas evolution. In this regard, nanosizing bulky catalysts into 2D nanosheet is regarded as an effective way to elevate the photogenerated carrier mobility due to their short migration path10,11,12. Additionally, 2D nanosheet catalysts with limited number of atoms represent ideal models for the understanding structure-performance relationships at atomic/molecular levels. Nevertheless, 2D nanosheet catalysts would inevitably suffer from the self-agglomeration due to the existence of strong van der Waals forces, leading to the blocking of photocarrier transfer channels and burial of the active centers13,14. Fortunately, orderly assembling the 2D nanosheet into 3D architecture provides a promising method to solve such agglomeration issue and access the special properties of 3D superstructure simultaneously. Given the structural virtue of 3D hierarchically porous structure in photocatalysis, we envision that controllably assemble 2D nanosheets into 3D ordered macroporous framework should be a promising solution in an endeavor to achieve a high yield of syngas, albeit challenging.

Although photocarrier transfer channels can be opened up via the elaborate construction of materials, high CO yields and desirable CO/H2 proportion are still hard to achieve simultaneously because of the uncontrollable interactions between the reaction intermediates and catalytic sites. Generally, such interactions between catalysts and the interface reaction intermediates are highly correlated with the electronic properties of metal sites15,16. Specifically, during the CO2 reduction process, electrons in d orbital of transition metal sites can transfer to the unpopulated antibonding orbital (i.e., π*) of CO2 or interfacial intermediates due to the similar orbital energy and symmetry, thus leading to CO2 activation and intermediates transformation17,18. As such, sufficient electron in metal sites is essential to stabilize the intermediates and enable bond breaking and recombination, that is, the metal sites are required to have strong electron localization capability to store electrons for the activation of interfacial molecules19,20,21. We thus posit that if we could find a way that finely manipulate the degree of electron localization in metal sites while maintaining their nano-architectures, we would have a chance to regulate the activation behaviors of interfacial molecules to achieve a promoted syngas generation kinetic.

Herein, we propose that such material design concept of topological transformation can be used for installing Co sites with tunable electron localization capability on 2D nanosheets assembled 3D ordered macroporous framework (3DOM-NS). As a proof of concept, 9 kinds of Co-based 3DOM-NS materials with regulable degree of electron localization are constructed via a phase transformation strategy using an 3D ordered macroporous metal-organic framework (MOF) single crystal as the mediator. All kinds of Co-based 3DOM-NS materials display high syngas evolution rates, among which 3DOM Co-SNS exhibits an apparent quantum yield of 9.4% at 450 nm, outperforming all the previous reports under similar conditions. Theoretical insights reveal that the controllable degree of electronic localization in Co center endows the electron modulation around metal sites, thus regulating the CO2 reduction kinetics. Taken 3DOM Co-SNS as an example, the introduction of S atoms raises the electron localization level of Co sites. Thus, the interaction between Co sites and HCOO* intermediate is strengthened through the dyz/dxz-p and s-s orbital interactions, which weakens the C-O bond in HCOO*, leading to a reduced energy barrier of CO2 conversion.

Results

Synthesis and characterization of 3DOM-NS

3DOM-NS materials were synthesized by using an ordered macroporous MOF single crystal (SOM MOF) mediated phase transformation strategy (Fig. 1a). In brief, 3D-ordered polystyrene spheres (PS) template was first prepared via assembling the monodispersed PS (270 nm in diameter) (Supplementary Fig. 1)22,23,24. Subsequently, the PS template was immersed into a methanol solution contained Co2+ and 2-methylimidazole, following by a crystallization treatment in a mixture of methanol/NH3 ∙ H2O to obtain the ZIF-67@PS (Supplementary Fig. 2). Afterward, the single-crystalline ordered macroporous ZIF-67 (SOM ZIF-67) was obtained via removing the PS template in a dimethylformamide solution. Field-emission scanning electron microscopy (FESEM) image clearly reveals the well-defined tetrakaidecahedron morphology of SOM ZIF-67 with eight (111) facets and six (100) facets (Supplementary Fig. 3a, c, d). Transmission electron microscopy (TEM) image unveils its high regularity of macroporous channels with an aperture size of 260 nm (Supplementary Fig. 3b).

a Schematic illustration of the fabrication strategy of 3DOM Co-OHNS; (b, c) FESEM, (d) TEM, (e) HAADF-STEM, (f) HRTEM, (g) AFM and (h) EDS elemental mapping images of 3DOM Co-OHNS. The inset of (g) shows the thickness of the 3DOM Co-OHNS; (i) HAADF-STEM images of 3DOM Co-OHNS obtained with different phase transformation time.

A phase transformation process was then intervened in a mixture of ethanol/water to convert the SOM ZIF-67 into Co(OH)2 nanosheets assembled 3D ordered macroporous polyhedron (3DOM Co-OHNS). XRD pattern and XPS spectra reveal the complete phases transformation from ZIF-67 into Co(OH)2 (Supplementary Figs. 4, 5)25. FESEM image indicates that 3DOM Co-OHNS inherits the tetrakaidecahedron morphology of SOM ZIF-67 with the oriented arrangement of ordered macropores (Fig. 1b and Supplementary Fig. 6). The high magnification FESEM, TEM and the high-angle annular dark-field scanning TEM (HAADF-STEM) images clearly show that the tetrakaidekahedron particles consist of nanosheets, which are assembled into the ordered macroporous framework (Fig. 1c–e). Obviously, the diameter of macropores is well-maintained during the phase transformation process (Supplementary Fig. 7). High-resolution TEM (HRTEM) and atomic force microscope (AFM) images further uncover the 2D nanosheet nature in the macroporous “wall” with a thickness of ca. 2.2 nm (Fig. 1f, g). Energy dispersive X-ray spectroscopy (EDS) mapping images and elemental line scan profiles show the homogeneous distributions of Co and O elements over the ordered macroporous framework (Fig. 1h and Supplementary Fig. 8).

To gain insight into the formation process of 3DOM-NS structure, 3DOM Co-OHNS particles obtained with different phase transformation time have been characterized by TEM. As shown in Fig. 1i and Supplementary Fig. 8, the core-shell structure with a ZIF-67 core and an Co(OH)2 nanosheet shell was formed after 4 min of phase transformation. As the reaction duration extended to 10 min, the inner ZIF-67 core disappeared accompanied with the formation of nanosheets assembled macroporous framework. To gain atomic understanding of the phase transformation process, the ab initio molecular dynamic (AIMD) simulation was performed for a duration of 9 ps at 343 K (Fig. 2a, Supplementary Movie 1 and Supplementary Data 1)26. During the phase transformation process, H2O molecule first attacks and breaks the Co-N bond in ZIF-67. Subsequently, the H+ and OH- in H2O bond to the N and Co sites, respectively, to form the imidazole moiety and Co-OH structure (Fig. 2b). Considering that an ammonium complex may be formed in SOM ZIF-67 because an aqueous ammonium solution was used in the preparation process, we performed AIMD simulation based on the ZIF-67 model with ammonium complex in the presence of water. The results show that the ammonium complex readily dissociates from the Co center during the AIMD process, followed by the breakage of Co-N bond similar to that over the pristine ZIF-67 model (Supplementary Figs. 9, 10). The variation of the coordination environment of Co sites in the phase transformation process is further witnessed by the X-ray absorption near-edge structure (XANES) and extended X-ray absorption fine structure (EXAFS). As shown in Fig. 2c–e and Supplementary Fig. 11, Co K-edge XANES spectrum of SOM ZIF-67 displays serval peaks assigned to the typical features of pure phase ZIF-6727,28,29. The simulated XANES spectrum, EXAFS fitting results and UV-vis-near IR absorption spectrum further reveal the tetracoordinated environment of Co-N center in SOM ZIF-67. During the phase transformation process, the hexa-coordinated Co-O bond emerges along with the breakage of tetracoordinated Co-N bond in SOM ZIF-67 (Supplementary Table 1, Fig. 2c–e and Supplementary Fig. 12)30.

a AIMD simulation for the phase transformation process (snapshot images about 8.5 ps of AIMD simulations). White, silver, red, blue and pink balls represent H, C, O, Co and N atoms, respectively; (b) Variations of Co-N and Co-O bonds during the AIMD simulation; (c) Co K-edge XANES spectra, (d) FT k3-weighted EXAFS curves and (e) wavelet-transformed k3-weighted EXAFS spectra of 3DOM Co-OHNS, SOM ZIF-67 and reference samples; (f) EDS element mapping images and the corresponding crystalline structures of 3DOM Co-SNS, 3DOM Co-ONS, 3DOM Co-PNS, 3DOM Co-SeNS, 3DOM NiCo-OHNS, 3DOM FeCo-OHNS, 3DOM CuCo-OHNS and 3DOM ZnCo-OHNS. Source data are provided as a Source Data file.

The oriented phase transformation mechanism of 3DOM-NS endows us to manipulate the metal sites in hydroxides. That is, our strategy can be extended to the synthesis of a serial of Co-based bimetallic hydroxides with 3DOM-NS structure by simply adding the foreign metal salts in the phase transformation process. As such, four kinds of Co-based bimetallic hydroxides, namely 3DOM NiCo-OHNS, 3DOM FeCo-OHNS, 3DOM CuCo-OHNS, and 3DOM ZnCo-OHNS have been fabricated. The FESEM and TEM images confirm their similar structures of nanosheets assembled ordered macropores (Supplementary Figs. 13–16). EDS mapping images show that various targeted metal elements (i.e., Ni, Fe, Cu and Zn) are homogeneously distributed over the macroporous frameworks (Fig. 2f). Apart from the synthesis of Co-based bimetallic hydroxides, the phase transformation proposal is also applicable to the synthesis of Co-based sulfide (3DOM Co-SNS), oxide (3DOM Co-ONS), phosphide (3DOM Co-PNS) and selenide (3DOM Co-SeNS) with 3DOM-NS structure by the post-processing of 3DOM Co-OHNS. XRD patterns and HRTEM images confirm the successful synthesis of these 3DOM-NS materials (Supplementary Figs. 17–20). To our delight, these materials also inherit the 2D nanosheets assembled ordered macroporous structure of 3DOM Co-OHNS. The thickness of the nanosheets in 3DOM Co-SNS and 3DOM Co-ONS is ca. 2.2 and 2.4 nm, respectively, which are similar to that in 3DOM Co-OHNS (Supplementary Fig. 21). In addition, selected area electron diffraction (SAED) and HRTEM images reveal that 3DOM Co-SNS and 3DOM Co-ONS are composed of polycrystalline particles with the crystalline sizes of ca. 4 nm and 7 nm, respectively (Supplementary Fig. 22). EDS mapping images show the uniform distributions of S, O, P and Se elements over the skeletons of 3DOM Co-SNS, 3DOM Co-ONS, 3DOM Co-PNS and 3DOM Co-SeNS, respectively (Fig. 2f). The above results verify the good flexibility and adaptability of the phase transformation strategy.

Interestingly, the controllability of the in situ phase transformation strategy endows a fine regulation of the electronic states of Co sites since the electronic properties of metals sites are affected by their surrounded micro-environments31,32. As expected, density functional theory (DFT) calculations reveal the distinct d-orbital distributions of Co(OH)2 when the coordinating atoms around Co sites are replaced by S, O, P, Se, Ni, Fe, Cu and Zn atoms (Supplementary Fig. 23). Such changes in the d-orbital distribution may affect the electron-exchange between d and π or sigma orbitals thus the interactions between Co centers and the interfacial molecules, which provide a possibility to regulate the reaction kinetics by matching the interaction between active sites and intermediates33.

Photocatalytic performance of 3DOM-NS

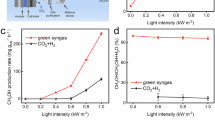

To better understand the structure-activity relationship of the 3DOM-NS, visible-light driven photocatalytic CO2 reductions were performed in a mixture of H2O/acetonitrile using [Ru(bpy)3]Cl2·6H2O (denoted as Ru, bpy = 2,2′-bipyridine) and triethanolamine (TEOA) as the photosensitizer and electron donor, respectively34. CO and H2 are detected as the only gaseous products, and no detectable liquid byproducts (e.g., CH3OH, HCHO, and HCOOH) derived from CO2 are observed (Supplementary Figs. 24, 25). Satisfyingly, all these as-prepared 3DOM-NS display high syngas (i.e., the mixture of CO and H2) yields under the irradiation of visible light (i.e., 450 nm of LED light) (Fig. 3a). Among these 3DOM-NS samples, 3DOM Co-SNS exhibits the highest photocatalytic efficiency with a syngas production rate of 347.3 μmol h−1. By contrast, 3DOM NiCo-OHNS, 3DOM FeCo-OHNS, 3DOM CuCo-OHNS, 3DOM ZnCo-OHNS, 3DOM Co-ONS, 3DOM Co-PNS and 3DOM Co-SeNS show slightly inferior syngas yields of 211.4, 262.3, 252.8, 200.3, 255.0, 249.7 and 268.3 μmol h−1, respectively. In this case, we selected 3DOM Co-SNS as the representative to deeply uncover the interfacial mechanism of photocatalytic CO2 reduction over Co-based 3DOM-NS.

a Photocatalytic performances in CO2 reduction; (b) FT k3-weighted EXAFS and (c) wavelet-transformed k3-weighted EXAFS spectra of 3DOM Co-SNS and reference samples; (d) Generation of CO, H2 and total syngas photocatalyzed by 3DOM Co-SNS as a function of reaction time; (e) Photocatalytic CO2 performances of various materials; (f) Mass spectra and total ion chromatography (inset) of generated 13CO using 13CO2 as the gas source; (g) Photocatalytic CO2 performances integrated with oxidation of biomass-derived molecules over CdS@3DOM Co-SNS. The inset of (g) shows the biomass-derived molecules transformation equation. h The photographs and photocatalytic performances of reaction system under outdoor sunlight irradiation on Mar. and Apr. of year 2024 at Wushan Road, Guangzhou city, China (23°8’N, 113°17’E). The error bars in (a) represent the standard deviations of at least three independent measurements of the same sample. Source data are provided as a Source Data file.

First, the coordination environment and the valence state of Co center in 3DOM Co-SNS were investigated. XRD pattern clearly revels the Co3S4 phase in 3DOM Co-SNS (PDF#42-1448) (Supplementary Fig. 17). X-ray photoelectron spectroscopy (XPS) further confirms the oxidation states of Co with the valance states of Co2+ and Co3+ (Supplementary Fig. 26). The post-edge oscillation in XANES spectrum and the k3χ(k) oscillation curve of 3DOM Co-SNS are distinct to that of metallic Co and Co3O4, suggesting their different coordination environments of Co (Supplementary Figs. 27a, b). Fourier transformed (FT) R-space extended XAFS (EXAFS) and the wavelet transform (WT) EXAFS spectra show a characteristic peak at ∼1.8 Å, which is assigned to the Co-S coordination (coordination number of ca. 4.7). No obvious Co-Co (~2.2 Å) and Co-O bonds ( ~ 1.48 Å) are observed, ruling out the presence of any metallic Co or cobalt oxide in 3DOM Co-SNS (Fig. 3b, c, Supplementary Fig. 27 and Table 1)35,36.

Upon acquiring the accurate electronic and coordination environment of 3DOM Co-SNS, we are now in a position to examine its photocatalytic performance toward CO2 reduction. As observed from the time-yield plot, 3DOM Co-SNS delivers a maximal syngas generation of 509.9 μmol within 3 hours of reaction with a CO/H2 ratio of 1.1 (Fig. 3d).

The effect of the amount of 3DOM Co-SNS on the photocatalytic performance of catalytic system was then studied. As shown in Supplementary Fig. 28 and Table 2, a syngas production rate of 78.5 μmol h−1 is obtained when only a small amount of 3DOM Co-SNS (0.1 mg) is added. The production of CO and H2 increases linearly when increasing quantity of 3DOM Co-SNS from 0.1 to 1.0 mg. However, further increase the 3DOM Co-SNS amount would not further promote the production of CO and H2. Accordingly, the syngas evolution rate in region I (Supplementary Fig. 28, 3DOM Co-SNS < 1.0 mg) is mainly limited by the number of catalytic centers which can be accessed by the sensitizer Ru, while the reaction rate in region II (Supplementary Fig. 28, 3DOM Co-SNS > 1.0 mg) is largely determined by the electron-transfer kinetics from the sensitizer Ru to Co sites and the light-shielding effect37,38,39. To break such the limitation of charge transfer, we expanded the solution volume of the reaction system and the mass of the photosensitizer Ru. Fortunately, the reaction rate can be back on track when expanding the reaction solution, delivering a syngas production rate of 1063.3 μmol h−1, i.e., 23.8 mL h−1, in the presence of 5.0 mg of 3DOM Co-SNS.

The apparent quantum yield (AQY) of syngas evolution at 450 nm is calculated to be ~9.4%, which outperforms that of all the previous reports under comparable conditions (Supplementary Table 3). However, the syngas yield reaches a plateau upon 3 h of visible light irradiation, which may be ascribed to the deactivation of Ru40. Fortunately, the reaction activity can be back on track when replenishing the equal amount of photosensitizer into the reaction system (Supplementary Fig. 29).

For comparison, Co-based sulfide nanosheets with solid dodecahedron architecture (DH-Co-SNS) and bulky Co-SNS were also fabricated using conventional ZIF-67 and commercial Co(OH)2 as the precursors, respectively (Supplementary Figs. 30, 31). As expected, both the DH-Co-SNS and bulky Co-SNS present modest photocatalytic performances for CO2 conversion with the syngas evolution rates of 276.1 and 168.9 μmol h−1, respectively, pointing out the structural advantage of 3D ordered macroporous skeleton with 2D nanosheets subunit in CO2 photoreduction (Fig. 3e).

The durability of 3DOM Co-SNS was further evaluated via the sequential cycling tests. As presented in Supplementary Fig. 32, the syngas yield over 3DOM Co-SNS can be kept at 335.4 μmol h−1 after four consecutive cycles. Moreover, the TEM image, XRD pattern and XPS spectra indicate that the morphology and structure of 3DOM Co-SNS remain intact after the catalytic reactions, highlighting its good stability (Supplementary Fig. 33).

Considering the significant role of solvent in the photocatalytic system, we conducted CO2 reduction in the mixture of acetonitrile and H2O with different ratios. As shown in Supplementary Fig. 34, the ratios of CO/H2 can be tuned from 0.2 to 1.1 by adjusting the H2O/acetonitrile ratios of the reaction solution from 0 to 0.25.

Control experiment demonstrates that no CO product is detectable in the atmosphere of argon (Supplementary Fig. 35, entry 2). In addition, 13CO2-labeled isotropic experiment points out the existence of 13CO (m/z = 29) and the absence of 12CO (m/z = 28) when 13CO2 is adopted as the feedstock gas, suggesting the CO is originated from the photo-splitting of CO2 (Fig. 3f and Supplementary Fig. 36).

The absence of Ru and 3DOM Co-SNS leads to a negligible syngas yield, implying the essential role of photosensitizer and photocatalyst in photocatalytic CO2 reduction (Supplementary Fig. 35, entries 3–4). In addition, the tendency of syngas generation stands in line with the characteristic absorption spectrum of Ru instead of that of 3DOM Co-SNS, corroborating that the photoreduction is indeed driven by the excitation of photosensitizer (Supplementary Fig. 37). Notably, excess photosensitizer Ru will result in the decrease in the production rate of syngas, which can be rationalized by the reduced light penetration when increasing the photosensitizer dosage (Supplementary Fig. 38). To conquer the deactivation and homogeneous nature of photosensitizer, we implanted the heterogeneous CdS species on the macropores of 3DOM Co-SNS (CdS@3DOM Co-SNS) to act as the light absorber (Supplementary Fig. 39). The photocatalytic system of CdS@3DOM Co-SNS can be smoothly proceeded within 7 h of continuous test (Supplementary Fig. 40).

The photocatalytic reaction is terminal in the absence of TEOA, reflecting the important role of electron donor (Supplementary Fig. 35, entry 5). However, the use of sacrificial agent (i.e., TEOA) will inevitably waste the oxidizing power of photogenerated holes41. In this regard, a cooperative reaction system is constructed by using alcohol oxidation reactions to replace the sacrificial agent involved reaction to simultaneously produce syngas and value-added oxidative products over CdS@3DOM Co-SNS. Control experiment shows that pure CdS exhibits modest syngas yields in the cooperative reaction system (Supplementary Fig. 41). Interestingly, 1,2-diphenyl-1,2-ethanediol, 1,2-di(2-furyl)-1,2-ethanediol and 2,5-furandicarboxaldehyde can be efficiently produced accompanied with the formation of syngas gas when benzyl alcohol, furfuryl alcohol and 5-hydroxymethylfurfural are adopted as the electron donors over the CdS@3DOM Co-SNS photocatalytic system, respectively, highlighting the potential of making the maximum use of solar energy (Fig. 3g and Supplementary Fig. 42, 44).

Considering the high activity of 3DOM Co-SNS, we conducted the photocatalytic CO2 reduction under the irradiation of natural sunlight in a sealed reactor (Supplementary Fig. 45a). As expected, 3DOM Co-SNS remains its high photocatalytic performance with an average syngas production rate of 131.5 μmol h−1 (Supplementary Fig. 45b). To expand the possibility of practical application, we then performed the photocatalytic reaction in a large-scale outdoor flow reactor. A compound parabolic concentrator and a light-trapping system were utilized to furthest harvest concentrated solar light. Delightfully, an average syngas yield of 1150.7 μmol h−1, that is 25.8 mL h−1, with a CO/H2 ratio of ca. 1.0 can be obtained with the direct irradiation of natural sunlight (Fig. 3h).

Reaction mechanism investigations

To uncover the catalytic mechanism of CO2 photoreduction, in situ Fourier transform infrared (in situ FTIR) spectroscopy was carried out to track the generated intermediates. As shown in Fig. 4a, the time-resolved diffuse reflectance infrared Fourier transform spectroscopy (DRIFT) spectra of 3DOM Co-SNS show that a set of peaks emerge and strengthen along with the prolongation of light irradiation times. Among these peaks, features emerged at 1372 and 1520 cm−1 are assigned to νs (O-C-O) and νas (O-C-O) of monodentate (m-CO32-), while peaks at 1560 and 1284 cm−1 are assigned to ν (C = O) and νas (O-C-O) of bidentate carbonate (b-CO32-) on the surface, respectively42. The peaks centered at 1455 and 1410 cm-1 are corresponding to the νs (O-C-O) mode of bicarbonates, polydentate carbonate, and/or ionic carbonate43,44. The bands at 1594 cm-1, 1340 cm-1, 2960 cm-1, 2884 cm-1, and 2730 cm-1 are characteristics of formate (HCOO*) species45 (Supplementary Table 4). Unfortunately, no absorption bands assigned to the adsorbed carbonyl (CO*) but gaseous CO are witnessed in the FTIR spectra, which may be due to the weak interaction between oxidized Co sites and CO. The weak chemical adsorption capacity of CO over 3DOM Co-SNS is further confirmed by the CO adsorption DRIFT spectra and CO-TPD-MS measurements (Supplementary Figs. 46, 47).

a In situ FTIR spectra for the photocatalytic CO2 reduction over 3DOM Co-SNS; (b) free energy diagrams and (c) the configurations of adsorbates for the CO2 reduction processes on Co3S4, Co(OH)2 and Co3O4; (d) XPS spectra of Co 2p of 3DOM Co-SNS exposing to CO2 and visible light condition; (e) Configurations of HCOO*on Co3S4 and Co3O4; COHP analysis of (f) Co3S4-HCOO* and (g) Co3O4-HCOO*. Co, O, S, C, H atoms are colored in blue, red, yellow, silver and white, respectively. Source data are provided as a Source Data file.

DFT calculations were conducted to gain atomic insight into the CO2 conversion process (Supplementary Data 1). To reveal the intrinsic role of sulfide on CO2 conversion, three Co-based theoretical models with different coordination structures (i.e., Co3S4, Co(OH)2 and Co3O4) are constructed based on the results of experimental characterization (Supplementary Fig. 48). Figure 4b, c show the reasonable reaction pathways and free energy levels of different intermediates and transient states on these models. It is observed that CO2 is firstly adsorbed on the surface of catalysts (CO2 + * → *CO2) via a barrierless chemisorption process. The facile CO2 adsorption process has been experimentally confirmed by the XPS spectra with the treatment of CO2 and light irradiation, which show an obviously positive shift in Co 2p peak when exposing to CO2 atmosphere (Fig. 4d). Such a positive shift in XPS spectra may be due to the formation of Co-O interaction on 3DOM Co-SNS and the electron transfer from Co sites to CO2 molecule (Supplementary Fig. 49)46.

A proton-coupled electron transfer (PCET) process is subsequently taken place to generate HCOO* (*CO2 + H+ + e- → HCOO*) via transition state TS147. C-O bond within HCOO* is then cleaved with an high energy barrier via transition state TS2 to give rise of *CO and *OH (HCOO* → *CO + *OH). *OH will undergo a protonation process to form *H2O and *CO, which finally escape from the catalyst in the form of dissociative products (i.e., CO and H2O). It is observed that the total energy barriers of the HCOO* → *CO process on Co3O4 and Co(OH)2 are calculated to be as high as 3.04 and 3.19 eV, respectively, which are higher than that on Co3S4 (1.69 eV). These results elucidate that the CO2 reduction should proceed more smoothly on Co3S4 compared with that on Co3O4 and Co(OH)2.

To gain insight into the C-O bond cleaving process on metal centers, the local structures of HCOO* adsorption configurations were studied (Fig. 4e). In the case of Co3S4-HCOO* and Co3O4-HCOO*, the adsorbed HCOO* exhibits a bent configuration via the formation of Co-O bond. The side O atom in HCOO* tends to be captured by another Co site. Different from the above two adsorption configurations, two O atoms in CO2 will preferentially form weak hydrogen bonds with the H atoms on the surface of Co(OH)2 due to the exposing of surface hydroxyl groups (Supplementary Fig. 50). Such the hydrogen bond interaction enables the bending of CO2 molecule and induces the formation of HCOO* species.

Projected crystal orbital Hamilton population (pCOHP) was then intervened to analyze the interaction between Co sites and adsorbed HCOO*. As shown in Fig. 4f, g and Supplementary Fig. 51, the positive (i.e., right side) and negative (i.e., left side) areas in the pCOHP diagrams indicate the bonding and antibonding contributions, respectively48. For Co3S4-HCOO* and Co3O4-HCOO*, most of valence states (below the Fermi level, EF) occur as bonding, while antibonding states appear on conduction band (above Fermi level, EF), signifying the strong bonding interaction between Co sites and HCOO*49. In the case of Co3S4-HCOO*, noticeable bonding states appear in Co-O via the orbital interactions of 3dxz-2pz and 4s-2s. Obvious Co-O bonding states via the orbital interactions of 3dyz-2pz and 4s-2s are observed in the pCOHP diagram of Co3O4-HCOO*. Integrated COHP (ICOHP) was then employed to quantitatively measure the bonding strength of Co-O bonds. It is clear that the ICOHP value of Co-O in Co3S4-HCOO* (-0.99 eV) is negative than that in Co3O4-HCOO* (-0.77 eV). Thus, the antibonding states of d-p and s-s in Co3S4-HCOO* would display lesser electron occupancy, leading to a stronger Co-O bonding on Co3S4-HCOO* compared with that on Co3O4-HCOO*48. Notably, the strong interaction between O in HCOO* and Co in Co3S4 may weaken the C-O bond within HCOO* and simultaneously accelerate the electron transfer from Co site to HCOO* during the PCET process, thus facilitating the breakage of C-O bond. The weak interaction of C-O bond within HCOO* is also visualized by the local structures of their transition state TS2, showing that the bond length of C-O of HCOO* on Co3S4 (1.43 Å) is longer than that on Co3O4 (1.39 Å) (Supplementary Fig. 52).

We subsequently adopted electron localization function (ELF) to disclose the effect of local electronic structure of catalysts on the adsorption and bond breaking behavior of HCOO*50. As shown in Fig. 5a, the Co sites in Co3S4 demonstrate higher degree of electron localization compared with that in Co3O4, that is, electrons tend to be confined on the Co centers of Co3S451. To quantitatively analyze the electron configurations of catalysts, the lowdin charges of Co and the surrounded atoms were calculated (Supplementary Tables 5, 6). Clearly, the average charge of Co sites in Co3S4 is calculated to be -0.84 eV, which is negative than that in Co3O4 (0.26 eV). These results elucidate that electrons are concentrated on the Co sites in Co3S4 and potentially transferred to HCOO* in the CO2 conversion process, thus accelerating the C-O bond cleaving. In fact, this electron transfer behavior was further confirmed by the differential charge density analysis, revealing that electrons are focusing on the interface between Co3S4 and adsorbed HCOO* (Fig. 5b). Conversely, electrons are evenly distributed over the Co3O4 framework apart from the interface between Co sites and HCOO*.

a ELF calculations of Co-based catalysts; (b) Integration of Δρ in planes along the Z-direction over Co3S4-HCOO* and Co3O4-HCOO*. Green and blue regions represent electron accumulation and electron depletion, respectively; (c) CO2-TPD curves of 3DOM Co-SNS, DH-Co-SNS and bulky Co-SNS; (d) TRPL decay spectra of Ru solution before and after adding 3DOM Co-SNS; (e) Average lowdin charges of Co sites in various Co-based catalysts. The inset of (e) shows the visual charge distributions of various Co-based catalysts. Source data are provided as a Source Data file.

The above results unambiguously illustrate that the high degree of electron localization in Co sites induced by S imbedding is able to convene electron around the interface of catalyst and adsorbed HCOO*, thus strengthens the interaction between Co and O in HCOO* and weakens the C-O bonding. This microenvironment engineering mechanism inspires us to finely tune the degrees of electron localization in Co centers. Fortunately, the in situ phase transformation strategy endows the design of 3DOM-NS materials with tunable coordination environments of Co sites (i.e., Co-based bimetallic hydroxide or Co-X, X = OH, S, O, P and Se) (Supplementary Fig. 53). We thus performed ELF and lowdin charges to study the local electronic structures of these catalysts (Fig. 5a, e and Supplementary Tables 5–13). Expectedly, we can easily manipulate the degree of electron localization in Co sites via altering the surrounding metal/non-metal atoms, that is, the charges in Co sites can be widely adjusted from -0.84 to 0.46 eV by replacing the non-metal or a part of metal atoms. Interestingly, the correlation analysis results reveal a linear trend between reaction activity and average lowdin charge of Co sites, that is, more negative lowdin charge in the Co sites will result in a higher syngas generation rate. Indeed, electron localization in Co site is able to affect the interaction between catalyst and adsorbed molecules, and thus manipulate the adsorption and activation behavior of the surface adsorbed species. In this regard, we have supplemented the DFT calculations to investigate the adsorption behaviors of reactant CO2 on nine kind of catalysts. As shown in Supplementary Fig. 54, a linear relationship between lowdin charge and adsorption energy of CO2 is established. Among the investigated models, Co3S4 with the most negative lowdin charge of Co sites affords the optimal adsorption capacity toward CO2 with a free energy of -0.446 eV. It can be speculated that electrons are concentrated on the Co sites in Co3S4 and potentially transferred to CO2 in the CO2 conversion process, thus strengthening CO2 adsorption and breaking the symmetrical charge distribution within CO2 molecules. It’s worth noting that the controllability of microenvironment made here potentially provides a toolbox for the manipulation of the interaction between catalysts and adsorbed molecules, thus realizing the controllability of CO2 conversion process and beyond.

Apart from the intrinsic activity, the exposure of active sites should be equally indispensable to obtain the high photocatalytic performance. In this case, the porous structure of 3DOM Co-SNS was analyzed by N2 sorption experiment. As shown in Supplementary Fig. 55, a type-II N2 sorption isotherm with H3-type hysteresis loop is observed, confirming the macroporous nature of 3DOM Co-SNS. Additionally, 3DOM Co-SNS exhibits a larger specific surface area of 151.1 m2 g-1 than DH-Co-SNS (71.1 m2 g-1) and bulky Co-SNS (17.4 m2 g-1). Considering that the photocatalytic reaction occurs on the surface of a catalyst, high surface area and 2D nanosheet structure of 3DOM Co-SNS potentially maximize the exposure of Co sites for landing and activating of substrates. Actually, 3DOM Co-SNS displays larger CO2 uptake and higher onset desorption temperature (262 °C) than DH-Co-SNS (246 °C) and bulky Co-SNS (238 °C) in the temperature programmed desorption (TPD) tests, further confirming the advantage of 2D nanosheets and ordered macroporous structures in the enhancement of CO2 adsorption (Fig. 5c). The high CO2 adsorption capability of 3DOM Co-SNS is also verified by the CO2 sorption isotherms, which show that 3DOM Co-SNS exhibits higher CO2 uptake compared with DH-Co-SNS and bulky Co-SNS (Supplementary Fig. 56).

A proper alignment of band structure is a prerequisite to assure a coherent electron transfer for driving reaction. As shown in Supplementary Fig. 57, the flat band potential of 3DOM Co-SNS (-0.94 V vs. NHE) estimated by the Mott-Schottky plot is more positive than the lowest unoccupied molecular orbital (LUMO) of Ru (-1.28 V vs. NHE) and more negative than the E(CO2/CO) (-0.53 V vs. NHE), suggesting the photo-excited electrons in Ru can be readily transferred to 3DOM Co-SNS for the conversion of CO2 (Supplementary Fig. 58). The charge transfer process was further confirmed by the time-resolved photoluminescence (TRPL) decay spectra, showing that a sharp decay of the singlet excited state Ru with a lifetime of 0.64 ns is formed upon the addition of 3DOM Co-SNS (Fig. 5d).

The charge transfer mechanism was then investigated by the steady-state fluorescence spectroscopy. As shown in Supplementary Fig. 59a, the intense emission peak of Ru located at 625 nm is sharply quenched by 3DOM Co-SNS. In addition, the curve for PL intensity versus the concentration of 3DOM Co-SNS presents linear upward as fitted with the Stern-Volmer equation, reflecting the exited Ru is directly quenched by 3DOM Co-SNS via an oxidation quenching mechanism (Supplementary Fig. 59b)52. Indeed, the typical IR absorption peaks of Ru are observed in the FTIR spectrum of spent 3DOM Co-SNS (Supplementary Fig. 60), suggesting a permitted absorption process on catalyst. Additionally, 3DOM Co-SNS exhibits the maximum quenching degree compared with the solid dodecahedron one (DH-Co-SNS) and bulky Co-SNS, demonstrating the advantage of nanosheets assembled ordered macroporous structure in promoting charge transfer (Supplementary Fig. 61). The electrochemical impedance spectroscopy (EIS) further reveals that 3DOM Co-SNS exhibits a low charge transfer resistance and high electron mobility, thus facilitating the transfer and aggregation of electron around Co sites for driving the CO2 reduction (Supplementary Fig. 62).

Discussion

In summary, we have successfully constructed a series nanosheets assembled ordered macroporous catalysts via a MOF-mediated phase transformation strategy. The 3D ordered macroporous and 2D nanosheet structures enhance not only the accessibility of active sites but also the transfer efficiency of photoexcited electrons. Additionally, the controllability of the proposed approach enables fine manipulation of the degree of electron localization in Co sites via simply altering their surrounding metal/non-metal atoms. As a result, 3DOM-NS exhibit high photocatalytic performance toward the reduction of CO. Among these 3DOM-NS catalysts, 3DOM Co-SNS achieves the highest syngas yield of 347.3 μmol h-1 under the irradiation of visible light and an apparent quantum yield of 9.4% at 450 nm. DFT calculations demonstrate that the high electron localization of Co sites in 3DOM Co-SNS reinforces the dyz/dxz-p and s-s orbital interactions between Co and HCOO*, thus accelerating the bond cleaving process of C-O. This work provides an angle of view for the rational design of advanced catalysts for CO2 conversion and presents a insight for manipulating the evolution behaviors of interfacial intermediates via tuning the degree of electron localization.

Methods

Materials

All chemicals were commercially purchased and directly used without purification. Cobalt nitrate hexahydrate (Co(NO3)2·6H2O, 99.95%), ammonium hydroxide (NH3·H2O, 28–30% NH3), styrene (99%), potassium persulfate (K2S2O8, 99%), 2-methylimidazole (2-MeIM, 98%), cobalt acetate tetrahydrate (Co(CH3COO)2·4H2O, 99%), thioacetamide (TAA, 99%), sodium hypophosphite monohydrate (NaH2PO2·H2O, 99%), selenium (Se, 99.9%), nickel nitrate hexahydrate (Ni(NO3)2·6H2O, 98%), iron nitrate nonahydrate (Fe(NO3)3·9H2O, AR), copper nitrate trihydrate (Cu(NO3)2·3H2O, 99%), zinc nitrate hexahydrate (Zn(NO3)2·6H2O, 99%), tris(2,2′-bipyridine) dichlororuthenium(II) hexahydrate ([Ru(bpy)3]Cl2·6H2O, 98%), benzyl alcohol (BA, 99%), 5-Hydroxymethyl-2-furaldehyde (HMF, 99%), furfuryl alcohol (FA, 99%) were purchased from Aladdin Industrial Co., Ltd. Cobalt hydroxide (Co(OH)2, 99.9%) and triethanolamine (TEOA, 99%) were purchased from Shanghai Macklin Biochemical Technology Co., Ltd.

Catalysts synthesis

Synthesis of 3D ordered PS templates. 15 mL of styrene was added into 250 mL of H2O and heated at 90 °C in a three-neck flask with bubbling nitrogen for 30 min. 0.1 g of K2S2O8 was then added into the mixture to trigger the polymerization under nitrogen atmosphere and the solution was kept stirring for 24 h. Finally the obtained monodispered PS solution was centrifuged at a rate of 2500 rpm for 24 h and dried overnight to yield the 3D ordered PS templates.

Synthesis of SOM ZIF-67. In a typical synthesis, a piece of 3D PS template was immersed into a methanolic solution containing 2-MeIM (1.0 g mL-1) and Co(NO3)2·6H2O (0.4 g mL-1). The mixed solution was then degassed under vacuum for 30 min to ensure the precursor solution completely entered into the voids of the 3D PS template. After that, the purple precursor@3D PS was taken out and dried at 50 °C overnight, which was then soaked in a mixture of NH3·H2O/CH3OH (1:1 v/v) and degassed under vacuum for 5 min to trigger the crystallization of ZIF-67. After aging for 24 h, the purple ZIF-67@3D PS was collected and fully dried at 50 °C. Finally, the obtained ZIF-67@3D PS was then immersed in N,N-Dimethylformamide for template removal to yield SOM ZIF-67.

Synthesis of 3DOM Co-OHNS. 5 mg of SOM ZIF-67 powder was dispered in a solution containing 10 mL of ethanol and 2 mL of deioned water. The mixture was then heated to 80 °C for 10 min for morphology transformation. The hot solution was centrifuged immediately and washed by ethanol for 3 times to obtian 3DOM Co-OHNS.

Synthesis of 3DOM NiCo-OHNS, 3DOM FeCo-OHNS, 3DOM CuCo-OHNS, and 3DOM ZnCo-OHNS. The Co-based bimetallic hydroxide NS with 3DOM structures were synthesized using the same procedure as 3DOM Co-OHNS except for addition of 5 mg of the foreign targeted metal salts (i.e., Ni(NO3)2·6H2O, Fe(NO3)3·9H2O, Cu(NO3)2·3H2O, and Zn(NO3)2·6H2O) to the hydrothermal process.

Synthesis of 3DOM Co-SNS, 3DOM Co-PNS, 3DOM Co-SeNS and, 3DOM Co-ONS. 3DOM Co-SNS was obtained via a chemical vapor deposition method. Briefly, 20 mg 3DOM Co-OHNS and 40 mg thioacetamide were separately placed on the down-stream and up-stream direction of the tubula furnace, respectively. Chemical vapor deposition was conducted by heating the furnace to 150 °C for an hour under the atmosphere of argon. Bulky Co-SNS was obtained via the same procedure except for using commercial Co(OH)2 as the precursor. The similar chemical vapor deposition procedure was used to prepare 3DOM Co-PNS and 3DOM Co-SeNS. In the case of 3DOM Co-PNS, NaH2PO2·H2O was selected as the P source and the calcination temperature was set at 300 °C. For the synthesis of 3DOM Co-SeNS, selenium powder was selected as the Se source and the calcination temperature was set at 280 °C. For the preparation of 3DOM Co-ONS, the as-prepared 3DOM Co-OHNS was directly pyrolyzed at 150 °C for 2 h under air atmosphere.

Synthesis of DH-Co-SNS. Firstly, the conventional ZIF-67 with rhombic dodecahedron was prepared via mixing the 2-MeIM containing aqueous solution (0.448 g mL-1) with the Co(CH3COO)2·4H2O aqueous solution (0.12 g mL-1). DH-Co-SNS was prepared via the similar procedures as 3DOM Co-SNS except for using conventional ZIF-67 as the precursor.

Synthesis of CdS@3DOM Co-SNS. In a typical synthesis, 60.8 mg of thiourea, 22.8 mg of cadmium chloride pentahydrate, 58.8 mg of sodium citrate, and 15 mg of 3DOM Co-SNS were added in 30 mL of deionized water. The pH value of mixture was adjusted to 12 by ammonia water, which was then transferred to an oil bath at 80 °C for 2 h. Subsequently, the solution was centrifuged at 4000 r min-1 for 3 min and the obtained solid was washed by deionized water and ethanol for three times.

Characterizations

The morphology of the samples was characterized by a field-emission scanning electron microscopy (FESEM, HITACHI SU8220) and a transmission electron microscope (TEM, JEOL, JEM 2100 F) equipped with an energy dispersive X-ray (EDX) analyzer (Bruker Xflash 5030 T). The crystal phases of the as-prepared catalysts were colleted by a power X-ray diffraction (XRD, Bruker D8 Advance diffractometer). The chemical compositions of the samples were analyzed by an X-ray photoelectron spectroscopy (XPS, Thermo Scientific NEXSA). All binding energies are referenced to the C1s peak of the surface adventitious carbon at 284.8 eV. Nitrogen adsorption-desorption isotherms were gather by an automatic rapid comparison surface and poriosity analyzer (Micromeritics, ASAP 2460). CO2-TPD was performed on a chemisorption analyzer (Micromeritics Instrument, AutoChem 2950 HP). The thickness of the as-synthezied sample was measured by a atomic force microscopy (AFM, Bruker Multimode 8). The photoluminescence (PL) spectra were collected by F-7000 spectrophotometer (HITACHI, Japan) with an excitation wavelength of 450 nm. Time-resolved photoluminescence (TRPL) decay spectra were examined by Edinburgh FLS1000 spectrophotometer with an excitation wavelength of 450 nm and an emission wavelength of 625 nm. The adsoroption spectrum of Ru was recorded by a ultraviolet spectrophotometer (U-T3C, Summit Instrument Manufacturing).

XPS measurements under CO2 and light irradaition were carried out on a Thermo Escalab 250Xi with a reference of C1s peak at 284.6 eV. The analysis chamber was first vacummed and then examined under the atmosphere of CO2 and irradaition. A 300 W xenon lamp was adopted as light source.

In situ Fourier transform infrared (FTIR) spectra were collected on a Thermo Fisher iS50 with a KBr plate as the infrared window. The scan number and resolution were set as 64 and 8 cm-1. In a typical test, 3DOM-SNS mixed with a certain amount of photosensitizer Ru was placed in the reaction chamber under the flow of N2 for background acqusition. The gasfeed was then switched to CO2 carried with TEOA/acetonitrile solution and the infrared spectra were recorded every 5 min under the irradition of 300 W xenon lamp. In the case of the procedure of CO-DRIFT, 10% CO/Ar was first introduced for 30 min for CO adsorption and then Ar was purged to sweep the residual gaseous CO.

The electrochemical experiments were conducted on a CHI660D work station (Shanghai Chenhua Instrument Co., Ltd.). A typical three-electrode system was adopted using Ag/AgCl and Pt foil as the reference and counter electrodes, respectively. The electrolyte was chosen as 0.1 M Na2SO4 aqueous solution. Mott-schottky plots were gathered by applying the frequency of 100 Hz.

The X-ray absorption spectra (XAS) including X-ray absorption near-edge structure (XANES) and extended X-ray absorption fine structure (EXAFS) of the samples at Co K-edge were collected using the Singapore Synchrotron Light Source (SSLS) center. Co foil, Co3O4 and CoO were chosen as the references. The acquired EXAFS data were extracted and processed according to the standard procedures using the ATHENA module implemented in the IFEFFIT software packages.

Photocatalytic CO2 reduction measurements

Visible-light driven photocatalytic CO2 reduction in a sealed reactor. In a typical photoreduction run, 5 mg of photocatalyst was first dispersed in 10 mL of acetonitrile to generate a catalyst stocked solution. 20 mg of [Ru(bpy)3]Cl2·6H2O (Ru), 3 mL of triethanolamine (TEOA), 2 mL of deionized water, 5 mL of acetonitrile and 1 mL of catalyst stocked solution were then added into a home-made 250 mL quartz reactor. 1 atm CO2 was introduced to the reactor after vacuuming for serval times. The photoreduction reaction was conducted under the irradiation of a 36 W monochromatic LED light with a wavelength of 450 nm (67.5 mW/cm2). Circulated water was applied to control the reaction temperature at 25 °C. After the photocatalytic reaction, gaseous products were examined and quantified by a gas chromatograph (GC 7920, Beijing China Education Au-light Co., Ltd.) equipped with a flame ionization detector (FID), a thermal conductivity detector (TCD) and a methane reformer. The liquid products were detected by a nuclear magnetic resonance spectrometer (Bruker AVANCE III HD). The experimental data variability for the activity tests was <±5%.

Natural sunlight driven photocatalytic CO2 reduction in a sealed reactor. The reaction condition was the same as the indoor photocatalytic CO2 reduction except changing the light source from the monochromatic light to natural sunlight (1116.3 W/m2). The photocatalytic performances were examined separately in 3 days (Jun. 23–25th, 2023) at Wushan Road, Guangzhou city, China (23°8’N, 113°17’E) and the average outdoor temperatures was measured as 30 °C, respectively.

Natural sunlight driven photocatalytic CO2 reduction in a continuous-flow system. The continuous-flow photocatalytic CO2 reduction was conducted in a row of DN 3 × 1 × 350 quartz tubes equipped on a light trapping system under the outdoor sunlight irradiation (1082.7 W/m2). The light trapping system will automatically capture the light direction and turn the reactor to the corresponding position. A compound parabolic concentrator was utilized to furthest harvest concentrated solar light. The photocatalytic tests were conducted at noon in Wushan Road, Guangzhou city, China (23°8’N, 113°17’E), 12th on 20th March, 13th and 14th April, 2024 and the outdoor average temperatures was measured as 30 °C, respectively.

Computational method

Spin-polarized DFT calculations were performed by the Vienna ab initio simulation package (VASP) and the exchange-correlation potential was approximately proposed Perdew, Burke, and Ernzerhof (GGA-PBE)53. Projector-augmented-wave (PAW) method was selected to calculate the pseudo-potential. The geometry optimization is performed until the Hellmann-Feynman force on each atom is <0.02 eV·Å−1. The energy criterion is set to 10-6 eV in iterative solution of the Kohn-Sham equation.

The mechanism for CO2 reduction is given bellow:

The Gibbs free energy is defined as follow:

where G, E, ZPE and TS are the free energy, total energy based on DFT calculations, zero-point energy and entropic contributions (T was set to be 300 K), respectively.

The adsorption free energy (∆E) between catalyst slab and CO2 was calculated by the following equation:

Ab initio molecular dynamics (AIMD) simulation. CP2K package and the QUICKSTEP module were selected to perform the AIMD simulations54. The molecularly optimized (MOLOPT) Godecker-Teter-Hutter (GTH) double-ζ valence single polarization short-ranged (DZVP-MOLOPT-SR-GTH) basis set was adopted and the GTH-PADE pseudopotential was employed to represent the core electrons. The valence electrons were treated explicitly, using the Perdew-Burke-Ernzerhof (PBE) functional as implemented in CP2K with a plane wave cutoff of 400 Ry. The Grimme D3 approximation was applied to describe dispersion forces. A convergence of 10-5 hartree was imposed for the ground-state energy. The simulation temperature (343 K) was controlled through a Nosé-Hoover thermosta with time step of 1 fs.

Data availability

The authors declare that the data supporting the findings of this study are available within this article and its Supplementary Information file, or from the corresponding authors upon a reasonable request. Source data are provided with this paper.

References

Li, X. et al. Selective visible-light-driven photocatalytic CO2 reduction to CH4 mediated by atomically thin CuIn5S8 layers. Nat. Energy 4, 690–699 (2019).

Stanley, P., Ramm, V., Fischer, R. & Warnan, J. Analysis of metal–organic framework-based photosynthetic CO2 reduction. Nat. Synth. 3, 307–318 (2024).

Wu, Y. et al. Facet-dependent active sites of a single Cu2O particle photocatalyst for CO2 reduction to methanol. Nat. Energy 4, 957–968 (2019).

Lyu, W. et al. Modulating the reaction configuration by breaking the structural symmetry of active sites for efficient photocatalytic reduction of low-concentration CO2. Angew. Chem. Int. Ed. 62, e202310733 (2023).

Stanley, P. et al. Photocatalytic CO2-to-syngas evolution with molecular catalyst metal-organic framework nanozymes. Adv. Mater. 35, 2207380 (2023).

Zhou, W. et al. Photocatalytic CO2 reduction to syngas using metallosalen covalent organic frameworks. Nat. Commun. 14, 6971 (2023).

Qian, G. et al. Efficient photoreduction of diluted CO2 to tunable syngas by Ni−Co dual sites through d-band center manipulation. Angew. Chem. Int. Ed. 61, e202210576 (2022).

Li, X., Yu, J., Jaroniec, M. & Chen, X. Cocatalysts for selective photoreduction of CO2 into solar fuels. Chem. Rev. 119, 3962–4179 (2019).

Maeda, K. Metal-complex/semiconductor hybrid photocatalysts and photoelectrodes for CO2 reduction driven by visible light. Adv. Mater. 31, 1808205 (2019).

Pan, Q. et al. Ultrafast charge transfer dynamics in 2D covalent organic frameworks/Re-complex hybrid photocatalyst. Nat. Commun. 13, 845 (2022).

Zhang, D. et al. 2D bismuthene metal electron mediator engineering super interfacial charge transfer for efficient photocatalytic reduction of carbon dioxide. ACS Appl. Mater. Interfaces 13, 21582–21592 (2021).

Di, J., Xiong, J., Li, H. & Liu, Z. Ultrathin 2D photocatalysts: electronic-structure tailoring, hybridization, and applications. Adv. Mater. 30, 1704548 (2018).

Wang, F. et al. Ultrathin nanosheet assembled multishelled superstructures for photocatalytic CO2 reduction. ACS Nano 16, 4517–4527 (2022).

Guo, X. et al. A general self-assembly induced strategy for synthesizing 2D ultrathin cobalt-based compounds toward optimizing hydrogen evolution catalysis. Adv. Funct. Mater. 32, 2209397 (2022).

Zeng, Y. et al. Unraveling the electronic structure and dynamics of the atomically dispersed Iron sites in electrochemical CO2 reduction. J. Am. Chem. Soc. 145, 15600–15610 (2023).

Zhang, Y., Xia, B., Ran, J., Davey, K. & Qiao, S. Atomic-level reactive sites for semiconductor-based photocatalytic CO2 reduction. Adv. Energy Mater. 10, 1903879 (2020).

Wu, Y. et al. Beyond d orbits: steering the selectivity of electrochemical CO2 reduction via hybridized sp band of sulfur-incorporated porous Cd architectures with dual collaborative sites. Adv. Energy Mater. 10, 2002499 (2020).

Dai, X. & Sun, Y. Reduction of carbon dioxide on photoexcited nanoparticles of VIII group metals. Nanoscale 11, 16723 (2019).

Zhou, Y. et al. Dopant-induced electron localization drives CO2 reduction to C2 hydrocarbons. Nat. Chem. 10, 974–980 (2018).

Wang, Y. et al. Constructing atomic surface concaves on Bi5O7Br nanotube for efficient photocatalytic CO2 reduction. Nano Energy 109, 108305 (2023).

Yan, S. et al. Electron localization and lattice strain induced by surface lithium doping enable ampere-level electrosynthesis of formate from CO2. Angew. Chem. Int. Ed. 60, 25741–25745 (2021).

Shen, K. et al. Ordered macro-microporous metal-organic framework single crystals. Science 359, 206–210 (2018).

Wang, F. et al. Ordered macroporous carbonous frameworks implanted with CdS quantum dots for efficient photocatalytic CO2 reduction. Adv. Mater. 33, 2102690 (2021).

Hong, H. et al. Ordered macro–microporous metal–organic framework single crystals and their derivatives for rechargeable aluminum-ion batteries. J. Am. Chem. Soc. 141, 14764–14771 (2019).

Hu, H., Guan, B. & Lou, X. Construction of complex CoS hollow structures with enhanced electrochemical properties for hybrid supercapacitors. Chem 1, 102–113 (2016).

Li, J. et al. Self-adaptive dual-metal-site pairs in metal-organic frameworks for selective CO2 photoreduction to CH4. Nat. Catal. 4, 719–729 (2021).

Terzopoulou, A. et al. Mineralization-inspired synthesis of magnetic zeolitic imidazole framework composites. Angew. Chem. Int. Ed. 58, 13550–13555 (2019).

Pattengale, B. et al. Exceptionally long-lived charge separated state in zeolitic imidazolate framework: implication for photocatalytic applications. J. Am. Chem. Soc. 138, 8072–8075 (2016).

Dou, S. et al. Atomic-scale CoOx species in metal-organic frameworks for oxygen evolution reaction. Adv. Funct. Mater. 27, 1702546 (2017).

Qi, D. et al. Cyclodextrin-supported Co(OH)2 clusters as electrocatalysts for efficient and selective H2O2 synthesis. Angew. Chem. Int. Ed. 62, e202307355 (2023).

Wang, J. et al. Precise regulation of the coordination environment of single Co(II) sites in a metal-organic framework for boosting CO2 photoreduction. ACS Catal. 13, 8760–8769 (2023).

Wang, Y. et al. Hydroxide ligands cooperate with catalytic centers in metal-organic frameworks for efficient photocatalytic CO2 reduction. J. Am. Chem. Soc. 140, 38–41 (2018).

Ran, L. et al. Engineering single-atom active sites on covalent organic frameworks for boosting CO2 photoreduction. J. Am. Chem. Soc. 144, 17097–17109 (2022).

Zhang, H. et al. Isolated cobalt centers on W18O49 nanowires perform as a reaction switch for efficient CO2 photoreduction. J. Am. Chem. Soc. 143, 2173 (2021).

Zhang, C., Shi, Y., Yu, Y., Du, Y. & Zhang, B. Engineering sulfur defects, atomic thickness, and porous structures into cobalt sulfide nanosheets for efficient electrocatalytic alkaline hydrogen evolution. ACS Catal. 8, 8077–8083 (2018).

Chen, T. et al. Self-templated formation of interlaced carbon nanotubes threaded hollow Co3S4 nanoboxes for high-rate and heat-resistant lithium-sulfur batteries. J. Am. Chem. Soc. 139, 12710–12715 (2017).

Wang, S., Yao, W., Lin, J., Ding, Z. & Wang, X. Cobalt imidazolate metal-organic frameworks photosplit CO2 under mild reaction conditions. Angew. Chem. Int. Ed. 53, 1034–1038 (2014).

Niu, K. et al. A spongy nickel-organic CO2 reduction photocatalyst for nearly 100% selective CO production. Sci. Adv. 3, e1700921 (2017).

Maschmeyer, T. & Che, M. Catalytic aspects of light-induced hydrogen generation in water with TiO2 and other photocatalysts: a simple and practical way towards a normalization? Angew. Chem. Int. Ed. 49, 1536–1539 (2010).

Guo, Z. et al. Core-shell-type all-inorganic heterometallic nanoclusters: record high-nuclearity cobalt polyoxoniobates for visible-light-driven photocatalytic CO2 reduction. Angew. Chem. Int. Ed. 62, e202305260 (2023).

Zhu, J. et al. Asymmetric triple-atom sites confined in ternary oxide enabling selective CO2 photothermal reduction to acetate. J. Am. Chem. Soc. 143, 18233–18241 (2021).

Baltrusaitis, J. & Schuttlefield, J. Zeitler, El. & Grassian, V. H. Carbon dioxide adsorption on oxide nanoparticle surfaces. Chem. Eng. J. 170, 471–481 (2011).

He, L. et al. Single-atom Mo-tailored high-entropy-alloy ultrathin nanosheets with intrinsic tensile strain enhance electrocatalysis. Nat. Commun. 15, 2290 (2024).

Kouva, S. et al. Water and carbon oxides on monoclinic zirconia: experimental and computational insights. Phys. Chem. Chem. Phys. 16, 20650–20664 (2014).

Wang, M. et al. Unraveling the tunable selectivity on cobalt oxide and metallic cobalt sites for CO2 hydrogenation. Chem. Eng. J. 446, 137217 (2022).

Sun, Q. M. et al. Boosted inner surface charge transfer in perovskite nanodots@mesoporous titania frameworks for efficient and selective photocatalytic CO2 reduction to methane. Angew. Chem. Int. Ed. 61, e202200872 (2022).

Tu, W., Zhou, Y. & Zou, Z. Photocatalytic conversion of CO2 into renewable hydrocarbon fuels: state-of-the-art accomplishment, challenges, and prospects. Adv. Mater. 26, 4607–4626 (2014).

Liu, X., Jiao, Y., Zheng, Y., Jaroniec, M. & Qiao, S. Z. Building up a picture of the electrocatalytic nitrogen reduction activity of transition metal single-atom catalysts. J. Am. Chem. Soc. 141, 9664–9672 (2019).

Qin, X. et al. Direct conversion of CO and H2O to hydrocarbons at atmospheric pressure using a TiO2-x/Ni photothermal catalyst. Nat. Energy 9, 154–162 (2024).

Cheng, Q. et al. Unraveling the influence of oxygen vacancy concentration on electrocatalytic CO2 reduction to formate over indium oxide catalysts. ACS Catal. 13, 4021–4029 (2023).

Zhou, F. et al. Utilizing Er-doped ZnIn2S4 for efficient photocatalytic CO2 conversion. Appl. Catal. B-Environ. 341, 123347 (2024).

Wang, J. et al. Facile electron delivery from graphene template to ultrathin metal-organic layers for boosting CO2 photoreduction. Nat. Commun. 12, 813 (2021).

Kresse, G. & Furthmüller, J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. J. Comput. Mater. Sci. 6, 15–50 (1996).

Kühne, T. D. CP2K: An electronic structure and molecular dynamics software package—quickstep: efficient and accurate electronic structure calculations. J. Chem. Phys. 152, 194103 (2020).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (22138003, 22208107, 21825802), China Postdoctoral Science Foundation (2023T160228, 2022M710051), the Natural Science Foundation of Guangdong Province (2023B1515040005, 2022A1515012575), the Guangdong Basic and Applied Basic Research Foundation (2021A1515110413), the Fundamental Research Funds for the Central Universities (2023ZYGXZR087), State Key Laboratory of Pulp and Paper Engineering (202302, 2023PY06).

Author information

Authors and Affiliations

Contributions

W. Lyu, F. Wang, and Y. Li developed the idea and designed experiments. W. Lyu and F. Wang performed experiments. Y. Liu and D. Chen conducted the theoretical calculation. F. Wang and Y. Li secured funding. W. Lyu, F. Wang, and Y. Li wrote the manuscript. All authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Elizaveta Fedorova, and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Lyu, W., Liu, Y., Chen, D. et al. Engineering the electron localization of metal sites on nanosheets assembled periodic macropores for CO2 photoreduction. Nat Commun 15, 10589 (2024). https://doi.org/10.1038/s41467-024-54988-3

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-024-54988-3

This article is cited by

-

Metal–Support Interaction Induced Electron Localization in Rationally Designed Metal Sites Anchored MXene Enables Boosted Electromagnetic Wave Attenuation

Nano-Micro Letters (2025)

-

BiVO4/SnS2 S-scheme heterojunction for improved photocatalytic performance under visible light: charge carrier mechanism validation by DFT and electrochemical studies

Applied Physics A (2025)

-

Thermally Conductive Ti3C2Tx Fibers with Superior Electrical Conductivity

Nano-Micro Letters (2025)