Abstract

2,2,6,6-tetramethylpiperidine-1-oxyl (TEMPO) derivatives are typical catholytes in aqueous organic redox flow batteries (AORFBs), but reported lifetime of them is limited. We find that the increase of Hirshfeld charge decreases the Gibbs free energy change (ΔG) values of side reactions of TEMPO, a near-linear relationship, and then exacerbates their degradation. Here we predict and synthesize a TEMPO derivative, namely TPP-TEMPO, by analyzing the Hirshfeld charge. TPP-TEMPO, with the smallest Hirshfeld charge and highest ΔG, is an order of magnitude more stable than TMA-TEMPO (N,N,N-2,2,6,6-heptamethylpiperidinyl oxy-4-ammonium chloride, a control with the largest Hirshfeld charge and lowest ΔG). We further elaborate on their decomposition pathways, identify byproducts, and mitigate degradation by supporting electrolyte engineering. Finally, a TPP-TEMPO/BTMAP-Vi (1,1′-bis[3-(trimethylammonio)propyl]-4,4′-bipyridinium tetrachloride) cell achieves a capacity density of ~12 Ah L−1 and a low capacity fade rate of 0.0018% per cycle (or 0.0067% per hour).

Similar content being viewed by others

Introduction

Traditional electricity supply is fulfilled by the consumption of huge amounts of fossil fuels and emitting an enormous amount of CO21. As the carbon neutrality goal has been proposed, electricity from renewable energy sources has grown rapidly2. However, the intermittency of wind, solar, and other renewable energy sources necessitates large-scale electricity storage technology3. Aqueous redox flow batteries are capable of massive-scale electricity storage, featuring high safety, decoupled power and energy, and easy scale-up4.

Metal-based aqueous redox flow batteries have been well-developed and commercially deployed, but they still face challenges5,6. For example, the high material costs and limited abundances of vanadium limit market penetration of VRFB; while Zinc dendrite growth and the formation of dead zinc hinder long-duration operation of Zn-based aqueous redox flow batteries7,8. By comparison, the emerging aqueous organic redox flow batteries (AORFBs) exploit redox-active organic compounds composed of earth-abundant elements (H, C, N, O, etc.), which are sustainable and potentially inexpensive9,10. The diversity and structural tunability of organic molecules endow AORFBs with more options and progressively improved performance11,12. In recent years, many organic compounds have been reported as electrolytes for AORFBs, including quinones13,14,15,16,17,18, phenazines19,20,21,22, bipyridiniums23,24,25,26,27,28,29,30,31,32,33, azobenzenes34, phenothiazines35, fluorenones36, naphthalene diimide37,38,39,40, ferrocenes25,41,42,43, and nitroxide radicals23,29,30,32,44,45,46,47,48,49,50. Of those electrolytes, anolytes represented by quinones and bipyridiniums possess higher durability and high capacity retention, while catholytes desire further improvement, and the purely organic molecule is mainly limited to nitroxide radicals51.

2,2,6,6-tetramethylpiperidine-1-oxyl (TEMPO) derivatives are the prime nitroxide radical-based catholytes for all-organic AORFBs52,53. In 2015, Poly-TEMPO and 4-OH-TEMPO were adopted to all-organic AORFBs with moderate capacity fade rates of 0.312% and 1.146% per h, respectively23,32,53. Molecular engineering was then conducted on TEMPO derivatives to extend the battery lifetime and to improve water solubility by introducing electron-withdrawing charged functional groups to the γ-position of TEMPO44,45,49,50. For example, in 2016, TMA-TEMPO was designed by grafting a trimethylammonium group to enhance solubility and redox potential44. However, the strong electron-withdrawing trimethylammonium group could lead to undesired side reactions, resulting in a capacity fade rate of 0.062% per h50. In 2019, TMAP-TEMPO was designed by inserting a spacer group to separate the trimethylammonium group from the TEMPO core, achieving a lower capacity fade rate of 0.026% per h45. Liu et al. inserted an acetylamino group between the trimethylammonium group and the TEMPO skeleton, affording a TMAAcNH-TEMPO with an even lower capacity fade rate of 0.014% per h49. Although previous studies tend to imply that TEMPO derivatives with weak electron-withdrawing groups (EWGs) exhibit lower capacity fade rates45,49,50, the underlying mechanism remains elusive, and stability of the six-membered ring of TMEPO was largely neglected.

The electrostatic charge and its distribution of electrolytes are determining factors that affect the corresponding cell performance. Song et al. disclosed that the charge population sum (CPS) of N-O head can determine the redox potential of TEMPO derivatives, but CPS can not explain the obvious difference in cycling stability for TEMPO derivatives54. Later, Song et al. recognized the N-O head of TEMPO derivatives as the vulnerable site causing side reactions during battery cycling. They analyzed the Fukui function (\(f\)+/\(f\)−) of MIAcNH-TEMPO and AcNH-TEMPO, which reflects the charge difference of TEMPO derivatives after getting/losing an electron, and tried to correlate the Fukui function of MIAcNH-TEMPO and AcNH-TEMPO with its stability in cell cycling48.

Herein, we quantitatively adjusted the six-membered ring of TEMPO derivatives by focusing on their Hirshfeld charge. Hirshfeld charge, which describes molecular charge density, was proposed by Hirshfeld in 197755. In this work, we proposed that the Hirshfeld charge is influenced by the γ-substituent group of TEMPO derivatives, i.e., weaker EWGs lead to smaller Hirshfeld charge, thereby higher Gibbs free energy change (ΔG) values of side reactions. This idea has been examined through analyzing TMAP-TEMPO and TMAAcNH-TEMPO, which possess a smaller Hirshfeld charge and lower capacity fade rates than that of TMA-TEMPO, with the largest Hirshfeld charge. To further demonstrate this idea and enhance the stability of TEMPO derivatives, we designed and synthesized 4-(4-(3-(trimethylammonio)propoxy)phenyl)-2,2,6,6-tetramethylpiperidin-1-oxyl chloride (TPP-TEMPO), by introducing an electron-rich phenyl group between the six-membered ring of TEMPO and EWGs. The resulting TPP-TEMPO has the smallest Hirshfeld charge and then the highest ΔG value. When paired with BTMAP-Vi (1,1′-bis[3-(trimethylammonio)propyl]-4,4′-bipyridinium tetrachloride), the TPP-TEMPO/BTMAP-Vi cell demonstrates a capacity fade rate of 0.0027% per cycle (or 0.010% per h) at 0.1 M, which is less an order of magnitude when compared with that of TMA-TEMPO (0.041% per cycle (or 0.16% per h)) under similar conditions. Post-mortem analysis revealed the ring opening side reaction for TMA-TEMPO, which was not detected for TPP-TEMPO. We observed serious hydrogenation side reactions for TMA-TEMPO, which were slight for TPP-TEMPO. We found that the improved stability can be attributed to variations in Hirshfeld charge, which regulates the ΔG value to suppress ring opening and hydrolyzation side reactions and then mitigate pH change during battery cycling. Finally, through the addition of NH4Cl and state-of-charge (SOC) control, we further mitigate the degradation of TPP-TEMPO. At 0.5 M, the TPP-TEMPO/BTMAP-Vi cell presents a peak power density of 135 mW cm−2, a capacity density of 12 Ah L−1, and a capacity fade rate of merely 0.0018% per cycle (or 0.0067% per h).

Results

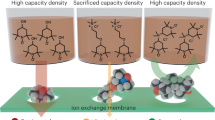

TEMPO derivatives have been extensively considered as catholytes for all-organic AORFBs52,53. However, TEMPO derivatives suffer from ring opening and hydrolyzation side reactions during battery operation (Fig. 1a). Although extensive research efforts have been devoted to modifying the γ-substituent groups to mitigate these decomposition reactions44,45,49,50, few tried to clarify the underlying mechanism of how γ-substituent groups impact the six-membered ring of TEMPO and the subsequent degradation of TEMPO derivatives.

a The ring opening and hydrolyzation side reactions of charged TEMPO derivatives. b The molecular structures and c density functional theory (DFT) calculated the Hirshfeld charge distribution of reported and suggested TEMPO derivatives, arranged in ascending order based on the Hirshfeld charge of β-H and N of the six-membered ring of charged TEMPO derivatives. d, e DFT calculated Gibbs free energy change (ΔG) of the ring opening and hydrolyzation side reactions for charged TEMPO derivatives versus the Hirshfeld charge of β-H and N are plotted, respectively. These reactions determine the battery cycle lifetime. Source data are provided as a Source Data file.

Herein, we propose that the electron-withdrawing effect of γ-substituent groups can influence the six-membered ring skeletons by increasing the Hirshfeld charge of β-H and N of the six-membered ring of charged TEMPO derivatives, thereby resulting in lower ΔG of ring opening and hydrolyzation side reactions of TEMPO derivatives and exacerbating their degradation. (Fig. 1).

To demonstrate, we select TMAAcNH-TEMPO49, TMAP-TEMPO45, and TMA-TEMPO50, which exhibit an increasing electron-withdrawing effect on TEMPO while possessing an identical trimethylammonio end group and having the same amount of electric charge. (Fig. 1b) We optimized their molecular structures through density functional theory (DFT) calculations and quantitatively analyzed their Hirshfeld charge using Gaussian, VMD, and Multiwfn56,57,58 (Supplementary Table 1 and Data 1). We computed the ΔG values of ring opening and hydrolyzation side reactions of these TEMPO derivatives using Gaussian and Shermo59. As shown in Fig. 1c–e, stronger electron-withdrawing effect on TEMPO leads to a larger Hirshfeld charge of β-H and N and greater ΔG for side reactions. This implies the increase in capacity fade rates from 0.014% per h for TMAAcNH-TEMPO, 0.026% per h for TMAP-TEMPO, and 0.062% per h for TMA-TEMPO during battery operation. (Supplementary Table 1).

To further illustrate this idea and enhance the stability of TEMPO derivatives, we insert the electron-rich phenyl group at the γ-C of TEMPO to separate the six-membered ring from the electron-withdrawing end group. The resulting TPP-TEMPO possesses the smallest Hirshfeld charge, as revealed by DFT calculations. (Fig. 1c) TPP-TEMPO also exhibits the highest ΔG for the side reactions, suggesting the excellent stability of TPP-TEMPO. (Fig. 1d, e) Interestingly, a near-liner relationship between Hirshfeld charge and ΔG of side reactions is observed (Supplementary Fig. 1).

To demonstrate, we synthesized TPP-TEMPO (Supplementary Fig. 2), and confirmed the products through 1H NMR and mass spectrometry (MS) (Supplementary Figs. 3–5). TMA-TEMPO (Supplementary Fig. 6), which possesses a much larger Hirshfeld charge and is a widely adopted catholyte, was selected as a control.

Electrochemical and spectroscopic studies of TPP-TEMPO have indicated that it is a promising catholyte candidate for all-organic AORFBs (Table 1). As depicted in Fig. 2a and Supplementary Fig. 7, TPP-TEMPO exhibits a reversible redox reaction at a redox potential of 0.77 V (vs. the standard hydrogen electrode, SHE), owing to the introduced electron-abundant phenyl group of TPP-TEMPO. The diffusion coefficient of TPP-TEMPO is 3.39 × 10−6 cm2 s−1 in water, and the electron-transfer rate constant is 5.37 × 10−3 cm s−1 (Supplementary Fig. 8). Its solubility in water is 2.3 M. The permeability of TPP-TEMPO through a Selemion AMVN membrane is 5.57 × 10−11 cm2 s−1 (Supplementary Fig. 9). UV-Vis spectroscopy study suggests that there is almost no decrease in absorbance intensity for TPP-TEMPO, while it is much more significant for TMA-TEMPO (Supplementary Fig. 10), implying less side reactions for TPP-TEMPO.

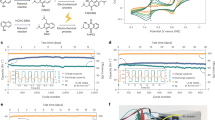

a Cyclic voltammograms (CVs) of TPP-TEMPO, TMA-TEMPO, and BTMAP-Vi (at 10 mM) in 1 M NaCl solution at a scan rate of 100 mV s−1. b Schematic of an all-organic AORFB assembled with TPP-TEMPO (or TMA-TEMPO) and excess BTMAP-Vi. c Galvanostatic cycling of flow cells assembled with 5 mL of 0.1 M TPP-TEMPO (or TMA-TEMPO) and 7.5 mL of 0.1 M BTMAP-Vi in 1 M NaCl solution at 20 mA cm−2, with voltage cutoffs at 0.5 V during discharge and 1.4 V (or 1.6 V for the TMA-TEMPO-based cell) during charge, and a potentiostatic hold was applied at the end of discharge process (until current drops below 4 mA cm−2). The rotational speed of the peristaltic pump is 60 rpm. Insets: the discharge curves of TPP-TEMPO and TMA-TEMPO at the 300th cycle. The voltage is not iR corrected. Source data are provided as a Source Data file.

We then separately evaluated TPP-TEMPO and TMA-TEMPO in flow cells by pairing them with excess BTMAP-Vi (Fig. 2a and Supplementary Figs. 11, 12) at an electrolyte concentration of 0.1 M. (Fig. 2b) We used a Selemion AMVN membrane as the separator. Then, we performed long-term galvanostatic cycling of both flow cells at 20 mA cm−2 for 300 consecutive cycles. The voltage cutoffs were 1.4 V (or 1.6 V for TMA-TEMPO/BTMAP-Vi) for charge and 0.5 V for discharge. A potentiostatic hold was set at the end of the discharge process until the current density dropped below 4 mA cm−2. TPP-TEMPO reached a capacity retention of 99.2% after 300 cycles, corresponding to a capacity fade rate of 0.0027% per cycle (or 0.010% per h); whereas TMA-TEMPO exhibited a much higher capacity fade rate of 0.041% per cycle (or 0.16% per h) over 300 cycles (Fig. 2c). Thus, the capacity fade rate of TPP-TEMPO is one order of magnitude lower than that of TMA-TEMPO.

TPP-TEMPO exhibits the lowest capacity fade rates among these TEMPO derivatives (Fig. 3a and Supplementary Fig. 13). The varied stability can be attributed to the different Hirshfeld charge that determines ΔG of side reactions, as discussed in Fig. 1. To verify our hypothesis, we conducted a post-mortem analysis on catholytes after cell cycling experiments to identify the degradation byproducts of TPP-TEMPO and TMA-TEMPO. (Fig. 3b, Supplementary Figs. 14, 15, and Supplementary Table 2). According to MS and 1H NMR, TMA-TEMPO suffered from ring opening side reactions, while TPP-TEMPO didn’t undergo such degradation (Fig. 3c, d and Supplementary Fig. 16). Additionally, we have also detected the hydrogenation side reactions for TMA-TEMPO, which was slight for TPP-TEMPO. We conclude that the smaller Hirshfeld charge of TPP-TEMPO can mitigate ring opening and hydrolyzation side reactions, and consequently higher pH of electrolyte during battery cycling as in situ pH monitor demonstrated, which mitigates the hydrogenation side reactions (Supplementary Fig. 17). The observed results and proposed decomposition pathways support our hypothesis.

a The capacity fade rates of these TEMPO derivatives, that of TPP-TEMPO, TMAAcNH-TEMPO (under identical conditions to TMAP-TEMPO), and TMA-TEMPO were measured in this work, while that of TMAP-TEMPO was reported by our group before45,49. b The 1H NMR spectra of TPP-TEMPO and TMA-TEMPO before and after cell cycling. Peaks from byproducts are marked with triangles. The proposed decomposition pathways for c TMA-TEMPO and d TPP-TEMPO. Source data are provided as a Source Data file.

The acidic nature of the charged catholyte solution facilitates the hydrogenation side reaction of TEMPO derivatives60,61, and this is also observed in this work, although with a slighter impact. This motivates us to further enhance the stability of TEMPO derivatives during battery operation. (Supplementary Fig. 17).

To impede the hydrogenation side reaction of TPP-TEMPO and the hydrolyzation process of the charged TPP-TEMPO, we employed NH4Cl as an electrolyte additive. Because NH4+ can form a hydrogen bond with the O atom of TPP-TEMPO62,63,64,65, which introduces additional Coulomb repulsion and steric hindrance to prevent the nitroxide radical from H+ attack and inhibits the hydrolyzation process (Supplementary Fig. 18a, b). We conducted DFT calculations and found that the dH…O is 172 pm between NH4+ and TPP-TEMPO, which increases to 231 pm as TPP-TEMPO is oxidized, due to the Coulomb repulsion between NH4+ and the positively charged six-membered ring of oxidized TPP-TEMPO65. The addition of NH4Cl enhances the redox kinetics of TPP-TEMPO, as the determined electron-transfer rate constant is 7.27 × 10−3 cm s−1 which is higher than that in NaCl solution (5.37 × 10−3 cm s−1)63. (Supplementary Figs. 18c and 19) The pH of the charged TPP-TEMPO solution with NH4Cl is also higher than that with NaCl, indicating a suppressed hydrolyzation process (Supplementary Fig. 18d). At 0.1 M, the TPP-TEMPO/BTMAP-Vi battery with NH4Cl exhibits a lower capacity fade rate of 0.0020% per cycle (or 0.0075% per h) than that with NaCl (0.0027% per cycle or 0.010% per h). It achieves a peak power density of ~89 mW cm−2, with a Coulombic efficiency (CE) of ~100% and an energy efficiency (EE) of ~88%. (Supplementary Fig. 20).

Finally, we configured a more concentrated TPP-TEMPO/BTMAP-Vi cell at 0.5 M in NH4Cl solution (Fig. 4). The battery demonstrates a peak power density of ~135 mW cm−2, with a capacity of ~12 Ah L−1, a CE of ~100% and EE of ~82% (Fig. 4a, b). Long-term galvanostatic cycling of this high-concentration battery exhibits a capacity fade rate of 0.0056% per cycle (or 0.013% per h) (Fig. 4c). We conducted SOC control to regulate the pH levels (Supplementary Fig. 21), and the capacity fade rate of the battery can be decreased to 0.0018% per cycle (or 0.0067% per h). (Supplementary Fig. 22) In a 2 M TPP-TEMPO/BTMAP-Vi cell, a high capacity of ~44 Ah L−1 and a low capacity fade rate of 0.012% per h have been achieved (Supplementary Fig. 23). In summary, TPP-TEMPO has demonstrated a low capacity fade rate among TEMPO derivatives and other nitroxide radical derivatives for AORFBs. (Supplementary Table 3) We believe that the proposed strategy of adjusting the Hirshfeld charge of electrolytes may apply to designing other organic molecular structures for AORFBs.

a Polarization curves of the cell at various SOCs. b Discharge capacity, Coulombic efficiency, and energy efficiency of this cell at various current densities. c Galvanostatic cycling of this cell at 60 mA cm−2, with voltage cutoffs at 0.5 V during discharge and 1.4 V during charge, and a potentiostatic hold was applied at the end of the discharge process (until current drops below 4 mA cm−2). The rotational speed of the peristaltic pump is 60 rpm. Source data are provided as a Source Data file.

Discussion

This work introduces an approach to enhance the stability of TEMPO derivatives by analyzing the Hirshfeld charge of β-H and N on the six-membered ring of TEMPO derivatives, which determines the ΔG of ring opening and hydrolyzation side reactions during battery cycling. We conducted DFT calculations to reveal the near-liner relationship between Hirshfeld charge and ΔG. We minimized the Hirshfeld charge of β-H and N by introducing an electron-donating γ-substituent group to the six-membered TEMPO core and synthesized an exemplar molecular TPP-TEMPO. When paired with BTMAP-Vi at 0.1 M, the as-configured all-organic AORFB demonstrates a capacity fade rate of 0.0027% per cycle (or 0.010% per h), which is an order of magnitude lower than that of TMA-TEMPO (a control that is usually adopted and with the largest Hirshfeld charge, 0.041% per cycle or 0.16% per h). We have identified the cause of the remaining minor capacity fades by identifying trivial byproducts of side reactions. Subsequently, we adopt strategies including NH4Cl addition and SOC control to improve capacity retention of TPP-TEMPO. Finally, at 0.5 M, the TPP-TEMPO/BTMAP-Vi cell achieves a low capacity fade rate of 0.0018% per cycle (or 0.0067% per h), with a peak power density of ~135 mW cm−2 and a capacity density of ~12 Ah L−1. This work provides insight into molecular Hirshfeld charge and their stability and reactivity. We believe the presented strategy of electrolyte design may apply more broadly to developing other organic molecules for AORFBs.

Methods

Materials

Palladium 10% on carbon (Pd/C, wet) was purchased from TCI (Shanghai, China). 3-Chloroperoxybenzoic acid (m-CPBA, 85%) was purchased from Adamas (Shanghai, China). 2,2,6,6-Tetramethyl-4-piperidone, phenol (98%), 1-bromo-3-chloropropane (99%), 1,3-dichloropropane (99%), 4,4’-bipyridine (99%), trimethylamine (TMA, 2 M in THF), and N,N-dimethylformamide (DMF, 99.9%) were purchased from Energy Chemical (Shanghai, China). TMA-TEMPO was offered by Suqian Time Energy Storage Technology Co., Ltd. (Jiangsu, China). The other chemicals were purchased from domestic vendors. All chemicals were used directly as received without further purification, except for m-CPBA, which was purified before use66. The 1H NMR spectra were recorded on the AVANCE III HD 400 spectrometer. MS was obtained on FTMS-cESI.

Electrolyte syntheses and characterizations

4-(2,2,6,6-tetramethyl-1,2,3,6-tetrahydropyridin-4-yl)phenol: A mixture of 2,2,6,6-Tetramethyl-4-piperidone (31 g, 200 mmol, 1 equiv) and phenol (82.8 g, 800 mmol, 4 equiv) in water (160 mL) was stirred in an ice-water bath. Subsequently, concentrated sulfuric acid (240 g) was slowly added. Then, the solution was degassed and heated at 100°C for 3 h under Ar. The resulting solution was cooled, neutralized, and extracted with dichloromethane (DCM, 200 mL \({{{\boldsymbol{\times }}}}\) 3). The organic extracts were washed with brine (100 mL \({{{\boldsymbol{\times }}}}\) 3) and dried over MgSO4. Finally, they were purified by column chromatography on silica gel (hexane/ethyl acetate/triethylamine (v/v/v) = 8:1:1) to give a white solid (39 g, 84% yield). 1H NMR (400 MHz, DMSO-d6) δ = 9.38 (s, 1H), 7.20 (d, J = 8.6, 2H), 6.71 (d, J = 8.7, 2H), 5.85 (s, 1H), 2.10 (s, 2H), 1.12 (d, J = 21.1, 12H).

4-(4-(3-chloropropoxy)phenyl)-2,2,6,6-tetramethyl-1,2,3,6-tetrahydropyridine: A mixture of 4-(2,2,6,6-tetramethyl-1,2,3,6-tetrahydropyridin-4-yl)phenol (12.72 g, 55 mmol, 1 equiv), 1-bromo-3-chloropropane (12.99 g, 82.5 mmol, 1.5 equiv), and K2CO3 (11.40 g, 82.5 mmol, 1.5 equiv) in ethanol (100 mL) was degassed and refluxed for 4 h under Ar. After ethanol was removed on a rotavap, 200 mL DCM was added, and then the solution was washed with water (100 mL \({{{\boldsymbol{\times }}}}\) 3). The DCM solution was dried over MgSO4 and finally purified by column chromatography on silica gel (hexane/ethyl acetate/triethylamine (v/v/v) = 16:2:1) to give a colorless, transparent liquid (13.00 g, 77% yield). 1H NMR (400 MHz, Chloroform-d) δ = 7.32 (d, J = 8.8, 2H), 6.87 (d, J = 8.8, 2H), 5.90 (s, 1H), 4.12 (t, J = 5.8, 2H), 3.75 (t, J = 6.3, 2H), 2.36–2.13 (m, 4H), 1.25 (d, J = 17.6, 12H).

4-(4-(3-chloropropoxy)phenyl)-2,2,6,6-tetramethylpiperidine: A mixture of 4-(4-(3-chloropropoxy)phenyl)-2,2,6,6-tetramethyl-1,2,3,6-tetrahydropyridine (13.00 g, 42 mmol) and Pd/C (1.30 g) was stirred in ethanol (100 mL) under H2 at room temperature for 72 h. After filtering out the Pd/C, the ethanol was removed on a rotavap to obtain a clear and colorless liquid (13.01 g, 99% yield). 1H NMR (400 MHz, Chloroform-d) δ = 7.14 (d, J = 8.7, 2H), 6.85 (d, J = 8.7, 2H), 4.09 (t, J = 5.8, 2H), 3.73 (t, J = 6.4, 2H), 2.97 (m, 1H), 2.21 (p, J = 6.1, 2H), 1.74 (m, 2H), 1.44–1.14 (m, 14H).

4-(4-(3-chloropropoxy)phenyl)-2,2,6,6-tetramethylpiperidine-1-oxyl: A mixture of 4-(4-(3-chloropropoxy)phenyl)-2,2,6,6-tetramethylpiperidine (13.01 g, 42 mmol, 1 equiv) and m-CPBA (14.49 g, 84 mmol, 2 equiv) was reacted in DCM (500 mL) from 0°C to room temperature for 2 h. Then, the solution was neutralized, and the DCM solution was collected. The DCM solution was washed with brine(100 mL \({{{\boldsymbol{\times }}}}\) 3), dried over MgSO4, and finally purified by column chromatography on silica gel (hexane/ethyl acetate (v/v) = 8:1) to give an orange liquid (9.86 g, 72% yield). 1H NMR (400 MHz, Chloroform-d) δ = 7.15 (d, J = 8.6, 2H), 6.84 (d, J = 8.7, 2H), 4.08 (t, J = 5.8, 2H), 3.73 (t, J = 6.4, 2H), 2.94 (m, 1H), 2.20 (p, J = 6.1, 2H), 1.80–1.66 (m, 4H), 1.26 (d, J = 6.2, 12H).

4-(4-(3-(trimethylammonio)propoxy)phenyl)-2,2,6,6-tetramethylpiperidin-1-oxyl chloride (TPP-TEMPO): A mixture of 4-(4-(3-chloropropoxy)phenyl)-2,2,6,6-tetramethylpiperidine-1-oxyl (9.86 g, 30 mmol) and 45 mL of TMA solution (2 M in THF) was reacted at 50°C for one week. Then, the resulting precipitate was collected and washed with ethyl acetate (20 mL \({{{\boldsymbol{\times }}}}\) 3) to obtain an orange solid (3.70 g, 32% yield). 1H NMR (400 MHz, Deuterium Oxide) δ = 7.28 (d, J = 8.6, 2H), 7.02–6.97 (m, 2H), 4.09 (t, J = 5.7, 2H), 3.49–3.38 (m, 2H), 3.09 (s, 9H), 3.08–2.99 (m, 1H), 2.25–2.14 (m, 2H), 1.83–1.67 (m, 4H), 1.26 (d, J = 11.8, 12H). 13C NMR (101 MHz, Deuterium Oxide) δ = 156.36, 138.29, 128.35, 114.81, 64.64, 63.88, 60.53, 52.82, 45.93, 32.88, 30.63, 22.65, 19.68. UV/Vis: λmax 222 nm. HRMS (m/z): [M]+ calculated for C21H36O2N2•+, 348.2772; found, 348.2767.

1,1′-bis[3-(trimethylammonio)propyl]-4,4′-bipyridinium tetrachloride (BTMAP-Vi) was synthesized according to the literature28. In a 250 mL round-bottom flask, 1,3-dichloropropane (22.6 g, 200 mmol) and TMA solution (2 M in THF, 75 mL, 150 mmol) were added and then reacted at 50 °C for 5 days. Then, the mixture was filtered and washed with ethyl acetate (50 mL \({{{\boldsymbol{\times }}}}\) 3) to obtain a white solid (3-chloro-propyl)-trimethylammonium chloride (22.4 g, 87% yield). Finally, (3-chloro-propyl)-trimethylammonium chloride (10.3 g, 60 mmol) and 4,4’-bipyridine (3.1 g, 20 mmol) in DMF (25 mL) were refluxed for 1 h under argon. Then, the mixture was cooled, filtered, and washed with DMF (50 mL \({{{\boldsymbol{\times }}}}\) 3) to obtain a white solid BTMAP-Vi (4.5 g, 45% yield). 1H NMR (400 MHz, Deuterium Oxide) δ = 9.23 (d, J = 7.1, 4H), 8.65 (d, J = 7.0, 4H), 4.89 (m, 4H), 3.61 (m, 4H), 3.22 (s, 18H), 2.77–2.65 (m, 4H).

The solvent signal is marked with an asterisk in all 1H NMR spectra. In the NMR experiments, phenylhydrazine was added to reduce the nitroxide radical.

DFT calculations

We conducted DFT calculations using the Gaussian 16 program at the B3LYP/6-311 + G(d,p) level57. The structure of electrolytes was optimized in water by vibrational frequency calculations. GD3BJ (empirical dispersion correction) and the universal solvation model SMD were applied. Finally, we analyzed the Hirshfeld charge by using Multiwfn and computed the ΔG values of side reactions of these TEMPOs by using Shermo58,59.

Electrochemical studies

Cyclic voltammetry (CV) of 10 mM as-synthesized electrolyte in 1 M NaCl solution (5 mL) was measured on a ZENNIUM E electrochemical workstation (ZAHNER, Germany). The working electrode (glassy carbon, the radius of the circle is 0.15 cm) was polished with alumina and then paired with a reference electrode (Ag/AgCl) and a counter electrode (platinum coil).

Rotating-disk-electrode (RDE) study of 1 mM as-synthesized electrolyte in 1 M NaCl solution (200 mL) was performed on CHI600E potentiostat (CH Instruments, Inc., Austin, US) and Pine E4TQ RDE. The 1 M NaCl solution was also measured as a background and subsequently subtracted. The working electrode (glassy carbon, the radius of the circle is 0.15 cm) was polished with alumina and then paired with a reference electrode (Ag/AgCl) and a counter electrode (platinum coil). The scan rate is 5 mV s−1, and the rotational speed is 225–2025 rpm. The diffusion coefficient (D) was calculated using the Levich equation:

where i is the limited current, n is the electron transfer number, Faraday’s constant F = 96485 C mol−1, electrode area A = 0.196 cm2, electrolyte concentration c = 1 × 10−6 mol cm−3, and the kinematic viscosity v = 9.56 × 10−3 cm2 s−1 (1 M NaCl aqueous solution) or 8.75 × 10−3 cm2 s−1 (1 M NH4Cl aqueous solution67). The electron transfer rate constant (k0) was calculated using the Tafel equation:

where ik is the kinetic current and η is the overpotential. The temperature is ~25 °C, controlled by air conditioning. The data are collected and directly used.

Solubility and permeability measurements

Solubility of TPP-TEMPO was measured by adding an excess of electrolyte to the deionized water to obtain a saturated solution which was then diluted for UV-Vis spectrophotometry tests. Besides, the calibration curves have also been established.

Permeability of TPP-TEMPO across a Selemion AMVN membrane was tested in a lab-made two-compartment cell. One compartment contained 0.1 M electrolyte and 1 M NaCl solution, while the other compartment contained only 1 M NaCl solution and was used as the receiving compartment. Both compartments were continuously agitated at room temperature, and the receiving compartment was intermittently measured by UV-Vis spectrophotometry to detect the permeable electrolytes. Finally, the permeability coefficient P (cm2 s−1) was calculated using equation25:

where t is the test time (s), Ct (mol L−1) is the concentration of TPP-TEMPO in the receiving compartment at test time t, C0 = 0.1 mol L−1, the solution volume V0 = 15 mL, the membrane thickness l = 95 μm, and the membrane area A = 1.86 cm2. The temperature is ~25 °C, controlled by air-conditioning.

Flow cell tests

Cell hardware was purchased from Fuel Cell Tech (Albuquerque, US), and pyrosealed POCO graphite flow plates with a serpentine flow field were used. The electrode consisted of three stacked sheets of carbon paper (Sigracet SGL 39AA), which had been baked at 400 °C for 24 h. A Selemion AMVN membrane (95 μm, Japan) was directly used to separate the anolyte and catholyte solution, and the effective area of the AMVN membrane was 5 cm2. Masterflex L/S peristaltic pump (Cole-Parmer, Vernon Hills, IL) was used to circulate the electrolyte solution at a rotational speed of 60 rpm. The 0.1 M all-organic ARFB was assembled with 7.5 mL of the 0.1 M BTMAP-Vi (anolyte) and 5 mL of the 0.1 M TPP-TEMPO (or TMA-TEMPO) (catholyte) in 1 M NaCl (or NH4Cl) solution. Polarization curves were measured by charging the battery to various states of charge (SOCs) and then polarized by LSV on a Bio-Logic BCS-815. Galvanostatic battery cycling was performed at various current densities with a charge/discharge cutoff voltage of 1.4/0.5 V (or 1.6/0.5 V for TMA-TEMPO/BTMAP-Vi). Prolonged galvanostatic battery cycling was conducted similarly, with a potential hold at the end of the discharge process, until the current density dropped below 4 mA cm−2. The 0.5 M battery was assembled using 10 mL of 0.5 M BTMAP-Vi in 1 M NH4Cl solution and 5 mL of 0.5 M TPP-TEMPO in 2.5 M NH4Cl solution. The 2 M battery was assembled using 15 mL of 1 M BTMAP-Vi in 0.5 M NH4Cl solution and 5 mL of 2 M TPP-TEMPO solution. The temperature is 20~25 °C, controlled by an air-conditioning or heating radiator.

Data availability

The authors declare that all data supporting the finding of this study are available within the paper and its Supplementary Information. Source data are provided with this paper.

References

Nejat, P., Jomehzadeh, F., Taheri, M. M., Gohari, M. & Abd. Majid, M. Z. A global review of energy consumption, CO2 emissions and policy in the residential sector (with an overview of the top ten CO2 emitting countries). Renew. Sustain. Energy Rev. 43, 843–862 (2015).

IRENA. Renewable capacity statistics 2023 [R]. International Renewable Energy Agency AD (2023).

Rugolo, J. & Aziz, M. J. Electricity storage for intermittent renewable sources. Energy Environ. Sci. 5, 7151–7160 (2012).

Zhu, Z. et al. Rechargeable batteries for grid scale energy storage. Chem. Rev. 122, 16610–16751 (2022).

Zhang, C. & Li, X. Perspective on organic flow batteries for large-scale energy storage. Curr. Opin. Electrochem. 30, 100836 (2021).

Zhang, C., Yuan, Z. & Li, X. Designing better flow batteries: an overview on fifty years’ research. ACS Energy Lett. 9, 3456–3473 (2024).

Choi, C. et al. A review of vanadium electrolytes for vanadium redox flow batteries. Renew. Sustain. Energy Rev. 69, 263–274 (2017).

Zuo, Y. et al. Zinc dendrite growth and inhibition strategies. Mater. Today Energy 20, 100692 (2021).

Luo, J., Hu, B., Hu, M., Zhao, Y. & Liu, T. L. Status and prospects of organic redox flow batteries toward sustainable energy storage. ACS Energy Lett. 4, 2220–2240 (2019).

Yao, Y., Lei, J., Shi, Y., Ai, F. & Lu, Y.-C. Assessment methods and performance metrics for redox flow batteries. Nat. Energy 6, 582–588 (2021).

Ding, Y., Zhang, C., Zhang, L., Zhou, Y. & Yu, G. Molecular engineering of organic electroactive materials for redox flow batteries. Chem. Soc. Rev. 47, 69–103 (2018).

Tang, G., Yang, Z. & Xu, T. Two-electron storage electrolytes for aqueous organic redox flow batteries. Cell Rep. Phys. Sci. 3, 101195 (2022).

Huskinson, B. et al. A metal-free organic–inorganic aqueous flow battery. Nature 505, 195–198 (2014).

Yang, B., Hoober-Burkhardt, L., Wang, F., Surya Prakash, G. K. & Narayanan, S. R. An inexpensive aqueous flow battery for large-scale electrical energy storage based on water-soluble organic redox couples. J. Electrochem. Soc. 161, A1371–A1380 (2014).

Lin, K. et al. Alkaline quinone flow battery. Science 349, 1529–1532 (2015).

Yang, Z. et al. Alkaline benzoquinone aqueous flow battery for large-scale storage of electrical energy. Adv. Energy Mater. 8, 1702056 (2018).

Wu, M. et al. Extremely stable anthraquinone negolytes synthesized from common precursors. Chem 6, 1432–1442 (2020).

Wang, C. et al. N-alkyl-carboxylate-functionalized anthraquinone for long-cycling aqueous redox flow batteries. Energy Storage Mater. 36, 417–426 (2021).

Hollas, A. et al. A biomimetic high-capacity phenazine-based anolyte for aqueous organic redox flow batteries. Nat. Energy 3, 508–514 (2018).

Pang, S., Wang, X., Wang, P. & Ji, Y. Biomimetic amino acid functionalized phenazine flow batteries with long lifetime at near-neutral pH. Angew. Chem. Int. Ed. 60, 5289–5298 (2021).

Xu, J., Pang, S., Wang, X., Wang, P. & Ji, Y. Ultrastable aqueous phenazine flow batteries with high capacity operated at elevated temperatures. Joule 5, 2437–2449 (2021).

Li, L., Su, Y., Ji, Y. & Wang, P. A long-lived water-soluble phenazine radical cation. J. Am. Chem. Soc. 145, 5778–5785 (2023).

Liu, T., Wei, X., Nie, Z., Sprenkle, V. & Wang, W. A total organic aqueous redox flow battery employing a low cost and sustainable methyl viologen anolyte and 4-HO-TEMPO catholyte. Adv. Energy Mater. 6, 1501449 (2016).

DeBruler, C. et al. Designer two-electron storage viologen anolyte materials for neutral aqueous organic redox flow batteries. Chem 3, 961–978 (2017).

Beh, E. S. et al. A neutral pH aqueous organic–organometallic redox flow battery with extremely high capacity retention. ACS Energy Lett. 2, 639–644 (2017).

Luo, J., Hu, B., Debruler, C. & Liu, T. L. A π-conjugation extended viologen as a two-electron storage anolyte for total organic aqueous redox flow batteries. Angew. Chem. Int. Ed. 57, 231–235 (2018).

Liu, Y. et al. Screening viologen derivatives for neutral aqueous organic redox flow batteries. ChemSusChem 13, 2245–2249 (2020).

Tang, G. et al. Designing robust two-electron storage extended bipyridinium anolytes for pH-neutral aqueous organic redox flow batteries. JACS Au 2, 1214–1222 (2022).

Gao, M., Salla, M., Song, Y. & Wang, Q. High-power near-neutral aqueous all organic redox flow battery enabled with a pair of anionic redox species. Angew. Chem. Int. Ed. 61, e202208223 (2022).

Pan, M. et al. Reversible redox chemistry in pyrrolidinium-based TEMPO radical and extended viologen for high-voltage and long-life aqueous redox flow batteries. Adv. Energy Mater. 12, 2103478 (2022).

Hu, S. et al. Phenylene-bridged bispyridinium with high capacity and stability for aqueous flow batteries. Adv. Mater. 33, 2005839 (2021).

Janoschka, T. et al. An aqueous, polymer-based redox-flow battery using non-corrosive, safe, and low-cost materials. Nature 527, 78–81 (2015).

Yao, Y. et al. Nonionic oligo(ethylene glycol)-substituted viologen negolytes for aqueous organic redox flow batteries. J. Mater. Chem. A 11, 12984–12991 (2023).

Zu, X., Zhang, L., Qian, Y., Zhang, C. & Yu, G. Molecular engineering of azobenzene-based anolytes towards high-capacity aqueous redox flow batteries. Angew. Chem. Int. Ed. 59, 22163–22170 (2020).

Zhang, C. et al. Phenothiazine-based organic catholyte for high-capacity and long-life aqueous redox flow batteries. Adv. Mater. 31, 1901052 (2019).

Feng, R. et al. Reversible ketone hydrogenation and dehydrogenation for aqueous organic redox flow batteries. Science 372, 836–840 (2021).

Medabalmi, V., Sundararajan, M., Singh, V., Baik, M.-H. & Byon, H. R. Naphthalene diimide as a two-electron anolyte for aqueous and neutral pH redox flow batteries. J. Mater. Chem. A 8, 11218–11223 (2020).

Liu, X. et al. Arylene diimide derivatives as anolyte materials with two-electron storage for ultrastable neutral aqueous organic redox flow batteries. CCS Chem. 0, 1–14 (2022).

Singh, V. et al. Controlling π–π interactions of highly soluble naphthalene diimide derivatives for neutral pH aqueous redox flow batteries. Adv. Mater. 35, 2210859 (2023).

Liu, X. et al. Commercializable naphthalene diimide anolytes for neutral aqueous organic redox flow batteries. Angew. Chem. Int. Ed. 63, e202405427 (2024).

Hu, B., DeBruler, C., Rhodes, Z. & Liu, T. L. Long-cycling aqueous organic redox flow battery (AORFB) toward sustainable and safe energy storage. J. Am. Chem. Soc. 139, 1207–1214 (2017).

Chen, Q. et al. Designer ferrocene catholyte for aqueous organic flow batteries. ChemSusChem 14, 1295–1301 (2021).

Luo, J., Hu, B., Hu, M., Wu, W. & Liu, T. L. An energy-dense, powerful, robust bipolar zinc–ferrocene redox-flow battery. Angew. Chem. Int. Ed. 61, e202204030 (2022).

Janoschka, T., Martin, N., Hager, M. D. & Schubert, U. S. An aqueous redox-flow battery with high capacity and power: the TEMPTMA/MV system. Angew. Chem. Int. Ed. 55, 14427–14430 (2016).

Liu, Y. et al. A long-lifetime all-organic aqueous flow battery utilizing TMAP-TEMPO radical. Chem 5, 1861–1870 (2019).

Huang, Z. et al. An “interaction-mediating” strategy towards enhanced solubility and redox properties of organics for aqueous flow batteries. Nano Energy 69, 104464 (2020).

Hu, B., Fan, H., Li, H., Ravivarma, M. & Song, J. Five-membered ring nitroxide radical: a new class of high-potential, stable catholytes for neutral aqueous organic redox flow batteries. Adv. Funct. Mater. 31, 2102734 (2021).

Fan, H. et al. Conjugate-driven electron density delocalization of piperidine nitroxyl radical for stable aqueous zinc hybrid flow batteries. Angew. Chem. Int. Ed. 61, e202115908 (2022).

Fan, H. et al. Mitigating ring-opening to develop stable TEMPO catholytes for ph-neutral all-organic redox flow batteries. Adv. Funct. Mater. 32, 2203032 (2022).

Nolte, O., Rohland, P., Ueberschaar, N., Hager, M. D. & Schubert, U. S. Stability of TMA-TEMPO-based aqueous electrolytes for redox-flow batteries. J. Power Sources 525, 230996 (2022).

Hu, B. & Liu, T. L. Tanking up energy through atypical charging. Science 372, 788–789 (2021).

Chen Q. et al. Organic electrolytes for pH-neutral aqueous organic redox flow batteries. Adv. Funct. Mater. 32, 2108777 (2021).

Kwabi, D. G., Ji, Y. & Aziz, M. J. Electrolyte lifetime in aqueous organic redox flow batteries: a critical review. Chem. Rev. 120, 6467–6489 (2020).

Fan, H. et al. Radical charge population and energy: critical role in redox potential and cycling life of piperidine nitroxyl radical cathodes in aqueous zinc hybrid flow batteries. ACS Appl. Mater. Interfaces 12, 43568–43575 (2020).

Hirshfeld, F. L. Bonded-atom fragments for describing molecular charge densities. Theor. Chim. Acta 44, 129–138 (1977).

Humphrey, W., Dalke, A. & Schulten, K. VMD: visual molecular dynamics. J. Mol. Graph. 14, 33–38 (1996).

Frisch M. J. et al. Gaussian 16 Rev. C.01. (2019).

Lu, T. & Chen, F. Multiwfn: a multifunctional wavefunction analyzer. J. Comput. Chem. 33, 580–592 (2012).

Lu, T. & Chen, Q. Shermo: a general code for calculating molecular thermochemistry properties. Comput. Theor. Chem. 1200, 113249 (2021).

Orita, A., Verde, M. G., Sakai, M. & Meng, Y. S. The impact of pH on side reactions for aqueous redox flow batteries based on nitroxyl radical compounds. J. Power Sources 321, 126–134 (2016).

Sen, V. D. & Golubev, V. A. Kinetics and mechanism for acid-catalyzed disproportionation of 2,2,6,6-tetramethylpiperidine-1-oxyl. J. Phys. Org. Chem. 22, 138–143 (2009).

Hu, B., Luo, J., Hu, M., Yuan, B. & Liu, T. L. A pH-neutral, metal-free aqueous organic redox flow battery employing an ammonium anthraquinone anolyte. Angew. Chem. Int. Ed. 58, 16629–16636 (2019).

Zheng, R. et al. Ammonium ion batteries: material, electrochemistry and strategy. Angew. Chem. Int. Ed. 62, e202301629 (2023).

Zhang, S. et al. The interactions between imidazolium-based ionic liquids and stable nitroxide radical species: a theoretical study. J. Phys. Chem. A 120, 6089–6102 (2016).

Heyrovska, R. Dependence of the length of the hydrogen bond on the covalent and cationic radii of hydrogen, and additivity of bonding distances. Chem. Phys. Lett. 432, 348–351 (2006).

Aggarwal, V. K., Gültekin, Z., Grainger, R. S., Adams, H. & Spargo, P. L. (1R,3R)-2-Methylene-1,3-dithiolane 1,3-dioxide: a highly reactive and highly selective chiral ketene equivalent in cycloaddition reactions with a broad range of dienes. J. Chem. Soc. Perkin Trans. 1, 2771–2782 (1998).

Easteal, A. J. & Woolf, L. A. Viscosity of aqueous NH4Cl and tracer diffusion coefficients of ions, water and non-electrolytes in aqueous NH4Cl, KI, and MgCl2 at 25 °C. J. Solut. Chem. 17, 447–457 (1988).

Hu, B., Hu, M., Luo, J. & Liu, T. L. A. Stable, low permeable TEMPO catholyte for aqueous total organic redox flow batteries. Adv. Energy Mater. 12, 2102577 (2021).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (no. U20A20127, T.X. and no. 22109036, Y.L.), the Fundamental Research Funds for the Central Universities (no. WK2060000059, K.P.), and the Strategic Priority Research Program of the Chinese Academy of Sciences (Grant no. XDB0450401, T.X.). The Supercomputing Center of the University of Science and Technology of China provided computational resources for DFT calculation. This work was partially carried out at the Instruments Center for Physical Science, University of Science and Technology of China.

Author information

Authors and Affiliations

Contributions

T.X. supervised this work. Z.Y. and G.T. conceived this project and wrote the paper. G.T. performed all the experiments and data analysis. G.T. and W.W. carried out DFT calculations. Y.L., K.P., and P.Z. assisted in the discussion of the results.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks the anonymous reviewers for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Tang, G., Wu, W., Liu, Y. et al. Adjusting Hirshfeld charge of TEMPO catholytes for stable all-organic aqueous redox flow batteries. Nat Commun 16, 47 (2025). https://doi.org/10.1038/s41467-024-55244-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-024-55244-4

This article is cited by

-

High selectivity framework polymer membranes chemically tuned towards fast anion conduction

Nature Communications (2025)