Abstract

Improved in vitro models are needed for regenerative therapy and drug screening. Here, we report on functionally aligned nanoparticle-trapped nanopattern arrays for spatially controlled, precise mesenchymal stem cell differentiation on a single substrate. The arrays comprise nanohole and nanoline arrays fabricated through interference lithography and selectively capture of UiO-67 metal–organic frameworks on nanoline arrays with a 99.8% efficiency using an optimised asymmetric spin-coating method. The UiO-67 metal–organic frameworks contain three osteogenic differentiation factors for sustained release over four weeks. The combination of differentiation factors and patterned array allows for generation of adipocytes, osteoblasts, and adipocyte–osteoblast mixtures on nanohole arrays, nanoline arrays, and at the nanohole–nanoline interface, respectively, with mature osteoblasts exhibiting higher marker expression and mineralisation. The sustained release patterned array holds potential for constructing advanced therapeutic and disease state in vitro cellular models.

Similar content being viewed by others

Introduction

In the field of drug discovery, conventional animal experimentation at the preclinical stage encounters challenges due to interspecies specificity and ethical concerns1,2,3,4,5. To minimise reliance on animal testing, extensive research has been conducted to advance an alternative: in vitro drug screening models6,7,8,9. These models have evolved from simple, two-dimensional monolayers to complex, three-dimensional multicellular systems such as spheroids, organoids, and organs-on-chips designed to better mimic the structural intricacies of real organs or tissues10,11,12,13,14.

To construct organ-mimicking in vitro models, the utilisation of stem cells has proven instrumental15,16,17,18. Stem cells, distinguished by their unique ability to generate myriad cell types, have emerged as pivotal resources in this endeavour19,20,21,22. Mesenchymal stem cells (MSCs) have been considered particularly promising due to their easy extraction from adult tissues (e.g., adipose, bone marrow, and dental pulp) and because fewer safety issues, such as teratoma formation and immune rejection, are associated with their use23,24,25,26,27. Moreover, they exhibit multipotency, enabling the generation of various cell types, including bone, fat, cartilage, and muscle cells, which can be generally induced by culture media containing growth factors28,29,30,31,32,33,34,35,36.

However, challenges arise during cultivation, as the entire cell population on the culture dish is exposed to the same differentiation medium, complicating spatially controlled differentiation37,38,39,40. To construct multicellular in vitro models that mimic organ structures, laborious and time-consuming steps, including cell detachment, precise reseeding, and cell reattachment, must be followed in repetitive cycles, often leading to cellular damage41,42,43,44,45,46. The challenge escalates when attempting to create an interfacial area where different cell types coexist, a phenomenon commonly observed in real organs, particularly around connective tissues47,48,49,50,51. Building on these challenges, Dalby et al. demonstrated the potential of nanopatterns to either maintain the multipotency of MSCs or enhance their osteogenesis, depending on the arrangement of nanostructures34. Other studies further showed that MSC differentiation into specific lineages, including adipogenesis, osteogenesis, and chondrogenesis, could be effectively controlled on a single platform by manipulating nanopattern features such as size, shape, and gap distance52,53,54,55,56. Besides, other physical cues, such as substrate elasticity, have been shown to guide stem cell differentiation mechanisms involving integrin accumulation, alignment, which affect the upstream signalling pathway and downstream transcriptional regulation57,58,59. Based on these previous discoveries, we hypothesised that stem cell differentiation could be more tightly and precisely regulated by simultaneously exposing cells to both physical (e.g., nanopatterns) and biochemical cues (e.g., differentiation factors)60. This approach may be crucial for constructing tissue-mimicking models where multiple cell types co-exist in spatially defined regions, as observed in complex organ structures.

In this study, we present an advanced cell cultivation platform, functionally aligned nanoparticle-trapped nanopattern arrays (FANTAs), aimed at achieving full automation of human MSC differentiation into osteoblasts, thereby enabling the spatially controlled multicellular differentiation of stem cells on a single substrate with high differentiation efficiency and selectivity (Fig. 1). Previous studies have demonstrated that porous nanoparticles can continuously release growth supplements and differentiation factors, facilitating stem cell homing and tissue repair in vivo61,62,63,64,65,66,67. Inspired by these findings, we presumed that exposing cells to nanoparticles releasing differentiation factors in specific regions in vitro will induce automatic differentiation while unexposed cells elsewhere on the substrate remain unaffected. To demonstrate this concept, we engineered two distinct nanopatterns, nanohole and nanoline arrays, on a single platform, intending to selectively capture nanoparticles in the nanoline area, as well as to serve as physical cues to guide stem cell behaviour. UiO-67 metal–organic framework (MOF) nanoparticles were designed to release three different key osteogenesis-related differentiation factors for up to four weeks68. Using an MSC model, we sought to generate bone and fat cells on a single platform, mimicking the cross-section of bone marrow and compact bone interfacial areas69. The successful capture of nanoparticles within nanolines was confirmed, and then MSC seeding and treatment with an adipogenesis medium were performed. We successfully achieved bone and fat cell differentiation on the nanoline and nanohole array areas, respectively, as well as the co-generation of bone and fat cells at the interfacial areas. Once fabricated, the FANTA platform eliminates the need for complex experimental setups or expensive instruments to control cellular differentiation. As a disposable platform, it is fully compatible with existing cell cultivation tools, offering significant advantages for the straightforward and efficient acquisition of multicellular tissue or organ-mimicking constructs in vitro. This advancement is crucial for realising more intricate and physiologically relevant organ-mimicking models.

a Differences between in vivo tissue development and in vitro cell differentiation for organ-mimicking models. b FANTAs consist of hierarchical nanoarrays including nanoline and nanohole nanopatterns with a spatially controlled distribution of nanocrystalline UiO-67s containing three osteogenic differentiation factors (ODFs), ascorbic acid, glycerol 2-phosphate, and dexamethasone (ODF⊂UiO-67), enabling the automatic, multicellular, spatially controlled differentiation (i.e., osteogenic and adipogenic differentiation) of mesenchymal stem cells (MSCs). This figure was partly generated by Servier Medical Art (Servier; https://smart.servier.com/), licensed under a Creative Commons Attribution 4.0 Unported License.

Results

Design, synthesis, and characterisation of triple differentiation factor-releasing MOF nanoparticles

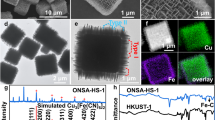

Key differentiation factors for inducing the osteogenesis of MSCs are ascorbic acid (AA), beta-glycerophosphate (BGP), and dexamethasone (DEXA), with molecular weights of 176.12, 216.04, and 392.464 g/mol, respectively (Fig. 2a). We selected Zr6O4(OH)4(BPDC)6 (UiO-67, where BPDC is 4,4′-biphenyldicarboxylate), leveraging its pore size of 1.89 nm for the prolonged release of these three osteogenic differentiation factors (ODFs). The synthesised UiO-67 showed a homogeneous size (ca. 170 nm) and a truncated octahedron geometry, as evidenced by scanning electron microscopy (SEM) images (Fig. 2b–d). Additionally, the powder X-ray diffraction (PXRD) pattern confirmed the highly crystalline nature of UiO-67, displaying sharp peaks below 10° (Fig. 2e). The characteristic microporous material nature of UiO-67 was further confirmed by a type I adsorption isotherm, in accordance with the IUPAC classification (Fig. 2f). The surface area and total pore volume of UiO-67, and the instrumental properties for the absorption and sustained release of ODFs, were 2192.80 m²/g and 0.369 cm³/g (P/P0 = 0.98), respectively.

a Schematic illustration showing the uptake and gradual release of the osteogenic differentiation factors (ODFs) ascorbic acid (AA), beta-glycerophosphate (BGP), and dexamethasone (DEXA) from UiO-67 particles. b, c FE-SEM images of the UiO-67 particles. The experiments were repeated more than three times with similar results. d Particle size distribution of UiO-67 particles, as measured by dynamic light scattering. e Powder X-ray diffraction (PXRD) pattern of UiO-67. f Nitrogen adsorption–desorption isotherm of UiO-67 (P/P0, relative pressure). g–j Curves describing absorption over time for the three ODFs and the ODF mixture in UiO-67. k–m Curves describing the release of ODFs, individually (top) and as a mixture (bottom), from ODF⊂UiO-67 over 21 d.

As shown in Fig. 2g–i, when each ODF was introduced separately, UiO-67 particles became saturated within 48 h of incubation with AA and BGP, whereas DEXA required 60 h, likely due to its higher molecular weight (Supplementary Figs. 1 and 2). The individual maximum loading capacities for AA, BGP, and DEXA in UiO-67 were found to be 49.80, 50.49, and 2.36 × 10−3 mmol/g, respectively, and the saturated UiO-67 particles are referred to as AA⊂UiO-67, BGP⊂UiO-67, and DEXA⊂UiO-67, respectively. Further experiments confirmed that UiO-67 could simultaneously accommodate all three ODFs as a mixed solution (ODF⊂UiO-67), maintaining effective loading and absorption kinetics (Fig. 2j).

The ODF release profiles of the saturated UiO-67 particles were characterised in Dulbecco’s phosphate-buffered saline (DPBS) solution, comparable to Dulbecco’s modified Eagle’s medium (DMEM). A gradual and stable cumulative release of all ODFs was observed over 21 d, without any initial bursts or release instability (Fig. 2k–m). Notably, DEXA exhibited a delayed release during the first 3 d from both DEXA⊂UiO-67 and ODF⊂UiO-67, aligning with its absorption characteristics (Fig. 2i,j). No statistically meaningful differences were observed between single- and mixed-ODF release profiles, indicating no interference among ODFs during the absorption and release processes.

The sustained and stable release of the ODF mix from UiO-67, with the osteogenic differentiation of MSCs extended over 28 d in vitro (DIV), underscores its potential for further investigation, particularly for inducing the automatic osteogenesis of MSCs on nanoline arrays.

FANTA fabrication

Physical cues, such as nanopattern geometry, are well-established in their ability to significantly influence cellular differentiation, with prior studies showing that nanotopography alone can induce osteogenesis34,35. Specifically, nanohole patterns limit cellular adhesion and promote adipogenic differentiation, whereas nanoline arrays encourage elongated cell morphology, significantly enhancing osteogenesis in MSCs. To enable spatially controlled multicellular differentiation on a single platform, a selective coating of ODF⊂UiO-67 in targeted areas is essential. Accordingly, we fabricated two homogeneous nanopatterns—nanoline and nanohole arrays—on a unified substrate using laser interference lithography (LIL), as illustrated in Fig. 3a. The physical parameters, including the gap distances and diameters of both patterns, were set at 400 nm to accommodate the UiO-67 particles (170 nm).

a Schematic illustrations showing laser interference lithography, a fabrication process, for the fabrication of hierarchical nanopattern arrays. b Illustration showing the major forces acting during the site-specific UiO-67 coating of nanopattern arrays: centrifugal forces (Fc), drag forces (Fd), evaporative forces (Fe), friction forces (Ff), and gravitational forces (Fg). c SEM images (scale bars = 1 μm) and corresponding quantitative analyses (n = 10 independent replicates of SEM analysis, “IP” = UiO-67-coated inside patterns and “EP” = UiO-67-coated outside patterns) of UiO-67-coated nanopattern arrays with different oxygen plasma pretreatments. The 0%, 50%, and 100% levels denote the intensity of the oxygen plasma treatment, indicating 0 W/100 sccm, 50 W/100 sccm, and 100 W/100 sccm, respectively. d, e SEM images (d scale bars = 1 μm) and the corresponding quantitative analysis (e) of UiO-67-coated nanopattern arrays produced using different concentrations of polysorbate 20 as a surfactant in the UiO-67 solution. In e the box plot describes the mean coating rate at each concentration (v/v) of polysorbate 20 (n = 11 independent replicates of SEM analysis), and the data were normalised to the control. f, g SEM images (f, scale bars = 1 μm) and the corresponding quantitative analysis g of UiO-67-coated nanopattern arrays at different spin speeds (rpm). The box plot describes the mean coating rate at each spin speed (n = 11 independent replicates of SEM analysis), and the data were normalised to the control. h Simulation results of UiO-67 distributions on the substrate (5 × 10 mm) according to the distance between the coating point and spin axis, inducing symmetrical (SSC) and asymmetrical (ASC) spin coating. i, j Confocal microscopy images of nanopattern arrays coated with UiO-67 particles loaded with rhodamine-6g (R6G⊂UiO-67) using each spin-coating mode (scale bars = 1 μm). k, l Optical mapping of emissions (555 nm) from R6G⊂UiO-67-coated nanopattern arrays k and the corresponding quantitative analysis l. In l emissions from the nanohole (NHP) and nanoline (NLP) pattern arrays are quantified (n = 171 replicates of points at different locations on the substrate used in optical mapping). m SEM images of UiO-67-coated NLP fabricated using SSC and ASC (scale bars = 1 μm). n Illustrations, a real picture, and SEM images of the NHP and NLP of a FANTA. The experiments were repeated more than three times with similar results. In all analyses, statistical significance was assessed using one-way ANOVA with Tukey’s posthoc test and is indicated using asterisks: *P < 0.05; **P < 0.01; and ***P < 0.001. Data represented as mean ± SD. The boxplot displays the median (center line), the lower and upper quartiles (box edges), as well as the minimum and maximum values represented by whiskers.

During the spin-coating process, several forces influence the movement of UiO-67 particles in solution: centrifugal (Fc), gravitational (Fg), viscous drag (Fd), friction (Ff), and evaporative (Fe) forces. The evaporative force, alongside capillary forces, becomes negligible with non-volatile solutions (e.g., DPBS, HEPES, DIW). Highly volatile solvents were not chosen for FANTA production because they diminish the structural stability of photoresist (PR) nanopatterns generated by LIL. Keeping Fg constant, we varied the spin speed, modified the dropping method, adjusted the solution’s viscosity, and altered the substrate’s hydrophilicity to influence Fc, Fd, and Ff. Initially, the spin speed ranged from 1000 to 5500 rpm, with the UiO-67-containing solution applied to the substrate before and during the spinning process (Supplementary Figs. 3–6). Subsequent experiments with TWEEN-20, which modulates solution viscosity and nanoparticle dispersion, helped to identify optimal conditions for trapping UiO-67 nanoparticles within the nanoline arrays (ɷ = 3500 rpm, t = 120 s, mode = dropping before spinning), as shown in Supplementary Fig. 7. However, the substrate’s hydrophobic nature caused nanoparticle aggregation, reducing trapping efficiency. This issue was mitigated by treating the nanopatterned platform with a mild oxygen plasma (Fig. 3b), increasing the number of nanoparticles trapped in the nanoline arrays to approximately 3.22 times that in the control due to improved particle dispersity and an increased friction coefficient of the nanopatterns (Fig. 3c–e).

Interestingly, we observed a higher saturation of MOF nanoparticles in the nanoline arrays at the substrate edges, which was attributed to the increased Fc with distance from the centre. MOF nanoparticle motion simulations confirmed that Fc dominated at the substrate’s edges (Fig. 3f), corroborating our observations. Exploiting this phenomenon, we employed asymmetric spin coating (ASC), strategically positioning nanoline and nanohole arrays at the substrate’s outer and central areas, respectively. This approach enabled the selective trapping of MOF nanoparticles in the nanoline arrays (Fig. 3h–m), achieving a capturing efficiency of 99.8%, as verified by SEM imaging (Supplementary Fig. 8). In summary, we successfully demonstrated the fabrication of a single platform integrating empty nanohole patterns and ODF⊂UiO-67-filled nanoline arrays, paving the way for advanced multicellular differentiation studies (Fig. 3n).

Automatic osteogenic differentiation of MSCs on ODF-loaded nanoline pattern arrays

After optimising the selective trapping of MOF nanoparticles, we aimed to determine whether the physical parameters of the nanopatterns were effective in guiding the multilineage differentiation of MSCs (Fig. 4a)70,71. We varied the size and gap distance of nanohole and nanoline arrays on separate substrates, producing 800S (pitch: 800 nm, size: 400 nm), 800 L (pitch: 800 nm, size: 600 nm), 1000S (pitch: 1000 nm, size: 400 nm), and 1000 L (pitch: 1000 nm, size: 600 nm) substrates (Supplementary Fig. 11). Key cellular functions, including growth, adhesion, and MSC differentiation, were evaluated. The 800S nanohole and nanoline arrays exhibited significantly enhanced extracellular matrix deposition and cellular growth compared to those on both bare glass and PR-coated substrates, confirming their biocompatibility and non-toxicity (Supplementary Figs. 12–16). Moreover, the nanohole patterns, without cell orientation along with the pattern morphology, limited cellular adhesion, leading to the reduced expression of integrin subunit (ITGa1), one of the cell adhesion molecules favourable for osteogenesis72,73. Specifically, the impact of nanotopographic signals (nanohole patterns) on differentiation can be observed in Supplementary Fig. 12, where the average quantity and size of lipid droplets were enhanced by 2.27- and 4.59-fold, respectively, on nanohole arrays compared to those of MSCs on a flat substrate. In contrast, as nanoline pattern arrays favour osteogenic differentiation, lipid droplet formation on these arrays was significantly reduced. Consequently, the nanohole patterns were more effective than nanoline patterns in promoting MSC adipogenesis (Fig. 4b–e and Supplementary Figs. 12–13). Conversely, the nanoline arrays exhibited substantially higher ITGa1 mRNA expression than that in the control, enhancing cellular adhesion and spreading (Supplementary Figs. 15–17). Among tested substrates, the 800S nanoline arrays were particularly effective in guiding cellular morphology towards an elongated shape beneficial for osteogenesis. Moreover, on the 800S nanoline arrays, osteoblast formation increased to 2.53-fold that on the control (Fig. 4f–h and Supplementary Fig. 18). As physical cues are important in determining cellular fate, we utilised these specific patterns to better guide differentiation on a single substrate.

a Illustrations showing nanohole pattern arrays and nanoline pattern arrays in FANTAs for adipogenic and osteogenic differentiation, respectively. b, c Oil red O (ORO) staining image b and BODIPY image c of MSCs cultured on bare nanohole pattern arrays (b, c scale bars = 200 μm). d Quantitative analysis of lipid droplet size calculated from immunocytochemistry images of MSCs stained with BODIPY. e RT-qPCR results for MSC-derived osteocytes quantifying the expression of several adipogenesis-associated genes. f Immunocytochemistry images with F-actin staining showing cellular alignment and orientation on nanolines (f, scale bars = 100 μm). The experiments were repeated more than five times with similar results. g, h Confocal images of MSCs cultured on ITO-coated glass (Control) and FANTAs with focal adhesion kinase (FAK; g, scale bars = 100 μm) and the corresponding quantification h. i Timelines (“DIV” denotes “days in vitro”) of the osteogenic induction treatments for ODF⊂UiO-67-embedded arrays (ODF-FANTA) and other groups, including ITO-coated glass (Control), nanoline pattern arrays (NLPs), and empty UiO-67-embedded nanopattern arrays (FANTAs). j Illustrations showing each treatment platform. k, l Alizarin red S (ARS) k and osteocalcin (OCN) l immunocytochemistry staining images of MSCs under each treatment for 4 weeks (l, scale bars = 200 μm). The experiments for (l) were repeated four times. Treatments correspond vertically to those illustrated in j. m Quantitative analyses based on the ARS staining images in k. n RT-qPCR analysis results comparing the relative expression of ALP (red bars), RUNX2 (blue bars), and OCN (yellow bars) in the MSCs under each treatment after 1, 2, 3, and 4 weeks; the data were normalised to the control. In all analyses, statistical significance was assessed using one-way ANOVA with Tukey’s posthoc test (n = 5 independent biological replicates) and is indicated using asterisks: *P < 0.05; **P < 0.01; and ***P < 0.001. Data represented as mean ± SD.

We then proceeded to utilise ODF⊂UiO-67-embedded 800S nanoline arrays for osteogenic differentiation using a standard culture medium (Fig. 4a). First, we created eight treatments by varying the ODF components in the MOFs, including all combinations of AA, BGP, and DEXA and one treatment containing no ODFs, and assessed their efficacy in directing osteogenesis using early (ALP) and late osteogenesis markers (osteocalcin [OCN]), as well as osteoblast mineralisation levels (alizarin red S [ARS]). As indicated in Supplementary Fig. 19, MOF nanoline arrays missing one or two of the essential ODFs demonstrated lower osteogenesis efficiency than those incorporating all three. Throughout the differentiation period, no cellular uptake of MOF nanoparticles was detected, and this was confirmed by fluorescence images using R6G-loaded UiO-67 nanoparticles (Supplementary Fig. 20). The stable release of ODFs from the nanoline arrays was also verified over 21 d of differentiation, indicating that the MOFs were securely incorporated within the nanoline arrays while retaining their unique structures. Subsequently, we the compared osteogenesis efficiency of ODF⊂UiO-67-embedded nanoline arrays (ODF-FANTAs) with that of other platforms, including MSCs on indium tin oxide (ITO)-coated glass (Control), nanoline pattern arrays (NLPs), and FANTAs loaded with empty MOFs. Crucially, a standard growth medium was used for the ODF⊂UiO-67-embedded nanoline arrays only, whereas other groups were subjected to a medium containing ODFs (Fig. 4i–j and Supplementary Fig. 22).

Notably, as shown in Fig. 4k–m, both OCN expression and osteogenesis mineralisation were significantly higher on the ODF⊂UiO-67-embedded nanoline arrays than on other arrays throughout the differentiation period (Fig. 4k–m and Supplementary Fig. 23). Specifically, calcium phosphate accumulation (i.e., mineralisation) and OCN protein expression were 26.53 and 2.64 times higher, respectively, than control values in the ODF-FANTA group using the standard growth medium after four weeks of differentiation. Moreover, even in the first week of differentiation, ALP, RUNX2, and OCN expression was 2.40, 12.44, and 4.15 times higher, respectively, in the ODF-FANTA group compared to the control (Fig. 4n). At week 4, the expression of OCN in the ODF-FANTA group was 59.46 times that in the control, indicating that the formation of mature osteoblasts was greatly improved on the ODF⊂UiO-67-embedded array. We also observed that MSCs exposed to osteogenic differentiation medium during the early stages of adhesion and proliferation (DIV0–DIV3) exhibited aggregated morphologies and low differentiation efficiencies, suggesting that the enhanced osteogenesis seen in the ODF-FANTA group was not a result of MSCs being exposed to ODFs released at the initial seeding stage from the UiO-67 particles embedded in the nanolines (Supplementary Figs. 24 and 25). After inhibiting BMP-2 signalling, MSCs on the ODF⊂UiO-67-embedded arrays showed extremely low osteogenesis efficiency, indicating that they undergo osteoblast formation via the typical TAB, TAK, and Smad pathways (Supplementary Fig. 26). In summary, the developed ODF⊂UiO-67-embedded nanoline arrays are suitable for automatic osteogenic differentiation, and the nanohole patterns effectively promote MSC adipogenesis on an adipogenic differentiation medium. These results indicate that physical cues regulating cell morphology and alignment synergize with biochemical cues to amplify the activation of signaling pathways, thereby enhancing MSC differentiation efficiency.

Spatially controlled multicellular differentiation of MSCs on the unified FANTA platform

Finally, we aimed to induce both MSC adipogenesis and osteogenesis on a single platform with coexisting nanohole and ODF⊂UiO-67-embedded nanoline arrays. Notably, osteoblasts and adipocytes regulate bone homeostasis through active interactions, and adipocytes are known to secrete bioactive materials that influence bone formation and metabolism74. Specifically, the ageing of bone tissue and the subsequent increase in bone marrow fat content can inhibit the osteogenesis of MSCs and the physiological activity of osteocytes, potentially leading to osteoporosis75. Thus, understanding the biointerface between osteocytes and adipocytes differentiated from the same precursor (MSCs) in the bone marrow is crucial for disease modelling and the functional screening of bone diseases such as osteoporosis. To mimic functional bone–lipid interfaces, we attempted spatially controlled osteo-adipogenesis on the FANTA platform by employing the automated release of ODF from UiO-67 in combination with adipogenic differentiation medium. We tested three hypotheses: (1) MSCs on nanoholes would undergo adipogenesis due to the adipogenic differentiation factors (ADFs) in the medium combined with nanotopographic effects; (2) MSCs on nanoline arrays would automatically differentiate into osteoblasts, driven by the continuous release of ODFs from the MOFs and the influence of their nanoline-guided elongated morphology; and (3) both adipocytes and osteoblasts would be generated at the nanohole–nanoline interfacial layer (Fig. 5a). After three weeks of differentiation, lipid droplets were observed in both the nanoline–nanohole interfacial and nanohole array regions (Fig. 5b and Supplementary Fig. 29). To further validate multilineage differentiation, all cells were stained with OCN and ARS as markers for mature osteoblasts, and with BODIPY and oil red O (ORO) as markers for adipocytes. As depicted in Fig. 5c, OCN and BODIPY expression was predominantly observed in ODF⊂UiO-67-embedded nanoline and nanohole pattern arrays, respectively. In the interfacial area, both adipocytes and osteoblasts co-existed, with OCN expression being 2.56 times higher than that of BODIPY (Fig. 5d). Regarding ARS and ORO staining, mineralisation levels were 5.39 times higher on nanoline arrays than on nanohole arrays, while lipid droplet deposition was approximately 3.01 times higher on nanohole arrays, as can be seen in fluorescence images of OCN and BODIPY double staining (Fig. 5e–h). Serial time-lapse images of ORO-stained nanohole-to-nanoline arrays revealed that the ORO-positive areas constituted 2.17–6.57%, 9.07–13.8%, and 14.16–16.93% of the nanoline, nanohole–nanoline interfacial, and nanohole areas, respectively (Fig. 5g–h, Supplementary Figs. 30–32, and Supplementary Movie 1). Next, to study the diffusion range of MOFs embedded in the nanoline arrays, we measured the area of osteogenesis using calcium staining, as directly measuring the release profile of each differentiation factor from MOFs is challenging. The area of calcium deposition, stained red by ARS, was then divided by the areas of the nanoline and nanohole arrays. As shown in Supplementary Fig. 31, the calcium-stained areas represented 1.58 ± 0.51% of the nanohole arrays and 98.33 ± 0.47% of the nanoline arrays, indicating an offset of approximately 1.5% for both regions. These results suggest that diffusion predominantly occurred within the areas where the MOFs were embedded, demonstrating the excellent capability of the FANTA platform for selectively and precisely controlling MSC differentiation. We also demonstrated that the nanoline array portion could be reduced by approximately 50% to generate a square-like morphology and could also be altered to a circular shape (Fig. 5i). This flexibility in array arrangement is advantageous for more accurately mimicking the bone marrow interface. Collectively, these findings confirm that the unified FANTA platform enables the spatially controlled multicellular differentiation of MSCs using automatic osteogenesis.

a Illustrations depicting the spatially controlled multicellular differentiation of MSCs on a single FANTA and its use for mimicking bone marrow. b Microscopic images of differentiated cells in each ODF-FANTA region: the nanoline array (Line), nanohole array (Hole), and nanoline–nanohole interface (Line/Hole). The experiments were repeated more than five times with similar results. c, d Immunocytochemistry images of osteocytes and adipocytes with OCN and BODIPY markers in each region of the ODF-FANTA c and the corresponding quantitative analysis of spatially controlled multicellular differentiation d. e, f OCN staining images depicting the osteogenesis of differentiated cells in each region of the ODF-FANTA e and the corresponding quantitative analysis f. g, h ORO staining images depicting the adipogenesis of differentiated cells in each region of the ODF-FANTA g and the corresponding quantitative analysis (h). i Actual photos, illustrations, and optical mapping results of nanopattern arrays coated with R6G⊂UiO-67 at different resolutions. Scale bars = 200 μm in all images. In all analyses, statistical significance was assessed using one-way ANOVA with Tukey’s posthoc test (n = 5 independent biological replicates) and is indicated using asterisks: ***P < 0.001. Data represented as mean ± SD. This figure was partly generated by Servier Medical Art (Servier; https://smart.servier.com/), licensed under a Creative Commons Attribution 4.0 Unported License. Additional elements of the figure were created in BioRender (Cho, Y.-W., 2025; https://biorender.com/c22s370).

To expand the feasibility of FANTA, we further attempted to generate two additional cell types, neurons and chondrocytes (Supplementary Figs. 34–35). Unlike osteo-adipogenesis, co-culturing MSCs and neurons can lead to neuronal apoptosis due to MSC-derived cytokines. Moreover, protein supplements (e.g., TGF beta-1, BMP-2, GDF-5, and IGF-1) were essential for chondrogenesis, which could negatively affect osteogenesis. To address these issues and induce osteo-neurogenesis or osteo-chondrogenesis on the FANTA platform, a PDMS mask was applied to the area where neurogenesis or chondrogenesis was to be induced for approximately two weeks. After removing the PDMS mask, neural stem cells or MSCs were seeded on the nanohole arrays and exposed to the appropriate differentiation medium. As shown in Supplementary Fig. 34–35, both neurogenesis and chondrogenesis were successfully induced, with efficiencies of 96% and 91%, respectively, along with osteogenesis, demonstrating the expanded potential of FANTA as a platform for effectively generating specific structures of target organs or tissues in vitro.

Discussion

We have demonstrated that triple factor-releasing MOF nanoparticles can be precisely trapped on designated nanopatterns with near-perfect efficiency, enabling (i) highly efficient osteogenesis through the simultaneous modulation of physical and biochemical cues (an 80-fold enhancement in differentiation efficiency) and (ii) spatially controlled multicellular differentiation accompanied by highly selective differentiation (over 98% differentiation selectivity).

The developed FANTA platform holds great potential for further advancement by incorporating a broader array of key differentiation factors, such as CHIR, BMP, bFGF, BDNF, and FGF, in combination with other types of nanomaterials (e.g., mesoporous silica nanoparticles, lipid nanoparticles, and biodegradable polymeric nanoparticles) that can carry high-molecular-weight factors. In comparison with previously reported methods, such as microfluidic or bioprinting devices used for the automation of cellular differentiation, the FANTA platform is simpler and more easily disposable, similar to tissue culture plates, making it fully compatible with existing cell culture protocols. Therefore, complex experimental setups, such as microfluidic channels, external controlling pumps, and extensive instrumentation, are not required, which is highly advantageous for most biological research. Furthermore, the refined combination of physical and biochemical cues facilitates spatial control of multicellular differentiation, enabling the FANTA platform to minimise batch-to-batch variation in the production of complex organ-mimicking constructs, such as bone–cartilage and bone–nerve biointerfaces. As a result, it enhances the reliability and utility of in vitro models for advanced drug screening applications, such as in osteoporosis, and offers considerable progress in biomedical research and therapeutic development, including patient-specific stem cell-based therapies.

Methods

Fabrication of hierarchical nanopattern arrays

To fabricate hierarchical nanopattern arrays, we used LIL, a nanopatterning technique that does not require an additional photomask, with a Lloyd’s mirror as an interferometer system. To prepare the LIL, ITO-coated glass (area: 12 × 17 mm; thickness: 0.7 mm; electrical resistance: 10 Ω) was first washed with a series of sequential cleaning steps in which the substrates were sonicated in 1% Triton X-100, distilled water, and then 70% ethanol for 20 min. The cleaned substrates were then dried with nitrogen gas. After drying, the glass was heated at 130 °C for 5 min to completely remove moisture on the surface of the substrate. Then, the dried glass was coated with negative PR diluted with thinner (PR–thinner at 3:2) using the spin-coating technique (maximum spin speed: 4000 rpm; spin acceleration: 166.7 rpm/s; coating time: 84 s) and heated at 130 °C for 1 min to eliminate the remaining organic solvent within the PR layer. Next, the PR-coated glass was exposed to a He–Cd ultraviolet (UV) laser (wavelength: 325 nm; power: 80 mW; polarisation: linear) twice by rotating it clockwise. To form both nanohole and nanoline patterns on the single substrate, after the first exposure was completed, the rotated substrate was subjected to a second exposure treatment after covering 50% of the total area using a mask coated with carbon tape. Then, the exposed substrates were heated at 130 °C for 1 min to increase the adhesion of the PR layer and immersed in a developer at room temperature for 1 min. Finally, the developed pattern arrays were washed several times in distilled water and dried with nitrogen gas. To fabricate nanopattern arrays with the desired dimensions, including the heights and sizes of the patterns, parameters such as exposure dose and angle were adjusted.

ODF-FANTA fabrication

To fabricate ODF⊂UiO-67, UiO-67 nanoparticles stored in distilled water were sonicated for 30 min to evenly disperse them. Then, the UiO-67 particles were immersed in a 50 mM AA, 200 mM BGP, 200 mM DEXA, and 10% DMSO ODF mixture and incubated at 25 °C for 72 h in the dark. To coat the FANTA with ODF⊂UiO-67, an oxygen plasma treatment was first performed (electrode: PE; pressure: 5 × 10−2 torr; gas flow rate: 100 sccm; plasma voltage: 100 mW; plasma time: 3 min). The ODF⊂UiO-67 nanoparticles were transferred to distilled water and evenly dispersed in solution through a 2 min sonication treatment (Power: 39 Ampl). This dispersion process was repeated immediately before coating each nanopattern array, and the oxygen plasma treatment was applied within 2 min of coating. Then, the nanopattern arrays were coated with 10 mg/mL UiO-67 (volume: 200 μL) as the optimum concentration for selective UiO-67 trapping on the nanolines, using ASC under various experimental conditions, as described in Fig. 3. Additionally, to achieve complete selective UiO-67 trapping, the substrate was treated with oxygen plasma while blocking the areas where MOF coating was not desired with glass immediately before the coating process. Immediately after treatment, the arrays were rinsed with distilled water to remove UiO-67 particles remaining on the outside, left at room temperature for 2 min, and then washed by spin coating with distilled water for 2 min.

UiO-67 and FANTA characterisation

The size and structures of UiO-67 were measured by field-emission scanning electron microscopy (FE-SEM; SIGMA 300; Carl Zeiss Co., Ltd; Germany). A PXRD pattern analysis was used to confirm the catalytic crystallinity of UiO-67. The pore size, internal space, and specific surface area of UiO-67 nanoparticles were determined using Brunauer–Emmett–Teller analysis (BELSORP-miniX; Verder Scientific, Inc; Germany) based on N2 adsorption. To analyse the structural features of UiO-67, nanopattern arrays, and FANTAs, FE-SEM and atomic force microscopy (NX-10 Complete AFM; Park Systems Corp.; South Korea) were used. Furthermore, energy-dispersive X-ray spectrometry (JEOL Ltd; United States) was performed to chemically characterise UiO-67-coated FANTA based on several elements, including Zr.

MSC cultivation and differentiation

Before seeding MSCs onto the treatment substrates, i.e., ITO-coated glass, nanoline arrays, FANTAs, and ODF-FANTAs, several preparations were required to cultivate the cells in the desired positions. First, 7.8 mm diameter polystyrene chambers capable of limiting cell cultures to specific areas were attached to the centre of the ITO-coated glass, nanoline arrays, and FANTAs using a 10:1 PDMS–curing agent solution, and subsequently, a 70 °C, 1 h thermal curing step was performed. As an alternative method, considering the potential thermal denaturation of ODFs during the thermal curing step in ODF-FANTAs, chambers inserted in a PDMS block (PDMS with curing agents at 30:1) were pressed onto the ODF-FANTA, enabling chamber attachment without the thermal curing step. Then, all groups with attached chambers were sterilised using ethanol and UV treatments. Specifically, the substrates were soaked in ethanol, washed with distilled water, and then immediately treated with UV for 30 min. Human MSCs at passage 4 were purchased from the American Type Culture Collection (United States) and cultured using DMEM with 2% foetal bovine serum and 10 μg/mL gentamicin as a normal growth medium. For all substrates, the MSCs were seeded at 1.47 × 104 cells/cm2 and cultured under standard conditions (5% CO2 and 37 °C) with a medium change every 2 d. In the ITO-coated glass, nanoline array, and FANTA groups, osteogenic or adipogenic differentiation began after cellular confluence reached 75–80%. The osteogenic differentiation medium for these groups contained 50 μM AA, 10 mM BGP, and 100 nM DEXA and was supplied for four weeks, being replaced every 2 d. In the ODF-FANTA group, osteogenic differentiation was induced for four weeks in the normal growth medium without any additional ODFs. For adipogenic differentiation, at 85–90% confluence, adipogenic differentiation medium was supplied for two weeks, being replaced every 3 d, in all groups.

Spatially controlled multicellular differentiation on ODF-FANTAs

Spatially controlled multicellular differentiation was achieved on ODF-FANTAs through the combined use of an adipogenic differentiation medium and the automatic ODF supply from the embedded ODF⊂UiO-67 particles. First, a PDMS block (PDMS–curing agents at 10:1) with an inserted chamber was attached to hierarchical nanopattern arrays in which adjacent nanohole and nanoline patterns each represented half of the total area of the nanopattern array. Then, the substrate with the attached chamber was sterilised with ethanol and UV treatments, and MSCs were seeded on the substrate at a density of 1.47 × 104 cells/cm2. On the fourth to fifth day of culture, when cell confluency reached 75–80%, the adipogenic differentiation medium was applied. Differentiation then proceeded for 14 d with media replacement every 3 d.

Analysis of MSC differentiation

Several tools, including staining assays, immunocytochemistry, and RT-qPCR, were used to monitor the osteogenic and adipogenic differentiation of the MSCs. To quantitatively analyse calcium deposits in the differentiated cells through ARS staining, the cells were first washed once with PBS and fixed by incubation in 10% neutral-buffered formalin at room temperature for 15 min. Then, 300 μL of a 40 mM ARS solution was applied to the fixed cells, and the system was incubated at room temperature for 20 min with shaking at 200 rpm. Next, the cells were washed five times with PBS, and ARS staining was visualised under a microscope. To quantify ARS staining, 300 μL of 10% cetylpyridinium chloride was added, and the ARS-stained cells were incubated for 30 min to extract the ARS stain from cells. The ARS solution extracted from each substrate was diluted to 1/10 with 10% CPC, and the absorbance of the solution was read at 570 nm. To monitor osteogenic differentiation, the relative expression of ALP, RUNX2, and OCN, as early, middle, and late markers of osteogenesis, respectively, was quantitatively and qualitatively examined. To analyse gene expression, cells attached to the substrate were first lysed using RLT buffer containing β-mercaptoethanol at 20 mM. Then, RNA was synthesised from the cell lysate using an RNA synthesis kit (QIAGEN GmbH; Germany) and used to produce cDNA using a cDNA synthesis kit (TAKARA BIO INC.; Japan). Next, the expression of specific genes in the synthesised cDNA was analysed using reverse transcription quantitative polymerase chain reaction (RT-qPCR). To analyse adipogenic differentiation, an ORO solution (ORO–distilled water at 2:3) was applied to fixed cells, and they were incubated at room temperature for 30 min to stain lipid droplets in cells differentiated by adipogenesis. Then, the dyed substrate was washed more than five times with distilled water. The ORO-stained adipocytes were then immediately observed under a microscope. To quantify ORO staining, the substrates were incubated in isopropanol at room temperature for 30 min to extract ORO from the cells, and the absorbance of the extract at 518 nm was measured. Additionally, to analyse the number and size of lipid droplets produced in differentiated adipocytes, fixed cells were stained with BODIPY. Finally, BODIPY-stained cell images were used to analyse the numbers and sizes of lipid droplets using ImageJ software.

Reporting summary

Further information on research design is available in the Nature Portfolio Reporting Summary linked to this article.

References

Festing, S. & Wilkinson, R. The ethics of animal research: talking point on the use of animals in scientific research. EMBO Rep. 8, 526–530 (2007).

Griesinger, C., Desprez, B., Coecke, S., Casey, W. & Zuang, V. Validation of alternative in vitro methods to animal testing: concepts, challenges, processes and tools. Validation of Alternative Methods for Toxicity Testing, 65-132 (2016).

Gross, D. & Tolba, R. H. Ethics in animal-based research. Eur. Surgical Res. 55, 43–57 (2015).

Martignoni, M., Groothuis, G. M. & de Kanter, R. Species differences between mouse, rat, dog, monkey and human CYP-mediated drug metabolism, inhibition and induction. Expert Opin. drug Metab. Toxicol. 2, 875–894 (2006).

Akhtar, A. The flaws and human harms of animal experimentation. Camb. Q. Healthc. Ethics 24, 407–419 (2015).

Doke, S. K. & Dhawale, S. C. Alternatives to animal testing: a review. Saudi Pharm. J. 23, 223–229 (2015).

Ebert, A. D. & Svendsen, C. N. Human stem cells and drug screening: opportunities and challenges. Nat. Rev. Drug Discov. 9, 367–372 (2010).

Park, J.-C. et al. A logical network-based drug-screening platform for Alzheimer’s disease representing pathological features of human brain organoids. Nat. Commun. 12, 280 (2021).

Arora, T. et al. Substitute of animals in drug research: an approach towards fulfillment of 4R’s. Indian journal of pharmaceutical sciences 73, (2011).

Huh, D. et al. Reconstituting organ-level lung functions on a chip. Science 328, 1662–1668 (2010).

Fujii, M. & Sato, T. Somatic cell-derived organoids as prototypes of human epithelial tissues and diseases. Nat. Mater. 20, 156–169 (2021).

Shin, J. et al. Monolithic digital patterning of polydimethylsiloxane with successive laser pyrolysis. Nat. Mater. 20, 100–107 (2021).

Ingber, D. E. Human organs-on-chips for disease modelling, drug development and personalized medicine. Nat. Rev. Genet. 23, 467–491 (2022).

Ju, F. N. et al. Gold nanostructure-integrated conductive microwell arrays for uniform cancer spheroid formation and electrochemical drug screening. Biosens. Bioelectron. 222, 115003 (2023).

Hayashi, R. et al. Generation of 3D lacrimal gland organoids from human pluripotent stem cells. Nature 605, 126–131 (2022).

Miura, Y. et al. Generation of human striatal organoids and cortico-striatal assembloids from human pluripotent stem cells. Nat. Biotechnol. 38, 1421–1430 (2020).

Cho, Y.-W. et al. Single metal-organic framework–embedded nanopit arrays: a new way to control neural stem cell differentiation. Sci. Adv. 8, eabj7736 (2022).

Hayashi, R. et al. Co-ordinated ocular development from human iPS cells and recovery of corneal function. Nature 531, 376–380 (2016).

Mahla, R. S. Stem cells applications in regenerative medicine and disease therapeutics. Int. J. cell Biol. 1, 6940283 (2016).

Zakrzewski, W., Dobrzyński, M., Szymonowicz, M. & Rybak, Z. Stem cells: past, present, and future. Stem cell Res. Ther. 10, 1–22 (2019).

Imaizumi, T. et al. Ocular instillation of conditioned medium from mesenchymal stem cells is effective for dry eye syndrome by improving corneal barrier function. Sci. Rep. 13, 13100 (2023).

Rana, D., Kumar, S., Webster, T. J. & Ramalingam, M. Impact of induced pluripotent stem cells in bone repair and regeneration. Curr. Osteoporos. Rep. 17, 226–234 (2019).

Han, Y. et al. Mesenchymal stem cells for regenerative medicine. Cells 8, 886 (2019).

Kim, H. J. & Park, J.-S. Usage of human mesenchymal stem cells in cell-based therapy: advantages and disadvantages. Dev. Reprod. 21, 1 (2017).

Wei, X. et al. Mesenchymal stem cells: a new trend for cell therapy. Acta Pharmacologica Sin. 34, 747–754 (2013).

Brown, C. et al. Mesenchymal stem cells: Cell therapy and regeneration potential. J. tissue Eng. regenerative Med. 13, 1738–1755 (2019).

Vahedi, P. et al. The use of infrapatellar fat pad-derived mesenchymal stem cells in articular cartilage regeneration: a review. Int. J. Mol. Sci. 22, 9215 (2021).

Jaiswal, N., Haynesworth, S. E., Caplan, A. I. & Bruder, S. P. Osteogenic differentiation of purified, culture‐expanded human mesenchymal stem cells in vitro. J. Cell. Biochem. 64, 295–312 (1997).

Muruganandan, S., Roman, A. A. & Sinal, C. J. Adipocyte differentiation of bone marrow-derived mesenchymal stem cells: Cross talk with the osteoblastogenic program. Cell. Mol. Life Sci. 66, 236–253 (2009).

Kratchmarova, I., Blagoev, B., Haack-Sorensen, M., Kassem, M. & Mann, M. Mechanism of divergent growth factor effects in mesenchymal stem cell differentiation. Science 308, 1472–1477 (2005).

Shibata, S. et al. The secretome of adipose-derived mesenchymal stem cells attenuates epithelial–mesenchymal transition in human corneal epithelium. Regenerative Ther. 11, 114–122 (2019).

Nho, Y., Kim, J. Y., Khang, D., Webster, T. J. & Lee, J. E. Adsorption of mesenchymal stem cells and cortical neural stem cells on carbon nanotube/polycarbonate urethane. Nanomedicine 5, 409–417 (2010).

Machado-Paula, M. M. et al. Rotary jet-spun polycaprolactone/hydroxyapatite and carbon nanotube scaffolds seeded with bone marrow mesenchymal stem cells increase bone neoformation. ACS Appl. Bio Mater. 5, 1013–1024 (2022).

Dalby, M. J. et al. The control of human mesenchymal cell differentiation using nanoscale symmetry and disorder. Nat. Mater. 6, 997–1003 (2007).

Oh, S. et al. Stem cell fate dictated solely by altered nanotube dimension. PNAS 106, 2130–2135 (2009).

Luo, J. et al. The influence of nanotopography on cell behaviour through interactions with the extracellular matrix – A review. Bioact. Mater. 15, 145–159 (2022).

McKee, C. & Chaudhry, G. R. Advances and challenges in stem cell culture. Colloids Surf. B: Biointerfaces 159, 62–77 (2017).

Duval, K. et al. Modeling physiological events in 2D vs. 3D cell culture. Physiology 32, 266–277 (2017).

Dakhore, S., Nayer, B. & Hasegawa, K. Human pluripotent stem cell culture: current status, challenges, and advancement. Stem cells international 2018 (2018).

Cahan, P. & Daley, G. Q. Origins and implications of pluripotent stem cell variability and heterogeneity. Nat. Rev. Mol. cell Biol. 14, 357–368 (2013).

Sohn, S., Buskirk, M. V., Buckenmeyer, M. J., Londono, R. & Faulk, D. Whole organ engineering: approaches, challenges, and future directions. Appl. Sci. 10, 4277 (2020).

Wang, X., Yan, Y. & Zhang, R. Recent trends and challenges in complex organ manufacturing. Tissue Eng. Part B: Rev. 16, 189–197 (2010).

Danhier, P. et al. Influence of cell detachment on the respiration rate of tumor and endothelial cells. PLoS One 8, e53324 (2013).

Ruiz, S. A. & Chen, C. S. Emergence of patterned stem cell differentiation within multicellular structures. Stem cells 26, 2921–2927 (2008).

Guillotin, B. & Guillemot, F. Cell patterning technologies for organotypic tissue fabrication. Trends Biotechnol. 29, 183–190 (2011).

Lee, H. & Cho, D.-W. One-step fabrication of an organ-on-a-chip with spatial heterogeneity using a 3D bioprinting technology. Lab a Chip 16, 2618–2625 (2016).

Mansoorifar, A., Gordon, R., Bergan, R. C. & Bertassoni, L. E. Bone‐on‐a‐chip: microfluidic technologies and microphysiologic models of bone tissue. Adv. Funct. Mater. 31, 2006796 (2021).

Ao, Z. et al. Human spinal organoid-on-a-chip to model nociceptive circuitry for pain therapeutics discovery. Anal. Chem. 94, 1365–1372 (2021).

Lee, J.-H. et al. Production of human spinal-cord organoids recapitulating neural-tube morphogenesis. Nat. Biomed. Eng. 6, 435–448 (2022).

Wu, W. et al. Decellularized brain extracellular matrix hydrogel aids the formation of human spinal-cord organoids recapitulating the complex three-dimensional organization. ACS Biomater. Sci. Eng. 10, 3203–3217 (2024).

Gribaudo, S. et al. Self-organizing models of human trunk organogenesis recapitulate spinal cord and spine co-morphogenesis. Nat. Biotechnol. 42, 1243–1253 (2023).

Abagnale, G. et al. Surface topography enhances differentiation of mesenchymal stem cells towards osteogenic and adipogenic lineages. Biomaterials 61, 316–326 (2015).

Park, K. S. et al. Mass‐producible nano‐featured polystyrene surfaces for regulating the differentiation of human adipose‐derived stem cells. Macromol. Biosci. 12, 1480–1489 (2012).

Loye, A. M. et al. Regulation of mesenchymal stem cell differentiation by nanopatterning of bulk metallic glass. Sci. Rep. 8, 8758 (2018).

Wu, Y.-N. et al. Substrate topography determines the fate of chondrogenesis from human mesenchymal stem cells resulting in specific cartilage phenotype formation. Nanomed.: Nanotechnol., Biol. Med. 10, 1507–1516 (2014).

Camarero-Espinosa, S. & Cooper-White, J. J. Combinatorial presentation of cartilage-inspired peptides on nanopatterned surfaces enables directed differentiation of human mesenchymal stem cells towards distinct articular chondrogenic phenotypes. Biomaterials 210, 105–115 (2019).

Engler, A., Sweeney, H., Discher, D. & Schwarzbauer, J. Extracellular matrix elasticity directs stem cell differentiation. J. Musculoskelet. Neuronal Interact. 7, 335 (2007).

Du, J. et al. Integrin activation and internalization on soft ECM as a mechanism of induction of stem cell differentiation by ECM elasticity. Proc. Natl Acad. Sci. 108, 9466–9471 (2011).

Smith, L. R., Cho, S. & Discher, D. E. Stem cell differentiation is regulated by extracellular matrix mechanics. Physiology 33, 16–25 (2018).

Ding, S., Kingshott, P., Thissen, H., Pera, M. & Wang, P. Y. Modulation of human mesenchymal and pluripotent stem cell behavior using biophysical and biochemical cues: a review. Biotechnol. Bioeng. 114, 260–280 (2017).

Liang, N. et al. Biomimetic metal−organic frameworks as targeted vehicles to enhance osteogenesis. Adv. Healthc. Mater. 11, 2102821 (2022).

Sun, Y. et al. Tunable and controlled release of cobalt ions from metal–organic framework hydrogel nanocomposites enhances bone regeneration. ACS Appl. Mater. Interfaces 13, 59051–59066 (2021).

Eom, Y.-S., Park, J.-H. & Kim, T.-H. Recent advances in stem cell differentiation control using drug delivery systems based on porous functional materials. J. Funct. Biomater. 14, 483 (2023).

Yu, D. et al. Hydrogen-bonded organic framework (HOF)-based single-neural stem cell encapsulation and transplantation to remodel impaired neural networks. Angew. Chem. Int. Ed. 61, e202201485 (2022).

Bhunia, S., Jaiswal, M. K., Singh, K. A., Deo, K. A. & Gaharwar, A. K. 2D covalent organic framework direct osteogenic differentiation of stem cells. Adv. Healthc. Mater. 11, 2101737 (2022).

Si, Y. et al. An efficient metal–organic framework-based drug delivery platform for synergistic antibacterial activity and osteogenesis. J. Colloid Interface Sci. 640, 521–539 (2023).

Yang, H. et al. Delivery of miRNAs through metal–organic framework nanoparticles for assisting neural stem cell therapy for ischemic stroke. ACS nano 16, 14503–14516 (2022).

Sun, C.-Y., Qin, C., Wang, X.-L. & Su, Z.-M. Metal-organic frameworks as potential drug delivery systems. Expert Opin. drug Deliv. 10, 89–101 (2013).

Travlos, G. S. Normal structure, function, and histology of the bone marrow. Toxicol. Pathol. 34, 548–565 (2006).

Kisuk, Y. et al. Nanotopographical manipulation of focal adhesion formation for enhanced differentiation of human neural stem cells. ACS Appl. Mater. interfaces 5, 10529–10540 (2013).

Kim, M.-J. et al. BMP-2 peptide-functionalized nanopatterned substrates for enhanced osteogenic differentiation of human mesenchymal stem cells. Biomaterials 34, 7236–7246 (2013).

Gong, T. et al. Nanomaterials and bone regeneration. Bone Res. 3, 1–7 (2015).

Becerra‐Bayona, S. M., Guiza‐Arguello, V. R., Russell, B., Höök, M. & Hahn, M. S. Influence of collagen‐based integrin α1 and α2 mediated signaling on human mesenchymal stem cell osteogenesis in three dimensional contexts. J. Biomed. Mater. Res. Part A 106, 2594–2604 (2018).

During, A., Penel, G. & Hardouin, P. J. P. i. l. r. Understanding the local actions of lipids in bone physiology. Prog. lipid Res. 59, 126–146 (2015).

Kan, B. et al. Association between lipid biomarkers and osteoporosis: a cross-sectional study. BMC Musculoskelet. Disord. 22, 1–8 (2021).

Acknowledgements

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government, the Ministry of Science and ICT (MSIT) (Grant No. NRF-2022R1A4A2000776), the Nano & Material Technology Development Program through the NRF funded by the MSIT (Grant No. RS-2024-00410437), and Korean ARPA-H Project through the Korea Health Industry Development Institute (KHIDI), funded by the Ministry of Health & Welfare, Republic of Korea (Grant No. RS-2024-00512240).

Author information

Authors and Affiliations

Contributions

These authors contributed equally: Y.-W.C., M.-J.K., and T.-H.K. conceived the idea and designed all the experiments. Y.-W.C. and M.-J.K. provided materials and performed the experiments. Y.-W.C. and M.-J.K. fabricated the ODF-FANTAs with nanopattern arrays and UiO-67 particles. Y.-W.C., J.-H.P., and Y.-S.E. conducted the characterisations of UiO-67 particles and FANTAs. Y.-W.C. and M.-J.K. performed most biological experiments, including immunocytochemistry and RT-qPCR analyses under the supervision of T.-H.K. M.-J.K. monitored the long-term storage and release of ODFs from UiO-67 particles under the supervision of T.-H.K., Y.-W.C. and M.-J.K. arranged the data. Y.-W.C., M.-J.K., J.-H.P., and T.-H.K. performed data analysis and wrote the manuscript. All the authors have reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Kristopher Kilian, who co-reviewed with Bram Soliman; and the other, anonymous, reviewer for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Cho, YW., Kang, MJ., Park, JH. et al. Spatially controlled multicellular differentiation of stem cells using triple factor-releasing metal–organic framework-coated nanoline arrays. Nat Commun 16, 1389 (2025). https://doi.org/10.1038/s41467-025-56373-0

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-025-56373-0