Abstract

Despite numerous efforts involving surface coating, doping, and alloying, maintaining surface stability of metal at high temperatures without compromising intrinsic properties has remained challenging. Here, we present a pragmatic method to address the accelerated oxidation of Cu, Ni, and Fe at temperatures exceeding 200 °C. Inspired by the concept that oxygen (O) itself can effectively obstruct the pathway of O infiltration, this study proposes the immobilization of O on the metal surface. Through extensive calculations considering various elements (C, Al, Si, Ge, Ga, In, and Sn) to anchor O on Cu surfaces, Si emerges as the optimal element. The theoretical findings are validated through systematic sputtering deposition experiments. The introduction of anchoring elements to reinforce Cu–O bonds enables the formation of an atomically thin barrier on the Cu surface, rendering it impermeable to O even at high temperatures (400 °C) while preserving its intrinsic conductivity. This oxidation resistance, facilitated by the impermeable atomic monolayer, opens promising opportunities for researchers and industries to overcome limitations associated with the use of oxidizable metal films.

Similar content being viewed by others

Introduction

While metals like Cu, Ni, and Fe are extensively used in various applications, their susceptibility to oxidation, especially in harsh environments, limits their broader utility. The degradation process is aggravated in harsh environments. The quest for metals that can maintain purity and properties under extreme thermal and chemical conditions fuels the search for alternatives to noble metals. While alloying and electroplating are common methods to combat oxidation1,2,3,4, attempts to develop surface passivation alternatives using organic molecules, inorganic compounds, or C-based materials have been numerous5,6,7,8,9,10,11,12.

Recently, a solvothermal treatment of Cu using sodium formate introduced crystallographic reconstruction of the Cu surface13. However, achieving passivated Cu capable of withstanding harsh high-temperature environments while retaining intrinsic physical properties has remained elusive within existing paradigms. In this study, we present a cost-effective, scalable, and easily adaptable methodology for achieving the high-temperature oxidation resistance (HTOR) of metal films. The approach involves forming an atomically thin skin layer, where oxygen (O) itself acts as a barrier to block O passage, while specific elements serve as anchors to immobilize the O.

To identify an appropriate anchoring element, we employed a materials design approach using density functional theory (DFT). Calculations with elements exhibiting strong O bonding potential, including C, Al, Si, Ge, Ga, In, and Sn, showed that Si emerged as the most suitable anchoring element. Subsequent experimental trials involved uniformly sputtering Si atoms onto oxidizable metals, revealing Si’s robust anchoring capability in preventing oxidation even at temperatures exceeding 400 °C, irrespective of the surface state or crystallinity of the oxidizable metal. Metals treated with Si showed no structural degradation or noticeable loss of electrical properties. Microscopy and theoretical modeling unveiled that HTOR originates from the formation of an atomically thin Si–Cu–O layer, named SiCuOx, on the surface.

Results

Blocking O passage using O self-passivation and an anchoring element

Preventing high-temperature oxidation of oxidizable metals is challenging. Despite surface coatings or alloying attempts, O can still infiltrate a metal due to its relatively small size compared to metal elements, allowing it to move within the metal. However, the mere entry of O does not immediately trigger oxidation. When the O-to-Cu atomic ratio exceeds a certain threshold14 or ambient temperature increases, oxygen readily penetrates the copper lattice, leading to oxidation. To address this, we devised a unique strategy using O itself to prevent high-temperature oxidation. Even under a vacuum, some O becomes physically adsorbed, enveloping the Cu surface. The adsorbed O ions then form Cu–O bonds at the surface, suggesting they might be able to act as a thinnest sealant agent blocking the passage of further O infiltration if they could be held in place by an anchoring element (Fig. 1a).

a Schematic model of the surface bonding of Si-deposited SCCF. b The energy profiles of O penetration into pristine SCCF and the Si-, Al-, Ge- and Ga-deposited SCCF. An activation energy higher than that of the pristine SCCF indicates the enhanced oxidation resistance of the anchoring element. Note that the energy calculations were performed using the atomistic models containing a triple layer of anchoring element–oxygen–Cu(111) surface, which are detailed in Supplementary Fig. 1. Source data are provided as a Source Data file. c Oxidation-driven color changes of SCCFs with thermal treatment at different temperatures in air. The A1-A6 represent a pristine SCCF (A1) heated at 200 °C for 5 min (A2), 200 °C for 10 min (A3), 260 °C for 1.5 min (A4), 300 °C for 3 min (A5) and 300 °C for 30 min (A6). d Invariant color of Si-deposited SCCFs under harsher conditions, indicating exceptional HTOR. The B1-B6 represent a 5 nm Si-deposited SCCF (B1) heated at 200 °C and 300 °C for 30 min (B2, B3), and a 10 nm Si-deposited SCCF (B4) heated at 200 °C and 400 °C for 30 min (B5, B6). For each designated temperature point, more than 10 experiments were conducted on fresh samples. Visual inspection indicated that the ten samples at each individual temperature were virtually identical.

To seek potential O-anchoring elements, a model of an anchoring system was developed in which the sealant O and the anchor layer were adsorbed onto a Cu(111) thin film. The binding energy of the anchor element was calculated using DFT for elements including C, Al, Si, Ge, Ga, and In (Supplementary Fig. 1). Of these, C and In had positive binding energies with Cu–O, indicating weak binding, whereas Ge, Ga, Si, and Al had negative binding energies, indicating strong binding with Cu–O (Supplementary Fig. 1). For the anchoring elements with negative binding energies, we constructed a model with a more realistic anchoring layer and calculated its oxidation resistance by calculating the activation energy of O penetration (Fig. 1b). Although the DFT calculations showed all four candidate elements had enhanced activation energies, the Si and Al anchoring systems had the highest oxidation resistance. Considering the necessity of a single-crystal target for atomic sputtering epitaxy (ASE)14 to achieve uniform atomic dimension surface deposition, Si, Ge, and Al were candidates for experiments. Ultimately, Si was selected as the primary anchoring material due to its availability as commercial wafers, while Al, despite being a single crystal, showed considerable surface oxidation, making uniform Cu surface coating unfeasible. The unavailability of Ge as a single-crystal target necessary for sputtering deposition supported Si as the best choice. The experimental findings are presented in Fig. 1c, d.

High-temperature oxidation resistance of Si-deposited single-crystal Cu thin films

To elucidate the origin of the high-temperature oxidation resistance (HTOR), we first used single-crystal Cu thin films (SCCFs, A1 in Fig. 1c) and Si-deposited SCCFs prepared by ASE (Methods section). Typically, SCCFs exhibit a full-color spectrum by precisely controlling their oxide layer thickness with heat treatment between 240 and 400 °C15, which reflects the coherent propagation of the oxide front on the SCCF surface. After heat treatment of pristine SCCFs (A1) at 200 °C for 5 min (A2), 200 °C for 10 min (A3), 260 °C for 1.5 min (A4), and 300 °C for 3 min (A5), the surfaces appeared vivid orange, plum, red, and yellow, respectively. When the heat treatment was overly high and long, such as 300 °C for 30 min (A6), the Cu film changed completely to a black CuO phase and became brittle16 (Fig. 1c). By contrast, the Si-deposited Cu surface exhibited HTOR. A 5 nm Si-deposited SCCF (B1 in Fig. 1d) retained its original color after heat treatment up to 300 °C for 30 min (B2, B3 in Fig. 1d). A 10 nm Si-deposited SCCF (B4 in Fig. 1d) was also unchanged after treatment up to 400 °C for 30 min (B5, B6 in Fig. 1d), which was the maximum temperature that the Si-deposited SCCF could withstand. More detailed structural information of the area enclosed in the dashed box in B4 and B6 of Fig. 1d is presented in Supplementary Fig. 2, which shows that the treated SCCF surface remains clean without oxidation-induced undulations or grain boundaries. The temperature triggering oxidation increased with the Si thickness to an extent but considering the invariance of physical properties such as conductivity, 10 nm Si was the optimal thickness to achieve HTOR.

X-ray diffraction (XRD) and grazing incidence XRD (GIXRD) analyses were performed to prove whether the structural integrity is sustained under high-temperature heating. Log-scale θ-2θ XRD results (Fig. 2a, b) show that the copper surface remains stable under heating up to 300 °C after Si deposition. When the incidence angle was set to 1° and 0.5° in GIXRD (Fig. 2d, e, g, h), no peak was detected, indicating that the Cu(111) orientation was well maintained up to 300 °C. Even after being heated at 450 °C, there was no significant sign of oxidation in the θ-2θ measurements (Fig. 2c). However, very weak peaks corresponding to (11\(\bar{1}\)) and (111) of CuO phase were detected in GIXRD (Fig. 2f, i), indicating the evidence of oxidation. Nanoscale analyses further confirmed that the Si-deposited SCCF heated at 300 °C showed no noticeable structural and chemical changes compared to the non-heated counterpart (Supplementary Fig. 3a, b). In contrast, when heated to 450 °C, it is revealed that the Si-deposited SCCF suffered from an oxidation-induced structural degradation (Supplementary Fig. 3c).

To understand the surface chemical states of the Si-deposited SCCF with HTOR, depth-profiling X-ray photoelectron spectroscopy (XPS) measurements were performed (Fig. 3). The depth-profiling XPS was carried out at a low etching rate of 0.1 nm/s to minimize damage, and the total thickness of the Si layers was estimated to be approximately 10 nm. The results confirmed that Si exists in a tetravalent state (Si4+, 103.3 eV) mixed with a substantial amount of trivalent state (Si3+, 102.5 eV) and elemental Si0 (99.5 eV) within a thin thickness range on the outermost part (0 s etching) of the deposited layer on the SCCF film (Fig. 3a). This is because the surface exposed to air is prone to undergo oxidation. After etching the initial part of the deposited layer, we discovered that the intermediate Si was mainly reduced to a trivalent state (Si3+, 102.5 eV)17,18. This suggests that the middle section (20 to 80 s etching, corresponding to 2–8 nm in depth) of the deposited Si layer underwent incomplete oxidation to form an amorphous silicon suboxide (SiOx, 0 < x < 2) before reaching the Cu film. More interestingly, we found that the relative portion of Si0 state turned out to be increased at the bottom part of the deposited layer proximate to the SCCF surface. This indicates that non-reacted elemental Si0 is highly concentrated just above the SCCF film. Taking the XPS depth-profiling results into account, three distinctive parts are formed in the deposited layer. Considering that the binding energy of Cu 2p3/2, indicating Cu0 state (932.5 eV)19, remained unchanged across the deposited layer, it is confirmed that the surface of SCCF was not oxidized (Fig. 3b). In samples heated at 300 °C (Fig. 3c), the change in the valence state of Si atoms exhibited similar to the Si-deposited SCCF sample. The outermost layer (0 s etching) predominantly consisted of a tetravalent state (Si4+, 103.3 eV), with a substantial portion of unreacted Si0 (99.5 eV). In contrast, the intermediate layer (2 to 8 nm in depth) displayed the characteristic reduced state (Si3+, 102.5 eV). Interestingly, the elemental Si0 peak present in the Si-deposited sample exhibited a subtle shift toward higher energy following heating. This shift is attributed to the moderate annealing temperature, which results in the minimal oxidation and the presence of lower oxidation states due to adsorbed oxygen. Given that the binding energy of Cu 2p3/2 slightly shifted to higher energy at the upper part of the deposited layer20, some diffused Cu atoms were oxidized. However, the surface of the SCCF remained unaltered (Fig. 3d). In contrast, the sample heated at 450 °C (Fig. 3e) shows a different chemical structure of the deposited layer. The oxidation state of all Si atoms was identified as Si4+, with a tiny portion of Si0, indicating that the whole deposited film at such a high temperature was almost oxidized to form a SiO2 phase. Consistently, the binding energy of Cu 2p3/2 showed a notable shift by ~0.4 eV compared to that of the SCCF film, indicating that all Cu atoms were also oxidized (Fig. 3f). The XPS measurements confirmed that the copper surface can remain stable at 300 °C and underwent a transition to a copper oxide at such a high temperature of 450 °C, consistent with the XRD results. The comprehensive XRD and XPS analyses confirmed that the HTOR effect, which keeps the Cu surface intact, remains stable at least up to 300 °C. Next, to gain insights into atomic-level surface characteristics associated with the origin of HTOR, we utilized advanced microscopy and spectroscopy techniques.

Profiles of Si 2p and Cu 2p peaks for a, b Si-deposited single-crystal Cu thin film (SCCF), c, d post-heated sample at 300 °C for 30 min, and e, f post-heated sample at 450 °C for 30 min, respectively. Note that the depth profiling was conducted at a low etching rate of 0.1 nm/sec to reduce a sputter-damage effect on the sample. The solid lines in Fig. 3a, c, e represented different oxidation states of silicon: black (4+), magenta (3+), green (2+), pink (1+), red (0) and navy (reproduced spectrum). Detailed information regarding the fitting parameters is provided in Supplementary Note 1 in supplementary materials, and source data are provided as a Source Data file.

Atomically thin, chemically modified surface

The characteristics of a Si-deposited SCCF were investigated using annular dark-field scanning transmission electron microscopy (ADF-STEM) combined with electron energy loss spectroscopy (EELS) (Fig. 4)21. The ADF-STEM image (top panel in Fig. 4a) showed the uniform surface of the Si-deposited SCCF. EELS elemental mapping of Si (green), O (red), and Cu (blue) in the film revealed an overlayer consisting of three distinct layers on the SCCF surface (Fig. 4a). The EELS intensity profiles of each element (Fig. 4b) indicated that the overlayer consisted of a SiOx–Si–SiOx triple structure. Low-loss EELS analysis revealed that the three layers were electronically independent and existed as amorphous layers. The spectra of the top and bottom SiOx layers showed a different feature compared to that of the Si layer or Cu film for the low loss energy range (5–35 eV), which is dominated by plasmon generation reflecting information on the local dielectric properties and electron density22. The core-loss EELS analysis for Si L edge further confirmed that the probable formation of either a Cu alloy or a solid solution was ruled out because it revealed the absence of Si diffusion into the Cu film (Supplementary Fig. 4). The ADF-STEM image of the Si-deposited SCCF revealed a flat surface with occasional monoatomic surface steps (Fig. 4c)14. The Cu L2,3 edges after ~930 eV originally exhibit a step-like edge structure because of the almost filled d-band. By contrast, a sharp L3 peak due to the transition of the 2p3/2 to d states is observed in the Cu2O (Fig. 4d). Hence, the change in the Cu bonding state could be detected by tracking the change in the Cu L3 intensity. Figure 4e shows a series of Cu L2,3 edges obtained for each Cu(111) layer from the inside to the surface. Moving to the Cu surface, we observed a slight increase in the L3 peak (see the red profiles). By measuring the intensity of the L3 peak (A) relative to that of the flat level (B) and comparing it with the pristine SCCF (Fig. 4f), we observed that the A/B ratio (red) increased gradually to a high value across the Cu surface compared to that of the untreated SCCF (blue). This implies that Cu atoms at the surface bonded with O atoms chemically.

a (top) Low-magnification annular dark-field (ADF) image and (bottom) electron energy loss spectroscopy elemental maps of Si (green), O (cyan), and Cu (blue) of the Si-deposited SCCF. b Normalized elemental profiles of the three elements. The gray profile of the signal contrast in the ADF image is given in reference to the Cu film. c Atomic resolution ADF image of the Si-treated SCCF showing the atomically clean surface. d Energy loss near edge structures (ELNES) of Cu L2,3 for Cu2O and the untreated SCCF. e Series of Cu L2,3 ELNES obtained across the Si-treated SCCF surface, as indicated by the vertical arrow in (c). f Profiles showing the change in the intensity ratio, A/B, of the Cu L3 (peak A at ~934 eV) to the flat level (peak B at ~940 eV) for the pristine SCCF (violet) and Si-treated SCCF (orange). Note that the A/B ratio of fully oxidized Cu2O is ~1.98 (orange spectrum in d). The solid line denotes the reference of pure Cu. Source data are provided as a Source Data file.

The elemental profiles across the interface between the bottom SiOx and the SCCF (Fig. 4b and Supplementary Fig. 5) show that the O K (red) profile is much delayed toward the SCCF surface than the Si L (green) profile, indicating the bond order of Si–O–Cu linkage formed at the SCCF surface. The corresponding Cu L, O K, and Si L spectra (Supplementary Fig. 5) extracted from the interface region support the formation of the atomic-level triple layer, which might be a core driver of the oxidation resistance. We designate the characteristic surface triple layer with Cu–O–Si linkage as the “SiCuOx” layer and will hereafter refer to these samples with a modified surface as “sioxed” SCCF instead of Si-deposited SCCF. To check whether the atomic-level triple layer contributes to the high-temperature oxidation resistance (HTOR) effect, the sioxed SCCF was heated at 300 °C for 30 min after peeling off the nanoscale SiOx–Si–SiOx triple overlayer (Supplementary Figs. 6 and 7). The result shows that the SCCF surface was maintained without forming oxide, the same as the one with the nanoscale triple overlayer, proving the significant role of the atomic-scale surface-modified layer in realizing the HTOR property. It is worth noting that the formation mechanism of the nanoscale triple overlayer remains elusive and seems inevitable empirically. However, we consider that the weakly bonded bottom SiOx layer has contributed to stably forming the anchor Si-sealant O on the Cu surface, i.e., the SiCuOx layer, for blocking posterior oxidation under high-temperature ambiance.

Surface structure analysis

Increasing the ionic bond character at the Cu surface induces lattice compression due to strong lattice-charge coupling23. To find structural evidence, we performed geometric phase analysis (GPA)24,25 to map the shear strain field distribution (Exy) for the sioxed SCCF (Fig. 5a). The results indicated that the sioxed SCCF had the same structural quality as the untreated SCCF without defects14. To assess the probable change in the Cu bond length at the surface, we measured the projected atomic distance (PAD) for the STEM image26,27,28. The out-of-plane (H) PAD difference map for the sioxed SCCF is shown on the right side of Fig. 5b. Histograms for the three regions (I–III) along the respective in-plane [\(11\bar{2}\)] and out-of-plane [111] directions are given in Fig. 5c, d, which show how the lattice changes towards the surface for in-plane (A) and out-of-plane (H) directions, respectively. For the out-of-plane direction (H), a subtle lattice contraction near the surface was observed (Fig. 5d), whereas no difference was observed for the in-plane direction (A) (Fig. 5c). The estimated magnitude of the out-of-plane contraction was ~6 pm (translating to approximately −2.8% as compressive strain), and the range of the compression extended to three atomic layers deep from the surface, which differed from the pristine SCCF showing no picoscale PAD displacement in any direction (Supplementary Fig. 8a–c). Additional measurements of a Si-treated sample prepared from a different batch showed the same feature (Supplementary Fig. 8d–f). The impact of the compressive strain on the oxygen infiltration was explicitly addressed by the theoretical calculation. (Supplementary Fig. 9) The microscopic and spectroscopic investigations revealed three features of the sioxed SCCF: first, the SCCF surface had HTOR induced by the characteristic surface structure with Si–O–Cu bonds (the SiCuOx skin layer); second, the Cu lattice structure was preserved without the formation of a Cu–Si alloy; and third, characteristic lattice contraction (−2.8%) for the out-of-plane direction was detected at the surface.

a Paired annular dark-field (ADF) images and the corresponding Exy maps for the surface part of the sioxed SCCF. The atomic resolution cross-sectional ADF-STEM images were obtained for the [\(1\bar{1}\)0] orientation, and the strain maps were obtained by geometric phase analysis (GPA). The reference area used to calculate the relative strain is marked by the white box in the map. The irrelevant complex patterns of the carbon film are shaded in gray for clarity. b Out-of-plane projected atomic distance (PAD) map of the sioxed SCCF. The schematic at the top left represents the PAD (A and H = B·cosθ) measurement. Note that the magnitude of the PAD map is expressed by false colors corresponding to the bottom color scale bar for visualization, representing the difference between the measured PADs and the values (A = 2.23 Å and H = 2.11 Å) of bulk Cu. c, d Histograms showing the PAD distribution of A (in-plane distance) and H (out-of-plane distance), obtained for the three regions marked I–III. Gaussian fits are represented by solid lines, while dashed lines denote the mean values of each region. Reproducibility was confirmed through additional measurements conducted on the Si-treated sample prepared from a different batch. e Schematic diagram of the structure of the sioxed Cu(111) thin film. f Structural model of the SiCuOx skin layer showing the side (top) and top (bottom) views. For clarity, the top view was generated after making a crosscut along the dotted line. Brown, red, and violet spheres represent Cu, O, and Si atoms, respectively. Small white spheres represent O atoms in the amorphous SiO2 layer. g Energy profiles of O atoms penetrating the pristine and sioxed SCCF surfaces. Path 1–4 represent slightly different paths the O atoms can take penetrating the sioxed SCCF surfaces. The solid black line denotes the SCCF surface, delineating the boundary between the external and internal structures. The dashed line indicates the region where SiCuOx has formed. Source data are provided as a Source Data file.

Discussion

Theoretical model and interpretation

To elucidate the high-temperature oxidation resistance (HTOR) of sioxed Cu, we used first-principles DFT29,30,31 to construct a microscopic model of the SiCuOx layer based on our experimental observations involving energy minimization of an extensive list of candidates. As noted in our STEM analysis, the SiCuOx layer (the boxed regions in Fig. 5e, f) showed no Si diffusion into the Cu thin film, and the face-centered cubic Cu structure was preserved up to the outermost Cu layer. This also indicated that the SiCuOx layer in direct contact with the Cu thin film was a layer of O atoms, consistent with the STEM-EELS profile analysis (Fig. 4b). The energetically favorable model of SiCuOx also exhibited lattice contraction for the out-of-plane direction across the surface (Supplementary Fig. 9), with a compressive strain of ~5.7%, consistent with the characteristic layer compression phenomenon observed in the sioxed Cu thin film (Fig. 5b–d). Our DFT calculation showed that the optimized structure of SiCuOx had an energetically stable interface with an interface energy of \(-2.72\,{\mbox{eV}}/{\mathring{\rm A} }^{2}\). The energy profile in Fig. 5g shows that the penetration of an O atom through a pristine Cu(111) surface requires an activation energy of 2.71 eV14. For the sioxed Cu thin film, the surface was fully covered with densely populated sealant O atoms blocking all adsorption sites and Si atoms anchoring O atoms in place (Fig. 5f). Due to the self-regulating behavior, diffusion through the SiO2 layer and penetration through the dense SiCuOx layer of external O atoms would be unlikely. Rather, the O atoms in contact with the Cu thin film at the interface would be more likely to infiltrate. Figure 5g shows that there are several different paths for O infiltration with high activation energies. Even along the easiest path, the O atom at the interface requires an activation energy of 5.41 eV to infiltrate into the second subsurface interlayer space (Supplementary Fig. 10). This activation energy exceeds that of the untreated Cu and dramatically reduces the oxidation reaction rate. Note that the activation energy (EA) for O-atom infiltration from the first to second subsurface interlayer space of the sioxed SCCF (2.89 eV) is much higher than that of the untreated SCCF (1.28 eV) (Fig. 5g). The diffusion of O atoms in the interior is hindered because the first few Cu(111) layers near the interface are compressed in the out-of-plane direction and form a hardened crust, as evidenced by the compressive strain observed in our STEM (Supplementary Fig. 8) and theoretical (Supplementary Figs. 9 and 11) data. Our analysis reveals that the HTOR provided by SiCuOx originates from the following three factors, as schematically illustrated in Fig. 5e: The sealant O atoms in the sioxed interface (red O atoms in Fig. 5f) block all entry of additional O atoms into the Cu film; the sealant O atoms in the interface are in turn anchored by Si atoms and require a much higher activation energy to break the bond with Si atoms and infiltrate the Cu film; and SiCuOx compresses the top layers of the Cu film (region I in Fig. 5b). To further elucidate the influence of Si–O-Cu triple bonds on the HTOR, additional DFT calculations for oxygen infiltration were performed when the SiCuOx layer had atomic defects such as Si point and Si–O pair defects. The results revealed that the activation energy for oxygen infiltration into Cu substantially decreases more than 3.6 eV compared to the case of the SiCuOx layer without defects, implying that the formation of atomically uniform SiCuOx layer is crucial for achieving effective HTOR (Supplementary Fig. 12). The bond character analysis shows that the O-atom in the SiCuOx layer is bonded with the anchoring elements much more strongly than the one near Si– or Si–O defects leading to the strong oxidation resistance of the SiCuOx layer (Supplementary Fig. 13).

No electrical degradation and high-temperature oxidation resistance in various forms of oxidizable metals

Figure 6a shows the resistivity of reference samples and sioxed SCCFs after heat treatment. The heat treatments lasted 30 min, and the Si deposited for the measurements was 10 nm thick. The first and second panels show the reference resistivity of three representative materials and the invariant resistivity after SiCuOx treatment, respectively. The last two panels show the critical temperature at or above which pristine and sioxed SCCFs can no longer exhibit high-temperature oxidation resistance (HTOR). Remarkably, the resistivity of the six films was maintained at almost the same value as that of pristine Cu, even after heat treatment up to 420 °C. Moreover, all sioxed samples remained unchanged for up to 60 h at 200 °C (Supplementary Fig. 14). The resistivity value close to that of an insulator after heat treatment above 470 °C indicated that the sioxed film was mostly oxidized above that temperature.

a Resistivity measurement of sioxed SCCFs as a function of temperature and comparison with reference materials and non-treated SCCF. Error bars represented the standard deviation of resistivity measurements obtained from five randomly selected samples. The dashed lines represent the reference resistivity values for bulk Au (\({\rho }_{{Au}}\)) and Cu (\({\rho }_{{Cu}}\)), respectively. Upward arrows indicate divergence of the resistance beyond the conductive regime with increasing heating temperature. Source data are provided as a Source Data file. b HTOR of sioxed Cu foils. c HTOR of a sioxed polycrystalline Cu film deposited and patterned on a polymer substrate for flexible devices. Note that the temperature of 150 °C is the maximum tolerable value for the polymer substrate. d Pictures of Fe foil (upper row) and sioxed Fe foil (bottom row) before and after heat treatment at 300 °C for 30 min. e Pictures of Ni foil (upper row) and sioxed Ni foil (bottom row) before and after heat treatment at 400 °C for 30 min. Scale bars are 5 mm. To ensure statistical validity, each experimental condition was conducted with a minimum of ten samples at each designated temperature. A visual assessment of the samples indicated a consistency in coloration across all replicates.

The HTOR effect in various forms of Cu was again demonstrated to be feasible. When the process was applied to commercial Cu foils (Fig. 6b), polycrystalline Cu grown on a polymer substrate of polyester (Fig. 6c), and polycrystalline Cu film on glass (Supplementary Fig. 15), a useful HTOR effect was observed. The commercial Cu foils generally oxidized when heated at 150 °C for 30 min (Fig. 6b, upper panel, middle) and then completely transformed into CuO, which is black, when heated at 300 °C for 30 min (upper panel, rightmost). In striking contrast, the sioxed foils did not show any color change up to 300 °C after 30 min and only showed a slight discoloration and oxidized phase above 400 °C after 30 min (Fig. 6 and Supplementary Fig. 16). At a moderately high temperature of 200 °C, the sioxed Cu foils withstood oxidation for 60 h or longer. The sioxed polycrystalline Cu on the polyester substrate is stable on heating for several hours at temperatures up to 150 °C, which is the maximum temperature the polyethersulfone (PES) substrate can withstand. Whereas the patterned circuitry using polycrystalline Cu/PES corroded completely after thermal treatment at 150 °C for 30 min (upper panel in Fig. 6), the sioxed Cu/PES showed no corrosion even after thermal treatment at 150 °C for 10 h and maintained the same conductivity after 1,000 bending cycles (lower panel in Fig. 6c). The SiCuOx process notably enhanced oxidation resistance even to Cu-specific etchants (Supplementary Fig. 17). Our extra DFT calculations further show that the sioxing process would give HTOR to Cu thin films with surfaces other than (111) orientation (Supplementary Fig. 18). The above sioxing effects were not limited to Cu but also worked for Fe (Fig. 6d) and Ni (Fig. 6e); thus, the sioxing effect is universally applicable to oxidizable metals. The features of the sioxed Fe and sioxed Ni forming the HTOR were almost the same as those of the sioxed Cu (Supplementary Fig. 19).

In summary, we achieved notable HTOR for Cu adaptable to high-temperature environments. This approach, realized through sputtering deposition of Si under optimized ASE conditions, is reliably applicable to some oxidizable metals (Ni and Fe in this case), ranging from single-crystalline thin films to patterned polycrystalline films and foils with rough surfaces. This versatility ensures a broad spectrum of applications. The HTOR is a result of effectively blocking O pathways by O atoms themselves, anchored in place by Si atoms. The formation of an atomically thin SiMOx layer, stemming from Si–O–M (M = Cu, Ni, or Fe) bonding at the surface, along with a few layers of metal crust hardened during SiMOx formation, further impedes O infiltration. Additionally, sioxed Cu retains the electrical properties and geometric uniformity of pristine Cu. This superior property is sustained up to 400 °C, representing near-permanent corrosion resistance at room temperature. Considering the operating temperature range of 70–125 °C required for all-round harsh-environment electronics32, our approach opens promising avenues for future technologies based on oxidizable metals.

Methods

Film growth and SiMOx treatment

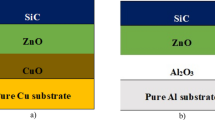

SCCFs were prepared using the ASE technique14,15. The base pressure of the sputtering chamber was maintained at <1.7 × 10−6 Torr and the working pressure at 5.4 × 10−3 Torr. The radio frequency (RF) (13.56 MHz) sputtering power was set to 25 W with an Ar gas flow of 50 sccm. The Ar gas purity was 99.9999% (6 N). A 430-μm-thick double-sided-polished 2-inch (001) Al2O3 wafer was used as the substrate for SCCF growth. The SCCFs grew to thicknesses between 100 and 200 nm at a substrate temperature of 170 °C and a growth rate of ~3 nm/min, which ensured an ultraflat Cu (111) surface with only occasional monoatomic steps14,15. Polycrystalline Cu thin films (PCCFs) were grown on glass substrates under the same sputtering conditions as SCCFs. For the formation of the SiMOx skin layer, Si was deposited on SCCFs, PCCFs, and commercial Cu, Fe, and Ni foils using an RF sputter system with a base pressure of <1.5 × 10−5 Torr and a working pressure of 5.4 × 10−3 Torr. The RF (13.56 MHz) sputtering power was set to 40 W with an Ar gas flow of 20 sccm. Under these conditions, the Si layer was deposited at an average growth rate of ~4 nm/min. For the Cu foil, the Si layer was deposited on both sides of the foil to prevent diffusive propagation of backside oxidation. The substrate temperature in the Si sputtering process was varied from room temperature to 200 °C. To test the effect of organic matter as a substrate, a Si layer was deposited at room temperature on a 188-μm-thick polyester substrate (V7610; SKC, Seoul, South Korea). The etching process for patterning was conducted using an etchant with a mixing ratio of CH3COOH:H2O2:H2O = 1:1:2. We conducted 10 independent repetitions of thermal treatment at each temperature point. Samples were not intentionally excluded, except in cases where they were damaged, such as being scratched on the surface or dropped in the thermal treatment furnace during handling. The sample dimensions were 10 ×10 mm, as a 2-inch wafer could yield 12 samples, and we assessed reproducibility by testing 10 samples from the same batch.

Structural and chemical characterizations

X-ray diffraction (XRD) measurements were performed using a PANalytical Empyrean Series 2 instrument with a Cu–Kα source (40 kV, 30 mA) and a linear detector (Malvern PANalytical, Malvern, UK). Data were collected within the range of 20° <2θ < 80°, with a step size of 0.0167° and a dwell time of 0.5 s per point. For GIXRD, the X’pert PRO MPD (PANalytical, England) instrument of the KBSI Daegu Center was used. Cu K beams served as the X-ray sources (40 kV, 30 mA). Data were collected within the range of 20° <2θ < 70°, with a step size of 0.04°, omega angle of 1° and a dwell time of 2 s per point. Scanning electron microscopy (SEM), EBSD, PF, and IPF measurements were made with a Zeiss SUPRA40 VP with a scanning electron microprobe (Zeiss, Oberkochen, Germany). X-ray photoelectron spectroscopy (XPS; ESCALAB250, Thermo Scientific, Waltham, MA, USA) was used for elemental depth profiling with a multichannel detector covering the energy range 0–1200 eV. The depth profiles were acquired with an energy step size of 0.1 eV and two different acquisition times of 5 and 51.3 s. To check whether the chemical state change was influenced during the sputtering process in XPS analysis, depth profiling was performed using two different ion beams: a finely focused 1 keV Ar+ and an unfocused 5 keV Ar+ broad beam. No noticeable variations in binding energy were observed throughout the depth profiling. The resistivities of the samples were measured using a Hall effect measurement system (Ecopia HMS-3000; Bridge Technologies, Oslo, Norway). For atomic-scale characterization, cross-sectional TEM thin samples were prepared using a focused ion beam system (Helios NanoLab 450 – FEI; Nanolab Technologies, Milpitas, CA, USA), and possibly damaged surface layers were removed from the samples by subsequent low-energy Ar ion beam surface milling at 700 eV for 15 min (Model 1040 NanoMill; Fischione, Export, PA, USA). The atomic structures of the samples were captured in ADF imaging mode using double Cs-corrected STEM (JEM-ARM200CF; JEOL, Tokyo, Japan) operating at 200 kV, equipped with EELS (Quantum ER965; Gatan, Pleasanton, CA, USA) and energy dispersive x-ray spectroscopy (EDX; JED-2300T, JEOL), which were used for chemical analysis of the samples. The angle ranges of the ADF detector and probe convergence semiangle were 45–180 and ~24 mrad, respectively. For quantitative analysis of local strain components in the pristine and sioxed SCCFs, the GPA technique was used, which allows the mapping of two-dimensional local displacement fields by analyzing the phase shift between noncollinear Fourier components of lattice vectors g1 and g2. This GPA mapping with atomic resolution structure images provides information on the relative lattice displacement field at subnanometer resolution. The atomic positions and projected bond lengths were measured from the ADF-STEM images using home-built software with a 1024 × 1024-pixel resolution. The shape of the energy loss near-edge structure (ELNES) of an element sensitively varies in response to the chemical and electronic changes around it14,23. Therefore, to assess the chemical nature of the SCCF surface, we examined the change in the fine structures of the Cu L edge across the surface from the inside of the film using monochromatic STEM (JEM-MonoARM200F; JEOL) at the Korea Basic Science Institute (KBSI). For EELS measurements of the samples, the core-loss EELS spectrum imaging (SI) datasets of the Cu L edge were obtained as 46 × 93 pixels, translated as 15.5 × 31.4 nm2, with a scan step of 0.3 nm from the inside to the surface of the samples. The vertical line scan data across the surface were extracted by horizontally averaging the SI data over a 0.3 nm length. The energy dispersion was 0.25 eV/ch and the dwell time 0.5 s/pix. The selected range of energy loss was set to 475–986 eV, including the O K and Cu L2,3 edges. The random noise in the core-loss spectra was reduced by principal component analysis, which was implemented in a commercial software package (MSA; HREM Research, Tokyo, Japan), and the power-law dependency of the background intensity was removed before signal extraction of the core-loss O K and Cu L2,3 edges. Min–max normalization between 0 and 1 was applied to the core-loss Cu L-edge for the energy loss range from 920 eV to 991 eV. To suppress the exaggerating effect of unrelated noise levels in evaluating the A/B peak ratio, the location-wise Cu L-edge profiles were obtained by averaging the energy width of 0.3 eV. Error bars for the A/B ratio reflect the local statistical variation, captured by the standard deviation of three spectral measurements acquired each single atomic row within the same sample. The low-loss EELS SI dataset for the sioxed SCCF sample was obtained with an energy dispersion of 0.1 eV/ch and a dwell time of 0.005 s/pix at 46 × 93-pixel points with a spatial dimension of 0.3 nm/pix and an energy range of 102 eV, including a zero-loss peak. Nanoscale STEM-EDX maps of the constituent elements of the samples were obtained at a 256 × 256-pixel resolution with a high-efficiency dual Si drift detector x-ray detector system with a 100 mm2 collection window for each detector, and the sample drift during acquisition was corrected by tracking the reference area assigned at the acquisition setup.

Theoretical calculations

All total energy calculations and geometry optimizations were performed with DFT in the generalized gradient approximation using the Perdew–Burke–Ernzerhof exchange-correlation functional29 with the projected augmented plane-wave method30, as implemented in VASP31. The electron wave functions were expanded in a plane-wave basis set with a cutoff energy of 400 eV, and the spin polarization effect was considered in all calculations. The structure of sioxed Cu was constructed as a supercell containing Cu substrate, an interface, a SiO2 layer, and a vacuum. The Cu substrate was represented by a slab of seven layers of a (2 × 2) lateral supercell of Cu(111). The SiO2 layer was represented by a slab of (1 × 1) lateral supercells of SiO2 (001) α-cristobalite (space group p41212). A 12 Å vacuum layer was used to eliminate the interaction between periodic images of the slabs. The exposed O atoms of the SiO2 layer were passivated by H atoms. The bottom three layers of the Cu substrate were fixed in their bulk positions, and the remaining atoms were fully relaxed until the force on each atom was less than 0.001 eV/Å and the change in total energy was less than 10–5 eV\(\,{{\rm{eV}}}\). The Brillouin zone was sampled using a gamma centered 5 × 5 × 1 k-point mesh. The activation energy for O infiltration was calculated using the nudged elastic band method33. The interface energy used to compare the stabilities of different models of the SiCuOx structure was calculated as \({E}_{{\mathrm{int}}}=\left[{E}_{{\mbox{tot}}}-{\sum}_{i}{N}_{i}{\mu }_{i}\right]/A\), where Etot is the total energy of the combined system, A is the lateral area of the supercell, and Ni and μi are the number and chemical potential of the \(i\)-th species, respectively. The atomic coordinates of the optimized computational model were provided as the Supplementary Data 1 in VASP POSCAR file format.

Data availability

The authors declare that the main data supporting the findings of this study are available within the article and its Supplementary Information files. The raw data are deposited in a public repository in Figshare https://doi.org/10.6084/m9.figshare.25237933. Source data are provided with this paper.

References

Naboka, M., Giordano, J. Copper Alloys: Preparation, Properties, and Applications (Nova Science Publishers, 2011).

Davis, J. R. ASM Specialty Handbook: Copper and Copper Alloys (ASM International, 2001).

Lin, C.-H., Teng, P.-J. Corrosion protection of copper foil by Ni-W electrodeposited coating in kaolin slurry. Int. J. Electrochem. Sci. 16, 210646 (2021).

Li, J., Mayer, J. W. & Colgan, E. G. Oxidation and protection in copper and copper alloy thin films. J. Appl. Phys. 70, 2820–2827 (1991).

Karthik, N. & Sethuraman, M. G. Surface protection of copper by allyl thiourea and hybrid sol–gel coatings. Prog. Org. Coat. 90, 380–389 (2016).

Wen, Z. et al. Anticorrosive copper current collector passivated by self‐assembled porous membrane for highly stable lithium metal batteries. Adv. Funct. Mater. 31, 2104930 (2021).

Laibinis, P. E. & Whitesides, G. M. Self-assembled monolayers of n-alkanethiolates on copper are barrier films that protect the metal against oxidaton by air. J. Am. Chem. Soc. 114, 9022–9028 (1992).

Khan, M. H. et al. Atomically thin hexagonal boron nitride nanofilm for Cu protection: the importance of film perfection. Adv. Mater. 29, 1603937 (2017).

Niu, Z. et al. Ultrathin epitaxial Cu@Au core-shell nanowires for stable transparent conductors. J. Am. Chem. Soc. 139, 7348–7354 (2017).

Chen, S. et al. Oxidation resistance of graphene-coated Cu and Cu/Ni Alloy. ACS Nano 5, 1321–1327 (2011).

Cui, C., Lim, A. T. O. & Huang, J. A cautionary note on graphene anti-corrosion coatings. Nat. Nanotechnol. 12, 834–835 (2017).

Berg, I., Amit, E., Hale, L., Toste, F. D. & Gross, E. N-heterocyclic carbene nanolayer for copper film oxidation mitigation. Angew. Chem. Int Ed. Engl. 61, e202201093 (2022).

Peng, J. et al. Surface coordination layer passivates oxidation of copper. Nature 586, 390–394 (2020).

Kim, S. J. et al. Flat-surface-assisted and self-regulated oxidation resistance of Cu(111). Nature 603, 434–438 (2022).

Kim, S. J. et al. Color of copper/copper oxide. Adv. Mater. 33, e2007345 (2021).

De Los Santos Valladares, L. et al. Crystallization and electrical resistivity of Cu2O and CuO obtained by thermal oxidation of Cu thin films on SiO2/Si substrates. Thin Solid Films 520, 6368–6374 (2012).

Czernohorsky, M. et al. X-ray photoelectron spectroscopy: Towards reliable binding energy referencing. Microelectron. Eng. 178, 262–265 (2017).

Riam Abu M., Heterojunction-based hybrid silicon nanowires solar cell, In Solar Cells (Intech Open, 2019).

Torres-Ochoa, J. A. et al. Peak-fitting of Cu 2p photoemission spectra in Cu0, Cu1+, and Cu2+ oxides: A method for discriminating Cu0 from Cu1+. Appl. Surf. Sci. 622, 156960 (2023).

Espinós, J. P. et al. Interface effects for Cu, CuO, and Cu2O deposited on SiO2 and ZrO2. XPS determination of the valence state of copper in Cu/SiO2 and Cu/ZrO2 catalysts. J. Phys. Chem. B 106, 6921–6929 (2002).

Pennycook, S. J. et al. Material structure, properties, and dynamics through scanning transmission electron microscopy. J. Anal. Sci. Technol. 9, 11 (2018).

Borisevich, A. Y. et al. Suppression of octahedral tilts and associated changes in electronic properties at epitaxial oxide heterostructure interfaces. Phys. Rev. Lett. 105, 087204 (2010).

Kim, Y. M. et al. Direct observation of ferroelectric field effect and vacancy-controlled screening at the BiFeO3/LaxSr1-xMnO3 interface. Nat. Mater. 13, 1019–1025 (2014).

Hytch, M. J., Snoeck, E. & Kilaas, R. Quantitative measurement of displacement and strain fields from HREM micrographs. Ultramicroscopy 74, 131–146 (1998).

Kim, Y. M., Lee, S. B., Lee, J. & Oh, S. H. Direct observation of an electrically degenerate interface layer in a GaN/sapphire heterostructure. Nanoscale 11, 8281–8292 (2019).

Kim, Y. M. et al. Probing oxygen vacancy concentration and homogeneity in solid-oxide fuel-cell cathode materials on the subunit-cell level. Nat. Mater. 11, 888–894 (2012).

Kim, Y. I. et al. Atomic-scale identification of invisible cation vacancies at an oxide homointerface. Mater. Today Phys. 16, 100302 (2021).

Kim, Y. H. et al. Self-oxidation resistance of the curved surface of achromatic copper. Adv. Mater. 35, e2210564 (2023).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Blochl, P. E. Projector augmented-wave method. Phys. Rev. B Condens Matter 50, 17953–17979 (1994).

Kresse, G. & Furthmuller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169–11186 (1996).

Ohadi, M., Jianwei Q. thermal management of harsh-environment electronics. In 20th IEEE SEMI-THERM Symposium (2004).

Henkelman, G. & Jónsson, H. Improved tangent estimate in the nudged elastic band method for finding minimum energy paths and saddle points. J. Chem. Phys. 113, 9978–9985 (2000).

Acknowledgements

This work was supported by Samsung Research Funding & Incubation Center of Samsung Electronics under Project Number SRFC-MA2202-02 for S.-Y.J., the Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Science, ICT & Future Planning (no. NRF−2022R1I1A1A01071367 and RS−2023-00301938 (LAMP) for S.J.K.; NRF−2023R1A2C2002403 for Y.-M.K.; NRF−2020R1A5A1016518 for M.-J.S.; and NRF−2021R1A5A1032937, RS−2024-00406152, and RS-2024-00455226 for S.-Y.J.) through the National Research Foundation of Korea (NRF). Y.-M.K. acknowledges the support of the Institute for Basic Science (IBS-R036-D1). Computer time allocation was provided by the High-Performance Computing Center (HPCC) for S.-G.K. at Mississippi State University. M.C. acknowledges support from the US Department of Energy (DOE), Office of Science, Basic Energy Sciences (BES), Division of Materials Sciences and Engineering.

Author information

Authors and Affiliations

Contributions

S.-Y.J. and S.J.K. conceived this work. S.-Y.J., Y.-M.K., and S.-G.K. supervised the work and wrote the manuscript. S.J.K. and Y.L. performed thin film growths and prepared sioxed samples. Y.-H.K., J.H.J., and Y.-M.K. performed STEM, EDX, and EELS analyses. Y.-H.K., and S.-H.Y. developed Python-based home-built code. M.-H.J., Seon J.K. and H.Y.J. conducted TEM sample preparation. S.J.K. and Y.L. performed EBSD and XPS experiments and Y.-H.K. assisted with the data analyses. M.C., M.-J.S. and H.S.C. performed data interpretation. S.-Y.J. and S.-G.K. established the theoretical model, and S.-G.K., B.L. and B.R. carried out first-principles calculations. All authors participated in the manuscript review.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks the anonymous reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Kim, S.J., Kim, YH., Lamichhane, B. et al. An impermeable copper surface monolayer with high-temperature oxidation resistance. Nat Commun 16, 1462 (2025). https://doi.org/10.1038/s41467-025-56709-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-025-56709-w