Abstract

The escalating food and water crisis, propelled by population growth, urbanization, and climate change, demands a reimagining of agricultural practices. Traditional water-saving irrigation methods have reached their limits, necessitating the exploration of innovative approaches. This perspective explores the potential of utilizing excess light and water in greenhouse cultivation through advanced materials and engineering technologies. We investigate the potential of four key technologies—sorption-based atmosphere water harvesting (SAWH), superabsorbent polymer water holding materials (SPWH), radiative cooling (RC), and seawater desalination. The perspective proposes suitable application methods and future development directions for greenhouse water conservation, aiming to introduce novel water-saving strategies and smarter resource management.

Similar content being viewed by others

Introduction

As global integration advances, the intricate relationship between food and water resources is becoming more complex. Projections indicate a yearly increase of 83 million in the global population, reaching 9.8 billion by 20501,2. This demographic expansion directly leads to an increasing demand for tangible goods, with global food requirements expected to surge by 100–110% from current levels by 20503,4. Concurrently, the annual deficit in water resources poses a formidable challenge to food supply, impacting over two billion individuals in nations grappling with inadequate water supplies5,6. Alarming forecasts suggest that by 2025, half of the world’s population may find themselves residing in regions confronting water scarcity7. Agriculture is a major contributor to global water consumption, accounting for ~70% of human water use8. Consequently, the development of resource-saving agriculture and the reduction of water usage in greenhouse cultivation have emerged as pivotal research directions. The primary focus is on formulating strategies to optimize the utilization of finite resources, thereby promoting sustainability in agricultural practices.

Greenhouses, as a typical representative of modern agriculture, utilize light-transmitting covering materials to construct either full or partial enclosed structures9. Compared to conventional farming methods, greenhouses exhibit reduced water consumption, ensuring sustainable and secure food production10. Notably, greenhouse cultivation can achieve agricultural water savings of 50% to 90%11. This reduction is primarily achieved through air humidification within the greenhouse, facilitated by long-wave radiation cooling which elevates humidity levels, thus reducing evapotranspiration by 60–85%12,13. Moreover, shading mechanisms14, such as shading nets or selective shading permitting only photosynthetically active radiation (PAR), effectively curtail plant water requirements. Despite the considerable water savings compared to open-field farming, greenhouses demonstrate suboptimal water resource utilization efficiency. In modern greenhouse cultivation, a significant portion of irrigation water is lost through deep soil seepage and ground evaporation15. While water-saving irrigation measures such as drip irrigation16, aeroponics17, and ebb-and-flow irrigation18 have improved water efficiency, their effectiveness remains limited. For instance, even the most water-efficient method, tidal irrigation, still requires a substantial amount of ~1.5 L m−2 water8. The emergence of urban horticulture, such as plant factories19, has also contributed to improved water usage. However, these advancements primarily address irrigation losses and fail to mitigate water loss caused by transpiration, which constitutes a significant challenge in greenhouse systems. Therefore, developing innovative strategies to improve irrigation efficiency while addressing transpiration-related losses is critical for advancing sustainable greenhouse cultivation.

Transpiration, the main physiological activity of plants, accounts for 98 to 99% of water absorbed by crops, leaving only a small portion being effectively utilized by plants20. Consequently, supplementary water sources, such as atmospheric water harvesting and seawater desalination, are often necessary to meet the water demands of greenhouse agriculture. The rapid growth and metabolism of crops in enclosed horticultural facilities further intensify the issue, as transpired water vapor rapidly saturates the air21. In such conditions, limited space and restricted airflow result in high humidity levels, often nearing or exceeding saturation22,23 (as shown in Fig. 1). This high humidity environment can obstruct light transmission, promote the spread of pathogenic spores, and cause wet leaves, all of which negatively affect nutrient absorption and crop growth24. Traditional dehumidification methods in greenhouses, such as ventilation25, heating26, and condensation27, primarily dissipate excess water vapor by consuming additional energy rather than recovering it. Moreover, these methods are generally characterized by low efficiency and high additional energy consumption. This underscores the imperative for further research and development of more efficient dehumidification as well as water recycle techniques in greenhouse cultivation.

As advancements in material and engineering science persist, innovative water procurement methods, such as sorption-based atmosphere water harvesting (SAWH), superabsorbent polymer water holding materials (SPWH), radiative cooling (RC), and seawater desalination, have garnered significant attention. The prospect of applying these novel materials and methodologies to address the interdependence of food and water in greenhouse production is compelling. Despite some small-scale attempts, there is still considerable room for improvement in terms of practicality and efficiency optimization. In this perspective, we provide an overview of existing implementation methodologies and innovative technologies that hold potential for water conservation in greenhouses, given the current suboptimal utilization of water in such production systems. Subsequently, we propose application methods that are more suitable for greenhouse production based on the specific characteristics of each technology and explore future development directions. The primary focus of this perspective is to propose novel water-saving methods for greenhouses based on new technologies, offering fresh insights for further conserving water resources in greenhouses. These next-generation approaches lay the groundwork for a more rational resource-saving production method, characterized by the adoption of limited but optimally utilized water resources.

Next-generation greenhouse water-saving prospects

Sorption-based atmosphere water harvesting

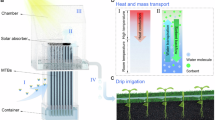

The recent achievement of SAWH enables a passive method of water extraction from the air28. This technology holds significant potential for enhancing the water sustainability of agriculture. In addition, it facilitates the development of solar-powered29 and distributed systems30, eliminating the need for centralized water and power supply. The working principle of SAWH involves the use of hygroscopic porous polymers (HPPs) (Different types shown in Fig. 2a) to efficiently capture water vapor in the air. Low-grade heat sources such as solar energy are then employed to regenerate HPPs and release water vapor31. This vapor condenses into liquid when it contacts a cooler surface, such as a condenser, below the dew point. In this case, the released water vapor condenses into liquid water, which may require further treatment before it is suitable for drinking. Remarkably, the performance of this technology is largely unaffected by geography32, demonstrating considerable water yield in both high- and low-humidity areas.

a Schematic illustration of various HPPs35,36,37,38,93,94,95,96,97. PDA@PP-Cl polydopamin @ PAAS−PNIPAA-HCL, POG hygroscopic photothermal organogel, PGF porous sodium polyacrylate/graphene framework, SMCA solar-driven and moisture-indicating cellulose aerogel, ILCA Loofah grafted calcium alginate sorbent with ink. Reproduced with permission36. Copyright 2019, Wiley. Reproduced with permission37. Copyright, AAAS. Reproduced with permission38. Copyright 2022, Royal Society of Chemistry. Reproduced with permission93. Copyright 2022, American Chemical Society. Reproduced with permission94. Copyright 2020, Wiley. Reproduced with permission95. Copyright 2020, Wiley. Reproduced with permission96. Copyright 2021, Royal Society of Chemistry. Reproduced with permission97. Copyright 2021, Elsevier. b Schematic representation of a greenhouse with SAWH covers. c Schematic depiction of crops with SAWH hoods. d Temperature and humidity fluctuations in a greenhouse during a typical sunny day in Singapore, where the average RH is ~90%. e Comparison of water production at 90% RH for different types of HPPs35,36,37,38,93,94,95,96,97. f Daily harvested water mass for SAWH covers and hoods. Relevant raw data are taken from ref. 30. Needed water: additional water needed to meet the needs of plant daily growth. Harvested water: water collected from SAWH cover or hood. The dashed lines in the figure represent the needed water amounts at different levels.

Greenhouses present an ideal environment for introducing SAWH technology, given their high humidity levels and significant dehumidification requirements33 (Fig. 2b, c). For instance, in Singapore, the relative humidity (RH) inside greenhouses is ~90% (Fig. 2d) during a typical sunny day, while the RH suitable for the growth of most crops is 60–80%34. It is noteworthy that almost all HPPs utilized in SAWH have excellent adsorption performance within this humidity range35 (Fig. 2e). As an illustration, Super Moisture-Absorbent Gels (SMAG)36, a type of hydrogel material, can adsorb 6.7 g g−1 water vapor under 90% RH conditions. Polymer-MOF (PC-MOF)37, an aerogel material, boasts an adsorption capacity of 3.3 g g−1 under 90% RH. Similarly, CaCl2-impregnated alginate with ink (IMFCA)38, featuring a foam or sponge material, demonstrates an adsorption capacity of 2.5 g g−1 under 90% RH. The ample space available in greenhouses, including the roof, aisle, and space between crop plants, provides an ideal location for placing HPP materials. To effectively apply these HPPs in greenhouses, it is essential to consider their performance in this specific context. Table 1 details the performance of various materials in terms of ease of synthesis, long-term performance, and adsorption capacity. HPPs that maintain stability in high humidity environments and are low-cost and easy to synthesize are more suitable for application in greenhouse scenarios. The effectiveness of water harvesting using these HPPs in greenhouses is foreseeable once the adsorption-desorption cycle challenge is addressed through light-driven, heat-driven, and other innovative methods.

The conventional method of ventilation and dehumidification in greenhouses involves expelling water vapor outside, resulting in significant greenhouse water vapor waste. Some studies have attempted to introduce HPPs into greenhouses for dehumidification instead of ventilation. For instance, Yang et al.39 developed an intelligent greenhouse system that uses Cu-complex materials as adsorbent materials. This system, a representative passive system, places adsorbent materials near the greenhouse roof, opens the roof for open absorption at night, and achieves closed desorption through photothermal behavior during the day. It achieved a water production rate of 2.24 g g−1 h−1 under natural sunlight. However, this method, essentially adsorbs water vapor around the greenhouse at night, and opening the roof in low-humidity areas such as deserts, may cause a sharp drop in humidity inside the greenhouse. Conversely, closed desorption during the day can lead to excessive humidity, causing condensation on walls that adversely affects greenhouse lighting and plant health. In another instance, Wang et al.40 designed a greenhouse heat and humidity recovery cycle system utilizing silica gels@CaCl2 as the adsorbent material. This system recovers humid air discharged from the greenhouse using a negative pressure fan, adsorbs water vapor using the adsorbent material, and then recovers condensed water through a closed-loop cycle to achieve water circulation in the greenhouse. The dehumidification unit can reduce the RH inside the greenhouse by 17.39% and the absolute humidity by 0.4 g kg−1, with a water harvesting coefficient reaching 0.70. However, this system’s operation is not entirely passive, and the specific energy consumption per unit mass of water production was 6.9 MJ kg−1. Moreover, it requires a substantial initial investment and poses challenges for large-scale implementation in agriculture known for its emphasis on economic viability.

For effective and sustainable water harvesting in greenhouses, passive SAWH systems can be installed in various parts of the greenhouse, in addition to centralized treatment of vapor. One potential location is the greenhouse roof. Referring to the structure of photovoltaic greenhouses41, an water harvesting greenhouse driven by photothermal energy can be made by covering part of the roof of the greenhouse with SAWH materials, absorbing at night and desorbing with irradiation during the day (Fig. 2b). This SAWH-cover greenhouse operates by adsorbing high-moisture water vapor from the surrounding environment during the night in an open adsorption process. During the day, sunlight is harnessed to desorb the adsorbed moisture, converting it into liquid irrigation water. This cyclical process allows for the efficient collection of irrigation water directly from the greenhouse roof, which is expected to obtain irrigation water in regions with abundant sunlight but scarce water resources. Some HPPs with good adsorption effects in low-humidity environments30,42,43 can adapt to this application scenario. Given a 50% roof installation area, the SAWH cover equipped with HPPs30 is capable of collecting ~453.87 g m−2 of irrigation water, which equates to roughly one-third of the daily water requirements of the crops (Fig. 2f). This efficient water collection method underscores the potential of the SAWH hood in promoting sustainable agricultural practices by optimizing water usage. Another potential location for the installation of SAWH systems is ventilation positions such as side windows of greenhouses. Polytetrafluoroethylene membranes44 and other materials can be used to transform HPPs into filter screens that only allow dry air to pass through without allowing water vapor to pass through. In this case, high-concentration water vapor can be effectively collected and reused during ventilation.

While the dehumidification method targeting the entire greenhouse environment is effective, it can sometimes be inefficient, especially for greenhouses growing lettuce and other green leafy vegetables. Given the limited height of plant growth in these greenhouses, most of the upper space is often underutilized. Therefore, for crops with low planting density, moisture recovery from individual plants in the form of hollow and transparent covers45 (Fig. 2c) could be a viable approach. These SAWH hoods specifically target the plant growth areas for adsorption and dehumidification. This is primarily due to the transpiration of plant resulting in a significant amount of water vapor redundancy, thereby creating a high humidity environment conducive to HPPs adsorption. To avoid interfering with normal plant growth, the operating conditions are the same as those of the SAWH covers: adsorption at night and closed desorption during the day with irradiation. This device can fully utilize the space between crop rows, ensuring normal plant growth while producing an additional 840.5 g m2 of water per day when equipped with already developed HPPs30 (Fig. 2f and Table S1). When operated in conjunction with SAWH covers, the entire system can meet 86% of the daily water requirements of the plants. This innovative approach underscores the potential of SAWH technology in promoting sustainable and efficient water usage in agriculture. Expanding on this, SAWH technology presents a promising solution for regions with water scarcity. By harnessing the natural processes of plant transpiration and solar radiation, it transforms the greenhouse into a self-sustaining ecosystem. The low cost and long-term performance stability of HPPs ensure its large-scale operation. Furthermore, the adaptability of this system allows for its implementation in various agricultural settings, potentially revolutionizing the way we approach irrigation and water conservation in the field of agriculture. This technology not only addresses the immediate needs of crops but also contributes to the larger goal of sustainable agriculture and water management.

Superabsorbent polymer water-holding materials

Effective water management in soil is a pivotal aspect of sustainable greenhouse agriculture, particularly given the controlled yet resource-intensive nature of greenhouse environments. Maintaining optimal soil moisture is critical in greenhouses, where water loss due to evaporation and drainage can significantly reduce water-use efficiency. Water retaining agents have gained popularity since their introduction to the market for their promotion of soil water availability33,46. Among them, SPWHs are garnering attention in agricultural management for their excellent water-holding ability. Constructed from materials such as polyacrylate and polyacrylamide, SPWHs absorb natural water through their hydrophilic network structure. They then gradually release this water back into the soil, providing a steady source of moisture for plant absorption and utilization. Unlike HPPs that have limited water-absorbing ability, these SPWHs have the capacity to rapidly absorb 20–700 times their weight in water and exhibit good reusability47 (Fig. 3a). This makes them particularly effective in maintaining soil moisture levels over extended periods. The versatility of SPWHs is further exemplified by the variety of natural and biobased precursors used in their synthesis. These include starch48, husk rice ash49, guar gum50, carrageenan51, gum Arabic52, wheat straw53, cotton linters54 and more. The use of these diverse materials not only enhances the sustainability of SPWHs but also allows for customization based on specific soil types and crop needs. When applied to different types of soils, these SPWHs have been shown to significantly improve soil properties. They can enhance the soil’s water holding ability by more than three times, delaying the onset of permanent wilting in crops for over a week (Fig. 3b). Furthermore, due to the superior water absorption capacity of SPWHs compared to soil, only a minimal amount of SPWHs is needed to meet the water needs of plants throughout their growth cycle even just irrigation once (Fig. 3c). This not only promotes healthier plant growth but also contributes to more efficient use of water resources. When considering the application of SPWHs in greenhouse plant production, various environmental and sustainability factors must be taken into account. Natural biobased SPWHs like those made from starch or guar gum are generally easier and cheaper to synthesize55. They often require less complex chemical processes compared to synthetic polymers. For example, SPWHs made from materials like carrageenan51 and gum Arabic52 show excellent adsorption capacities, making them highly effective for water retention. Synthetic SPWHs such as those made from polyacrylate or polyacrylamide often exhibit superior long-term performance due to their higher water absorption capacities and stability56,57. However, their biodegradability is a concern. Given their direct contact with soil and plant roots, the toxicity of SPWHs must be carefully evaluated. SPWHs that maintain stability in high humidity environments and are low-cost and easy to synthesize are more suitable for greenhouse scenarios. Natural SPWHs, while biodegradable and less toxic, often suffer from poor stability and lower water retention over time58. Synthetic SPWHs, although stable and highly effective, may pose environmental risks due to potential toxicity and non-biodegradability59.

a Water holding capacity of different SPWHs47,48,49,51,53,54. SAH super-absorbent hydrogel, OK-PAA4 okara-poly (acrylic acid) superabsorbent hydrogels, SH-20RHA superabsorbent hydrogel composite based on the biopolymer starch, and 20 wt% rice husk ash. C-P3-MMT2 carrageenan/psyllium sodium/montmorillonite clay hydrogels, WS3-CA4% wheat straw modified hydrogel crosslinked with 4% citric acid, Gel-1-SN single-network hydrogel. b Soiling water increasing capacity of different SPWHs47,48,49,51,53,54. c SPWHs needed for different crops for their entire growth period without irrigation. Taking SAH as an example of SPWHs. The irrigation needs of corps are taken from refs. 8,9. d Schematic illustration of self-watering SPWHs. Passive water irrigation: At night, SPWHs absorb atmospheric moisture and release it as liquid water into the soil, passively irrigating plants. Solar-powered humidification: During the day, sunlight drives water evaporation from SPWHs, increasing humidity and helping retain soil moisture. e Schematic illustration of adding nutrition in SPWHs before bleeding. No more irrigation is needed during the entire crop growth period.

In addition to water-holding capabilities, the watering absorption properties of SPWHs are of significant interest. If SPWHs could independently adsorb water vapor from the air and continuously supply this absorbed water to plants, they would enable plant growth without the need for additional irrigation (Fig. 3d). Specifically, water can be passively absorbed from atmospheric moisture at night to achieve passive water irrigation, while during the day, sunlight drives the process to enable solar-powered humidification. This atmospheric water irrigation system could revolutionize agriculture, making it geographically and hydrologically independent. Consequently, crop cultivation in underdeveloped and drought-prone areas could be liberated from the constraints of long-distance water and power supplies. Zhou et al.60 have made strides in this direction by experimenting with super moisture absorbent gels composed of hygroscopic polypyrrole and thermoresponsive poly(N-isopropylacrylamide). When mixed with sandy soil, this gel-soil was able to maintain ~40% of its water content after 4 weeks, while sandy soil alone lost ~80% of its contained water within just 1 week. This research opens new possibilities for sustainable agriculture in challenging environments.

However, most of these SPWHs mentioned above must be mixed with soil or other cultivation substrates and cannot independently support the entire planting cycle. While some research has explored plant germination47,54, further investigation is needed into the ability to retain nutrient solution and its impact on plant growth. As arable land area gradually decreases and crop cultivation trends towards soilless farming, water-retaining materials that can fully support the entire crop cultivation cycle are the future research direction. This requires SPWHs to have good salt tolerance61 and excellent nutrient solution retention ability. For mature SPWHs, a reasonable expectation is to add sufficient concentration of nutrients and water before use according to the growth and development requirements of plants, and then slowly release them as the plants grow (Fig. 3e). In this way, there is no need to supply water and fertilizer during the entire growth stage of the plant. Taken SAH48 as an example, only less than 100 g of SAH is sufficient to meet the entire cycle’s water requirements for crops8,9 such as cabbages in 1 m2 (Fig. 3c and Table S2). This growth model also saves a large amount of daily management costs and manpower input in the cultivation process. This approach is a significant step forward in agricultural technology, offering great potential for sustainable farming, especially in areas with limited arable land or challenging irrigation conditions.

Radiative cooling

Performing as a totally passive cooling method without energy and water consumption, daytime RC has attracted much attention in recent years. The concept of radiative cooling is that terrestrial objects can spontaneously release their heat to colder outer space (~3 K) in the form of infrared thermal radiation through the atmospheric window (8–13 μm)62,63. This passive cooling process involves the conversion of thermal energy from a surface into radiative energy, which is then emitted as infrared radiation. Over the past few years, there has been much interest in utilizing RC to reduce building energy consumption. Given its exceptional cooling performance, there is also significant potential for its application in water conservation in greenhouses. Its use in greenhouse water saving can be primarily divided into reducing water used for evaporative cooling and RC atmospheric water harvesting (RAWH). The former involves leveraging the material’s cooling properties to lower the temperature within the greenhouse, thereby reducing the amount of water needed for evaporative cooling systems. In this process, the RC materials convert the thermal energy accumulated on greenhouse surfaces into radiative energy that is emitted into space, effectively lowering the internal temperature of the greenhouse without consuming additional energy. This energy conversion process is particularly beneficial for reducing dependence of the greenhouses on mechanical cooling systems, which typically require significant water and energy input64. RAWH is a novel approach that utilizes the material’s RC properties to condense atmospheric water vapor, providing an additional source of water for irrigation.

With advancements in materials science, daytime RC technology is now used in various forms, including paints and coatings62, windows65, roofs66, and, most commonly, thin films67. It should be noted that all substrates, when wet, nevertheless exhibit the same cooling properties68. This gives RC materials opportunities to mitigate heat stress in greenhouses, performing as cover materials and mulches in hot regions (Fig. 4a). Zou et al.69,70 developed a specially designed transparent RC film (T-RC) to reduce heat stress and excess evaporation inside greenhouses without sacrificing photosynthesis. This T-RC film considered the whole unique irradiation environment inside the greenhouses, with high emissivity in the atmospheric window, high transmittance in PAR, and high reflectivity in near-infrared radiation. This film is demonstrated to lower the indoor temperature of a greenhouse by 18.6 °C compared with the control group, together with reducing leaf and soil transpiration by more than 120 kg m−2. Simultaneously, the maximum reduction in water consumption reaches up to 64.8% after substituting the T-RC film. In addition to reducing water use for cooling, the T-RC films’ ability to suppress excessive soil and leaf transpiration makes it an ideal candidate for greenhouse water management, especially in regions facing severe water shortages. The RC materials efficiently convert excess heat into infrared radiation, eliminating the need for external energy inputs and improving overall energy efficiency. The common supplementary cooling method of most commercial greenhouses is the fan-pad system, based on the conversion of sensible heat into latent heat of evaporated water, which results in significant water loss and further burdens the water shortage of the agricultural sector. When using the T-RC film, the situation of excessive water use can be significantly improved.

a Schematic illustration of the daytime radiative cooling and water saving ability of RC films in greenhouses. b Schematic illustration of the nighttime radiative cooling atmospheric water harvesting ability of RC films in greenhouses. c Water consumption and harvesting for a 500 m2 greenhouse covered with RC film during 100 days of planting. Relevant raw data are taken from refs. 69,70,71.

Compared to SAWHs, RAWH systems offer a simpler approach to water harvesting, leveraging the inherent properties of RC materials to cool and condense moisture from humid air, followed by water collection (Fig. 4b). This process eliminates the need for complex water harvesting processes or energy-intensive operations, making RAWH a more sustainable and efficient method for atmospheric water harvesting. Inspired by windshields, Bu et al.71 developed porous RAWHs using polyethylene (PE) nets and porous PE films. Even in low-humidity environments, these RAWHs can harvest up to 293.89 g m−2 of water each night. While this figure may seem small compared to SAWHs, it represents a simple and necessary method for providing additional water in a completely passive environment. Moreover, it can be fully adapted to greenhouse covering materials. During the night, when sunlight is not needed, greenhouses can utilize T-RC covering materials for RAWH. For a conventional greenhouse of 500 m2, the nightly water harvesting rate could reach as high as 159.1 kg day−1.

Moreover, the implementation of daytime RCs and nighttime RAWHs does not interfere with each other and can be simultaneously achieved within a single greenhouse. For a greenhouse spanning 500 m2, the application of RC film can result in substantial water savings (Fig. 4c and Table S3). Over a growth cycle of 100 days, it can save 108068 kg of water during the day compared to a traditional glass greenhouse. Additionally, it can harvest an extra 15905 kg of water at night. This dual functionality enhances the water efficiency of the greenhouse, further emphasizing the sustainable potential of this technology. This could have significant implications for crop cultivation in remote, arid, and island areas. Furthermore, RC materials can also be combined with systems such as thermoelectric power generation72 and heat pumps73. By enhancing diurnal temperature differences through sky RC, the water production and power generation of SAWHs can be further improved74. This innovative approach holds great promise for the future of sustainable agriculture and energy production.

The cost and long-term stability of RC films are major concerns for greenhouse applications. The inclusion of precious metals like silver in certain RC materials currently constrains their scalability, limiting them to small-scale demonstrations within greenhouse settings64,70. Addressing the cost factor associated with RC films, potentially through the substitution of aluminum for silver, emerges as a pivotal imperative for their widespread adoption in large-scale deployments. When considering the long-term stability of RC materials, it is pertinent to assess their resistance to solid contaminants such as dust or water stains, as these substances tend to accumulate on the surface of RC materials, thereby impacting their cooling and water harvesting performance. In summary, the integration of RC technology with greenhouse systems offers a promising avenue for enhancing water efficiency and sustainability in agriculture, albeit with challenges related to cost and material stability that warrant further attention.

Seawater desalination and floating planting

Despite advancements in this field, the high-energy-consumption requirement remains a fundamental challenge of seawater desalination. Reverse osmosis (RO), the leading and most energy-efficient technology, still consumes 3–4 kWh of electricity per cubic meter of produced water75. The high cost of recent seawater desalination approaches makes them unfeasible for agriculture, which requires large amounts of water. Moreover, many water-deficient regions often lack access to electricity due to inadequate infrastructure, further limiting the applicability of such technologies. In addition, traditional desalination devices also require substantial land areas and extensive distribution tubes, adding to their impracticality.

Solar energy is the most abundant natural energy source on Earth. In recent years, low-carbon solar-driven desalination technology has been highlighted as a research hotspot. Two prominent technologies leading this field are solar-thermal interfacial evaporation (STIE) and solar-thermal membrane distillation (STMD).

STIE is an improvement of the conventional solar still. Unlike the traditional design, which operates on volumetric heating and results in significant heat loss, STIE localizes solar energy at the water-air interface where evaporation occurs (Fig. 5a). This is achieved through a typical double-layered STIE system, composed of a light absorber and a porous substrate76. The substrate not only suppresses heat loss to the underlying bulk water but also continuously supplies water to the heated region via capillary forces. The selective membrane plays a crucial role in this process, allowing water molecules to pass while rejecting dissolved salts and contaminants, ensuring purified water vapor generation. The evaporation process is further enhanced by the salinity gradient, which drives the movement of water molecules across the membrane, increasing desalination efficiency. Owing to their rational design, STIE systems can achieve a high thermal efficiency of up to ~90% at reduced solar concentrations77. Over the past decade, enormous progress has been made to further increase STIE productivity. This includes advancements in solar-thermal converters, dimensional water pathways, and interface engineering78. Due to its high efficiency and low manufacturing cost, STIE technology holds promise for distributed agricultural applications79. STMD represents a hybrid thermal-membrane process. In STMD, a porous, hydrophobic membrane separates the saline and permeate stream but allows the transport of water vapor under the drive of a temperature gradient across the membrane80. The solar-thermal coating achieves localized heating to increase the overall system efficiency. Compared with RO, STMD has the capability of treating high salinity brine and is also expected to be less prone to fouling than RO81. This outstanding benefit makes STMD a potentially more sustainable and efficient solution for desalination, particularly in regions with high-salinity water sources.

a Schematic illustration of water desalination and energy generation using STIE. Solar-driven evaporation occurs through a selective membrane, which separates clean water from pollutants and salts due to a salinity gradient. b Schematic depiction of the STIE floating farm (STIE-FF). The concentrator acts as a solar thermal collector, enhancing seawater evaporation for desalination. c Schematic depiction of the STMD floating greenhouse (STMD-FG). d Schematic representation of the integration of photovoltaics and multistage membrane distillation using in a greenhouse. e Daily water production rate of STIE-FF and STMD-FG. Relevant raw data are taken from refs. 79,83,84,85,86. Needed water: water needed to meet the needs of plant daily growth.

Building on existing seawater desalination technologies, several floating crop cultivation methods have been proposed. Wang et al.82 presented an integrated desalination-power generation-cultivation trinity system in a previous study. Powered entirely by solar energy, this system can produce fresh water, generate electricity, and provide spaces for crop cultivation. The system maintains an evaporation rate of ~1.42 kg m−2 h−1, which is able to effectively irrigate wheat crops. Zou et al.79 proposed a biomimetic 3D bridge-arch solar evaporator, which boasts an efficiency of 91% for pure water production at a rate of 1.64 kg m−2 h−1 and 2.5 kg m−2 day−1. This provides a self-sustainable and solar-powered desalination cultivation platform for crop cultivation. However, these devices essentially represent a simple combination of photovoltaic/seawater desalination systems and greenhouse cultivation systems. As these two systems operate independently, the production efficiency per unit area is relatively low. Wang et al.83,84 attempted to couple these two systems and proposed a solar freshwater self-produced ecological film floating on the sea. The film consists of a floating transparent material with multiple cavities that concentrate sunlight and produce fresh water. This film has enough additional space on top to grow crops, enabling seawater desalination for irrigation in the gaps between every two rows of crops. It has been reported that the coupled concentrator system achieves a pure water production rate of 195.1 g m−2 h−1 and 2.1 kg m−2 day−1 without compromising plant growth. The combined methods of photovoltaic/seawater desalination systems and greenhouse cultivation concentrator systems can operate independently without interfering with each other and can be coupled to create a STIE floating farm (Fig. 5b), which enables seawater desalination from both the bottom of the planting platform and the outer solar evaporator. This integrated planting system has the potential to produce 4.6 kg m−2 of pure water per day, an amount that surpasses the daily water requirements of typical crops. This innovative approach not only optimizes water usage but also paves the way for sustainable agricultural practices in offshore environments. However, it is important to note that the open-air cultivation approach needs to expose crops to the vagaries of weather, including extreme conditions such as wind and rain, making production unreliable.

Recent studies85,86 have proposed the integration of photovoltaics and multistage membrane distillation. In such a system design, excess heat from the solar cell is effectively removed by feeding seawater, which lowers the solar cell temperature and leads to higher electricity generation performance (Fig. 5c). High water production of 2.45 kg m−2 h−1 and 8.09 kg m−2 day−1 is ensured by recycling condensation heat at each distillation stage. Drawing upon the principles of photovoltaic greenhouse design, the integration of an STMD module on the greenhouse roof is not only feasible but also advantageous. This STMD floating greenhouse (STMD-FG) (Fig. 5d) harnesses capillary action to draw seawater to the roof, where it undergoes seawater desalination, which is able to generate both fresh water for crop irrigation and the electricity for daily greenhouse operations. Considering a 50% roof installation area, the STMD-FG device is capable of producing 4.38 kg m2 of pure water per day (Fig. 5e and Table S4). This result demonstrates that, more than being sufficient to meet the daily irrigation requirements of crops, a highly efficient and integrated planting device that significantly enhances the production of water, electricity, and crop yield per unit area. Furthermore, the indoor design of the STMD-FG device offers protection against external factors such as rainfall, further improving the output performance. While this device has not yet been conceptually applied in real-world marine agriculture scenarios, the strategy of synergistic production of electricity and freshwater opens the door for benefiting the water-energy-food nexus simultaneously. The concept of an energy-water self-sustainable greenhouse is already on our future research agenda.

Analyzing the cost and life cycle assessment of solar thermal desalination technologies highlight their distinct advantages and limitations (Fig. 6). STIE is characterized by its cost-effectiveness and simplicity, involving low initial and operational costs and requiring less technical support, making it particularly suitable for resource-limited areas76. However, STIE is hampered by low efficiency and significant dependency on weather conditions, as well as potential issues with scaling that can affect long-term performance77. Conversely, STMD demonstrates higher efficiency and produces superior water quality with low salinity and impurities, making it more applicable for scenarios requiring high-quality desalinated water87. Nevertheless, STMD entails higher initial investment and long-term operational costs due to the need for specialized membrane materials and more complex system design, along with periodic membrane replacement and maintenance, which can be technically demanding88. The environmental impact of STIE is relatively lower due to simpler manufacturing processes, whereas STMD’s impact is higher due to chemical use in membrane production. Future research should aim to enhance the efficiency of STIE by addressing scaling and optimizing system design while focusing on developing cost-effective, durable membranes and reducing the environmental footprint of STMD, thus improving the overall sustainability and practical applicability of both technologies.

Cost-effectiveness: evaluates the overall financial viability, considering both initial investment and long-term operational expenses. Technical support: assesses the level of expertise and maintenance required to operate the system efficiently. Efficiency: measures the effectiveness of the system in utilizing resources, particularly in water conversion and utilization. Water quality: refers to the purity and suitability of the produced water for irrigation, taking into account factors such as salinity, contaminants, and overall usability for crops. Environmental impact: considers the ecological footprint of the system, including energy consumption, waste generation, and potential adverse effects on the surrounding environment. Scaling issues: addresses potential challenges related to system scalability, including material degradation, performance limitations, and maintenance frequency when expanding the system for large-scale applications.

Future directions and synergy of the four technologies

The previous sections have detailed the unique contributions of each of the four key technologies to greenhouse water conservation. While each technology offers specific advantages, their combined application has the potential to bring about transformative changes in agricultural sustainability.

Synergy between technologies

Integrating these four technologies offers a novel approach to enhancing water and energy efficiency in greenhouse systems. While SAWH and SPWH can function independently, they complement each other within the greenhouse environment. SAWH continuously harvests atmospheric moisture for irrigation, while SPWH stores this water in the soil, ensuring a steady supply for plants. This synergy reduces the need for frequent irrigation, providing a stable water supply even in arid or low-humidity conditions. RC, primarily used as a greenhouse cover or mulch, further optimizes internal temperatures by reducing dependence on water-intensive evaporative cooling. Additionally, RC’s cooling effect enhances the effectiveness of SAWH by maintaining optimal humidity levels for water harvesting, allowing these technologies to work in harmony. Collectively, RC, SAWH, and SPWH help create a balanced temperature and humidity environment, significantly lowering both water and energy consumption.

Seawater desalination, meanwhile, broadens the scope of greenhouse operations by offering an alternative source of irrigation water, particularly in coastal or water-scarce regions. Desalinated water can supplement SAWH during periods of low atmospheric moisture, ensuring continuous irrigation. In essence, the combination of these four technologies has the potential to create a closed-loop system, where greenhouse operations are entirely independent of external freshwater sources, achieving near-zero freshwater input.

Integration with existing greenhouse operations

Introducing these advanced technologies into existing greenhouse systems requires a careful approach to ensure they enhance, rather than disrupt, current operations. Traditional greenhouses typically rely on mechanical ventilation, active cooling, and irrigation, all of which are resource-intensive89. By incorporating SAWH and RC, greenhouses can shift toward more passive environmental control, reducing dependence on energy-intensive systems, while simultaneously cutting operational costs and lowering greenhouse gas emissions.

However, integrating these technologies presents certain engineering challenges. For instance, SPWH materials must be carefully managed to avoid over-saturating the soil, which could result in root rot or other plant health issues90. Similarly, the energy demands of desalination, even if solar-powered, must be balanced with the overall energy consumption of the greenhouse. While RC films hold great promise, they currently face challenges related to material costs and long-term durability, especially in environments prone to dust or dirt accumulation. Advances in material science, such as the development of self-cleaning coatings91, will be critical to improving the economic viability of RC technology. The long-term cost-effectiveness of these technologies will depend on initial capital investments, material durability, and maintenance requirements. For example, the materials used in SAWH and SPWH systems must be both long-lasting and require minimal replacement to be viable for large-scale agricultural applications.

Challenges and future research directions

Despite their promising potential, several challenges must be overcome before these technologies can be widely adopted. One major barrier is the need for reliable, cost-effective materials that can endure the harsh conditions inside greenhouses, such as high humidity, temperature fluctuations, and constant sunlight exposure. Advances in material science, particularly in the development of durable and affordable hydrogels for SPWH and advanced coatings for RC, will be key to overcoming these obstacles.

Moreover, more research is needed to optimize the integration of these technologies and ensure that they work together efficiently without causing unintended consequences. For instance, excessive humidity caused by SAWH might counteract the cooling effects of RC if not carefully controlled92. Similarly, the energy balance between solar-driven desalination and other greenhouse operations, such as lighting and ventilation, must be fine-tuned to prevent energy waste. Future research should also focus on developing intelligent control systems that use real-time data on temperature, humidity, and soil moisture to automate the operation of these technologies. Such systems could optimize water harvesting, storage, and usage, further reducing labor costs and resource waste.

The escalating food crisis, propelled by population growth, expanding urbanization, and intensifying climate change, necessitates a shift in our understanding of production and consumption in agriculture. The pressing need for optimization in agricultural practices is driving us to address the paramount issue of water usage in agriculture. Existing water-saving irrigation methods, while refined over time, have reached a level of maturity that leaves little room for further water conservation. Therefore, alternative approaches are needed to address the issue of agricultural irrigation. In this perspective, we focus on the redundant light and water resources in the greenhouse crop cultivation process. Leveraging advancements in modern materials and engineering technologies, we analyze the potential of four technologies—SAWH, SPWH, RC, and seawater desalination—to address the water usage challenge in greenhouses.

SAWH technologies align well with the issue of high humidity in greenhouses. By tackling the dehumidification needs of greenhouses and concurrently harvesting liquid water for irrigation, these technologies offer a dual solution. SPWH materials, with their exceptional water retention capabilities, hold the potential to address irrigation issues. The vision of self-watering soil, which requires no additional irrigation, becomes a tangible prospect. RC materials, leveraging their superior cooling abilities, can contribute to the reduction of water evaporation and plant transpiration while simultaneously extracting fresh water from the air for irrigation. The integration of seawater desalination and floating planting opens up new possibilities for developing fresh irrigable water resources and cultivating on the sea. Envisioning vast expanses of greenhouses on the sea might become a reality, expanding the potential of agriculture.

These emerging technologies instill new confidence in addressing global food and water challenges. Implementing them in greenhouse cultivation necessitates collaboration among material scientists, energy experts, horticulturists, economists, and more, sparking numerous scientific problems awaiting resolution. These technologies present promising avenues for sustainable and efficient water management in agriculture. As we continue to explore and refine these approaches, we are paving the way towards a more sustainable future in agriculture, where water is used efficiently, and every plant has the opportunity to thrive.

References

Hickey, L. T. et al. Breeding crops to feed 10 billion. Nat. Biotechnol. 37, 744–754 (2019).

Chen, X. et al. Producing more grain with lower environmental costs. Nature 514, 486–489 (2014).

Tilman, D. et al. Global food demand and the sustainable intensification of agriculture. Proc. Natl. Acad. Sci. USA 108, 20260–20264 (2011).

Bajželj, B. et al. Importance of food-demand management for climate mitigation. Nat. Clim. Change 4, 924–929 (2014).

Richter, B. D. et al. Alleviating water scarcity by optimizing crop mixes. Nat. Water 1, 1035–1047 (2023).

Proctor, J. et al. More accurate specification of water supply shows its importance for global crop production. Nat. Food 3, 753–763 (2022).

Boretti, A. & Rosa, L. Reassessing the projections of the World Water Development Report. npj Clean Water 2, 15 (2019).

FAO. Water for Sustainable Food and Agriculture (FAO, 2017).

Hanan, J. J. et al. Greenhouse Management Vol. 5 (Springer Science & Business Media, 2012).

Badji, A. et al. Design, technology, and management of greenhouse: a review. J. Clean. Prod. 373, 133753 (2022).

Czyzyk, K. A. et al. Quantifying water savings with greenhouse farming. In Proc. IEEE Global Humanitarian Technology Conference (GHTC) 325–332 (IEEE, 2014).

Li, J. et al. A photosynthetically active radiative cooling film. Nat. Sustain. 1–10. https://doi.org/10.1038/s41893-024-01350-6 (2024).

Mpusia, P. T. O. Comparison of Water Consumption Between Greenhouse and Outdoor Cultivation (ITC, 2006).

Abdel-Ghany, A. M. et al. Covering materials incorporating radiation-preventing techniques to meet greenhouse cooling challenges in arid regions: a review. ScientificWorldJournal 2012, 906360 (2012).

Chen, B. et al. The climate cost of saving water by different plastic mulching patterns. J. Clean. Prod. 359, 132011 (2022).

Ding, W. et al. Improving potential of reactive nitrogen and carbon footprint of intensified greenhouse cucumber-tomato production with optimized drip irrigation with nitrogen reduction strategies. J. Clean. Prod. 424, 138898 (2023).

Schmidt Rivera, X. et al. The role of aeroponic container farms in sustainable food systems—the environmental credentials. Sci. Total Environ. 860, 160420 (2023).

Carotti, L. et al. Improving water use efficiency in vertical farming: effects of growing systems, far-red radiation and planting density on lettuce cultivation. Agric. Water Manag. 285, 108365 (2023).

Zhang, L. et al. Plant factory technology lights up urban horticulture in the post-coronavirus world. Hort. Res. 9. https://doi.org/10.1093/hr/uhac018 (2022).

Zhu, J. K. Abiotic stress signaling and responses in plants. Cell 167, 313–324 (2016).

Ma, D. et al. Greenhouse environment modeling and simulation for microclimate control. Comput. Electron. Agric. 162, 134–142 (2019).

Shamshiri, R. R. et al. Model-based evaluation of greenhouse microclimate using IoT-Sensor data fusion for energy efficient crop production. J. Clean. Prod. 263, 121303 (2020).

Rahman, M. S. et al. Dehumidification requirement modelling and control strategy for greenhouses in cold regions. Comput. Electron. Agric. 187, 106264 (2021).

Lu, N. et al. Control of vapor pressure deficit (VPD) in greenhouse enhanced tomato growth and productivity during the winter season. Scientia Horticulturae 197, 17–23 (2015).

Zhang, G. et al. Nonlinear simulation for coupling modeling of air humidity and vent opening in Chinese solar greenhouse based on CFD. Comput. Electron. Agric. 162, 337–347 (2019).

Sethi, V. P. & Sharma, S. K. Greenhouse heating and cooling using aquifer water. Energy 32, 1414–1421 (2007).

Campen, J. B. et al. Dehumidification of greenhouses at Northern latitudes. Biosyst. Eng. 86, 487–493 (2003).

Ejeian, M. & Wang, R. Z. Adsorption-based atmospheric water harvesting. Joule 5, 1678–1703 (2021).

Shan, H. et al. Improving solar water harvesting via airflow restructuring using 3D vapor generator. Device 1, 100065 (2023).

Shao, Z. et al. High-performance solar-driven MOF AWH device with ultra-dense integrated modular design and reflux synthesis of Ni2Cl2(BTDD). Device 1, 100058 (2023).

Tu, Y. et al. Progress and expectation of atmospheric water harvesting. Joule 2, 1452–1475 (2018).

Song, Y. et al. Hierarchical engineering of sorption-based atmospheric water harvesters. Adv. Mater. 36, 2209134 (2024).

Zeng, Z. et al. Water based adsorption thermal battery: sorption mechanisms and applications. Energy Storage Mater. 54, 794–821 (2023).

Amani, M. et al. Comprehensive review on dehumidification strategies for agricultural greenhouse applications. Appl. Therm. Eng. 181, 115979 (2020).

Deng, F. et al. Hygroscopic porous polymer for sorption-based atmospheric water harvesting. Adv. Sci. 9, e2204724 (2022).

Zhao, F. et al. Super moisture-absorbent gels for all-weather atmospheric water harvesting. Adv. Mater. 31, 1806446 (2019).

Yilmaz, G. et al. Autonomous atmospheric water seeping MOF matrix. Sci. Adv. 6, eabc8605 (2020).

Deng, F. et al. Sorption-tree with scalable hygroscopic adsorbent-leaves for water harvesting. J. Mater. Chem. A 10, 6576–6586 (2022).

Yang, J. et al. A moisture-hungry copper complex harvesting air moisture for potable water and autonomous urban agriculture. Adv. Mater. 32, e2002936 (2020).

Wang, C. et al. Water and heat recovery for greenhouses in cold climates using a solid sorption system. Energy 270, https://doi.org/10.1016/j.energy.2023.126919 (2023).

Yano, A. & Cossu, M. Energy sustainable greenhouse crop cultivation using photovoltaic technologies. Renew. Sust. Energy Rev. 109, 116–137 (2019).

Guo, Y. et al. Scalable super hygroscopic polymer films for sustainable moisture harvesting in arid environments. Nat. Commun. 13, 2761 (2022).

Li, R. et al. An integrated solar-driven system produces electricity with fresh water and crops in arid regions. Cell Rep. Phys. Sci. 3, 100781 (2022).

Shan, H. et al. High-yield solar-driven atmospheric water harvesting with ultra-high salt content composites encapsulated in porous membrane. Cell Rep. Phys. Sci. 2, 100664 (2021).

Zou, H. et al. Solar-driven scalable hygroscopic gel for recycling water from passive plant transpiration and soil evaporation. Nat. Water 2, 663–673 (2024).

Paiva, H. et al. Rheology and hardened properties of single-coat render mortars with different types of water retaining agents. Constr. Build. Mater. 23, 1141–1146 (2009).

Zhu, J. et al. Synthesis and characterization of okara-poly(acrylic acid) superabsorbent hydrogels for enhancing vegetable growth through improving water holding and retention properties of soils. ACS Food Sci. Technol. 3, 553–561 (2023).

Sarmah, D. & Karak, N. Biodegradable superabsorbent hydrogel for water holding in soil and controlled-release fertilizer. J. Appl. Polym. Sci. 137, 48495 (2020).

de Vasconcelos, M. C. et al. Superabsorbent hydrogel composite based on starch/rice husk ash as a soil conditioner in melon (Cucumis melo L.) seedling culture. J. Polym. Environ. 28, 131–140 (2020).

Satriani, A. et al. The role of superabsorbent hydrogel in bean crop cultivation under deficit irrigation conditions: a case-study in Southern Italy. Agric. Water Manag. 195, 114–119 (2018).

Aydınoğlu, D. et al. Natural carrageenan/psyllium composite hydrogels embedded montmorillonite and investigation of their use in agricultural water management. J. Polym. Environ. 29, 785–798 (2021).

Hasija, V. et al. Green synthesis of agar/Gum Arabic based superabsorbent as an alternative for irrigation in agriculture. Vacuum 157, 458–464 (2018).

Heise, K. et al. From agricultural byproducts to value-added materials: wheat straw-based hydrogels as soil conditioners? ACS Sustain. Chem. Eng. 7, 8604–8612 (2019).

Zhang, Z. et al. Biomass-based single- and double-network hydrogels derived from cellulose microfiber and chitosan for potential application as plant growing substrate. Carbohyd. Polym. 319, 121170 (2023).

Tariq, Z. et al. Significance of biopolymer-based hydrogels and their applications in agriculture: a review in perspective of synthesis and their degree of swelling for water holding. RSC Adv. 13, 24731–24754 (2023).

Wen, P. et al. Rapid synthesis of a corncob-based semi-interpenetrating polymer network slow-release nitrogen fertilizer by microwave irradiation to control water and nutrient losses. Arab. J. Chem. 10, 922–934 (2017).

Kenawy, E.-R. et al. Swelling capacity of sugarcane bagasse-g-poly(acrylamide)/attapulgite superabsorbent composites and their application as slow release fertilizer. Eur. Polym. J. 133, 109769 (2020).

Zhu, J. et al. Recent advances in superabsorbent hydrogels derived from agro waste materials for sustainable agriculture: a review. J. Agric. Food Chem. 72, 22399–22419 (2024).

Chen, J. et al. Superabsorbent polymers: from long-established, microplastics generating systems, to sustainable, biodegradable and future proof alternatives. Prog. Polym. Sci. 125, 101475 (2022).

Zhou, X. et al. Super moisture absorbent gels for sustainable agriculture via atmospheric water irrigation. ACS Mat. Lett. 2, 1419–1422 (2020).

Milimouk, I. et al. Swelling of neutralized polyelectrolyte gels. Polymer 42, 487–494 (2001).

Mandal, J. et al. Hierarchically porous polymer coatings for highly efficient passive daytime radiative cooling. Science 362, 315–319 (2018).

Hossain, M. M. & Gu, M. Radiative cooling: principles, progress, and potentials. Adv. Sci. 3, 1500360 (2016).

Wang, C. et al. Enhancing food production in hot climates through radiative cooling mulch: a nexus approach. Nexus 1, https://doi.org/10.1016/j.ynexs.2023.100002 (2024).

Wang, S. et al. Scalable thermochromic smart windows with passive radiative cooling regulation. Science 374, 1501–1504 (2021).

Tang, K. et al. Temperature-adaptive radiative coating for all-season household thermal regulation. Science 374, 1504–1509 (2021).

Zhai, Y. et al. Scalable-manufactured randomized glass-polymer hybrid metamaterial for daytime radiative cooling. Science 355, 1062–1066 (2017).

Trosseille, J. et al. Effective substrate emissivity during dew water condensation. Int. J. Heat Mass Transf. 183, 122078 (2022).

Zou, H. et al. Solar spectrum management and radiative cooling film for sustainable greenhouse production in hot climates. Sci. Bull. 68, 1493–1496 (2023).

Zou, H. et al. Eliminating greenhouse heat stress with transparent radiative cooling film. Cell Rep. Phys. Sci. 4, https://doi.org/10.1016/j.xcrp.2023.101539 (2023).

Bu, K. et al. Enhanced dew harvest with porous wind covers. Sol. Energy Mat. Sol. Cells 250, 112099 (2023).

Li, T. et al. Simultaneous atmospheric water production and 24-hour power generation enabled by moisture-induced energy harvesting. Nat. Commun. 13, 6771 (2022).

Poredoš, P. & Wang, R. Sustainable cooling with water generation. Science 380, 458–459 (2023).

Poredoš, P. et al. Sustainable water generation: grand challenges in continuous atmospheric water harvesting. Energy Environ. Sci. 15, 3223–3235 (2022).

Deshmukh, A. et al. Membrane distillation at the water-energy nexus: limits, opportunities, and challenges. Energy Environ. Sci. 11, 1177–1196 (2018).

Tao, P. et al. Solar-driven interfacial evaporation. Nat. Energy 3, 1031–1041 (2018).

Pang, Y. et al. Solar–thermal water evaporation: a review. ACS Energy Lett. 5, 437–456 (2020).

Zheng, Y. et al. Large-scale solar-thermal desalination. Joule 5, 1971–1986 (2021).

Zou, M. et al. 3D printing a biomimetic bridge-arch solar evaporator for eliminating salt accumulation with desalination and agricultural applications. Adv. Mater. 33, e2102443 (2021).

Santoro, S. et al. The advent of thermoplasmonic membrane distillation. Chem. Soc. Rev. 51, 6087–6125 (2022).

Tow, E. W. et al. Comparison of fouling propensity between reverse osmosis, forward osmosis, and membrane distillation. J. Membr. Sci. 556, 352–364 (2018).

Wang, M. et al. An integrated system with functions of solar desalination, power generation and crop irrigation. Nat. Water 1, 716–724 (2023).

Wang, Q. et al. Energy analysis and experimental verification of a solar freshwater self-produced ecological film floating on the sea. Appl. Energy 224, 510–526 (2018).

Wang, Q. et al. Performance of seawater-filling type planting system based on solar distillation process: numerical and experimental investigation. Appl. Energy 250, 1225–1234 (2019).

Wang, W. et al. Integrated solar-driven PV cooling and seawater desalination with zero liquid discharge. Joule 5, 1873–1887 (2021).

Wang, W. et al. Simultaneous production of fresh water and electricity via multistage solar photovoltaic membrane distillation. Nat. Commun. 10, 3012 (2019).

Wang, Z. et al. Pathways and challenges for efficient solar-thermal desalination. Sci. Adv. 5, eaax0763 (2019).

Li, Z. et al. Solar-powered sustainable water production: state-of-the-art technologies for sunlight–energy–water nexus. ACS Nano 15, 12535–12566 (2021).

Abedrabboh, O. et al. Modelling and analysis of a renewable energy-driven climate-controlled sustainable greenhouse for hot and arid climates. Energy Convers. Manag. 273, 116412 (2022).

Dengxiao, Z. et al. Combined biochar and water-retaining agent application increased soil water retention capacity and maize seedling drought resistance in Fluvisols. Sci. Total Environ. 907, 167885 (2024).

Zhong, S. et al. Self-cleaning and spectrally selective coating on cotton fabric for passive daytime radiative cooling. Chem. Eng. J. 407, 127104 (2021).

Xu, J. et al. All-in-one hybrid atmospheric water harvesting for all-day water production by natural sunlight and radiative cooling. Energy Environ. Sci. 17, 4988–5001 (2024).

Zhang, Z. et al. Sustainable hierarchical-pored PAAS-PNIPAAm hydrogel with core-shell structure tailored for highly efficient atmospheric water harvesting. ACS Appl. Mater. Interfaces 14, 55295–55306 (2022).

Ni, F. et al. Tillandsia-inspired hygroscopic photothermal organogels for efficient atmospheric water harvesting. Angew. Chem. Int. Edit. 59, 19237–19246 (2020).

Yao, H. et al. Highly efficient clean water production from contaminated air with a wide humidity range. Adv. Mater. 32, 1905875 (2020).

Sun, J. et al. Moisture-indicating cellulose aerogels for multiple atmospheric water harvesting cycles driven by solar energy. J. Mater. Chem. A 9, 24650–24660 (2021).

Deng, F. et al. Bioinspired topological design of super hygroscopic complex for cost-effective atmospheric water harvesting. Nano Energy 90, 106642 (2021).

Acknowledgments

R.W. acknowledges the financial support from Shanghai Agriculture Applied Technology Development Program, China (No. 2019-02-08-00-08-F01124), and the Fundamental Research Funds for the Central Universities (Shanghai Jiao Tong University, No. 23X010201008). J.L. acknowledges the financial support from the National Research Foundation, Singapore, under the Singapore-China Joint Flagship Project on Water and Environment (A-8001631-00-00) and the Intra-CREATE Thematic Grant on Science of Sustainable Cities—Food (A-0001440-00-00). D.H. acknowledges the financial support from the National Natural Science Foundation of China (No. 32171890).

Author information

Authors and Affiliations

Contributions

H.Z.: conceptualization, methodology, investigation, writing—original draft. F.W.: methodology, investigation, writing—original draft. Z.Z.: methodology, investigation, writing—original draft. J.Z.: methodology, investigation, writing—review and editing. L.Z.: methodology, investigation, writing—review, and editing. D.H.: conceptualization, supervision, writing—review and editing, funding acquisition. J.L.: conceptualization, supervision, writing—review and editing, funding acquisition. R.W.: conceptualization, supervision, writing—review and editing, funding acquisition.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Daniel Beysens and the other, anonymous, reviewers for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zou, H., Wang, F., Zeng, Z. et al. Next-generation water-saving strategies for greenhouses using a nexus approach with modern technologies. Nat Commun 16, 2091 (2025). https://doi.org/10.1038/s41467-025-57388-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-025-57388-3