Abstract

Traditional high-temperature and high-pressure synthesis routes make transition metal nitride (TMN) grains prone to sintering and agglomeration, thus synthesis of architectures with high specific surface area and pore volume is an urgent problem to be solved for the applications of TMNs. Here, a general single-source precursor route is designed to synthesize cubic-phase γ-Mo2N multilayered hollow spheres with high specific surface area (191.3 m2 g–1) and pore volume (0.69 cm3 g–1) under relatively mild conditions. Furthermore, by changing the metal composition of the precursor through ion exchange, a series of TMN (WN, TiN, VN, NbN, MoN/WN, MoN/WN/TiN) multilayer hollow spheres with high specific surface area (178.6–193.7 m2 g–1) and pore volume (0.57–0.72 cm3 g–1) are prepared. Particle size of precursor is found to be a key factor affecting the crystal phase and composition of molybdenum nitride nanostructures, and hexagonal-phase δ-MoN hierarchical hollow spheres composed of nanosheets are synthesized by adjusting the precursor particle size. The γ-Mo2N multilayered hollow spheres exhibit enhanced Raman activity for applications in trace detection of polychlorophenol and microplastics.

Similar content being viewed by others

Introduction

Transition metal nitrides (TMNs) are a class of important functional materials1,2,3. As one of the TMNs, molybdenum nitride has good conductivity and electron structure characteristics of platinum group metals, which has great application value in catalysis4,5, energy storage6,7,8, superconduction9,10, sensing, and other fields11,12. Moreover, molybdenum nitride also has thermal stability, oxidation resistance, and mechanical strength, which is expected to replace platinum group metals as an important medium in related processes13,14,15,16,17,18. Reducing particle size, forming nanostructures, and exposing more surface atoms are effective means to improve material properties19,20,21,22,23. Therefore, the construction of architectures composed of nanoparticles with a specific surface area as high as 193.7 m2 g–1 and pore volume is an effective way to obtain high-SERS activity molybdenum nitride.

Traditionally, to cross the high reaction barrier, the synthesis of molybdenum nitride with high lattice energy usually requires the precursor to be nitrided with NH3 under high temperature (>900 °C) and high pressure (several GPa), which often leads to a significant increase of the grain size and sharp reduction of the surface area and pore volume of the products24,25. Although researchers have synthesized MoN and other TMNs (WN, TiN, VN, etc.) with relatively high specific surface area using molten salt and exfoliation methods at relatively mild temperatures and pressures26,27,28, the yield is relatively limited and subsequent sample processing is cumbersome. In addition, the corrosive effect of high-temperature molten salts or exfoliated reagents on reaction equipment is also inevitable. Until now, the large-scale production of highly crystalline molybdenum nitride with a specific surface area as high as 193.7 m2 g−1 and pore volume maintain a challenge. Due to its hierarchical hollow structure, multilayer hollow spheres (MLHSs) naturally have advantages such as high specific surface area and pore volume29,30,31,32. Therefore, constructing TMN MLHSs is an effective way to solve the above problems. However, due to the harsh synthesis conditions (high temperature and pressure) of TMNs, the preparation of TMN MLHSs with precise structures composed of nanoparticles is a huge challenge, which severely limits the property and application research of TMNs. The vast majority of reported MLHS materials are inorganic metal oxides, sulfides, metal-organic frameworks (MOFs), and oxysalts33,34,35,36,37,38, while for TMNs, their MLHS structures have not been reported. Therefore, the development of simple and efficient TMN MLHS preparation methods will promote the application of TMNs in catalysis, energy, sensing, and other fields.

Recently, we found that a metallic TMN, hexagonal-phase MoN single-crystal nanosheets exhibit surface-enhanced Raman scattering (SERS) activity39, which can be used for the detection of various trace organic molecules. Compared to noble-metal SERS substrates, the high chemical stability, and lower price make TMN to be a promising low-cost SERS substrate material. However, compared to the high sensitivity and Raman enhancement factors (EFs) of precious metal SERS substrates, the sensing performance of TMN-based SERS substrates still needs to be further improved. The MLHS structure has a higher specific surface area and structural complexity compared to the single-crystal nanosheet structure39, which will promote its adsorption of analyte molecules and harvesting of incident light, thereby enhancing its Raman sensing performance.

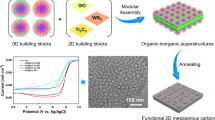

Here, a general single-source-precursor route has been developed to synthesize cubic-phase molybdenum nitride (γ-Mo2N) and hexagonal-phase molybdenum nitride (δ-MoN) in a controlled manner. The γ-Mo2N present a multilayer hollow sphere (MLHS) structure composed of nanocrystals, while the δ-MoN contains hierarchical hollow spheres (HHSs) composed of nanosheets, and they exhibit specific surface area as high as 193.7 m2 g–1 and pore volume. As precursor, particle size of molybdenum-glycerate (MoG) was found to be the key factor to determine the crystalline phase of molybdenum nitride. Furthermore, by changing the metal composition of the precursor through ion exchange, a series of TMN (WN, TiN, VN, NbN, Mon/WN, MoN/WN/TiN) MLHSs with a specific surface area as high as 193.7 m2 g–1 and pore volume were prepared. As a sensitive and stable SERS substrate, the γ-Mo2N MLHSs exhibit sensing for polychlorophenol and microplastic detection.

Results

Synthesis and characterization of cubic-phase γ-Mo2N MLHSs

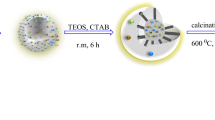

As one of the coordination compounds of molybdenum, it was reported that MoG can be used as the precursor to synthesized molybdenum sulfide40, which inspired us that MoG is a potential molybdenum source in the synthesis of molybdenum nitride. On the one hand, the coordination molecules (glycerate) can provide a natural steric hindrance effect, which limits the excessive growth of grains41,42. On the other hand, the chemical activity of the coordination compound is generally greater than that of nitrogen sources such as molybdenum oxide and molybdenum sulfide, so it can be expected that the nitridation reaction take place under relatively mild conditions. Using MoG as a precursor, we designed a general single-source-precursor route to synthesize a series of TMN MLHSs (Fig. 1).

As shown in Fig. 1, to synthesize cubic-phase γ-Mo2N MLHSs, MoG microspheres were prepared by an improved hydrothermal reaction of molybdenyl acetylacetonate (MoO2(acac)2) and glycerol (C3H8O3), and their X-ray diffraction (XRD) pattern (Supplementary Fig. 1) is consistent with that reported in the ref. 40. The diameter of the as-synthesized MoG microspheres is about 500–800 nm, the surface is smooth, and the interior is solid (Supplementary Fig. 2). It is worth pointing out that the synthesis method of MoG microspheres reported by Lou, etc.40 that we adopted with slight modifications is very simple and efficient, and can be up-scaled. Under the condition of constant reactant concentration, when the 100 mL high-pressure autoclave was upgraded to a 5 L high-pressure autoclave (Supplementary Fig. 3a), and the obtained product is still MoG microspheres with a diameter of ≈500–800 nm (Supplementary Fig. 3b, c), which provides convenient conditions for large-scale synthesis of TMN MLHSs.

After these MoG microspheres were immersed in aqueous ammonia for 7 h at room temperature, scanning electron microscopy (SEM) and transmission electron microscope (TEM) images show that the MoG solid microspheres were etched into MoG MLHSs (Supplementary Fig. 4a), and the spherical shells were composed of nanoparticles with a size of 4–7 nm (inset in Supplementary Fig. 4b). Energy dispersion spectrum (EDS) mapping images shows that C, O, and Mo elements are evenly distributed in the MoG MLHSs (Supplementary Fig. 5). Under an atmospheric pressure, when the MoG MLHSs were heated to 550 °C with a heating rate of 0.5 °C min−1 in NH3/N2 atmosphere and kept for 0.5 h, γ-Mo2N MLHSs were generated. SEM images show that the γ-Mo2N also presents a microsphere shape (Fig. 2a). It should be noted that, although the electron beam energy of SEM is weak (10 kV), the multilayer hollow structure can be clearly seen, indicating that each layer is considerable thin.

TEM images further proved the multilayered characteristics of the γ-Mo2N microspheres (Fig. 2b). The magnified TEM image clearly reveals that the γ-Mo2N microspheres contain three layers of shells with a thickness of about 20 nm, each layer is composed of 3–5 nm nanoparticles (Fig. 2c). High-resolution TEM (HRTEM) image shows that the grains have clear lattice fringes (Fig. 2d), showing their high crystallinity. The mutually orthogonal planes with a spacing of 0.21 nm can be indexed as (020) and (002) planes of cubic-phase γ-Mo2N, which corresponds to their fast Fourier transform (FFT) pattern (inset in Fig. 2d). EDS analysis showed that Mo and N were uniformly distributed on the whole microsphere (Fig. 2e–g and Supplementary Fig. 6), and the atomic ratio was 2.06 (Mo/N, Supplementary Fig. 7), which was highly consistent with the stoichiometric ratio of γ-Mo2N. X-ray photoelectron spectroscopy (XPS) measurements further demonstrated that the MLHSs are γ-Mo2N (Supplementary Fig. 8)15,43,44,45. XRD pattern showed that these products have high crystallinity (Supplementary Fig. 9). N2 adsorption/desorption isotherms revealed that the specific surface area and the pore volume of the γ-Mo2N MLHSs were 191.3 m2 g–1 and 0.69 cm3 g−1, respectively (Supplementary Fig. 10). As comparison, Supplementary Table 1 lists the specific surface area and pore volume of various TMN structures previously reported. Moreover, the pore size distribution is narrow, with a peak value of ≈2.6 nm (inset in Supplementary Fig. 10), which proves the mesoporous uniformity of the spherical shell. The γ-Mo2N MLHSs do not show clear Raman signals, which reflects their metallic character (Supplementary Fig. 11).

Synthesis and characterization of δ-MoN HHSs

When the MoG solid microspheres were directly used as molybdenum source (without going through the step of etching), and other reaction conditions are consistent with the synthesis of γ-Mo2N MLHSs, the obtained products are hexagonal-phase δ-MoN HHSs. SEM image shows that after the nitriding reaction, the MoG microspheres were transformed into microspheres consisting of flexible nanosheets (Fig. 3a). TEM image further demonstrates that these microspheres are composed of nanosheets, and the interior of the microspheres is hollow (Fig. 3b). High-magnification TEM image reveals that the thickness of the nanosheets is only 1.5–2.9 nm (Fig. 3c), which is consistent with the characterization results of atomic force microscopy (Supplementary Fig. 12). HRTEM image reveals that the nanosheets are highly crystalline. Two sets of lattices can be identified as (200) crystal planes with a spacing of 0.24 nm and (112) crystal planes with a spacing of 0.20 nm, respectively (Fig. 3d), which is consistent with the corresponding FFT pattern (inset in Fig. 3d). EDS mapping images show that Mo and N are uniformly distributed on the whole microsphere (Figs. 3e–g and Supplementary Fig. 13), and the atomic ratio was 1.02 (Mo/N, Suppl. Fig. 14). XRD pattern (Supplementary Fig. 15) and XPS spectra (Supplementary Fig. 16) also demonstrate that these products are pure and highly crystalline δ-MoN6,15,39,46,47. Benefiting from the nanosheet structure, these δ-MoN HHSs have a specific surface area of up to 186.2 m2 g−1 (Supplementary Fig. 17). The products transformed from cubic-phase γ-Mo2N MLHSs to hexagonal-phase δ-MoN HHSs, the above results suggest that the microstructure of the precursor has a significant impact on the crystal phase and morphology of the final products.

Key factors in crystal phase and morphology control

To obtain the key parameters that determine the crystal phase and morphology of these molybdenum nitride hollow architectures, we explored the formation process of the γ-Mo2N MLHSs and the δ-MoN HHSs. The monitoring of the formation process of γ-Mo2N MLHSs showed that the step of etching MoG solid microspheres into MoG MLHSs is crucial for the formation of γ-Mo2N MLHSs. Under the etching of NH3·H2O, the shells of the MoG microspheres were formed layer by layer with the extension of reaction time (Fig. 4a–f). High-magnification TEM images revealed that these shells are composed of a large number of amorphous nanoparticles with a particle size of ≈4–7 nm (Supplementary Fig. 18). These phenomena indicate that MoG solid microspheres under the etching action of NH3·H2O, the original μm-sized particles are decomposed into smaller nanoparticles, achieving particle nanoization. This structural change greatly increased the specific surface area of MoG microspheres from the original 6.7 m2 g−1 to 302.1 m2 g−1 (Supplementary Fig. 19). From the perspective of reaction kinetics, nanoparticles, specific surface area as high as 193.7 m2 g−1, and porous and amorphous structure of the MoG MLHSs significantly promotes the adsorption of NH3 and also facilitates the permeation and transportation of NH3 in the internal space of MoG MLHS (Fig. 4g), thus greatly improve the nitridation reaction kinetics. The results show that the transition from MoG MLHSs to γ-Mo2N MLHSs only takes 0.5 h (Fig. 4h). In contrast, at the same temperature and NH3 concentration, the conversion process from MoG solid microspheres to δ-MoN HHSs is up to 5 h due to the lack of MoG nanoization processes. Monitoring of the nitriding process shows that these MoG solid microspheres (Fig. 4i) first changed into a MoG/δ-MoN core–shell structure under the nitridation of NH3 (Fig. 4j). The shell is composed of δ-MoN nanosheets, while the core is composed of MoG. It can be seen that under this condition, nitridation gradually progresses from the surface to the interior of the MoG microspheres (Fig. 4k), resulting in a slower growth speed. Finally, all MoG was consumed after 5 h, the MoG/δ-MoN core–shell structure completely transforms into the δ-MoN HHSs (Fig. 4l). SEM images also demonstrate the process of transformation from MoG solid microspheres to core–shell microspheres and then to hollow microspheres (Supplementary Fig. 20). Through the analysis of the formation process of γ-Mo2N MLHSs and δ-MoN HHSs, it is evident that the particle size of the MoG precursor is directly related to the crystal phase and morphology of the final nitrided product. The formation process investigation suggests that the nanoparticles with a specific surface area as high as 193.7 m2 g–1 of MoG MLHSs can significantly promote the nitriding reaction kinetics and generate cubic-phase γ-Mo2N MLHSs, while large-sized precursors with low specific surface area tend to generate hexagonal-phase δ-MoN. Moreover, the difference in reaction kinetics caused by the size of the precursor leads to the transformation of the secondary structure of the product from zero-dimensional nanoparticles (γ-Mo2N) to two-dimensional (2D) nanosheets (δ-MoN). To further verify the phase transition caused by the precursor size, MoG microspheres composed of nanosheets (obtained by etching MoG microspheres with ethylenediamine) were used to prepare molybdenum nitride (Supplementary Fig. 21). The detection results showed that these MoG microspheres composed of nanosheets were also nitrided into γ-Mo2N nanosheets (Supplementary Figs. 22 and 23). The above results all demonstrate that the precursor size has a significant impact on the crystal phase and morphology of the products. Although the underlying mechanism is still unclear, the current results provide a feasible route for the selective preparation of γ-Mo2N and δ-MoN with a specific surface area as high as 193.7 m2 g−1.

a–f Under the etching effect of NH3·H2O, MoG solid microspheres gradually transformed to MoG MLHSs within 7 h. g Schematic illustrating the nitriding process of the γ-Mo2N MHSs. h TEM image of the obtained γ-Mo2N MLHSs after 0.5 h nitriding. i TEM image of the original MoG microsphere. j TEM image of the MoG/δ-MoN core–shell structure after 3 h nitridation. k Schematic illustrating the nitriding process of δ-MoN HHSs. l TEM image of the δ-MoN HHSs after 5 h nitridation. Scale bars are 150 nm. Source data are provided as a Source Data file.

General synthesis of TMN MLHSs

Molybdenum ions were replaced by other metal ions, forming corresponding MG (M is metal ions) MLHSs48,49,50,51. Then these MG MLHSs can be converted into corresponding TMN MLHSs after the nitriding reaction. Figure 5 shows four TMN MLHSs prepared by this method, which are WN, TiN, VN, and NbN, respectively. Taking WN MLHSs as an example, it can be seen from the HAADF-STEM image that they maintain the well-defined MLHS structure (Fig. 5a). EDS mapping images demonstrate that W element and N element are evenly distributed throughout the WN MLHSs (Fig. 5b, c). HRTEM image shows the clear lattice fringes, confirming the high crystallinity (Supplementary Fig. 24a). The structure and composition characterization results of the other three TMN MLHSs are also exhibited (Figs. 5d–l and Supplementary Fig. 24b, c), which clearly demonstrates the universality of this single-source-precursor method for the synthesis of TMN MLHSs. Furthermore, N2 adsorption and desorption data reveal that the as-synthesized TMN MLHSs have high specific surface area of 181.8 m2 g−1 (WN), 193.7 m2 g–1 (TiN), 178.6 m2 g–1 (VN), 185.2 m2 g−1 (NbN) respectively, and high pore volume of 0.61 cm3 g−1 (WN), 0.72 cm3 g−1 (TiN), 0.57 cm3 g−1 (VN), and 0.64 cm3 g−1 (NbN), respectively (Fig. 5m–p).

a–c HAADF and EDS mapping images of WN MLHSs. d–f HAADF and EDS mapping images of TiN MLHSs. g–i HAADF and EDS mapping images of VN MLHSs. j–l HAADF and EDS mapping images of NbN MLHSs. m–p N2 adsorption and desorption data of the TMN MLHSs. Scale bars are 200 nm. Source data are provided as a Source Data file.

More importantly, this single-source precursor method through ion exchange can also be used to prepare multi-component heterogeneous TMN MLHSs with uniform composition. For instance, MoN/WN binary heterogeneous MLHSs were prepared through multiple ion exchanges. HAADF-STEM image (Fig. 6a) shows that these MoN/WN maintain a good MLHS structure. EDS mapping images clearly demonstrate the uniform distribution of N, Mo, and W elements (Fig. 6b–d). MoN/WN/TiN ternary heterogeneous MLHSs with homogeneous chemical composition were also prepared by the single-source-precursor nitriding method through multiple ion exchange (Fig. 6e–i). These binary and ternary heterogeneous TMNs also exhibit high specific surface area and pore volume, which are 197.5 m2 g−1 and 0.65 m3 g−1 (MoN/WN) and 185.3 m2 g−1 and 0.54 m3 g−1 (MoN/WN/TiN), respectively (Fig. 6j–k).

SERS activity of γ-Mo2N MLHSs

We recently reported the SERS effect of hexagonal-phase δ-MoN nanosheets33, which suggests that metallic δ-MoN nanosheets are a promising SERS sensing material. These cubic-phase γ-Mo2N MLHSs exhibit a stronger SERS effect than that of the δ-MoN nanosheets. As shown in Fig. 7a, under the excitation of 532 nm laser, as a classical probe molecule, rhodamine 6 G (R6G) exhibited strong SERS signals, and the four characteristic Raman signals were clearly detected. By detecting a series of samples with different concentrations, the limit of detection (LOD) of the γ-Mo2N MLHS substrate for R6G molecules even can reach 10–12 M (Supplementary Fig. 25), which is 100 times higher than the sensitivity of δ-MoN nanosheets to R6G33. The Raman EF calculation results show that the γ-Mo2N MLHS substrates have an EF of up to 7.54 × 107 for R6G molecules (Fig. 7b), which is about an order of magnitude higher than that of δ-MoN nanosheets39. Compared to single-crystal nanosheets39, the increased SERS activity of MLHS structures can be attributed to their larger specific surface area, easier-to-obtain molecular permeability, and more intense hotspots of the electromagnetic field. These factors will be further discussed in detail below.

a SERS spectra of R6G with different concentrations obtained on the γ-Mo2N MLHS substrate. b Raman EFs with R1 and R2 at different concentrations of the γ-Mo2N MLHSs. The error bars are based on the standard deviations of ten measurements at each concentration. The data has been normalized to the integration time. c SERS spectra of 2,4-DCP obtained in the γ-Mo2N MLHSs. d High stability of the γ-Mo2N MLHSs. LOD limit of detection, PB phosphate buffer, NS normal saline. e Coupling matching between excitation light, SPR of substrate, and probe molecule. f Schematic diagram of the multiple-reflection effect of the γ-Mo2N MLHSs. g SEM image of the γ-Mo2N MLHSs adsorbed PS nanospheres from 1000 μg mL–1 suspension. h SEM image of the γ-Mo2N MLHSs adsorbed PS nanospheres from 10 μg mL–1 suspension. i SERS spectra of PS nanospheres with different concentrations obtained on the γ-Mo2N MLHS substrate. Excitation wavelength: 532 nm, laser power: 0.6 mW, integration time: 2 s for 10−9 M, 5 s for 10−10 M, 15 s for 10−11 M R6G, 3 s for 10−9 M, 7 s for 10−10 M, 18 s for 10−11 M 2,4-DCP, 1 s for 50–1000 μg mL−1, 3 s for 25 μg mL−1, 7 s for 10 μg mL−1 PS spheres. Source data are provided as a Source Data file.

The γ-Mo2N MLHSs also exhibit highly sensitive responses to environmental pollutants such as dichlorophenol (2,4-DCP), trichlorophenol (2,4,5-TCP), tetrachlorophenol (2,3,4,5-TCP), bisphenol A (BPA), and polycyclic aromatic hydrocarbons (PAHs), with the lowest detection limit of 1 × 10–11 M (Fig. 7c and Supplementary Figs. 26 and 27). It should be noted that contact-angle measurements showed that these γ-Mo2N MLHSs are hydrophilic (Supplementary Fig. 28). To solve the problem of incompatibility between hydrophilic substrate surfaces and hydrophobic molecules, 2,4-DCP and 2,4,5-TCP were dissolved in hydrophilic ethanol. In the drying process, with the volatilization of ethanol, 2,4-DCP and 2,4,5-TCP molecules can be uniformly adsorbed in γ-Mo2N MLHSs. Moreover, the γ-Mo2N substrates exhibit strong environmental resistance, even after harsh processes with acid/alkali corrosion, high-temperature oxidation, laser irradiation, biochemical reagent immersion, etc., their microstructure (Supplementary Fig. 29) and crystal lattice (Supplementary Fig. 30) have not undergone noticeable changes and still remain almost unchanged SERS performance (Fig. 7d and Supplementary Fig. 31), implying their high environmental tolerance. In addition to detection sensitivity, these γ-Mo2N substrates also exhibit high signal repeatability.

To investigate the signal repeatability, the intensity of the obtained scattering peaks at 4000 randomly selected measuring points on a 2.25 cm2 substrate were calculated, and their relative standard deviation (RSD) were calculated. The calculation results show that for R6G and 2,4-DCP with a concentration of 1 × 10−9 M, The RSD of the signal at 4000 measuring points is 5.9% (Supplementary Fig. 32a) and 6.3% (Supplementary Fig. 32b), which is at an excellent level in the reported SERS substrates (see ref. 52). The origin of the SERS sensing properties of these γ-Mo2N MLHSs was investigated. On the one hand, the SERS performance of the γ-Mo2N MHSs can be attributed to the enhanced electromagnetic resonance effect caused by the resonance coupling between excitation light (μe), localized surface plasmon resonance (LSPR) of the substrate (μs), and probe molecule (μm). As shown in Fig. 7e, the vibration wavelengths of μe, μs, and μm are 532, 519, and 526 nm, respectively, which are close to each other, so the coupling resonance behavior is easy to occur, the so-called surface-enhanced resonant Raman scattering (SERRS) phenomenon53,54,55. To further investigate the coupling effect between the excitation light, the SPR effect of the substrate, and the probe molecule, and verify the degree of influence of a single factor in the detection process. We use the method of controlling variables to conduct experimental exploration of excitation light and probe molecules, respectively. First, the influence of excitation light on the coupling effect was explored. We selected a light source with a wavelength of 633 nm that was not in the coupling range (around 530 nm) as the excitation light, kept the integration time unchanged, and selected different concentrations of R6G solution as the probe molecule for sensitivity testing. The results are shown in Supplementary Fig. 33a, b, when the light source with a wavelength of 633 nm is used as the excitation light, the LOD of γ-Mo2N MLHS substrate for R6G is 10–11 M. Compared to the light source with a wavelength of 532 nm as the excitation light, the sensitivity to R6G is reduced by a factor of 10. The Raman EF calculations show that the EF of γ-Mo2N MLHS substrate for R6G is 8.36 × 106 at 633 nm, which is about an order of magnitude lower than at 532 nm (Supplementary Fig. 33c). The experimental results show that compared with the excitation light with a wavelength of 532 nm, the SERS performance of the substrate will be reduced to a certain extent when the wavelength of the excitation light is outside the coupling region. Secondly, we investigated the effect of probe molecules on the coupling effect.

4-mercaptobenzoic acid (MBA, UV–vis absorption between 200 and 300 nm) that is not in the coupled range was selected as the probe molecule. Keeping the excitation light (532 nm) and integration time unchanged, the sensitivity of the 4-MBA solution at different concentrations was tested. The results are shown in Supplementary Fig. 34a, b, with an LOD of 10–11 M for 4-MBA from γ-Mo2N MLHS substrate under other experimental conditions. The Raman EF calculations show that the EF of γ-Mo2N MLHS substrate for 4-MBA is 8.05 × 106, which is about an order of magnitude lower than that of R6G as a probe molecule (Supplementary Fig. 34c). The experimental results show that when the probe molecule does not match the excitation light and the SPR range of the substrate, the SERS performance of the substrate will be reduced to a certain extent. The experimental results of the excitation light and the probe molecule further verify that the SPR effect between the wavelength of the excitation light and the substrate and the coupling effect between the probe molecules can bring better SERS performance. As a result, this SERRS behavior greatly enhances the near-field resonance effect and promotes the generation of a lot of electromagnetic hotspots. It should be noted that the density function theory (DFT) calculations show that the free electron density in the cubic-phase γ-Mo2N lattice is high, forming Mo–Mo metal bonds with high conductivity similar to metals (Supplementary Fig. 35), which is the origin of its SPR behavior.

On the other hand, this special MLHS structure also enhanced the SERS effect of the γ-Mo2N MLHSs. It is found that materials with MLHS structure exhibit high photocatalysis and photoconversion efficiency due to multiple reflecting and scattering of incident light in the hierarchical hollow spherical structure56,57,58. As shown in Fig. 7f, similar to the findings of Wang etc., these γ-Mo2N hollow spheres with multilayer structures provide favorable conditions for multiple-reflection effect. Comparative experiments showed that once the γ-Mo2N MLHSs are replaced by single-layer hollow spheres (SLHSs) (Supplementary Fig. 36, for synthesis, see “Methods”), their localized SPR effect is obviously weakened (Supplementary Fig. 37), which may be attributed to the SLHS structure lacking the light multi-reflection effect of the MLHS structure59,60. Furthermore, when these single-layer γ-Mo2N hollow spheres are used as the SERS substrate, their lowest detection limit for R6G is only 10–9 M (Supplementary Fig. 38), which is three orders of magnitude lower than that of γ-Mo2N MLHSs. The above results demonstrated that constructing MLHS structure is an effective strategy to improve the SERS activity of the substrates. To verify the universality of the SERS effect of this particular MLHS structure, we also investigated the SERS effects of WN, TiN, and MoN/WN MLHSs. The experimental results show that these three metallic TMN MLHS also exhibit SERS performance, with a lowest detection limit of 1 × 10–11 M, 1 × 10–10 M, and 1 × 10–11 M for R6G, respectively (Supplementary Fig. 39). These results indicate that these low-cost TMN MLHS are a promising candidate for non-noble-metal SERS substrates.

Microplastics refer to plastic particles with a diameter of less than 5 mm, which have become the fourth internationally recognized environment pollutant after persistent organic pollutants, endocrine disruptors, and antibiotics. The detection technology for microplastics with large particle sizes is relatively mature, but sensitive detection for microplastics with particle sizes less than 100 nm still needs to be developed urgently. Given the specific surface area as high as 193.7 m2 g−1 and the high-SERS activity of these molybdenum nitride microspheres, we next evaluated their potential application in the field of plastic detection. In the experiment, PS with a diameter of 50 nm was used as microplastic model, and a series of PS samples with varying concentrations were prepared from high to low (1000–10 μg mL−1). SEM images show that these γ-Mo2N MLHSs exhibit good adsorption on PS nanospheres. Figure 7g shows the SEM image of the γ-Mo2N MLHSs adsorbed PS nanospheres from 1000 μg mL–1 suspension. Even if the concentration drops to 10 μg mL–1, PS nanospheres can still be enriched on the surface of γ-Mo2N MLHSs. Under 532 nm excitation, γ-Mo2N MLHSs exhibit sensitive responsiveness to PS nanospheres, and the Raman characteristic peaks at positions 1007 and 1036 cm–1 can be clearly observed. Even if the sample concentration was diluted to 10 μg mL–1, identifiable Raman signals can still be detected (S/N > 5). Compared with previous reports on microplastic detection, the sensitivity of these γ-Mo2N MLHS substrate to PS spheres can even be comparable to that of noble-metal substrates (Supplementary Table 2). It is worth mentioning that due to the metallic character of γ-Mo2N, similar to the noble-metal SERS substrates, its Raman spectrum does not exhibit its own Raman peak, which avoids interference from the substrate. Moreover, considering that the price of γ-Mo2N is much lower than that of noble-metal SERS substrates, it can be expected that it will have broad application prospects as a sensitive and stable SERS substrate.

Discussion

In summary, highly crystalline γ-Mo2N MLHSs and δ-MoN HHSs with a specific surface area as high as 193.7 m2 g−1 and pore volume were selectively prepared by a simple single-source-precursor nitriding strategy. The particle size of the precursor was found to be a key factor in determining the crystal phase and morphology of molybdenum nitride. When the particle size of the precursor is below 10 nm, the nitriding product is cubic-phase γ-Mo2N composed of nanoparticles. However, when the particle size of the precursor is at the micrometer level, the nitriding product is hexagonal-phase δ-MoN and exhibits a 2D nanostructure. WN, TiN, VN, NbN, MoN/WN, and MoN/WN/TiN MLHSs have also been synthesized by this single-source-precursor strategy. These results have reference value for promoting the synthesis and application of highly crystalline TMNs with a specific surface area as high as 193.7 m2 g−1 and pore volume.

Methods

Synthesis of MoG microspheres

In a typical synthesis of MoG solid microspheres, 244 mg of MoO2(acac)2 and 15 mL of glycerol were added into a mixed solution containing 65 mL of isopropanol and 15 mL of distilled water. After sonication for 30 min at room temperature, the mixture was transferred into a Teflon-lined high-pressure autoclave and reacted at 160 °C for 3 h. After natural cooling to room temperature, dark brownish product was washed three times with deionized water and absolute ethanol, and dried in a vacuum oven at 50 °C for 3 h.

Synthesis of MoG MLHSs

In a typical synthesis, 0.5 g MoG microsphere powder was added to 30 mL of 25 wt.% ammonia aqueous solution (NH3·H2O). The mixed solution was left standing at room temperature for 7 h. After immersion, the obtained precipitate was washed three times with deionized water and absolute ethanol, and dried in a vacuum oven at 50 °C for 3 h.

Synthesis of γ-Mo2N MLHSs

In a typical synthesis, 0.25 g of MoG MHS powder was evenly dispersed on the bottom of an alumina ceramic crucible. The crucible was placed in the middle of the heating section of a tube furnace. Before heating, the air in the tube furnace was exhausted with nitrogen, and then NH3 was introduced at a rate of 15–20 mL min–1. After 10 min, the tube furnace began to heat to 550 °C and was kept for 30 min at a heating rate of 0.5 °C min–1. After the reaction, the black product was washed three times with deionized water and absolute ethanol, and dried in a vacuum oven at 50 °C for 3 h.

Synthesis of δ-MoN HHSs

In a typical synthesis, 0.25 g of MoG microsphere powder was evenly dispersed on the bottom of an alumina ceramic crucible. The crucible was placed in the middle of the heating section of a tube furnace. Before heating, the air in the tube furnace was exhausted with nitrogen, and then ammonia gas was introduced at a rate of 15–20 mL min–1. After 10 min, the tube furnace began to heat to 550 °C and was kept for 5 h at a heating rate of 0.5 °C min–1. After the reaction, the black product was washed three times with deionized water and absolute ethanol, and dried in a vacuum oven at 50 °C for 3 h.

Synthesis of MoG microspheres composed of nanosheets

In a typical synthesis, 0.3 g MoG microsphere powder was added to 30 mL of 15 wt.% ethylenediamine (H2NCH2CH2NH2) aqueous solution. The mixed solution was left standing at room temperature for 8 h. After immersion, the obtained precipitate was washed three times with deionized water and absolute ethanol, and dried in a vacuum oven at 50 °C for 3 h.

SERS analytics

The SERS performance of the synthesized γ-Mo2N MHSs was recorded by a confocal micro-Raman spectrometer (Renishaw-inVia Qontor). In the experiments, disperse 30 mg of γ-Mo2N MLHSs in 3 mL of anhydrous ethanol and ultrasound for 2 min. Add the obtained uniform γ-Mo2N MLHS suspension droplets into a glass circular groove with an area of about 2.25 cm2. After the anhydrous ethanol volatilizes, drip the remaining suspension until all the suspension is used up. Finally, a layer of γ-Mo2N MLHS substrate was formed in the groove, with a thickness of about 0.1 mm (Supplementary Fig. 40). The test samples are all standard solutions, such as R6G with a concentration of 10–6–10–12 M. A series of standard solution of 2,4-DCP and 2,4,5-TCP with concentrations of 10–5–10–11 M were used as the probe molecules. The fluorescent background of the probe molecule was removed using the “Subtract baseline” procedure in WiRE 5.1 software. In all SERS experiments, unless otherwise specified, the excitation wavelength of 532 nm was used, the laser power is 0.6 mW, the magnification of the objective is ×50 L, the laser beam is perpendicular to the top of the sample, the beam spot diameter is 5 μm. The fluorescent background of the probe molecule was removed using the “Subtract baseline” procedure in WiRE 5.1 software.

Microplastics detection

To investigate the sensing properties of the synthesized γ-Mo2N MLHSs towards microplastics (diameter <100 nm), a series of standard aqueous solution of PS with diameter of 40 nm and concentrations of 1000–10 µg mL–1 are used as the probe samples. To enrich these PS spheres from the solution, 15 mg of γ-Mo2N MLHSs are immersed into a probe solution (30 mL) to be measured for 5 min, then use a pipette gun to dispense a 30 μL drop of the mixture onto a blank glass substrate, forming a droplet, and allow it to air-dry for 5 min at room temperature. In all SERS experiments, the excitation wavelength of 532 nm was used, the laser power is 0.6 mW, the magnification of the objective is ×50 L, the laser beam is perpendicular to the top of the sample, the beam spot diameter is 5 μm. The fluorescent background of the probe molecule was removed using the “Subtract baseline” procedure in WiRE 5.1 software.

Calculation of the Raman EF of R6G molecule under 532 nm laser

To calculate the Raman EF of the γ-Mo2N MHS sample, the ratio of SERS to non-enhanced Raman scattering (NRS) of R6G was determined by using Eq. (1)61:

where ISERS and INRS are the Raman intensities in the SERS experiments and of the bulk dye molecules, respectively, and NSERS and NNRS are the amounts of molecules involved in the SERS experiments and the bulk Raman measurements. Here we use the R6G peak at 612 cm–1 to estimate the EFs. The peak at 612 cm–1 intensity of R6G/γ-Mo2N (1.0 × 10–10 M) is 226.6 counts with 5 s acquisition time, and that of bulk R6G is 403.5 counts with 0.5 s acquisition time. After normalizing the Raman intensities with respect to the acquisition time, where the acquisition time for the SERS signal was 5 s and for the NRS signal was 0.5 s, the Raman intensity ratio was calculated as ISERS/INRS = (75.5/5)/(403.5/0.5) = 1.87 × 10–2. This normalization process involved dividing the measured intensity of the SERS signal (75.5) by its acquisition time (5 s) and dividing the measured intensity of the NRS signal (403.5) by its acquisition time (0.5 s), to account for the different acquisition durations and obtain a more accurate comparison of the intensities. In our SERS experiments, the dye solution with 10 μL volume was drop-casted on the SERS material with ≈0.8 cm2 substrate area followed by a gentle dry process. NSERS is written as NSERS = c V NA A1/Asub, where c is the dye concentration, V is the dye droplet volume, NA is the Avogadro constant, A1 is the laser spot area, and Asub is the substrate area. To obtain the NNRS, the high concentration (0.1 M) R6G solution was drop-casted onto the bare glass. The bulk R6G crystals (thickness is larger than the laser penetration depth) were formed when the solution was dried out. Hence, we could use the density of R6G to calculate the number of molecules. NNRS is written as NNRS =d h NA A1/M, where d is the density of bulk dye (1.15 g cm–3 for R6G), h = 21 μm is the laser penetration depth62, and M is the molar mass of dye (479.01 g mol–1 for R6G). Taking all the above-mentioned factors into account, the EF in the R6G/γ-Mo2N under 532 nm laser measurements can be derived as

Therefore, for R6G/γ-Mo2N, the EF at 1.0 × 10–10 M R6G under 532 nm laser is estimated to be 7.54×107. To decrease the measuring error, the intensities are obtained by continually running the test procedure at randomly selected 10 points and taking the average.

Calculation of the Raman EF of R6G molecule under 633 nm laser

The calculation method of R6G molecule under 633 nm laser is consistent with the calculation method of R6G molecule under 532 nm laser. The peak at 612 cm–1 intensity of R6G/γ-Mo2N (1.0 × 10–10 M) is 8.35 counts with 5 s acquisition time, and that of bulk R6G is 403.5 counts with 0.5 s acquisition time. After normalizing the Raman intensities with respect to the acquisition time, where the acquisition time for the SERS signal was 5 s and for the NRS signal was 0.5 s, the Raman intensity ratio was calculated as ISERS/INRS = (8.35/5)/(403.5/0.5) = 2.07 × 10–3. This normalization process involved dividing the measured intensity of the SERS signal (8.35) by its acquisition time (5 s) and dividing the measured intensity of the NRS signal (403.5) by its acquisition time (0.5 s), to account for the different acquisition durations and obtain a more accurate comparison of the intensities. Taking all the above-mentioned factors into account, the EF in the R6G/γ-Mo2N under 633 nm laser measurements can be derived as

Therefore, for R6G/γ-Mo2N, the EF at 1.0 × 10–10 M R6G under 633 nm laser is estimated to be 8.36 × 106. To decrease the measuring error, the intensities are obtained by continually running the test procedure at randomly selected 10 points and taking the average.

Calculation of the Raman EF of 4-MBA molecule under 532 nm laser

The calculation method of 4-MBA molecule under 532 nm laser is consistent with the calculation method of R6G molecule under 532 nm laser. Here we use the 4-MBA peak at 1601 cm–1 to estimate the EFs. The peak at 1601 cm–1 intensity of 4-MBA/γ-Mo2N (1.0 × 10–10 M) is 12.6 counts with 5 s acquisition time, and that of bulk 4-MBA is 2218.3 counts with 0.5 s acquisition time. After normalizing the Raman intensities with respect to the acquisition time, where the acquisition time for the SERS signal was 5 s and for the NRS signal was 0.5 s, the Raman intensity ratio was calculated as ISERS/INRS = (12.6/5)/(2218.3/0.5) = 5.68 × 10–4. This normalization process involved dividing the measured intensity of the SERS signal (12.6) by its acquisition time (5 s) and dividing the measured intensity of the NRS signal (2218.3) by its acquisition time (0.5 s), to account for the different acquisition durations and obtain a more accurate comparison of the intensities. In our SERS experiments, the solution with 10 μL volume was drop-casted on the SERS material with ≈0.8 cm2 substrate area followed by a gentle dry process. NSERS is written as NSERS = cVNAA1/Asub, where c is the concentration, V is the droplet volume, NA is the Avogadro constant, A1 is the laser spot area, and Asub is the substrate area. To obtain the NNRS, the high concentration (0.1 M) 4-MBA solution was drop-casted onto the bare glass. The bulk 4-MBA crystals (thickness is larger than the laser penetration depth) were formed when the solution was dried out. Hence, we could use the density of 4-MBA to calculate the number of molecules. NNRS is written as NNRS =dhNAA1/M, where d is the density of bulk 4-MBA (1.3 g cm–3 for 4-MBA), h = 21 μm is the laser penetration depth62, and M is the molar mass of dye (154.19 g mol–1 for 4-MBA). Taking all the above-mentioned factors into account, the EF in the 4-MBA /γ-Mo2N measurements can be derived as

Therefore, for 4-MBA /γ-Mo2N, th μe EF at 1.0 × 10–10 M 4-MBA is estimated to be \(8.05\times {10}^{6}\). To decrease the measuring error, the intensities are obtained by continually running the test procedure at randomly selected 10 points and taking the average.

Electronic structure calculations

All calculations were carried out using the DFT, implemented in the Vienna Ab-Initio Simulation Package (VASP)63,64. The exchange-correlation functional was described by generalized gradient approximation of Perdew–Burke–Ernzerhof (GGA-PBE)65,66 and an energy cutoff of 400 eV for the plane-wave basis was set to expand the one-electron wave function, and Brillouin zone (BZ) integrations were performed using a Monkhorst–Pack theme67 with k-point mesh of 8 × 8 × 1. Geometry optimizations were stopped until the forces on each atom were less than 0.01 eV Å–1. The qvasp code was used to post-processed the raw data of VASP.

Material characterization

XRD patterns of the products were obtained on a Bruker D8 focus X-ray diffractometer by using CuKα radiation (λ = 1.54178 Å). XPS experiments were performed in a ESCALab250Xi using monochromated AlKα X-rays at hυ = 1486.6 eV. SEM images were obtained on a HitachiS-4800. UV-vis spectra were recorded by a Shimadzu UV-3600i-Plus with an integrating sphere. TEM and HRTEM characterizations were performed with a JEOL F200 operated at 200 kV. The specific surface area was measured in a Micro Tristar II 3020. Raman spectra were recorded using a Renishaw-inVia Qontor.

Reporting summary

Further information on research design is available in the Nature Portfolio Reporting Summary linked to this article.

Data availability

The data that support the findings of this study are available from the corresponding author upon request. Source data are provided with this paper.

References

Jrondi, A., Buvat, G., De La Pena, F., Marinova, M. & Huvé, M. Major improvement in the cycling ability of pseudocapacitive vanadium nitride films for micro-supercapacitor. Adv. Energy Mater. 13, 2203462 (2023).

Zeng, R. et al. Nonprecious transition metal nitrides as efficient oxygen reduction electrocatalysts for alkaline fuel cells. Sci. Adv. 8, 1584 (2022).

Wang, H. et al. Transition metal nitrides for electrochemical energy applications. Chem. Soc. Rev. 50, 1354–1390 (2020).

Huo, L. L. et al. Spatial confinement and electron transfer moderating MoN bond strength for superior ammonia decomposition catalysis. Appl. Catal. B 294, 120254 (2021).

Ye, C. et al. A Mo5N6 electrocatalyst for efficient Na2S electrodeposition in room-temperature sodium-sulfur batteries. Nat. Commun. 12, 7195 (2021).

Zhang, X. Q. et al. Exploring the origin of pseudocapacitive energy storage differences for molybdenum nitride-based electrodes. Chem. Eng. J. 462, 142250 (2023).

Xu, H. T. et al. Hierarchical molybdenum nitride nanochexes by a textured self-assembly in gas-solid phase for the enhanced application in lithium-ion batteries. ACS Nano 9, 6817–6825 (2015).

Tian, D. et al. MoN supported on graphene as a bifunctional interlayer for advanced Li-S batteries. Adv. Energy Mater. 9, 1901940 (2019).

Li, G. R., Song, J., Pana, G. L. & Gao, X. P. Highly Pt-like electrocatalytic activity of transition metal nitrides for dye-sensitized solar cells. Energy Environ. Sci. 4, 1680–1683 (2011).

Khazaei, M. et al. Novel electronic and magnetic properties of two-dimensional transition metal carbides and nitrides. Adv. Funct. Mater. 23, 2185–2192 (2013).

Lv, F. J. et al. Wearable helical molybdenum nitride super capacitors for self-powered healthcare smart sensors. ACS Appl. Mater. Interfaces 13, 29780–29787 (2021).

Wang, L. et al. Signal-on electrochemiluminescence of self-ordered molybdenum oxynitride nanotube arrays for label-free cytosensing. Anal. Chem. 90, 10858–10864 (2018).

Xie, J. F. et al. Atomically-thin molybdenum nitride nanosheets with exposed active surface sites for efficient hydrogen evolution. Chem. Sci. 5, 4615–4620 (2014).

Gong, S. Q. et al. Noble-metal-free heterostructure for efficient hydrogen evolution in visible region: molybdenum nitride/ultrathin graphitic carbon nitride. Appl. Catal. B 238, 318–327 (2018).

Song, X. Y. et al. Selective preparation of Mo2N and MoN with high surface area for flexible SERS sensing. Nano Lett. 21, 4410–4414 (2021).

Guan, H. M. et al. General molten-salt route to three-dimensional porous transition metal nitrides as sensitive and stable Raman substrates. Nat. Commun. 12, 1376 (2021).

Yu, Z. L. et al. Selective dehydrogenation of aqueous formic acid over multifunctional γ-Mo2N catalysts at a temperature lower than 100 °C. Appl. Catal. B 313, 121445 (2022).

Li, Y. Z. et al. Selective liquid hydrogenation of long chain linear alkadienes on molybdenum nitride and carbide modified by oxygen. Chem. Eng. J. 99, 213–218 (2004).

Zhang, S. M., Shi, W. X., Cheng, B. Y. & Wang, X. Versatile inorganic subnanometer nanowire adhesive. J. Am. Chem. Soc. 144, 16389–16394 (2022).

Xu, H. et al. In situ confinement of ultrasmall metal nanoparticles in short mesochannels for durable electrocatalytic nitrate reduction with high efficiency and selectivity. Adv. Mater. 35, 2207522 (2022).

Liu, J. L. et al. Polyoxometalate cluster-incorporated high entropy oxide sub-1 nm nanowires. J. Am. Chem. Soc. 144, 23191–23197 (2022).

Zhang, P. F. et al. Sub-10 nm corrugated TiO2 nanowire arrays by monomicelle-directed assembly for efficient hole extraction. J. Am. Chem. Soc. 144, 20964–20974 (2022).

Xu, K. et al. Sub-10 nm nanopattern architecture for 2D material field-effect transistors. Nano Lett. 17, 1065–1070 (2017).

Zhang, Y. Y. et al. Epitaxial superconducting δ-MoN films grown by a chemical solution method. J. Am. Chem. Soc. 133, 20735–20737 (2011).

Wang, S. M. et al. A new molybdenum nitride catalyst with rhombohedral MoS2 structure for hydrogenation applications. J. Am. Chem. Soc. 137, 4815–4822 (2015).

Jin, H. Y. et al. Molten salt-directed catalytic synthesis of 2D layered transition-metal nitrides for efficient hydrogen evolution. Chem 6, 2382–2394 (2020).

Wang, C. X. et al. Effect of TiN diffusion barrier on elements interdiffusion behavior of Ni/GH3535 system in LiF-NaF-KF molten salt at 700 °C. J. Mater. Res. Technol. 45, 125–132 (2020).

Zhu, Y. P., Chen, G., Zhong, Y. J., Zhou, W. & Shao, Z. P. Rationally designed hierarchically structured tungsten nitride and nitrogen-rich graphene-like carbon nanocomposite as efficient hydrogen evolution electrocatalyst. Adv. Sci. 5, 1700603 (2018).

Wang, J. Y., Wan, J. W. & Wang, D. Hollow multishelled structures for promising applications: understanding the structure-performance correlation. Acc. Chem. Res. 52, 2169–2178 (2019).

Hou, P. et al. Delicate control on the shell structure of hollow spheres enables tunable mass transport in water splitting. Angew. Chem. Int. Ed. 133, 6926–6931 (2021).

Wang, J. W., Cui, Y. & Wang, D. Design of hollow nanostructures for energy storage, conversion and production. Adv. Mater. 31, 1801993 (2019).

Yu, L., Yu, X. Y. & Lou, X. W. The design and synthesis of hollow micro-/nanostructures: present and future trends. Adv. Mater. 30, 1800939 (2018).

Zhang, J. et al. Hollow multi-shelled structure with metal-organic-framework-derived coatings for enhanced lithium storage. Angew. Chem. Int. Ed. 131, 5320–5325 (2019).

Shen, L. F. et al. Formation of nickel cobalt sulfide ball-in-ball hollow spheres with enhanced electrochemical pseudocapacitive properties. Nat. Commun. 6, 6694 (2015).

Wang, J. Y. et al. Accurate control of multishelled Co3O4 hollow microspheres as high-performance anode materials in lithium-ion batteries. Angew. Chem. Int. Ed. 125, 6545–6548 (2013).

Mao, D., Wan, J. W., Wang, J. Y. & Wang, D. Sequential templating approach: a groundbreaking strategy to create hollow multishelled structures. Adv. Mater. 31, 1802874 (2019).

Teng, Z. G. et al. Organosilica: mesoporous organosilica hollow nanoparticles: synthesis and applications. Adv. Mater. 31, 1970273 (2019).

Yang, H. Z. & Wang, X. Secondary-component incorporated hollow MOFs and derivatives for catalytic and energy-related applications. Adv. Mater. 31, 1800743 (2019).

Guan, H. M. et al. Low temperature synthesis of plasmonic molybdenum nitride nanosheets for surface enhanced Raman scattering. Nat. Commun. 11, 3889 (2020).

Wang, Y. W., Yu, L. & Lou, X. W. D. Synthesis of highly uniform molybdenum-glycerate spheres and their conversion into hierarchical MoS2 hollow nanospheres for lithium-ion batteries. Angew. Chem. Int. Ed. 55, 7423–7426 (2016).

Wu, J. R. et al. Unique tridentate coordination tailored solvation sheath towards highly stable lithium metal batteries. Adv. Mater. 35, 2303347 (2023).

Tian, Z. et al. Electrolyte solvation structure design for sodium ion batteries. Adv. Sci. 9, 2201207 (2022).

Yu, Z. L. et al. Formic acid as a Bio-CO carrier: selective dehydration with γ-Mo2N catalysts at low temperatures. ACS Sustain. Chem. Eng. 8, 13956–13963 (2020).

Zhang, H. J., Jia, Q. C. & Kong, L. B. γ-Mo2N nanobelts with controlled grain and mesopore sizes as high-performance anodes for lithium-ion capacitors. ACS Appl. Nano Mater. 4, 12514–12526 (2021).

Zhang, Z. S. et al. Intrinsically active surface in a Pt/γ-Mo2N catalyst for the water-gas shift reaction: molybdenum nitride or molybdenum oxide? J. Am. Chem. Soc. 142, 13362–13371 (2020).

Zhang, H. Y. et al. Bimetallic nitride modified separator constructs internal electric field for high-performance lithium-sulfur battery. Chem. Eng. J. 429, 132454 (2022).

Qi, G. C., Zhang, J. X., Chen, L., Wang, B. & Cheng, J. L. Binder-free MoN nanofibers catalysts for flexible 2-electron oxalate-based Li-CO2 batteries with high energy efficiency. Adv. Funct. Mater. 32, 2112501 (2009).

Feng, Y. G. et al. Synthesis of noble metal chalcogenides via cation exchange reactions. Nat. Syn. 1, 626–634 (2022).

Ling, T., Jaroniec, M. & Qiao, S. Z. Recent progress in engineering the atomic and electronic structure of electrocatalysts via cation exchange reactions. Adv. Mater. 32, 2001866 (2020).

Zhou, H. et al. Cation-exchange induced precise regulation of single copper site triggers room-temperature oxidation of benzene. J. Am. Chem. Soc. 142, 12643–12650 (2020).

Rivest, J. B., Prashant, K. & Jain, P. K. Cation exchange on the nanoscale: an emerging technique for new material synthesis, device fabrication, and chemical sensing. Chem. Soc. Rev. 42, 89–96 (2013).

Chen, H. Y., Lin, M. H., Wang, C. Y., Chang, Y. M. & Gwo, S. Large-scale hot spot engineering for quantitative SERS at the single-molecule scale. J. Am. Chem. Soc. 137, 13698–13705 (2015).

Yang, L. L. et al. A novel ultra-sensitive semiconductor SERS substrate boosted by the coupled resonance effect. Adv. Sci. 6, 1900310 (2019).

Tao, L. et al. 1T’ transition metal telluride atomic layers for plasmon-free SERS at femtomolar levels. J. Am. Chem. Soc. 140, 8696–8704 (2018).

James, P. et al. Application of a 2D molybdenum telluride in SERS detection of biorelevant molecules. ACS Appl. Mater. Interfaces 12, 47774–47783 (2020).

Dong, Z. H. et al. Quintuple-shelled SnO2 hollow microspheres with superior light scattering for high-performance dyesensitized solar cells. Adv. Mater. 26, 905–909 (2014).

Qian, J. F. et al. TiO2-coated multilayered SnO2 hollow microspheres for dye-sensitized solar cells. Adv. Mater. 21, 3663–3667 (2009).

Chen, M., Ye, C. Y., Zhou, S. X. & Wu, L. M. Recent advances in applications and performance of inorganic hollow spheres in devices. Adv. Mater. 25, 5343–5351 (2013).

Wang, X. J., Feng, J., Bai, Y. C., Zhang, Q. & Yin, Y. D. Synthesis, properties, and applications of hollow micro-/nanostructures. Chem. Rev. 116, 110983–111060 (2016).

Wei, Y. Z. et al. Steering hollow multishelled structures in photocatalysis: optimizing surface and mass transport. Adv. Mater. 32, 202002556 (2020).

Yilmaz, M. et al. Nanostructured organic semiconductor films for molecular detection with surface-enhanced Raman spectroscopy. Nat. Mater. 16, 918–924 (2017).

Cai, W. B. et al. Investigation of surface-enhanced Raman scattering from platinum electrodes using a confocal Raman microscope: dependence of surface roughening pretreatment. Surf. Sci. 406, 9–22 (1998).

Kresse, G. & Furthmüller, J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comp. Mater. Sci. 6, 15–50 (1996).

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169–11186 (1996).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Kresse, G. & Joubert, D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B 59, 1758–1775 (1999).

Monkhorst, H. J. & Pack, J. D. Special points for Brillouin-zone integrations. Phys. Rev. B 13, 5188–5192 (1976).

Acknowledgements

This work received financial support from the Technology Innovation Talent Program of State Administration for Market Regulation (No. KJLJ202311, G.X.) and the National Natural Science Foundation of China (No. 22374139, G.X.).

Author information

Authors and Affiliations

Contributions

G.X. proposed and designed the project. X.S. prepared materials. Y.L. and J.L. performed UV-vis and TEM characterization. H.Y. and W. L. performed XPS, XRD, and SEM characterization. M.Y. drew all the schematic diagrams. X.W. participated in the discussion about the enhancement mechanism. X.S. conducted SERS and EFs measurement. All authors contributed to the preparation of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Olga Guselnikova who co-reviewed with Alina Gorbunova; and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Song, X., Li, Y., Yin, M. et al. Multilayered hollow transition metal nitride spheres made from single-source precursors for SERS analytics. Nat Commun 16, 2678 (2025). https://doi.org/10.1038/s41467-025-58031-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-025-58031-x