Abstract

Ceramic circuit boards (CCBs) have been extensively utilized in 5G communications, aerospace, and artificial intelligence due to their excellent thermal conductivity and electrical performance. However, due to the limitation of manufacturing technologies, the existing CCBs can not take into account both the resolution and thickness, which restricts the miniaturization and high power of the resulting electronics. Herein, we report a standing-CCBs (S-CCBs) with both high-resolution and high aspect-ratio fabricated via sacrificial coating-assisted micro-3D printing. Benefiting from this technique, S-CCBs can be easily printed as a tall and thin-walled structure without landslides and sintered to be highly conductive wire with an overall shrinkage on the rough ceramic substrates, achieving a line width of 7 µm and aspect-ratio of 2.3 on various ceramic substrates (Al2O3, AlN, and ZrO2) with conductivity of 5.1 × 107 S m-1. Such circuits also possess environmental compatibility under mechanical tests (1000 adhesion test and scratch test) and harsh environments (500 °C aging for 500 h and chemical attack for 500 h). The proposed technique free from traditional lithography, etching, and plating processes opens up a promising strategy of implementing both high-density integration and large current-carrying capacity.

Similar content being viewed by others

Introduction

With the rapid development of strategic emerging industries including 5G communications, aerospace, artificial intelligence (AI), self-driving cars, and the Internet of Things (IoT) in recent years1,2,3,4,5, ceramic circuit boards (CCBs) have become a dependable alternative to traditional resin-based printed-circuit-board (PCB) due to high thermal conductivity, high heat resistance, excellent dielectric properties, and mechanical strength. Nowadays, no matter whether in the industrial field, consumer electronics field, or communications field, the relevant electronic devices are developing towards to the development directions of miniaturization and high power6,7,8. This also puts forward higher requirements for CCBs as the carrier of integrated electronics. On one hand, miniaturization requires a circuit with a high resolution (small line width/line spacing) to reduce the occupied area9; On the other hand, the small line width/line spacing will irreversibly leads to an increase in the circuit resistance, which severely limits the current carrying capacity. Increasing the aspect ratio (AR) is one of the most effective ways to enhance the current carrying capacity or decrease power consumption for a constant line width/line spacing10,11,12 (Fig. 1a, b). Therefore, the high-performance CCBs with both high resolution and high AR have become one of the key factors for miniaturization and high power of electronics.

a The schematic of commercial ceramic circuit boards (CCBs) with a large line width and low film thickness. b The schematic of S-CCBs with a small line width and large film thickness. c Chart comparing line width versus film thickness for different fabrication methods. DBC direct bonding copper17,18, IJP inkjet printing18,19, AJP aerosol jet printing49,50, DPC direct plating copper19,20, LAM laser-activated metallization21,22,23,40, SP screen printing24,25,26, LPBF laser powder bed fusion23. The inset demonstrates cross-section of the wire of CCBs and S-CCBs, Ws is line width, Hs is the film thickness. d The uneven charges distributed on the rough Al2O3 causes unstable jet, e charges distributed uniformly on the sacrificial coating (SC)-Al2O3 makes a stable jet. f The change of electric field intensity along the X-axis on the surface of Al2O3 and SC-Al2O3. g The silver wires cannot be stacked with high aspect-ratio (AR) on the Al2O3, h fine silver wires with high AR can be printed on the SC-Al2O3. i Contact angle of the silver paste on the Al2O3 and SC-Al2O3. j The silver wires shrink locally on the Al2O3 with holes, k the silver wires shrink uniformly on the SC-Al2O3. l Thermal gravity (TG) analysis curves of the silver paste with/without sacrificial coating. m The appearance of a circuit on the Al2O3 substrate with a line width of 40 μm and size of 45 mm × 45 mm, which is similar to the resolution of the commercially printed circuit board (PCB). n A scaled integrated circuit with a line width of 10 μm and size of 5 mm × 5 mm. o The high magnification image of subfigure (l). p The SEM image of a 4 layers printed silver wire with a line width of 10 μm and an AR of 1.37 (thickness of 13.7 μm). Source data are provided as a Source Data file.

To date, there have been many methods, including photolithography, nano-imprinting, and electrohydrodynamic (EHD) jet printing, to achieve the manufacturing of high resolution (even up to the nanoscale) and high AR metal structures on the fine substrates such as glass, silicon, and flexible film (PET, PI)13,14,15,16. However, the manufacturing of CCBs with both high resolution and high AR is still a big challenging issue due to the rough surface of ceramic substrates and very high requirements for performance such as the conductivity and adhesion strength. Manufacturing approaches to achieve metallization patterns on the ceramic substrates essentially include direct bonding copper (DBC)17,18, direct plating copper (DPC)19,20, laser-activated metallization (LAM)21,22,23, and screen printing (SP)24,25,26 (Fig. 1c). Among them, SP and DBC are mostly employed for fabricating thick films. For instance, SP, which is broadly utilized in high-temperature co-fired ceramics (HTCC) and low-temperature co-fired ceramics (LTCC), is capable of achieving a metal circuit film with a thickness of several to tens of micrometers24. And thick copper foils (105–700 µm) are able to be bonded to the ceramic substrate in DBC. These thick films can be greatly supportive for strong current-carrying capacity, however, it is difficult to obtain high-resolution patterns (SP is usually larger than 40 µm and DBC is larger than 100 µm)27,28,29,30. Although the currently existing high-resolution SP has achieved 600 DPI resolution (20-μm line width), it only works on the fine ceramic substrates and some flexible substrates such as the PI films31,32. The DPC and LAM approaches offer greatly improved resolution; however, they are usually employed for fabricating thin films and are not appropriate for making thick films. For example, DPC is capable of reaching a line width of 10–30 µm; however, it commonly utilizes magnetron sputtering to deposit a metal layer with less than 2-µm thick. In addition, it requires lithography and plating process for patterning, which has many costly and numerous process steps and also causes severe environmental pollution33. In the LAM process, the ceramic substrate is structured by a high-resolution laser and subsequently metalized with copper/nickel/gold metal by electroless plating34,35,36,37,38,39. Zhao et al.33 could achieve a line width of 33.2 μm in Al2O3, Wang et al.40 fabricated a 60 μm pattern on the LTCC ceramic, Yang et al.41 reached a line width as small as 16 µm. However, the thickness of the metal circuit strongly depends on the plating time, costing 4 h to obtain a 10 μm thick copper layer40.

Besides, additive manufacturing methods such as inkjet printing (IJP) and aerosol jet printing (AJP) have also been explored42,43,44,45. Uttiya et al. inkjet-printed Ag with a line width of 400 μm46, and Lim et al. fabricated a 40 μm Au pattern on the Al2O3 substrate47. Nevertheless, it suffers from general drawbacks such as the need for low viscosity inks (less than 20 cP), low resolution, and relatively low conductivity42. AJP offers several advantages such as design flexibility, and high resolution (down-10 μm)48. However, such resolution has not been achieved on the ceramic substrate due to its large roughness. For example, Ihle et al. printed 27.4 μm Ag wires49, and Delage et al. achieved 16.5 μm Ag patterns on the Al2O3 ceramic50. Therefore, from the perspective of comparing the technical specifications (Fig. 1c), the main technical capability of techniques such as SP and DBC is producing large line widths and thicknesses, whereas those of the DPC and LAM techniques are the production of small line widths and small thicknesses. There is actually a gap between these two types of technology, that is, they lack capabilities in fabricating small line widths and large thicknesses, which mostly hinders the realization of miniaturization and high-power of electronics.

In the present work, we proposed a standing-CCBs (S-CCBs) with both high-resolution and high aspect ratio (AR) using a fabrication strategy of sacrificial-coating-assisted micro-3D printing. In this strategy, a flat, hydrophobic, sacrificial coating is combined with electric-field-driven (EFD) micro-3D printing. The flatness ensures a more stable electric field for a stable jet comparing with the uncoated rough ceramic substrate. The hydrophobic effect results in a small line width and a large AR in the multi-layer printing, and the sacrifice in the sintering process makes the printed silver wire fully shrink to overcome the locking effect of the uneven ceramic surface and ensure conductivity. The printed ceramic circuits exhibited a high resolution of 7 μm and a large AR of 2.3 (thickness of 16.1 μm), which is much higher than existing fabrication methods (Fig. 1c), and high electrical properties, strong adhesion, thermal stability, and corrosion resistance.

Results

Fabrication process and forming mechanism of S-CCBs

The fabrication procedure and the forming mechanism of S-CCBs are schematically displayed in Fig. 1d–l and Supplementary Fig. 1. This approach chiefly consists of three steps: Covering a sacrificial layer on a ceramic surface; Silver paste printing via EFD micro-3D printing process; Sintering to solidify the silver wires and removing the sacrificial coating. In the whole fabrication process, the sacrificial coating plays a decisive role: first, it prevents the jet instability caused by the uneven distribution of the electric field on the rough surface (see Fig. 1d, e and the comparison of jet behavior in Supplementary Movie 1) in the printing process. The simulation results indicate that the sacrificial coating substantially improves the uniformity of the electric field on the Al2O3 ceramic surface (see Fig. 1f and Supplementary Fig. 2). Second, it separates the silver paste from the rough ceramic substrate for forming a fine pattern with high ARs, which can be further enhanced by multi-layered printing in the presence of the charge-induced self-alignment effect (see Fig. 1g, h and Supplementary Movie 2)51,52,53 since the contact angle of silver paste on the SC-Al2O3 is much higher (see Fig. 1i). Third, the sacrificial coating alters the sintering behavior, which differs from the traditional shrinkage behavior of silver paste on the uncoated Al2O3. If on the Al2O3, the shrinkage of the ceramic circuit in the sintering process is hindered by the locking effect of the rough ceramic surface, only local shrinkage is allowed, causing the silver wires to break with holes (see Fig. 1j). Concerning the SC-Al2O3, the silver wires are able to achieve a large shrinkage on the sacrificial coating. This results in improving the resolution and configuring a mechanical interlock between a full contact interface between silver wires and the ceramic substrate after removing the sacrificial coating (see Fig. 1k, Supplementary Fig. 3). This issue is essentially attributed to the fact that the sacrificial coating removal temperature is higher than the silver paste separation temperature and lower than the silver paste solidification temperature (see Fig. 1l). Therefore, based on this proposed method, ceramic circuits with different resolutions/thickness can be suitably fabricated according to Eqs. (1) and (2) (the derivation details of these relations are provided in Supplementary Fig. 4 and Supplementary Note 1).

Where, Ws is line width, Hs is the sintered total thickness of n layers, the shrinkage in the direction of line width and thickness are defined as Zw and Zh, respectively, μ is the viscosity of printing material, Dn and Ln are the inner diameter and length of the nozzle, ΔP is the value of air pressure, ε0 is permittivity of vacuum, E is the magnitudes of external electric field, γ is the surface tension of the air-liquid interface, θ1 is the contact angle (rad) between silver paste and SC-Al2O3, and θ2 is the contact angle (rad) between the deposited silver paste (nst layer) and already printed silver wire ((n-1)st layer). However, these equations have demonstrated the physical quantity and physical meaning behind its printing behavior and sintering behavior, but not been directly compared with the experimental data because multiple physical parameters were involved such as material viscosity, dielectric constant, electric field intensity, surface tension.

To this end, first, we fabricated a circuit on an Al2O3 substrate with a line width of 40 μm and a size of 45 mm × 45 mm (see Fig. 1m), which is similar to the typical resolution of a commercial printed circuit board (PCB). The high-resolution capability of the proposed approach is able to further lessen the size of the circuit with the same functions, which can be reduced to 5 mm × 5 mm with a line width of only 10 μm (see Fig. 1n, o and Supplementary Fig. 5). In addition, if a high current is required for the ceramic circuit, the large thickness can be fabricated by multi-layer printing. A 4 layers silver wire with a line width of 10 μm and an AR of 1.37 can be easily obtained by 4 times printing (see Fig. 1p and Supplementary Movie 2). Therefore, by combining sacrificial coating and EFD micro-3D printing, a S-CCBs with high resolution and large AR can be achieved, which solves the problem that the existing technology is not able to achieve high resolution and large thickness simultaneously.

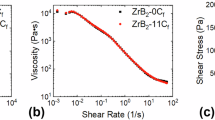

To demonstrate the advantage of the proposed printing method, the printing behavior on both the Al2O3 substrate and the SC-Al2O3 substrate is systematically examined. The Al2O3 substrate usually possesses a very rough surface (see Fig. 2a) and its surface roughness (Ra) is obtained as 153 nm in an area of 10 × 10 μm, as presented in Fig. 2b, and the measured (Ra) of 2.7 μm in a 2 × 2 mm area by 3D optical microscopy in Supplementary Fig. 6), while the roughness of the SC-Al2O3 substrate decreased to Ra = 33 nm (see Fig. 2c), and the height difference between the peak and bottom position across 10 μm length of the line sweep also decreased from 871 nm of Al2O3 substrate to 73 nm of SC-Al2O3 (see Fig. 2d). Similar results can also be achieved on the AlN and ZrO2 ceramic substrates (see Supplementary Fig. 7). Then we compared the printing behaviors on the Al2O3 and SC-Al2O3 substrates (see Supplementary Fig. 8). Supplementary Figs. 8a–d illustrate that the line width printed on SC-Al2O3 rises with increasing voltage and pressure and with decreasing printing height and printing speed. Therefore, the line width can be gradually reduced by increasing the printing speed from 1 to 35 mm s−1 (see Supplementary Figs. 8e, f). However, the line width on the Al2O3 substrate is much larger using the same printing process parameters due to the existence of diverse surfaces between Al2O3 and SC-Al2O3 substrates (see Supplementary Figs. 8g–i). In order to compare the printed morphology, the silver wires with various line widths were printed on both the Al2O3 and SC-Al2O3 substrates using the printing parameters in Supplementary Table 1. The line edge roughness of the printed wire was evaluated to present the printed line morphology (see Fig. 2e and Supplementary Fig. 9). The standard deviation of the line width increases from 3.1 μm to 5 μm as the line width grows from 10 to 60 μm in Al2O3. Such a fact is essentially attributed to the rough surface of the ceramic substrates, which not only causes instability of the Taylor cone jet due to the non-uniform electric field distribution (Supplementary Movie 1 and Supplementary Fig. 10) but also makes the silver wire deposition on the rough ceramic surface unevenly (see Fig. 2i). However, these drawbacks can be overcome on the SC-Al2O3 substrate (see Fig. 2m). The values on the SC-Al2O3 substrate remain at 0.7 μm, indicating greatly improved consistency of line width and line edge roughness because of the more uniform electric field distribution on the SC-Al2O3 substrate.

a The surface morphology of the Al2O3 and SC-Al2O3 substrates. b Surface roughness of Al2O3 in an area of 10 × 10 μm. c Surface roughness of the SC-Al2O3 substrate in an area of 10 × 10 μm. d Comparison between the surface morphology of the SC-Al2O3 substrate and that of the Al2O3 substrate. e Standard deviation of the line width printed on both the SC-Al2O3 and Al2O3 substrates. f Shrinkage of the line width after sintering on both the SC-Al2O3 and Al2O3 substrates. g The AR of the Ag wire vs. the number of printed layers on both the SC-Al2O3 and Al2O3 substrates. The inset picture is a enlarged view of the values on the SC-Al2O3. h The line width of the Ag wire vs. the number of printed layers on both the SC-Al2O3 and Al2O3 substrates. i The printed silver wires on the Al2O3 substrate (10.2 μm). j The sintered silver wires on the Al2O3 substrate (8.6 μm). k The sintered 6 layers of the silver wires on the Al2O3 substrate with a line width of 44 μm. l The contour lines of the multi-layer silver wires on Al2O3 substrate. m The printed silver wires on the SC-Al2O3 substrate (10.6 μm). n The sintered silver wires on the SC-Al2O3 substrate (7 μm). o The sintered 6 layers of silver wires on the SC-Al2O3 substrate with a line width of 10 μm and an AR of 1.7. p The contour lines of the multi-layer silver wires on SC-Al2O3 substrate. Data are presented as the mean values ± SD, n = 3 independent samples (e–h). Source data are provided as a Source Data file.

Subsequently, the sintering behaviors of the above-printed silver wires were investigated (Supplementary Figs. 11 and 12), and the sintering parameter was optimized to 870 °C for 20 min according to the adhesion properties (Supplementary Fig. 13). During sintering, the silver wire will shrink due to the thermal decomposition of the organic matter of the silver paste and the bonding effect of nano-sized silver particles. As shown in Fig. 2f, the shrinkage of the silver wire on SC-Al2O3 is almost twice that of the Al2O3 substrate in the line width range of 10–60 μm, especially for the wire of width 10.6 μm on the coated substrate, the shrinkage is about reached 34% and obtained the lowest line width of 7 µm. However, due to the interaction between the rough surface of Al2O3 and the printed silver wire, local shrinkage was achieved instead of complete shrinkage, thereby causing the silver wire to appear with many fracture points on the Al2O3 substrate (see Fig. 2j and Supplementary Fig. 14b). Once the coating is applied, the silver wire is able to complete the debonding process before the sacrificial coating volatilizes. Therefore, the silver wires on the SC-Al2O3 substrate can be sintered with a perfect morphology (see Fig. 2n and Supplementary Fig. 14d), which not only ensures the morphology and conductivity of the silver circuit but also reduces the line width. Meanwhile, the current-carrying capacity of high-resolution circuits can be enhanced to meet power electronics applications by increasing the AR of the circuits. In the case of multi-layer on the SC-Al2O3 substrate, the AR continuously increases from 0.24 to 2.3 as the number of printed layers increases from 1 to 8 layers (see Fig. 2g), whereas the line width almost remains unchanged (see Fig. 2h). It has been proved by Fig. 2o, Supplementary Fig. 15. However, when printing on the Al2O3 substrate, the line width continuously rises, while the AR is essentially unchanged (see Fig. 2k). This significant difference has been demonstrated by the evolution of cross section morphology with the number of printing layers in Fig. 2l, p, according to Supplementary Fig. 16. The no landslides stacking of silver wire on the SC-Al2O3 is mainly ascribed to the charge-induced self-alignment effect of EFD jet micro-3D printing51 and the effective support of sacrificial coating for the high viscosity of silver paste (Supplementary Fig. 17 and Supplementary Note 2). Furthermore, in the sintering process, the printed multi-layer silver wire changes from a flat interface to fit to the rough surface of Al2O3 substrate when the sacrificial coating is gradually removed, and then forms a full contact with the Al2O3 substrate for the mechanical interlock and sintered-joining (see Supplementary Figs. 18–20, and Table 2, and details of sintering behavior in Supplementary Note 3), which is crucial for the adhesion strength.

Printing typical structures of S-CCBs

Various typical structures are fabricated using optimized processing parameters to demonstrate their printing capability. First, a small inductor pattern with 60 turns and a line width of 10 μm was fabricated to exhibit the application as a miniature inductor (see Fig. 3a). The small line width/spacing is essential for high-resolution miniature circuits, the printed 5 mm × 5 mm interdigital electrodes (IDEs) pattern with 10 µm line width and 10 µm line spacing proves its ability to achieve both small line width and line spacing (see Fig. 3b). A 3 × 4 lamp array was mounted on the ceramic substrate and connected by a printed silver circuit (Fig. 3c). Subsequently, the 10 µm silver circuit on three distinct types of ceramic substrates (Al2O3 substrate with a roughness of Ra = 153 nm, AlN substrate with a roughness of Ra = 386 nm, and ZrO2 substrate with a roughness of Ra = 62 nm) are presented in Fig. 3d–f, and Supplementary Fig. 21. In addition, several different types of patterns have been printed, including a five-pointed star array (line width of 7.8 μm, side length of 470 μm) (Fig. 3g), a circular array with a line width of 14 μm and a diameter of 500 μm (Fig. 3h), and other structures (Supplementary Figs. 22 and 23). We also demonstrated the possible printing of 2–8 layers of silver wires with an unchanged line width of 10 μm and increasing AR in the range of 0.46–2.3 (see Fig. 3i–k, Supplementary Figs. 15 and 16), which is the largest AR in the reported results. Therefore, the proposed approach is of great technical universality and can be employed to fabricate arbitrary circuits with small line widths, small line spacing, and large ARs on various ceramic substrates.

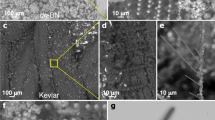

a The appearance and SEM image of a small inductor (60 turns, 10 μm line width). b The appearance and SEM image of interdigital electrodes (IDEs) pattern with line width of 10 µm and line spacing of 10 µm. c The LED array connected by printed silver circuit (power on and power off). d The SEM image of a silver wire with an area of 40 mm × 40 mm and a line width of 10 μm on an Al2O3 substrate with a roughness of Ra = 153 nm. The inset is the enlarged view of (d). e The SEM image of a silver line with an area of 40 mm × 40 mm and a line width of 10 μm on an AlN substrate with a roughness of Ra = 386 nm. The inset is the enlarged view of (e). f The SEM image of a silver wire with an area of 40 mm × 40 mm and a line width of 10 μm on a ZrO2 substrate with a roughness of Ra = 62 nm. The inset is the enlarged view of (f). g The SEM image of a five-pointed star array (line width of 7.8 μm, side length of 470 μm). h The SEM image of a circular array (line width of 14 μm, diameter of 500 μm). i The SEM image of a 2 layers silver wire with a line width of 10 μm and an AR of 0.46. j The SEM images of a 6 layers silver wire with a line width of 10 μm and AR of 1.75. k The SEM image of a 8 layers silver wire with a line width of 10 μm and an AR of 2.3.

Electrical and mechanical performance of S-CCBs

To demonstrate the excellent electrical properties of S-CCBs, the silver wire resistance and the silver mesh square resistance are presented (Supplementary Figs. 24, 25, and Table 3). Figure 4a–c compares the square resistance and resistance of various line widths (Fig. 4a), different printed layers with 10 µm line width (Fig. 4b), and different line spacing (Fig. 4c). Both the square resistance of the silver mesh and the silver wire resistance lessen with increasing the line width, growing the printing layers, and decreasing the line spacing. The conductivity trend as a function of the temperature for printed ceramic circuits was also compared with the pure bulk metal of gold, silver, and copper. Our fabricated silver circuit using a high content of silver paste (above 70 wt%) exhibits a very similar tendency in terms of the pure metal bulk of silver (Fig. 4d). Then, the measured electrical properties and line width of the present work were compared with other state-of-the-art results in the literature. The obtained results reveal that the proposed technique is capable of achieving the smallest line width of 7 µm and the highest conductivity of 5.1 × 107 S m−1. Compared to reported line widths made by other methodologies, such as 16.5 μm with 2.1 × 107 S m−1 obtained by the AJP50, 40 μm by the inkjet printing47, 20 μm with 4 × 107 S m−1 by the direct gravure printing54, and 33.2 μm with 3.23 × 104 S m−1 by the LAM33, our proposed method not only has a distinct resolution advantage, but also excellent conductivity (Fig. 4e). Therefore, to the best of the authors’ knowledge, such ultra-high-resolution circuits with excellent electrical properties have not been reported before (see Supplementary Table 4 for further details of the work performed by other processes).

a Relationship between the resistance and the line width. b Effect of the number of layers of Ag wire on the resistance. c Relationship between the mesh resistance and the line spacing of silver mesh. d The resistance change rate of the silver wire as a function of the temperature. e Comparison of conductivity and line width of our work with other state-of-the-art results in refs. 25,26,33,40,49,50,54,61,62. (Supplementary Table 4). AJP-aerosol jet printing, DGP-direct gravure printing, LAM-laser-assisted metallization, SP-screen printing, DIW-direct ink writing, IJP-inkjet priting. f The change of RS and the number of adhesion tests measured with 3 M Scotch tape. g The variation of RS as a function of the number of scratching tests for the silver meshes. h The variation of Rs after chemical corrosion (Water, HCl and NaOH). i The change of Rs during the 500 h aging test at 500 °C and 800 °C. Data are presented as the mean values ± SD, n = 3 independent samples. Source data are provided as a Source Data file.

Compared to other substrate materials such as polymers and metals, ceramics are able to combine the advantages of high chemical stability and high-temperature resistance, which enables its wide application in severe environments. To demonstrate the excellent performance of the fabricated ceramic circuit for application in extreme environments, the mechanical properties, thermal aging, and corrosion resistance are methodically examined (Fig. 4f–i and Supplementary Fig. 26). Figure 4f and Supplementary Movie 3 display the resistance change of silver meshes after performing 1000 times of peeling test via 3 M tape. Benefiting from the mechanical locking effect between the silver wire and the rough ceramic substrate, the resistance change rate (RS) of the silver meshes changed by only 0.64% without any change in the tested sample (Supplementary Fig. 27). To further explore their adhesion, the amount of resistance change of ceramic silver meshes was measured in the scratch test (Fig. 4g and Supplementary Movie 4). The obtained results indicate that RS changes quickly to about 7% in the 110 scraping cycles, and then keeps stable until to 1000 scraping cycles. Although the silver wire is flattened on the ceramic substrate, only a small amount of silver material is removed during scraping (Supplementary Fig. 28), indicating the strong adhesion strength between the silver wire and the Al2O3 substrate55. This is also confirmed by the results of tensile strength and shear strength test in Supplementary Fig. 29 and Supplementary Note 4. Despite that, future investigation is still needed to understand if the sacrificial coating may apply to other circuit material and ceramic substrate material combinations. Figure 4h and Supplementary Fig. 30 show the environmental stability of the ceramic circuit. The samples were soaked in water (pH = 7), HCl solution (pH = 2.11), and NaOH solution (pH = 13.67). There was no significant change in the resistance change rate (2.1%) of the circuit in the water, whereas the resistance change rates in the chemical corrosion environment of HCl (pH = 2.11) and NaOH (pH = 13.67) after 500 h were attained as 8.5% and 7.2%, respectively. However, the value of resistance only varies by 0.0644 Ω in HCl and 0.0553 Ω in NaOH due to the very small initial values, and no obvious changes are observed in the corroded samples (Supplementary Fig. 31). Therefore, the ceramic circuit exhibits excellent environmental stability after long-term test. The thermal aging properties of the circuit were then tested on the ceramic substrate at 500 °C and 800 °C (see Fig. 4i and Supplementary Fig. 32a)10,56. The change rate of the circuit resistance slightly varies from 0 to 9.8% during the 500 h aging test at 500 °C. However, when tested at 800 °C, the value increases from 0% to 2% in the first 100 h and also sharply rises from 2% to 133% in the last 100 h. These pieces of evidence reveal good stability of the appropriately designed circuit in long-time high-temperature (under 500 °C) environments (Supplementary Fig. 32).

Performance of S-CCBs on reducing heat generation

Finally, to demonstrate the unique advantage in terms of the miniaturization and high power of the proposed S-CCBs, the temperature rise for the printed ceramic circuit was evaluated in the presence of various currents (see Fig. 5a). The ceramic circuit used for this experiment is designed as 10 µm silver wires with different printed layers (1–6) on the Al2O3 substrate and 4 LEDs (Fig. 5b, c). Due to the increase in the thickness of the silver wire with the number of layers, the resistance of the ceramic circuit is remarkably reduced. Therefore, the circuits with larger layers are capable of forming a larger current at a constant voltage. For instance, the current of a 6 layers ceramic circuit under a voltage of 6 V is 4.49 A, which is more than twice that (2.03 A) of 2 layers and 3 times that (1.35 A) of 1 layer ceramic circuit (Fig. 5d). Furthermore, resistance reduction also plays a noticeable role in current-carrying capacity. Figure 5e illustrates the temperature increase of the printed ceramic circuit with different numbers of layers for various currents (1, 1.5, and 2 A). The number of printing layers exhibits a great effect on increasing the temperature. The more layers there are, the thicker it will be and it will produce less heat subjected to the same current. This can be clearly observed from the temperature distribution under various conditions in Fig. 5f. When the circuit board is not powered on, the temperature is 28.2 °C (Fig. 5f (i)). When the current is 1.5 A, the temperature of the 1 layer printed wires is about 160 °C (Fig. 5f (iv)), and the temperature of the 2 layers printed mesh is about 90.7 °C (Fig. 5f (iii)), while the temperature of the 6 layers mesh is below 38.9 °C (Fig. 5f (ii)) for a current of 1.5 A. This fact proves that the increase of the printed layers is able to noticeably reduce heat generation, and the current-carrying capacity of proposed S-CCBs can be also enhanced by the number of printed layers. More than 200 current on-off cycles in the temperature range of 0–350 °C demonstrate a very high heating stability (Fig. 5g, h).

a Schematic representation of temperature-rise test of the S-CCBs. b The circuit with 4 LED used for the temperature-rise test. c Printed 1 layer and 6 layers circuits. d The relationship between the applied voltage and the electric current for the circuit with various number of layers (N = 1, 2 and 6). e Comparison of the heat generation by the printed circuit with various number of layers (N = 1, 2 and 6) subjected to different currents (1, 1.5, and 2 A). f Temperature distribution at different conditions: (i) the sample is not energized, (ii) 6 layers with 1.5 A, (iii) 2 layers with 1.5 A, (iv) 1 layer with 1.5 A. g Heating stability test in the temperature range of 0–350 °C, and h the enlarged image of (g). i Schematic diagrams of planar inductors with different sizes (L1 with line width (W) of 20 μm, line spacing (S) of 20 μm, single layer, turns of 52; L2 with line width of 10 μm, line spacing of 10 μm, 6 layers, turns of 60). j Inductance and quality factor (Q) versus frequency for inductors of L1 and L2. k The comparison of the heat generation for L1 and L2 under currents of 50 mA and 100 mA. l Schematic diagrams of interdigital electrodes (IDEs) sensor (S1 with line width of 20 μm, line spacing of 20 μm, single layer, pairs of 40; S3 with line width of 10 μm, line spacing of 10 μm, 6 layers, pairs of 40). m Impedance test results of IDEs sensors (S1, S3). The data was acquired by testing three time using one device (panels d, e, g, h, j, k, m). Data are presented as the mean values ± SD, n = 3 independent samples. Source data are provided as a Source Data file.

Planar inductors and interdigital electrodes sensors

Therefore, we apply this advantage to the passive components, including planar inductors and interdigital electrodes (IDEs) sensors. Firstly, we designed two printed inductors (L1, L2) with the same calculated inductance of 11 μH using different structure parameters (L1 with line width of 20 μm, line spacing of 20 μm, single layer; L2 with line width of 10 μm, line spacing of 10 μm, 6 layers) (Supplementary Fig. 33a, b, e, f, Supplementary Table 5), which have much smaller area but higher inductances than the reported planar inductors57,58. The inductances for L1 and L2 were then measured as 11.2 μH and 11.8 μH, respectively (Fig. 5i), and the quality factor of L2 is much larger than that of L2 due to the significantly decreased resistance from 243 Ω of L1 to the 109 Ω for L2 (Supplementary Table 5). However, they present a very dissimilar temperature distribution in the presence of the same currents (50 mA and 100 mA). The temperature of L2 is much reduced compared to that of L1 (Fig. 5k and Supplementary Fig. 33c, d, g, h). Therefore, the high resolution and high AR CCBs not only decrease the area of the inductor (from 24.4 mm2 to 10.74 mm2) but also incorporate into the reduction of the heat generation under the condition that the inductance performance is guaranteed. Secondly, as well known that the performance of IDEs is closely related to structural parameters (line width, line spacing, and pairs)59,60. Thus, the sensitivity of three IDEs (S1, S2, S3) with various electrode parameters for detecting very low-concentration solutions (0.01–0.03 ppm) was appropriately explored via electrochemical impedance spectroscopy (EIS) (Fig. 5l and Supplementary Fig. 34a–e, Supplementary Table 5). The results are indicative of the fact that in the presence of the solution concentration range (i.e., 0.01–0.03 ppm), the impedance of the IDEs sensor of S1 exhibits minimal variation, which cannot distinguish concentration of 0.01 ppm, S2 is able to detect it but the impedance variation is very small, whereas S3 presents an obvious impedance variation (Fig. 5m and Supplementary Fig. 34). Meanwhile, with the increase of AR, the impedance is also reduced. It indicates that the increase in electrode density (line width/spacing) and height (AR) greatly improved sensitivity for detecting low solution concentration, but also minimized devices (The effective area of S3 is only 50% that of S1).

In summary, we have developed S-CCBs with both high-resolution and high AR using a fabrication strategy of sacrificial-coating-assisted micro-3D printing provides both high-density integration and large current carrying capacity. The newly developed approach provides us with new functionalities (both high-density integration and large current carrying capacity) using existing technologies. The fabrication of printed circuits with arbitrary patterns on the ceramic substrate has been successfully demonstrated with a minimum line width of 7 µm, line width/line spacing of 1:1, and AR of 2.3, which are much better than circuits produced by traditional lithography-based or plating-based technologies. This process can be directly extended to the fabrication of high-resolution circuits on various ceramic substrates, including Al2O3, AlN, ZrO2 ceramics because sacrificial coating-assisted EFD micro-3D printing is simple and feasible. Our S-CCBs exhibits conductivity of 5.1 × 107 S m−1 and environmental adaptability with a negligible increase of Rs under various cyclic tests and harsh working conditions (1000 adhesion tests, 1000 scratch tests, 500 h thermal test, and 500 h chemical attack). As such, the fabrication methodology of the S-CCBs proposed in this work fills the gap of existing techniques, advancing or capabilities in the miniaturization of high power electronics.

Methods

Materials

The silver paste (NT-TL20E) with a solid content of 70 wt.% and viscosity of 35,000 mPa·s was purchased from Beijing Zhongkenatong Electronic Technology Co., Ltd (China). The ceramic substrates were purchased from the Taizhou Jingwei special ceramics co. The sacrificial coating solution of aqueous polyurethane emulsion (CT-PT) with a viscosity of 56 mPa·s was purchased from the Beijing Dahua boke intelligent technology co., Ltd, which can be completely removed without any residues when the temperature is higher than 625 °C (Supplementary Fig. 35).

Fabrication of the S-CCBs

Aqueous polyurethane emulsion was first spinned coating on the ceramic substrate to obtain a flat thin layer with a thickness about 2 μm as the sacrificial coating with a spin speed of 30 r/s for 35 s, and then was cured at 70 °C for 30 min. Next, the silver wires with ultrahigh-resolution were printed on the ceramic substrates using a homemade EFD jet micro-3D printer with a nozzle of 40 μm inner diameter (Supplementary Fig. 36), in which the width, pitch, AR, and pattern of the silver wires could be controlled by adjusting the processing parameters of the EFD jet micro-3D printing. Multi-layer printing was carried out as follows: After printing the first layer, the nozzle was moved up to keep a constant distance between the top surface of the first layer and the nozzle tip according to the height of printing first layer. A relatively stable and focused electric field will be reformed between the nozzle and the top surface of the printed silver wire, ensuring the jet of silver paste will stack accurately onto the top of the printed silver wire. This process will be repeated as layer by layer to form a multi-layer thin wall structure. Then the printed silver wire was put into an atmosphere furnace at a constant temperature of 870 °C for 25 min (GR.AF12/11, Shanghai Guier Mechanical Equipment Co., Ltd, China) for removing the sacrificial coating, debinding, and sintering.

Characterization

The surface roughness of the ceramic substrate was determined using an atomic force microscope (AFM, Dimension Icon, Bruker AXS). Optical microscopy images of the silver wires were captured using an optical microscope (DSX510, OLYMPUS, Japan; YF0012, Leyes, China). The morphology and microstructure of the silver wires and silver paste were characterized by field-emission SEM (MERLIN Compact, Zeiss, Germany). The elemental profiles of interface was investigated using Oxford X-Max50 energy-dispersive spectrometer (Oxford Instruments, UK) with an accelerating voltage of 10 keV, beam current of 1.8 nA, and step size of about 30 nm. Line width consistency was evaluated by the standard deviation of printed line width according to 18 values of measured very 10 µm distance. The process of the EFD jet micro-3D printing silver wires was captured using a digital microscope (Leyes, YF0012, China). The Rs of the silver wires/meshes were measured using a milliohmmeter (AT516, Applent Instruments Co., LTD, China). The adhesion test was completed with 3 M Scotch tape. The hardness test of the silver meshes was demonstrated by a pencil hardness tester (QHQ-A, Quzhou Aipu Measuring Instrument Co., LTD, China). The aging test of the silver meshes was completed with a muffle furnace under air atmosphere (GR.AF12/11, Shanghai Guier Mechanical Equipment Co., Ltd, China). The corrosion resistance was also tested in the acidic (dilute hydrochloric acid solution with pH = 2.11), alkaline (sodium hydroxide solution with pH = 13.59), and deionized water (pH = 7). The planar inductors were tested using a precision LCR meter (Tonghui electronics Co., Ltd, China) with a frequency range of 20 Hz to 1 MHz. The IDEs sensors were tested by electrochemical impedance spectroscopy (EIS) with a frequency range of 10–104 Hz using the CHI 760E workstation (Chenhua, Shanghai) in the sulfate solution concentration ranging from 0.01 ppm to 0.03 ppm.

Statistics and reproducibility

All experiments were repeated independently with similar results for at least three times.

Reporting summary

Further information on research design is available in the Nature Portfolio Reporting Summary linked to this article.

Data availability

The raw data of the figures in the main manuscript are available in figshare with the identifier(s) https://doi.org/10.6084/m9.figshare.28558604. The authors declare that the data supporting the findings of this study are available within this paper and its Supplementary Information files. Additional data are available from the corresponding author upon request. Source data are provided with this paper.

References

Han, M. et al. Solution-processed Ti3C2Tx MXene antennas for radio-frequency communication. Adv. Mater. 33, 2003225 (2021).

Dong, K., Peng, X. & Wang, Z. L. Fiber/fabric-based piezoelectric and triboelectric nanogenerators for flexible/stretchable and wearable electronics and artificial intelligence. Adv. Mater. 32, 1902549 (2020).

Pang, J. et al. Applications of carbon nanotubes in the internet of things era. Nano Micro Lett. 13, 1–15 (2021).

Cai, H. et al. Brain organoid reservoir computing for artificial intelligence. Nat. Electron. 6, 1032–1039 (2023).

Cho, H. et al. Real-time finger motion recognition using skin-conformable electronics. Nat. Electron. 6, 619–629 (2023).

Ahmed, F. U., Sandhie, Z. T., Ali, L. & Chowdhury, M. H. A brief overview of on-chip voltage regulation in high-performance and high-density integrated circuits. IEEE Access 9, 813–826 (2020).

Liu, L. et al. Aligned, high-density semiconducting carbon nanotube arrays for high-performance electronics. Science 368, 850–856 (2020).

Madhusoodhanan, S. et al. High-temperature analysis of optical coupling using AlGaAs/GaAs LEDs for high-density integrated power modules. Sci. Rep. 12, 3168 (2022).

Park, Y.-G., An, H. S., Kim, J.-Y. & Park, J.-U. High-resolution, reconfigurable printing of liquid metals with three-dimensional structures. Sci. Adv. 5, eaaw2844 (2019).

Alhendi, M. et al. Printed electronics for extreme high temperature environments. Addit. Manuf. 54, 102709 (2022).

Sheng, A. et al. Ultrahigh temperature copper-ceramic flexible hybrid electronics. Nano Lett. 21, 9279–9284 (2021).

Valdez-Nava, Z., Kenfaui, D., Locatelli, M.-L., Laudebat, L. & Guillemet, S. Ceramic substrates for high voltage power electronics: past, present and future. In: 2019 IEEE International Workshop on Integrated Power Packaging (IWIPP)) (IEEE, 2019).

Schneider, J. et al. Electrohydrodynamic nanodrip printing of high aspect ratio metal grid transparent electrodes. Adv. Funct. Mater. 26, 833–840 (2016).

Qi, X. et al. Microscale hybrid 3D printed ultrahigh aspect ratio embedded silver mesh for flexible transparent electrodes. Mater. Today Phys. 33, 101044 (2023).

Zhang, Y., Lu, Z., Zhou, X. & Xiong, J. Metallic meshes for advanced flexible optoelectronic devices. Mater. Today, 73, 179–207 (2024).

Chen, X. et al. Printable high-aspect ratio and high-resolution Cu grid flexible transparent conductive film with figure of merit over 80 000. Adv. Electron. Mater. 5, 1800991 (2019).

Wei, X. et al. Comparative studies on microstructures, strengths and reliabilities of two types of AlN direct bonding copper substrates. Ceram. Int. 44, 18935–18941 (2018).

Mouawad, B. et al. Direct copper bonding for power interconnects: design, manufacturing, and test. IEEE Trans. Compon. Packaging Manuf. Technol. 5, 143–150 (2017).

Ma, S., Liu, L., Bromberg, V. & Singler, T. J. Electroless copper plating of inkjet-printed polydopamine nanoparticles: A facile method to fabricate highly conductive patterns at near room temperature. ACS Appl. Mater. Interfaces 6, 19494–19498 (2014).

Xu, W.-Z. et al. Direct copper plating on ultra-thin sputtered cobalt film in an alkaline bath. J. Electrochem. Soc. 160, D3075 (2013).

Lv, M., Liu, J., Wang, S., Ai, J. & Zeng, X. Higher-resolution selective metallization on alumina substrate by laser direct writing and electroless plating. Appl. Surf. Sci. 366, 227–232 (2016).

Zhang, J. et al. Laser-induced selective metallization on polymer substrates using organocopper for portable electronics. ACS Appl. Mater. interfaces 11, 13714–13723 (2019).

Cheng, D. et al. Additive manufacturing of lithium aluminosilicate glass-ceramic/metal 3D electronic components via multiple material laser powder bed fusion. Addit. Manuf. 49, 102481 (2022).

Wang, P. et al. Multimaterial additive manufacturing of LTCC matrix and silver conductors for 3D ceramic electronics. Adv. Mater. Technol. 7, 2101462 (2022).

Pursula, P. et al. 60-GHz millimeter-wave identification reader on 90-nm CMOS and LTCC. IEEE Trans. Microw. Theory Tech. 59, 1166–1173 (2011).

Jaziri, N. et al. Low-temperature co-fired ceramic-based thermoelectric generator with cylindrical grooves for harvesting waste heat from power circuits. Appl. Therm. Eng. 184, 116367 (2021).

Trabert, J. F. et al. High functional density low-temperature co-fired ceramic modules for satellite communications. In: 2005 European Microwave Conference (IEEE, 2005).

Wolff, I. Design and technology of microwave and millimeterwave LTCC circuits and systems (IEEE, 2007).

Synkiewicz, B., Kulawik, J., Skwarek, A. & Yashchyshyn, Y. & Piasecki, P. High resolution patterns on LTCC substrates for microwave applications obtained by screen printing and laser ablation. In: 2016 39th international spring seminar on electronics technology (ISSE)) (IEEE, 2016).

Kiele, P., Čvančara, Langenmair, P., Mueller, M. & Stieglitz, M. T. Thin film metallization stacks serve as reliable conductors on ceramic-based substrates for active implants. IEEE Trans. Compon. Packaging Manuf. Technol. 10, 1803–1813 (2020).

Hyun, W. J. et al. Screen printing of highly loaded silver inks on plastic substrates using silicon stencils. ACS Appl. Mater. Interfaces 7, 12619–12624 (2015).

Go, M., Qi, X., Matteini, P., Hwang, B. & Lim, S. High resolution screen-printing of carbon black/carbon nanotube composite for stretchable and wearable strain sensor with controllable sensitivity. Sens. Actuators A Phys. 332, 113098 (2021).

Zhao, F. et al. Research on laser-assisted selective metallization of a 3D printed ceramic surface. RSC Adv. 10, 44015–44024 (2020).

Heininger, N., John, W. & Boßler, H.-J. Manufacturing of molded interconnect devices from prototyping to mass production with laser direct structuring. In: International Congress MID (MID, 2004).

Islam, A., Hansen, H. N., Tang, P. T. & Sun, J. Process chains for the manufacturing of molded interconnect devices. Int. J. Adv. Manuf. Technol. 42, 831–841 (2009).

Xu, H., Zhang, J., Feng, J. & Zhou, T. Fabrication of copper patterns on polydimethylsiloxane through laser-induced selective metallization. Ind. Eng. Chem. Res. 60, 8821–8828 (2021).

Yu, Z., Wang, J. H., Li, Y. & Bai, Y. Glass fiber reinforced polycarbonate composites for laser direct structuring and electroless copper plating. Polym. Eng. Sci. 60, 860–871 (2020).

Wang, L., Silva, L., Süß-Wolf, R. & Franke, J. Prediction of surface roughness of laser selective metallization of ceramics by multiple linear regression and artificial neural networks approaches. J. Laser Appl. 32, 042013 (2020).

Wang, L. et al. Laser-associated selective metallization of ceramic surface with infrared nanosecond laser technology. Adv. Eng. Mater. 21, 1900096 (2019).

Wang, P. et al. Selectively metalizable low-temperature cofired ceramic for three-dimensional electronics via hybrid additive manufacturing. ACS Appl. Mater. Interfaces 14, 28060–28073 (2022).

Yang, J. -u, Cho, J. H. & Yoo, M. J. Selective metallization on copper aluminate composite via laser direct structuring technology. Compos. Part B Eng. 110, 361–367 (2017).

Park, Y. G. et al. High-resolution 3D printing for electronics. Adv. Sci. 9, 2104623 (2022).

Dong, Y., Bao, C. & Kim, W. S. Sustainable additive manufacturing of printed circuit boards. Joule 2, 579–582 (2018).

Kirtania, S. G. et al. Inkjet printing on a new flexible ceramic substrate for internet of things (IoT) applications. Micromachines 11, 841 (2020).

Kim, F. et al. Direct ink writing of three-dimensional thermoelectric microarchitectures. Nat. Electron. 4, 579–587 (2021).

Uttiya, S. et al. Inkjet printing of conducting silver patterns on alumina and insulating ceramic-glass by saline precursors. Thin Solid Films 642, 370–376 (2017).

Lim, J. et al. Development of the embedded capacitor with ceramic/resin hybrid films for LNA module. Ceram. Int. 40, 10177–10182 (2014).

Jing, Q. et al. Aerosol-jet printed fine-featured triboelectric sensors for motion sensing. Adv. Mater. Technol. 4, 1800328 (2019).

Ihle, M., Partsch, U., Mosch, S. & Goldberg, A. Aerosol printing of high resolution films for LTCC-multilayer components. Additional Pap. Present. 2012, 000071–000076 (2012).

Delage, A. et al. Aerosol jet printing of millimeter wave transmission lines on 3D ceramic substrates made by additive manufacturing. In: 2018 IEEE/MTT-S International Microwave Symposium-IMS) (IEEE, 2018).

Zhang, G., Lan, H., Qian, L., Zhao, J. & Wang, F. A microscale 3D printing based on the electric-field-driven jet. 3D Print. Addit. Manuf. 7, 37–44 (2020).

Zhu, X. et al. Templateless, plating-free fabrication of flexible transparent electrodes with embedded silver mesh by electric-field-driven microscale 3D printing and hybrid hot embossing. Adv. Mater. 33, 2007772 (2021).

Li, H. et al. 3D printed high performance silver mesh for transparent glass heaters through liquid sacrificial substrate electric-field-driven jet. Small 18, 2107811 (2022).

Kittila, M., Hagberg, J., Jakku, E. & Leppavuori, S. Direct gravure printing (DGP) method for printing fine-line electrical circuits on ceramics. IEEE Trans. Electron. Packaging Manuf. 27, 109–114 (2004).

Chua, S. & Siow, K. Microstructural studies and bonding strength of pressureless sintered nano-silver joints on silver, direct bond copper (DBC) and copper substrates aged at 300 C. J. Alloy. Compd. 687, 486–498 (2016).

Nasiri, A. et al. High-temperature electronics packaging for simulated Venus condition. J. Microelectron. Electron. Packaging 17, 59–66 (2020).

Gu, Y., Park, D., Bowen, D., Das, S. & Hines, D. R. Direct-write printed, solid-core solenoid inductors with commercially relevant inductances. Adv. Mater. Technol. 4, 1800312 (2019).

Ostfeld, A. E., Deckman, I., Gaikwad, A. M., Lochner, C. M. & Arias, A. C. Screen printed passive components for flexible power electronics. Sci. Rep. 5, 15959 (2015).

Zhao, Y., Yang, B. & Liu, J. Effect of interdigital electrode gap on the performance of SnO2-modified MoS2 capacitive humidity sensor. Sens. Actuators B Chem. 271, 256–263 (2018).

Tan, J. et al. Fabrication of flexible capacitive pressure sensors by adjusting the height of the interdigital electrode. ACS Appl. Electronic Mater. 6, 4539–4547 (2024).

Huang, Z. et al. 3D printing of ceramics and graphene circuits-on-ceramics by thermal bubble inkjet technology and high temperature sintering. Ceram. Int. 46, 10096–10104 (2020).

Raynaud, J. et al. Hybridization of additive manufacturing processes to build ceramic/metal parts: example of HTCC. J. Eur. Ceram. Soc. 41, 2023–2033 (2021).

Acknowledgements

This study was supported by the National Natural Science Foundation of China (Grant No. 52275345 received by G.Z., Grant No. 52175331 received by H.L.), the Support Plan for Outstanding Youth Innovation Team in Universities of Shandong Province, China (2021KJ044 received by G.Z.), and Natural Science Foundation of Shandong Province, China (Granted No. ZR2020ZD04 received by H.L., ZR2023ME194 received by G.Z.).

Author information

Authors and Affiliations

Contributions

G.Z. and Z.Y. contributed equally to this work. G.Z. conceived the idea, wrote the original draft, and supervised the experiments. Z.Y. verified the feasibility of the experiments through simulations and experimental validation, and performed the preparation, characterization, and performance testing of silver wires. Z.F. investigated the relationship between the heat treatment time of silver wires and AR, as well as conducted impedance testing. D.S. and P.D. organized and analyzed the experimental data. L.Q. and H.L. captured, illustrated, and organized the images for the manuscript. J.Z. and Q.X. validated the experimental results. H.L., D.L., J.H., and X.Z. supervised the experiments and revised the original draft.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Ziquan Cao and the other, anonymous, reviewers for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhang, G., Yu, Z., Song, D. et al. Directly printed standing ceramic circuit boards for rapid prototyping of miniaturization and high-power of electronics. Nat Commun 16, 5258 (2025). https://doi.org/10.1038/s41467-025-60408-x

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-025-60408-x