Abstract

Breaking the structural symmetry of active sites in single-atom catalysts (SACs) allows efficient regulation of the electron distribution around the metal centers, holding great promise for promoting their performance in electrocatalytic carbon dioxide reduction reaction (ECO2RR). Herein, we propose a vacancy-engineering strategy for constructing asymmetric carbon-nickel-chlorine (C–Ni–Cl) sites in Ni SAC (Ni1-C/Cl). In strongly acidic media (pH=1), Ni1-C/Cl achieves Faradaic efficiency over 98% for carbon monoxide (CO) product at the operated current density of 500 mA cm−2. In situ X-ray absorption spectra reveal that during electrocatalysis, the C3–Ni–Cl sites exhibit potential-dependent structure evolutions, which can optimize their adsorption configurations for the reactive species. Theoretical calculations demonstrate that the Ni–C/Ni–Cl co-coordination induces the asymmetric electron distribution in C3–Ni–Cl sites, resulting in the regulation of the electronic properties of the Ni centers, thereby optimizing the reaction pathway of CO2-to-CO on these single-atom sites. This work extends the synthesis of SACs containing asymmetric single-atom sites, provides insights into designing industrial-oriented electrocatalysts toward other important electrocatalytic reactions.

Similar content being viewed by others

Introduction

Electrocatalytic carbon dioxide reduction reaction (ECO2RR) offers a promising way for the sustainable conversion of CO2 into valuable chemicals and fuels, facilitating the closing of carbon cycle and accelerating the carbon neutrality process1,2,3. Single-atom catalysts (SACs), as new-generation electrocatalysts, have attracted great attention for electrocatalytic CO2 conversion, owing to their maximized atom utilization and fully exposed active sites4,5,6. Among various SACs, carbon-supported nickel (Ni) SACs, especially those containing single-atom Ni sites with Ni–N4 coordination structure, have exhibited favorable selectivity in ECO2RR to carbon monoxide (CO)7,8,9,10,11. However, the symmetric electron distribution in the Ni–N4 moieties leads to the unfavorable adsorption and activation of *COOH intermediate on central Ni atoms, resulting in unsatisfactory activities for ECO2RR on these Ni SACs12.

In order to break this bottleneck, great efforts have been devoted in engineering the local coordination environments of atomic Ni sites13,14. Recently, the construction of coordination-asymmetric Ni single-atom sites provides an effective way to regulate the electronic properties of Ni centers and enhance their adsorption/activation capacity for *COOH intermediate14,15,16. Moreover, during electrocatalysis, the geometric distortion in these asymmetric sites can induce potential-dependent evolutions of their coordination structures, resulting in the rearrangements of electron distribution at these sites and thus promoting the adsorption/activation/desorption of reactive species17. Heteroatom doping, is widely applied in breaking the structural symmetry of the Ni–N4 hosts through forming Ni–Nx–My (M = O, S, Cl,…) asymmetric coordination structures18,19,20. The electronegativity differences between the dopant atoms and the host N atoms regulate the electron arrangement around the Ni centers, thus influencing their adsorption and activation capacities for the reactive species. However, in these asymmetric single-atom sites, the strong electron transfer between the Ni centers and the adjacent Lewis acidic N ligands induces the electron localization at the N ligands, which limits the flexible modulation of the electronic structures of the Ni centers from the dopant atoms. In our opinion, due to the weaker electronegativity of C element than N element, the Ni–C4 configuration can be an alternative of Ni–N4 as the host for constructing the asymmetric single-atom sites. In this host, the moderate electron transfer in the Ni–C bonding reduces the electron localization, which allows the dopant atoms to more effectively modulate the asymmetry of the electron distribution in these single-atom sites, to achieve more efficient electrochemical CO2 conversion.

As a proof of concept, in this work, we selected Cl element as a coordination symmetry regulator for constructing asymmetric C–Ni–Cl single-atom sites in Ni SAC (Ni1-C/Cl). The significant electronegativity difference between C and Cl element (0.61, Pauling electronegativity) can strengthen the asymmetry of the electron distribution in the C–Ni–Cl single-atom sites. The synthesis of Ni1-C/Cl was based on a carbon vacancy engineering strategy. In this strategy, abundant Cl-doped carbon vacancies served as trapping and anchoring sites for binding the migrated Ni species and forming asymmetric C–Ni–Cl moieties. X-ray absorption fine structure (XAFS) spectroscopy and aberration-corrected high-angle annular dark-field scanning transmission electron microscopy (AC HAADF-STEM) revealed that the Ni species in Ni1-C/Cl existed as isolated single atoms, with coordination structure of C3–Ni–Cl. In strongly acidic media (pH = 1), Ni1-C/Cl achieved Faradaic efficiency (FE) over 98% for CO product (FECO) at the operated current density of 500 mA cm−2. Even in an acidic medium containing 0.02 M K+, Ni1-C/Cl still achieved FECOs greater than 95% in the current density range of 150 to 500 mA cm−2. In situ XAFS spectra revealed that during electrocatalysis, the C3–Ni–Cl single-atom sites exhibited potential-dependent structure evolutions, which can self-optimize their adsorption configurations for the reactive species, thus accelerating the generation and desorption of CO product17. Density functional theory (DFT) calculations and in situ attenuated total reflectance-surface-enhanced infrared absorption spectroscopy (ATR-SEIRAS) measurements indicated that the asymmetric electron distribution in C3–Ni–Cl sites optimized the reaction pathway of CO2-to-CO and promoted CO desorption on the active Ni centers. We also extended the application of Ni1-C/Cl in a Ni1-C/Cl@cuprous oxide tandem system for ethylene (C2H4) electrosynthesis. This system achieved C2H4 selectivity of ~33%, with a corresponding C2H4 partial current density above 0.37 A cm−2. Our work demonstrated a vacancy-engineering strategy for the specific construction of asymmetric Ni single-atom sites with C3–Ni–Cl coordination structure, and revealed their catalytic mechanisms in promoting CO2 electroreduction. These findings provided insights into the development of industrial-oriented electrocatalysts for other important electrocatalytic reactions.

Results

Synthesis and characterization

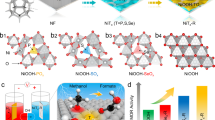

The theoretical criterion and schematic diagram of this vacancy-engineering strategy for specific constructing C–Ni–Cl asymmetric single-atom sites were shown in Fig. 1a. In this strategy, the construction of abundant Cl-doping carbon vacancies facilitated the trapping and anchoring of isolated Ni atoms. In order to verify the feasibility of this strategy, we systematically synthesized Cl-doped vacancy-rich/vacancy-deficient carbon supported Ni catalysts, named as Ni1-C/Cl and Nin-C/Cl, respectively. The synthesis of Ni1-C/Cl involved the encapsulation of Ni salt in agarose aerogel, and a dual molten salt-assisted (ZnCl2/KCl) pyrolysis of the Ni/agarose complex. Unlike Ni1-C/Cl, in the synthesis of Nin-C/Cl, only KCl was selected as the molten salt template. We also prepared Ni-free catalyst through similar synthetic procedure with Ni1-C/Cl, denoted as Zn1-C/Cl, for comparison.

a Pauling electronegativity scales of different elements and schematic diagram of the vacancy-engineering strategy for constructing asymmetric single-atom sites. b XRD patterns of Ni1-C/Cl, Zn1-C/Cl, and Nin-C/Cl. c EPR spectra of Ni1-C/Cl, Zn1-C/Cl, and Nin-C/Cl. d Raman spectra of Ni1-C/Cl, Zn1-C/Cl, and Nin-C/Cl. In order to obtain an accurate ID/IG, the two broad peaks in the Raman spectra were deconvoluted into five Lorentzian peaks43. e HAADF-STEM image of Zn1-C/Cl. f HAADF-STEM image of Ni1-C/Cl. g HAADF-STEM image of Nin-C/Cl. Source data are provided as a Source data file.

The X-ray diffraction (XRD) patterns in Fig. 1b only exhibited two broad graphite peaks, indicating the amorphous state of the metal species in these three samples21. In the electron paramagnetic resonance (EPR) spectra (Fig. 1c), the single Lorentzian lines with a g value of 2.002 were derived from the unpaired electrons in the carbon vacancies22. The stronger peak intensities in the Lorentzian lines of Zn1-C/Cl and Ni1-C/Cl indicated their higher vacancy concentrations than that of Nin-C/Cl23. Moreover, the higher vacancy concentrations in Zn1-C/Cl and Ni1-C/Cl were also confirmed by the Raman spectra (Fig. 1d), in which Zn1-C/Cl and Ni1-C/Cl demonstrated higher ratios of disorder band to graphite band (ID/IG) compared to Nin-C/Cl23. The increased vacancy concentrations in Zn1-C/Cl and Ni1-C/Cl stemmed from the sufficient activation and etching of the carbon precursors by ZnCl2 with a low melting point during pyrolysis24. Then we conducted TEM measurements to characterize the microscopic morphologies of these samples. As can be seen from Supplementary Fig. 1, the carbon carrier in Nin-C/Cl exhibited a three-dimensional porous structure. Different from Nin-C/Cl, the carbon carriers in Zn1-C/Cl and Ni1-C/Cl were assembled from stacked carbon fragments (Supplementary Figs. 2, 3). The corresponding high-resolution TEM images of these samples demonstrated the absence of Ni nanoparticles on their carbon carriers (Supplementary Figs. 1d, 2d, and 3d). The AC HAADF-STEM technique enabled identifying the dispersion of metal species at atomic-level resolution25,26. In the HAADF-STEM images of Zn1-C/Cl (Fig. 1e and Supplementary Fig. 4), isolated bright dots assigned to Zn single atoms were observed on the carbon carriers. The energy-dispersive X-ray spectroscopy (EDS) mapping of Zn1-C/Cl (Supplementary Fig. 5) showed the uniform distribution of C, Cl, and Zn elements on the carbon carriers. These observations suggested that during pyrolysis, the molten or evaporated Zn species were captured by the vacancy-rich carbon carriers, and consequently formed single-atom Zn sites. In Ni1-C/Cl, Ni/Zn single atoms were homogeneously dispersed on the carbon carriers (Fig. 1f and Supplementary Figs. 6, 7), which further demonstrated the strong capture effect of the vacancy-rich carbon substrates to these metal species. Unlike Zn1-C/Cl and Ni1-C/Cl, the vacancy-deficient carbon carriers in Nin-C/Cl induced the formation of atomically dispersed Ni clusters and trace amounts of isolated Ni single atoms. These Ni clusters were assembled from dozens of Ni atoms, and exhibited an amorphous state (Fig. 1g, Supplementary Figs. 8, 9). An inductively coupled plasma optical emission spectrometer (ICP-OES) was used to quantify the metal loadings in these samples (Supplementary Table 1). The Zn loadings in Zn1-C/Cl and Ni1-C/Cl were 0.32 and 0.25 wt%, respectively. Ni1-C/Cl and Nin-C/Cl exhibited similar Ni loadings of 1.88 and 1.71 wt%, respectively.

The aforementioned characterizations validated the feasibility of our vacancy-engineering strategy for preparing carbon-supported SACs, as well as confirmed the importance of vacancy sites in carbon carriers for anchoring the migrated metal species and constructing single-atom sites.

X-ray photoelectron spectroscopy (XPS) was applied to investigate the chemical states of different elements in these three samples. The high-resolution C 1s XPS spectra in Supplementary Fig. 10 were deconvoluted into four peaks at 284.4, 286.1, 288.6 and 290.8 eV, assigning to C = C/C–C, C–O/C–Cl, C = O moieties and C 1s satellite peaks, respectively27. The C KLL first-derivative Augar spectra of these three samples were shown in Supplementary Fig. 11. The energy difference between the intensity maximum and minimum in the C KLL first-derivative Augar spectrum was defined as D-parameter for evaluating the degree of C sp2/sp3 hybridizations in the carbon materials28. The vary sp3-like materials possessed D-parameter values from 11 to 13 eV, the D-parameter values of vary sp2-like materials located in the range of 21 to 23 eV29. The calculated D-parameter values of these three samples were demonstrated in Supplementary Table 2. Apparently, both Zn1-C/Cl and Ni1-C/Cl had lower D-parameter values than Nin-C/Cl, indicating the higher proportion of sp3-hybridized carbon atoms in their substrates, which represented the higher degree of intrinsic defects in their carbon carriers30. In the high-resolution Cl 2p XPS spectra (Supplementary Fig. 12), the binding energies of Ni/Zn-Cl moieties in Ni1-C/Cl and Zn1-C/Cl were much lower than that in Nin-C/Cl, indicating the existence of strong electron transfer between the doped Cl species and the Ni/Zn single atoms in Ni1-C/Cl and Zn1-C/Cl31. The high-resolution O 1 s XPS spectra were deconvoluted into two peaks, representing C = O and C–O moieties, respectively (Supplementary Fig. 13), which excluded the presence of Ni/Zn-O bonding in these samples. As can been seen from the high-resolution Zn 2p XPS spectra in Supplementary Fig. 14, the Zn species in Ni1-C/Cl and Zn1-C/Cl possessed close chemical states. Due to the different existence form of Ni species in Ni1-C/Cl and Nin-C/Cl, in the high-resolution Ni 2p XPS spectra, Ni1-C/Cl showed a higher binding energy of Ni 2p3/2 compared to that of Nin-C/Cl. (Supplementary Fig. 15).

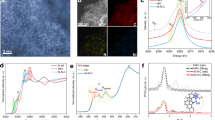

We then applied XAFS spectroscopy to acquire more information about the electronic properties and the local coordination environments of the metal species in these three samples. The Zn K-edge X-ray absorption near-edge structure (XANES) spectra were shown in Fig. 2a. The absorption edges of Zn1-C/Cl and Ni1-C/Cl located between those of Zn foil and ZnO, which indicated that the valence states of Zn species in these two samples were between 0 to +2. In the Zn K-edge Fourier-transformed extend X-ray absorption fine structure (FT-EXAFS) spectra (Fig. 2b), the broad peaks of Zn1-C/Cl and Ni1-C/Cl at ~1.75 Å represented the co-coordination of C/Cl atoms with the central Zn atoms in the first shell32. No peaks attributed to Zn-Zn bonds were observed in the FT-EXAFS spectra of both Zn1-C/Cl and Ni1-C/Cl, suggesting that the Zn species in Zn1-C/Cl and Ni1-C/Cl existed in the form of single atoms. The fitted EXAFS results at Zn K-edge indicated that in Zn1-C/Cl and Ni1-C/Cl, most single-atom Zn sites were existed with asymmetric coordination structure of C3-Zn-Cl (Fig. 2c, Supplementary Fig. 16, and Table 3). As can been seen from the Ni K-edge XANES spectra (Fig. 2d), in Nin-C/Cl, the valence state of Ni species was slightly higher than zero valence. In Ni1-C/Cl, The Ni species showed a higher valence state than those in Nin-C/Cl, stemming from the strong electron transfer between the Ni single atoms and the surrounding C/Cl atoms. The corresponding Ni K-edge FT-EXAFS spectra were shown in Fig. 2e. For Ni foil, the main peak at ~2.19 Å was attributed to Ni-Ni bond in the first shell. Different from Ni foil, the average Ni-Ni bond length in Nin-C/Cl was shorter, with the location of primary peak at ~2.09 Å in the FT-EXAFS spectra. For Ni1-C/Cl, two peaks located at ~1.25 Å and ~1.91 Å were assigned to Ni-C and Ni–Cl bonds, respectively, demonstrating the co-coordination of C/Cl atoms with the central Ni atoms in single-atom Ni sites27. The fitted EXAFS results of Ni1-C/Cl and Nin-C/Cl at Ni K-edge verified that the single-atom Ni sites in Ni1-C/Cl existed with C3–Ni–Cl coordination structure (Fig. 2f, Supplementary Fig. 17, and Table 4). The Ni–Ni coordination number for Nin-C/Cl was much lower than 12 (≈7.4, Supplementary Table 4), due to the structural disorders in Ni clusters. This distinction suggested that the Ni clusters in Nin-C/Cl had a different structure from typical crystalline Ni metal, in agreement with the HAADF-STEM results. The wavelet transform (WT) spectra of Zn1-C/Cl and Ni1-C/Cl at Zn K-edge exhibited similar intensity maximums at ~5.46 Å−1, shifted toward a negative direction compared to that of Zn foil (~6.53 Å−1), indicating the absence of aggregated Zn species in Zn1-C/Cl and Ni1-C/Cl (Fig. 2g–i). In the Ni K-edge WT spectra of Ni foil and Nin-C/Cl, their intensity maximums located at a similar position (~7.30 Å−1), showing the existence of Ni-Ni bonds in Ni clusters (Fig. 2j, k). In the WT spectrum of Ni1-C/Cl at Ni K-edge, only one intensity maximum at ~3.85 Å−1 was observed, further confirming that in Ni1-C/Cl, the Ni species existed as isolated single atoms (Fig. 2l). Taking C4 and C3Cl vacancy sites as examples, we investigated the contribution of Cl-doping to the anchoring of Ni single atoms on the carbon vacancies. The binding energies between Ni atoms and the C4/C3Cl vacancy sites were 0.538 and −0.451 eV, respectively (Supplementary Fig. 18). Obviously, the Cl-doping enhanced the interaction between the Ni atom and the carbon vacancies, resulting in a transition from a non-spontaneous to a spontaneous process for the anchoring of Ni single atoms to vacancy sites. Therefore, in the synthesis of Ni1-C/Cl, the migrating Ni species preferentially bonded to Cl-containing carbon vacancies to form single-atom Ni sites. The lack of vacancy sites in the carbon carriers of Nin-C/Cl led to the formation of Ni clusters during pyrolysis. The above detailed observations demonstrated the feasibility of our vacancy-engineering strategy for the specific construction of asymmetric single-atom sites.

a XANES spectra of Zn foil, ZnO, zinc phthalocyanine (ZnPc), Zn1-C/Cl, and Ni1-C/Cl at Zn K-edge. b FT-EXAFS spectra of Zn foil, ZnO, ZnPc, Zn1-C/Cl, and Ni1-C/Cl at Zn K-edge. c Experimental and fitted FT-EXAFS spectra of Zn1-C/Cl and Ni1-C/Cl at Zn K-edge. d XANES spectra of Ni foil, NiO, NiPc, Ni1-C/Cl, and Nin-C/Cl at Ni K-edge. e FT-EXAFS spectra of Ni foil, NiO, NiPc, Ni1-C/Cl, and Nin-C/Cl at Ni K-edge. f Experimental and fitted FT-EXAFS spectra of Ni1-C/Cl and Nin-C/Cl at Ni K-edge. g–i WT spectra of Zn foil (g), Zn1-C/Cl (h), and Ni1-C/Cl (i) at Zn K-edge. j–l WT spectra of Ni foil (j), Nin-C/Cl (k), and Ni1-C/Cl (l) at Ni K-edge. Source data are provided as a Source data file.

The evaluation of ECO2RR performances

The ECO2RR performance evaluations of these three catalysts were conducted in a typical H-type cell. As can be seen from the linear sweep voltammetry (LSV) curves in Fig. 3a, Ni1-C/Cl achieved higher polarization current densities in the potential rage of −0.54 to −0.90 V versus the reversible hydrogen electrode (vs. RHE) compared to Zn1-C/Cl and Nin-C/Cl, suggesting that the introduced Ni single atoms in Ni1-C/Cl contributed to the higher electrocatalytic activity. Moreover, Ni1-C/Cl and Zn1-C/Cl exhibited different onset potentials for electrochemical reactions (CO2 reduction reaction or hydrogen evolution reaction (HER)), which represented a switch in the active sites from Zn single atoms to Ni single atoms or possibly existed Ni-Zn dual atoms in Ni1-C/Cl. Due to the significant difference in Ni and Zn loadings, we believed that the possibly existed Ni–Zn interactions had a weak influence on the catalytic activity of Ni1-C/Cl. Chronoamperometry was applied for evaluating their catalytic selectivity and activity for CO2 electroreduction, the gas-phase products were detected and analyzed by an online gas chromatography (GC), the liquid-phase products were detected by an offline nuclear magnetic resonance (NMR) spectrometer. Among these three catalysts, Ni1-C/Cl showed the optimal selectivity for ECO2RR-to-CO, with FECOs higher than 90% from −0.5 to −0.9 V vs. RHE (Fig. 3b). Only gaseous products of CO and H2 were detected during the whole electrocatalysis process (Supplementary Figs. 19, 20). The maximum CO partial current density (jCO) of Ni1-C/Cl reached ~51.7 mA cm−2 at −0.9 V vs. RHE, much higher than that of Zn1-C/Cl (~18.12 mA cm−2) and Nin-C/Cl (~0.3 mA cm−2) (Fig. 3c). These results verified that the single-atom Ni sites served as the active sites for ECO2RR. We then conducted the electrochemical capacitance measurements to quantify the electrochemically active surface area (ECSA) of these catalysts (Supplementary Fig. 21a–c). Ni1-C/Cl showed a higher double layer capacitance (Cdl) of 261.9 mF cm−2 compared to that of Nin-C/Cl (123.3 mF cm−2) and Zn1-C/Cl (217.8 mF cm−2), which suggested that Ni1-C/Cl had the maximum ECSA, favoring for the exposure of more active sites for ECO2RR (Fig. 3d)33. The ECSA normalized jCOs of Nin-C/Cl, Zn1-C/Cl, and Ni1-C/Cl in Fig. 3e indicated that the introduced single-atom Ni sites in Ni1-C/Cl contributed to the intrinsic activity for electrocatalysis of CO2 to CO. The comparisons of the ECO2RR performances between Ni1-C/Cl and the recently reported Ni catalysts were shown in Fig. 3f and Supplementary Fig. 21d. Ni1-C/Cl demonstrated advanced catalytic activity for CO production over other single-atom Ni catalysts in ECO2RR. In a 190-h continuous electrolysis at −0.6 V vs. RHE, Ni1-C/Cl maintained FECOs higher than 95%, indicating the structural stability of the asymmetric C3–Ni–Cl active sites in long-term electrolysis (Fig. 3g).

a LSV curves of Nin-C/Cl, Zn1-C/Cl, and Ni1-C/Cl under CO2 atmosphere. b FECOs of Nin-C/Cl, Zn1-C/Cl, and Ni1-C/Cl under different potentials. c jCOs of Nin-C/Cl, Zn1-C/Cl, and Ni1-C/Cl under different potentials. d Cdls of Nin-C/Cl, Zn1-C/Cl, and Ni1-C/Cl. e ECSA normalized jCOs of Nin-C/Cl, Zn1-C/Cl, and Ni1-C/Cl. f ECO2RR performance comparisons of Ni1-C/Cl with other recently reported electrocatalysts in H-cell (0.5 M KHCO3 as the electrolyte)33,35,44,45,46,47,48,49. g Long-term stability test of Ni1-C/Cl. The flow rate of CO2 inlet was 30 mL min−1 (sccm). The measured resistance of the H-cell containing 0.5 M KHCO3 electrolyte was 5.89 ± 0.04 Ω. The potentials were presented without iR compensation. The error bars correspond to the standard deviations were acquired based on three independent experiments under the same testing conditions. Source data are provided as a Source data file.

The clarification of the catalytic mechanisms

In situ XAFS spectroscopy was applied to monitor the structure evolution of the single-atom sites in Ni1-C/Cl during the ECO2RR process. The schematic diagram of the in situ electrochemical cell was shown in Fig. 4a. Figure 4b demonstrated the Ni K-edge XANES spectra of Ni1-C/Cl recorded at different applied potentials and after electrochemical reaction. When cathodic potentials were applied from open-circuit voltage (OCV) to −0.4, −0.6, and −0.8 V vs. RHE, significant shifts of the absorption edge toward lower energies were observed, representing a distinct decrease in the valence state of the central Ni atoms in single-atom sites. This phenomenon indicated that when cathodic potentials were applied for driving ECO2RR, the transported electrons were enriched at the Ni centers, thereby forming electron-rich catalytic sites to enhance the adsorption and activation of reactive species. After the electrochemical reaction, the absorption edge shifted back to a higher energy, reflecting a rebound in the valence state of these active Ni centers. The local coordination structure evolutions of the single-atom Ni sites during ECO2RR were revealed by the EXAFS spectroscopy (Fig. 4c and Supplementary Fig. 22). Figure 4c showed the experimental and fitted Ni K-edge FT-EXAFS spectra of Ni1-C/Cl at different potentials and after electrochemical reaction. In the FT-EXAFS spectra, peaks located at ~1.30 Å and ~1.94 Å were assigned to Ni–C and Ni–Cl bonds, respectively. The local coordination structure of the active Ni sites showed potential-dependent evolutions during ECO2RR, with a ~0.02 Å and a ~0.015 Å variations in Ni-C and Ni–Cl bond lengths, respectively (Supplementary Table 5). The structure evolutions in these asymmetric sites at various potentials can optimize their absorption configurations for reactants and intermediates, thus accelerating the ECO2RR process17. In particular, after electrocatalysis, the C3–Ni–Cl sites exhibited similar coordination structure with that at OCV, confirming their structural stability during ECO2RR.

a The schematic diagram of the electrochemical cell for in situ XAFS measurements. b In situ Ni K-edge XANES spectra of Ni1-C/Cl recorded at different potentials. c Experimental and fitted FT-EXAFS spectra of Ni1-C/Cl recorded at different potentials. d Charge density map of NiC4 site. e Charge density map of NiC3Cl site. f Calculated free energies of CO2-to-CO and HER-Volmer step on NiC4 and NiC3Cl sites. g The total DOS of the NiC4 site, as well as the corresponding projected DOS of Ni-3d and C-2p. h The total DOS of the NiC3Cl site, as well as the corresponding projected DOS of Ni-3d, Cl-2p, and C-2p. (i) IR spectra of Ni1-C/Cl recorded at different potentials. The red and green color in Fig. 4d and Fig. 4e represent charge accumulation and charge loss, respectively. Source data are provided as a Source data file.

DFT calculations were performed to theoretically understand the CO2-to-CO conversion on C3–Ni–Cl sites. The C3–Ni–Cl structural model (denoted as NiC3Cl) embedded in a graphene substrate was built based on the XAFS results, a symmetric NiC4 structural model was also established for comparison (Supplementary Figs. 23–25, Supplementary Data 1). The charge density maps of NiC4 and NiC3Cl sites are shown in Fig. 4d and Fig. 4e, respectively. Apparently, a symmetric electron distribution can be observed in the NiC4 site. In the NiC3Cl site, the asymmetric local coordination environment induced a symmetry-broken electron distribution. The calculated free energies of CO2-to-CO and HER-Volmer step on NiC4 and NiC3Cl sites indicated that both NiC4 and NiC3Cl sites had a preference for ECO2RR over HER (Fig. 4f). However, the desorption of CO product on the NiC4 site was unfavorable, with a free energy for the rate-determining step (RDS) of 0.540 eV. In contrast, an optimized reaction pathway of CO2-to-CO conversion was achieved on the asymmetric NiC3Cl site, with a RDS free energy of 0.386 eV. The electronic density of states (DOS) of NiC4 and NiC3Cl sites were shown in Fig. 4g and Fig. 4h. The d-band center of the NiC3Cl site showed a lower shift toward Fermi energy than that of the NiC4 site, suggesting a weaker adsorption capacity of the NiC3Cl site to the reactant/intermediates for CO2-to-CO conversion34. These DFT calculations theoretically indicated that the Cl doping induced the formation of an asymmetric electron distribution in the single-atom Ni site, which optimized the adsorption strength of the reactants/intermediates on the Ni center in ECO2RR, resulting in a moderate reaction pathway for CO2-to-CO conversion.

The in situ ATR-SEIRAS measurements were conducted to identify the reaction intermediates on Ni1-C/Cl during the ECO2RR process (Supplementary Fig. 26). Figure 4i showed the IR spectra recorded at different potentials. The bands located at 1364-1391 cm−1 were assigned to the C-O stretching in *COOH intermediate35. The bands located at ~1650 cm−1 were attributed to the H–O–H bending of water12. The increased bands of *COOH intermediates and decreased bands of water from −0.4 to −0.9 V vs. RHE represented the efficient proton supply from water dissociation for the formation of *COOH intermediates during ECO2RR. No distinct bands referring to *CO intermediate were observed, indicating the rapid desorption of CO products from the active sites. These investigations in ATR-SEIRAS measurements experimentally confirmed the fast reaction kinetics of CO production and desorption on the asymmetric C3–Ni–Cl single-atom sites during ECO2RR.

ECO2RR in strongly acidic media

We first conducted ECO2RR in an acid-fed flow cell electrolyzer, in which 0.05 M K2SO4 solution (pH=1) was selected as the cathodic and anodic electrolytes. Figure 5a and Supplementary Fig. 27 showed the schematic diagrams of the flow cell. Chronopotentiometry was applied for evaluating the ECO2RR performances of Ni1-C/Cl, Zn1-C/Cl, and Nin-C/Cl in the acidic flow cell. Ni1-C/Cl exhibited lower full-cell voltages (Ecells) in the current density range of 50 to 500 mA cm−2 compared to Zn1-C/Cl and Nin-C/Cl, indicating the higher electrochemical activity of Ni1-C/Cl for ECO2RR (Supplementary Fig. 28). Moreover, Ni1-C/Cl also realized FECOs greater than 90 % within the current density range of 50 to 500 mA cm−2. (Fig. 5b). In contrast, Nin-C/Cl was barely selective for electrocatalytic CO2-to-CO conversion in the acidic flow cell, with a maximum FECO of ~15.7% at the current density of 50 mA cm−2. The limited selectivity of Zn1-C/Cl in acidic ECO2RR was identified from the dramatic decrease in the FECOs on Zn1-C/Cl at current densities higher than 150 mA cm−2. These investigations further revealed the irreplaceable contribution of the asymmetric C3–Ni–Cl active sites in Ni1-C/Cl for highly selective electrocatalytic CO2 conversion, endowing Ni1-C/Cl with jCO of ~491.4 mA cm−2 at the applied current density of 500 mA cm−2 (Fig. 5c). In a 40-h continuous electrolysis at the current density of 200 mA cm−2, Ni1-C/Cl consistently maintained FECOs above 97 %, which represented the stability of Ni1-C/Cl for industrial-level ECO2RR (Fig. 5d). We then investigated the effect of different K+ concentrations on the activity and selectivity of ECO2RR on Ni1-C/Cl. The corresponding Ecells recorded at different current densities in Supplementary Fig. 29 showed that increasing the K+ concentrations promoted the kinetics of the cathodic CO2 reduction and the anodic oxygen evolution reactions, thus reducing the Ecells for CO electrosynthesis. Notably, even in a strongly acidic medium (pH = 1) containing 0.01 M K2SO4, Ni1-C/Cl still achieved FECOs greater than 95% in the current density range of 150 to 500 mA cm−2 (Supplementary Fig. 30).

a Schematic diagram of the flow cell electrolyzer. b FECOs of Nin-C/Cl, Zn1-C/Cl, and Ni1-C/Cl at different applied current densities. c jCOs of Nin-C/Cl, Zn1-C/Cl, and Ni1-C/Cl at different applied current densities. d Long-term stability test of Ni1-C/Cl in flow cell. e Ecells in flow cell and MEA at different applied current densities using Ni1-C/Cl as the cathodic electrocatalyst. f FECOs of Ni1-C/Cl at different applied current densities in MEA. g Long-term stability test of Ni1-C/Cl in MEA. The flow rate of CO2 inlet was 20 sccm. The measured resistances of flow cell and MEA electrolyzers containing 0.05 M K2SO4 electrolyte were 4.37 ± 0.31 Ω and 0.60 ± 0.01 Ω, respectively. The Ecells were recorded without iR compensation. The error bars correspond to the standard deviations were acquired based on three independent experiments under the same testing conditions. Source data are provided as a Source data file.

The ECO2RR performance evaluations of Ni1-C/Cl were also carried out in an acid-fed membrane electrode assembly (MEA) electrolyzer (Supplementary Fig. 31), using 0.05 M K2SO4 solution (pH=1) as the anodic electrolyte, humidified CO2 as the feedstock for CO production. In the acid-fed MEA, Ni1-C/Cl achieved much lower Ecells for ECO2RR than those in the flow cell, due to the lower resistance and faster mass transport in MEA (Fig. 5e and Supplementary Fig. 32). In the current density range of 50 to 350 mA cm−2, the FECOs were consistently above 90% (Fig. 5f). The single-pass carbon efficiency in MEA for CO2-to-CO conversion (SPCECO) reached about 70% at the industrial current density of 200 mA cm−2, under the flow rate of CO2 inlet of 2 sccm. (Supplementary Fig. 33). The SPCECO comparisons of Ni1-C/Cl with other reported electrocatalysts in MEA demonstrated the higher carbon utilization on Ni1-C/Cl during CO2-to-CO conversion (Supplementary Fig. 34). Moreover, the CO selectivity on Ni1-C/Cl remained above 90% throughout a 10-h continuous electrolysis at the current density of 200 mA cm−2 (Fig. 5g).

In order to minimize the formation of (bi)carbonates during CO2 electrolysis, we further used 0.01 M K2SO4 solution (pH = 1) as the anodic electrolyte to evaluate the long-term stability of Ni1-C/Cl for ECO2RR in MEA. As can be seen from Supplementary Fig. 35a, in a ~80 h continuous electrolysis at 200 mA cm−2, Ni1-C/Cl consistently maintained the FECO over 93% and the SPCECO over 28%. The long-term stability comparisons between Ni1-C/Cl and other reported electrocatalysts proved the advances of Ni1-C/Cl toward industrial CO2 electrolysis (Supplementary Fig. 35b). The ex situ XRD, XPS, and AC HAADF-STEM measurements disclosed that the Ni species in Ni1-C/Cl still existed in the form of single atoms after the stability test, verifying the structural stability of the single-atom sites in Ni1-C/Cl (Supplementary Figs. 36, 37). The in situ ATR-SEIRAS measurements were conducted to monitor the ECO2RR process on Ni1-C/Cl after long-term stability test in MEA. Obvious bands assigned to the *COOH intermediates were observed in the recorded IR spectra, which indicated that the C3-Ni–Cl single-atom sites still retained a good activation capacity for CO2 reactants during ECO2RR, even after a long period of continuous electrolysis (Supplementary Fig. 38).

To compare the catalytic activity and selectivity differences between C–Ni–Cl and N–Ni–Cl single-atom sites, we introduced nitrogen source in the synthesis of Ni1-C/Cl and changed the coordination structure of the single-atom Ni sites from C–Ni–Cl to N–Ni–Cl, the prepared electrocatalyst was named as Ni1-N/Cl. The XRD pattern and TEM images of Ni1-N/Cl in Supplementary Figs. 39, 40 verified the absence of nanoparticle species in Ni1-N/Cl. The HAADF-STEM images and the corresponding EDS mapping in Supplementary Fig. 41 confirmed that the Ni species in Ni1-N/Cl were anchored on the carbon carriers as single atoms. The XPS spectra of Ni1-N/Cl indicated the existence of Ni–N and Ni–Cl moieties in Ni1-N/Cl (Supplementary Fig. 42). The XAFS measurements further revealed the N3–Ni–Cl coordination structure of most single-atom Ni sites in Ni1-N/Cl (Supplementary Fig. 43 and Supplementary Table 6). The ECO2RR performance evaluation of Ni1-N/Cl in the H-cell confirmed the higher activity of Ni1-C/Cl than Ni1-N/Cl (Supplementary Fig. 44). In the flow cell, Ni1-C/Cl also achieved lower Ecells for ECO2RR to CO than Ni1-N/Cl at industrial current densities, further validating the advanced performance of C3–Ni–Cl single-atom sites in CO2 electrolysis (Supplementary Fig. 45). The normalizations of partial current for CO production by the concentration of electrochemical active Ni sites were shown in Supplementary Figs. 46, 47. Obviously, the active Ni sites in Ni1-C/Cl exhibited higher electrocatalytic activity than those in Ni1-N/Cl and Nin-C/Cl. The recorded Nyquist plots during ECO2RR under different potentials in Supplementary Fig. 48 demonstrated that the constructed Ni single-atom sites facilitated the electron transfer from the active centers to the reactants/intermediates during ECO2RR, endowing Ni1-C/Cl and Ni1-N/Cl with higher activity for CO2 conversion compared with Nin-C/Cl and Zn1-C/Cl.

Extended application of Ni1-C/Cl in tandem electrocatalysis

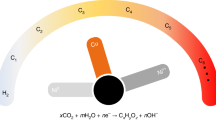

The combination of CO2-to-CO and CO-to-C2+ in tandem CO2 electrolysis provided a transit route for improving the selectivity of C2+ products in acidic ECO2RR36,37. Herein, we extended the application of Ni1-C/Cl in a tandem electrode to investigate the promotion of Ni1-C/Cl for C2+ production on the cuprous oxide (Cu2O) electrocatalyst in a flow cell. 0.05 M K2SO4 solution (pH = 1) was used as the cathodic/anodic electrolyte. The tandem electrode contained two distinct catalyst layers, Ni1-C/Cl layer and Cu2O nanocubes (Cu2O NCs) layer, respectively (Fig. 6a). The structural characterization of Cu2O NCs was shown in Supplementary Figs. 49, 50. ECO2RR in this tandem system exhibited lower Ecells compared to those in the system containing sole Cu2O catalyst, representing the faster reaction kinetics on the Ni1-C/Cl@Cu2O tandem catalysts (Supplementary Fig. 51). Notably, the Ni1-C/Cl@Cu2O tandem catalysts exhibited effective promotion for selective C2H4 generation at high current densities (Fig. 6b, c and Supplementary Figs. 52–54). These advances may stem from the regulation of the local pH over the Cu2O catalyst layer by the generated OH- during CO2–CO conversion on Ni1-C/Cl36. Moreover, the optimized coverage of *CO and *H species also facilitated the improvement of C2H4 selectivity. This tandem system realized maximum C2H4 Faradaic efficiency (FEC2H4) of ~33%, with a considerable C2H4 partial current density (jC2H4) over 0.37 A cm−2. The XRD patterns in Supplementary Fig. 55 revealed that in the Cu2O NCs layer, the Cu2O-derived Cu (111) planes contributed to the catalytic activity and selectivity for ECO2RR to C2H4. DFT calculations were then conducted to reveal the intrinsic synergy in the coupled Cu (111)@C3–Ni–Cl sites (Supplementary Figs. 56–59). The calculated free energies for C2H4 formation on Cu (111) plane and coupled Cu (111)@NiC3Cl site in Fig. 6d and Fig. 6e indicated that the coupled Cu (111)@NiC3Cl site reduced the energy barrier for C-C coupling compared with bare Cu (111) plane, with an optimized free energy of 1.679 eV for the formation of *OCCO intermediate on Cu (111)@NiC3Cl site. Moreover, the spontaneous formation of *OCCOH intermediate from *OCCO intermediate on coupled Cu (111)@NiC3Cl site facilitated the formation and hydrogenation of *CCO intermediate, to favor the C2H4 production. This application of Ni1-C/Cl@Cu2O tandem electrocatalysis revealed the neighboring synergy between asymmetric C3–Ni–Cl single-atom sites and active Cu species for selective electrosynthesis of C2H4 products.

a Schematic diagram of Ni1-C/Cl@Cu2O NCs tandem electrocatalysis for C2H4 production. b FEC2H4s of Ni1-C/Cl@Cu2O tandem electrocatalysts and sole Cu2O electrocatalysts at different applied current densities. c jC2H4s of Ni1-C/Cl@Cu2O tandem electrocatalysts and sole Cu2O electrocatalysts at different applied current densities. d Calculated free energies for C2H4 formation on Cu (111) plane. e Calculated free energies for C2H4 formation on Cu (111)@NiC3Cl coupled site. The flow rate of CO2 inlet was 10 sccm. The measured resistance of the flow cell electrolyzer containing 0.05 M K2SO4 electrolyte was 4.37 ± 0.31 Ω. The error bars correspond to the standard deviations were acquired based on three independent experiments under the same testing conditions. Source data are provided as a Source data file.

Discussion

In summary, we developed a vacancy-engineering strategy for constructing asymmetric C3–Ni–Cl single-atom sites on carbon supports. Detailed characterizations revealed that the abundant Cl-doping vacancy sites facilitated the trapping and anchoring of Ni atoms, to form asymmetric C3–Ni–Cl single-atom sites. The symmetry-broken electron distribution in C3–Ni–Cl coordination structure regulated the reaction pathway of CO2-to-CO on the Ni center, promoting the selective CO electrosynthesis on Ni1-C/Cl. In situ experiments clarified the potential-dependent structure evolutions of the C3–Ni–Cl active sites during ECO2RR, the C3–Ni–Cl sites with self-optimized coordination structure at various potentials can modulate their adsorption configurations for reactant and intermediates to promote CO production. Benefitting from the highly selective ECO2RR on Ni1-C/Cl, even in the strongly acidic media (pH = 1), Ni1-C/Cl still exhibited near 100% selectivity for CO products under industrial-level current densities. The extended application of Ni1-C/Cl in a Ni1-C/Cl@Cu2O tandem electrocatalysis system revealed the neighboring synergy between single-atom Ni sites and active Cu species for facilitating the selective production of C2H4 from CO2 electrolysis. This work highlighted the significance of coordination engineering in the Ni SACs for promoting CO2 electroreduction, offering new insights for designing industrial-oriented electrocatalysts toward other important electrocatalytic reactions.

Methods

Chemicals

ZnCl2 (MACKLIN, Z885069, 99%), KCl (Aladdin, P112134, AR, 99.5%), agarose (Aladdin, A104062, for biochemistry), nickel(II) chloride (NiCl2, N433839, 99.99% trace metals basis), sodium hydroxide (NaOH, Aladdin, S580606, ≥ 98%), copper(II) chloride (CuCl2, Aladdin, C106774, ≥98%), ascorbic acid (Aladdin, A103533, AR, ≥99%), potassium bicarbonate (KHCO3, Aladdin, P110485, 99.5%), sulfuric acid (H2SO4, Sinopharm Chemical Reagent Co., Ltd, GR), potassium sulfate (K2SO4, Aladdin, P112580, AR, 99%), cyanuric acid (Aladdin, C106082, 98%), Ar and CO2 (Hangzhou BESTGAS Co., Ltd, 99.999%). The Nafion D520 dispersion (alcohol based 1000 EW at 5 wt%), proton exchange membranes (212 µm-thickness Nafion 212 membrane and 115 µm-thickness Nafion 115 membrane), and gas diffusion electrode (GDE, Sigracet, 39BB) were purchased from SCI Materials Hub (www.scimaterials.cn). The IrOx/Ti felt with IrOx loading of 2 mg cm−2 was purchased from Suzhou Sinero Technology Co., Ltd. The H-cell (CH2010-S), Pt mesh electrode (2 × 2 cm2, Pt purity of 99.99%), working electrode clip (J110), as well as Ag/AgCl electrode (R0303-Φ6 mm) were purchased from Ada Hengsheng Technology Co., Ltd.). The flow cell and MEA electrolyzers were designed and fabricated by Suzhou Sinero Technology Co., Ltd. Ultrapure water (Millipore, 18.2 MΩ·cm) was used throughout the experimental process.

Preparation of Ni1-C/Cl

First, 800 mg of KCl was dissolved in 7 mL of water and heated at 120 °C with continuous stirring. Then 200 mg of agarose powder was added to the stirred solution. After the agarose powder was dissolved, 1 mL of aqueous solution containing 12.5 mg NiCl2 was added dropwise with continued stirring for 10 min. At the end of the stirring period, the above solution was poured onto a Petri dish and left at room temperature to transform into a hydrogel. The obtained hydrogel was frozen at −100 °C for 30 min and freeze-dried at −50 °C for 24 h to remove the water content. The dried sample was grounded into powder before mixed with 2 g of ZnCl2. Subsequently, the above mixture was treated in a gradient pyrolysis at 300 °C for 3 h and 1000 °C for 1 h in a tube furnace under Ar atmosphere (Ar flow rate, 80 sccm). The harvested product was washed with water several times to remove the salt templates, and vacuum dried at 60 °C for 24 h to obtain Ni1-C/Cl. The Ar flow rate was controlled by an electronic flowmeter (HORIBA, SEC-Z714AGX).

Preparation of Nin-C/Cl

The preparation of Nin-C/Cl was similar to that of Ni1-C/Cl, with the absence of ZnCl2 salt template.

Preparation of Zn1-C/Cl

The preparation of Zi1-C/Cl was similar to that of Ni1-C/Cl, with the absence of NiCl2 aqueous solution.

Preparation of Ni1-N/Cl

The preparation of Ni1-N/Cl was similar to that of Ni1-C/Cl, accompanied by the addition of 2 g of cyanuric acid as the nitrogen source.

Preparation of Cu2O NCs

First, 30 mL of 2 M NaOH aqueous solution (denoted as Solution A), 300 mL of 10 mM CuCl2 aqueous solution (denoted as Solution B), and 30 mL of 0.6 M ascorbic acid solution (denoted as Solution C) were prepared, respectively. Then Solution A was added dropwise into Solution B, with continuous stirring at 55 °C for 30 min. Subsequently, Solution C was added dropwise into the above solution and kept stirring at 55 °C for 5 h. The harvested product was washed with water and ethanol several times, and vacuum dried at 60 °C for 24 h to obtain Cu2O NCs.

Characterizations

The XRD patterns were collected from a micro-X-ray diffractometer (Rigaku) and a powder X-ray diffractometer (Bruker D8 Advance). The TEM measurements were performed on a transmission electron microscope (Thermo Fisher, Talos F200X G2) at an accelerating voltage of 200 kV. The AC-HAADF-STEM measurements were conducted on a spherical aberration corrected transmission electron microscope (Thermo Fisher, Themis Z) at an accelerating voltage of 300 kV. The EPR spectra were collected from a pulsed electron paramagnetic resonance spectrometer (Bruker, A300). The Raman spectra were collected from a VIS-NIR confocal Raman microscope system (WITec, Alpha300R). The XPS spectra were collected from an XPS spectrometer (Thermo Fisher, ESCALAB Xi + ). The XAFS spectra at Zn K-edge and Ni K-edge of Ni1-C/Cl, Nin-C/Cl and Zn1-C/Cl were obtained at the 1W1B beamline of Beijing Synchrotron Radiation Facility. The XAFS spectra at Ni K-edge of Ni1-N/Cl were collected at the BL14W1 beamline of Shanghai Synchrotron Radiation Facility. The XAFS data were recorded under fluorescence mode, processed and analyzed with Athena and Artemis software codes.

Electrode preparation for evaluating the ECO2RR performances of Ni1-C/Cl, Zn1-C/Cl, and Nin-C/Cl

First, the catalyst (5 mg) was homogeneously dispersed in a mixed solution containing isopropanol (300 μL), water (100 μL), and Nafion D520 solution (50 μL) through 30-min sonication. Then the catalyst dispersion was drop-casted onto the GDE (1 × 2 cm2 for electrochemical tests in H-cell, 1.5 × 1.5 cm2 for electrochemical tests in flow cell and MEA electrolyzers) and dried at room temperature, with the catalyst loading of 0.5 and 1 mg cm−2 for electrochemical tests in H-cell and flow cell/MEA electrolyzers, respectively.

Electrode preparation for evaluating the ECO2RR performances of Ni1-C/Cl@Cu2O tandem electrocatalysts

First, 20 mg of Cu2O catalyst was homogeneously dispersed in a mixed solution containing isopropanol (300 μL), water (100 μL), and Nafion solution (100 μL) through 30-min sonication, and 5 mg of Ni1-C/Cl catalyst was homogeneously dispersed in a mixed solution containing isopropanol (300 μL), water (100 μL), and Nafion solution (50 μL) through 30-min sonication. Then the Cu2O catalyst dispersion was drop-casted onto the GDE (1.5 × 1.5 cm2) and dried at room temperature, with the Cu2O catalyst loading of 5 mg cm−2. The Ni1-C/Cl catalyst dispersion was drop-casted onto the Cu2O catalyst layer and dried at room temperature, with the Ni1-C/Cl catalyst loading of 1 mg cm−2.

Electrochemical measurements

The electrochemical measurements for evaluating the ECO2RR performances were performed on a Biologic VMP3 electrochemical workstation under ambient conditions (room temperature, 22 °C). In the typical H-cell system, 0.5 M KHCO3 solution was used as the electrolyte. Specifically, 50.3 g of KHCO3 were transferred into a volumetric flask (1 L), then adding 800 mL of ultrapure water to the volumetric flask and stirred until KHCO3 was completly dissolved. Finally, added ultrapure water to adjust the volume of the solution to 1 L to obtain 0.5 M KHCO3 solution. Before ECO2RR tests, the KHCO3 electrolyte was stored at room temperature. The volume of the single cell in the H-cell was 100mL, with 50mL of electrolyte in each cell. The cathode and anode chambers were separated by a 212 µm-thickness Nafion 212 membrane. Before using, the Nafion 212 membrane was sequentially treated with 5% H2O2 solution and 5% H2SO4 solution at 80 °C for 1 h. Pt mesh electrode and Ag/AgCl electrode (saturated KCl) were used as counter electrode and reference electrode, respectively. Before ECO2RR performance evaluation H-cell, continuous CO2 stream was fed into the cathodic KHCO3 electrolyte for 1 h to obtain CO2-saturated KHCO3 electrolyte. The pH value of the CO2-saturated KHCO3 electrolyte was measured using a pH meter (METTLER TOLEDO, SevenExcellence), with pH value of 7.5 ± 0.02 in three independent measurements. The polarization curves were acquired from the linear sweep voltammetry, with a scan rate of 10 mV s−1. The cyclic voltammetry was used in the electrochemical capacitance measurements. The potentio electrochemical impedance spectroscopy with a frequency range from 200 kHz to 10 mHz was carried out to obtain the Nyquist plots of the catalysts during ECO2RR under various potentials.

The potential conversion from Ag/AgCl reference electrode scale to the RHE reference scale was performed in a three-electrode system, with hydrogen-saturated 0.5 M H2SO4 solution as the electrolyte. The preparation of 0.5 M H2SO4 solution was in a 1 L volumetric flask. First, added 500 mL of ultrapure water into the volumetric flask, then slowly added 27.17 mL of concentrated H2SO4 into the volumetric flask. After the solution temperature dropped to room temperature, added ultrapure water to adjust the volume of the solution to 1 L to obtained 0.5 M H2SO4 solution. In the three-electrode system, two Pt wire electrodes were used as the working and counter electrodes, respectively. An Ag/AgCl electrode (saturated KCl) was used as the reference electrode. The calibration was performed using cyclic voltammetry, with a scan rate of 1 mV s−1. The average of two potential values at zero current represented the thermodynamic potential of the hydrogen electrode reaction (0.197 V). Therefore, the potential conversion from Ag/AgCl reference electrode scale to the RHE reference scale was acquired based on the following equation12:

In the flow cell system, K2SO4 solutions with various concentrations were used as the cathodic/anodic electrolyte (0 M, 0.01 M, 0.05 M, 0.1 M and 0.25 M, pH = 1, adjusted by concentrated H2SO4). The preparation process of K2SO4 electrolyte was the same as that of KHCO3 electrolyte. The pH value of the electrolytes was measured using a pH meter to ensure the pH value of the electrolyte was within 1 ± 0.05. Before using, the electrolytes were stored at ambient conditions. The schematic diagram of the flow cell electrolyzer was shown in Supplementary Fig. 27. GDE loaded with target catalyst was used as the working electrode (1.5 × 1.5 cm2), commercial IrOx/Ti felt catalyst (1.5 × 1.5 cm2) was used as the counter electrode. A piece of 115 µm-thickness Nafion 115 membrane (2 × 2 cm2) was selected as the proton exchange membrane. Before using, the Nafion 115 membrane was sequentially treated with 5% H2O2 solution and 5% H2SO4 solution at 80 °C for 1 h. The flow rate of CO2 inlet was controlled by an electronic flowmeter (HORIBA, SEC-Z714AGX). The flow rate of the anodic and cathodic electrolytes was controlled by a peristaltic pump (Gaoss Union, EC200-01), with a specific flow rate of 8 mL min−1. Chronopotentiometry was applied in the evaluation of the acidic ECO2RR performances, the Ecells were recorded without iR compensation. The area contacting electrolyte in the flow cell was 1 × 1 cm2.

In MEA system, 0.05 M K2SO4 solution (pH=1, adjusted by concentrated H2SO4) was used as the anodic electrolyte. The schematic diagram of the MEA electrolyzer was shown in Supplementary Fig. 31. GDE loaded with target catalyst was used as the working electrode (1.5 × 1.5 cm2), commercial IrOx/Ti felt catalyst (1.5 × 1.5 cm2) was used as the counter electrode. A piece of 115 µm-thickness Nafion 115 membrane (2 × 2 cm2) was selected as the proton exchange membrane. Before using, the Nafion 115 membrane was sequentially treated with 5% H2O2 solution and 5% H2SO4 solution at 80 °C for 1 h. Humidified CO2 was used as the cathodic feedstock, the humidifier was purchased from SCI Materials Hub. The flow rate of CO2 inlet was controlled by an electronic flowmeter. The flow rate of the anodic electrolyte was controlled by a peristaltic pump, with a specific flow rate of 8 mL min−1. Chronopotentiometry was applied in the evaluation of the acidic ECO2RR performances, the Ecells were recorded without iR compensation. The active area in MEA was 1 × 1 cm2.

Before ECO2RR performance evaluations, the resistance value of the electrochemical cell was measured by ZIR tool in EC-Lab software, with a specific frequency of 100 KHz at open-circuit voltage.

The gaseous products were detected and analyzed by a chromatography equipped with a methanizer, a thermal conductivity detector, and a flame ionization detector (GC2014, Shimadzu). The liquid-phase products were detected and analyzed by a 500 MHz solution NMR spectrometer (Cryo Probe, AVANCE NEO, Bruker BioSpin).

The FEs of CO, H2, and C2H4 products were calculated based on the following equation21:

where z is the number of electrons needed for H2, CO and C2H4 formation, respectively (z = 2 for CO and H2, z = 12 for C2H4), n is the molar amount of the corresponding products, F is Faraday’s constant (96485 C mol−1), and Qtotal is the recorded charge flowing through the working electrode during ECO2RR process.

The partial current density of a specific product (jproduct) was calculated as follows:

where j is the total current density.

In situ ATR-SEIRAS measurements

The in situ ATR-SEIRAS measurements were conducted on an FT-IR spectrometer (Thermo Fisher, Nicolet iS50) equipped with an MCT detector and an in situ IR optical accessory (SPEC-I, Shanghai Yuanfang Tech.). A single-cell containing 20 mL of CO2-saturated 0.5 M KHCO3 electrolyte was used as the reactor. The schematic diagram of the electrochemical cell is shown in Supplementary Fig. 26. During the ECO2RR tests, CO2 gas was continuously fed to the reactor. A Pt wire was selected as the counter electrode, an Ag/AgCl reference electrode was used as the reference electrode. A monocrystalline silicon coated with a gold film was applied as the working electrode. The Ni1-C/Cl catalyst was sprayed on the gold film for ECO2RR tests. A CHI 660 electrochemical workstation was applied for potential control. An 8 cm−1 resolution and 16 scans were set for collecting the IR spectra during ECO2RR.

In situ XAFS measurements

The in situ XAFS spectra at Ni K-edge were recorded at the 1W1B beamline of Beijing Synchrotron Radiation Facility. The schematic diagram of the electrochemical cell was shown in Fig. 4a. The GDE loaded with Ni1-C/Cl catalyst was sealed in a cell by Kapton film for electrochemical tests. CO2-saturated 0.5 M KHCO3 solution was used as electrolyte. During the ECO2RR tests, CO2 gas was continuously fed to the reactor. A CHI 660 electrochemical workstation was applied for potential control. The in situ XAFS spectra were collected during the ECO2RR process, under fluorescence mode.

Computational Details

The first principle DFT calculations were performed by Vienna Ab initio Simulation Package with the projector augmented wave method38,39. The exchange functional was processed using the generalized gradient approximation of Perdew–Burke–Ernzerhof functional40. The spin polarizations were employed for all calculations. The energy cutoff for the plane wave basis expansion was set to 450 eV. The convergence criterion for geometric relaxation was a force less than 0.03 eV/Å per atom. The k-points in the Brillouin zone were sampled in a 3× 3 × 1 grid. The convergence energy threshold for self-consistent calculations was 10–5 eV. The DFT-D3 method was employed to consider the van der Waals interaction41. In order to avoid interactions between the periodic structures, a 15 Å vacuum was added along the z-axis.

The free energies were calculated as follows42:

where ΔEDFT is the DFT electronic energy difference of each step, ΔEZPE is the correction of zero-point energy, and ΔS is the variation of entropy, obtained by vibration analysis. T is the temperature (T = 300 K).

Data availability

The data that support the findings of this work are available within the manuscript, Supplementary Information files, and Source Data File. Source data are provided with this paper.

References

Birdja, Y. Y. et al. Advances and challenges in understanding the electrocatalytic conversion of carbon dioxide to fuels. Nat. Energy 4, 732–745 (2019).

Zheng, T. et al. Copper-catalysed exclusive CO2 to pure formic acid conversion via single-atom alloying. Nat. Nanotechnol. 16, 1386–1393 (2021).

Yang, Y. et al. Operando studies reveal active Cu nanograins for CO2 electroreduction. Nature 614, 262–269 (2023).

Ding, J. et al. A tin-based tandem electrocatalyst for CO2 reduction to ethanol with 80% selectivity. Nat. Energy 8, 1386–1394 (2023).

Li, J. et al. Selective CO2 electrolysis to CO using isolated antimony alloyed copper. Nat. Commun. 14, 340 (2023).

Hung, S.-F. et al. A metal-supported single-atom catalytic site enables carbon dioxide hydrogenation. Nat. Commun. 13, 819 (2022).

Zhao, C. et al. Ionic exchange of metal–organic frameworks to access single nickel sites for efficient electroreduction of CO2. J. Am. Chem. Soc. 139, 8078–8081 (2017).

Zheng, T. et al. Large-scale and highly selective CO2 electrocatalytic reduction on nickel single-atom catalyst. Joule 3, 265–278 (2019).

Yang, H. et al. Carbon dioxide electroreduction on single-atom nickel decorated carbon membranes with industry compatible current densities. Nat. Commun. 11, 593 (2020).

Shu, S., Song, T., Wang, C., Dai, H. & Duan, L. [2+1] Cycloadditions modulate the hydrophobicity of Ni-N4 single-atom catalysts for efficient CO2 Electroreduction. Angew. Chem. Int. Ed. 63, e202405650 (2024).

Yang, H. B. et al. Atomically dispersed Ni(I) as the active site for electrochemical CO2 reduction. Nat. Energy 3, 140–147 (2018).

Hao, Q. et al. Nickel dual-atom sites for electrochemical carbon dioxide reduction. Nat. Synth. 1, 719–728 (2022).

Zhou, Y. et al. Asymmetric dinitrogen-coordinated nickel single-atomic sites for efficient CO2 electroreduction. Nat. Commun. 14, 3776 (2023).

Gong, Y.-N. et al. Regulating the coordination environment of MOF-templated single-atom nickel electrocatalysts for boosting CO2 reduction. Angew. Chem. Int. Ed. 59, 2705–2709 (2020).

Yan, C. et al. Coordinatively unsaturated nickel–nitrogen sites towards selective and high-rate CO2 electroreduction. Energy Environ. Sci. 11, 1204–1210 (2018).

Jiang, K. et al. Isolated Ni single atoms in graphene nanosheets for high-performance CO2 reduction. Energy Environ. Sci. 11, 893–903 (2018).

Jin, Z. et al. Boosting electrocatalytic carbon dioxide reduction via self-relaxation of asymmetric coordination in Fe-based single atom catalyst. Angew. Chem. Int. Ed. 63, e202318246 (2024).

Huang, M. et al. Template-sacrificing synthesis of well-defined asymmetrically coordinated single-atom catalysts for highly efficient CO2 electrocatalytic reduction. ACS Nano 16, 2110–2119 (2022).

Chen, Z. et al. Achieving efficient CO2 electrolysis to CO by local coordination manipulation of nickel single-atom catalysts. Nano Lett. 23, 7046–7053 (2023).

Peng, J.-X., Yang, W., Jia, Z., Jiao, L. & Jiang, H.-L. Axial coordination regulation of MOF-based single-atom Ni catalysts by halogen atoms for enhanced CO2 electroreduction. Nano Res. 15, 10063–10069 (2022).

Hao, Q. et al. Fully exposed nickel clusters with electron-rich centers for high-performance electrocatalytic CO2 reduction to CO. Sci. Bull. 67, 1477–1485 (2022).

Yuan, F. et al. Unraveling the effect of intrinsic carbon defects on potassium storage performance. Adv. Funct. Mater. 32, 2208966 (2022).

Wu, Q. et al. Ultra-dense carbon defects as highly active sites for oxygen reduction catalysis. Chem. 8, 2715–2733 (2022).

Liu, W.-J., Jiang, H. & Yu, H.-Q. Development of BIochar-based Functional Materials: toward A Sustainable Platform Carbon Material. Chem. Rev. 115, 12251–12285 (2015).

Li, Y. et al. Precisely constructing charge-asymmetric dual-atom Fe sites supported on hollow porous carbon spheres for efficient oxygen reduction. Energy Environ. Sci. 17, 4646–4657 (2024).

Han, L. et al. A single-atom library for guided monometallic and concentration-complex multimetallic designs. Nat. Mater. 21, 681–688 (2022).

Li, Z. et al. Stabilizing highly active atomically dispersed NiN4Cl sites by Cl-doping for CO2 electroreduction. SusMat 3, 498–509 (2023).

Theodosiou, A., Spencer, B. F., Counsell, J. & Jones, A. N. An XPS/UPS study of the surface/near-surface bonding in nuclear grade graphites: a comparison of monatomic and cluster depth-profiling techniques. Appl. Surf. Sci. 508, 144764 (2020).

Lesiak, B. et al. C sp2/sp3 hybridisations in carbon nanomaterials—XPS and (X)AES study. Appl. Surf. Sci. 452, 223–231 (2018).

Xia, H. et al. Boosting oxygen reduction reaction kinetics by designing rich vacancy coupling pentagons in the defective carbon. J. Am. Chem. Soc. 145 (2023).

Guo, D. et al. Active sites of nitrogen-doped carbon materials for oxygen reduction reaction clarified using model catalysts. Science 351, 361–365 (2016).

Ding, S. et al. Engineering atomic single metal–FeN4Cl sites with enhanced oxygen-reduction activity for high-performance proton exchange membrane fuel cells. ACS Nano 16, 15165–15174 (2022).

Jiao, L. et al. Non-bonding interaction of neighboring Fe and Ni single-atom pairs on MOF-derived N-doped carbon for enhanced CO2 electroreduction. J. Am. Chem. Soc. 143, 19417–19424 (2021).

Li, P. et al. p–d Orbital hybridization induced by p-block metal-doped Cu promotes the formation of C2+ products in ampere-level CO2 electroreduction. J. Am. Chem. Soc. 145, 4675–4682 (2023).

Wang, Q. et al. Attenuating metal-substrate conjugation in atomically dispersed nickel catalysts for electroreduction of CO2 to CO. Nat. Commun. 13, 6082 (2022).

Li, F.-Z. et al. Another role of CO-formation catalyst in acidic tandem CO2 electroreduction: Local pH modulator. Joule 8, 1772–1789 (2024).

Chen, Y. et al. Efficient multicarbon formation in acidic CO2 reduction via tandem electrocatalysis. Nat. Nanotechnol. 19, 311–318 (2024).

Kresse, G. & Furthmüller, J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput. Mater. Sci. 6, 15–50 (1996).

Blöchl, P. E. Projector augmented-wave method. Phys. Rev. B 50, 17953–17979 (1994).

Perdew, J. P. et al. Atoms, molecules, solids, and surfaces: applications of the generalized gradient approximation for exchange and correlation. Phys. Rev. B 46 (1992).

Grimme, S., Antony, J., Ehrlich, S. & Krieg, H. A consistent and accurate ab initio parametrization of density functional dispersion correction (DFT-D) for the 94 elements H-Pu. J. Chem. Phys. 132 (2010).

Skúlason, E. et al. A theoretical evaluation of possible transition metal electro-catalysts for N2 reduction. Phys. Chem. Chem. Phys. 14, 1235–1245 (2012).

Li, Z. et al. Mechanism of Na-Ion storage in hard carbon anodes revealed by heteroatom doping. Adv. Energy Mater. 7, 1602894 (2017).

Zhang, Y., Jiao, L., Yang, W., Xie, C. & Jiang, H.-L. Rational fabrication of low-coordinate single-atom Ni electrocatalysts by MOFs for highly selective CO2 reduction. Angew. Chem. Int. Ed. 60, 7607–7611 (2021).

Sheng, X., Ge, W., Jiang, H. & Li, C. Engineering the Ni–N–C catalyst microenvironment enabling CO2 electroreduction with nearly 100% CO selectivity in Acid. Adv. Mater. 34, 2201295 (2022).

Li, X. et al. Convergent paired electrosynthesis of dimethyl carbonate from carbon dioxide enabled by designing the superstructure of axial oxygen coordinated nickel single-atom catalysts. Energy Environ. Sci. 16, 502–512 (2023).

Zhang, T. et al. Atomically dispersed Nickel(I) on an alloy-encapsulated nitrogen-doped carbon nanotube array for high-performance electrochemical CO2 reduction reaction. Angew. Chem. Int. Ed. 59, 12055–12061 (2020).

Jia, C. et al. Nitrogen vacancy induced coordinative reconstruction of single-atom Ni catalyst for efficient electrochemical CO2 reduction. Adv. Funct. Mater. 31, 2107072 (2021).

Cao, X. et al. Atomic bridging structure of nickel–nitrogen–carbon for highly efficient electrocatalytic reduction of CO2. Angew. Chem. Int. Ed. 61, e202113918 (2022).

Acknowledgements

This work was supported by the Leading Innovative and Entrepreneurial Projects in Zhejiang Province (2023R01007), Westlake Education Foundation (Grant No. 103506022001) and Nanyang Westlake-Muyuan Institute of Synthetic Biology (Program ID: N14116522401). We acknowledge the help from the 1W1B beamline at the Beijing Synchrotron Radiation Facility for synchrotron-based measurements. We thank the assistance for DFT calculations from CESHIGO Research Service. Q. Hao thanks Dr. Peiyu Ma from the University of Science and Technology of China for his help in proofreading the manuscript.

Author information

Authors and Affiliations

Contributions

This work was conducted under supervisions of K.L. and J.L. Q.H. conceived the idea and designed the experiments. Q.H. prepared the samples. Q.H. and Q.T. conducted the characterizations and experiments. Q.H., Q.T. and L.R.Z. conducted the in situ XAFS measurements. Q.H. wrote the manuscript. Q.H., Q.T., J.W., K.L., and J.L. revised the manuscript. All authors discussed the results and provided suggestions for the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Yuhang Wang, Lei Wang, and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Hao, Q., Tang, Q., Zheng, L. et al. Specific construction of asymmetric carbon-nickel-chlorine single-atom sites via carbon vacancy engineering for efficient CO2 electroreduction. Nat Commun 16, 8365 (2025). https://doi.org/10.1038/s41467-025-62287-8

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-025-62287-8