Abstract

Integrating materials onto optical fibers, enabling optical signal tuning during low-loss light transmission, is essential in optical communications, biosensors, and implantable devices. Such tuning, based on light-matter interaction, requires tight physical and optical contact between materials and fibers. However, large surface curvature (>105 m−1) of fiber makes it challenging for most materials to transfer onto fibers with tight contact, due to insufficient small-range forces. This induces weak light-matter interaction and ineffective optical coupling. Here, we propose a general strategy for conformal integration of nanomembranes—including metals, oxides, semiconductors, and polymers—onto microfibers. This integration relies on engineered elastic and surface energies between nanomembranes and fibers, enabling tight wrapping. We demonstrate homogeneous and inhomogeneous nanomembranes conformally integrated on microfibers, which are further developed into sensors, modulators, filters, and photodetectors as plug-and-play devices. Our study provides a versatile platform for integrating multifunctional materials on fibers, enabling health monitoring and on-fiber photonic computing.

Similar content being viewed by others

Introduction

Integrated photonics has revolutionized various fields, including telecommunications, biological sensing, and medical imaging, by enabling compact, efficient, and multifunctional optical systems1,2,3,4,5,6. Optical fibers, with unique characteristics such as small size, ultrahigh aspect ratio, and high mechanical robustness, serve as one of the most promising platforms for optical integration5,6. However, the material properties of optical fibers (mostly silica) hinder further functionalization and applications6. Therefore, to meet the trends of multifunctionality, optical fibers are being integrated with different structures and materials to extend their photonic and optoelectronic applications7,8,9,10.

Nowadays, multifunctional optical devices can be realized by fabricating nanoscale structures on optical fibers. Techniques such as three-dimensional (3D) printing11, two-photon polymerization12, thin-film transfer13, and femtosecond laser processing14 enable the integration of nanophotonic structures onto the fiber tip or within the core. For example, nanoscale glass gratings can be directly 3D printed on the fiber tip, functioning as refractive index sensors and polarization beam splitters11; compact multi-lens objectives have been achieved by fabricating 3D nanostructures on the fiber tip using two-photon polymerization12; femtosecond laser inscription enables the formation of Bragg nanogratings within the fiber core for high-sensitivity refractive index sensing13. Fiore et al. developed a universal, wafer-scale, high-throughput transfer technique for integrating two-dimensional nanophotonic crystal arrays onto fiber tips14,15, which enabled the development of nanoparticle sensors16, hybrid electro-photonic sensors17, and nanomechanical sensing devices18. In addition to structural design, many attempts have been made to develop fibers as integrated multi-material platforms17,19,20. Over a decade ago, Fink et al. focused on a fiber fabrication method that integrates materials with different electrical, optical, and thermal properties into a single fiber, aiming to realize multifunctional fiber devices, capable of seeing, hearing, sensing, and communicating21,22. Through traditional preform-based fiber processing, materials such as chalcogenide glass, metal, and polymer can be melted and then reshaped into a single fiber to produce multi-material fibers23. However, the as-fabricated fiber faces challenges in conveniently connecting with the universal silica optical fiber networks due to the mode-field mismatch and material compatibility problems6. Another approach is to employ commercial optical fiber as the integration substrate. While fiber endface integration provides direct light–matter interaction, it suffers from difficulties with planar fabrication strategies6. Given the large aspect ratio of the fiber, the outer cylindrical surface can serve as an ideal location to integrate multiple devices along its length24. To further enhance the evanescent field intensity around the fiber, microfibers (MFs) are usually chosen for integration along the length due to their tight optical confinement and strong evanescent field25,26.

Specifically, in MF, light interacts with the surrounding materials and environment through an evanescent field, which decays rapidly omnidirectionally and exponentially8,27. Consequently, to achieve efficient light–matter interaction in the integration platform, it is crucial to design and obtain sufficiently large areas for this interaction. However, directly patterning microstructures (such as deposition) onto small curved objects is challenging because current microfabrication processes are primarily tailored to flat substrates, making them unsuitable for achieving large interaction angles and areas28,29. In addition to processing the MF surface directly, nanomembrane (NM) transfer methods have been developed as an indirect assembly approach30,31,32. Several attempts have been made to transfer NMs around the MF surface. Li et al. and Chen et al. transferred two-dimensional materials onto MF using a precise micro-manipulation method30,31. Akhavan et al. and Barbot et al. picked up floating micrometer-thick membranes in a liquid environment from underneath to provide better conformability of the fiber (hundreds of micrometer scale)33,34. Nevertheless, when transferring micrometer-scale NM onto MF with the aim of achieving 3D conformal wrapping, the attachment between the NM and the sharply bending cylindrical surface (curvature >105 m−1) becomes a critical issue, since micrometer-size NMs can provide very little adhesion forces to the MF surface34. Consequently, developing a universal strategy to precisely position the NMs onto MFs with omnidirectional 3D conformality remains a challenge, despite the high demand for efficient light–matter interaction and integration of optical functionalities.

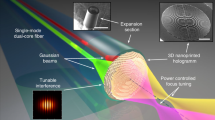

In this work, we develop a versatile MF integration platform using a self-assembly process. Pre-strained functional NMs are wrapped around the MF surface via a self-rolled-up approach, forming a multifunctional 3D microstructured MF system. Microdroplet-triggered behavior facilitates precise micrometer-scale control of the 3D wrapping process, while strain engineering and adhesion energy control assist in achieving flexible, omnidirectional, and tightly conformal wrapping around the MF surface, ensuring sufficient light–matter interaction. Additionally, this generic strategy is suitable for a wide range of NMs to form both homogeneous and heterogeneous microstructures, enabling the construction of complex 3D microstructures on demand. Further, we demonstrated environmental sensors, tunable filters, long-period fiber gratings, and photodetectors as essential components of the multifunctional MF platform, highlighting promising applications for intelligent optical regulation. Our intelligent 3D conformal MF platform shows potential to meet advanced demands in next-generation optical computing and integration.

Results

Enhanced light–matter interaction based on multi-material conformal microfiber

To show the advantages of the multi-material conformal MF, we use finite element analyses (FEA, see “Methods” for details) to study the light–matter interaction in MF wrapped by NM. First, the NM-wrapped region on MF is tunable, and the wrapping angle is defined as θ, as shown in Fig. 1a. We discuss the FEA results for the bare fiber, which means that θ is 0° (Situation I in Fig. 1b). In such a situation, part of the electric field can be outside the MF, but it is mainly concentrated within hundreds of nanometers from the surface of MF (see Figs. S1–S5 for evanescent field distribution and tuning). This phenomenon has been reported as evanescent fields in MF, which provides opportunities for achieving light–matter interaction on fiber27,35. Based on the unique optical properties in diverse kinds of materials, properties of light in different dimensions can be controlled, including frequency, intensity, polarization, and chirality30,36. However, previous attempts mainly involved partial wrapping of MFs with NMs (θ in 0°−270°, situation II in Fig. 1b), leading to limited regions for the light–matter interaction. In addition, we simulate the electric field distribution around the MF with increasing NM-wrapped regions (angle θ from 0° to 800°). To quantify, we defined the light–matter interaction intensity as the ratio of the integrated electric field intensity outside the MF to that inside the MF. With increased θ in situation II, the light–matter interaction intensity increased slowly (Fig. 1b). When the wrapped angle exceeds 360° (Situation III in Fig. 1b), which means the fiber is fully conformal by NMs, as shown in Fig. 1a, the intensity would further increase. When the wrapped angle is about 430°, the intensity can be up to an order of magnitude higher than that of the bare fiber. For different refractive indices and NM thicknesses, the light–matter interaction intensity also rises with θ, as shown in Figs. S6 and S7. Secondly, tight conformal contact between MFs and NMs plays an essential role in effective light–matter interaction, as shown in Fig. S8. Importantly, the fully conformal NM on MF is an extendable platform for all fiber devices, because the enhanced light–matter interaction is suitable for all materials and various fiber structures. We refer to our versatile platform as “Nanomembrane on Fiber,” as shown in Fig. 1c. Using different materials and the fully conformal strategies, a comprehensive optical fiber system will be built, such as optical gratings with periodic metal NMs, the sensors with stimuli-responsive NMs, and optoelectronic devices with semiconductor NM—all essential components for optical systems, with promising applications in future optical computing and communication.

a Schematic diagram of the enhanced light–matter interaction with nanomembranes on optical fibers. b Analysis of light–matter interaction with different wrapping angles for nanomembranes on fiber, showing the continuously enhanced interaction with increased wrapping angles. c Schematic of nanomembranes on fiber platform. In this platform, multiple devices can be integrated into a single fiber for multifunctional applications. d SEM images of homogeneous materials, including metal (Ti), oxide (VO2), and semiconductors (Si) conformal on optical fiber, achieved by our proposed conformal strategies. Insets are the corresponding optical images. e SEM images of heterogeneous nanomembranes including Pd/Cr, Si/Te, and SU-8/pNIPAM. Insets are the optical images of each structure. Scale bars, 20 μm.

To realize such a versatile platform, we demonstrate NMs with a large variety of materials, all of which can be fully conformal on MFs. As shown in Fig. 1d, the NMs are composed of homogeneous materials, including metals (Titanium), oxides (Vanadium dioxide, VO2, Fig. S9), and semiconductors (Silicon, Fig. S10). The insets show the optical images of each NM on MF, and the scanning electron microscope (SEM) images illustrate that the NMs are fully and uniformly conformal on MFs. This platform could also be extended to heterogeneous systems. For example, we show that different heterogeneous NMs—including Pd/Cr metals, Si/Te semiconductors, and SU-8/pNIPAM polymers—can be fully conformally wrapped around MFs, as shown in Fig. 1e. Therefore, the enhanced light–matter interaction, which is based on NMs being conformal on MFs, could be realized in various material systems. Such a concept can also be extended into different practical fields, such as implantable devices and optical communications.

Conformal strategies of nanomembranes on microfiber based on strain engineering and curvature adaptation

The fabrication process of NMs-on-MF conformal microstructures involves two main steps: (1) releasing the NMs into 3D structures, and (2) adapting the curvature of the NM to match that of the microfiber surface, as illustrated in Fig. 2a. In the releasing step, microfibers with controllable diameters were fabricated using a home-made flame-brush tapering system (see Supplementary Note 1 and Figs. S11 and S12). The microfiber was then placed onto the nanomembrane, and a liquid was introduced to initiate the roll-up process. This liquid served to weaken the van der Waals interactions between the NM and the substrate, allowing the NM to roll up due to the strain gradient pre-engineered during its deposition process37,38. This release strategy is applicable to various NM materials, as the strain gradient can be tailored through different deposition techniques (e.g., VO2 NMs deposited by magnetron sputtering39, or Ag/Ti/Py and Si/Te multilayer NMs prepared via electron-beam evaporation, see Supplementary Note 2 and Figs. S13 and S14 for details). However, the curvature of the rolled-up nanomembranes in this process is predetermined by the deposition conditions and cannot match the curvature of the target microfibers40.

a Schematic diagram illustrating the fabrication process using pre-strained nanomembranes (NMs) and surface tension-assisted assembly. b TEM images showing NMs conformally wrapped on optical MF. Scale bar, 250 nm. c Enlarged view of the red-boxed region in (b), showing the tight wrapping of NMs on the microfiber (MF). Left, high-resolution TEM image sequentially displays the Pd NM, Cr NM, and SiO2 MF. Scale bar: 20 nm. Right, EDX analysis shows the elemental composition of each layer. d Nanoindentation test of Ti NM conformal on MF, arrow points to the critical load when the scratching depth displays a sudden change, indicating delamination of the NM. The inset in (d) shows the optical image after the nanoindentation test, proving the delamination behavior. Scale bar: 20 μm. e, f The systematic analysis for achieving tight wrapping in experiments by tuning structural parameters. For metal NMs (e) and oxide NMs (f), we change diameters of MFs (D) and the thickness of NMs (t), obtaining regions for tight wrapping (blue regions, experimental data are marked as blue squares) and unconformable wrapping (red regions, experimental data are marked as red symbols). g The mechanism for achieving conformal structures. Pre-strain is introduced into the NM layer to induce self-rolling of the NM, and surface forces from the liquid further enhance the conformal wrapping. The theoretical calculation for metal NMs (h) and oxide NMs (i) tightly wrapping on MFs. For NMs conformal on MFs with smaller diameters, the required additional bending energy is increased. When the adhesion energy (dashed line) cannot support such bending energy, NMs are untightly wrapped on MFs. The square symbols in (h, i) are experimental data with tight wrapping, and the “X” symbols are untight wrapping. The insets in (h, i) show the SEM images for tight and untight wrapping structures, respectively. Scale bar: 20 μm.

To address this limitation, we developed a core step in the conformal integration strategy, the curvature adaptation step. A small amount of liquid was introduced into the gap between the curved NM and the MF, which could also be added during the initial releasing step. Due to the inherently high curvature of the rolled-up NMs, the narrow gap between the NM and MF enables surface tension forces to become effective. The resulting capillary forces at the NM-liquid-MF interface drive further bending of the rolled-up NM, ultimately promoting its adhesion to the MF surface (see Supplementary Video 1). This newly formed NM-liquid-MF interface provides additional adhesion energy, stabilizing the conformal structure, as demonstrated in Supplementary Note 3 and Figs. S15–S17. This curvature adaptation process can be implemented with various types of liquids (Figs. S18 and S19), and the volume of liquid used significantly affects the behavior and final morphology of the NM during conformal integration (Fig. S20). Following the conformal process, a low-temperature baking step is applied to remove any residual liquid trapped between the NM and MF, thereby enhancing interfacial bonding and ensuring a more robust conformal attachment (Fig. S21).

To show the quality of fully conformal conditions, we characterized the contacted interface between Pd/Cr NMs and MF by transmission electron microscope (TEM) images, as shown in Fig. 2b. The NMs are curved and tightly wrapped on MFs. The zoomed region (highlighted as the red box) is further examined using a high-resolution electron microscope (HR-TEM), as presented in Fig. 2c. The structure in Fig. 2c consists of three parts from top to bottom: 40 nm Pd NM, 40 nm Cr NM, and SiO2 MF. The energy dispersive X-ray spectroscopy (EDX) results show the presence of three elements: Pd, Cr, and Si. The elements are arranged sequentially, with no gaps between Pd and Cr layers or between Cr and Si layers. The lack of a gap between Cr and Si layers demonstrates the excellent conformality in our strategy. We further tested the surface adhesion between the NM and MF. Various viscous liquids were used to adhere the NM conformally to the MF, and no surface slip or detachment was observed (Figs. S22–S24). Additionally, a nanoindentation test was conducted to measure the adhesive strength between the NM and MF. We tested structures made from different materials, as shown in Figs. 2d and S25 and S26. The critical load of the Ti NM on the MF is approximately 18.1 mN. Compared to NMs directly evaporated onto a substrate surface41, the NMs in the conformal structure exhibited comparable adhesion strength, confirming that the NM-MF interface has a strong adhesive force. We also tested the durability of the NM-on-MF structure under various environmental conditions, demonstrating that the structure possesses excellent stability and resilience (Figs. S27–S30).

Given the critical role of the curvature adaptation step in our conformal integration strategy, we further investigated the maximum allowable curvature difference between the NMs and microfibers that still enables a successful adaptation process (Figs. 2e, f and S31). We examined the conformality of Ag/Ti/Fe NMs on MFs, where the NM layers have uniform thicknesses. When the NM thickness was 90 nm, the diameter of the released NMs was approximately 15 µm. In this case, the NMs could fully conform to MFs with diameters greater than 6.3 µm. When the NM thickness increased to 150 nm, the free-standing curvature diameter of the NMs increased to 30 µm, and the minimum MF diameter required for full conformality increased to 9.3 µm. A similar trend was observed for SiO2/Ag/Ti/Fe NMs, where the metallic layers (Ag/Ti/Fe) were of equal thickness (30 nm), as shown in Fig. 2f. For a total NM thickness of 91 nm, the free curvature diameter was 14.5 µm, and the minimum MF diameter for full conformality was 8.9 µm. When the NM thickness was increased to 100 nm, the free curvature diameter reached 32 µm, and the minimum MF diameter required rose to 15.9 µm. Notably, compared to Ag/Ti/Fe NMs, SiO2/Ag/Ti/Fe NMs with the same thickness and curvature exhibited a higher minimum MF diameter required for full conformality.

To explain these observations, we developed an energy-based analytical model for our conformal integration process, as discussed in Fig. 2g. Internal strain gradient during NM deposition leads to the elastic energy stored in NMs, which, upon release, provides the bending energy necessary for the film to transform from a flat to a curved structure. The curvature of the film is related to its thickness, material properties, and the strain gradient, according to the bending theory, as discussed in Supplementary Note 4 and Figs. S32 and S33. Second, during the curvature adaptation process, the curved NMs were further bent, enabling perfect conformality even for smaller diameter MF structures. This additional strain energy required for further bending can be provided by the surface tension of the liquid used in the conformal strategy, as well as the interfacial adhesion forces after stable contact is achieved. Thus, we propose that to achieve conformation on smaller diameter MFs, additional strain energy for film deformation must be provided42. This energy is supplied by the adhesion energy after the interface conforms. Specifically, the additional strain energy per unit film, \({\Delta E}_{{\mathrm{bending}}}\), must be less than the adhesion energy per unit interface \({E}_{{\mathrm{adhesion}}}\)43. The additional bending strain energy can be expressed as

where \({E}_{{\mathrm{bend}}\,{\mathrm{to}}\,{\mathrm{fiber}}}\) is the strain energy for NMs bent to the diameters of fiber, and \({E}_{{\mathrm{rolled}}-{\mathrm{up}}}\) is the strain energy for NMs after releasing. The work of adhesion energy is44

where \({W}_{12}\) is the surface energy of NMs-fiber interface, \({W}_{31}\) is the surface energy of liquid-NM interface, and \({W}_{23}\) is the surface energy of liquid-fiber interface. When Ag/Ti/Fe NMs conform to MFs, the contact interface between NM and MF is Fe-ethanol-SiO245,46. In this case, the adhesion energy per unit area is, for the Fe-ethanol-SiO2 interface, calculated to be 0.19 J/m3, as indicated by the dashed line in Fig. 2h. As NMs of different thicknesses bend further to smaller diameters, the required strain energy increases rapidly. When the required energy exceeds the adhesion energy, conformation theoretically cannot be achieved. In Fig. 2h, we marked the experimental cases of NMs with different thicknesses conforming to various MF diameters. The “x” marks indicate non-conformation, and the solid squares indicate conformation. We found that the experimental results agree well with the theoretically predicted minimum MF diameters. The inset image shows the complete conformation of Ag/Ti/Fe NMs on MFs. This consistency between theory and experiment is also verified in the SiO2/Ag/Ti/Fe NMs system (Fig. 2i). Specifically, when the NM and MF contact interface is SiO2-ethanol-SiO2, the adhesion energy is 0.039 J/m3. When the required additional strain energy exceeds this value, conformation theoretically cannot be achieved, which is also confirmed in the experiment. The inset image shows that SiO2/Ag/Ti/Fe NMs cannot conform to MFs with a diameter of 6.7 µm. Hence, by applying the theoretical bending model (Supplementary Note 4) and precisely controlling the NM deposition parameters, we can tune the curvature diameter of NMs after the release process. Moreover, the developed energy model can guide the selection of suitable NM materials and liquids to ensure a successful curvature adaptation process. For instance, the curvature diameter of a thicker Ag/Ti/Cr NM (150 nm) can be reduced to below 10 μm through optimized deposition conditions (Fig. S13), enabling conformal integration with MFs of diameters less than 10 μm. In summary, through strain engineering of NMs combined with the curvature adaptation strategy, tight NM conformal integration on MFs can be achieved, an outcome that cannot be realized by liquid-induced release alone33 (Fig. S34).

Multiple structural designs of nanomembranes conformal on microfiber

Based on the strategy proposed in Fig. 2, we can fabricate arbitrary two-dimensional NM structures with a well-developed flat patterning process, and further realize complicated 3D conformal microstructures on MFs. It is convenient to use shadow marks or lithography to pattern pre-strained NMs into different shapes. As shown in Fig. 3a, we fabricated NMs in square, triangle, and circular shapes, and then successfully achieved various microstructures on MF surfaces. Owing to the columnar structure of MF, there is no need to specifically control the precise position of MF above NM, as long as MF is on the rolling path of NM (Fig. S35). The second and third columns of Fig. 3a present the optical images and FEA results of conformal microstructures, respectively. In the first two examples, MF is placed on one side above the NM, then the underlying NM rolls up and wraps around the MF when triggered by a microdroplet. Consequently, MF with conformal square and triangle surface shapes can be realized. As for the third example, the MF is placed in the middle part above the circular NM. The entire NM can then wrap around MF with twice successive triggers, forming a bi-semicircle shape on the MF surface. FEA results present good consistency between simulation and experimental results. More NM-on-MF structures were fabricated, including ultra-long structures (millimeter scale, Figs. S36 and S37), multi-turn structures (over 10 turns, Figs. S38–S41), etc., further proving the feasibility of fabricating versatile MF structures.

a Nanomembranes (NMs) with different planar patterns tightly wrapped on microfibers (MFs). Left, design for conformal various patterned NMs on MFs. Middle, the experiments for achieving conformal structures with such patterns. Scale bars, 20 μm. Right, the simulation results confirm the tight wrapping. b The programmable conformal structures by tuning the position relationship between NMs and MFs. By changing the angle θ, the conformal helical structures have distinguished geometrical parameters, including turns and pitches. Scale bars, 50 μm. c The detailed analysis of the helical structures in (b). The changed angle θ results in the different pitches of conformal structures, as shown in (b). Theoretical calculation shows the high consistency with experiments. d Array assembly and layer-by-layer assembly of NMs on MFs. Top, the schematic for array assembly and layer-by-layer assembly. Bottom, the different assembly achieved by NMs pattern design. Scale bars, left: 100 μm, right: 20 μm. e Complex patterns of NMs on MFs. We use “W” and “V” shaped patterns for achieving complicated conformal structures. Scale bars, 100 μm.

Secondly, with patterned NMs of a single geometry, we can realize the assembly of several MF structures. As demonstrated in Fig. 3b, we fabricate a series of MF microstructures with simple rectangle-shaped NMs by manipulating the angle θ between MF and NM. Starting from θ = 0°, similar to the square case in Fig. 3a, as the two short edges are perpendicular to the MF axis, they wrap around MF along the long side and form a tubular microstructure. Then, when it comes to θ = 10°, the two short edges become not perpendicular to the MF axis, thus the two corners attach to the MF surface with an angle and form a long-helix structure. Similarly, as shown in the third to fifth frames, we can simply fabricate helix microstructures with different geometries by tuning θ. Finally, a microstructure with multilayer NMs is obtained in the sixth frame when θ turns to 90°. In this case, the longer edge is perpendicular to the MF axis, resulting in a smaller wrapping surface with several turns. To conclude, NMs are wrapped around the MFs to form microstructures with helix surface geometries except θ = 0° and 90°, and we can calculate the pitch of the helices with \(a/\tan (\theta )\), in which a represents the length of shorter rectangle edge, as shown in Fig. 3c. As the angle θ increases, the pitch of the helices decreases correspondingly, which is in good agreement with experimental results.

As shown above, the NM-on-MF microstructures with a single NM can be designed and regulated by creating patterns in two-dimensional graphics or by altering the relative positioning between NM and MF. Moreover, we can further design and fabricate complex NM-on-MF microstructures with a series of NMs. In the left column of Fig. 3d, we present an array-assembly scheme using this method. When the MF is placed on a series of patterned NMs, all NMs can be fully conformal by the one-step triggering (see Supplementary Video 2). This is because the liquid can be controlled to be transported along the axial directions of MF due to the surface tension, and the liquid can easily trigger each NM to be conformal on MF (Figs. S42 and S43). We use Ag/Ti/Fe NMs to fully wrap an array of NMs on MF (Fig. 3d), illustrating the potential for massive production of microstructures on MFs. This array structure can also be implemented through one-by-one triggering, as presented in Fig. S44. Moreover, diverse kinds of NMs can be in situ layer-by-layer assembled on MFs at the same place, regardless of the growth incompatibility of different NMs during the deposition process. As shown in the right column of Fig. 3d, Ag/Ti/Fe NMs wrap MFs and Au/Ag NMs can then be fully conformal on the same place on MFs, according to the adhesion energy between two NMs. This strategy might be extended to heterojunction structures with electronic applications. Finally, the NMs with the long axial length and complex patterns can also be fully conformal on MFs. As shown in Figs. 3e and S45, we utilized “V”-shaped and “W”-shaped patterned NMs with a length over 1000 μm to wrap on MFs. In a word, based on the conventional lithography technology, our conformal strategies have a large design space for multiple NMs-MF conformal structures showing large potential for electronic and photonic applications on fiber.

Simulation analysis of nanomembrane-wrapped microfiber structure for light–matter interaction

Based on the proposed strategy, we have successfully achieved multi-structure integration of various NM materials on MFs. Next, we analyze the light–matter interaction between the NM and the microfiber under tight wrapping conditions (Fig. 4a, left), and explore how to modulate optical signals by controlling the properties of the nanomembrane. In Fig. 1a, we briefly described the evanescent field distribution of light. Here, we provide a more detailed discussion. We performed FEAs on a MF with a diameter of 5 µm, with the LP01 mode as the main propagation mode. When the surrounding medium is air, the electric field distribution is shown in the middle panel of Fig. 4a. Specifically, there exists a certain electric field distribution outside the microfiber (indicated by the light blue region), which corresponds to the evanescent field region—i.e., the effective light–matter interaction zone. This is also confirmed by the field strength seen outside the microfiber in the right panel of Fig. 4a. Because the conformal boundary of the NM-MF structure is located on the microfiber surface, the NM resides within the effective interaction region and can thus be used for optical device fabrication.

a Left: schematic of a microfiber (MF) conformally wrapped by a nanomembrane (NM). Middle: electric field distribution of the LP01 mode in a bare MF with a diameter of 5 μm (gray region). The blue region indicates the evanescent field outside the fiber, which is available for light–matter interaction. The pink curve denotes the NM boundary after conformal wrapping. Right: electric field distribution of the LP01 mode after NM wrapping on the MF with D = 5 μm. b Variation of the electric field intensity and effective refractive index in MFs with different diameters when conformally wrapped with a VO2 NM. c Distribution of electric field intensity among the MF core, cladding, and NM overlay layer as a function of MF diameter. As the MF diameter decreases, the field intensity in the cladding decreases, while the intensity in the NM overlay increases. d Electric field distribution and effective refractive index changes in a 10 μm-diameter MF induced by refractive index variation of the conformally wrapped VO2 NM.

We further optimize the NM-on-MF structure to achieve high-performance optical devices, such as by adjusting the MF diameter. Taking VO2 NM as an example, we analyze the electric field distribution within the MF and the effective refractive index when the MF is wrapped with VO2 NM, as shown in Fig. 4b. As the MF diameter decreases, the field confinement weakens, and the electric field intensity within the MF decreases. Simultaneously, the effective refractive index of the guided modes also decreases. This is because the ability of the microfiber to confine the mode diminishes, reducing the transmitted field intensity. Furthermore, in the NM-MF coupling structure, the optical mode field can be distributed among the core, cladding, and the overlay layer. We analyzed how this distribution ratio changes with the MF diameter, as shown in Fig. 4c. As the MF diameter decreases, the mode proportions in the core and cladding decrease, while the proportion in the overlay increases. More components of the mode are concentrated on the NM surface, leading to enhanced light–matter interaction within the NM and MF modes. Considering practical fabrication constraints and the evanescent field range, we conclude that a microfiber diameter of around 10 µm is suitable for high-efficiency optical device fabrication.

Based on this, we investigated the modulation capability of the VO2 NM on optical signals within the MF. Due to the phase transition properties of VO247, its refractive index changes from n = 3.0 at low temperatures to n = 2.3 during the metal-insulator transition at 68 °C48. We studied how the mode distribution evolves during the VO2 phase transition. As illustrated in Fig. 4d, the effective refractive index of the mode decreases as the refractive index of the VO2 NM drops, while the field intensity in MF increases (as shown in the insets). Therefore, it has been demonstrated that by controlling the temperature, the light signal intensity in the VO2 NM-wrapped MF can be modulated. This also enables the detection of temperature changes via the refractive index variation during the VO2 phase transition. In summary, we have clarified the fundamental light–matter interaction mechanism in the NM-on-MF system. Based on this understanding, we can develop effective integrated photonic devices.

Photonic and photoelectronic applications using nanomembranes-on-fiber systems

Based on the conformal integration process and the simulation results of light–matter interactions, we can develop diverse kinds of optical and optoelectronic devices to show that our platform has great potential in practical applications. Devices in the fiber system basically include sensors, gratings, modulators, lasers, and photodetectors; we demonstrate all these devices based on our conformal strategy.

As mentioned in Fig. 4, we fabricated on-fiber sensors using NMs with stimuli-responsive materials, including the temperature sensor and the gas sensor. The temperature sensor is VO2 NMs conformal on MF with 8.5 μm diameter, as shown in Fig. 5a. VO2 is a temperature-sensitive phase change material, which has the metal-insulator-transition (MIT)49. From the low temperature (e.g., 30 °C) to the high temperature (e.g., 90 °C), the VO2 changes from the insulator state to the metal state; during the cooling process (from 90 °C to 30 °C), the VO2 changes from the metal to the insulator state. During the MIT, the optical, mechanical, and electronic properties of VO2 quickly change. Thus, we fabricated VO2 NMs by magnetron sputtering, and released VO2 NMs to conform fully on MFs using strain engineering and a surface tension-assisted strategy. The SEM image in Fig. 5a shows the perfect conformality of VO2 NM on MF. The performance of our VO2-based sensors was tested as follows: the single-mode laser (wavelength: 1550 nm) transmitted continuously through the fiber, and the signal was received at one end. The temperature sensor underwent the heating-cooling cycle, and changes in the signal were measured, as shown in Fig. 5b. During the heating process, the signal intensity gradually increased (from 0.21 to 0.52 mW) from 30 to 90 °C. The different intensity is due to the MIT process, which leads to significant reflective index changes of VO2. During the cooling process, the signal intensity decreased, and finally got back to the original state (0.21 mW) at 30 °C, due to the reversible MIT. Due to the non-linear characteristics of the phase transition in VO2 materials, the transmitted optical power in the MF changes nonlinearly with temperature. This phenomenon leads to a hysteresis loop marked as a purple shadow in Fig. 5b. The hysteresis behavior was due to the intrinsic properties of VO2 MIT47. As shown in the inset of Figs. S46 and S47, we tested the electrical behaviors (resistance) and Raman spectra of VO2 during MIT, showing the obvious hysteresis loop. Besides, it was observed that between 50 °C and 80 °C, the phase transition of the material is quite abrupt, resulting in a nearly linear variation of the optical power. Therefore, the sensing range of this temperature detector is approximated to be between 50 °C and 80 °C. A linear fit was performed on the changes in optical power transmission in the MF within this temperature range, yielding sensitivities of 0.0862 dB/°C for the heating process and 0.0803 dB/°C for the cooling process. Compared to the sensitivity of several reported fiber-optic temperature sensors, as shown in Supplementary Table 2, our VO2 NM-on-MF temperature sensor exhibits a relatively higher sensitivity. Moreover, a gas sensor composed of Pd NMs on MFs was demonstrated in Fig. S48. Because Pd NMs have mechanical and reconfigurable actuation with H2 gas, we realized a highly sensitive gas sensor with a response time of tens of seconds49.

a Schematics of the VO2 nanomembrane (NM) wrapped on microfiber (MF) structures for temperature sensors. The inset shows the SEM of the conformal structure. Scale bar, 10 μm. b Performances of the temperature sensor fabricated by VO2 NM and MF. The light intensity in the fiber changed when measured at different temperatures. The purple shadow shows the hysteresis phenomenon during the heating and cooling progress. c The detailed analysis of the temperature dependence of light power, as presented in (b). d The light modulator composed of MKR and metal NMs. Top, the schematic of modulator structures. Bottom, the optical images of modulator devices when illuminated. The inset shows the NM-wrapped MKR. Scale bar, 100 μm. e The modulator performances. With increased temperature, the wavelength of the peak is modulated. f The comparison between the MKR modulators with NMs and without NMs. g Design of NM-on-MF-based composite resonator. Scale bar: 20 μm. h Controllable switching characteristics of the composite resonator. i Flexible assembly of the composite structure. Scale bar: 50 μm.

Second, we show a wavelength modulator, as one of the core devices in optical communications and computing50. The modulator was fabricated using metal (Ag/Ti/Fe) NMs and MF with 15 μm diameter, as shown in Fig. 5d. Several NM patterns were simultaneously wrapped on MFs to form the conformal structures. Subsequently, MF was bent and knotted to fabricate a micro-knot resonator (MKR) due to its good mechanical properties. The fabrication coupling process is presented in Supplementary Note 6 and Figs. S49–S51. The optical images in Fig. 5d show the MKR structure when the light was turned on inside the MF. The white dashed box illustrates the optical microscopy image, showing that the two metal NMs on the MFs remain conformal. This demonstrates that the conformal structure based on our strategy can be further developed, for instance, by modifying MFs to realize complex shapes, indicating significant potential. The wavelength modulation device worked by temperature control, as shown in Fig. 5e. At a room temperature of 30 °C, we observed resonance peaks near 1500 nm with a free spectral range of 0.16 nm. The origin of these resonances is attributed to the ring-shaped characteristics of the MKR structure, which induces whispering gallery modes (WGMs). Upon heating the modulator device, we observed a controllable redshift in the peak positions. Over the temperature range from 30 to 70 °C, the position of a single resonance peak shifted by 0.34 nm. This shift is caused by the temperature-responsive refractive index of the Ag/Ti/Fe metal NMs, which undergoes changes during heating, thereby enabling wavelength modulation through light–matter interaction51. The light–matter interaction in the modulator was further studied by using FEAs. By simulating the electric field near the NMs, which are conformal on MKR structures, we find that the light–matter interaction is enhanced with increased MF diameters and decreased MKR radius, as shown in Fig. S52. With such a large light–matter interaction, our device has more efficient wavelength modulation with temperature actuation. As shown in Fig. 5f, on the same MKR structure, there is a significant difference in wavelength modulation between the device with conformal metal NMs and that without NMs (Fig. S53). The MKR with conformal metal NMs generates more than three times the wavelength modulation under the same temperature drive compared to the device without NMs, demonstrating its better spectral modulation capability. We also designed another resonator device, as shown in Fig. 5g. By assembling rhodamine-doped hydrogel droplets on the VO2 NM-on-MF structure (Fig. S54), a composite resonant cavity structure was fabricated. In this composite structure, the gain characteristics of rhodamine and the loss characteristics of the VO2 NM are present simultaneously. The modulation of the WGM resonant modes can be achieved through the change in the loss coefficient induced by the reversible phase transition of the VO2 material. Figure 5h illustrates the reconfigurable characteristics of the device. As the temperature increases, the resonant properties undergo significant changes. At 30 °C, clear resonant peaks are observed in the spectrum, indicating that the device maintains relatively low optical loss. As the temperature rises to 60 °C, the resonant peak intensity decreases (e.g., the resonant peak near 670 nm, marked by the red arrow), suggesting increasing loss. At 90 °C, the spectrum flattens, and the resonant peaks almost completely disappear, indicating that the structure has entered a high-loss state, suppressing the optical resonant modes. In a word, the composite resonant cavity based on NM-on-MF can achieve temperature-controlled optical resonance switching functionality. Based on the periodicity of the NM patterns, such switchable resonators can be assembled either individually or collectively (Fig. 5i), offering new opportunities for the development of reconfigurable photonic devices, dynamic optical filters, and intelligent optical control systems.

Third, we fabricated a long-period fiber grating based on our conformal strategy. Periodic structures are often designed and fabricated to modulate light52,53,54. Here, the grating on fiber is based on a periodic variation in the refractive index around the fiber, resulting in filtering specific wavelengths of light, as shown in Fig. 6a. Since the NMs can be patterned in the deposition process, we use metal NMs, which have different refractive indices compared with SiO2 MFs, and apply periodic patterns during the deposition. Applying the proposed strategy, more than 10 periodic metal NMs can be simultaneously conformal on the MFs, and the inset SEM image in Fig. 6a and EDX line scanning in Fig. S55 show the full conformality and orderly arrangement of NMs on MFs. We tested the performance of the fiber grating, as shown in Fig. 6b. When the MF is not wrapped by NMs, the spectrum is found with multiple peaks, corresponding to multimode interference in fibers55. When the MF is wrapped by 10-period NMs, there is a significant dip at 1560 nm in the spectrum. By further increasing the number of NM patterns to 20, the depth of the dip increases. This is because the additional periodic metal structures further enhance the coupling between the core and cladding modes, resulting in larger loss at the resonant wavelength. The grating’s filtering capability, according to the formula:

where \({n}_{{\mathrm{eff}}}^{{\mathrm{core}}}\) and \({n}_{{\mathrm{eff}}}^{{\mathrm{cladding}}}\) represent the effective index of core mode and cladding mode, and \(\lambda\), \({\mathrm{period}}\) represent the resonant wavelength and structural period56,57, is also promoted. This phenomenon has also been confirmed by simulations in Figs. 6c, S56 and S57. As the number of metal NMs increases, the ability of the grating to function as a filter gradually strengthens. This result demonstrates that our method enables the convenient fabrication of precise periodic structures, which can interact with signals transmitted in the fiber to achieve wavelength selection and other spectral modulation functions. In addition, by directly conforming the NM around the optical fiber grating, we achieved reconfigurable grating filtering performance, as shown in Fig. S58.

a Schematic of the long-period fiber grating by using periodic nanomembranes (NMs) wrapped on microfiber (MF). Inset shows the part of periodic NMs on MF. Scale bar, 10 μm. b The performance of long-period fiber grating with different periodic NMs arrays. Both devices with 10-period and 20-period metal NMs can select the wavelength. c The simulation of fiber grating used the same parameters as the experiments. d The photodetector device based on Te/Si NM wrapped on MF triggered by the laser out of the MF. Top, the schematics of the photodetector device and the light is illuminated out of the fibers. Bottom, the optical image of the device. Scale bar, 100 μm. e The current–voltage performance of the photodetector. f Response time of the photodetector. g Fabrication of the photodetector triggered by the laser in the MF. Top, the schematics of the photodetector by using the evanescent field along the fiber. Bottom, the optical image of the device. h The current–voltage performance of the evanescent field photodetector. i Photovoltage changes with increased laser power in the fiber. Inset shows frequency response performance of the evanescent field photodetector.

Finally, we show that the photodetector devices can be integrated on the MF platform using our technology, which can also operate in different schemes. In fiber and broader photonic systems, photodetectors are conventional devices that detect light and convert it into an electronic signal, widely applied in imaging, optical communications, and sensing19,20,58. One of the core components of photodetectors is photovoltaic NMs that respond to light, such as silicon, GaAs, graphene, and Te, along with electrodes that conduct electrical signals, such as Au and Cr NMs59,60. Since our strategy is compatible with various NM materials, we can precisely assemble both photovoltaic and electrode NMs on MFs without causing damage during material-specific deposition processes. Firstly, Te/Si NMs were employed as photo-responsive materials, while Cr/Au NMs were deposited onto a substrate to serve as electrodes, as depicted in Fig. 6d. After conformally wrapping the NMs on MFs, we measured the current–voltage characteristics of the photodetectors, as shown in Fig. 6e. Within the voltage range of −10 V to 10 V, the I–V curve shows near-linearity, with slight nonlinearity near zero, possibly due to Schottky contacts between the Te NM and the electrodes. Figure 6f shows the response time of the device tested under periodic illumination with a 940 nm laser at a frequency of 50 mHz. The rise time of the device was 0.57 s, while the fall time was 0.75 s. We consequently tested the optoelectrical performance under irradiation at various wavelengths, frequencies and laser powers, as shown in Figs. S59 and S60. The Te/Si photodetector is responsive to wavelengths from ultraviolet (360 nm) to near-infrared (940 nm), suggesting its potential for wide-range environmental light monitoring, which may be beneficial in industrial monitoring and biomedical imaging22. In addition to environmental light, evanescent fields generated by light inside the MF can also be detected. As presented in Figs. 6g, S61 and S62, in this scheme we adopted layer-by-layer assembly to construct a metal-semiconductor-metal structure on the MF. First, a pair of Au/Cr NMs was wrapped around the MF as electrodes. Then, a Si/Te NM was placed between them, maintaining contact at both ends. In Fig. S63, Raman spectra confirm almost no structural changes for Te NM during the fabrication process. Figure 6h presents the electrical characteristics of the evanescent field photodetector under light-on and light-off conditions. The non-linear I–V curve indicates Schottky contacts at both ends, and the difference between light and dark conditions confirms sensitivity to the evanescent field despite its extremely weak intensity. When a laser is coupled into one end of the MF, as shown in Fig. 6i, photovoltage increases with the laser power. The inset of Fig. 6i presents the frequency response performance of the evanescent field photodetector, indicating optimal performance at around 1000 Hz, with performance degradation at both high and low frequencies due to limited response time and capacitive effects. This evanescent field photodetector may have potential in optical communication systems for fault detection and distributed sensing.

As mentioned above, a wide range of fiber devices can be constructed with our conformal strategy, indicating a promising and flexible platform in optical communications and sensing applications. In addition, we wrapped Au/Ag NMs on MF to realize light signal enhancement, as shown in Fig. S64. Building upon this foundation, we propose the design of an intelligent all-fiber system, as illustrated in Fig. 7. The system is primarily composed of three components: modulation unit (A), non-linear unit (B), and feedback unit (C). The modulation unit is composed of a tunable MKR, which can generate WGMs to modulate the optical signal via peak shifting. The non-linear unit employs a phase transition material structure to introduce nonlinearity, thereby enabling complex signal processing. The feedback unit, comprising a photodetector, is designed to monitor and adjust system performance in real-time. Light is initially directed into a wavelength-division-multiplexing layer, followed by a Mach–Zehnder interferometer layer. Through targeted laser heating in free space, the material properties of units A and B can be dynamically modified, facilitating the modulation of signal weights and the implementation of non-linear activation functions, respectively. Additionally, the feedback unit (C) continuously monitors laser intensity throughout the system, providing real-time adjustments to optimize input signals. By means of the dynamic process, an all-in-fiber intelligent system can be established, which may have potential in optical computing and real-time data processing.

The system consists of three main components: a modulation unit (A) with a tunable micro-knot resonator for optical signal modulation via whispering gallery mode peak shifting; a non-linear unit (B) utilizing phase transition material for non-linear signal processing; and a feedback unit (C) with a photodetector for real-time system adjustments. Light initially passes through a wavelength-division-multiplexing and Mach–Zehnder interferometer, and targeted laser heating allows dynamic modulation of units A and B, enabling signal weight modulation and non-linear activation. This setup demonstrates potential applications in optical computing and real-time data processing.

Discussion

To conclude, we propose a universal conformal strategy to build an NM-on-fiber platform with enhanced light–matter interaction. With the assistance of elastic energy and liquid surface energy, the NMs can spontaneously roll up and conform to the surface of the optical fiber, making this approach suitable for a wide range of materials, including metals, oxides, semiconductors, and polymers. Besides, for MFs and other complex fiber structures, our method enables the construction of 3D surface architectures, including geometric design, helix pitch control, periodic structure fabrication along the fiber direction, and in situ multilayer film assembly. Employing this strategy, we demonstrate diverse kinds of optical and optoelectronic devices, illustrating the platform’s significant potential in practical applications, such as sensors with stimuli-responsive materials, tunable MKR filter, long-period fiber grating, and photodetectors for different environments—all of which are crucial components in advanced integrated optical systems.

The material singularity in fiber systems limits their potential for further functional expansion and integration. To address this limitation, our method can effectively incorporate the intrinsic specificity and functional characteristics of diverse materials into the fiber-based systems, ensuring tightly coupled interfaces at the same time. Leveraging the inherent flexibility and ease of integration of optical fibers, we aim to develop a plug-and-play multifunctional fiber-based platform. For example, we can assemble multi-material structures on fibers to further functionalize the fibertrodes for light signal control, which has recently been applied in neural interfacing as implantable devices61,62,63. Moreover, we can also apply the NM-based optical devices to the electronic fibers or textiles (Figs. S65 and S66) for display and optical computing64,65. Our strategy shows the ability to establish an all-fiber intelligent platform, potentially paving the way for the next generation of highly integrated photonic systems.

Materials and methods

Fabrication of microfibers

MFs with different diameters were fabricated with a home-made fiber-tapering system. Tapered MFs were made by heating with the fire of a water-electrolyzing oxy-hydrogen generator and stretching a commercial single-mode fiber (Corning SMF-28e) with two stepper motors on both sides of the desired fiber waist. A flame-brush system was designed and employed to obtain longer waist length, in which the two stepper motors on both sides of the MF stretched in the opposite direction and simultaneously moved in the same direction repeatedly to achieve a larger equivalent heating length. Through adjusting the number of the fire-brush cycles, MF with controllable diameters can be fabricated.

Fabrication of pre-strained nanomembranes

Diverse pre-strained NMs were prepared with CMOS-compatible processes. As for electron-beam evaporation (DETECH, DE400), the glass substrate was covered by a shadow mask with structured pores to pattern the NMs. Through controlling the evaporation speeds and thicknesses, NMs with different strain status were obtained. Typical evaporation for Ag/Ti/Fe NM series was 1.5 Å/s and 30 nm for each layer; for Pd/Cr NM series was 1.0 Å/s for Pd layer and 0.2 Å/s followed by 1.0 Å/s for Cr layers, each layer was 30 nm; for Ti NM was 1.5 Å/s followed by 0.2 Å/s, each layer was 40 nm. To adapt to the characteristics of diverse materials, different substrates were chosen. Si/Te NMs were evaporated on a graphene substrate with speeds of 1.0 Å/s and 0.1 Å/s, respectively, and 50 nm thickness for each layer.

For VO2 NM deposition, we use direct-current magnetron sputtering (Kurt J. Lesker, PVD75) to build the intrinsic strain gradient during the growth process. VO2 NM were grown on SiO2/Si substrates by magnetron sputtering using a pure vanadium metal (99.9%) target in oxygen-argon flux. In detail, the SiO2/Si substrate was heated to 500 °C for deposition. The oxygen-argon ratio was set at 36 sccm: 64 sccm, and the sputtering power was 200 W. Then the NMs were deposited on the substrate for 1800 s. Due to the different thermal expansion coefficients of SiO2 and VO2, the deposited VO2 NM near the SiO2 substrate obtains a larger compressive strain, and the VO2 NM away from the SiO2 substrate has a smaller compressive strain, due to lattice relaxation. Hence, the intrinsic strain gradient is achieved in VO2 NM, which can be tuned by controlling the deposition parameters.

As for Si NM in Fig. 1d, a commercial (100) SOI wafer (top silicon: 20 nm and buried oxide: 150 nm) was patterned with photolithography and reactive ion etching, and then immersed in HF solution to remove the buried oxide layer and obtain suspended Si NM at the same time. And for pNIPAM/SU-8 NMs, the pNIPAM NM (thickness: 2 μm) was spin-coated on a Si substrate and covered with a metal layer, then the SU-8 layer was spin-coated. The NMs were patterned with photolithography layer by layer.

Material analysis and structural characterizations

Raman characterizations and PL tests were carried out on a Renishaw inVia Qontor Raman spectrometer with a 100× objective lens under 532 nm laser irradiation. The structure characterizations were observed by optical microscopy (Motic-BA310) and SEM (Zeiss Sigma) for morphology. The conformal characterizations and EDX mapping were collected by STEM (JEOL ARM200F).

Optical simulation

Optical simulations for the interaction between conformal NM and MF were performed with COMSOL Multiphysics. In Fig. 1a, b, MF with a diameter of 2 μm and NM with a thickness of 20 nm were considered. The structure was placed in a box with perfectly matched layers and scattering boundary conditions to absorb the reflection at the boundary, and the simulation was performed near the wavelength of 1550 nm. The refractive indices of the MF and NM were set to 1.4468 and 2, respectively. Under mode analysis based on the wave equation, the electrical field distribution of the NM-wrapped MF structure was obtained (mode LP01). The light–matter interaction is defined as the ratio of the surface integral of the electric field intensity in the NM layer and MF. In Fig. 4b–d, the MF diameter is 10 µm, and the NM thickness is 100 nm. The refractive indices before and after the phase transition are 3.0 and 2.3, respectively.

Simulation results of LPFG in Figs. 5c, S56 and S57 were carried out with RSoft. The MF structure was set to be tapered on both sides to fit the real structure in experiments, and light was transported in the core of the MF structure. The refractive indices of the fiber core and cladding were set to 1.4502 and 1.4468, respectively. The real and imaginary parts of the NMs’ refractive index were set to 2.78 and 8.37, which is calculated from equation

to be the average refractive index of Ag/Ti/Fe multilayer NMs. The launch power was monitored to visualize the loss in the propagation path. Wavelengths from 1480 to 1600 nm were simulated to obtain the spectra and the electrical field distribution correspondingly.

Optical measurement

An optical fiber system was utilized for optical measurements of the NM-wrapped MF structures. One side of the MF was coupled with a single-mode, tunable external-cavity laser (Ando 4321D, linewidth 200) and the other side was connected with an indium gallium arsenide photoelectric detector (Thorlabs PDA10CS-EC), in which electrical signals was converted by light in the fiber was monitored with a digit multimeter (Keysight 34401A) and further visualized by a computer with a general-purpose interface bus data acquisition card (National Instruments). Through sweeping the wavelengths of the laser over a wide spectral range, the behaviors of the MF structures can be obtained.

Simulation of nanomembranes wrapping on microfibers

The simulation for NMs wrapped on MFs is based on FEAs. Both NM and MF are modeled according to the experimental data. The multilayer pre-strains are set in NMs before releasing. The contact area between MF and planar NM before releasing is fixed during the rolling process.

Optoelectrical characterization of a nanomembrane-wrapped microfiber photodetector

The electrical measurements were performed using a commercial Keysight B2902B. The optoelectrical behavior in Figs. 5f and S59 was obtained under the irradiation of 940 nm laser, and the optoelectrical behavior in Fig. S60 was obtained under the irradiation of adjustable monochromatic light source (TLS3-X300). As for the evanescent field photodetector, the power of the laser irradiation was indirectly represented via measuring the output power of the MF, which was around 8 mW (at 635 nm) during the measurement of I–V curves with light illumination. A waveform generator (Keysight 33500B) and DSP lock-in amplifier (Stanford Research Systems Model SR830) were utilized to extract photocurrent signals.

Data availability

The data that support the findings of this study are available from the corresponding author upon request. Source data are provided with this paper.

References

Bogaerts, W. & Chrostowski, L. Silicon photonics circuit design: methods, tools and challenges. Laser Photonics Rev. 12, 1700237 (2018).

Chang, L., Liu, S. T. & Bowers, J. E. Integrated optical frequency comb technologies. Nat. Photonics 16, 95–108 (2022).

Wilson, D. J. et al. Integrated gallium phosphide nonlinear photonics. Nat. Photonics 14, 57 (2020).

Liu, Y. et al. A photonic integrated circuit-based erbium-doped amplifier. Science 376, 1309 (2022).

Xiong, Y. F., Ding, Z. X. & Xu, F. Active fiber tips with optoelectronic integration: state-of-the-art, future trends, and challenges. J. Light. Technol. 41, 4248–4261 (2023).

Xiong, Y. F. & Xu, F. Multifunctional integration on optical fiber tips: challenges and opportunities. Adv. Photonics 2, 064001 (2020).

Chen, J. H., Xiong, Y. F., Xu, F. & Lu, Y. Q. Silica optical fiber integrated with two-dimensional materials: towards opto-electro-mechanical technology. Light Sci. Appl. 10, 78 (2021).

Zhang, L., Tang, Y. & Tong, L. M. Micro-/nanofiber optics: merging photonics and material science on nanoscale for advanced sensing technology. iScience 23, 100810 (2020).

Pisco, M. & Cusano, A. Lab-on-fiber technology: a roadmap toward multifunctional plug and play platforms. Sensors 20, 4705 (2020).

Ricciardi, A. et al. Lab-on-fiber technology: a new vision for chemical and biological sensing. Analyst 140, 8068–8079 (2015).

Lai, L. L. et al. 3D printing of glass micro-optics with subwavelength features on optical fiber tips. ACS Nano 18, 10788–10797 (2024).

Gissibl, T. et al. Two-photon direct laser writing of ultracompact multi-lens objectives. Nat. Photonics 10, 554–560 (2016).

Picelli, L. et al. Scalable wafer-to-fiber transfer method for lab-on-fiber sensing. Appl. Phys. Lett. 117, 151101 (2020).

Pham, X. T. et al. Wide range refractive index measurement based on off-axis tilted fiber Bragg gratings fabricated using femtosecond laser. J. Light. Technol. 37, 3027–3034 (2019).

Cano-Velázquez, M. S. et al. Temperature-compensated solution concentration measurements using photonic crystal fiber-tip. Sensors 23, 7703 (2023).

Hendriks, A. L. et al. Detecting single nanoparticles using fiber-tip nanophotonics. Optica 11, 512–518 (2024).

Picelli, L., van Veldhoven, P. J., Verhagen, E. & Fiore, A. Hybrid electronic-photonic sensors on a fibre tip. Nat. Nanotechnol. 18, 1162 (2023).

Hendriks, A. L. et al. Nano-optomechanical fiber-tip sensing. npj Nanophotonics 1, 10 (2024).

He, R. R. et al. Integration of gigahertz-bandwidth semiconductor devices inside microstructured optical fibres. Nat. Photonics 6, 174–179 (2012).

Liu, Z. H. et al. Fiber end-facet integrated non-volatile optical switch based on Ge2Sb2Te5. J. Light. Technol. 40, 3968–3973 (2022).

Abouraddy, A. F. et al. Towards multimaterial multifunctional fibres that see, hear, sense and communicate. Nat. Mater. 6, 336–347 (2007).

Loke, G., Yan, W., Khudiyev, T., Noel, G. & Fink, Y. Recent progress and perspectives of thermally drawn multimaterial fiber electronics. Adv. Mater. 32, 1904911 (2020).

Qian, S. T., Liu, M. Y., Dou, Y. H., Fink, Y. & Yan, W. A. ‘Moore’s law’ for fibers enables intelligent fabrics. Natl Sci. Rev. 10, nwac202 (2023).

Vaiano, P. et al. Lab on Fiber Technology for biological sensing applications. Laser Photonics Rev. 10, 922–961 (2016).

Tong, L. M. et al. Subwavelength-diameter silica wires for low-loss optical wave guiding. Nature 426, 816–819 (2003).

Tong, L. M., Zi, F., Guo, X. & Lou, J. Y. Optical microfibers and nanofibers: a tutorial. Opt. Commun. 285, 4641–4647 (2012).

Wu, X. Q. & Tong, L. M. Optical microfibers and nanofibers. Nanophotonics 2, 407–428 (2013).

Chen, X. Y. et al. Wrap-like transfer printing for three-dimensional curvy electronics. Sci. Adv. 9, eadi0357 (2023).

Li, H. C., Wang, Z. H., Cao, Y., Chen, Y. & Feng, X. High-efficiency transfer printing using droplet stamps for robust hybrid integration of flexible devices. ACS Appl. Mater. Interfaces 13, 1612–1619 (2021).

Li, W. et al. Ultrafast all-optical graphene modulator. Nano Lett. 14, 955–959 (2014).

Chen, J. H. et al. Tunable and enhanced light emission in hybrid WS2 optical-fiber-nanowire structures. Light Sci. Appl. 8, 8 (2019).

Chen, J. H. et al. An all-optical modulator based on a stereo graphene-microfiber structure. Light Sci. Appl. 4, e360 (2015).

Akhavan, S. et al. Graphene-perovskite fibre photodetectors. Adv. Mater. 36, 2400703 (2024).

Barbot, A., Tan, H. J., Power, M., Seichepine, F. & Yang, G. Z. Floating magnetic microrobots for fiber functionalization. Sci. Robot. 4, eaax8336 (2019).

Yao, B. C. et al. Graphene enhanced evanescent field in microfiber multimode interferometer for highly sensitive gas sensing. Opt. Express 22, 28154–28162 (2014).

Li, J.-H. et al. Versatile hybrid plasmonic microfiber knot resonator. Opt. Lett. 42, 3395–3398 (2017).

Mei, Y. F. et al. Versatile approach for integrative and functionalized tubes by strain engineering of nanomembranes on polymers. Adv. Mater. 20, 4085 (2008).

Wang, Y. et al. Rolling origami with smart materials. Sci. Bull. 64, 1080–1082 (2019).

Sakai, J., Zaghrioui, M., Matsushima, M., Funakubo, H. & Okimura, K. Impact of thermal expansion of substrates on phase transition temperature of VO2 films. J. Appl. Phys. 116, 123510 (2014).

Xu, B. R. et al. Microdroplet-guided intercalation and deterministic delamination towards intelligent rolling origami. Nat. Comm. 10, 5019 (2019).

Wu, Y. et al. Nanomembrane on graphene: delamination dynamics and 3D construction. ACS Nano 19, 331–344 (2025).

Wang, L. et al. On-chip rolling design for controllable strain engineering and enhanced photon-phonon interaction in graphene. Small 15, 1805477 (2019).

Yi, X. & Gao, H. J. Cell membrane wrapping of a spherical thin elastic shell. Soft Matter 11, 1107–1115 (2015).

Sitti, M. Mobile Microrobotics (MIT Press, 2017).

Yang, J. L. et al. Ultrathin-film growth of para-sexiphenyl (II): formation of large-size domain and continuous thin film. J. Phys. Chem. B 112, 7821–7825 (2008).

Tyson, W. R. & Miller, W. A. Surface free energies of solid metals: Estimation from liquid surface tension measurements. Surf. Sci. 62, 267–276 (1977).

Wang, Y. et al. Terrestrial locomotion of microscopic robots enabled by 3D nanomembranes with nonreciprocal shape morphing. Proc. Natl. Acad. Sci. USA 122, e2500680122 (2025).

Lysenko, S. et al. Light-induced ultrafast phase transitions in VO2 thin film. Appl. Surf. Sci. 252, 5512–5515 (2006).

Xu, B. R. et al. Stimuli-responsive and on-chip nanomembrane micro-rolls for enhanced macroscopic visual hydrogen detection. Sci. Adv. 4, eaap8203 (2018).

Jiang, X. S. et al. Demonstration of optical microfiber knot resonators. Appl. Phys. Lett. 88, 223501 (2006).

Xuan, H. F., Jin, W. & Zhang, M. CO2 laser induced long period gratings in optical microfibers. Opt. Express 17, 21882–21890 (2009).

Liu, S. J. et al. Structural long period gratings made by drilling micro-holes in photonic crystal fibers with a femtosecond infrared laser. Opt. Express 18, 5496–5503 (2010).

Wang, Y. Q. et al. Single whispering gallery mode in mesh-structured tubular microcavity with tunable axial confinement. Adv. Photonics Res. 2, 2000163 (2021).

Yu, Y., Zhang, X., Song, Z., Wang, J. & Meng, Z. Precise control of the optical microfiber tapering process based on monitoring of intermodal interference. Appl. Opt. 53, 8222–8228 (2014).

Reddy, H. et al. Temperature-dependent optical properties of single crystalline and polycrystalline silver thin films. ACS Photonics 4, 1083–1091 (2017).

Sun, L. P., Li, J., Jin, L. & Guan, B. O. Structural microfiber long-period gratings. Opt. Express 20, 18079–18084 (2012).

Vengsarkar, A. M. et al. Long-period fiber gratings as band-rejection filters. J. Light. Technol. 14, 58–65 (1996).

Song, E. M., Guo, Q. L., Huang, G. S., Jia, B. & Mei, Y. F. Bendable photodetector on fibers wrapped with flexible ultrathin single crystalline silicon nanomembranes. ACS Appl. Mater. Interfaces 9, 12171–12175 (2017).

Huang, J. Y. et al. Enhanced photothermoelectric conversion in self-rolled tellurium photodetector with geometry-induced energy localization. Light Sci. Appl. 13, 153 (2024).

Wu, B. M. et al. Self-rolled-up ultrathin single-crystalline silicon nanomembranes for on-chip tubular polarization photodetectors. Adv. Mater. 35, 2306715 (2023).

Park, S. et al. One-step optogenetics with multifunctional flexible polymer fibers. Nat. Neurosci. 20, 612 (2017).

Sahasrabudhe, A. et al. Multifunctional microelectronic fibers enable wireless modulation of gut and brain neural circuits. Nat. Biotechnol. 42, 892–904 (2023).

Spagnolo, B. et al. Tapered fibertrodes for optoelectrical neural interfacing in small brain volumes with reduced artefacts. Nat. Mater. 21, 826 (2022).

Shi, X. et al. Large-area display textiles integrated with functional systems. Nature 591, 240 (2021).

Rein, M. et al. Diode fibres for fabric-based optical communications. Nature 560, 214 (2018).

Acknowledgements

This work is supported by the National Key Technologies R&D Program of China (2021YFA0715302, G.H.), the National Natural Science Foundation of China (62375054, Y.M.), the Science and Technology Commission of Shanghai Municipality (24520750202, Y.M., 24CL2900202, Y.M., 25CL2900202, Y.M.).

Author information

Authors and Affiliations

Contributions

Y.M. conceived the idea and led the research. Yunqi W. conducted the MF fabrication, optical measurement, optical simulation, SEM characterizations, Raman spectroscopy, and NM fabrication with the assistance of H.Z. and Y.Z. Yang W. conducted the theoretical calculation and simulation of the NM wrapping process. The TEM characterization was conducted by Z.Z. and X.D., and the optoelectronic characterization was conducted by C.Y. and Y.H. Yunqi W., Yang W., and Y.M. co-wrote the paper. E.S., X.C., J.C., and G.H. discussed the results and gave advice on the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Marco Pisco and the other anonymous reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wang, Y., Wang, Y., Zhu, H. et al. Conformal integration of multifunctional nanomembranes on fibers towards intelligent optical platform. Nat Commun 16, 8413 (2025). https://doi.org/10.1038/s41467-025-63562-4

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-025-63562-4