Abstract

It is crucial to break the low metal-loading limitation and reveal the intersite synergy-governed catalytic behavior of single-atom catalysts (SACs). Here, a universal synthesis strategy achieves record loadings of transition metals (Fe 41.31 wt%, Mn 35.13 wt%), rare-earth metals (La 28.62 wt%), and noble metals (Ag 27.04 wt%). The strong oxalic acid-metal chelation and concurrent entangled polymer networks enable high-loading SACs. High-density single atoms induce site-intensive effects, modulating electron density and valence states to achieve peroxymonosulfate-based Fenton-like reactions with rate constants 1-2 orders of magnitude higher than conventional SACs. Elevated metal loading boosts Fenton-like potential jumps, facilitates electron transfer, and reduces the rate-limiting energy barrier in 1O2 production. This material is also proven effective in real wastewater treatment, combining high decontamination efficiency with operational stability. It is anticipated that the cascade-anchoring synthesis strategy will take SACs a step closer to practical applications.

Similar content being viewed by others

Introduction

Improving catalytic efficiency in chemical conversion and reducing energy cost and environmental impact are the central goals of heterogeneous catalytic reactions1. SACs show great potential for achieving this goal by controlling the active sites on an atomic scale and maintaining maximum utilization of active metals2,3. However, a common challenge limiting the high catalytic efficiency is the limited number of active sites in monodispersed metals, which limits the overall catalytic performance of unit catalysts in many applications4,5. It is well known that the catalyst performance is closely related to the number of intrinsic active sites6. Therefore, an intuitive solution strategy is to maximize the metal loading on the basis of guaranteeing atomic dispersion to increase the overall catalytic activity7. However, the inherent high surface energy of single atoms makes them tend to condense into thermodynamically stable particles due to the Gibbs–Thomson effect8,9, which leads to the key challenge of accurately regulating the metal loading over a wide range in the field of SACs development.

Various strategies based on carrier engineering (e.g., nanostructure design and defect structure regulation)10,11, coordination geometry modulation (including first ligand and adjacent environment)12,13, and intermolecular interactions (involving precursor molecule design and molecular catalyst grafting)14,15, can be used to enhance the stability of individual metal atoms and inhibit their aggregation kinetically. However, to date, the metal loading of most reported SACs is still limited to 5 wt%, with only a few studies reporting loadings greater than 10 wt%16,17,18,19. Higher concentrations of metal precursors can lead to partial or complete agglomeration of the metal fraction into nanoparticles, carbides, or nitrides during pyrolysis, requiring careful design and control of the subsequent nanoparticles removal step4,5. By using graphene quantum dots with high surface-area-to-volume ratios and multi-coordination environments as substrates, the metal loading in Ir-SAC and Pt-SAC has been achieved progress16,20. However, the complex preparation processes, high equipment requirements, and low catalyst yields limit the spread of this highly loaded SACs synthesis method. The development of a simple and cost-effective synthesis strategy to achieve atomically homogeneous dispersion of dense metal and full utilization of coordination species remains a great challenge.

On the other hand, when densely distributed monodisperse metal atoms are embedded in the substrate and fully occupy the ligand species, more unique geometries and electronic structures are produced21,22. However, less attention has been paid to two important factors—the changes in the intrinsic activity of metal sites at high density and their effects on the catalytic behavior of reaction substrates, which can be carefully investigated by designing SACs with wide mass loading gradients. It is evident that the increase in metal loading provides more active sites to accelerate the reaction by facilitating interactions between reaction substrates, thereby providing higher mass-specific activity (MSA)23. In addition, increasing the mass loading improves the density of active sites and shortens the distance between metal atoms, resulting in more pronounced interaction between metal sites in high-loading SACs when compared with traditional SACs24,25. Moreover, due to the site-intensive effect, adjacent metal sites simultaneously adsorb or catalyze different substrates, which cannot be achieved by conventional SACs26. Therefore, it is of great significance to develop a simple SACs synthesis method to achieve a breakthrough in metal mass loading, and systematically study the relationship between single-atom sites and their catalytic performance.

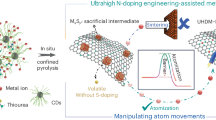

In this study, a universal cascade anchoring strategy by using a facile one-step calcination was applied to prepare Fe-SAC-x with metal loadings that can be tuned within a wide gradient of x = 0–41.31 wt%, achieving the highest metal loading of Fe-based SAC to date. The mechanism for such high metal loading was systematically studied, and found that the uniform and firm anchoring of Fe3+ by oxalic acid (OA) onto the simultaneously generated entangled polymer networks is the key factor. In addition, the successful preparation of high-loading transition metal (Mn), rare earth metal (La), and noble metal (Ag) SAC demonstrates the universality of this synthesis strategy. As a demonstration, the structure-catalysis conformational relationship was systematically studied by the activation of peroxymonosulfate (PMS) for toxic organics degradation. Combining experimental analysis and theoretical calculations, the site-intensive effects, site-to-site interactions, and the dependence of catalysis on metal loading were observed. This work not only provides a synthetic strategy for breaking the low loading limitation, but also provides important guidance for controllable regulation of the electronic structure of metals, to promote the understanding of catalytic mechanisms and efficient practical applications.

Results

Characterization of gradient-loaded Fe-SAC

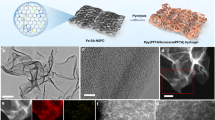

It is challenging to modulate the metal load in SACs over a wide range using a facile method. Here, a breakthrough in metal loading was achieved in Fe-SAC through a cascade anchoring strategy, obtaining the highest metal load in Fe-based SAC to date (41.31 wt%). The morphology of the samples was observed by high-resolution transmission electron microscopy (HRTEM), the obtained Fe-SAC inherited the stacked-layered features of C3N4 with a rich porous structure (Fig. 1a). In addition, the imaging at high magnification did not show any iron crystal-like aggregates, and the carbon substrate exhibited distinct amorphous characteristics (Supplementary Fig. 1). Elemental mapping showed that Fe, N, C, and O species were uniformly distributed in density on the substrate (Fig. 1b), suggesting that iron element may be anchored to the carbon substrate in an atomically dispersed form. The high-angle annular dark field scanning transmission electron microscopy (HAADF-STEM, Fig. 1c–f) further revealed the dispersion imaging of Fe atoms, manifested as isolated bright spots densely distributed on the carbon substrate, which is due to the much higher electron density of Fe than that of nonmetals, proving that high-mass-loaded Fe exists in the form of single atoms. By controlling the content of iron salts in the precursors, Fe-SACs with different iron loadings were prepared. The inductively coupled plasma-atomic emission spectroscopy (ICP-AES) analysis verified the Fe content was 0 wt%, 5.16 wt%, 15.82 wt%, 24.62 wt%, and 41.31 wt%, respectively (Supplementary Table 1), and they were named as Carbon nitride (CN), Fe-SAC-5.16, Fe-SAC-15.82, Fe-SAC-24.62, and Fe-SAC-41.31.

a, b HRTEM and elemental mappings of Fe-SAC-41.31. c–f HAADF-STEM images of Fe-SAC-x with metal loads was 41.31 wt%, 5.16 wt%, 15.82 wt% and 24.62 wt%, respectively. g X-ray diffraction (XRD) patterns of as-prepared Fe-SAC-x (the shaded area shows the trend of signal intensity changes with increasing Fe loading). h N2 sorption isotherms and pore size distribution (inset) for iron-anchored catalysts with different iron loadings. i Normalized XANES spectra of Fe-SAC-x samples (the inset figure is an enlarged version of the near-edge data). j The oxidation state of iron decreased with the increase of metal loading (the relationship between Fe K-edge energy and Fe valence state was fitted with a linear regression model: y = ax − b.). k k3-weighted Fourier transforms. l The wavelet transform of the experimental EXAFS spectra of the indicated catalysts. Scale bars: a, b 100 nm, c–f 5 nm.

The X-ray diffraction (XRD) spectra of all Fe-SACs samples did not reveal features associated with iron metals or iron oxides, only showing the reflection of the carrier material (Fig. 1g). In pristine CN, two typical diffraction peaks at 21.4° and 27.8° corresponded to the repetitive heptazine structural units and interlayer stacking in carbon nitride27. It is worth noting that the signal intensities decreased and eventually disappeared with the increase in metal loading of the pyrolyzed catalyst, suggesting that the highly loaded monatomic metals disrupted the native structure of CN. In addition, the Raman peaks of all samples were relatively broad, and the peak intensities were significantly weaker after loading Fe-SAC (Supplementary Fig. 2), reflecting the amorphous nature of the catalysts. When the Fe loading was elevated to 41.31 wt%, it was found that the Raman spectral peaks were significantly shifted, suggesting iron atoms significantly altered the molecular vibration or the rotational energy levels of the CN substrate. As the N2 adsorption–desorption isotherms and pore size distribution of different catalysts shown in Fig. 1h and Supplementary Table 2, all catalysts showed typical Type IV curves and H2 hysteresis curves, reflecting the presence of mesoporous pores28.

The chemical configurations and local coordination environments of Fe-SAC-x were investigated by X-ray absorption spectroscopy (XAS). It can be seen from the X-ray absorption fine structure spectroscopy (XANES) curves of Fe K-edge that the near-edge energy adsorption thresholds of all Fe-SAC-x are higher than that of FeO but lower than that of Fe2O3 (Fig. 1i), suggesting that the valence states of Fe atoms in Fe-SAC-x lie between +2 and +329. Notably, the increase in the density of Fe sites promotes the shift of the absorption edge towards lower energy, suggesting that the electron density of Fe sites in high-loading Fe-SAC is higher than that in low-loading Fe-SAC30. The valence states of the catalyst with different metal loading were fitted (Fig. 1j), and it was found that the valence states of Fe were 2.6, 2.4, 2.3, 2.2 in sequence as the iron loading increased. Therefore, elevating the Fe loading in Fe-SACs is beneficial to regulate the local electron density of Fe single atoms. The Fourier transform (FT) k3-weighted EXAFS spectra (Fig. 1k) show that the extended-edge X-ray absorption fine spectra of all Fe-SACs display a main peak near 1.5 Å, corresponding to the Fe-N/C bond, suggesting the presence of isolated Fe-based species in all samples. In addition, no metal-metal distance feature between 2.1 Å and 2.5 Å was observed in any samples, confirming the absence of metal nanoparticles or clusters31. The wavelet transform (WT) further provides radial distance resolution, as well as K-space analysis, and the Fe-SACs show a maximum peak at ~4.4 Å−1 (Fig. 1l), which is consistent with the EXAFS results in R-space. These results consistently support that Fe in Fe-SAC with different Fe loading is atomically dispersed. It is noteworthy that a decrease in k value is observed on the WT isograms of all Fe-SAC-x samples compared to FePc, which is attributed to the introduction of C in the first coordination shell layer of Fe atoms32, suggesting that in addition to N atoms, Fe atoms also coordinate with C atoms. In addition, the exact coordination structure of Fe atoms was determined by quantitative least-squares EXAFS fitting (Supplementary Table 3), supporting that the coordination environment of Fe in Fe-SAC-x is similar to that of FePc, and the coordination number of the first coordination layer of Fe in Fe-SAC is 4.1 ± 0.4.

Cascade anchoring enables ultrahigh-loading SACs

What is the driving force behind such a high monodisperse metal load? As is well known, when metals are dispersed from particles into clusters or even individual atoms, it leads to significantly higher surface free energy and triggers higher mobility. Therefore, the successful preparation of single-atom catalysts must be premised on the realization of strong metal center-support (usually non-metallic coordination atoms such as C, N, O, and S) interactions. On the other hand, the full utilization of ligand atoms is another key to achieving high metal loading, which requires chemical control of the metal at the atomic or molecular level to achieve its homogeneous dispersion on the carrier or precursor and to fully occupy the chelation sites of the metal. Unfortunately, it is extremely challenging to simultaneously fulfill the above requirements using traditional methods, which is why the metal loading of SACs has been severely limited for a long time. At present, there is still a lack of facile and universal synthesis strategies.

Carbon nitride is an excellent carrier of single atoms due to its thermal stability and high content of coordination sites, mainly provided by nitrogen atoms. Although it exhibits the homogeneity of ligand site, the chemical stability of the triazine or heptazine unit limits the effective utilization of numerous N sites in CN. Considering this limitation, a bottom-up in-situ assembled cascade anchoring mechanism was adopted in this study.

During the preparation of Fe-SAC precursor, the metal ions are strongly assembled into the supramolecular organic skeleton (SOK) through chemical bonding, and the subsequent high-temperature pyrolysis further anchors the metal atoms in situ at the nearby N sites. Figure 2a illustrates this simple synthesis strategy. Fe3+ was assembled into the SOK of oxalate-MA macromolecules using OA because it can either chelate with Fe3+ [Eq. (1)] or react with MA to form a supramolecular organic framework [Eq. (2)]. Supplementary Fig. 3a further demonstrates the composite reaction between MA and OA, yielding a milky-white supramolecular organic framework. Fourier transform infrared (FTIR) spectroscopy (Fig. 2b) revealed that the characteristic peaks of MA (580.8 cm−1, 1025.2 cm−1, 3133.7 cm−1) or OA (713.5 cm−1, 1686.9 cm−1, 3388.7 cm−1) disappeared in the supramolecular framework, while a new amide peak emerged at 3254.5 cm−1, confirming chemical assembly rather than physical mixing between MA and OA. Upon introducing Fe3+, the resulting supramolecular polymer exhibited a homogeneous yellow-green color (Supplementary Fig. 3b) with a clarified solution, indicating that OA not only chelates Fe3+ but also co-assembles with MA, thereby synchronously anchoring Fe3+ into the organic framework. In the FTIR profile, the appearance of a Fe-O bonding peak at 533 cm−1 (Fig. 2b) confirmed successful integration of Fe atoms into the skeleton via chemical bonds. The spectrum of the Fe-SAC precursor perfectly matched that of the supramolecular polymer framework, demonstrating that the chelation of Fe3+ with OA did not disrupt the skeleton structure. In stark contrast, the precursor prepared by the solvent evaporation method (Supplementary Fig. 3c) displayed a spectrum nearly identical to that of pure MA, with no detectable Fe–O bonding peaks (Fig. 2b), confirming only physical adsorption of Fe3+ onto MA.

a Schematic synthesis process for Fe-SAC-x catalyst with high Fe loading. b Fourier transformed infrared (FTIR) spectra of catalyst precursors (SOK: supramolecular organic skeleton). c Elemental mappings of Fe-SAC precursor obtained by the cascade anchoring strategy. d Nonlinear correlation between Fe-SAC loading and metal salt dosage. e Nonlinear correlation between SA wt% and OA dosage. f The metal loading of SAC prepared using different metal salts (nitrate, chloride, or sulfate) and metal types (transition, rare-earth, or noble metals). g–i FT of K-edge EXAFS spectra of Mn-SAC, Ag-SAC, and La-SAC, respectively.

TEM characterization further demonstrated the homogeneous dispersion of Fe on the precursor, which made it possible to fully utilize the coordination species. For the conventional solvent evaporation method, the Fe-SAC precursor was a fine rod structure (Supplementary Fig. 4a), surrounded by unevenly distributed metal particles, indicating physical combination and the non-uniform distribution of metal on the precursor, which led to insufficient utilization of coordination species on the carrier. This indicates either acid washing after pyrolysis or a tedious multistep annealing procedure is required to remove unbound metal species17, resulting in a low loading of catalysts. In stark contrast, the Fe-SAC-41.31 precursor synthesized via our cascade anchoring strategy displayed an irregular morphology without particle aggregation (Supplementary Fig. 4b). Energy-dispersive X-ray spectroscopy (EDX) mapping further confirmed the homogeneous distribution of Fe elements across the framework (Fig. 2c). This sharp contrast conclusively demonstrates the critical role of OA as a specific carrier that enables targeted delivery of Fe3+ into the supramolecular organic framework. This mechanism ensures the full utilization of coordination species on the precursor during subsequent pyrolysis, directly contributing to the ultrahigh metal loading.

The synthesis process of SAC through pyrolysis of Fe-SAC precursor was monitored by thermogravimetric analysis (TGA) (Supplementary Fig. 5). The initial mass attenuation below 110 °C is attributed to the volatilization of residual moisture in the sample. A pronounced mass attenuation observed in the MA sample between 250 °C and 350 °C corresponds to its thermal polycondensation into C3N4. In contrast, the MA-OA composite supramolecular framework exhibited significant mass attenuation at lower temperatures due to the thermal decomposition of thermally labile OA. Notably, direct pyrolysis of MA without OA yielded C3N4 with a densely packed bulk structure (Supplementary Fig. 6a), demonstrating a specific surface area of merely 18.74 m2 g−1 (Supplementary Table 2). The pyrolysis of the supramolecular framework produced C3N4 with a petal-like flaky architecture (Supplementary Fig. 6b), exhibiting an enhanced specific surface area of 100.05 m2 g−1. This structural modification is ascribed to the liberation of CO2 from the decomposed oxalate species during calcination, which disrupts the polycondensation of MA and facilitates the formation of porous structures conducive to reactant diffusion in the catalytic processes. Remarkably, the Fe-SAC precursor anchored with Fe3+ ions displayed accelerated mass attenuation at reduced temperatures (Supplementary Fig. 5), indicating the catalytic role of Fe species in promoting the volatilization of thermally unstable components. Notably, the presence of metal components also impacts the porosity and surface area of the catalyst. As shown in Fig. 1h, at fixed concentrations of OA and MA, the specific surface area of the catalyst decreased with increasing metal loading. This trend arises because metal species catalyze the decomposition of unstable components and competitively scavenge nitrogen atoms from MA during pyrolysis, thereby hindering the polycondensation of the supramolecular polymer into ordered C3N4. This effect intensifies at higher metal loadings, as evidenced by the gradual disappearance of characteristic heptazine unit diffraction peaks in the XRD patterns (Fig. 1g).

Intriguingly, for the final synthesized SAC, its Fe mass fraction increases nonlinearly with iron salt content in precursors (Fig. 2d). This indicates that a smaller incremental increase in Fe salt injection in the later stage can cause a significant rise in Fe loading. To elucidate this anomalous behavior, we systematically investigated the synthesis process of high-loading Fe-SACs. Given the critical role of OA in coordinating metal ions, the amount of OA added was adjusted while maintaining a fixed concentration of MA and Fe salt. It was found that the OA content significantly influences the yield of the Fe-SAC precursor and the ultimate metal loading of the SAC (Supplementary Table 4). This demonstrates a concentration-dependent relationship between MA, OA, and Fe3+, and reveals that the supramolecular organic framework possesses a maximum metal loading capacity. Increasing the OA content generates more catalyst substrate (Supplementary Table 4), resulting in a corresponding reduction in metal loading (Fig. 2e). This counterintuitive phenomenon is the inverse of the trend observed in Fig. 2d, where increasing the Fe salt dosage while keeping MA and OA fixed gradually approaches the maximum loading capacity of framework, resulting in a rapid surge in metal loading. This systematic investigation reveals that oxalate acts as a “structure-directing agent” that governs framework integrity and metal stabilization capacity, rather than just a sacrificial template. The dosage of Fe3+ salt directly controls the loading level. The orthogonal tunability of these two parameters provides exceptional flexibility for SAC design.

To investigate the relationship between sintering temperature and the structure of SACs, the structural characteristics of the catalysts prepared at different pyrolysis temperatures (450 °C, 550 °C, and 650 °C) were characterized. TGA analysis reveals that the pyrolysis process of Fe-SAC precursor can be divided into three stages (Supplementary Fig. 5): decomposition of thermally unstable oxalate components (80–250 °C), polycondensation of melamine (MA) to form the catalyst substrate (250–350 °C), and stabilization of atomic sites via metal capture of N-coordination species (350–550 °C). As shown in Supplementary Fig. 8a, XRD analysis proved that no diffraction peaks of the metal phase were observed for the catalyst prepared at 450 °C, and no metal particle aggregates were observed by HRTEM (Supplementary Fig. 8b), indicating the formation of Fe-SACs during calcination at 450 °C. However, the XRD patterns exhibit distinct C3N4 diffraction peaks, indicating well-preserved periodic triazine units in the substrate. This suggests that substantial N-coordination sites remained unutilized. Therefore, the incomplete decomposition of unstable components in the substrate resulted in a relatively low metal proportion, with a loading of 15.31 wt% (Supplementary Table 1). In contrast, calcination at 550 °C produced Fe-SACs with a high metal loading of 41.31 wt%. Further increasing the temperature to 650 °C led to the emergence of distinct lattice diffraction peaks in XRD patterns (Supplementary Fig. 8a), indicating intensified thermal motion of metal atoms at elevated temperatures and subsequent formation of crystalline structures (Supplementary Fig. 8d). Therefore, 550 °C is identified as the optimal synthesis temperature for preparing high-loading single-atom catalysts.

When densely distributed monodisperse metal atoms are embedded in the substrate and fully occupy the ligand species, more unique geometries and electronic structures are produced. The changes in chemical configuration of the catalyst under gradient iron loading were further studied by XPS (Supplementary Fig. 9). The C 1s XPS spectrum of pristine CN showed a typical carbon nitride characteristic peak near 287.7 eV, which is attributed to the sp2 N–C=N bond in the aromatic ring. However, after the loading of monatomic Fe, this peak generally shifted toward high binding energy, and the characteristic peak of sp2 C–C bond appeared at 284.8 eV, with the peak intensity increasing with the increase of Fe loading. This result, combined with XRD and Raman analyses, consistently demonstrated that the high-loading Fe atoms significantly altered the skeletal structure of the CN substrate to meet the requirement for overall structural stability of the catalyst. Meanwhile, the Fe 2p spectra shifted towards lower binding energies with increasing Fe loading (Supplementary Fig. 10), which echoes the XANES results and further indicates that higher loading facilitates the acquisition of Fe reaction centers with higher local electron density. Compared with the pristine CN, the anchoring of a single Fe atom resulted in the appearance of distinct Fe–N characteristic peaks in the N 1s spectra (Supplementary Fig. 11), further demonstrating the coordination of Fe with nitrogen atoms. Notably, the elemental content analysis (Supplementary Table 5) showed that a higher Fe loading did not induce an increase in the C, N elemental percentage in the catalyst, but rather showed a decreasing trend. However, with the increase of Fe loading, the content of elemental oxygen showed an overall increasing trend, suggesting that oxygen content might play an important role in controlling SA loading. Han et al. pointed out that during the formation of highly loaded single atoms, the center metal atoms coordinate with O at low temperatures (less than 200 °C) first, and the coordinated O is successively replaced by N or C at high temperatures (400–600 °C)33. Thus, the coordination environment of metal atoms is closely related to the terminal temperature.

The above analysis indicates that the density distribution of metal not only affects the overall structure of the catalyst, but also significantly influences the electronic structure of the metal centers. Therefore, the charge redistribution caused by the site-dense effect was further demonstrated by DFT, which is important for understanding the conformational relationship between structure and catalytic activity. Based on the Fe-CN optimization model established by EXAFS and XPS, three possible CN coordination modes are considered. As shown in Supplementary Fig. 12, the isolated Fe atom has a more negative binding energy when combined with the C1N3 configuration, so this coordination configuration is more stable compared with the others. In order to theoretically better understand the effect of metal loading on the electronic structure of Fe atoms, different numbers of Fe sites were uniformly embedded into the same 4 × 8 graphene cells to represent different metal-loaded Fe-SAC (The green area in Supplementary Figs. 13–16. The atomic coordinates of optimized computational models for different metal loadings were provided in Source Data). Such a grid region accommodates 1, 3, 4, and 8 Fe-C1N3 sites, respectively. The calculated theoretical mass loading in the enlarged models is 6.66 wt%, 18.43 wt%, 23.59 wt%, and 40.68 wt% (Supplementary Figs. 13–16), which is very close to the actual Fe mass loading of 5.16 wt%, 15.82 wt%, 24.62 wt%, and 41.31 wt% measured by ICP. These models with different numbers of Fe-C1N3 sites can reliably represent Fe-SACs with different mass loadings for theoretical studies, which is an important guideline for exploring the interactions between Fe sites and constructing efficient SACs.

Notably, the evolution of the coordination environment occurred with the increase in the metal loading. Specifically, the Fe–N/C bond lengths increase from 2.08 Å (5.16 wt%) to 2.13 Å (41.31 wt%) (Supplementary Table 6), reflecting the weakening of local hybridization. Meanwhile, PDOS analysis shows diminished overlap between Fe 3d and C/N 2p states at higher loadings (Supplementary Fig. 17). This reduction in orbital overlap corroborates the structural relaxation observed in bond lengths. It is worth noting that long-range electronic coupling was observed through the d-band shift. The Fe d-band center shifts negatively from −1.51 eV to −2.72 eV relative to the Fermi level as the loading increases, indicating enhanced metal-support charge transfer34, which is consistent with the analysis results of Bader charge (Supplementary Table 6) and charge density difference (Supplementary Fig. 18). These findings demonstrate that an increase in single-atom loading optimizes the proximity between adjacent Fe sites, inducing long-range Fe–Fe interactions mediated by the support. Such long-range interactions modulate the electronic structure of Fe atoms and the hybridization of atomic orbitals with coordinated atoms, thereby optimizing the adsorption/desorption kinetics of reactive intermediates. Specifically, the downshifted d-band weakens the intermediate binding strength, while the enhanced electron transfer (ETP) kinetics through long-range coupling may improve catalytic efficiency, as evidenced by the reduced Rct in electrochemical impedance tests (Fig. 3d). Consequently, tailoring metal site density enables precise electronic structure modulation and facilitates efficient ETP through improved hybridization and bonding interactions between metal atomic orbitals, ultimately influencing catalytic performance.

Inspired by the above studies, transition metal (Mn), rare earth (La), and noble metal (Ag) SACs were prepared to verify the universality of the synthesis strategy. As shown in Supplementary Fig. 19, no metallic phase was observed in the XRD patterns of Mn-SAC, La-SAC, and Ag-SAC, suggesting that Mn, Ag, and La may exist in an atomically dispersed form. The HAADF-STEM images observed densely distributed isolated bright spots, further confirming the successful preparation of Mn-SAC, La-SAC, and Ag-SAC (Supplementary Fig. 20). The ICP-AES results showed that the contents of Mn, La, and Ag were 35.13 wt%, 28.62 wt%, and 27.04 wt%, respectively, which were the highest loadings recorded in the existing literatures35,36,37. XAS spectroscopy also demonstrated the separation characteristics of metal atoms. The FT of K-edge EXAFS spectra showed the main peak at ~1.5 Å (Fig. 2j–i), corresponding to the M-N/C scattering path, and no M-M scattering signals are detected, which further proves the successful preparation of ultrahigh metal loading SACs. In addition, the choice of metal salt (e.g., chlorides or sulfate) does not interfere with the cascade anchoring process. XRD (Supplementary Fig. 21) and HAADF-STEM (Supplementary Fig. 22) characterizations confirm the absence of crystalline phases and the atomic dispersion of Fe. ICP analysis reveals that Fe-SACs synthesized using Fe2(SO4)3 and FeCl3·6H2O achieve metal loadings of 37 wt% and 40.04 wt%, respectively (Fig. 2f), further validating the universal applicability of this method38.

Dependence of catalytic activity on metal loading

PMS-based advanced oxidation processes (PMS-AOPs) have great potential in sustainable water purification. Here, sulfamethoxazole (SMX) was selected as the target toxic organic, and the dependence of Fe-SAC-x catalytic activity on metal loading was investigated in terms of PMS activation and SMX degradation kinetics. In the absence of any catalyst, PMS could only remove 13.4% of SMX within 5 min (Supplementary Fig. 23). The adsorption of SMX by Fe-SAC-x without the addition of PMS was also very low (6.1%). As shown in Fig. 3a, Fe-SAC-x showed a significant difference in the SMX degradation upon different Fe loading, in which the degradation kinetics of SMX significantly accelerated with the increase of Fe loading. The SMX degradation rate constant of the Fe-SAC-41.31 system was 1.06 min−1, which was 53 times higher than that of pristine CN (0.02 min−1) (Supplementary Fig. 24). The iron dissolution after degradation was positively correlated with the Fe loading of Fe-SAC (Supplementary Fig. 25), but all much less than the limitation of EU and US (<2 mg L−1)39. To examine the contribution of these dissolved iron ions to the SMX degradation, experiments were carried out using a homogeneous system with the same iron concentration, confirming that such a removal of SMX was only 26.6% after 20 min (Fig. 3b), whereas the Fe-SAC-41.31 system achieved 96.4% removal of SMX within just 3 min. This suggests that the SMX degradation should be mainly attributed to the activation of PMS by the catalyst, rather than the dissolved Fe2+ or Fe3+. In addition, Fe-SAC-T with a metal loading of 1.61 wt% was synthesized using the traditional evaporation solvent method to accentuate the promoting effect of high loading on catalytic performance. As shown in Fig. 3c, Fe-SAC-41.31 has a slightly increased turnover frequency (TOF) compared with Fe-SAC-T, indicating that the activity of a single metal site did not significantly increase. However, due to the site-dense effect, the Fe-SAC-41.31 system exhibited much higher SMX and TOC removal efficiency, and the SMX removal rate constant k value was 28.65 times higher than that of the Fe-SAC-T system (0.037 min−1) (Supplementary Fig. 26). The MSA per unit mass of Fe-SAC-41.31 for SMX degradation was calculated to be 2.19 mmol g−1, which is 24.9 times higher than that of Fe-SAC-T. In addition, the Fe-SAC-41.31 system could achieve efficient removal of SMX even if the initial concentration was 50 mg L−1 within 20 min (Supplementary Fig. 27a), whereas Fe-SAC-T exhibited complete degradation of SMX only at 2 mg L−1 within 20 min (Supplementary Fig. 27b). pH represents a critical determinant of aquatic matrices in practical settings. The initial solution pH fundamentally governs both the interfacial characteristics of electrocatalytic surfaces and the oxidative capacity of reactive oxygen species. Consequently, pollutant degradation efficiency across varying pH conditions serves as a pivotal metric for evaluating the real-world applicability of water treatment technologies.

a Differences in degradation of SMX in the PMS-based heterogeneous catalytic oxidation systems. b Contribution of homogeneous Fe ions to SMX degradation in Fe-SAC-41.31/PMS system. c Comparison of removal efficiency, k, TOF, TOC, and MSA in Fe-SAC-41.31/PMS system and Fe-SAC-T/PMS system, respectively. d Nyquist plots of indicated catalysts. e LSV curves and f corresponding Tafel plots of different catalysts with the addition of PMS. g Degradation performance of SMX by Fe-SAC-41.31/PMS system under the interference of inorganic anion and NOM. h Removal kinetic constants of personal care and pharmaceutical products (PPCPs), phenolics, and dyes, and their comparison with literature (data points are annotated with reference numbers, and full datasets are provided in Supplementary Table 7). i Reuse performance of Fe-SAC-41.31. The error bars in the figures represent the standard deviations from triplicate tests.

Considering that Fe-SAC-x has significantly different catalytic activities, electrochemical performance tests were performed to explore possible catalytic mechanisms. Electrochemical impedance tests were conducted to discover the electron-transfer kinetics (Fig. 3d). The metal loading showed a good negative correlation with the charge transfer resistance (Rct), indicating that increasing the single-atom loading was conducive to enhancing the charge transfer kinetics of the catalysts and promoting the catalytic performance40. This observation is echoed by the XPS fine spectroscopy analysis of C 1s, in which more sp2 C–C fractions are observed in Fe-SAC-x catalysts with higher Fe loading, which is more favorable for facilitating ETP. Furthermore, linear scanning voltammetry (LSV) tests clearly indicated a higher current response as the number of monodisperse iron sites increases, supporting the most effective ETP between PMS and Fe-SAC-41.31 (Fig. 3e). In addition, as shown in Fig. 3f, the Tafel slope of Fe-SAC-41.31 (430 mV dec−1) was much lower than that of pristine CN (1514 mV dec−1) and Fe-SAC-5.16 (1330 mV dec−1), suggesting that a higher Fe atomic loading is favorable to provide higher kinetic activity for PMS activation41, therefore Fe-SACs with different Fe loading reflected significantly different PMS catalytic activation properties.

To more intuitively reflect the superior performance of Fe-SAC-41.31 activated PMS, the influence of different anions (HCO3−, H2PO4−, Cl−, SO42−, NO3−, and humic acid) on SMX degradation was investigated (Fig. 3g), observing almost no effect. Therefore, the Fe-SAC-41.31/PMS system has strong environmental anti-interference ability, which indirectly explains that Fe-SAC-41.31 is mainly based on the non-free radical activation pathway of PMS as discussed in detail later. Furthermore, this system showed excellent degradation for different types of pollutants such as PPCPs (SMX, Tetracycline), phenolic (Bisphenol A, Phenol), dyes (Rhodamine B, Methyl orange), etc., and their degradation rate constant is at least 1–2 orders of magnitude higher than that of most current catalysts (Fig. 3h and Supplementary Table 7). This result should be attributed to the significantly more active sites of Fe-SAC-41.31, which provided sufficient reaction centers for the adsorption and activation of PMS, as well as the degradation of SMX. In addition, the reuse performance of Fe-SAC-41.31 was also tested, and the complete removal of SMX could be achieved after 5 times of reuse (Fig. 3i), indicating that Fe-SAC-41.31 had good reuse performance.

Catalytic mechanism under gradient metal loading

In order to explore the dependence between the catalytic mechanism and the Fe loading, chronopotential analysis was carried out (Fig. 4a). When PMS was introduced into the system, different catalyst systems showed different degrees of potential jumps (ΔEPMS). The ΔEPMS increased with the increase of Fe loading, up to a maximum of ΔEFe-SAC-41.31,PMS = 0.898 V, which was 4.01 or 2.27 times higher than that of pristine CN or Fe-SAC-5.16, respectively (ΔECN,PMS = 0.224 V; ΔEFe-SAC-5.16,PMS = 0.898 V). This suggests that atomically dispersed Fe is the adsorption site for PMS, and Fe-SAC-41.31 with the highest Fe loading has significantly more adsorption centers, which results in the formation of more catalyst-PMS complexes with high redox potentials. When an equal dose of SMX was applied to the system, a potential decrease occurred in the different systems, suggesting that the catalyst-PMS steady-state complex extracted electrons from SMX, resulting in an overall decrease in the system potential. Among them, the potential reduction was the most obvious in the Fe-SAC-41.31 system, which corresponded to the fastest SMX degradation. Thus, the effective ETPs from SMX to Fe-SAC-PMS* are driven by the potential difference, leading to the efficient SMX degradation42.

a The open-circuit potential changes of Fe-SAC-x when PMS or SMX is added, respectively. b Effects of PMS or SMX addition on the i–t curves at the corresponding open circuit potential. c In situ FTIR spectra of Fe-SAC, PMS alone, and Fe-SAC combined with PMS (The shaded area corresponds to the stretching vibration of the -OH bond produced by the adsorption of PMS on the catalyst surface). d Effects of quenching reactive oxygen species on the degradation of SMX. e Electron paramagnetic resonance spectra of TEMP−1O2 during SMX degradation in the Fe-SAC-4.31/PMS system. f Exponential Association model fit of apparent rate constant vs metal loading (R2 = 0.99). g Adsorption energy of PMS by Fe-SAC-x and the differential charge density, Bader charge transfer after the adsorption of PMS by Fe-SAC-x with different Fe loading. h Energy profiles of 1O2 derived reaction on varying Fe density models. The error bars in the figures represent the standard deviations from triplicate tests.

The ETP process between catalyst-PMS-SMX was visualized more definitely by the amperometric i–t curve (Fig. 4b). The negative increase in current after the addition of PMS proves the transfer of electrons from the catalyst to PMS until a steady state is reached. Fe-SAC-41.31 shows the highest current drop ΔIFe-SAC-41.31, PMS, proving that it has the highest ETP potentials, which also corresponds to the highest ΔEFe-SAC-41.31,PMS in Fig. 4a. In contrast, the sustained positive current rebound after the addition of SMX demonstrates the continuous electron extraction process from the pollutant by the catalyst-PMS steady-state complex. Similarly, the rapid and highest current rebound of the Fe-SAC-41.31/PMS system corresponds to its optimal SMX degradation performance.

This catalytic process was further proved by in-situ FTIR spectroscopy, as shown in Fig. 4c. The infrared band at 1101 cm−1 arises from the S–O stretching vibration of HSO5− in solution43. When the catalyst was mixed with PMS solution, a new vibrational peak appeared near 3217 cm−1, corresponding to the stretching vibration of the –OH bond produced by the adsorption of PMS on the catalyst surface. In addition, the infrared band of pristine PMS located at 770 cm−1 showed a significant red-shift, further demonstrating the strong binding of PMS on the catalyst surface, as well as the formation of catalyst-PMS* steady-state complex44. The weakening of the peak intensity over time proved the continuous activation of PMS. It is worth noting that the degradation of SMX via this ETP-mediated pathway requires strong bonding (covalent or ionic bond) between PMS and the catalyst45, so the complexation type of PMS on the catalyst was explored through ionic strength control experiments. Supplementary Fig. 28 shows that increasing the concentration of ClO4− has no significant effect on SMX degradation, suggesting that there is an inner-sphere complexation between PMS and Fe-SAC-41.3146.

The open-circuit potential test was performed with only SMX addition (Supplementary Fig. 29). The potential equilibrium on the catalyst surface was broken when a 10 mg L−1 SMX was added, indicating that SMX was adsorbed onto the catalyst surface. Different from the potential decrease triggered by SMX in Fig. 4a, the addition of SMX here resulted in a slight increase in the surface potential of the catalyst steady-state system, which is due to the fact that the redox potential of SMX itself is higher than that of Fe-SAC-41.31. Therefore, the steady-state potential increases when SMX is adsorbed onto the catalyst surface. However, to inspire an ETP process to degrade pollutants, the overall potential of the catalyst-PMS* steady-state complex is required to be higher than the redox potential of SMX itself, thus, the Fe-SAC-41.31/PMS system with the highest ΔEPMS exhibited the fastest SMX degradation kinetics. Based on the above analysis, SMX and PMS are co-adsorbed on the Fe-SAC surface, and the catalyst acts as a conducting bridge to transfer electrons from SMX to the catalyst-PMS* steady-state complex with higher redox potential.

In order to verify the key role played by atomically dispersed Fe sites in SMX degradation, potassium thiocyanate (KSCN) was used to block the Fe sites to inhibit their catalytic activity47. The degradation of SMX was almost completely inhibited when 50 mM SCN- was introduced (Fig. 4d), suggesting that the Fe sites play a dominant role in activating PMS to degrade SMX48. Furthermore, radical quenching experiments were conducted to confirm the active species in the Fe-SAC/PMS system. Methanol (MeOH) and tert-butanol (TBA) showed high reaction kinetics with SO4•− and •OH, respectively (\({k}_{{{{{\rm{SO}}}}}_{4}^{{{{\bullet }}}-},{{{\rm{MeOH}}}}}\) = 9.7 × 108 M−1S−1, \({k} _{{}^{\bullet }{{\rm{OH}}},{{{\rm{TBA}}}}}=\) 7.6 × 108 M−1 S−1), and were therefore used as selective probes for the detection of SO4•− and •OH in the reaction system. A high concentration of MeOH and TBA had almost no effect on the degradation of SMX, suggesting that SO4•− and •OH are not the main active species responsible for SMX degradation. To further verify this conclusion, time-resolved electron paramagnetic resonance (EPR) detection was performed. When 5,5-dimethyl-1-pyrroline N-oxide (DMPO) was used as a spin trapping agent, no characteristic peaks of DMPO−•OH and DMPO-SO4•−were observed in different reaction periods (Supplementary Fig. 30), which further proves that Fe-SAC-41.31 does not activate PMS through SO4•− and •OH-dominated radical pathways.

The non-radical PMS activation pathway mediated by 1O2 has been reported in literature, with typical generation pathways including the self-decomposition of PMS and the evolution of species such as O2•−, dissolved oxygen, and SO549. Furfuryl alcohol (FFA) has a high reaction kinetic constant with 1O2 (kFFA,1O2 = 1.2 × 108 M−1 S−1)50. When 10 mM FFA was introduced into the system, it was found that the quenching of 1O2 led to a decrease in SMX degradation (Fig. 4d). In addition, 2,2,6,6 tetramethyl-4-piperidinol (TEMP) was used as a spin trapping agent for time-resolved EPR test, and a distinct trilinear characteristic peak after initiation was observed, which was significantly stronger than the background value (Fig. 4e). This also indicates that 1O2 was produced in the Fe-SAC-41.31/PMS system. In order to clarify the 1O2 generation pathway, degradation experiments were conducted with continuous nitrogen aeration, and no effect on SMX degradation was observed (Supplementary Fig. 31), suggesting that 1O2 did not evolve from O2. In addition, EPR analysis found that there was almost no O2•− in the system (Supplementary Fig.32), so 1O2 in the system was generated through the activation of PMS.

Previous studies have reported that a variety of Fe-based catalysts can effectively activate PMS to produce high-valent metal-oxygen species (HV-Fe: FeV = O or FeIV = O)51. Considering the high iron loading of Fe-SAC-41.31 and the weak contribution of the radical pathway to SMX degradation, it is necessary to confirm the presence or absence of HV-Fe in the Fe-SAC-41.31/PMS system. Therefore, dimethyl sulfoxide (DMSO) was first used as a trapping agent for surface active species, and it was found that 10 mM DMSO had no effect on the degradation of SMX. This indicates that HV-Fe may not be produced in the system. Furthermore, considering that methyl phenylsulfoxide (PMSO) can be oxidized by HV-Fe to produce dimethylsulfoxide (PMSO2) through an oxygen atom transfer process52,53, the conversion process of PMSO-PMSO2 in the system was monitored by HPLC (Supplementary Fig. 33). However, the conversion rate of PMSO2 in the Fe-SAC-41.31/PMS system did not increase compared with the CN/PMS system, therefore no HV-Fe should be produced in the Fe-SAC-41.31/PMS system.

Based on the detected intermediates (Supplementary Table 8) by liquid chromatography coupled with a mass spectrometer, the possible degradation pathways of SMX in the Fe-SAC-41.31/PMS system are derived as shown in Supplementary Fig. 34. P-1 is generated via electrophilic addition of hydroxyl groups on the benzene ring of SMX. In addition, the isoxazole fraction undergoes a ring-opening reaction to form P-254,55. In the other degradation pathway, the amino group of SMX is attacked by 1O2 to form P-4 after the electrophilic oxidation56. This product continues to undergo successive oxygen transfer reactions at the N site to promote the formation of nitro-SMX derivative P-5. P-8 is a hydroxylation product generated by the attack on the N site of SMX57. In contrast, the breakage of the S–N bond under attack produces P-9, while the methyl group undergoes further oxidation to form an aldehyde group. In the overall degradation process, SMX and its degradation intermediates are subjected to successive attacks, first oxidized to monocyclic organic compounds, and then degraded to ring-opening molecules.

Notably, Fig. 4f reveals a positive correlation between k and the number of active sites. However, this positive correlation is non-linear, and the catalytic kinetics are significantly accelerated at high loadings. Assuming that each site exhibits similar intrinsic activity, the apparent rate constant k should theoretically display a linear or quasi-linear relationship with the total number of active sites. Combined with the electronic structure changes of Fe sites at high loadings, it collectively demonstrates the potential existence of long-range Fe–Fe interactions at elevated metal loadings, which enhances the catalytic activity of active sites. In addition, when the metal loading exceeds 24.62 wt%, the evolution of k values accelerates markedly, suggesting the existence of a critical loading threshold beyond which these long-range interactions become significantly enhanced.

To validate the above conclusions, we investigated the PMS catalytic performance at identical Fe active sites in catalyst models with varying metal loadings by DFT. It was observed that the PMS adsorption energy significantly increased when the metal loading reached 24.62 wt%, and as the loading continued to rise, the adsorption energy further changed (Fig. 4g). Additionally, the interaction between Fe sites and PMS exhibited enhanced differentiation due to intermetallic effects. Specifically, the electron depletion region of the Fe adsorption center expanded markedly, while the bonded O atom accumulated more electrons. Bader charge analysis further revealed an increase in ETP from isolated Fe atoms to PMS molecules under higher Fe loading (Fig. 4g). This demonstrates that long-range metallic interactions at high loadings facilitate the activation of PMS by the Fe site. This result is consistent with the open circuit potential test, indicating that catalysts with higher mass loading triggered higher potential jumps (Fig.4a). Catalysts with higher metal loading simultaneously exhibited lower charge transfer resistance (Fig. 3d), which collectively proves that elevated metal loading is beneficial for promoting the conductive bridging of Fe atoms to facilitate charge migration. Notably, when the metal loading surpassed the critical threshold of 24.62 wt%, the energy barriers of the 1O2 generation pathway and rate-determining step (RDS) decreased substantially (Fig. 4h, ΔErds,41.31 = 1.16 eV < ΔErds,24.62 = 1.19 eV < ΔErds,15.82 = 1.47 eV < ΔErds,5.16 = 2.12 eV). These theoretical analyses, combined with experimental results, including the open-circuit potential (Fig. 4a), i–t curves (Fig. 4b), and SMX degradation kinetics (Fig. 4f), collectively demonstrate that long-range Fe–Fe interactions are significantly enhanced beyond the critical loading threshold of 24.62 wt%. These interactions play a pivotal role in reducing energy barriers and improving ETP efficiency.

Based on the above analyses, the changes in intrinsic activity of high-density metal sites and their effects on the catalytic behavior of reaction substrates were proposed (Fig. 5). Obviously, due to the site-intensive effect, high-loading Fe-SAC provides more active centers for catalytic reactions. When the same dose of PMS was introduced, the Fe-SAC-41.31/PMS system underwent a higher potential jump (ΔE = 0.898 V) than the Fe-SAC-5.16/PMS system (ΔE = 0.395 V), indicating a stronger ability to capture electrons from the contaminants, thus overcoming the catalytic efficiency limitation caused by insufficient active sites. In addition, the substrate structure of the catalyst changed significantly to accommodate the needs of catalyst stability under high loading, while the valence state of the Fe atom decreased from 2.6 to 2.2, which increased the ETP of Fe to PMS from −0.12 e to 0.75 e, making it more conducive to the degradation of pollutants through ETP. Moreover, the energy barrier of the rate-determining step (ΔErds) of activating PMS to generate 1O2 by a single Fe site decreased from ΔErds,5.16 = 2.12 eV to ΔErds,41.31 = 1.16 eV due to the site-to-site interactions. This indicates that high Fe loading not only provides richer active sites, but also thermodynamically promotes the activation of PMS, thus exhibiting excellent pollutant degradation performance.

Practical application potential of high-loading SAC

The practical application potential of the Fe-SAC-41.31/PMS system was further evaluated. The effective removal of SMX has been realized in tap water, medical wastewater, and lake water (Fig. 6a), and the water quality parameters are listed in Table S10. In addition, virtually all SMX can be completely degraded in the wide pH range of 3.0-11.0 (Fig. 6b), which indicates that Fe-SAC-41.31 has good environmental adaptability. Moreover, it is found that the morphology changes in the TEM image of the catalyst are negligible (Supplementary Fig. 35), no metal agglomeration particles are observed, and no diffraction peaks of metal oxides are detected by XRD (Fig. 6c), which indicates that Fe-SAC-41.31 has good stability.

a Removal efficiency of SMX in different actual water bodies. b Effect of pH on the degradation of SMX. c XRD characterization of Fe-SAC-41.31 before and after reaction. d 3D-EEM fluorescence spectra of coal chemical reverse osmosis inlet water before treatment. e, f 3D-EEM fluorescence spectra of coal chemical reverse osmosis inlet water with the addition of 2 mM PMS and 0.1 g L−1 Fe-SAC-T (e), or 0.1 g L-1 Fe-SAC-41.31 (f). g SMX removal and total iron leaching of Fe-SAC-41.31 during continuous operation before and after applying an external electric field. h SMX removal from the coal chemical reverse osmosis inlet water by Fe-SAC-41.31 and Fe-SAC-T (inset) during continuous operation after applying an external electric field. The error bars in the figures represent the standard deviations from triplicate tests.

In addition, the elimination of complex organics in an actual water body (coal chemical reverse osmosis concentrated wastewater) was assessed through a three-dimensional excitation and emission matrix (3DEEM), and the water quality parameters were listed in Supplementary Table 10. As shown in Fig. 6d and Supplementary Table 11, the fluorescent substances in the wastewater were categorized into four regions, which were aromatic protein-like fluorophores (I), fulvic acid-like fluorophores (II), soluble microbial byproduct (III), and the humic acid-like substance (IV)58. Fe-SAC-T and Fe-SAC-41.31 were used to treat this actual water body, respectively (Fig. 6e, f). It can be seen that the low Fe loading catalysts prepared by conventional methods have limited effectiveness, while the Fe-SAC-41.31 almost completely decomposes the organic pollutants. The 3DEEM results confirm that the Fe-SAC-41.31-PMS system has a promising prospect for the actual wastewater treatment due to its high efficiency decontamination performance.

To further promote the practical application of the Fe-SAC-41.31/PMS system, a flow-through module was designed to facilitate the recovery of the catalyst, and the operation parameters were investigated by using simulated laboratory wastewater (Supplementary Fig. 36a). During continuous operation, the effluent flowed in from one side of the filter assembly and out from the other side. Fe-SAC-5.16 exhibited only 61% removal of SMX (5 mg L−1) at a flow rate of 5 mL min−1 due to the limited number of active sites, while Fe-SAC-41.31 achieved complete removal throughout the operation (Fig. 6g), which proves that catalysts with high metal loading have better practical application prospects. Unfortunately, due to the higher metal loading, more total Fe leaching occurred in Fe-SAC-41.31 (1.7 mg L−1) than in Fe-SAC-5.16 (0.02 mg L−1). Our previous studies demonstrated that the application of a cathode electric field helps to promote the iron cycling of the catalyst and reduce metal leaching, and there is a significant synergy between electro-activation and catalytic activation to PMS50. So here the catalyst coated carbon felt (CF) was connected as the cathode, while DSA was used as the anode (Supplementary Fig. 36b). As expected, the modified continuous flow reaction system achieves lower ion leaching (0.06 mg L−1) while maintaining efficient decontamination, which enhances the stability of the system (Fig. 6g). The application of electric field is cost-effective to treat saline organic wastewater, such as actual coal chemical wastewater, pharmaceutical wastewater (7000 μS cm−1) and landfill leachate (12,770–25,000 μS cm−1), etc59., without the need to add electrolytes. To demonstrate the significant performance improvement of the cascade anchoring strategy in the treatment of actual water bodies, the catalyst prepared by the traditional method was compared. Due to the complexity of organic pollutants and uncertainty of their concentration in actual water bodies, SMX (5 mg L−1) was formulated in the actual coal chemical reverse osmosis concentrated wastewater (water quality parameters are shown in Supplementary Table 10) to better quantify the treatment effect (Fig. 6h). The continuous flow reactor assembled with Fe-SAC-41.31 achieved an actual wastewater treatment volume of 36.4 L. During this period, the SMX removal from the wastewater remained above 95%, TOC removal was 74.35%, and the mass specific activity (MSA) of unit catalyst to remove SMX was 31.3 mmol g−1, whereas Fe-SAC-T prepared by the conventional method showed only 50% SMX removal, 34.18% TOC removal, and 4.3 L wastewater treatment volume, respectively, and the MSA was only 2.1 mmol g−1. This further proved that the high-loading Fe-SAC-41.31 prepared by the cascade anchoring strategy has better prospects in practical wastewater treatment.

Discussion

In this study, Fe-SACs with metal loading that is tunable within a gradient of 0–41.31 wt% were prepared using a facile cascade anchoring strategy. HAADF-STEM and XAS demonstrated the successful acquisition of Fe single atoms with different mass occupancies, and they all coordinated with the substrate in the form of Fe-C2N2. The densely distributed Fe sites enhance interatomic interactions and increase the Bader charge of Fe atoms from BaderFe-SAC-5.16 = 7.038 eV to BaderFe-SAC-41.31 = 7.120 eV, which is consistent with the change in valence state of Fe confirmed by XAS. Experimental results and DFT analyses indicate that increased metal loading leads to a significant increase in catalytic activity, which facilitates the ETP pathway of PMS activation and reduces the energy barrier of the rate-limiting step during 1O2 generation. The present study overcomes the long-standing bottleneck of limited overall catalytic activity of catalysts caused by low Fe-SAC loading, which contributes to the rational design of advanced SACs.

Methods

Fabrication of catalysts

Single-atom catalysts with different Fe mass loadings were prepared using a facile one-step calcination method. Specifically, 30 mmol of MA, 30 mmol of OA, and 1 mmol of Fe(NO3)3·9H2O were dissolved in deionized water, and the resulting mixture was stirred at 500 rpm using a magnetic stirrer for 4 h at room temperature. The product was collected by centrifugation, dried in a 60 °C oven for 24 h, and thoroughly ground into a homogeneous powder. The obtained catalyst precursor powder was annealed at 550 °C for 2 h under argon atmosphere to obtain Fe-SAC-x (where x referred to the Fe mass fraction in the catalyst) at a heating rate o f 5 °C min−1. Under the same conditions, Fe-SAC-x with different Fe mass fractions were prepared by adjusting the amount of iron salts (0.3 mmol, 0.75 mmol, 0.9 mmol, and 1 mmol, respectively). The mass fractions of Fe in the catalysts were 5.16 wt%, 15.82 wt%, 24.62 wt%, and 41.31 wt%, respectively, as measured by ICP-AES, so the catalysts were named Fe-SAC-5.16, Fe-SAC-15.82, Fe-SAC-24.62, and Fe-SAC-41.31, respectively. In addition, as a control group, the catalyst substrate was prepared under the same conditions without the addition of iron salts and named CN. The chelating ligand selected for cascade anchoring-directed assembly should not only be able to coordinate with metal ions to form complexes, but also be able to co-assemble with MA to construct macromolecular organic frameworks, thereby achieving precise immobilization of metal ions within the framework. The synthesis of Mn-SAC, Ag-SAC, and La-SAC is similar to that of Fe-SAC, except that Mn ions are still ligand chelated with OA, while Ag and La are ligand chelated with CA. Reagent ratios and the rest of the procedure are consistent with Fe-SAC.

Fe single-atom catalyst (Fe-SAC-T) was also prepared by the traditional method. Thirty millimoles of MA and 0.3 mmol of Fe(NO3)3·9H2O were dissolved in deionized water at 80 °C. After drying the solvent, the obtained powder was fully ground and calcined in a tube furnace under argon protection at 550 °C for 2 h, and the heating rate was 5 °C min−1. After natural cooling to room temperature, the obtained Fe-SAC-T was stored for later use.

To prepare the electrode for the reactor, 20 mg of catalyst was dispersed homogeneously into 5 mL of ethanol, then 100 μL of Nafion (5 wt%) solution was added, and the mixture was fully dispersed by ultrasonic treatment for 15 min. The resulting slurry was drop-coated onto commercial CF with a diameter of 4 cm and left to dry naturally. According to the type of catalyst, the prepared electrode was named Fe-SAC-x/CF.

Measurements of catalytic performance

In a representative experiment of PMS activation, 10 mg of Fe-SAC-x was added to a 100 mL configuration of contaminant aqueous solution. The pH of the solution was adjusted with 0.1 M H2SO4 and 0.1 M NaOH prior to the reaction. When the suspension kept stirring reached the adsorption–desorption equilibrium, 2 mM of PMS was added to the system, and the timing was started. Then 2 mL of suspension was extracted at predetermined time intervals. After filtration, the concentration of target pollutants was determined by high-performance liquid chromatograph (HPLC, Ultimate 3000, ThermoFisher, America) equipped with a C18 column (3 µm, ϕ3.0 × 100 mm), and the operating parameters are listed in Supplementary information, Table 13.

The removal of SMX followed the pseudo-first-order kinetic model:

where C0 is the initial concentration of SMX (mg L−1), t is the sampling time (min), Ct is the SMX concentration at sampling time, k is the rate constant (min−1).

The turnover frequencies (TOF, per Fe atom) for SMX removal were calculated based on the initial removal rate (Rd) of SMX, where Rd = k × SMX concentration60.

In order to promote the application of the Fe-SAC-x/PMS system in practical scenarios, a continuous flow filtration reactor was designed. The solution flow rate was controlled at 5 mL min−1 by a peristaltic pump, and the concentration of SMX was 5 mg L−1. The CF cathode was connected to a DC power supply to enhance the stability of the catalyst and reduce metal leaching. Ti/RuO2-IrO2 (DSA) disks with a diameter of 4 cm were used as the anode. During the continuous degradation process, the current was set at 10 mA. The preparation of the cathode is as follows: 30 mg of catalyst powder was dispersed into ethanol (5 mL) containing 100 μL of Nafion (5 wt%), which was ultrasonically dispersed homogeneously and then drop-coated onto a CF with a diameter of 4 cm.

Data availability

The authors declare that all data supporting the findings of this study are available within the article and the supplementary information. Any additional data are available from the corresponding author. Source data are provided with this paper.

References

Ji, S. et al. Chemical synthesis of single atomic site catalysts. Chem. Rev. 120, 11900–11955 (2020).

Rong, H., Ji, S., Zhang, J., Wang, D. & Li, Y. Synthetic strategies of supported atomic clusters for heterogeneous catalysis. Nat. Commun. 11, 5884 (2020).

Gloag, L., Somerville, S. V., Gooding, J. J. & Tilley, R. D. Co-catalytic metal–support interactions in single-atom electrocatalysts. Nat. Rev. Mater. 9, 173–189 (2024).

Pu, T. et al. Dual atom catalysts for energy and environmental applications. Angew. Chem. Int Ed. 62, e202305964 (2023).

Liang, X., Fu, N., Yao, S., Li, Z. & Li, Y. The progress and outlook of metal single-atom-site catalysis. J. Am. Chem. Soc. 144, 18155–18174 (2022).

Wang, L. et al. A polymer tethering strategy to achieve high metal loading on catalysts for Fenton reactions. Nat. Commun. 14, 7841 (2023).

Kumar, P. et al. High-density cobalt single-atom catalysts for enhanced oxygen evolution reaction. J. Am. Chem. Soc. 145, 8052–8063 (2023).

Jones, J. et al. Thermally stable single-atom platinum-on-ceria catalysts via atom trapping. Science 353, 150–154 (2016).

Wang, L. et al. A sulfur-tethering synthesis strategy toward high-loading atomically dispersed noble metal catalysts. Sci. Adv. 5, eaax6322 (2019).

Zhao Y. F. et al. Anchoring sites engineering in single-atom catalysts for highly efficient electrochemical energy conversion reactions. Adv Mater 33, e2102801 (2021).

Li, X. et al. Functional CeOx nanoglues for robust atomically dispersed catalysts. Nature 611, 284 (2022).

Yin, X.-P. et al. Engineering the coordination environment of single-atom platinum anchored on graphdiyne for optimizing electrocatalytic hydrogen evolution. Angew. Chem. Int Ed. 57, 9382–9386 (2018).

Liu, S., Wang, Y., Lyu, K. F., Lan, X. & Wang, T. A one-pot strategy for anchoring single Pt atoms in MOFs with diverse coordination environments. Nat. Synth. 3, 1158–1167 (2024).

Wan, C., Duan, X. & Huang, Y. Molecular design of single-atom catalysts for oxygen reduction reaction. Adv. Energy Mater. 10, 1903815 (2020).

Zeng, X. et al. Single-atom to single-atom grafting of Pt1 onto Fe-N4 Center: Pt1@Fe-N-C multifunctional electrocatalyst with significantly enhanced properties. Adv. Energy Mater. 8, 1701345 (2018).

Wang, B. et al. Room-temperature laser planting of high-loading single-atom catalysts for high-efficiency electrocatalytic hydrogen evolution. J. Am. Chem. Soc. 145, 13788–13795 (2023).

Hai, X. et al. Scalable two-step annealing method for preparing ultra-high-density single-atom catalyst libraries. Nat. Nanotechnol. 17, 174–181 (2022).

Wan, X. et al. Fe–N–C electrocatalyst with dense active sites and efficient mass transport for high-performance proton exchange membrane fuel cells. Nat. Catal. 2, 259–268 (2019).

Zhao, L. et al. Cascade anchoring strategy for general mass production of high-loading single-atomic metal-nitrogen catalysts. Nat. Commun. 10, 1278 (2019).

Xia, C. et al. General synthesis of single-atom catalysts with high metal loading using graphene quantum dots. Nat. Chem. 13, 887–894 (2021).

Jin, H. et al. Understanding the density-dependent activity of Cu single-atom catalyst in the benzene hydroxylation reaction. ACS Cat. 13, 1316–1325 (2023).

Jin, H. et al. Regulating the electronic structure through charge redistribution in dense single-atom catalysts for enhanced alkene epoxidation. Nat. Commun. 14, 2494 (2023).

Mehmood, A. et al. High loading of single atomic iron sites in Fe–NC oxygen reduction catalysts for proton exchange membrane fuel cells. Nat. Catal. 5, 311–323 (2022).

Wang, B. Q. et al. A site distance effect induced by reactant molecule matchup in single-atom catalysts for fenton-like reactions. Angew. Chem. Int. Ed. 61, e202207268 (2022).

Jin, Z. et al. Understanding the inter-site distance effect in single-atom catalysts for oxygen electroreduction. Nat. Catal. 4, 615–622 (2021).

Ren, W. et al. Isolated diatomic Ni-Fe metal–nitrogen sites for synergistic electroreduction of CO2. Angew. Chem. Int. Ed. 58, 6972–6976 (2019).

Xiao, X. et al. A promoted charge separation/transfer system from Cu single atoms and C3N4 layers for efficient photocatalysis. Adv. Mater. 32, 2003082 (2020).

Yang, Q. et al. Understanding the activity of Co-N4−xCx in atomic metal catalysts for oxygen reduction catalysis. Angew. Chem. Int. Ed. 59, 6122–6127 (2020).

Su, L., Wang, P., Ma, X., Wang, J. & Zhan, S. Regulating local electron density of iron single sites by introducing nitrogen vacancies for efficient photo-fenton process. Angew. Chem. Int. Ed. 60, 21261–21266 (2021).

Li, J. J. et al. Highly active and stable metal single-atom catalysts achieved by strong electronic metal–support interactions. J. Am. Chem. Soc. 141, 14515–14519 (2019).

Li, F. et al. Revealing isolated M−N3C1 active sites for efficient collaborative oxygen reduction catalysis. Angew. Chem. Int. Ed. 59, 23678–23683 (2020).

Hossain, M. D., Huang, Y. F., Yu, T. H., Goddard, W. A. & Luo, Z. T. Reaction mechanism and kinetics for CO2 reduction on nickel single atom catalysts from quantum mechanics. Nat. Commun. 11, 2256 (2020).

Han, L. et al. A single-atom library for guided monometallic and concentration-complex multimetallic designs. Nat. Mater. 21, 681–688 (2022).

Ma, P. Y. et al. Site-specific synergy in heterogeneous single atoms for efficient oxygen evolution. Nat Commun 16, 2573 (2025).

Jiang, X.-H. et al. Silver single atom in carbon nitride catalyst for highly efficient photocatalytic hydrogen evolution. Angew. Chem. Int. Ed. 59, 23112–23116 (2020).

Hu, S. et al. Selective photocatalytic reduction of CO2 to CO mediated by silver single atoms anchored on tubular carbon nitride. Angew. Chem. Int. Ed. 62, e202304585 (2023).

Chang, J. et al. Synthesis of ultrahigh-metal-density single-atom catalysts via metal sulfide-mediated atomic trapping. Nat. Synth. 3, 1427–1438 (2024).

Li, S. et al. Performance enhancement and mechanism of electroenhanced peroxymonosulfate activation by single-atom Fe catalyst modified electrodes. Proc. Natl. Acad. Sci. USA 121, e2404965121 (2024).

Li, X. et al. Highly dispersed Pd/PdO/Fe2O3 nanoparticles in SBA-15 for Fenton-like processes: confinement and synergistic effects. Appl. Catal. B Environ. 165, 79–86 (2015).

Su, P. et al. Nanoscale confinement in carbon nanotubes encapsulated zero-valent iron for phenolics degradation by heterogeneous Fenton: spatial effect and structure-activity relationship. Sep. Purif. Technol. 276, 119232 (2021).

Meng, H. et al. Optimizing electronic synergy of atomically dispersed dual-metal Ni–N4 and Fe–N4 sites with adjacent Fe nanoclusters for high-efficiency oxygen electrocatalysis. Energy Environ. Sci. 17, 704–716 (2024).

Zhang, Y. J. et al. Simultaneous nanocatalytic surface activation of pollutants and oxidants for highly efficient water decontamination. Nat. Commun. 13, 3005 (2022).

Zhang, T., Zhu, H. & Croué, J.-P. Production of sulfate radical from peroxymonosulfate induced by a magnetically separable CuFe2O4 spinel in water: efficiency, stability, and mechanism. Environ. Sci. Technol. 47, 2784–2791 (2013).

Miao, J., Geng, W., Alvarez, P. J. J. & Long, M. 2D N-doped porous carbon derived from polydopamine-coated graphitic carbon nitride for efficient nonradical activation of peroxymonosulfate. Environ. Sci. Technol. 54, 8473–8481 (2020).

Wang, G. et al. Monodispersed CuO nanoparticles supported on mineral substrates for groundwater remediation via a nonradical pathway. J. Hazard. Mater. 429, 128282 (2022).

Guo, Z. et al. Electron delocalization triggers nonradical Fenton-like catalysis over spinel oxides. Proc. Natl. Acad. Sci. USA 119, e2201607119 (2022).

Gao, Y. et al. Activity trends and mechanisms in peroxymonosulfate-assisted catalytic production of singlet oxygen over atomic metal-N-C catalysts. Angew. Chem. Intm Ed. 60, 22513–22521 (2021).

Hu, J. J. et al. Duet Fe3C and FeNx sites for H2O2 generation and activation toward enhanced electro-fenton performance in wastewater treatment. Environ. Sci. Technol. 55, 1260–1269 (2021).

Zhao, C. et al. Ultrafast degradation of emerging organic pollutants via activation of peroxymonosulfate over Fe3C/Fe@N-C-x: singlet oxygen evolution and electron-transfer mechanisms. Applm Catal. B Environ. 321, 122034 (2023).

Li, S. et al. High-efficiency degradation of carbamazepine by the synergistic electro-activation and bimetals (FeCo@NC) catalytic-activation of peroxymonosulfate. Appl. Catal. B Environ. 338, 123064 (2023).

Liang, X. et al. Coordination number dependent catalytic activity of single-atom cobalt catalysts for fenton-like reaction. Adv. Funct. Mater. 32, 2203001 (2022).

Cheng, C. et al. Generation of FeIV=O and its contribution to fenton-like reactions on a single-atom Iron−N−C catalyst. Angew. Chem. Int Ed. 62, e202218510 (2023).

Zhao, Z. et al. Improved electronic structure from spin-state reconstruction of a heteronuclear Fe–Co diatomic pair to boost the fenton-like reaction. Environ. Sci. Technol. 57, 4556–4567 (2023).

Yan, J. et al. Activation CuFe2O4 by hydroxylamine for oxidation of antibiotic sulfamethoxazole. Environ. Sci. Technol. 52, 14302–14310 (2018).

Luo, M. et al. Insights into the role of in-situ and ex-situ hydrogen peroxide for enhanced ferrate(VI) towards oxidation of organic contaminants. Water Res. 203, 117548 (2021).

Qi, Y. et al. Three-dimensional porous graphene-like biochar derived from Enteromorpha as a persulfate activator for sulfamethoxazole degradation: Role of graphitic N and radicals transformation. J. Hazard. Mater. 399, 123039 (2020).

Long, X. et al. Sustainable Fe(III)/Fe(II) cycles triggered by Co-catalyst of weak electrical current in Fe(III)/peroxymonosulfate system: Collaboration of radical and non-radical mechanisms. Appl. Catal. B Environ. 317, 121716 (2022).

Jacquin, C., Lesage, G., Traber, J., Pronk, W. & Heran, M. Three-dimensional excitation and emission matrix fluorescence (3DEEM) for quick and pseudo-quantitative determination of protein- and humic-like substances in full-scale membrane bioreactor (MBR). Water Res. 118, 82–92 (2017).

Moreira, F. C., Boaventura, R. A. R., Brillas, E. & Vilar, V. J. P. Electrochemical advanced oxidation processes: a review on their application to synthetic and real wastewaters. Appl. Catal. B Environ. 202, 217–261 (2017).

Wang, Z. W. et al. Cobalt single atoms anchored on oxygen-doped tubular carbon nitride for efficient peroxymonosulfate activation: simultaneous coordination structure and morphology modulation. Angew. Chem. Int. Ed. 61, e202202338 (2022).

Acknowledgements

This work was supported by the National Key R&D Program International Cooperation Project (2023YFE0108100), the National Natural Science Foundation of China (nos. 22376107 and U23B20165), the Natural Science Foundation of Tianjin (no. 24JCYBJC01640), the Tianjin Key Research and Development Plan of China (no. 22YFYSHZ003000), and the Key Project of Natural Science Foundation of Tianjin (no. 21JCZDJC00320). We thank beamline BL14W1 (Shanghai Synchrotron Radiation Facility) for providing the beam time and thank staff member PanZhe Qiao for his contribution to the characterization.

Author information

Authors and Affiliations

Contributions

S.L. designed the study and performed the catalyst preparation, characterization, catalytic tests, data analysis, and wrote the paper. W.W. and M.Z. conceptualization, supervision, funding acquisition, resources, and writing—review and editing. H.W., X.W., S.D., and J.L. writing—review and editing, and data curation. X.Z., J.S., and C.F. review and edit, and perform validation.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Liang Huang, and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Li, S., Wang, W., Wu, H. et al. Facile cascade-anchored synthesis of ultrahigh metal loading single-atom for significantly improved Fenton-like catalysis. Nat Commun 16, 8796 (2025). https://doi.org/10.1038/s41467-025-63858-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-025-63858-5