Abstract

Liquid crystal elastomer (LCE) is a type of soft active material that generates large and reversible spontaneous deformations upon temperature changes, facilitating various environmentally responsive smart applications. Despite their success, most existing LCE metamaterials are designed in a forward fashion based on intuition and feature regular material patterns, which may hinder the reach of LCE’s full potential in producing complex and desired functionalities. Here, we develop a computational inverse design framework for discovering diverse sophisticated temperature-activated and -interactive nonlinear behaviors for LCE metamaterials in a fully controllable fashion. We generate intelligent LCE metamaterials with a wide range of switchable functionalities upon temperature changes. By sensing the environment, these metamaterials can realize maximized spontaneous area expansion/contraction, precisely programmable enclosed opening size change, and temperature-switchable nonlinear stress–strain relations and deformation modes. The optimized unit cells feature irregular LCE patterns and form complex and highly nonlinear mechanisms. The inverse design computational framework, optimized material patterns, and revealed underlying mechanisms fundamentally advance the design capacity of LCE metamaterials, benefiting environment-aware and -adaptive smart materials.

Similar content being viewed by others

Introduction

Active materials can act spontaneously upon changes in surrounding environments such as temperature, humidity, and electromagnetic fields. Examples of active materials are hydrogels1, electroactive polymers2, magnetic soft materials3,4, and liquid crystal elastomers (LCE)5,6. They are widely used for environment-adaptive or -activated smart structures where other external control is unavailable or unfavorable. As an important class of soft active material, LCE can generate large and fully reversible spontaneous deformations upon temperature changes5, producing a work density comparable to or surpassing human muscles7. The spontaneous deformation is caused by temperature-induced changes in the statistical orientation order of rod-like molecules known as mesogen5 as illustrated in Fig. 1a. Temperature rise increases the molecular entropy and weakens the anisotropy order, which causes a macroscopic contraction along the original orientation known as the director. Temperature rise beyond a critical value destroys the order and produces the maximum contraction. A decrease in temperature recovers the order and generates an elongation back to the original shape. The reversibility enables cyclic actuation/motions under recurring temperature changes.

a Temperature-induced anisotropic shape change of LCE; b material with periodic unit cells made of LCE; c topology optimization design variables; d maximized temperature-induced area expansion; e programmable temperature-dependent porosity; f temperature-switchable stress–strain relations; and g temperature-switchable deformation mode.

The large spontaneous deformation has spurred numerous applications with special functionalities, including soft robotics8,9,10, self-folding and morphing structures11,12,13,14, and artificial muscles7,15,16. The key to realizing different designed functionalities lies in the strategic design of spatial distribution of LCE directors17,18. Most current designs, however, have been produced based on intuition and experience with relatively regular director patterns. Given LCE’s complex nonlinear behaviors, simple patterning may fail to produce more sophisticated and desired responses and limit our perception of achievable behaviors. In contrast to experience, optimization-based inverse design holds the key to systematic and accurate realization of wide-ranging complex functionalities owing to its physics-based and algorithm-driven process. This enables the programming of complex shape morphing such as a human face19 and various objects18.

As a free-form computational morphogenesis approach, topology optimization20,21,22 has demonstrated great capacity and flexibility in producing optimized designs for a broad range of applications with diverse physics and engineering backgrounds. It is also widely used for inverse designs of metamaterials to attain prescribed properties, including effective elastic modulus23, tunable Poisson’s ratios24,25, nonlinear force-displacement curves26,27 and 3D deformation modes28, nonlinear magneto-mechanical behaviors29,30,31, and temperature-switchable mechanical responses32.

Integration with topology optimization can unleash LCE’s full potential in realizing rich families of exotic and complex environmentally adaptive or responsive behaviors in a fully programmable fashion. Topology optimization is used for programming the origami folding of LCE sheets33 and the bending of LCE beams34 where the LCE’s spontaneous deformation is modeled as thermal expansion. Topology optimization is also used to minimize the compliance of LCE composite structures under a small deformation setup35. More recently, a statistical mechanics-based and fully nonlinear LCE model has been integrated with topology optimization for the precise inverse programming of a broad range of temperature-induced deformed shapes for LCE composites18. While demonstrated promising, the synergy between LCE and topology optimization remains in the early stage of development with huge room for innovation and many challenges to address.

Function-wise, most investigated LCE applications have focused on the structural level instead of the metamaterial perspective, with their functionalities associated with specific sizes, boundary conditions, and surrounding environments. Different from structures, metamaterials made of periodic unit cells can scale to any size and shape for different applications while retaining their macroscopic properties; however, their synthesis with LCE and the resulting behaviors remain severely under-explored. Further, LCE’s thermal actuation can be harnessed to alter the macroscopic mechanical behavior of metamaterials, such as effective stress–strain relations and deformation modes, thereby imbuing thermal intelligence into mechanical metamaterials.

In this study, we use topology optimization to inversely design diverse temperature-induced and -involved exotic responses for LCE metamaterials made of periodic unit cells in a fully programmable fashion as illustrated in Fig. 1. This is made possible by incorporating a rigorous nonlinear LCE model with multimaterial topology optimization36,37 and developing special optimization formulations tailored for a wide range of extreme functionalities. As illustrated in Fig. 1b, c, we consider four LCE orientations and a passive elastomer as candidate materials that can be algorithmically synthesized into complex shapes and material phase distributions. We create LCE metamaterials with maximized temperature-induced area expansion/contraction, precisely controlled area change of an opening in the unit cell while retaining the overall size, programmable temperature-switchable stress–strain relations, and nonlinear deformation modes as illustrated in Fig. 1d–g, respectively. The inverse design methodology and specific formulations developed herein can serve as a systematic, intelligent, and automotive design paradigm for LCE metamaterials with precisely and arbitrarily manipulatable thermomechanical responses.

Results and discussion

This study focuses on planar LCE composite metamaterials comprised of 2D periodic unit cells under the plane-stress condition as illustrated in Fig. 1b. The deformation of the cells under thermal or mechanical loading is assumed to be also periodic and absent of symmetry breaking, which allows us to focus on designing the behavior of a single unit cell under periodic boundary conditions. Throughout this study, we consider five candidate soft materials, which are LCEs with 0∘, 45∘, 90∘, and 135∘ directors and a passive neo-Hookean elastomer as illustrated in Fig. 1b. The director as a unit vector enters the LCE’s model (stored-energy density function) as quadratic forms that are independent of the sign (see Eq. (1) and Supplementary Note 1). Hence, the four candidate directors equally divide the full 360∘ circle, and adding 180∘ to a candidate orientation does not alter the LCE’s behavior. The planar size of all unit cells is 10 mm × 10 mm, and the thickness is 1 mm. The out-of-plane thickness does not influence the plane-stress computation model but would impact the fabrication and experimental testing as later discussed.

The incorporation of rigorous LCE models that accurately capture the large deformation, material anisotropy, spontaneous deformation, and semi-soft elasticity into a topology optimization framework is achieved in one of the authors’ recent studies18. The LCE model adopted here is one based on the non-ideal neo-classical model38,39,40,41 with frozen-director condition42,43, which suits LCE fabricated in the nematic phase. The model is in the form of an anisotropic, order-dependent stored-energy density function:

where F is the deformation gradient with \(\det ({{{\boldsymbol{F}}}})\,=\,1\), C ≔ FTF is the right Cauchy–Green deformation tensor, unit vector n0 is the LCE director, μ is the shear modulus, ω is a material constant that characterizes the non-ideality of LCE, and Q0 and Q ∈ [0, 1] are the initial and current order parameters, respectively, where smaller values indicate less-ordered and higher-temperatures states. The temperature-induced actuation is through the difference between Q and Q0. In this study, we focus on the situation of temperature rise with Q0 ≥ Q. We note that model (1) does not require the explicit input of temperature but that of Q0 and Q. Their relation to temperature depends on the type of LCE but shows the general trend of nonlinear decay to zero (nematic-isotropic transition) as temperature increases5. In this study, we use μ = 0.0829 MPa and ω = 0.0401, which are chosen based on LCE material characterization44. More details of the model (1) are given in Supplementary Note 1. The resulting highly nonlinear state equations are solved using the finite element method (FEM) with the Newton–Raphson approach.

The behavior programming is formulated as an inverse problem where the errors between the actual behavior index predicted by the nonlinear FEM and the prescribed target index are minimized. The design variables are the geometry and material phase defined by the density design field and material phase design field, respectively, as illustrated in Fig. 1c. The design fields are linked to the candidate materials’ properties, i.e., stored energy density functions, through interpolation schemes (see Supplementary Note 2 for details). Based on this setup, we develop four optimization formulations tailored to produce four distinct behavior groups for LCE metamaterial. The resulting constrained optimization problems are solved by the gradient-based Method of Moving Asymptotes45. Details of the topology optimization framework are given in Supplementary Notes 2 and 3, and the nonlinear FEA with periodic boundary conditions are provided in Supplementary Note 4.

We aim to realize four families of exotic programmed temperature-actuated or -adaptive nonlinear behaviors for the LCE metamaterial as illustrated in Fig. 1d–g. First, we aim to achieve a maximum spontaneous area expansion under temperature rise by optimizing the geometry and material distribution of the unit cell. Second, we focus on precisely programming the thermally induced area change of an irregular opening in the unit cell to realize a wide spectrum of prescribed values while retaining the overall unit cell size. Third, we harness LCE’s thermal actuation as a switch to realize temperature-switchable nonlinear stress–strain relations with dissimilar features. Finally, we generate temperature-switchable deformation modes where the metamaterial’s lateral deformation under mechanical load shows opposite patterns at different temperatures. The topology optimization formulations for realizing the four behaviors are provided in Supplementary Notes 5.1– 5.4 and will be elaborated on in the “Results” sections. Sensitivity analysis and detailed setups of the optimization problems are provided in Supplementary Notes 5.5 and 5.6, respectively.

Maximized temperature-induced spontaneous area expansion

In this section, we focus on LCE metamaterials with programmable spontaneous area expansion under temperature rise while satisfying a minimal stiffness requirement, which finds applications in, for example, self-deployable structures. The setup is shown in Fig. 2a, where we aim to maximize the total area expansion ratio defined by \({J}_{\rm{ave}}:=\det ({{{{\boldsymbol{F}}}}}_{\rm{ave}})\) (the deformed unit cell area over the undeformed area), where Fave is the planar averaged deformation gradient of the unit cell. The passive material’s shear modulus is twice of the LCE’s, i.e., μP = 0.1658 MPa. We prescribe a feature size of 6% of the unit cell size (through topology optimization filter radius), and impose a minimal axial stress requirement for the unit cell when loaded uniaxially in X and Y directions to ensure structural connectivity and minimal stiffness (see Supplementary Note 5.1 for more details about the formulation).

a Unit cell design domain with periodic boundary conditions and targeted maximized expansion (schematics); b an intuitive design and its simulated deformed configuration for area maximization upon temperature rise; c optimized design and its simulated deformed configuration upon temperature rise with axial design symmetry; and d optimized design and its simulated deformed configuration upon temperature rise with rotational design symmetry.

A heuristic design for maximum expansion can align the LCE director in the X and Y direction as shown in Fig. 2b to directly exploit the LCE’s extension perpendicular to the director. This heuristic design produces a Jave = 1.48. The expansion is driven solely by the LCE material behavior instead of geometry or kinematics as the members remain straight after the deformation. We then use topology optimization to produce an optimized unit cell with axial symmetry as shown in Fig. 2c together with the undeformed and deformed 3 × 3 assembly. The optimized metamaterial produces an expansion ratio of 3.38—more than twice larger than the heuristic design. The unit cell features highly curved members and complex LCE distributions with little passive material. When heated, the LCE actuates locally and straightens the curved members, significantly enlarging the metamaterial as demonstrated in the deformed assembly in Fig. 2c. Unlike the heuristic design, the optimized design exploits both the LCE’s local actuation and global geometric nonlinearity (large rotation) to maximize expansion.

Switching axial design symmetry to rotational symmetry further increases the expansion as demonstrated in the optimized design in Fig. 2d, which produces a 4.39 total area expansion. As in the case of axial symmetry, the design features four highly curved members occupied mainly by LCE and four shorter straight members connecting to adjacent cells to provide the required stiffness. What is different from the axial symmetry case is the spiral pattern that further increases the expansion. Also, the spiral pattern perturbs the unit cell’s principal axes away from the global X–Y axes and tilts the overall orientation in the deformed configuration as shown in Fig. 2d. We highlight that, upon temperature rise, although the LCE material naturally contracts locally, the topology optimized LCE metamaterial assembly can expand drastically.

The obtained area expansions, however, do not necessarily represent a global optimum or the physical upper bound for a general LCE metamaterial because the obtained design is likely to be a local minimum of the highly non-convex optimization problem, and the design is affected by the chosen setup of, for example, feature size and overall stiffness requirements. Changes in these requirements such as allowing for smaller feature sizes and lower stiffness could further raise the expansion ratio but at the potential cost of worsened fabricability and reduced structural integrity.

Programmable spontaneous area change of opening with unaltered overall size

In this section, we focus on programming the area change of an opening in an LCE metamaterial unit cell, which can benefit applications such as smart evaporation control for plants or human thermal management as indicated in Fig. 3a. For these applications, the porous opening of the material would expand or contract in a controllable fashion upon temperature variations. Importantly, while the opening morphs, the total area of the unit cell (and hence the product’s size) is required by many applications to maintain its size under temperature fluctuations. As an example, smart wearable fabrics for active thermal management shall change the porosity but not the overall size as the latter would lead to shrinking or sagging and cause discomfort for the wearer. The seemingly contradictory temperature-sensitive opening and temperature-insensitive overall size can hardly be achieved by heuristics or experience. Here, with the inverse design framework, we show that both requirements can be met, and a wide range of targeted area changes of the opening, including different levels of contraction and expansion, can be accurately realized without severely perturbing the overall size.

a Potential applications: smart evaporation and heat management (schematics); b optimized LCE metamaterial (Dsg. I) and its simulated deformed configuration with a target deformed opening area of one-third of the undeformed area upon temperature rise, a metamaterial design without area constraint is provided for comparison; c optimized LCE metamaterials (Dsgs. II–V) and their simulated deformed configurations with various target deformed opening areas upon temperature rise; and d deformed opening area change as Q decreases (i.e., temperature increases).

We focus on a unit cell with a butterfly-shaped opening as illustrated in Fig. 3a, where the current area of the opening is the summation of the current areas of the elements in the void region defined by zero-density design variables. For this set of designs, we optimize only the material design variable (material types) and freeze the density variable to the prescribed geometry. The inverse problem minimizes the error between the current deformed void area and the prescribed target values. To retain the total area under temperature variations, we impose a constraint on the total area change ratio Jave by requiring \({({J}_{\rm{ave}}\,-\,1)}^{2}\,\le\,{\epsilon }_{J}\) where ϵJ = 0.01 is a small prescribed constant. To facilitate large LCE-induced deformation, we use a relatively soft passive material with shear modulus μP = 0.0083 MPa, which is one-tenth of the LCE’s shear modulus. A nematic-isotropic transformation with Q0 = 0.5 and Q = 0 is assumed. For more details of the optimization formulation, please refer to Supplementary Note 5.2.

To begin, we use a target opening area of one-third of the undeformed butterfly-shaped opening, indicating the opening would contract to a third of its undeformed size under temperature rise while keeping the unit cell’s overall area unchanged. The obtained design and its deformed configurations in both unit cell and assembly are shown in Fig. 3b. The design features rather complex LCE distributions, with X-director LCE members (indicated in blue) aligned in the Y direction, and Y-director LCE aligned in the X direction. LCEs with the other two directors are placed mainly on the diagonals of the unit cell. When heated, the deformed opening’s area AH contracts to 0.31 of the undeformed AH0, which accurately achieves the target ratio of 0.33. Importantly, the current total area of the unit cell is A = 0.92 A0, close to the ideal value of 1. The discrepancy is mainly due to the post-processing that projects the optimized design to a discrete design, as the A = 0.98 A0 for the as-optimized design. Fluctuations appear at the top and bottom boundaries of the unit cells but do not contribute to the total area change because they are periodic. As all LCEs tend to shrink in-plane under temperature rise, the retained total area is therefore realized by the planar expansion of the passive materials mechanically stretched by the optimized LCEs. Such sophisticated mechanisms and delicate balance cannot be achieved by experience-based designs.

Lifting the total area constraint results in a completely different design as shown in the right-most unit cell of Fig. 3b. The LCEs surround the opening and are aligned in the tangential direction of the envelope to produce a contraction to the encircled opening. While the design accurately achieves the target opening area, the overall unit cell size also shrinks significantly to 0.86 A0, which is undesired for many applications.

The inverse design facilitates the precise realization of a broad range of thermally induced area changes for the opening while retaining the unit cell’s overall size. This is demonstrated in Fig. 3c, which shows the optimized design with target opening area \({A}_{H}^{* }=0.67\), 1.5, 2.0, and 2.5 times AH0. All designs accurately achieve the target opening areas with relative errors \(({A}_{H}\,-\,{A}_{H}^{* })/{A}_{H}^{* }\) less than 6% while retaining their overall size with less than 2% variations. The optimized LCE distributions are generally complex and reveal qualitative trends. As \({A}_{H}^{* }\) grows, the orientation of the X-director LCE members (blue) changes from vertical to horizontal, as the vertical ones squeeze the opening and the horizontal ones pull and expand the opening. In a similar trend, Y-director LCE members change from horizontally oriented to vertically oriented. We note that it is possible to achieve a zero deformed area with a closed opening, but that would induce self-contact issues that are not modeled in the current framework.

The relation between the thermally induced opening area change and the order parameter Q is close to linear as demonstrated in the AH–Q plots of the five optimized designs in Fig. 3d. However, as the Q—temperature relations of LCE are generally highly nonlinear, the opening’s area is also expected to vary nonlinearly under a steady temperature rise.

Thermally switchable nonlinear stress–strain relations

In this section, we harness temperature change as a switch that alters the effective stress–strain relation and deformation mode of LCE metamaterial in a programmable fashion. Most mechanical metamaterials’ behaviors remain static throughout their service life and do not adapt to environmental changes in a controllable fashion, limiting their applicability in varying environments. To introduce different mechanical behaviors at different temperatures, one effective strategy is to adopt materials with temperature-sensitive material properties such as polymers, but polymers below the glass transition temperature are typically hard relative to elastomers and may not suit applications requiring softness. An alternative to temperature-dependent material properties is to use materials with temperature-induced shape changes, such as LCE and shape-memory polymers. Although effectively varying the overall metamaterial behavior, most established metamaterials require large changes in the initial configuration before applying the mechanical load, which can be undesired or prohibited in certain applications. It remains unclear how to harness temperature to alter microstructural geometry and hence mechanical behaviors without perturbing the initial unloaded size or length.

With the proposed LCE inverse design framework, we can precisely program drastic changes in mechanical responses under temperature variations while retaining the initial size or length at different temperatures. Here, we focus on programming temperature-switchable effective stress–strain relations for LCE metamaterials. The effective stress and strain of the periodic metamaterial unit cell are defined as the normal component (in the loading direction) of the volume-averaged first Piola–Kirchhoff stress and the normal component of the volume-averaged deformation gradient subtracted by one, respectively. Based on this setup, we assign different target stress–strain curves for the inverse design under different temperatures. As shown by the circle target points in Fig. 4a, we aim to achieve a linear stress–strain relation at the low temperature (Q = Q0 = 0.5) and a bilinear plateau curve at high temperature (Q = 0) with a much higher initial stiffness under an 0.2 averaged applied strain. Further, we require that the metamaterial’s length in the loading direction (Y direction) remains almost unchanged under temperature changes through an optimization constraint that limits the Y-direction effective strain under purely temperature rise from Q = 0.5 to Q = 0 before applying the mechanical load. To ensure the optimized design will have sufficient loading stiffness and effective stress magnitude, we adopt a relatively stiff passive material with shear modulus μP = 0.829 MPa, i.e., ten times the shear modulus of LCE. Such a passive material can be realized by polydimethylsiloxane, for example. For more details about the formulation, the readers are referred to Supplementary Note 5.3. We note that achievable target stress–strain curves should satisfy certain physical and material-specific requirements. Target curves violating the requirements are physically impossible to realize. These requirements are discussed in detail in Supplementary Note 5.3.1.

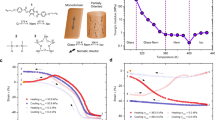

a Target stress–strain relations under hot (Q = 0) and cold (Q = 0.5) temperatures and the actual effective stress–strain relations under various Q of the optimized metamaterial (Dsg. I); b optimized LCE metamaterial (Dsg. I) for linear stress–strain target at Q = 0.5 and bi-linear plateau target at Q = 0; c optimized LCE metamaterial (Dsg. II) for linear stress–strain target at Q = 0.5 and plateau target with one-half the stiffness of Dsg. I at Q = 0; d effective stress–strain relations of Dsg. II for 0.2 vertical strain; and e effective stress–strain relations of Dsg. II for 0.4 vertical strain. Several simulated deformed configurations are included for Dsgs. I and II. Deformed 1 is the deformed configuration of the metamaterial under mechanical loading at a low temperature, Deformed 2 is the deformed configuration of the metamaterial (without mechanical loading) upon temperature rise, and Deformed 3 is the deformed configuration under mechanical loading at a high temperature.

The optimized metamaterial (Dsg. I) and its configurations at four states of initial at low temperature (undeformed), mechanical load at low temperature (Deformed 1), spontaneous deformation at high temperature (Deformed 2), and subsequent mechanical load at high temperature (Deformed 3) are shown in Fig. 4b. The design has four branches and a bulk center connected through two pairs of slender beams where the LCE is allocated. When loaded vertically at the low temperature and deformed into the Deformed 1 configuration in Fig. 4b, the metamaterial accurately achieves the prescribed linear stress–strain relation as indicated by the dark blue curve in Fig. 4a. When heated to Q = 0, the metamaterial shrinks in the lateral direction (X direction) due to LCE actuation while largely retaining the initial size in the loading direction (Y direction) as shown in the Deformed 2 configuration in Fig. 4b because of the length-preserving constraint. When loaded mechanically at the high temperature, the metamaterial deforms into the Deformed 3 configuration in Fig. 4b and also accurately produces the prescribed bi-linear force plateau behavior as demonstrated by the top red curve in Fig. 4a with mild fluctuations over the plateau. The large behavioral change is mainly caused by the thermally induced spontaneous configuration change before the mechanical loading. At low temperatures, the two pairs of beams are largely horizontal and deform mainly in flexure without buckling, producing a linear and steady stress–strain curve. The temperature rise causes the LCE parts to contract, in turn shrinking the metamaterial laterally and displacing the beams to form acute angles to the loading direction. When loaded vertically, the new orientations induce axial compression in the beams and raise the initial stiffness. When loaded further, the compressed beams buckle and result in a sudden drop of stiffness, entering the plateau stage. The nonlinear buckling behavior continues and results in the beams’ large rotation, thereby producing the subsequent long plateau of the stress–strain curve.

The stress–strain relations at intermediate temperatures, i.e., those corresponding to Q = 0.4, 0.3, 0.2, and 0.1, are also evaluated as shown in the curves between the Q = 0.5 and Q = 0 of Fig. 4a. The curves demonstrate a continuous variation from the linear to the plateau curves as the temperature gradually rises. This provides a wide spectrum of thermally tunable nonlinear behaviors that further broaden the applicability of the LCE metamaterial.

The inverse design offers high freedom for tuning the stress–strain relations at different temperatures as demonstrated by the optimized Dsg. II metamaterials in Fig. 4c, which is obtained with a target plateau curve with one-half initial stiffness for the high temperature and identical linear behavior for the low temperature. The overall geometry and mechanism are similar to the previous metamaterial but feature a more slender center with some LCE placed in the middle. Also, only LCEs with horizontal and vertical directors are allocated. As shown in Fig. 4d, The actual stress–strain curve at the high temperature matches the target well while retaining its linear behavior at the low temperature. Similar to the previous metamaterial, this design also has a negligible change of length in the loading direction when heated. While dissimilar below the 0.2 strain range, the two stress–strain curves merge when loaded beyond 0.2 as demonstrated in Fig. 4e because the large applied strain ultimately deforms the metamaterial to a stretch-dominated mode. Interestingly, the two curves form a cross at 0.2 strain, switching their relative stress magnitudes.

Thermally switchable deformation mode

The inverse design method also allows for programming dissimilar deformation modes of mechanical loading in two temperatures while retaining their initial lateral size under pure temperature variations. We demonstrate this capacity by realizing maximized opposite lateral deformation (expansion vs contraction) of a metamaterial unit cell under uniaxial vertical loading at two temperatures. To this end, we assign a large positive target lateral strain at the low temperature and a large negative target at the high temperature. The programmed metamaterial is expected to expand laterally at low temperatures and contract at high temperatures. We consider a passive material with μP = 0.829 MPa and under a 0.2 applied vertical strain as in the programmable stress–strain case. Unlike the programmable stress–strain case where the targets are assigned for the entire loading process, here, the target lateral strains are assigned only at the end of the loading. The lateral widths of the unit cell under the two temperatures before mechanical loading are required to be close to 1 through optimization constraints (see Supplementary Note 5.4, for the detailed optimization formulation). The goal of achieving opposite lateral deformation patterns at two temperatures while retaining the initial width is highly challenging and beyond the reach of intuition.

The optimized metamaterial unit cell and assembly are shown in Fig. 5a with the three deformed configurations under mechanical and thermal loading. As seen in the two deformed configurations under mechanical loading, the metamaterial achieves the targeted behavior of expanding laterally at the low temperature (Deformed 1) and contracting at the high temperature (Deformed 3). The magnitudes of both lateral strains are 0.11, more than half of the applied 0.2 strain. Meanwhile, the unit cell largely retains its initial width under purely temperature rise as seen in the Deformed 2 (Q = 0) configuration of Fig. 5a.

a Optimized LCE metamaterial with lateral expansion at Q = 0.5 (Deformed 1) and contraction at Q = 0 (Deformed 3). Several simulated deformed configurations are included, Deformed 1 is the deformed configuration of the metamaterial under mechanical loading at the low temperature (Q = 0.5), Deformed 2 is the deformed configuration of the metamaterial upon temperature rise (Q = 0), and Deformed 3 is the deformed configuration under mechanical loading at the high temperature (Q = 0) and b lateral strain–vertical strain relations under various Q and deformed configurations at three stages for Q = 0.

The exotic behavior is a result of the optimized geometry and LCE distributions. The unit cell features a ring-like structure with four branches at the four corners and a horizontal member in the middle with little usage of LCE. As will be revealed in the following, the middle horizontal beam plays a critical role in generating the designed temperature-switchable lateral deformation. The overall geometry is somewhat similar to the re-entrant mechanism producing the negative Poisson’s ratio as seen in the assembly of the undeformed configuration. Indeed, vertical loading at the low temperature straightens the originally curved vertical members and compresses the middle horizontal beam, which in turn blocks the two vertical members from coming closer and forces the overall shape to expand laterally, as seen in the Deformed 1 (Q = 0.5) configuration. When heated, the top and bottom LCEs contract and bend the vertical members to an even more curved initial configuration as seen in the Deformed 2 (Q = 0) configuration. When loaded mechanically at a high temperature, the additional bending leads to a stronger squeezing effect in compressing the horizontal beam, which causes it to buckle and bend downward as shown in the Deformed 3 (Q = 0) configuration. Once severely bent, the beam cannot resist the squeezing of the two vertical members and hence enable their overall lateral contraction.

The above analysis reveals the critical role of the middle horizontal beam: it remains largely straight resists the lateral squeezing effect during the mechanical loading at the low temperature, and severely bends and enables the squeezing at the high temperature. The behavioral shift is due to the LCE’s pre-strain or pre-stress effect that causes an initial bending and further curves the two vertical members, magnifying their squeezing force when straightened by the subsequent loading. This mechanism is verified by the lateral strain–vertical strain history during the mechanical loading at various temperatures (various Q values) shown in Fig. 5b. The Q = 0.5 (low temperature) curve is monotonic and smooth, indicating a stead lateral expansion during the entire loading process, but the Q = 0 (high temperature) curve is non-monotonic and shows a slight expansion in the initial stage then reverses to the subsequent contraction. The reversal is caused by the buckling of the middle horizontal beam as demonstrated by the unit cell’s deformed configurations at 0.04, 0.10, and 0.15 vertical strain labeled by (i), (ii), and (iii) in Fig. 5b. At 0.04 strain, which corresponds to the peak of the curve, the beam member is still largely straight, and at 0.10 and 0.15 strains, the beam is severely bent. The stage where the buckling occurs directly relates to the magnitude of the initial LCE contraction, which in turn is determined by the current temperature (through Q). This is revealed in the lateral strain–vertical strain curves with intermediate Q values shown in Fig. 5b. The increase of Q lowers the pre-stress level and delays the beam’s buckling (indicated by the turning points). The plot also indicates the realization of sequential lateral expansion-contraction under monotonic vertical loading, which is also explored in28 using passive materials.

We anticipate challenges in experimentally reproducing the temperature-switchable stress–strain relations and deformation modes as they involve local buckling sensitive to geometric defects and out-of-plane thickness. The defects from fabrication or experimental setup can break the symmetry of the buckling behavior in metamaterial assembly, and overly thin specimens can cause out-of-plane buckling instead of in-plane as predicted by the computation. High fabrication precision and sufficient thickness are therefore necessary for experimental validations. These challenges warrant a comprehensive future investigation.

Final remarks

This study harnesses the free-form design capability of topology optimization and the temperature-induced spontaneous deformation of LCE to intelligently synthesize thermally responsive and adaptive metamaterials with extreme behaviors under large deformations. Upon temperature changes, these LCE metamaterials are optimized to achieve maximized expansion/contraction, accurately programmed area change of openings, and thermally switchable nonlinear stress–strain relations and deformation modes. Importantly, the various programmed behaviors are achieved with the requirement of negligible changes in the overall size or length under temperature rise even though the LCE produces large spontaneous deformations locally. This is facilitated by the strength of topology optimization-driven synthesis. The proposed strategy and the discovered exotic thermally induced behaviors unlock a wide range of possibilities for LCE-related applications.

For future research, extension to programming out-of-plane deformation and other physical stimuli (such as light) would be valuable directions. Also, an extension to the 3D setup would be a promising direction, but this may require an increase in computational power not only due to the curse of dimensionality and the severe nonlinearity of LCE but also because of the potential inclusion of a Lagrange multiplier field associated with material incompressibility.

Methods

Details of the numerical framework

The main technical components for this study are provided as Supplementary Notes. The continuum model of LCE and related conditions are elaborated in Supplementary Note 1. The multi-material design characterization and interpolation rules of LCE composites are provided in Supplementary Notes 2 and 3, respectively. The nonlinear FEA with periodic boundary conditions with a special implementation technique is provided in Supplementary Note 4. The optimization formulations for the four families of programmed LCE metamaterial behaviors, i.e., maximized total area expansion, programmed area change of an opening with unchanged total area, temperature-switchable stress–strain curves, and thermally tunable deformation modes, are presented in Supplementary Notes 5.1–5.4, respectively. The sensitivity analysis and detailed optimization setup are provided in Supplementary Notes 5.5 and 5.6, respectively.

Data availability

All data are available from the main text or Supplementary Information.

Code availability

The code generated during the current study is available from the corresponding author upon reasonable request.

References

Peppas, N., Hilt, J., Khademhosseini, A. & Langer, R. Hydrogels in biology and medicine: from molecular principles to bionanotechnology. Adv. Mater. 18, 1345–1360 (2006).

Mirfakhrai, T., Madden, J. D. & Baughman, R. H. Polymer artificial muscles. Mater. Today 10, 30–38 (2007).

Lum, G. Z. et al. Shape-programmable magnetic soft matter. Proc. Natl. Acad. Sci. USA 113, E6007–E6015 (2016).

Kim, Y., Yuk, H., Zhao, R., Chester, S. A. & Zhao, X. Printing ferromagnetic domains for untethered fast-transforming soft materials. Nature 558, 274–279 (2018).

Warner, M. & Terentjev, E. M. Liquid Crystal Elastomers, Vol. 120 (Oxford university press, 2007).

Ula, S. W. et al. Liquid crystal elastomers: an introduction and review of emerging technologies. Liq. Cryst. Rev. 6, 78–107 (2018).

He, Q. et al. Electrospun liquid crystal elastomer microfiber actuator. Sci. Robot. 6, eabi9704 (2021).

Liu, K., Hacker, F. & Daraio, C. Robotic surfaces with reversible, spatiotemporal control for shape morphing and object manipulation. Sci. Robot. 6, eabf5116 (2021).

Zhang, Y. et al. Seamless multimaterial 3d liquid-crystalline elastomer actuators for next-generation entirely soft robots. Sci. Adv. 6, eaay8606 (2020).

Hebner, T. S., Korner, K., Bowman, C. N., Bhattacharya, K. & White, T. J. Leaping liquid crystal elastomers. Sci. Adv. 9, eade1320 (2023).

Ware, T. H., McConney, M. E., Wie, J. J., Tondiglia, V. P. & White, T. J. Voxelated liquid crystal elastomers. Science 347, 982–984 (2015).

Yuan, C. et al. 3D printed reversible shape changing soft actuators assisted by liquid crystal elastomers. Soft Matter 13, 5558–5568 (2017).

Kotikian, A., Truby, R. L., Boley, J. W., White, T. J. & Lewis, J. A. 3D printing of liquid crystal elastomeric actuators with spatially programed nematic order. Adv. Mater. 30, 1706164 (2018).

Ren, L. et al. Programming shape-morphing behavior of liquid crystal elastomers via parameter-encoded 4d printing. ACS Appl. Mater. Interfaces 12, 15562–15572 (2020).

Roach, D. J. et al. Long liquid crystal elastomer fibers with large reversible actuation strains for smart textiles and artificial muscles. ACS Appl. Mater. Interfaces 11, 19514–19521 (2019).

Liu, H. et al. Shape-programmable, deformation-locking, and self-sensing artificial muscle based on liquid crystal elastomer and low-melting point alloy. Sci. Adv. 8, eabn5722 (2022).

Chen, M. et al. Recent advances in 4D printing of liquid crystal elastomers. Adv. Mater. 35, e2209566 (2023).

Li, W. & Zhang, X. S. Arbitrary curvature programming of thermo-active liquid crystal elastomer via topology optimization. Comput. Methods Appl. Mech. Eng. 417, 116393 (2023).

Aharoni, H., Xia, Y., Zhang, X., Kamien, R. D. & Yang, S. Universal inverse design of surfaces with thin nematic elastomer sheets. Proc. Natl. Acad. Sci. USA 115, 7206–7211 (2018).

Bendsøe, M. P. & Kikuchi, N. Generating optimal topologies in structural design using a homogenization method. Comput. Methods Appl. Mech. Eng. 71, 197 – 224 (1988).

Bendsøe, M. P. & Sigmund, O. Topology Optimization: Theory, Methods and Applications (Springer, 2003).

Wang, C., Zhao, Z., Zhou, M., Sigmund, O. & Zhang, X. S. A comprehensive review of educational articles on structural and multidisciplinary optimization. Struct. Multidiscip. Optim. 64, 2827–2880 (2021).

Sigmund, O. Materials with prescribed constitutive parameters: an inverse homogenization problem. Int. J. Solids Struct. 31, 2313 – 2329 (1994).

Clausen, A., Wang, F., Jensen, J. S., Sigmund, O. & Lewis, J. A. Topology optimized architectures with programmable poisson’s ratio over large deformations. Adv. Mater. 27, 5523–5527 (2015).

Wang, F. Systematic design of 3D auxetic lattice materials with programmable poisson’s ratio for finite strains. J. Mech. Phys. Solids 114, 303 – 318 (2018).

Li, W., Wang, F., Sigmund, O. & Zhang, X. S. Design of composite structures with programmable elastic responses under finite deformations. J. Mech. Phys. Solids 151, 104356 (2021).

Li, W., Wang, F., Sigmund, O. & Zhang, X. S. Digital synthesis of free-form multimaterial structures for realization of arbitrary programmed mechanical responses. Proc. Natl. Acad. Sci. USA 119, e2120563119 (2022).

Li, W., Jia, Y., Wang, F., Sigmund, O. & Zhang, X. S. Programming and physical realization of extreme three-dimensional responses of metastructures under large deformations. Int. J. Eng. Sci. 191, 103881 (2023).

Zhao, Z. & Zhang, X. S. Topology optimization of hard-magnetic soft materials. J. Mech. Phys. Solids 158, 104628 (2022).

Zhao, Z. & Zhang, X. S. Encoding reprogrammable properties into magneto-mechanical materials via topology optimization. npj Comput. Mater. 9, 57 (2023).

Wang, C., Zhao, Z. & Zhang, X. S. Inverse design of magneto-active metasurfaces and robots: theory, computation, and experimental validation. Comput. Methods Appl. Mech. Eng. 413, 116065 (2023).

Li, W., Wang, Y., Chen, T. & Zhang, X. S. Algorithmic encoding of adaptive responses in temperature-sensing multimaterial architectures. Sci. Adv. 9, eadk0620 (2023).

Fuchi, K. et al. Topology optimization for the design of folding liquid crystal elastomer actuators. Soft Matter 11, 7288–7295 (2015).

Athinarayanarao, D. et al. Computational design for 4D printing of topology optimized multi-material active composites. npj Computational Mater. 9, 1 (2023).

Akerson, A., Bourdin, B. & Bhattacharya, K. Optimal design of responsive structures. Struct. Multidiscip. Optim. 65, 111 (2022).

Zhang, X. S., Chi, H. & Paulino, G. H. Adaptive multi-material topology optimization with hyperelastic materials under large deformations: a virtual element approach. Comput. Methods Appl. Mech. Eng. 370, 112976 (2020).

Zhang, X. S., Chi, H. & Zhao, Z. Topology optimization of hyperelastic structures with anisotropic fiber reinforcement under large deformations. Comput. Methods Appl. Mech. Eng. 378, 113496 (2021).

Warner, M., Gelling, K. P. & Vilgis, T. A. Theory of nematic networks. J. Chem. Phys. 88, 4008–4013 (1988).

Warner, M. & Wang, X. J. Elasticity and phase behavior of nematic elastomers. Macromolecules 24, 4932–4941 (1991).

Bladon, P., Terentjev, E. M. & Warner, M. Deformation-induced orientational transitions in liquid crystals elastomer. J. Phys. II Fr. 4, 75–91 (1994).

Biggins, J. S., Terentjev, E. M. & Warner, M. Semisoft elastic response of nematic elastomers to complex deformations. Phys. Rev. E 78, 041704 (2008).

Cirak, F., Long, Q., Bhattacharya, K. & Warner, M. Computational analysis of liquid crystalline elastomer membranes: Changing gaussian curvature without stretch energy. Int. J. Solids Struct. 51, 144–153 (2014).

Mihai, L. A., Wang, H., Guilleminot, J. & Goriely, A. Nematic liquid crystalline elastomers are aeolotropic materials. Proc. Math. Phys. Eng. Sci. 477, 20210259 (2021).

Küupfer, J. & Finkelmann, H. Liquid crystal elastomers: influence of the orientational distribution of the crosslinks on the phase behaviour and reorientation processes. Macromol. Chem. Phys. 195, 1353–1367 (1994).

Svanberg, K. The method of moving asymptotes—a new method for structural optimization. Int. J. Numer. Methods Eng. 24, 359–373 (1987).

Acknowledgements

Authors X.S.Z. and W.L. acknowledge the support from the U.S. National Science Foundation (NSF) CAREER Award CMMI-2047692 and NSF Award CMMI-2245251.

Author information

Authors and Affiliations

Contributions

X.S.Z. and W.L. conceived the research. W.L. and X.S.Z. developed the inverse design framework and generated the results. W.L. and X.S.Z. wrote and revised the paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Li, W., Zhang, X.S. Computational morphogenesis for liquid crystal elastomer metamaterial. npj Comput Mater 10, 125 (2024). https://doi.org/10.1038/s41524-024-01300-y

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41524-024-01300-y