Abstract

Triboelectricity-driven acoustic transducers with various merits have demonstrated significant potential in energy harvesting and self-powered sensing. The transducers generally require additionally a spacer and a corresponding exquisite process for smooth operation, which provides an unnecessary interface between the elements. The exploration of a novel manufacturing approach for triboelectricity-driven acoustic transducers is warranted to resolve this issue. Here, Triboelectricity-driven Oscillating Nano-Electricity generator (TONE) developed via mechanically guided four-dimensional (4D) printing is introduced for acoustic energy harvesting and self-powered voice recognition. The mechanically buckled structure of the TONE facilitates its smooth oscillation by sound wave without the use of an additional spacer, enabling the TONE to exhibit outputs of 156 V and 10 μA. The output characteristics of the TONE are analyzed based on the acoustic-structural-triboelectric interaction mechanism. The TONE demonstrates practical versatility by providing power to commercial electronics from controlled/daily sound and being utilized in artificial intelligence-based human voice recognition sensors.

Similar content being viewed by others

Introduction

The Internet of Things (IoT) is a crucial technology that is driving the Fourth Industrial Revolution and enhances the quality of life in many areas, including privacy, industry, and public facilities. As technology continues to evolve, the IoT is transforming into the Internet of Everything (IoE). This shift has been accompanied by various types of sensors for acquiring real-time data and generating signals, thereby requiring the use of additional detection devices in different fields and places1,2,3. In terms of the electrical energy supply to the device, the technical demand might be confronted with the issues of existing centralized electrical distribution systems, including high costs and congested grids based on wire installation4,5. In this regard, triboelectricity-driven transducers are considered promising decentralized electricity generation solutions that address these issues and have attracted interest6,7,8. This technology transforms mechanical energy into electrical energy through contact-separation between two different materials9,10,11,12,13. Owing to their diversity in usable material and shape, transducers can target various mechanical energies, such as sound, water droplets, and wind14,15,16,17,18,19,20,21,22,23,24.

Among types of mechanical energy that can be converted into electrical energy by a triboelectricity-driven transducer, sound has the characteristic of being easily encountered in the surrounding environment without temporal-spatial constraints, such as machine operation noise, human voice, music, and traffic noise25,26,27,28. Given this feature, several researchers are currently focusing on developing triboelectricity-driven acoustic transducers as independent power sources and self-powered sensors29,30,31,32. In previous reports on triboelectricity-driven acoustic transducers, energy conversion is achieved by precisely controlling the friction between two materials through the vertical vibration of a thin membrane using sound33,34,35. To exquisitely use contact-separation based on vertical vibration, an additional thin spacer in the existing triboelectricity-driven acoustic transducer has been exploited generally36,37,38. The spacer attachment inevitably builds a needless interface with space that enables contact between materials. Unfortunately, this interface acts as a fixed support, restraining the motion of the thin membrane. Considering this, the intrinsic and extrinsic properties of the spacer should be carefully tailored to facilitate low-energy-density sound transfer. Therefore, the introduction of an additional spacer for existing triboelectricity-driven acoustic transducers demands supplementally precise processing. In place of the spacer introduction, several studies have developed spacer-free designs of triboelectricity-driven transducers, including V-shaped, beam, integral, and textile types39,40,41,42,43. However, these designs face challenges in precisely controlling the gap required for sound response and often involve complex fabrication processes. In this regard, a sophisticated method for regulating the room, without an additional spacer and corresponding interface, could expect smooth device operation using sound. In addition, given that manufacturing technology occupies a significant portion of the electronic device field, a novel approach for easy and economical manufacturing processes of triboelectricity-driven transducers should be explored.

Among the reported novel manufacturing process technologies, mechanically guided four-dimensional (4D) printing technology, recently demonstrated by our group, is a method for easily processing a three-dimensional (3D) printed object into complex pop-up structures using buckling44. 4D printing, introduced in a 2013 TED talk, is a concept that adds the dimension of time to conventional 3D printing45,46. In other words, a 3D-printed object changes its shape over time. In previous studies, the shape change mechanism of 3D-printed objects is based on smart materials that respond to specific stimuli such as heat, light, electricity, or magnetic field47,48,49,50. Unlike existing 4D printing methods, which rely on a specific trigger environment/material, our approach is not limited to specific materials because the mechanisms are based on solid mechanics. In particular, the 4D printed architecture fabricated by this process allows precise shape control through structural reversibility. Given these advantages, a novel form factor produced using mechanically guided 4D printing technology is expected to provide innovation in the manufacture of triboelectricity-driven acoustic transducers.

In this article, we introduce a Triboelectricity-driven Oscillating Nano-Electricity generator (TONE) for acoustic energy harvesting and self-powered voice recognition using artificial intelligence (AI). The fabrication of the TONE can be easily realized by mechanical buckling-based 4D printing without additional spacers or needless processes. The resulting TONE generates electricity from sound waves via a mechanism based on acoustic-structural-triboelectric interaction. Finite element analysis (FEA) of the acoustic-structural interaction determines the key design elements of the TONE. Therefore, the effects of the sound and design parameters are explored to characterize the TONE. Demonstrations of acoustic energy harvesting for small commercial electronics operations and voice recognition sensors with AI highlight the potential applications of the TONE.

Results

Mechanically guided 4D printing of the TONE

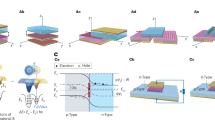

TONE fabrication utilizes a novel 4D printing technology, developed by our group based on the mechanical buckling phenomenon (Fig. 1a). The first process involves the general 3D printing of two precursors for exploitation as the framework of the TONE. The components for triboelectricity, such as the dielectric and electrode, adhere to the 3D printed precursors (Fig. S1, Supplementary Information). The two electrodes are attached to the lower side of the top precursor and the upper side of the bottom precursor, respectively. Additionally, a dielectric film, which acts as a contact layer, is fixed to the electrode of the bottom precursor. The prepared precursors are selectively bonded to the biaxially prestrained elastomeric substrate with the prestrain (\({\varepsilon }_{p}\)) of 0.225. As the \({\varepsilon }_{p}\) of the elastomer is released, the compressive force due to the elasticity of the substrate causes the two precursors to buckle. Because of the mechanical trigger, the precursors are mechanically transformed into pop-up architectures, resulting in TONE production. The manufacturing process used in TONE fabrication features a one-step formation of complex structures with a space between the two structures. In the completed structures, the gap, which is necessary for the vertical contact-separation mode triboelectricity-driven transducer, is naturally created owing to the size difference between the top and bottom pop-up structures without an additional spacer. This reasonable gap by the mechanically guided 4D printing process resolves the needless interface based on the spacer that is required for existing triboelectricity-driven acoustic transducers. In particular, because of the solid mechanics-based principle, the 4D printed architecture might be reconfigured by controlling the strain applied to and released from the elastomer substrate, which can lead to sophisticated regulation of the gap space for smooth oscillation of the TONE by sound.

a The TONE fabrication process progresses in the order of 3D printing, component attachment, selective bonding, and mechanical buckling. b FEA prediction of the shape of the TONE depending on applying or releasing strain. The results show the continuous reversibility of the mechanically guided 4D printed structure. c Von Mises stress distribution in the TONE structure during mechanical buckling. The concentrated stress occurs in the small bridge-shaped linkage. d Real image of the fabricated TONE. e Conceptual illustration of the TONE in two applications: acoustic energy harvesting for small commercial electronics and voice recognition with artificial intelligence.

The complex geometric transformation in mechanically guided 4D printing can be easily predicted by simulations using FEA for structural and solid mechanics. The FEA results in Fig. 1b show the reconfigurable shape prediction of the TONE structure (normalized displacement in the height direction) using an elastomeric substrate, including the 4D printing process. The numerical simulation confirms that a gap could naturally be obtained in the pop-up TONE when the precursors are buckled. As mentioned above, the shape of the TONE is reversibly convertible from a pop-up structure to a flat structure, depending on the strain (\({\varepsilon }_{a}\)) applied on the elastomer. Thus, the mechanical trigger for the substrate allows the gap distance (\({d}_{g}\)) of the TONE to be controlled reversibly and precisely. The TONE with the state where the \({\varepsilon }_{p}\) is fully released in the 4D printing process has a maximum \({d}_{g}\) (\({\varepsilon }_{a}\) = 0), whereas \({d}_{g}\) is zero because the shape is flattened like the original precursors when \({\varepsilon }_{a}\) is adjusted as much as \({\varepsilon }_{p}\). Furthermore, the change in the von Mises stress distribution in the TONE structure is simulated, as shown in Fig. 1c, during the buckling phenomenon by mechanically guided 4D printing. Notably, the largest stress is concentrated at the small bridge-shaped linkage that connects the middle part with the supporting part in the top architecture of the TONE. In this regard, the FEA implies that linkage can become a key design element in the TONE.

Figure 1d is an actual photo of a TONE fabricated using mechanically guided 4D printing technology; it is in accordance with the predicted final geometry (Fig. 1b) via numerical simulation. The potential application concept of TONE that transduces sound into electricity is shown in Fig. 1e. The TONE is operated by the sound pressure of the acoustic energy generated from various sources, resulting in electrical signal generation based on triboelectrification. Electrical outputs can not only be utilized as energy to supply power for small electronics but can also be exploited to recognize voices in a self-powered manner.

Energy transduction mechanism in the TONE by acoustic-structural-triboelectric interaction

The mechanism to transform sound into electricity in the TONE consists of two interactions: acoustic-structural and structural-triboelectric interactions. Figure 2a, b show the FEA of dynamic behavior and stress distribution in the structure of the TONE (\({\varepsilon }_{a}\) = 0.2125) by sound pressure. When sound is applied to the TONE, the middle part of the top pop-up structure is descended as a result of pressure, leading to contact with the bottom pop-up structure (Fig. 2a). At this moment, the sound pressure causes more stress in the small bridge-shaped linkages of the top architecture, as shown in Fig. 2b. These simulation results indicate that the linkage is the main element that is resistant to the structural deformation of the top pop-up structure by sound. In particular, the concentrated stress in the linkage implies that some of the applied acoustic energy is transformed into resilience in the form of potential energy and is stored in the deformed linkage owing to the natural elasticity of the material. Therefore, when the stored resilience is released, the descended middle part of the top pop-up structure recovers its original state. The actual behavior of TONE by sound waves is shown in Fig. S2 (Supplementary Information), and the vibration of the top layer is confirmed without movement of the bottom layer. In this regard, the linkage dominantly affects the acoustic-structural interaction, which can be considered as the key design element that determines the performance of the TONE.

a, b FEA prediction of acoustic-structural interaction in the TONE. Change of structural shape (a) and von Mises stress distribution (b) by sound pressure. c Schematic illustration of the structural-triboelectric interaction in the TONE. d, e Output voltage (d) and current (e) of the TONE by a controlled sound wave with a sound pressure level of 110 dB and a frequency of 72 Hz. f Fast Fourier transform result of (d).

The structural motion of the TONE activated by sound generates electrical energy via its interaction with triboelectricity. Figure 2c shows the working principle of the vertical contact-separation mode triboelectricity-driven transducer utilized in the TONE. The contact layer (dielectric) in a neutral state touches the descended counter layer (top electrode) due to sound pressure, resulting in a triboelectric charge. An opposite charge is induced in the top electrode to maintain the electrical neutrality of the system. Subsequently, when the counter layer returns to its original position owing to the force of resilience, the induced charge migrates to the bottom electrode via electrostatic induction. Subsequently, as the counter layer approaches the contact layer again under sound pressure, the induced charge flows in the opposite direction. Owing to the vibration characteristics of sound, the top and bottom structures of the TONE perform repetitive contact-separation, generating alternating current electrical energy.

The output voltage (\({V}_{{output}}\)) and current (\({I}_{{output}}\)) of the proposed TONE are measured using a sound source with a sound pressure level of 110 dB and a frequency of 72 Hz. The TONE successfully generates an output peak voltage of approximately 156 V and an output peak current of approximately 10 μA (Fig. 2d, e). These outputs are consistent and show no statistically significant difference as shown in Table S1 (Supplementary Information). To confirm whether the TONE responds to sound and generates the corresponding electrical signals well, Fourier analysis of Fig. 2d is performed using the fast Fourier transform. Figure 2f is obtained by transforming Fig. 2d from the time domain to the frequency domain. This result shows that the frequencies of the output signal by sound match well with the 72 Hz input sound. This means that the TONE effectively converts acoustic energy to electrical energy through a mechanism based on acoustic-structural and structural-triboelectric interactions.

Electrical output characterization depending on sound and design

Considering the energy conversion mechanism of the TONE from sound to electricity via acoustic-structural-triboelectric interaction, it is essential to investigate the effects of different sound-related and TONE design parameters (Fig. 3a). A sound wave, defined as a type of mechanical wave, transfers energy through a medium such as air and is characterized by its frequency (\(f\)) and pressure amplitude (\({P}_{{amp}}\)). Using logarithms, the sound pressure is expressed by the sound pressure level (\({L}_{P}\)) on the decibel scale as follows27:

where \({P}_{{ref}}\), the lowest audible sound pressure, is approximately 20 μPa. In addition, sound pressure is related to the distance from the sound source as follows27:

where \({d}_{s1}\) and \({d}_{s2}\) denote the distance of positions 1 and 2 from the sound source, respectively, and \({P}_{{amp}1}\) and \({P}_{{amp}2}\) denote the pressure amplitude of the sound at positions 1 and 2, respectively. Consequently, if position 2 is farther from the sound source than position 1, \({P}_{{amp}2}\) is smaller than \({P}_{{amp}1}\).

a Schematic illustration for explanation of the sound-related and design parameters of the TONE: Frequency (\(f\)), sound pressure level (\({L}_{P}\)), sound source-TONE distance (\({d}_{s}\)), thickness (\(t\)), width (\(w\)), Young’s modulus (\(E\)), and applied strain (\({\varepsilon }_{a}\)). b The effect of \(f\) on the output voltage of the TONE. The natural frequency of the TONE exists within 72 and 76 Hz ranges. c The effect of \({L}_{P}\) on the output voltage of the TONE. d The effect of \({d}_{s}\) on the output voltage of the TONE. e The effect of \(t\) on the output voltage of the TONE. f The effect of \(w\) on the output voltage of the TONE. g The effect of \(E\) on the output voltage of the TONE. Here, \(t\) is fixed at 200 μm by the limited specification of the 3D printer. h The effect of \({\varepsilon }_{a}\) on the output voltage and gap distance (\({d}_{g}\)) of the TONE.

The pressure of the sound wave transmitted to the TONE from the sound source is applied to the top pop-up structure, which causes deformation, as shown in Fig. 2a, b. As previously described, the extent of this deformation can be altered by interference from the linkages. To perform a systematic analysis, assuming the small bridge-shaped linkage is a beam, the deformation of the top pop-up structure due to sound pressure is considered a beam deflection (\(\nu\)). Thus, the acoustic-structural interaction can be modeled in a straightforward manner as follows:

where \(F\) denotes the force from the sound pressure and \(K\) denotes the flexural stiffness of the beam (linkage). The value of \(K\) is controlled by different variables: the Young’s modulus (\(E\)) of the material constituting the beam and the width (\(w\)) and thickness (\(t\)) of the beam. Therefore, the sound pressure and design of the small bridge-shaped linkage are involved in the movement of the middle part of the top pop-up structure. This affects the triboelectrification and electrostatic induction, thereby enabling the determination of the TONE output.

The effects of the parameters shown in Fig. 3a are explored by measuring the TONE output voltage. To facilitate the intuitive comparison of output behavior according to parameter variation, relative voltage (\({V}_{r}\)) based on the peak voltage of Fig. 2d is exploited. The parameter values of the standard device are listed in Table S2 (Supplementary Information). Figure 3b–d show the influence of \(f\), \({L}_{P}\), and the distance between the sound source and the TONE (\({d}_{s}\)). As \(f\) increases to 72 Hz, the output increases, and a decrease occurs in the region following 76 Hz (Fig. 3b). A comparison of this behavior with the natural frequency (74.22 Hz) calculated from the mass (0.58 g) and stiffness (126.18 N/m) of the fabricated TONE confirms that the natural frequency of the device is in the range of 72–76 Hz. As illustrated in Fig. 3c, d, the TONE output increases with an increase in \({L}_{P}\) or a decrease in \({d}_{s}\). This result is attributable to the augmented force exerted on the TONE: \({P}_{{amp}}\) of sound transmitted to the TONE is greater when \({L}_{P}\) is larger and \({d}_{s}\) is smaller, as indicated by Eqs. (1) and (2). As shown in Eq. (3), this leads to more movement of the middle part of the top pop-up structure, thereby facilitating conformal contact of the TONE. Such a conformal contact increases the triboelectric charge within the triboelectric device, resulting in an increase in the output performance51. The effects of the TONE design parameters that can be tuned during the 4D printing process are shown in Fig. 3e–h. The larger the \(t\), \(w\), and \(E\) values of the small bridge-shaped linkage, the smaller the \({V}_{r}\) (Fig. 3e–g). According to Eqs. (3) and (4), the increase in these parameters restricts the deformation of the middle part of the top pop-up structure owing to the \(K\) growth, and subsequently, the output is reduced by making conformal contact of the TONE difficult. It is noteworthy that thinner cases (\(t\) = 60 μm) result in reduced output (Fig. S3, Supplementary Information). At this point, the bridge-shaped linkage is observed to be damaged, making it difficult to restore the structure deformed by sound, which leads to a decrease in output. In particular, the damage to the bridge-shaped linkage indicates that the vibration of the structure due to sound is dominant in the bridge-shaped linkage. Furthermore, \({\varepsilon }_{a}\), which is capable of modulating \({d}_{g}\), exhibits a positive correlation with the output performance of the TONE, as illustrated in Fig. 3h. As \({d}_{g}\) decreases by the increment in \({\varepsilon }_{a}\), the contact-separation of the TONE functions smoothly, leading to enhanced output. Consequently, the results of the parameter study regarding sound and design indicate that the output of the TONE complies with a behavior similar to the beam deflection of the equivalent model in Eq. (3). Furthermore, according to previous studies, the natural frequency of the pop-up structure formed by mechanical buckling is controlled by the dimensions and material properties of the structure52,53. Using a simple model, it is confirmed that the natural frequency can be controlled by tailoring the design parameters of the structure (Fig. S4, Supplementary Information). Through this result, it can be inferred that the natural frequency of the TONE proposed in this study can also be controlled. This finding serves as a guideline for the design and application of the system, which is contingent on its operational environment.

Demonstration of TONE application in acoustic energy harvesting and voice recognition with AI

The proposed TONE is used in two potential applications, as illustrated in Fig. 1e. The first application involves harvesting acoustic energy to supply power to small electronics (Fig. 4). To demonstrate the energy harvesting application of the TONE, the conditions listed in Table S2 (Supplementary Information) are employed during the fabrication and operation of the device. First, when employing the TONE as an energy harvester, it is imperative to maximize the power transfer. Achieving maximum power transfer is contingent upon matching the impedances between the power source and external load; thus, the impedance of the energy harvester is a pivotal specification. Figure 4a shows the output peak voltage (\({V}_{{peak}}\)) and corresponding peak power (\({P}_{{peak}}\)) according to the impedance of the external load (\({R}_{{ext}}\)), and the \({P}_{{peak}}\) is calculated as follows:

a The peak voltage and the corresponding peak power by the TONE depending on the external load. b Durability and reliability of the TONE output for 20 min (over 80,000 cycles). c Real-time powering on a custom-built LED display with 25 LEDs. d Intermittent powering on thermo-hygrometer using a capacitor of 1000 μF. Here, a controlled sound wave with 72 Hz and 110 dB is used. e Intermittent powering on thermo-hygrometer using a capacitor of 22 μF. The capacitor is charged from various daily sounds, including music, voice, and noise.

The TONE transfers the maximum power of approximately 420 μW when subjected to an external load of 10 MΩ, indicating an impedance of 10 MΩ for the device. Given that the triboelectric effective area (\(A\)) of TONE is 9 cm2, the peak power density of TONE is 466.7 mW/m2. Also, the energy conversion efficiency (\(\eta\)) of TONE is quantified as follows:

where \({\sigma }_{{average}}\) and \({I}_{{sound}}\) represent the average power density from TONE and the intensity of the sound wave, respectively. Here, \({\sigma }_{{average}}\) is expressed as follows:

where \(T\) and \(V(x)\) are the time interval during the generation of electrical energy, and the output voltage corresponding to \(T\), respectively. Also, according to literature, \({I}_{{sound}}\) has the following relationship with LP27:

where \({I}_{{standard}}\), the standard reference intensity, is 10−12 W/m2. By Eqs. (6–8), \({\sigma }_{{average}}\) and \({I}_{{sound}}\) are calculated as 17.1 mW/m2 and 100 mW/m2, respectively, and as a result, \(\eta\) of TONE is 17.1%. Compared with the previously related works, TONE shows superiority in voltage and peak power density at similar sound pressure levels (Table S3, Supplementary Information). The durability and reliability of the device are assessed using sound waves with 72 Hz and 110 dB (Fig. 4b). Under these input conditions, the TONE generates electrical energy with peak voltages of 156 and −125 V steadily for 20 min (equaling over 80,000 cycles). Also, the long-term durability is conducted during multiple days as shown in Fig. S5 (Supplementary Information), which shows no significant output degradation under slight temperature and humidity change for 5 days. Furthermore, the reliability under typical variations in temperature and humidity conditions is explored, resulting in output decrease (Fig. S5, Supplementary Information). According to the literature, temperature and humidity are the main environmental factors affecting the output of TENG, and an increase in these factors causes a decrease in the output of TENG54,55,56. Therefore, to secure the practicality of TONE, further research is needed on the use of triboelectric materials that can resist temperature and humidity.

Demonstration of real-time and intermittent operation of commercial small electronics, such as light-emitting diodes (LEDs) and thermo-hygrometers, is performed via electricity from the TONE driven by controlled or surrounding sound (Fig. 4c–e). The controlled speaker sound (72 Hz and 110 dB) is transformed using the TONE, in which the generated alternating current illuminates a custom-built LED display with 25 LEDs in real-time (Fig. 4c and Video S1 (Supplementary Information)). Also, a capacitor with a capacitance of 1000 μF is charged to 2.8 V (charged voltage in the capacitor, \({V}_{{cap}}\)) using the TONE driven by the speaker sound during 36 min (Fig. 4d). Connecting the charged capacitor to the thermo-hygrometer and supplying the energy stored in the capacitor enables intermittent operation of the thermo-hygrometer for 60 s (Video S2, Supplementary Information). To confirm the capability in a practical environment beyond acoustic energy harvesting in controlled conditions, the small electronics operation is exhibited using daily sounds, including music, talk, and surrounding noise (Fig. 4e). The capacitor with 22 μF connected to the TONE is charged nonlinearly to 3.5 V for 18 min by ambient sounds. Subsequently, the capacitor supplies electrical energy to the thermo-hygrometer, leading to the operation of electronics (Video S3, Supplementary Information). The successful demonstration of real-time and intermittent operation of commercial small electronics from these various sound sources highlights the broad practical potential of the presented TONE as an energy harvester.

The second application pertains to voice recognition with AI, which is self-powered. To improve the responsiveness of the TONE to voice, thermoplastic polyurethane (TPU) with a relatively low Young’s modulus (70 MPa) is used according to the guidelines of parametric study. The proof-of-concept for AI-assisted voice recognition using the TONE is illustrated in Fig. 5. The human voice is transformed into an electrical signal using the TONE and acquired as data (Fig. 5a). As the training data composed of voice information (word or speaker) with signal data are provided, predictive algorithms can be found using learning algorithms that generate models by deep learning from patterns in data. The predictive algorithm predicts voice information regarding new unknown signal data, and the predicted output is used for voice recognition. The convolutional neural network (CNN) used in deep learning is an optic nerve-inspired structure and shows excellent performance for image classification (Fig. 5b)57,58. Electrical signals from the voice vary according to the pronunciation of words, speech organs, and the speaker’s manner of speaking. Although such signals can be intuitively understood using images, computers perceive image data as numerous pixels. CNN-based deep learning preserves the spatial properties of images and reduces the image data size using the convolutional and pooling layers of the CNN. After the convolutional and pooling layers, the extracted features of the images are passed through a flattening and fully connected layer, resulting in the predicted outputs. Figure 5c, d demonstrate the word detection and voice recognition using the TONE with predictive algorithms. For word detection, the electrical signals from voices saying five words (cherry, peach, pineapple, strawberry, and watermelon) are collected in advance and used to learn the predictive algorithm (Fig. 5c(i)). The distinguishing capability of the predictive algorithm for various words is presented in a confusion matrix with 98% accuracy (Fig. 5c(ii)). This AI-based sensor using the TONE is capable of real-time word detection (Fig. 5c(iii) and Video S4 (Supplementary Information)). Furthermore, beyond basic word detection, the AI-based sensor using the TONE can classify different voices saying the same sentence (“We demonstrate the mechanically 4D printed triboelectric platform for voice”). The predictive algorithm is trained using voice data recorded by Girak Gwon (GG), Donghan Lee (DL), and Yu-seop Kim (YK) (Fig. 5d(i)). Figure 5d(ii) and Video S5 (Supplementary Information) demonstrate a voice recognition-based identification system that allows authorized users (GG) to access the system and denies access to other users. As a result, the successful demonstration of AI-based real-time voice recognition using the TONE demonstrates the potential of the human-machine interface, robotics, and security access.

Discussion

The TONE proposed in this study offers a successful transformation between sound and electricity, with potential applications in energy harvesting and self-powered sensors. The pop-up structure, which is configured by mechanically guided 4D printing, uses the elasticity of the materials and the natural gap, thereby eliminating the need for an additional spacer. This approach enables the smooth oscillation of the TONE without the presence of an unnecessary interface. Therefore, the TONE generates an output voltage of 156 V and a current of 10 μA under 110 dB and 72 Hz. The FEA results for structural and solid mechanics imply that the linkage of the top pop-up structure plays a major role in TONE performance, as confirmed in the parametric study. Moreover, a systematic investigation of the sound-related and design parameters establishes guidelines for the fabrication and application of the TONE. Real-time or intermittent power supply to commercial electronics from controlled or daily sound represents features of relevance for use as a potential power source for low-power devices in the IoT and IoE. The integration of the TONE with AI trained by CNN-based deep learning demonstrates successful word detection and security systems via voice recognition, which can emerge as a promising solution for robotics and human-machine interfaces. This study presents a meaningful direction for the development of groundbreaking ideas for future work by proposing a novel process for the design and fabrication of triboelectricity-driven transducers. Furthermore, the potential for large-area production of the mechanically guided 4D printing process has been demonstrated in previous studies by our group, highlighting its potential for large-scale and roll-to-roll production44. Therefore, if further in-depth exploration and development of this process, which is currently at the foundational research stage, are conducted, cost-effective and high-yield production of triboelectricity-driven transducers, such as TONE, is expected to be achievable.

Methods

Fabrication of TONE

The flat frameworks for the TONE were prepared using fused deposition modeling 3D printing (Ultimaker S5 Pro Bundle, Ultimaker). Acrylonitrile butadiene styrene copolymer (ABS, Ultimaker) was mainly used as the composition material for the TONE, and polylactic acid (PLA, Ultimaker) or TPU (TPU 95 A, Ultimaker) was used in parametric studies and applications of the TONE. The precursors were assembled by attaching a fluorinated ethylene propylene film as the dielectric layer and conductive tape as the electrode to the flat frameworks. The dimensions of the 3D printed precursors, dielectric, and electrode were detailed as shown in Fig. S6 (Supplementary Information). The reason for designing the bridge-shaped linkage in the bottom layer was to ensure the flatness of the middle part of the bottom layer when converted to a pop-up structure, thereby ensuring smooth conformal contact of the TONE. An elastomeric substrate with 8 × 8 cm2 (Dragon Skin 20, SMOOTH-ON) was stretched using a custom mechanical stretching system, and the prepared precursors were selectively bonded to the prestrained substrate using a commercial adhesive. The release of the prestrain led to a mechanically guided geometric transformation by buckling, resulting in the assembly of the TONE.

Finite element analysis

3D FEA for the geometric transformation and deformation of the TONE was performed using commercial software (SOLIDWORKS). The 3D model was designed with the same dimensions as the TONE. The Young’s modulus, Poisson’s ratio, and density of ABS were 2 GPa, 0.394, and 1020 kg/m3, respectively. The transformation from the precursors to a pop-up structure and the deformation of the pop-up structure by sound pressure were included in the FEA simulation process. The boundary condition was set such that the displacement of the bonding site reached the required prestrain or applied strain. The load was applied as a corresponding sound pressure amplitude. The results of the 3D FEA focused on the displacement and von Mises stress distribution in the structure.

Characterization and measurement for electrical output of the TONE

To characterize the TONE, a controlled sound wave was generated by a speaker woofer (TK-6, Taikan) equipped with a function/arbitrary waveform generator (DG1022Z, RIGOL) and a system power amplifier (AMP-1506, TERA audio). The frequency and sound pressure level were tuned using a function/arbitrary waveform generator and system power amplifier, respectively, and the sound pressure level was evaluated using a sound level meter (GM1357, BENETECH). An oscilloscope (DS1074Z Plus, RIGOL) equipped with a high-voltage differential probe (DP-22Kpro, PINTEK) was used to measure the TONE output voltage. The output current was measured using a low-noise current preamplifier (SR570, Stanford Research Systems) connected to an oscilloscope (DS1074Z Plus, RIGOL).

Demonstration of TONE applications

To investigate the TONE impedance, the output voltage was measured using an external load that is parallel-connected to an oscilloscope (DS1074Z Plus, RIGOL) equipped with a high-voltage differential probe (DP-22Kpro, PINTEK). A custom-built LED display, which was prepared by connecting 25 LEDs in series, was directly connected to the TONE. To supply intermittent power to small commercial electronics using the TONE, a capacitor was connected to the TONE through a rectifier. The charged voltage in the capacitor was monitored using an electrometer (Model 6514, KEITHLEY). To acquire signals according to different words or voices, an oscilloscope (DS1074Z Plus, RIGOL) equipped with a passive probe (PVP2150, RIGOL) was used, and the signals were recorded as images.

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Code availability

The code used for CNN-based deep learning is available from the corresponding authors upon reasonable request.

References

Mukhopadhyay, S. C. et al. Artificial intelligence-based sensors for next generation IoT applications: a review. IEEE Sens. J. 21, 24920–24932 (2021).

Kam, D. et al. Mechanical buckling assisted formation of 3D conductive composite meso-structure for highly sensitive piezoresistive pressure sensor. Composite Struct. 311, 116808 (2023).

Dingorkar, S. et al. Real-time data processing architectures for IoT applications: a comprehensive review. In 2024 First International Conference on Technological Innovations and Advance Computing (TIACOMP) (ed. Naveen Garg) 507-513 (IEEE, 2024).

Ackermann, T., Andersson, G. & Söder, L. Distributed generation: a definition. Electr. Power Syst. Res. 57, 195–204 (2001).

Guerrero, J. M. et al. Distributed generation: toward a new energy paradigm. IEEE Ind. Electron. Mag. 4, 52–64 (2010).

Lee, Y. et al. Liftoff of a soft-actuated micro-aerial-robot powered by triboelectric nanogenerators. Nano Energy 126, 109602 (2024).

Choi, D. et al. Recent advances in triboelectric nanogenerators: from technological progress to commercial applications. ACS Nano 17, 11087–11219 (2023).

Kam, D. et al. Tailoring dielectric constant via anodic aluminum oxide-based nanoparticle for boosting the output performance of a triboelectric nanogenerator. Chem. Eng. J. 500, 157123 (2024).

Chung, S.-H. et al. Boosting power output of fluttering triboelectric nanogenerator based on charge excitation through multi-utilization of wind. Nano Energy 111, 108389 (2023).

Kim, J.-K. et al. Electric-field-driven interfacial trapping of drifting triboelectric charges via contact electrification. Energy Environ. Sci. 16, 598–609 (2023).

Fan, F.-R., Tian, Z.-Q. & Wang, Z. L. Flexible triboelectric generator. Nano Energy 1, 328–334 (2012).

Park, J. G. et al. Shear thickening and charge-storing interlayer-based all-aerosol-sprayed wearable triboelectric sensor for industrial wireless human-machine interfaces. Nano Energy 124, 109444 (2024).

Lee, Y. et al. Triboresistive touch sensing: grid‐free touch‐point recognition based on monolayered ionic power generators. Adv. Mater. 34, 2108586 (2022).

Zheng, J. et al. Acoustic core–shell resonance harvester for application of artificial cochlea based on the piezo-triboelectric effect. ACS Nano 15, 17499–17507 (2021).

Jang, S. et al. Beyond metallic electrode: spontaneous formation of fluidic electrodes from operational liquid in highly functional droplet-based electricity generator. Adv. Mater. 36, 2403090 (2024).

Lee, D. et al. Bidirectional rotating direct-current triboelectric nanogenerator with self-adaptive mechanical switching for harvesting reciprocating motion. Int. J. Extrem. Manuf. 6, 045502 (2024).

Gwon, G. et al. Development of multi droplet-based electricity generator system for energy harvesting improvement from a single droplet. Funct. Compos. Struct. 6, 035009 (2024).

Kim, B. et al. Environmentally robust triboelectric tire monitoring system for self-powered driving information recognition via hybrid deep learning in time-frequency representation. Small 20, 2400484 (2024).

Hwang, H. J. et al. Integrated system of mechanical regulator and electrical circuitry on triboelectric energy harvesting with near-field communication for low power consumption. Adv. Energy Mater. 15, 2400481 (2024).

Cho, S. et al. Physical intelligence-based working mode adaptable triboelectric nanogenerator for effective wind energy harvesting in broad range. Nano Energy 113, 108608 (2023).

Ra, Y. et al. Portable triboelectric-electromagnetic hybrid biomechanical energy harvester for driving various functional light-emitting diodes with a wide range of wavelengths. Nano Energy 119, 109052 (2024).

Kam, D. et al. Toward droplet energy harvesting in harsh environment: mechanical buckling-induced 3D structured droplet-based electricity multigenerator. Small 21, 250271 (2025).

Yuan, M. Tympanic membrane metamaterial inspired multifunctional low-frequency acoustic triboelectric nanogenerator. Nano Energy 128, 109816 (2024).

Son, J. H. et al. Ultrahigh performance, serially stackable, breeze driven triboelectric generator via ambient air ionizing channel. Adv. Mater. 35, 2300283 (2023).

Zhang, L. et al. Advances in triboelectric nanogenerators in acoustics: energy harvesting and sound sensing. Nano Trends 8, 100064 (2024).

Choi, J., Jung, I. & Kang, C.-Y. A brief review of sound energy harvesting. Nano Energy 56, 169–183 (2019).

Halliday, D., Resnick, R. & Walker, J. Fundamentals of Physics (John Wiley & Sons, 2013).

Zhang, Z. et al. Theory and shape optimization of acoustic driven triboelectric nanogenerators. Mater. Today Phys. 27, 100784 (2022).

Chung, Y. et al. Gigantic triboelectric power generation overcoming acoustic energy barrier using metal-liquid coupling. Joule 8, 2681–2695 (2024).

Guo, H. et al. A highly sensitive, self-powered triboelectric auditory sensor for social robotics and hearing aids. Sci. Robot. 3, eaat2516 (2018). p.

Liu, J. et al. Triboelectric hydrophone for underwater detection of low-frequency sounds. Nano Energy 99, 107428 (2022).

Wang, Z. et al. A universal power management strategy based on novel sound‐driven triboelectric nanogenerator and its fully self‐powered wireless system applications. Adv. Funct. Mater. 31, 2103081 (2021).

Yuan, M. et al. A 3D-printed acoustic triboelectric nanogenerator for quarter-wavelength acoustic energy harvesting and self-powered edge sensing. Nano Energy 85, 105962 (2021).

Zhao, H. et al. Dual‐tube Helmholtz resonator‐based triboelectric nanogenerator for highly efficient harvesting of acoustic energy. Adv. Energy Mater. 9, 1902824 (2019).

Fan, X. et al. Ultrathin, rollable, paper-based triboelectric nanogenerator for acoustic energy harvesting and self-powered sound recording. ACS Nano 9, 4236–4243 (2015).

Cui, N. et al. High performance sound driven triboelectric nanogenerator for harvesting noise energy. Nano Energy 15, 321–328 (2015).

Liu, J. et al. A three-dimensional integrated nanogenerator for effectively harvesting sound energy from the environment. Nanoscale 8, 4938–4944 (2016).

Yang, J. et al. Triboelectrification-based organic film nanogenerator for acoustic energy harvesting and self-powered active acoustic sensing. ACS Nano 8, 2649–2657 (2014).

Naval, S. et al. Mode-coupled synergistic triboelectric device for biomechanical applications. IEEE Sens. J. 24, 2588–2597 (2023).

Wu, Y. et al. Integrated spacer-free triboelectric textiles for subtle movement tracking and natural body motion energy harvesting. J. Mater. Sci. Technol. 232, 294–301 (2025).

Naval, S. et al. Flexible V-shaped piezoelectric-triboelectric device for biomechanical energy harvesting and sensing. J. Phys. D: Appl. Phys. 55, 365501 (2022).

Zhao, D. et al. Eco-friendly in-situ gap generation of no-spacer triboelectric nanogenerator for monitoring cardiovascular activities. Nano Energy 90, 106580 (2021).

Naval, S. et al. Bandwidth tunable vibration energy harvester based on hybrid triboelectric-piezoelectric array. Eng. Res. Express 4, 045022 (2022).

Kam, D. et al. Advancing energy harvesting efficiency from a single droplet: a mechanically guided 4D printed elastic hybrid droplet‐based electricity generator. Adv. Mater. 35, 2303681 (2023).

Kuang, X. et al. Advances in 4D printing: materials and applications. Adv. Funct. Mater. 29, 1805290 (2019).

Fu, P. et al. 4D printing of polymers: techniques, materials, and prospects. Prog. Polym. Sci. 126, 101506 (2022).

Liu, Y. et al. 4D printing of thermal responsive structure for environmentally adaptive radiative cooling and heating. J. Adv. Manuf. Process. 4, e10107 (2022).

Kehret, D. et al. 4D printing of magnetoresponsive soft gripper and phenomenological approach for required magnetical actuation field. Int. J. Adv. Manuf. Technol. 135, 1–3 (2024).

Ren, Z. et al. 4D printing light-driven actuator with lignin photothermal conversion module. Int. J. Biol. Macromol. 253, 126562 (2023).

Shao, L.-H. et al. 4D printing composite with electrically controlled local deformation. Extrem. Mech. Lett. 39, 100793 (2020).

Liu, Y. et al. Quantifying contact status and the air-breakdown model of charge-excitation triboelectric nanogenerators to maximize charge density. Nat. Commun. 11, 1599 (2020).

Nan, K. et al. Soft three-dimensional microscale vibratory platforms for characterization of nano-thin polymer films. ACS Nano 13, 449–457 (2018).

Ning, X. et al. 3D tunable, multiscale, and multistable vibrational micro‐platforms assembled by compressive buckling. Adv. Funct. Mater. 27, 1605914 (2017).

Xu, C. et al. Raising the working temperature of a triboelectric nanogenerator by quenching down electron thermionic emission in contact‐electrification. Adv. Mater. 30, 1803968 (2018).

Somkuwar, V. U. et al. Influence of relative humidity and temperature on the performance of knitted textile triboelectric nanogenerator. ACS Appl. Electron. Mater. 6, 931–939 (2024).

Hu, Y. et al. Effect of humidity on tribological properties and electrification performance of sliding-mode triboelectric nanogenerator. Nano Energy 71, 104640 (2020).

LeCun, Y. et al. Gradient-based learning applied to document recognition. Proc. IEEE 86, 2278–2324 (1998).

Nguyen, K. et al. Iris recognition with off-the-shelf CNN features: a deep learning perspective. IEEE Access 6, 18848–18855 (2017).

Acknowledgements

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) (No. RS-2024-00344920). This work was also supported by the Human Resources Development of the Korea Institute of Energy Technology Evaluation and Planning (KETEP) grant funded by the Ministry of Trade, Industry and Energy of Korea (No. RS-2023-00244330).

Author information

Authors and Affiliations

Contributions

D.K. and G.G. contributed equally to this work. D.K. contributed to conceptualization, data curation, formal analysis, investigation, methodology, software, validation, visualization, writing–original draft, and writing–review & editing. G.G. contributed to data curation, formal analysis, investigation, methodology, software, visualization, and writing–original draft. Y.R. contributed to investigation and software. D.L., Y.K., J.C. and J.W.K. contributed to investigation. D.C. contributed to conceptualization, funding acquisition, project administration, resources, supervision, validation, writing–review & editing. All authors have read and approved the final version of the article.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Kam, D., Gwon, G., Ra, Y. et al. Mechanically guided 4D printing of a triboelectricity-driven acoustic transducer for self-powered and intelligent voice recognition. npj Flex Electron 9, 73 (2025). https://doi.org/10.1038/s41528-025-00451-2

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41528-025-00451-2