Abstract

Understanding hydrogen embrittlement mechanisms requires insights into nanoscale hydrogen isotope segregation in materials. Cryogenic-transfer atom probe tomography (APT) can provide this insight, if the sample exposure is precisely controlled. Therefore, we quantified the nanoscale changes of in austenitic FeCrNi alloy during ultrahigh vacuum transfer using a LEAP 6000 XR APT system with UV laser-assisted and voltage-pulsed modes. We introduced a quasi-in situ method to study deuterium out-diffusion kinetics from electrochemically charged FeCrNi needles, which involved analyzing a deuterium-charged sample using APT, pausing for controlled thermal treatments at room temperature and 150°C, followed by reanalysis. Comparison of experimental results with a heat transfer–hydrogen diffusion model showed that slow deuterium out-diffusion was due to an oxide layer acting as a permeation barrier. These findings highlight the importance of managing sample exposure during cryogenic-transfer APT and demonstrate this quasi-in situ method’s potential for studying hydrogen isotope diffusion in metallic alloys.

Similar content being viewed by others

Introduction

Hydrogen is the lightest, smallest, and the most abundant element in the universe. Hydrogen can diffuse into steel during manufacturing and service, leading to hydrogen embrittlement1,2. This has significant implications for fields such as nuclear fission/fusion reactors, and for the development of future clean energy technologies, where hydrogen interaction with materials plays a critical role3. The mechanistic interpretation of HE in iron alloys involves several theories, including hydrogen-enhanced decohesion, hydrogen-enhanced local plasticity, adsorption-induced dislocation emission, and hydrogen-enhanced strain-induced vacancies3,4. Experimental validation of these mechanisms requires spatially resolved mapping of hydrogen distribution in alloys at near-atomic resolution. Despite its importance, detecting and characterizing hydrogen at the nanoscale remains challenging5.

Traditional methods, such as inert gas fusion6, X-ray or neutron scattering or diffraction7,8, and thermal desorption spectroscopy2,9 have been widely used to quantify hydrogen content in various materials1,3,10. However, these bulk analysis methods are unable to provide spatially resolved nanoscale distribution of hydrogen within a material1. Only a limited number of advanced analytical techniques can map hydrogen distribution in materials at a nanoscale spatial resolution, like time-of-flight secondary ion mass spectrometry (ToF-SIMS)10, scanning kelvin probe microscopy11,12, scanning tunneling microscope13,14, and atom probe tomography (APT)15. Among these methods, APT is the only technique that can provide three-dimensional compositional mapping of hydrogen distribution in materials at sub-nanometer scale spatial resolution5,15. In recent years, an increasing number of studies have used APT to detect hydrogen2,16,17, deuterium4,18,19,20, and hydrides17,21,22 in Fe-4,23,24, Al-25,26, Ti-17,27,28, and Zr-19,22 based alloys in which the hydrogen was introduced following direct ion implantation29, water corrosion19, gas charging29,30,31, electrochemical or cathodic charging2,20,32. Despite the increasing usage of APT for hydrogen detection, the analysis is subject to extreme sensitivity to experimental details like residual hydrogen gas concentration in the analysis chamber, hydrogen isotope loading method, pre- and post-loading and handling of the APT sample, and parameters followed during APT data acquisition, making quantitative analysis of hydrogen distribution still challenging5.

Several researchers have made significant progress toward analyzing hydrogen in materials using APT quantitatively or semi-quantitatively1,2,3,16,17. Deuterium (denoted as D from here onwards), an isotope of hydrogen with a larger atomic mass (2 Da) while exhibiting similar chemical reactivity, is often employed as a substitute for hydrogen in APT studies. This approach helps to mitigate the convolution between hydrogen isotope that is intentionally charged into materials from the hydrogen already within the material and from the residual hydrogen signal from the APT analysis chamber5. Meier et al. compared the voltage pulsed vs. pulsed UV laser APT in D-charged and uncharged materials16. While voltage-pulsing only yielded a clear D-peak (at 2 Da) for D charged specimens, both D-charged and uncharged samples produced significant peaks at 2 Da in laser-pulsing APT, complicating peak assignment. Therefore, voltage-pulsing APT is often recommended for hydrogen analysis of conductive materials to achieve better analytical yields and improved quantification. Chen et al. compared H/D electrochemical charging using electrolytes with different combinations of H2O, D2O, NaOH, and NaOD and demonstrated that D2O, combined with either NaOD or NaOH electrolytes, is equally effective in introducing D into steel specimens, which can be followed by voltage-pulsed APT analysis32.

APT fitted with cryogenic transfer is now the preferred route for quantitative hydrogen-isotope analysis in metals with high hydrogen diffusivity, because it suppresses hydrogen out-diffusion between specimen preparation and analysis1,2,4,5,25,33,34,35,36. The enabling hardware—an ultra-high-vacuum cryogenic transfer shuttle (UHVCTS)—links the focused ion beam (FIB) workstation, glovebox and atom probe chamber without ever exposing the needle to ambient conditions. Although room-temperature transfers have yielded useful measurements after hydrogen charging2,4,37,38, cryogenic UHVCTS transfers are indispensable for environment-sensitive systems25,33,34,35,36 such as magnesium35,39, aluminum25, and iron alloys2,4. Pairing cryogenic FIB milling with cryogenic transfer further suppresses inadvertent hydrogen uptake and hydride formation during specimen preparation2,40.

Recent studies illustrate these benefits. Chen et al.20 used cathodic charging followed by cryogenic transfer-APT to show that hydrogen traps differently in V–Mo–C versus NbC carbides; their follow-up work revealed trapping both at interfaces and at carbon vacancies in the carbide bulk41. Zhao et al.26 mapped grain-boundary and precipitate traps in aluminum alloys, clarifying hydrogen-embrittlement mechanisms. More recently, Barton et al.4 compared the D pick up in pure iron (ferrite) and austenitic FeCrNi alloy after electrochemical charging followed by transfer to the atom probe performed either at room temperature or after cryogenic-plunging prior to APT analysis, revealing that cryogenic plunge freezing and transfer prevented the D out-diffusion from samples. Collectively, these studies demonstrate that maintaining ultra-high vacuum and cryogenic temperature from charging through analysis is essential for preserving the true hydrogen or deuterium inventory in APT specimens.

However, all the aforementioned literature discussion on the cryogenic sample transfer approach predominantly used the CAMEA LEAP 30002,20, 40004,20,25,40,41, and 50002,26,35,36 APT systems. The LEAP 6000 XR is the latest generation of APT with deep UV laser (257.5 nm wavelength) and 52% detector efficiency (DE) compared to 3000 HR (green laser with 532 nm wavelength, 37% DE), 4000 XR (UV laser with 355 nm wavelength, 37% DE) and 5000 XR (UV laser with 355 nm wavelength, ~52% DE)42. Given that the LEAP 6000 XR is the latest APT model, very limited studies37,43 have used LEAP 6000 XR APT for material characterization so far. Notably, no studies have been reported on hydrogen detection following cryogenic-transfer workflow into a LEAP 6000 XR so far. Therefore, we hereby focus on providing the first results from cryogenic-transfer APT utilizing a LEAP 6000 XR APT.

Moreover, studies to date which have analyzed hydrogen isotope diffusion within materials using cryogenic transfer-APT are predominantly focused on examining hydrogen-charged materials immediately after cryogenic transfer1,2,4,5,20,26,30,37. Interestingly, to the best of our knowledge, no efforts have been made to investigate hydrogen out-diffusion from cryogenically transferred, hydrogen-charged samples as they are warmed up to different time periods. The analysis chamber stage within the atom probe is stypically held at cryogenic temperatures, but a given experiment can be interrupted and the sample moved to the instrument’s buffer chamber or load lock (LL) while maintaining vacuum conditions, presenting a quasi-in situ approach to study hydrogen out-diffusion from materials at room or higher temperatures. Such an approach provides a pathway to analyze the Hydrogen out-diffusion and H-trapping in the APT needles. However, this method remains unexplored in the literature. In this work, we test the feasibility and address the challenges of analyzing hydrogen out-diffusion from materials using this quasi-in situ approach.

Results

Cryogenic transfer procedure between PFIB, APT, and N2-Glovebox using UHVCTS

The experimental setup, including the plasma-focused ion beam (PFIB), APT, Ferrovac extension kit connected to an N2-glovebox, and the UHVCTS used for shuttling Fe18Cr14Ni alloy needles between systems is given in Fig. 1a. The FeCrNi model alloy needle, with an apex diameter of 40–100 nm, was prepared via electropolishing followed by annular milling in PFIB. The prepared needle can be seamlessly transferred between the atom probe, PFIB, and N2-glovebox using the UHVCTS, with each system equipped with dedicated docking stations for the UHVCTS suitcase, as shown in Fig. 1a. The electrochemical D-charging experiment is conducted inside the N2-glovebox.

a the overview of the cryogenic transfer-APT system and components including an optical image of the electropolished FeCrNi needle sample, photographs of the PFIB, a LEAP 6000 XR instrument with an ultra-high vacuum cryogenic transfer suitcase (UHVCTS), and N2-glovebox with Ferrovac extension kit and schematic of D-charging set up. Detailed photographs of individual parts of the cryogenic transfer system: b Ferrovac extension kit connected to N2-glovebox c the cryogenic load lock inside the glove box with a receptacle elevator d the receptacle base and support tool used to load APT samples into the receptacle elevator e an APT sample puck with an FeCrNi needle sample sitting on the receptacle base f the puck manipulator used to transfer the APT puck with pre-loaded electropolished FeCrNi wire to the electrochemical charging station inside the N2 glovebox g The electrochemical charging set up with inverted APT puck as working electrode as well as Pt counter electrode (CE) and Ag/AgCl reference electrode (RE) h The 360° rotation cryogenic stage in the PFIB i UHVCTS connected to the LEAP 6000 XR load lock j APT sample puck loaded on to a pre-cooled piggyback puck.

Detailed photographs of individual instrumentation and parts of the cryogenic transfer-APT workflow are presented in Fig. 1b–j. The Ferrovac extension kit allows seamless integration between the UHVCTS and the N2 glovebox (Fig. 1b). A cryogenic Load Lock (LL) with a vertical receptacle elevator allows the transfer of an APT sample puck into and out of the liquid nitrogen (LN2) basin situated within the N2 glove box (Fig. 1c, d). The supporting tool and guide rail within the LN2 basin facilitate the manual removal of the APT puck with the pre-loaded needle sample and then loading it, which is then loaded into the receptacle base (Fig. 1d–f). For electrochemical charging, the APT needle sample pre-loaded in the APT puck is oriented upside down using a puck manipulator located inside the glove box, allowing only the apex of the sample to be immersed in a 0.1 M NaOD electrolyte with 8 g/L thiourea for D electrochemical charging at −2.2 V (vs. Ag/AgCl) for 300 s, as shown in Fig. 1g. During D-charging, the LN2 basin was filled with LN2 (Fig. 1b) for cooling the receptacle base and supporting tool. Following D-charging, the APT puck with the needle sample was placed onto the LN2-cooled receptacle base within 30 s of stopping the power supply, transferred back to the cryogenic LL, and moved to the UHVCTS. It was subsequently transferred to the 360° rotation cryogenic stage installed within the PFIB for annular milling (Fig. 1h). The final needle sample was then transferred from PFIB to the atom probe using UHVCTS. The LN2 dewar attached to the UHVCTS maintained the needle at cryogenic temperatures during the transfer, as shown in Fig. 1i. The so-called ‘piggyback’ puck (also referred to as ‘cryo dock’ or ‘cryo carrier puck’), pre-cooled in the analysis chamber (Fig. 1j), ensures the needle remains at cryogenic temperatures while being transported from the atom probe LL to the analysis chamber for the APT analysis conducted in voltage or laser pulsing modes.

Quantifying the hydrogen and oxygen pickup in FeCrNi alloys during the cryogenic transfer process

First, we aimed to quantify the hydrogen (H) and oxygen (O) pickup on FeCrNi needle samples during the transfer process between the atom probe buffer chamber and N2-glovebox under laser and voltage pulsing modes, referred to as Workflow 1 and presented schematically in Fig. 2a. The FeCrNi needle was prepared via electropolishing, followed by annular milling in PFIB. The prepared needle was first transferred to the atom probe using the UHVCTS for collecting baseline data, first in voltage-pulsed mode and then in laser-pulsed mode, collecting 1 million ions in each analysis. Subsequently, the APT analysis was interrupted, and the needle sample was taken out of the analysis chamber and transferred to the N2-glovebox using the UHVCTS and held in the glove box nitrogen environment for 30 min before transferring it back into the atom probe analysis chamber and conducting laser and then voltage pulsing mode APT analysis. An additional dataset of 0.5 million ions was acquired for each APT analysis to quantify the O and H pickup that occurred cumulatively due to the 30 min glove box exposure and the transfer process to and from the glove box. After that, the APT analysis was again interrupted, and the same needle sample was allowed to warm up to room temperature in the atom probe buffer chamber (maintained between 1.6 × 10−8 to 1.2 × 10−8 torr) for 30 min, followed by transferring the sample back into the atom probe analysis chamber. The recorded pressure in the buffer chamber during the 30 min hold in the buffer chamber is presented in Supplementary Fig. 1. The sample was re-analyzed first in laser pulsing mode and then in voltage pulsing mode immediately after, and an additional dataset of 0.7 million ions each was collected to assess how much O and H pickup occurred in the sample during the 30 min exposure to the buffer chamber vacuum and how the laser vs voltage mode influences the compositional quantification of H and O under the same conditions.

a Illustrative layout for Workflow 1 (for quantifying H & O pickup during transfer process). Overlay of the mass-to-charge spectra peaks with peak indexing for b 0–80 Da, c 23–47 Da, and d 49–80 Da for the APT datasets collected using laser pulsing along with corresponding 1D composition profiles of e H and f O and g bulk H-concentration of the entire reconstruction for the baseline, buffer chamber (30 min), and glovebox (30 min) experimental conditions of Workflow 1.

The mass-to-charge spectra from the APT dataset collected in laser pulsing mode for baseline, buffer chamber (30 min), and glovebox (30 min) conditions are shown in Fig. 2b–d. The laser pulsed mode mass-to-charge spectra for all conditions exhibited similar peaks for H, H2, C, and O in the +1 charge state and C, Fe, Cr, and Ni in the +2 charge state, and Fe, Cr, and Ni peaks in the +1 charge state for all conditions, as indexed in Fig. 2b–d. Moreover, oxide molecular peaks of Fe, Cr, and Ni in both +1 and +2 charge states were observed across all conditions in laser pulsing mode (Fig. 2c, d). For all compositional analysis, overlapping peaks for Cr+2/Fe+2 (at 27 Da), Fe+2/Ni+2 (at 29 Da), Ni+2/O2+2 (at 32 Da), Fe+1/Cr+1 (at 54 Da), and Fe+1/Ni+1 (at 58 Da) was deconvoluted using non-overlapping isotopic peaks and assuming natural abundances.

A 10 nm diameter cylinder was used as a region of interest (ROI) in which to quantify the one-dimensional (1-D) composition profile of the baseline APT data reconstruction where the cylinder ROI was specifically placed well below the top surface of the reconstruction to avoid the PFIB damage layer. This allowed us to quantify the composition of the needle surface at the end of the baseline clean-up APT analysis before it was exposed to buffer chamber or glove box environments. In the case of the APT reconstructions after 30 min exposure in buffer and glove box, the 10 nm cylinder ROI was placed to quantify the composition change right from the top surface of those reconstructions. The 1-D concentration profiles of Fe, Cr, Ni, O, H, C, and N for laser pulsing mode datasets are provided in Supplementary Fig. 2. The hydrogen composition profiles of baseline, 30 min buffer chamber, and 30 min glovebox conditions in laser pulsed mode are presented in Fig. 2e. The hydrogen detected in the baseline clean-up APT analysis condition may result from the hydrogen introduced to the sample during the electropolishing and PFIB annular milling or from the desorption of absorbed hydrogen from the atom probe analysis chamber. After 30 min exposure of the same sample to the buffer chamber or glove box environment, the hydrogen concentrations within the topmost 0.6 nm of the reconstructions increased considerably compared to the end (e.g., bottommost few nm) of the baseline APT analysis (Fig. 2e). Additionally, from the 1-D composition profiles for each of the laser-pulsed mode datasets (given in Fig. 2f), it is clear that oxygen concentrations within the topmost 0.7 nm are increased after buffer chamber (30 min) or glovebox (30 min) exposures compared to the baseline, suggesting near-surface oxidation of the needle samples even during the exposure to the buffer chamber vacuum and glove box environment and during the UHVCTS transfer. The bulk hydrogen concentration quantified from the entire reconstructions after 30 min exposure in the buffer chamber and glove box clearly showed an increase when compared with the H concentration in the baseline APT data (Fig. 2g).

As described above, after 30 min exposure to the buffer chamber and to glove box environments, first, a laser pulsed mode APT analysis was conducted. Each of those laser-pulsed APT analyses was interrupted after collecting at least 0.5 million ions, and a voltage-pulsed APT analysis was conducted immediately afterward to quantify the change between laser and voltage modes of analysis. The mass-to-charge state ratio (m/Z) spectra from the APT dataset collected in back-to-back voltage pulsing modes for baseline, buffer chamber (30 min), and glovebox (30 min) conditions are shown in Fig. 3a, b. The voltage-pulsed mode mass-to-charge spectra for all conditions exhibited similar peaks for H, C, and O in the +1 charge state and C, Fe, Cr, and Ni in the +2 charge state, as indexed in Fig. 3b. Only for the APT reconstruction of the baseline cleanup step, Xenon peaks were observed at 64–68 Da, resulting from beam damage during PFIB sample preparation (Fig. 3a).

The mass-to-charge spectra for a 0–80 Da and b magnified view of 23–35 Da for the APT datasets collected using voltage pulsed mode analysis of the same needle sample and 1D composition profile showing the change in c H-concentration d O-concentration and e bulk H-concentration of the entire reconstructed dataset of baseline, buffer chamber (30 min), and glovebox (30 min) exposed conditions of Workflow 1.

The 1-D concentration profiles of Fe, Cr, Ni, O, H, C, and N for the voltage pulsing mode datasets are provided in Supplementary Fig. 3. The 1-D composition profile of H in the three back-to-back voltage analyses given in Fig. 3c still showed an increased H concentration within the top 0.3 nm of the reconstructions after exposure to the buffer chamber and glove box. Essentially, the H concentration measured at the end of the laser-pulsed analysis and the back-to-back voltage analysis for each of these conditions appeared to differ. The oxygen 1-D concentration profiles from the back-to-back voltage analysis show no apparent surface oxidation, which can be expected since the top oxidized surface of needle samples were already analyzed in the laser mode before (Fig. 3d) and the UHV and cryo conditions within the analysis chamber prevented new oxidation. Moreover, like the observations in the laser mode datasets, in the back-to-back voltage mode datasets also there was clear evidence for increased bulk H concentration in the samples after exposure to the glove box and buffer chamber vacuum for 30 min (Fig. 3e). However, the quantified amount of hydrogen was substantially lower in the case of voltage mode datasets versus laser mode dataset for the same needle sample for the baseline and 30 min exposed conditions. Meir et al. and other authors showed the pulsed laser mode led to the H2 peak at 2 Da in the case of UV laser1,5,16. This observation appears to remain consistent in the case of the deep UV laser used in the LEAP 6000 XR, and therefore possibly directly contributing to an over-estimation of the hydrogen concentration when analyzed in pulsed laser mode. Also given the H2 peak at 2 Da will overlap with the D peak, for the electrochemical D charging experiments in Workflow 2, we only used voltage mode of analysis.

This detailed understanding of the changes to the near-surface H and O concentration of APT needle samples during the transfer process to the atom probe buffer chamber and glove box allows us to better understand the changes in the composition of D-charged samples measured before and after cryogenic transfer APT, which is described next.

Quantification of D pickup and desorption kinetics from the electrochemically D-charged FeCrNi model alloy

The quantification of D pickup after electrochemical D charging in the N2-glovebox and D desorption kinetics after sequential warm-up inside the atom probe buffer chamber is investigated in Workflow 2, as presented in Fig. 4a. Initially, a second needle of FeCrNi alloy was prepared via electropolishing, followed by PFIB annular milling. The PFIB-prepared FeCrNi needle was initially transferred to the atom probe instrument via the UHVCTS for baseline measurements in voltage pulsing mode (Fig. 1a). After collecting the baseline APT data, the needle was transferred to the glovebox via the UHVCTS, facilitated by the Ferrovac extension kit for the D-charging experiment (at −2.2 V (vs. Ag/AgCl) for 300 s in 0.1 M NaOD electrolyte with 8 g/L thiourea as a recombination poison). Post-charging, the needle was immediately plunged in LN2, frozen, and transferred by UHVCTS first to the PFIB to remove frost, then to the APT analysis chamber to quantify D pickup in voltage-pulsed mode. After collecting at least 1 million ions, the APT experiment was interrupted and the needle sample transferred to a carousel in the buffer chamber (without piggyback puck) to be held at room temperature for 30 min before returning to the analysis chamber to resume followed by voltage-pulsed APT analysis. The APT analysis was again interrupted after collecting 1 million ions and then the sample was transferred back to the buffer chamber and held for an additional 90 min at room temperature on the same regular carousel slot and transferred back into the analysis chamber and analyzed again in voltage pulsed mode. During the warm-up, the buffer chamber vacuum fluctuations were recorded and are presented in Supplementary Fig. 4. The buffer chamber vacuum fluctuated between 4 × 10−8 and 1 × 10−7 Torr during the 30-min hold and between 3.5 × 10−8 and 4.5 × 10−7 Torr during the 90-min hold. The analysis chamber vacuum during the APT runs of baseline, D-charged, 30-min, and 90-min hold conditions are monitored and displayed in Supplementary Fig. 4c–f, respectively. This 30-min and 90-min warm-up of the D-charged sample in the buffer chamber, followed by APT analysis, was conducted to analyze the D out-diffusion from the sample at room temperature.

a Graphical representation of Workflow 2 (D electrochemical charging experiment). Comparisons of b m/Z spectra, c 1-D concentration profile of D, d 1-D concentration profile of oxygen, e bulk concentration of D, and f reconstructed ion maps of D+ and O+, for the APT experiments of baseline, D-charged, 30 min and 90 min warm up in buffer chamber conditions.

The APT mass-to-charge spectra of baseline, D-charged, and after 30 min and 90 min warm up in buffer chamber exhibited similar peaks for H, O, N, Fe, Ni in +1 charge state and C, Fe, Cr, and Ni in +2 charge state (Fig. 4b). Additionally, the oxide molecular peaks of Fe, Cr, and Ni in +1 and +2 charge states are observed in all four conditions. The oxide molecular peaks were most predominant in D-charged conditions. The carbon peaks at 6 and 12 Da were observed only initially in the baseline cleanup APT reconstruction, which could be minor surface contamination. The D peak at 2 Da was observed in D-charged, buffer chamber 30 min and 90 min warmed conditions.

Like the data analysis for Workflow 1, a 10 nm diameter cylinder was used to quantify the 1D composition profile of the baseline clean-up APT reconstruction where the cylinder ROI was specifically placed well below the top surface of the reconstruction to avoid any PFIB surface damage layer. This allowed us to quantify the composition of the needle surface at the end of the baseline clean-up APT analysis before it was electrochemically charged with D. In the case of the APT reconstructions after D charging and warm-up for 30 min and 90 min in the buffer chamber, the 10 nm cylinder ROI was placed to facilitate the quantification of the composition change right from the top surface of those reconstructions. The 1D concentration profiles of Fe, Cr, Ni, O, H, C, and N for the baseline, D-charged, 30-min, and 90-min warmed samples in the buffer chamber are provided in Supplementary Figs. 5 and 6. The overlay of 1D composition profiles of D, and O in the baseline, D-charged, 30-min, and 90-min warmed samples in the buffer chamber are given in Fig. 4c, d, respectively. At the end of the baseline condition, the D and O concentrations were notably low. However, after the electrochemical D charging, cryogenic transfer of FeCrNi samples from the N2-glove box to PFIB and then to LEAP 6000 XR using UHVCTS resulted in a significant increase in the near-surface concentrations of O, which interestingly coincided with a near-surface depletion of D. We attribute this oxygen enrichment to surface oxidation of the sample that occurred during transfer from PFIB cryogenic stage to UHVCTS cryogenic stage. The D concentration deeper in the needle was highest after the electrochemical charging and cryogenic transfer. The bulk D concentration is quantified and plotted in Fig. 4e, along with corresponding ion maps in Fig. 4f. Following D-charging, the bulk D concentration peaked at ~1.36 ± 0.01 at% and declined to ~1.15 ± 0.01 at% after 30 min and ~0.71 ± 0.005 at% after 90 min of warming at room temperature in the buffer chamber vacuum, signifying the D out-diffusion from the sample.

Interestingly, following the 90-min warmup in the buffer chamber, although the bulk D concentration decreased, the local D concentration near the top surface of reconstruction within ~1 nm depth increased to ~7 at%. After the 90-min warmup in the buffer chamber, we noticed a minor increase in O concentration within the top 0.5 nm of the APT reconstructions (Fig. 4d, green curve). This region with high O concentration on the needle surface might have acted as a diffusion barrier leading to a near-surface accumulation of D. These findings underscore the dynamic desorption behavior of D and the interactions between oxygen, and the FeCrNi needle sample after D charging and during warm-up to room temperature in the buffer chamber environment.

Time resolved investigation of D desorption kinetics under progressive heat treatments

The third experimental Workflow 3, depicted in Fig. 5a, systematically examines the quantification of D uptake after electrochemical D charging, warming to room temperature within the buffer chamber, and gradual heating to 150 °C in the atom probe LL. A third FeCrNi alloy needle was fabricated through electropolishing followed by PFIB annular milling. Additionally, after the electrochemical charging, Transmission Kikuchi Diffraction (TKD) was performed on the FeCrNi needle to ascertain the crystallographic orientation at the needle apex. Supplementary Fig. 7 presents a micrograph of the FeCrNi needle alongside an inverse pole figure map. The apex of the needle exhibits a marked <111> orientation along its longitudinal axis. To eliminate any carbon deposition resultant from the TKD process, the needle tip was subjected to a low kV ion shower after TKD.

a Visual layout of Workflow 3 (D quantification during progressive heating). Comparisons of b m/Z spectra, c 1-D concentration profile of D, d 1-D concentration profile of oxygen, e bulk concentration of D, and f reconstructed ion maps of D+ and O+ for the APT experiments of baseline, D-charged, 30 min warm up in buffer chamber, 10 min, 30 min and 7 h heating in load lock conditions.

Consistent with the procedure in Workflow 2, the prepared FeCrNi needle was transferred to the atom probe using UHVCTS for baseline assessment under voltage pulsing conditions. Following the baseline APT analysis, the needle was transferred to the nitrogen-filled glovebox via UHVCTS for D-charging. The D-charging was conducted similar to Workflow 2, and post D-charging, the needle was rapidly submerged in LN2 and transferred at cryogenic temperatures to the PFIB removal of any frost formed by low kV milling. After the frost removal, TKD was conducted on the sample at cryogenic temperatures, and post-TKD, an additional 60–100 nm of material was carefully milled away to mitigate potential beam-induced artifacts44. Subsequently, the needle was transferred using UHVCTS at cryogenic temperatures to the APT for analysis in voltage pulsing mode to quantify D uptake. The APT analysis was paused after collecting 2 million ions, and the needle was transferred to the atom probe buffer chamber and placed on a regular carousel slot, without the piggyback puck, for a 30-min warming period at room temperature, similar to Workflow 2. During the warm-up period, vacuum fluctuations in the buffer chamber were monitored and are detailed in Supplementary Fig. 8a. The vacuum within the buffer chamber ranged between 1 × 10−8 and 3 × 10−7 Torr throughout the 30-min hold period. After this duration, APT analysis in voltage pulsing mode was resumed, and 1 million ions were collected. Again, the APT analysis was stopped and the needle was transferred to a regular carousel slot (without the piggyback puck) within the LL, where it was subjected to heating at a rate of approximately 1.45 K/min. The vacuum fluctuations recorded in the LL during this process are presented in Supplementary Fig. 8b, showing a range between 2.4 × 10−9 and 3.6 × 10−9 Torr during a 10 min heating. Subsequently, the needle underwent APT voltage pulse analysis again, resulting in the collection of an additional 1 million ions. The analysis was paused once more, and the needle was returned to the LL for further heating over a 30 min period, post which another APT analysis was conducted, yielding 1 million ions. During this heating cycle, the vacuum in the LL chamber fluctuated from 2.3 × 10−9 to 1.9 × 10−8 Torr, as indicated in Supplementary Fig. 8c. The analysis cycle was iterated further, with the needle subjected to a 7 h heating in the LL, followed by APT analysis, collecting an additional 2 million ions, with LL vacuum levels ranging from 2.4 × 10−9 to 3.3 × 10−6 Torr over the 7 h heating period. The needle underwent a 2 h hold in the buffer chamber prior to the prolonged 7 h heating session. For simplicity, this combined process is referred to as “7 h heating in the LL”. Supplementary Fig. 9 presents the analysis chamber pressure monitored during warmups in the buffer chamber and heating in LL. This systematic warm-up and heating of the D-loaded sample within both the buffer and LL chambers, paired with successive APT analysis, was undertaken to understand the D desorption kinetics and evaluate the duration necessary for completing the D out-diffusion from the sample.

The APT mass-to-charge spectra for the baseline condition, the D charged, and after 30 min warm up in buffer chamber, 10 min, 30 min and 7 h heating in LL exhibited consistent peaks for H, O, N, Fe and Ni in the +1 charge state, as well as C, Fe, Cr, and Ni in the +2 charge state (Fig. 5b). Additionally, molecular oxide peaks of Fe, Cr, and Ni in both +1 and +2 charge states were detected across all six experimental conditions, with the oxide peaks being most pronounced in the D-charged states. Carbon peaks at 6 and 12 Da were observed in the APT reconstruction following 7 h of heating in the LL condition. The D peak at 2 Da was apparent in the D-charged conditions and persisted through the 30-min warm-up in the buffer chamber and the 10-min, 30-min, and 7-h heating periods in LL.

Consistent with the procedure outlined in Workflows 1 and 2, a 10 nm diameter cylindrical ROI was utilized to quantify the 1D composition profile of the baseline clean-up in the APT reconstruction. The cylinder-shaped ROI was positioned well below the top surface, similar to workflow-2. For the APT reconstructions following D-charging, subsequent warmup, and heating, a 10 nm cylindrical ROI was defined to enable precise quantification of compositional changes starting from the top surface of each reconstruction. The ID concentration profiles of Fe, Cr, Ni, O, H, C, and N for the baseline, D-charged, subsequent warmup, and heating conditions are presented in Supplementary Fig. 10. Overlaid 1D concentration profiles for D, and oxygen across all six experimental conditions are illustrated in Figs. 5c, d. Initially, in the baseline condition, the concentrations of D, and oxygen were notably low. However, following electrochemical D charging, there was a marked increase in the near-surface concentrations of oxygen (e.g., topmost ~9 nm), along with the depletion of D, a pattern similarly observed in Workflow 2. Notably, the D concentration was maximally observed deeper in the needle (below ~9 nm) post-D-charging. A similar trend was observed in the warmup and heating conditions i.e., higher D-concentrations right after the O-concentration spike.

The bulk concentrations of D are quantified in Fig. 5e, with corresponding ion maps presented in Fig. 5f. Initially, the bulk D-concentration in the baseline condition was the lowest (~0.02 at%) and increased to ~2.53 at% following D-charging. After a 30 min warmup in the buffer chamber and 10 min of heating in the LL conditions, the D concentration slightly increased to ~2.88 and ~2.94 at%, respectively. Prolonged heating periods of 30 min facilitated the D outward diffusion, and the D concentration was recorded as ~1.65 at% and further decreased to ~0.06 at% after 7 h of heating in LL.

Discussion

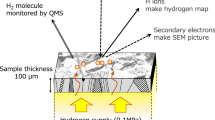

Deuterium desorption kinetics as a function of nanoscale oxide layer

In both Workflows 2 and 3 a nanoscale surface oxide layer formed over the needle surface (Figs. 4f and 5f), primarily composed of chromium and iron oxides. This oxide layer formed when the D charged sample is transferred into the APT after PFIB cleaning of frost formed on the surface. This oxide layer can function as a diffusion barrier for hydrogen and its isotopes emanating from the bulk material45. The characteristics of hydrogen diffusion and permeation vary among different oxides due to variations in chemical composition, atomic structure, and the thickness of the oxide layers45,46. Among the iron-based alloys, iron oxide and chromium oxide are the most prevalent oxides. The literature clearly indicates that chromium oxide functions effectively as a permeation barrier for hydrogen and its isotopes47,48,49,50. Ishikawa et al.49,50 conducted a study on D permeability in different grades of stainless steel, focusing on variations in the thickness of iron and chromium oxide layers. The oxide layers in their study were formed under controlled atmospheric conditions with specific oxygen partial pressures to yield either iron oxide or a combination of iron and chromium oxides. Their study concluded that a chromium oxide layer of ~10 nm is adequate to serve as a permeation barrier for hydrogen and its isotopes, whereas the effectiveness of iron oxide as a barrier is largely independent of the film thickness50. Other studies show that the diffusivity of hydrogen in iron oxide is much slower than metallic iron at ambient temperature51. In agreement with Ishikawa et al.49,50, many studies reported49,52,53,54 that D permeability in the oxide layer tends to decrease with reductions in both pressure and temperature.

These past studies describing the role of the oxide layer as a permeation barrier for hydrogen isotopes in Fe-based alloys provide a framework for correlating the observed variations in D diffusion between Workflow 2 and Workflow 3. The thickness of the oxide layer formed on the D-charged needle surface was ~5 nm in Workflow 2 and ~10 nm in Workflow 3, as shown in Figs. 4d and 5d. After the APT analysis of the D-charged condition, the oxide layer on the needle apex will be removed, yet the lateral oxide film along the surface of the needle below the field evaporated region of the needle apex will remain intact. Thereafter, when the needles were transferred to the buffer chamber for a 30-min warm-up, D could diffuse outwards from the needle in all directions, and simultaneously, a much thinner but high oxygen-concentration layer could form at the needle apex (Fig. 6). The D diffusion rate out of the needle apex is presumed to be faster compared to the diffusion out of the lateral surface of the needle below the apex because of the oxide layer thickness variation. We attribute the greater lateral oxide layer thickness in workflow 3 to be contributing to the longer retention of D in workflow 3 compared to workflow 2 (Fig. 6a, b).

Schematic presenting the D outward diffusion kinetics as a function of oxide film thickness in a Workflow 2 and b Workflow 3. Note: The needles corresponding to Workflows 2 and 3 are electrochemically charged under similar conditions. Oxide layer variation in Workflow 2 and 3 needles likely formed during brief exposure to relatively high pressures (~10−6 Pa) while transferring the D-charged sample between cryogenic stages via VCTM.

It is also to be noted that during D charging, the needle apex is manually immersed inside the electrolyte. We approximate the length of sample immersed inside the electrolyte to be <500 microns and this entire submerged volume should be charged with D although the top few 100 nm is usually analyzed in APT. The D concentration within the rest of the needle could potentially act as a reservoir, supplying D to the needle apex during subsequent warm up steps of Workflows 2 and 3, especially when a lateral oxide formed all along the needle surface limits lateral out-diffusion of D. The combined effect of a thicker lateral oxide film, freshly forming oxide film at the needle apex and reservoir D diffusion in Workflow 3, presumably resulted in higher D concentrations compared to Workflow 2. A comparable explanation holds for the 90 min buffer chamber condition in Workflow 2 and 10 min LL condition in Workflow 3.

During the prolonged 30 min and 7 h LL heating, the external thermal driving force accelerated D outward diffusion, leading to a significant reduction in D concentration (Fig. 5e). Post 7 h treatment, a thin oxide layer of less than 0.5 nm was observed, alongside residual D concentrations at the needle apex. Notably, even extensive 7 h heating proved inadequate for completely removing D from the needle. This underscores the role of the oxide film as a permeation barrier, significantly impeding D outward diffusion.

Temperature evolution and D diffusion calculations following warm-ups and heat treatments in Workflows 2 and 3

To determine the D diffusion kinetics following each warm-up and heating step in Workflow 2 and 3, we developed a heat transfer model coupled with a D diffusion model. The heat transfer between the sample puck and the carousel assembly was simulated to estimate the temperature changes after the 30 min and 90 min warm-up periods in Workflow 2, as well as the 30 min warm-up, and 10 min, 30 min, and 7 h heating phases in the LL conditions of Workflow 3.

The heat transfer model comprised the cryogenic APT puck, made of Tellurium Copper 145 alloy (0.4–0.7% Te and 0.004–0.12% P) and weighing 9.8 grams, and the Al6061 carousel with a 0.001 inch pure Ni coating, weighing 93 grams. Using Fourier’s law, heat transfer was calculated, considering the puck and the FeCrNi needle as a single unit and the carousel as an adjacent unit with a contact area between puck and carousel of 288 mm². The contact area was calculated by the 3D carousel puck assembly drawings from CAMECA. The intial temperature of the puck was considered to be 70 K (the set point of the sample temperature during APT experiments) and the carousel was considered to be constant at 298 K. Based on these assumptions, our simulations indicated the puck reaching 298 K in ~1.01 min, staying constant throughout 30 min and 90 min warm-up period, as presented in Supplementary Fig. 13a. In Workflow 3, the initial puck temperature is 70 K, and the carousel is heated at a rate of 1.45 K/min to reach 150 °C (~423 K) and continues to heat at 150 °C until stopped32. Based on the model, the temperature reached 313 K after 10 min and 342 K after 30 min of the heat treatment in the LL, as depicted in Supplementary Fig. 13b. During the 7 h heat treatment, the puck’s initial temperature was at 298 K (the sample was held in the buffer chamber for 2 h before heating) and reached 423 K within 1.44 h, maintained constant throughout the 7 h heating period, as shown in Supplementary Fig. 13c. Details of the heat transfer simulations and results are presented in the supplementary section—Heat transfer model.

From the temperature calculations of the heat transfer model, diffusion simulations were performed to analyze D concentration in the charged needles after buffer chamber warmup and LL heat treatments. The 10 min and 30 min heat treatments were modeled as isothermal holds at the final temperatures (313 K and 342 K, respectively).

The APT needle was modeled as a finite cylinder of radius 100 nm and height 500 nm using initial D-concentration (~2.5 at%) determined from the APT datasets. From our simulation, the D-concentration in the APT needles without a D reservoir (as mentioned in the Discussion on Deuterium desorption kinetics as a function of nanoscale oxide layer) is expected to diminish below APT detection limits within minutes at room temperature, with significantly faster depletion at higher temperatures, as presented in Supplementary Fig. 14. Considering the D reservoir, D remains detectable throughout the buffer chamber warmup at 298 K and during heat treatments at 313 K and 342 K until being depleted in 4 min at 423 K, as shown in Supplementary Fig. 15. With the D reservoir, D remains detectable under warm-up and brief heat treatment conditions, emphasizing the reservoir’s role as a sustained D source. In our simulations, we modeled D diffusion within the APT needle by assuming that the D atoms diffuse through the material at a slower rate than they are ejected from the surface. In addition, we assumed a uniform diffusion coefficient to simplify the complex interactions occurring at the atomic level. Detailed setup, methodological specifications, and results of this model are provided in the Supplementary section—Diffusion model calculations for a variable reservoir model. These findings are consistent with present experimental results indicating detectable D after the buffer chamber warmups and shorter heat treatments in the LL. However, simulated D content post-warm-up or brief heat treatments were lower than experimental results, a discrepancy also noted in prior electrochemically charged APT experiments55.

Connecting back to the experimental results, the discrepancy in the D-concentration from the model calculations post-warmup and heat treatments can be explained by the oxide layer observed on the needle surface. This oxide layer mainly formed during the transfer of the D charged sample from PFIB to APT using the VCTM. Only during this transfer, the final needle was exposed to lower vacuum level of ~10−6 Pa briefly when the sample is transiting from the PFIB cryogenic stage to the UHVCTS cryogenic stage. This oxide layer acting as a permeation barrier retards the mobility of D outward diffusion is inevitable and thus necessitates adjustments in the theoretical models to account for the decreased diffusion rates through the oxide layer. Therefore, accurate modeling of D diffusion must incorporate both the uniform diffusion coefficient within the bulk material and the modified diffusion characteristics imparted by any oxide layer.

We would like to disclaim that the D concentrations observed following electrochemical charging in Workflows 2 and 3 significantly exceed the thermodynamically predicted solubility limits for D in austenite. The variation in crystallographic orientation of the needle apex could also modify the D concentration even in the same alloy as shown in Workflows 2 and 3. Nevertheless, these elevated D concentration values are consistent with previous APT studies reporting D levels above 1000 ppm across various alloys2,4,38,44. This apparent discrepancy may be explained by the logarithmic relationship between electrochemical potential and hydrogen fugacity, as described by the Nernst equation56. Under an applied potential of −2.2 VAg/AgCl within an electrolyte containing thiourea as H-recombination poison, the local hydrogen fugacity can effectively reach pressures well above 1 atm, thereby increasing hydrogen solubility in steels57. Our future investigations will focus on systematically evaluating how different electrochemical charging conditions influence the D uptake and desorption from the same sample using the quasi-in situ approach with an aim to further refine our understanding of hydrogen behavior in metallic alloys and improve measurement accuracy.

In summary, we first analyzed the nanoscale compositional changes near the top surface of an austenitic Fe18Cr14Ni alloy needle sample during the cryogenic transfer process and after prolonged exposure to the buffer chamber vacuum at room temperature. To achieve this, we did a series of experiments using laser and voltage modes on the same FeCrNi alloy needle sample. The needle sample was first analyzed in voltage and laser mode to obtain a quantitative analysis of H and O within the sample initially. Subsequent exposure of the same needle sample in the buffer chamber vacuum for 30 min revealed surface oxidation and hydrogen absorption. The same sample was also transferred to the glove box using UHVCTS, then held in the glove box for 30 min and transferred back into the atom probe, which led to a higher extent of oxidation and H ingress. The comparison of back-to-back laser-pulsed and voltage-pulsed analysis (Workflow 1) revealed that laser-pulsing tends to overestimate the hydrogen concentration in the samples, and the H2 peak at 2 Da observed previously with longer wavelength laser systems was also observed when using the deep UV laser in the LEAP 6000 XR. This understanding of the influence of sample exposure during the transfer process was then used to better interpret the results of a second needle sample (Workflow 2) that was D-charged electrochemically and cryogenically transferred to PFIB and then to the atom probe using UHVCTS. In addition, subsequent measurement of changes in D, H, and O concentrations in the same needle due to 30 min and 90 min warm-ups to room temperature within the buffer chamber aided in analyzing the D-desorption kinetics from the D-charged FeCrNi alloy sample. The D concentration in the sample progressively reduced during the warm-up time in the buffer chamber. Experiments conducted on a third FeCrNi alloy needle sample revealed the influence of a thicker surface oxide layer on modifying the D diffusion kinetics during the quasi-in situ approach (Workflow 3). The experimental findings were compared with a heat transfer model and hydrogen diffusion model to further highlight the role of surface oxides on delaying hydrogen diffusion by acting as a permeation barrier. The findings from this work provide a detailed description of the factors to be considered during the cryogenic transfer APT experiments and its potential to achieve a nanoscale understanding of hydrogen diffusion kinetics within metal alloys, which could be applied to a broad class of metal alloys.

Methods

Experimental methods

Fe18Cr14Ni alloy was fabricated by induction melting high-purity elements, followed by casting and homogenizing through five remelting cycles. These alloys were subsequently cold rolled to reduce their cross sectional area by 50% and recrystallized into 3 mm thick sheets by annealing at 900 °C for 4 h. Using electric discharge machining, bars with a 1 mm² cross-section were cut from the fabricated Fe18Cr14Ni alloy. These bars were ground and polished on all sides, progressively using finer grits to a 1 µm diamond suspension. The prepared 1 mm² bars were sharpened into needles using a two-step polishing procedure. Initially, coarse polishing was performed with a 25% perchloric acid solution in glacial acetic acid. This was followed by fine polishing using a 2% perchloric acid solution in 2-butoxyethanol.

Thermo Fisher Helios Hydra plasma-focused ion beam (PFIB) with Xe plasma was used to final polish the needles to 40–80 nm apex diameter following the annular milling process. The ion milling process was carried out at a voltage of 30 kV, gradually decreasing the current, with the final milling step performed at 2 kV and 10 pA. TKD was performed using Thermo Fisher Helios Hydra equipped with an EBSD detector. Measurements were conducted on the PFIB polished needle (before the start of Workflow 3) at accelerating voltage of 30 kV with a step size of 0.01 µm. Data acquisition and indexing were carried out using Oxford Aztec software. APT was conducted using a CAMECA local electrode atom probe (LEAP) 6000 XR, operating in voltage-pulsing mode with a 0.20 voltage pulse fraction or laser-pulsing mode with 25 pJ laser pulse energy while maintaining 200 kHz pulse frequency and a target detection rate of 0.005 ions per pulse. The sample temperature was maintained at 50 K for all APT data collection in workflow 1. The collected APT data was reconstructed and analyzed using Interactive Visualization and Analysis Software (IVAS version 6.3). The ultra-high vacuum cryo transfer shuttle (UHVCTS, Ferrovac) suitcase was used to transfer samples between the PFIB, the APT LEAP 6000, and the N2-glovebox. In Workflow 2, the D desorption experiments were conducted by warming the samples within the LEAP buffer chamber for 30 and 90 min and followed by APT data collection in voltage-pulsing mode. For the APT experiments of D charged samples, the sample temperature was maintained at 70 K. All the experiments and analyses for Workflows 1 and 2 were repeated twice for reproducibility. In Workflow 3, the D desorption experiments were conducted by warming the samples within the LEAP buffer chamber for 30 and then heating for 10 min, 30 min and 7 h in LL chamber and followed by APT data collection in voltage pulsing mode. For the APT experiments of D charged samples, the sample temperature was maintained at 70 K.

Electrochemical experiments were carried out using an Ossila potentiostat with a FIB-prepared FeCrNi needle acting as the working electrode (WE), Ag/AgCl (0.1 M KCl) as the reference electrode (RE), and Pt wire as the counter electrode (CE). The FIB-prepared FeCrNi needles were subjected to -2.2 VAg/AgCl constant voltage for 300 s in 0.1 M NaOD with 8 g/L thiourea electrolyte for D electrochemical charging. Prior to the electrochemical experiments, the open circuit potentials were recorded while the specimen was stabilized in the test electrolyte for 100 s. All the electrochemical experiments were conducted inside the N2 glovebox while maintaining <1 ppm oxygen and <10 ppm moisture.

Heat transfer model

To investigate the temperature evolution during buffer chamber warmup and heat treatments, we simulated the heat conduction between the carousel and puck, Supplementary Fig. 10.

During the buffer chamber warmup, the puck maintained at 70 K in the analysis chamber was allowed to rest on the carousel maintained at room temperature 298 K for 30 and 90 min. Because of contact with the vertical transfer arm, the carousel temperature is expected to remain constant at the room temperature throughout this warmup. The equilibrium temperature is therefore 298 K. Then, heat transferred \(({dQ})\) may be calculated using Fourier’s Law of Heat Conduction:

Where, \({T}_{{Carousel}}\) and \({T}_{{Puck}}\) are temperature of the carousel and puck, respectively; \(A\) is the contact area between the two, measured to be \(288\,{{mm}}^{2}\); \(U\) is the thermal conductance in W/m2K. Rc is the specific contact resistance in m2K/W. The thermal conductance for the Carousel | Puck interface was calculated as per Bagrets et al.58.:

Where m is the number of contacts, assumed to be 1; \({l}_{{Carousel}}\) and \({l}_{{Puck}}\) are the total thicknesses of the carousel and puck, respectively. \({\lambda }_{{Carousel}}\) and \({\lambda }_{{Puck}}\) are the thermal conductivities of the materials constituting the carousel and puck, respectively. \({k}_{{composite}}\) is the composite thermal conductivity of the Puck | Carousel system calculated as follows:

We then used numerical calculations using the finite difference method to calculate the temperature evolution of the puck. Assuming a finite time step \(\Delta t\), \(\Delta {Q}^{i}\) at the ith time step can be calculated as:

Then, temperature of the puck at this time step is given by

Where \({c}_{{Puck}}\) is the specific heat capacity of the puck and \({m}_{{Puck}}\) is the mass of the puck. Equilibrium is reached when \({T}_{{Carousel}}^{i}-{T}_{{Puck}}^{i} < 0.01{K}\). The temperature evolution during the buffer chamber warmup is given in Supplementary Fig. 13a. After reaching room temperature around 1 min, the puck maintains this temperature for the entire duration of the warmup.

To simulate the heat treatment in LL, we assume uniform heating of the carousel and puck. Based on LL pressure changes, we estimated that equilibrium temperature of 423 K is reached after about 1.44 h. We assume a linear heating rate of the carousel in the present calculations for simplicity. During the heatup to 423 K,

Beyond the heatup, the puck and carousel are maintained at 423 K until the heat treatment is stopped. Based on this model, the puck temperature was simulated to be 313 K, 342 K, and 423 K after heat treatments for 10 min, 30 min, and 7 h, respectively Supplementary Fig. 13b, c. All the constants used are summarized in Supplementary Table 1.

Diffusion model calculations for a variable reservoir model

We conducted simulations to observe the variations in D content within the charged needles, based on temperatures corresponding to the buffer chamber warmup and LL heat treatments. Currently, in our setup, it is challenging to manually control the depth at which the needles are submerged in the electrochemical bath. As a result, an additional volume of the needle, immediately adjacent to the APT tip, may also become charged with D. This additional volume could act as a temporary reservoir, supplying D to the APT tip until it is depleted. The APT tip resembles a finite hemi-ellipsoid with a high surface area. For simplicity, a finite cylinder was used to for the diffusion model, which is comparable with prior diffusion calculations on APT tips55. In our calculations, we assume that both the APT tip and the reservoir are finite cylinders. The APT tip is modeled with a radius of 100 nm and a height of 500 nm, while the reservoir is modeled with a radius of 10 μm and a height of 50 μm. To model diffusion through a solid finite cylinder:

However, assuming homogenous distribution of C wrt \(\phi\),

Initial conditions:

From the APT experiments, the initial concentration of D was determined to be 2.5 at%. This concentration was converted into units of mol/m³ by multiplying it by the molar mass of the needle and dividing by the material’s density. The molar mass, calculated from our APT datasets, was found to be 52.5 g/mol, and a density of 7.85 g/cm³ for 316 stainless steel59 was used in the calculation. We assume the same initial concentration of the needle and reservoir.

Then, boundary conditions for reservoir:

At every time step \(i\), average composition of the reservoir \({C}_{{reservoir}}^{i}\) is obtained by solving the above partial differential equation (PDE) using the finite volume method60. To validate the model, an analytical approximation was employed to calculate the average concentration of D in the reservoir at time \(t\). This approximation uses Dilthey’s solution, which has previously been utilized to study diffusion in pipeline steels61.

This formulation uses the roots of Bessel function \({\alpha }_{n}\). The first 5 roots of Bessel function were used to calculate the above expression.

Further, D in the above equation is the diffusion coefficient is calculated using

Where \({D}_{0}\) is diffusivity (\({m}^{2}/s\)), \({E}_{a}\) is the activation energy \((J/{mol})\), R is the universal gas constant (8.314 Jmol−1K−1), and T is the absolute temperature in K.

Then, the PDE for the tip was solved noting the following boundary conditions:

The simulations were stopped as soon as the tip composition \({C}_{{tip}}^{i}\) decreased to below the detection limit of APT. The detection limit for D was calculated from APT datasets using the Poisson counting statistics to be 0.015 at%, such that \(\frac{{C}_{{tip}}^{{stop}}}{{C}_{0}} < 0.0059\).

Because the diffusion parameters for low-temperature D diffusion in \(\gamma -{Fe}({FCC})\) or steels are not available, we extrapolated high-temperature Arrhenius equations for 316SS from data reported in Lee et al.48. The calculated room temperature diffusion parameter for steel \((1.15\times {10}^{-16}\,{m}^{2}/s)\) is in good agreement with the experimentally measured diffusion parameter of \(1.4\times {10}^{-16}\,{m}^{2}/s\) at 298 K62.

With no reservoir and no oxide barrier, the D content of the APT tip falls below the measurement threshold in slightly over a minute at room temperature, 21 s at 313 K, 3 s at 342 K, and less than a second at 423 K, Supplementary Fig. 13. As shown in the figure, the modeled D-content is in good agreement with the analytical solution.

When the reservoir is considered, average D content in the tip is detectable throughout the buffer chamber warmup (total 2 h) at 298 K, after a 10 min long hold at 313 K, and after a 30 min long hold at 342 K. At 423 K, however, all the D content of the tip is eliminated in about 4 min, Supplementary Fig. 15. The analytically calculated D-concentration ignoring the reservoir is also presented in Supplementary Fig. 14 to demonstrate the impact of the reservoir on the temporal evolution of D-concentration in APT tips.

Data availability

The data can be made available upon reasonable request.

Code availability

Code for heat transfer and hydrogen-diffusion are available upon reasonable request.

References

Chen, Y.-S. et al. Atom probe tomography for the observation of hydrogen in materials: a review. Microsc. Microanal. 29, 1–15 (2023).

Breen, A. J. et al. Solute hydrogen and deuterium observed at the near atomic scale in high-strength steel. Acta Mater. 188, 108–120 (2020).

Chen, Y.-S. et al. Hydrogen trapping and embrittlement in metals—a review. Int. J. Hydrog. Energy https://doi.org/10.1016/j.ijhydene.2024.04.076 (2024).

Barton, D. J. et al. Towards quantitative analysis of deuterium absorption in ferrite and austenite during electrochemical charging by comparing cyclic voltammetry and cryogenic transfer atom probe tomography. Int J. Hydrog. Energy 50, 30–40 (2024).

Gault, B. et al. Towards establishing best practice in the analysis of hydrogen and deuterium by atom probe tomography. Microsc. Microanal. https://doi.org/10.1093/mam/ozae081 (2024).

Weiss, Z. Analysis of hydrogen in inorganic materials and coatings: a critical review. Hydrogen 2, 225–245 (2021).

Yang, L. X. et al. Three-dimensional hydrogen distribution and quantitative determination of titanium alloys via neutron tomography. Analyst 145, 4156–4163 (2020).

Arif, M., Hussey, D. S. & Jacobson, D. L. in Neutron Scattering Applications and Techniques 191–207 (Springer US, 2009).

Silverstein, R., Eliezer, D. & Tal-Gutelmacher, E. Hydrogen trapping in alloys studied by thermal desorption spectrometry. J. Alloy Compd. 747, 511–522 (2018).

Paudel, B. et al. ToF-SIMS in material research: a view from nanoscale hydrogen detection. Mater. Today 75, 149–165 (2024).

Evers, S., Senöz, C. & Rohwerder, M. Hydrogen detection in metals: a review and introduction of a Kelvin probe approach. Sci. Technol. Adv. Mat. 14, 01420110 (2013).

Koyama, M. et al. Spatially and kinetically resolved mapping of hydrogen in a twinning-induced plasticity steel by use of scanning kelvin probe force microscopy. J. Electrochem. Soc. 162, C638–C647 (2015).

G. Andreasen, A. Visintin, R. C. Salvarezza, W. E. Triaca, A. & Arvia, A. J. Hydrogen-induced deformations of metals followed by in situ scanning tunneling microscopy. Palladium electrolytic hydrogen charging and discharging in alkaline solution. https://doi.org/10.1021/la980633 (1998).

An, B., Iijima, T., San Marchi, C. & Somerday, B. Micromechanisms of Hydrogen-Assisted Cracking in Super Duplex Stainless Steel Investigated by Scanning Probe Microscopy. Volume 6B: Materials and Fabrication https://doi.org/10.1115/PVP2014-28181 (2014).

Devaraj, A. et al. Three-dimensional nanoscale characterisation of materials by atom probe tomography. Int. Mater. Rev. 63, 68–101 (2017).

Meier, M. S., Jones, M. E., Felfer, P. J., Moody, M. P. & Haley, D. Extending estimating hydrogen content in atom probe tomography experiments where H molecule formation occurs. Microsc Microanal. 28, 1231–1244 (2022).

Chang, Y. H. et al. Characterizing solute hydrogen and hydrides in pure and alloyed titanium at the atomic scale. Acta Mater. 150, 273–280 (2018).

Kesten, P. et al. H- and D distribution in metallic multilayers studied by 3-dimensional atom probe analysis and secondary ion mass spectrometry. J. Alloy Compd. 330, 225–228 (2002).

Sundell, G., Thuvander, M., Yatim, A. K., Nordin, H. & Andrén, H. O. Direct observation of hydrogen and deuterium in oxide grain boundaries in corroded Zirconium alloys. Corros. Sci. 90, 1–4 (2015).

Chen, Y. S. et al. Direct observation of individual hydrogen atoms at trapping sites in a ferritic steel. Science 355, 1196–1199 (2017).

Takahashi, J., Kawakami, K., Otsuka, H. & Fujii, H. Atom probe analysis of titanium hydride precipitates. Ultramicroscopy 109, 568–573 (2009).

Hudson, D., Cerezo, A. & Smith, G. D. W. Zirconium oxidation on the atomic scale. Ultramicroscopy 109, 667–671 (2009).

Takahashi, J., Kawakami, K. & Kobayashi, Y. Origin of hydrogen trapping site in vanadium carbide precipitation strengthening steel. Acta Mater. 153, https://doi.org/10.1016/j.actamat.2018.05.003 (2018).

Takahashi, J., Kawakami, K., Kobayashi, Y. & Tarui, T. The first direct observation of hydrogen trapping sites in TiC precipitation-hardening steel through atom probe tomography. Scr. Mater. 63, https://doi.org/10.1016/j.scriptamat.2010.03.012 (2010).

Macauley, C., Heller, M., Rausch, A., Kummel, F. & Felfer, P. A versatile cryo-transfer system, connecting cryogenic focused ion beam sample preparation to atom probe microscopy. PLoS ONE 16, e0245555 (2021).

Zhao, H. et al. Hydrogen trapping and embrittlement in high-strength Al alloys. Nature 602, 437 (2022).

Chang, Y. H. et al. Ti and its alloys as examples of cryogenic focused ion beam milling of environmentally-sensitive materials. Nat. Commun. 10, 942 (2019).

Chang, Y. H. et al. Quantification of solute deuterium in titanium deuteride by atom probe tomography with both laser pulsing and high-voltage pulsing: influence of the surface electric field. New J. Phys. 21, 053025 (2019).

Takamizawa, H. et al. Three-dimensional characterization of deuterium implanted in silicon using atom probe tomography. Appl. Phys. Express 6, 066602 (2013).

Khanchandani, H. et al. Laser-equipped gas reaction chamber for probing environmentally sensitive materials at near atomic scale. Plos ONE 17, e0262543 (2022).

Takahashi, J., Kawakami, K., Sakiyama, Y. & Ohmura, T. Atomic-scale observation of hydrogen trap sites in bainite-austenite dual-phase steel by APT. Mater. Charact. 178, 111282 (2021).

Chen, Y. S., Bagot, P. A. J., Moody, M. P. & Haley, D. Observing hydrogen in steel using cryogenic atom probe tomography: a simplified approach. Int. J. Hydrog. Energy 44, 32280–32291 (2019).

Chen, Y.-S., Griffith, M. J. & Cairney, J. M. Cryo atom probe: freezing atoms in place for 3D mapping. Nano Today 37, https://doi.org/10.1016/j.nantod.2021.101107 (2021).

McCarroll, I. E., Bagot, P. A. J., Devaraj, A., Perea, D. E. & Cairney, J. M. New frontiers in atom probe tomography: a review of research enabled by cryo and/or vacuum transfer systems. Mater. Today Adv. 7, https://doi.org/10.1016/j.mtadv.2020.100090 (2020).

Stephenson, L. T. et al. The Laplace Project: an integrated suite for preparing and transferring atom probe samples under cryogenic and UHV conditions. PLoS One 13, e0209211 (2018).

Woods, E. V. et al. A versatile and reproducible cryo-sample preparation methodology for atom probe studies. Microsc. Microanal. 29, 1992–2003 (2023).

Jakob, S., Sattari, M., Sefer, B., Ooi, S. & Thuvander, M. Characterization of hydrogen traps in a co-precipitation steel investigated by atom probe experiments without cryogenic transfer. Scr. Mater. 243, https://doi.org/10.1016/j.scriptamat.2023.115963 (2024).

Wang, S. et al. Systematic quantification of hydrogen in pipeline steel by atom probe tomography after ambient charging and transfer. Npj Mater. Degrad. 8, https://doi.org/10.1038/s41529-024-00528-9 (2024).

Schwarz, T. M. et al. Quasi‐“in situ” analysis of the reactive liquid‐solid interface during magnesium corrosion using cryo‐atom probe tomography. Adv. Mater. 36, https://doi.org/10.1002/adma.202401735 (2024).

Zhou, Z. et al. Cryogenic atom probe tomography and its applications: a review. Microstructures 3, https://doi.org/10.20517/microstructures.2023.38 (2023).

Chen, Y. S. et al. Observation of hydrogen trapping at dislocations, grain boundaries, and precipitates. Science 367, 171 (2020).

Jakob, S. & Thuvander, M. Revisiting compositional accuracy of carbides using a decreased detector efficiency in a LEAP 6000 XR atom probe instrument. Microsc. Microanal. https://doi.org/10.1093/mam/ozae069 (2024).

Jakob, S., Thuvander, M. & Ooi, S. W. Comparison of hydrogen resilience of three different corrosion-resistant martensitic steels. https://doi.org/10.2139/ssrn.5028452.

Saksena, A. et al. Optimizing site-specific specimen preparation for atom probe tomography by using hydrogen for visualizing radiation-induced damage. Int. J. Hydrog. Energy 50, https://doi.org/10.1016/j.ijhydene.2023.09.057 (2024).

Li, Y. et al. Mechanism and evaluation of hydrogen permeation barriers: a critical review. Ind. Eng. Chem. Res. 62, https://doi.org/10.1021/acs.iecr.3c02259 (2023).

Rai, S. et al. Deuterium permeation studies through bare and Er2O3 coated SS 316L. Fusion Eng. Des. 206, https://doi.org/10.1016/j.fusengdes.2024.114587 (2024).

He, D. et al. Preparation of Cr2O3 film by MOCVD as hydrogen permeation barrier. Fusion Eng. Des. 89, 35–39 (2014).

Lee, S. K., Yun, S. H., Joo, H. G. & Noh, S. J. Deuterium transport and isotope effects in type 316L stainless steel at high temperatures for nuclear fusion and nuclear hydrogen technology applications. Curr. Appl Phys. 14, 1385–1388 (2014).

Ishikawa, Y., Yoshimura, T. & Arai, M. Effect of surface oxide layers on deuterium permeation through stainless steels with reference to outgassing reduction in ultra-to extremely high vacuum. Vacuum 47, 357–361 (1996).

Ishikawa, Y., Yoshimura, T. & Arai, M. Effect of surface oxides on the permeation of deuterium through stainless steel. Vacuum 47, 701–704 (1996).

Xing, B., Wu, J., Cheng, J., Zhang, L. & Wu, M. Hydrogen diffusion in α-Fe2O3: Implication for an effective hydrogen diffusion barrier. Int J. Hydrog. Energy 45, 32648–32653 (2020).

Stover, D., Buchkremer, P. H. & Hecker, R. Hydrogen and deuterium permeation through metallic and surface-oxidized chromium. Surf. Coat. Technol. 28, 281–290 (1986).

Hecker, R., Stover, D., Jonas, H. & Buchkremer, H. P. Properties of chromia scales on high temperature alloys used as barriers against hydrogen permeation. J. Nucl. Mater. 171, 84–93 (1990).

Oya, Y. et al. Effect of surface oxide layer on deuterium permeation behaviors through a type 316 stainless steel. Fusion Eng. Des. 87, 580–583 (2012).

Haley, D., Merzlikin, S. V., Choi, P. & Raabe, D. Atom probe tomography observation of hydrogen in high-Mn steel and silver charged via an electrolytic route. Int J. Hydrog. Energy 39, 12221–12229 (2014).

Padavala, S. K. M. & Stoerzinger, K. A. Role of hydride formation in electrocatalysis for sustainable chemical transformations. ACS Catal. 13, https://doi.org/10.1021/acscatal.3c00204 (2023).

Fukai, Y. & Suzuki, T. Iron‐water reaction under high pressure and its implication in the evolution of the Earth. J. Geophys. Res. Solid Earth 91, https://doi.org/10.1029/JB091iB09p09222 (1986).

Bagrets, N., Heller, R., Weis, J. R. & Weiss, K. P. Thermal resistance between metallic surfaces of copper and stainless steel at different temperatures and applied forces for high current HTS cable-in-conduit conductors. IEEE Trans. Appl Supercond. 32, 1–5 (2022).

Röttger, A. et al. Microstructure and mechanical properties of 316L austenitic stainless steel processed by different SLM devices. Int J. Adv. Manuf. Technol. 108, 769–783 (2020).

Guyer, J. E., Wheeler, D. & Warren, J. A. FiPy: Partial differential equations with Python. Comput Sci. Eng. 11, 6–15 (2009).

Dilthey, U., Trube, S., Pokhodnya, I. & Pavlik, V. Determination of the diffusion coefficient of hydrogen in steel subjected to deformation and in weld deposits of basic and rutile coated electrodes. Weld Res. Abroad 4, 2–5 (1993).

Farrell, K. & Lewis, M. B. The hydrogen content of austenite after cathodic charging. Scr. Met. 15, 661–664 (1981).

Acknowledgements

This research was supported by the Department of Energy (DOE), Office of Science, Basic Energy Sciences, Materials Sciences, and Engineering Division as part of the Early Career Research Program FWP 76052. V.B.V. acknowledges Mengkong (Andrew) Tong for developing the electrochemical charging assembly fixture.

Author information

Authors and Affiliations

Contributions

V.B.V. performed the experiments, including electropolishing, FIB, APT, electrochemical charging, APT data analysis, and heat transfer model. Z.L., J.R.G., and S.M. contributed to FIB and APT experiments. S.M. contributed to heat transfer and deuterium diffusion models. V.S. and V.B.V. led the installation of the glovebox and Ferrovac extension kit. T.L. supported TKD experiments. A.D. guided the APT experiments and data analysis and supervised the entire project and acquired the funding for the project. The original manuscript was drafted by V.B.V. and reviewed and revised by all authors.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Vukkum, V.B., Li, Z., Grimm, J.R. et al. Insights from quasi-in situ cryogenic-transfer atom probe tomography for analyzing hydrogen diffusion in metallic alloys. npj Mater Degrad 9, 85 (2025). https://doi.org/10.1038/s41529-025-00626-2

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41529-025-00626-2