Abstract

An element-resolved electrochemical database of a ZnAlMg alloy coating is presented, obtained via atomic emission spectroelectrochemistry (AESEC) linear sweep voltammetry (LSV). Nominally pure Zn, Al and Mg metals as well as MgZn2, ZnAl intermetallic phases, and commercial ZnAl alloy coatings were investigated using AESEC-LSV to understand the complex electrochemical response of multi-phase ZnAlMg alloys. The elemental dissolution rates extrapolated from AESEC-LSV curves showed a linear relationship with spontaneous elemental dissolution rates. This demonstrates the possible use of AESEC-LSV for determining long-term elemental corrosion rates, as well as the use of element-specific electrochemical data as input parameters for more accurate machine learning based corrosion resistant alloy design. Element-resolved electrochemistry reveals important corrosion phenomena not detectable in conventional electrochemistry such as cathodic dissolution, chemical dissolution, cathodic dealloying, negative correlation effects, and anomalous hydrogen evolution. These phenomena may be significant and should be taken into account in the rate equations used for numerical modeling.

Similar content being viewed by others

Introduction

Since the 2010s, the materials science community has witnessed a significant paradigm shift in alloy design driven by artificial intelligence (AI) and leveraging data obtained from machine learning (ML). This approach can accelerate the discovery of optimal chemical compositions, reducing the waste of rare resources compared to conventional alloy design methods. Numerical simulations and AI are helping in the selection of compositions to be tested experimentally. One major limitation of this approach is the difficulty in obtaining reliable experimental data needed to train ML models for improved predictive accuracy. In terms of data quantity, high-throughput approaches in metallurgy, electrochemistry and CALPHAD (CALculation of PHAse Diagrams) simulations have been employed to supply data for screening all possible material/environment scenarios of interest1,2,3,4,5.

For corrosion-resistant alloy design, datasets used to train ML models have primarily been derived from conventional electrochemical analyses, providing an overview of materials’ corrosion resistance, often represented by a corrosion rate6 based on conventional theories7,8. However, this method often neglects element-specific data, as conventional electrochemical techniques cannot provide in situ element-resolved information. The absence of element-resolved data as input parameters for ML-based alloy design is a critical limitation as the quality of input data is key to effective ML model training.

Another example demonstrating the importance of element-resolved data is corrosion modeling using finite element methods (FEM)9,10. For example, corrosion mechanisms on the cut-edge of galvanized steel have been modeled11,12,13,14,15 using global electrochemical data as input for the FEM-based simulation. Cut-edge corrosion refers to the situation where galvanized steel has been cut and both the Zn alloy coating and the steel are exposed on the edge with an unfavorable Zn and steel surface ratios, typically 10 µm Zn/700 µm Fe. The corrosion rates and mechanisms depend upon the nature of the precipitated corrosion products that are formed from the specific ions released at the anode and usually hydroxide released at the cathode. Attempts to include precipitation in numerical models have proven interesting14,15, however, they have been based on global electrochemical data and do not necessarily account for the possibility of selective dissolution. This is particularly significant for multi-phase alloy systems.

In the present work, pure metals and pure phases consisting of ZnAlMg alloy coatings were analyzed by atomic emission spectroelectrochemistry (AESEC), providing element-resolved electrochemical parameters. The ZnAlMg alloy coating was primarily developed in the automotive industry to enhance corrosion resistance and reduce the total weight of galvanized steel16. This alloy has also been used in the marine and offshore industries17,18, construction materials19 and as a biodegradable material20,21.

Apart from its significant industrial interest, the ZnAlMg alloy coating system was chosen for this work because it exhibits a multi-phase structure with complicated chemistry22,23,24,25. For example, each alloying element will react differently depending on the interfacial pH and electrochemical potential. Selective dissolution results in changes in the composition of the metallic phase. In addition, different corrosion products precipitate depending on the elemental dissolution rates, forming local galvanic coupling. These factors make it difficult to interpret conventional electrochemical data without element-specific information. The complex nature of multi-phase, multi-element alloy coatings such as ZnAlMg has been demonstrated in terms of their chemical composition, galvanic coupling between phases, and the effect of organic/inorganic coatings, all of which play an important roles in estimating corrosion performance in diverse environments. This ultimately highlights the importance of establishing a catalog of element-resolved electrochemical data to better design ZnAlMg-based multi-phase alloys and more accurately predict their corrosion behavior.

The elemental dissolution mechanism is a key consideration in the corrosion of ZnAlMg alloys. For example, the presence of Zn2+ released from the galvanized steel alloy coating during cut-edge corrosion has been reported to modify the Fe-based oxide resulting in the inhibition of direct oxygen reduction on the steel surface. The exchange of Zn2+ with Fe2+ donor sites at the surface lowers the oxygen reduction activity, which is further enhanced in the presence of Mg2+ in the electrolyte26,27. In the case of the corrosion resistant layered double hydroxide (LDH) film formation mechanism, the metal substrate and thin metallic oxide layer may act as sources of metallic cations that form the LDH28. For Zn-Al based LDHs, intermediate species such as Al(OH)4− and Zn(OH)+ are considered precursors to LDH formation. However, in situ measurements of these species to verify the LDH formation mechanism have not been carried out29. In other words, if we had direct access to these dissolved species, we might be able to shed light on the existence of these precursors and their underlying formation mechanisms. An element-resolved electrochemical database is therefore necessary to provide high-quality datasets for training ML models to address these issues, taking into account the elemental contributions to the reaction mechanism and ultimately enabling the effective design of corrosion-resistant multi-phase alloys such as ZnAlMg.

In this work, the major anodic reactions of the multi-phase alloy coatings were identified based on the relative reactivity of the individual phases and pure metals via AESEC-linear sweep voltammetry (AESEC-LSV). The spontaneous elemental dissolution rate, which represents the free corrosion rate (i.e., spontaneous corrosion or the AESEC open circuit potential, AESEC-OCP, measurement) can be predicted by extrapolating AESEC-LSV curves. These findings may contribute to the development of a new approach to ML-based alloy design by providing element-resolved electrochemical datasets for training models.

Results

Thermodynamic simulations

Figure 1 presents a thermodynamic simulation of the ZnAlMg system in the presence of Cl- at T = 20 °C, using the default database of PhreeplotTM software. Soluble species are listed in the figure caption, and the predominant species are indicated by arrows above the figure. All element show pH-dependent solubility, with specific pH ranges where their hydroxides or oxides precipitate. The thermodynamic simulation will be compared in the following sections to elemental dissolution rates, depending on the pH of the solution.

The arrows above indicate the predominant species. Soluble species used are: ZnOH+, ZnCl+, ZnCl3−, ZnCl42−, HZnO2−, ZnHCO3+, Zn(OH)3−, ZnO22−, Zn(CO3)22−, Zn(OH)42−; Al(OH)4−, AlO2−, Al(OH)2+, Al3+; Mg2+, MgOH+, MgHCO3+, and insoluble species are: ZnO, Zn(OH)2, Zn5(OH)8Cl2, AlO(OH), Al2O3, Mg4Al2(OH)12(CO3)·10H2O, Mg(OH)2. The subscripted “tot” indicates total concentration of the element. Vertical dashed lines indicate the three pH values investigated in this work.

AESEC polarization curve of the material—pure metals

Figure 2 shows the AESEC-LSV curves for nominally pure Zn, Al and Mg measured at pH = 8.4, pH = 10.1 with 30 mM NaCl, as well as at pH = 12.8 with 0.1 M NaOH (without NaCl). All electrolytes were deaerated with Ar. For pure Zn (Fig. 2a, left), an oxidation peak of je near −1.1 V vs. SCE (a1) was observed in the pH = 8.4 and 10.1 electrolytes. At this point, a non-faradaic reaction was indicated by the lower Zn dissolution rate (jZn) compared to je. The unaccounted charge can be attributed to the formation of less soluble Zn species, such as ZnO or Zn(OH)2. The difference between je and jZn was more pronounced at pH = 10.1 because the solubility of Zn is lowest at this pH, as predicted by the thermodynamic simulations shown in Fig. 1. Faradaic Zn dissolution was observed at potentials above this point in the pH = 8.4 and 10.1 electrolytes. At pH = 12.8, Zn dissolution was nearly faradaic, i.e., jZn ≈ je, above the j = 0 potential (Ej=0) because Zn(OH)2 is highly soluble at this pH (Fig. 1)30,31.

For pure Al (Fig. 2a, middle), anodic dissolution in the cathodic potential domain for the pH = 8.4 and 10.1 electrolytes, −1.8 V vs. SCE < E < Ej=0, was monitored. In this potential domain, Al dissolution was potential dependent and closely followed the cathodic current. This phenomenon is referred to as the cathodic dissolution of Al32,33,34,35 and cannot be detected using conventional electrochemical measurements. The dissolved Al species, such as Al(OH)4−, and the electron stoichiometry follow the ratio described by the following reaction:

This yields a mole ratio of Al:e- = 1:1, or a current density ratio of jAl:│je│ = 3:1, where jAl = zAlFvAl. Here, vAl is the elemental dissolution rate of Al in mol cm−2 s−1. For both pH = 8.4 and 10.1 electrolytes, the observed ratio jAl:│je│ was approximately 2.9:1 in the cathodic potential domain, confirming the cathodic Al dissolution mechanism (Reaction 1). Unlike pure Zn, insoluble species indicated by je > jAl for pure Al at pH = 10.1 contradicts the thermodynamic predictions in Fig. 1 as higher Al solubility is expected at pH = 10.1 than at pH = 8.4. This discrepancy may be related to the enhanced cathodic reaction at pH = 8.4 (evidenced by a higher je and a larger cathodic potential domain) which increased the interfacial pH to a value even higher than that of the pH = 10.1 solution.

At pH = 12.8, however, Al dissolution was potential independent31,36, indicating that the dissolution was controlled by the steady state formation and dissolution of an Al(OH)3 passive film as described by:

Reactions 2 and 3 were in a steady state. There was no correlation between je and jAl at pH = 12.8, suggesting that Al dissolution was not driven by the electrochemical reaction. This phenomenon has been referred to in the literature as “chemical corrosion”37. At this pH, most of the OH− in Reactions 2 and 3 comes from the electrolyte and is limited by mass transfer. In this case, the rate determining step of Al dissolution is not the electrochemical reaction (Reaction 4) and the dissolution rate remains constant, independent of both current and potential. It should be noted that the noise signal of jAl was proportional to the quantity of the evolved H2 gas. The stoichiometry between the dissolved Al species (Al(OH)4−, Reaction 3) and the evolved H2 gas (Reaction 4), in a ratio of 1:1.5, has been demonstrated using AESEC coupled gravimetric gas measurement38.

One important point to note in the case of AESEC-LSV curves for pure Al is the determination of the “true” corrosion rate. According to conventional Tafel extrapolation method, the corrosion rate may be estimated as the intersection of the anodic and cathodic Tafel lines extrapolated to Ej=0. However, this approach may significantly underestimate the true corrosion rate. The true Al dissolution rate at Ej=0 determined using an “element-resolved mixed potential theory” as indicated by arrows in Fig. 2, was more than an order of magnitude higher than the rate obtained from conventional method39,40,41. This highlights the critical importance of element-resolved analysis in accurately measuring corrosion rates as well as its value as an input parameter for ML modeling.

Mg dissolution (Fig. 2a, right) at pH = 8.4 and 10.1 occurred in the cathodic potential domain, i.e., E < Ej=0, which again cannot be monitored by conventional electrochemical measurements. Mg dissolution was potential dependent at pH = 8.4 and 10.1 within the potential range investigated in this work. In these solutions, Mg dissolution exhibited perturbed jMg signals, though not highly prominent on a logarithmic scale, especially at more positive potentials, i.e., E > −1.2 V vs. SCE, which can be attributed to the evolution of hydrogen bubbles42, often referred to as anomalous anodic hydrogen evolution (AHE). The evolved gas bubbles were visibly present inside the capillary. In these solutions, jMg > je was monitored with jMg/je = 1.44 (pH = 8.4) and jMg / je = 1.14 (pH = 10.1). This also indicates AHE because the hydrogen evolution current (\({\rm{j}}_{{\rm{H}}_{2}}\)) results from a cathodic reaction, i.e., \({\rm{j}}_{{\rm{H}}_{2}}\) < 0, and je = jMg + \({\rm{j}}_{{\rm{H}}_{2}}\), thus yielding jMg > je in the case of AHE. At pH = 12.8, no Mg dissolution was observed in agreement with the thermodynamic prediction shown in Fig. 1. The spikes in jMg observed under these conditions were due to the detachment of Mg(OH)2 precipitates as indicated by the upward increase in jMg.

The same series of experiments was performed for pure metals in electrolytes saturated with O2 by bubbling directly pure O2 gas into the solution, as shown in Fig. 3. Nearly the same conclusions as in the Ar deaerated solution can be drawn for pure Al and Mg. However, Zn dissolution was observed in the cathodic potential domain in the presence of O2 in the solution (44 mg L−1 as measured by an oxygen meter). Notably, this cathodic Zn dissolution was not observed in Ar deaerated electrolyte shown in Fig. 2. This is likely due to the enhancement of the interfacial pH by oxygen reduction. The presence of O2 increased the interfacial OH− concentration in the unbuffered solution via the reaction:

which accelerated the formation of soluble Zn(OH)3− and/or Zn(OH)42− species.

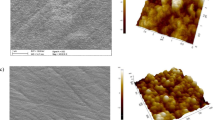

AESEC polarization curve of the material—intermetallic phases

Figure 4 shows the AESEC-LSV curves of intermetallic phases obtained in the same electrolyte as in Fig. 2. For the MgZn2 intermetallic phase at pH = 8.4 and 10.1, the jMg value decreased by a factor of 100 to 1000 compared to that measured for pure Mg (shown in Fig. 2). In these electrolytes, the onset potential of Zn dissolution, EcZn, was shifted 30–100 mV in the more positive direction compared to pure Zn in Fig. 2. Selective Mg dissolution was observed for E < EcZn leading to the formation of a metallic Zn layer, Zn(0), on the surface43. The lower jMg for the MgZn2 phase compared to pure Mg was attributed to the formation of this Zn(0) layer which inhibited further Mg dissolution. Under spontaneous corrosion conditions43, significantly reduced Mg and Zn dissolution rates were observed compared to those of the pure metals. Selective Mg dissolution was also observed in spontaneous corrosion, again forming a Mg depleted Zn(0) enriched layer that blocked elemental dissolution. The selective Mg dissolution maintained the potential just below the onset of Zn dissolution. For MgZn2 in pH = 8.4 and 10.1 electrolytes, the onset potential for Mg dissolution was identical within experimental error to that of Zn (EcZn), indicating simultaneous dissolution of Mg and Zn. For E > EcZn, Mg and Zn dissolved nearly congruently as indicated by jZn / jMg ≈ 2 (with oxidation states of Zn and Mg, zZn = zMg = 2). The faradaic yield of anodic dissolution (jZn + jMg) / je ≈ 1 indicated no significant formation of insoluble species. At pH = 12.8, no Mg dissolution was observed similar to pure Mg. Zn was oxidized but at a significantly lower rate than pure Zn (Fig. 2) due to the blocking effect of Mg-based less soluble species formed at this pH.

For all three Zn-Al intermetallic phases shown at pH = 8.4 and 10.1, selective Al dissolution in the cathodic potential domain, i.e., cathodic dealloying, was observed. In these electrolytes, Al dissolution in the cathodic potential domain was potential dependent as seen for pure Al in Fig. 2. This demonstrates that the Zn(0) layer formed by selective Al dissolution in Zn-Al intermetallic phases does not significantly alter the kinetics of cathodic Al dissolution, unlike in the case of MgZn2. At pH = 8.4 and 10.1, the Al dissolution rate profile in the cathodic potential domain for Zn68Al (Fig. 3d) was similar to that of Zn22Al (Fig. 3c) even though the latter contains significantly less Al, indicating that cathodic dealloying varies little with Al composition. For Zn68Al, the origin of the oxidation peak (a2) was previously demonstrated to be the oxidation of the Zn(0) layer formed during selective Al dissolution, as confirmed by the AESEC potentiodynamic step experiment32. At pH = 12.8, potential independent Al dissolution was observed similar to pure Al, indicating that the formation and dissolution of Al(OH)3 were in a steady state. The onset dissolution of Zn resulted in a decrease in Al dissolution rates, a phenomenon previously referred to as the “negative correlation effect (NCE)”31. This effect was attributed to the dissolution of the Zn(0) enriched layer leading to the precipitation/dissolution of Zn(OH)2, which retards Al dissolution. In the passive domain where the Zn dissolution rate decreased and became independent of potential, the Al dissolution rate increased. In this domain, Al dissolution occurred through the passive ZnO layer, as indicated by a significantly reduced perturbation signal of jAl compared to that observed in the cathodic potential domain44.

The NCE can be clearly seen in Fig. 5 where Zn22Al in a deaerated pH = 12.8, 0.1 M NaOH solution underwent a fixed frequency of f = 0.0046 Hz at an applied potential of −1.31 V vs. SCE (active domain as shown in Fig. 4). The jZn oscillation was in-phase with the sinusoidal applied potential while jAl was 180° shifted.

Figure 6 shows the same series of experiments for intermetallic phases in O2 saturated electrolytes. Note that O2 saturation did not change the dissolution profile for pure Al (Figs. 2 and 3). Significantly lower Mg dissolution in the cathodic potential domain compared to the Ar deaerated electrolyte was observed for the MgZn2 intermetallic phase at pH = 8.4 and 10.1. This reduced Mg dissolution rate is attributed to the enhanced formation of Mg-based insoluble species caused by the increased interfacial OH− concentration. A slight Mg dissolution peak at E = −1.75 V vs. SCE was monitored for MgZn2 in the pH = 12.8 solution which may be due to the dissolution of Mg-based particles released from Mg-based insoluble species. Cathodic Zn dissolution was monitored for Zn-Al intermetallic phases similar to pure Zn (Fig. 3) at this pH. In this case, Al dissolution was again restrained by Zn dissolution, confirming the NCE mechanism.

AESEC polarization curve of the material—commercial alloy coatings

Commercial ZnAl (Zn5Al and Zn55Al) and ZnAlMg alloy coatings were investigated to compare them with the results for pure metals and intermetallic phases, as shown in Fig. 7. Selective Al dissolution in the cathodic potential domain, i.e., cathodic dealloying, was observed in all three alloys at pH = 8.4 and 10.1. The stoichiometry of cathodic dealloying was less evident than that of intermetallic phases because jAl:| je | ≠ 3:1 for the alloy coatings. This demonstrates the effect of microstructure on cathodic reaction kinetics: selective dissolution of Al occurred not across the entire surface but at highly localized Al-rich phases45. Therefore, OH− did not sufficiently react with Al in multi-phase alloys.

For ZnAlMg alloy at pH = 8.4 and 10.1, Mg also dissolved in the cathodic potential domain and followed an opposite trend to Al: when jAl increased, jMg decreased, and vice versa. The origin of this opposing dissolution trend of Al and Mg in the cathodic domain remains unclear. One possible explanation is that, at pH = 8.4 and 10.1, the Al-rich α-phase Al (i.e., Zn68Al) is electrochemically more active than the MgZn2 phase as evidenced by the more negative Eoc of the α-phase Al compared to the MgZn2 intermetallic phase. When a cathodic potential was applied, the α-phase Al selectively dissolved via the cathodic dealloying mechanism (Reaction 1). This selective Al dissolution may expose the MgZn2 phase to the electrolyte. As the potential was swept in a more positive direction (−1.6 V < E < −1.2 V vs. SCE) the Mg dissolution rate increased while the selective Al dissolution rate decreased. Both Mg and Al dissolution rates decreased for E > Ej=0 at which Zn became electrochemically active.

The elemental Tafel slopes determined from jZn, ba, \({{\rm{j}}}_{{\rm{Zn}}}\), are provided in Supplementary Tables 1–6. For the ZnAlMg alloy ba, \({{\rm{j}}}_{{\rm{Zn}}}\) was 55 mV decade−1 at both pH = 8.4 (Supplementary Table 1) and 10.1 in Ar deaerated electrolytes (Supplementary Table 3), similar to that of the η-phase Zn (Zn0.7Al, ≈56 mV decade−1) and other η-phase containing alloys, i.e., Zn5Al (≈57 mV decade−1) and Zn55Al (≈52 mV decade−1) in deaerated electrolytes. For comparison, the ba, \({{\rm{j}}}_{{\rm{Zn}}}\) values for non-η-phase of Zn containing specimens, e.g., pure Zn (71 ~ 75 mV decade−1), MgZn2 (20 ~ 79 mV decade−1), Zn22Al (39 ~ 48 mV decade−1) and Zn68Al (27 ~ 47 mV decade−1) differ from those of the η-phase of Zn containing samples. These results demonstrate that Zn dissolution occurs at the η-phase, following Tafel kinetics.

The simultaneous dissolution of Zn and Mg in the ZnAlMg alloy for E > EcZn at pH = 8.4 and 10.1 was attributed to the dissolution of the MgZn2 intermetallic phase and Zn from the substrate. For E > EcZn, the NCE was also observed for all ZnAl and ZnAlMg alloy coatings31.

At pH = 12.8, the effect of microstructure was less pronounced than at the lower pH solutions. For example, Zn55Al (Fig. 7) exhibited an AESEC-LSV trend almost identical to that of Zn68Al (Fig. 4). Similarly, Zn5Al and ZnAlMg displayed analogous elemental dissolution trends to each other as well as to Zn0.7Al (Fig. 4), as a function of the potential sweep. This is primarily due to the highly reactive Al and non-solubility of Mg at pH = 12.8 which makes the chemical system predominant in determining the elemental dissolution profile.

The decrease in jAl in Fig. 8 for O2 saturated electrolytes was attributed to the enhanced Zn dissolution, particularly in the cathodic potential domain. This phenomenon, as observed in Fig. 6 for the intermetallic phases, is linked to the NCE.

Predicting corrosion: galvanic series of materials

The galvanic series of materials tested in this work was investigated via open circuit potential (Eoc) values in each electrolyte, as shown in Fig. 9. The Eoc values averaged over at least 300 s of measurement are provided as a function of Zn content (% Zn) for both Ar deaerated and O2 saturated electrolytes under three pH conditions. For pH = 10.1 and 12.8, Eoc increased with increasing % Zn because the presence of Al or Mg shifted the potential in a more negative direction. In this pH range, Al selectively dissolved while Zn and Mg formed stable oxides/hydroxides (Fig. 1). This is evidenced by the more positive Eoc of MgZn2 which does not contain Al.

At pH = 8.4, no clear relationship between Eoc and % Zn was observed. At this pH, both Mg and Zn are thermodynamically soluble whereas Al forms a stable oxide/hydroxide (Fig. 1). The effect Mg dissolution shifting Eoc in a more negative direction may not be as significant as in the higher pH range because Zn dissolution shifted the potential in a more positive direction, potentially counteracting the effect of Mg dissolution.

The spontaneous elemental dissolution rates at near steady state (jsM) under open circuit conditions were recorded via AESEC prior to all AESEC-LSV measurements. The jsM values of pure metals and ZnAlMg alloy coating in three pH electrolytes are presented in Fig. 10, while those for other pure metals and intermetallic phases are shown in Fig. 11. The open circuit elemental dissolution profiles of all samples investigated in this work for each electrolyte are provided in Supplementary Figs. 1–9. Note that the jsM of the ZnAlMg alloy coating in Fig. 10 was normalized based on its molar composition. The trend of jsM for pure metals reasonably followed that of thermodynamically simulated solubility (Fig. 1). For example, at pH = 10.1 (Ar deaerated), jsZn < jsAl < jsMg, which aligns with thermodynamic predictions of solubility at this pH (Fig. 1). However, for the ZnAlMg alloy coating, jsAl exhibited the highest value in the Ar deaerated electrolyte at pH = 10.1, deviating from thermodynamic predictions. This discrepancy may be explained by the Eoc values of the specimens shown in Fig. 9: At pH = 10.1, the Al-rich α-phase (Zn68Al) was the most electrochemically reactive as evidenced by its more negative Eoc compared to intermetallic phases, such as Zn0.7Al, Zn22Al, and MgZn2. Consequently, the selective dissolution of the Al-rich α-phase would result in higher Al dissolution than predicted by thermodynamic simulations.

Under the conditions of these experiments, the presence of oxygen had little effect on the Mg dissolution rate of pure Mg: jsMg values in Ar deaerated electrolytes were slightly higher than those in O2 saturated electrolytes (194 μA cm−2 for Ar deaerated vs. 165 μA cm−2 for O2 saturated electrolytes at pH = 8.4; 93 μA cm-2 for Ar deaerated vs. 82 μA cm−2 for O2 saturated electrolytes at pH = 10.1). This may be due to the more pronounced formation of a protective Mg(OH)2 film in the presence of O2. However, this tendency was not systematically observed for MgZn2 and ZnAlMg samples.

Figure 12 presents the spontaneous steady state elemental dissolution rates, jsM (AESEC-OCP, as shown in Figs. 10 and 11), vs. the elemental dissolution rates extrapolated from AESEC-LSV curves at Ej=0, jM (AESEC-LSV). For the AESEC-LSV, jM values were extracted at Ej=0, similar to the conventional mixed potential theory, where the corrosion rate is determined at the intersection of the anodic and cathodic Tafel lines at Ej=0.

A linear relationship between the two measurements was observed, indicating that elemental dissolution rates extrapolated using the “element-resolved mixed potential theory” from AESEC-LSV curves can be used to estimate spontaneous elemental corrosion rates46. This is a crucial finding, as element-specific corrosion rates cannot be obtained using conventional electrochemical techniques, especially under open circuit conditions where the faradaic current is, by definition, zero. A direct correlation of the elemental corrosion rate under open circuit conditions (AESEC-OCP) with that from a relatively short AESEC-LSV measurement can significantly reduce both the time required and the uncertainties involved in quantifying elemental corrosion rate. In this way, long-term elemental corrosion rates can be simply determined through an AESEC-LSV assessment.

The slight discrepancy between the two methods may be attributed to the challenge of defining the corrosion potential, i.e., the spontaneous potential (Eoc), which often differs from Ej=0.

Discussion

In this work, we have demonstrated a variety of different mechanisms and provided a database of electrochemical kinetics for a wide range of ZnAlMg alloys, intermetallic phases, and pure metals. The element-resolved dissolution mechanisms depending on solution pH, alloy composition, and applied potential have been elucidated. The AESEC-LSV results of a multi-phase ZnAlMg alloy system can be predicted through a bottom-up analysis starting from pure metals and intermetallic phases. The cathodic dissolution mechanism, the negative correlation effect, and the anomalous hydrogen evolution mechanism were investigated across different pH values and elemental compositions. Elemental Tafel slopes determined from jZn, as well as the onset dissolution potential of Zn, which are difficult to determine using conventional electrochemical analysis, are provided and can be used as input parameters to train ML models for predicting element-specific corrosion behavior. We have also demonstrated how to predict the elemental spontaneous dissolution (corrosion) rate using AESEC-LSV measurements. This approach allows the true corrosion rate to be determined from elemental signals, enabling the development of an unprecedented element-resolved corrosion rate database.

Conventionally, FEM has been used as a numerical method to simulate electrical, mechanical, and chemical systems using differential equations. FEM-based simulations have been conducted to understand galvanic corrosion47 at the cut-edge of galvanized steel13,48, cathodic delamination of paint on Zn49,50, galvanic corrosion from intermetallic particles in Al-based alloys51,52, metallic protective coatings53,54, atmospheric corrosion55,56, and localized corrosion57,58. More recently, FEM has also been applied to simulate localized corrosion59 and the design of additive manufactured alloys60,61. FEM corrosion models assume idealized corrosion conditions, such as uniform corrosion, constant environmental factors, and the results depend highly on how boundary conditions are defined, which may be difficult to determine accurately. The use of the FEM relies on the validated material data, e.g., exchange current density, which may not always be available for all material/environment combinations. To leverage these issues, a ML-based surrogate model has recently been proposed, yielding more robust and reliable FEM simulations62, although the necessity of training the model with element-resolved electrochemical data still persists.

The conventional polarization curve has been used to provide input parameters for ML model to design corrosion resistant alloys and predict corrosion rates. However, extracting elemental dissolution rates from the conventional je vs. E curve is challenging. For example, anodic Al dissolution in the cathodic potential domain is completely masked by the intense cathodic current as evidenced by jAl (Al) > je (Al) in Figs. 2–4 and 6–8. Quantifying the potential dependent Al dissolution rate in the cathodic potential domain could be critical for LDH conversion coating system using Al-containing alloys where cathodic Al dissolution could serve as a source of Al3+ to form Zn-Al-based LDHs. This example demonstrates the importance of training ML models that incorporate element-resolved information.

Another complexity in predicting corrosion behavior using the conventional polarization curve is defining a “corrosion potential”, as briefly introduced in Fig. 11. Table 1 summarizes Eoc, Ej=0, and EcZn for all systems investigated at pH = 10.1 in Ar deaerated and O2 saturated solutions containing 30 mM NaCl. Results for other electrolyte conditions including the ba, \({{\rm{j}}}_{{\rm{Zn}}}\) and spontaneous elemental dissolution rates (jsM) are provided in the Supplementary Tables 1– 6.

In most cases, Eoc and Ej=0 were different, with the difference ranging from 10 mV to 240 mV in Ar deaerated electrolytes. The Eoc values did not show a clear relationship with chemical composition or microstructure. It should be noted that corrosion rate measurements are generally performed using separate cathodic and anodic polarization curves starting from Eoc. Therefore, this difference can be critical in determining the true “corrosion potential” for predicting corrosion rates. The Eoc values are currently used to train the ML model; thus, uncertainty in their determination could lead to inaccurate predictions of corrosion rate, even if the dataset is sufficiently large. To improve accuracy, it is necessary to investigate element-resolved electrochemical parameters such as EcZn and ba, \({{\rm{j}}}_{{\rm{Zn}}}\), to provide higher-quality, element-specific information to ML models.

In O2 saturated electrolytes, this difference was generally less significant. The effect of dissolved O2 on the discrepancy between Eoc and Ej=0 was evident only for α-phase Al containing samples (Zn55Al and Zn68Al). This can be attributed to the cathodic Zn dissolution observed in the O2 saturated electrolyte, which shifted Ej=0 to a more positive value. This potential shift is in turn correlated with the NCE.

The EcZn values in Ar deaerated electrolyte for all samples were close to −1.10 V vs. SCE, except for MgZn2. An approximatively 160 mV more positive EcZn observed for MgZn2 was attributed to the formation of a Zn(0) layer during the cathodic potential scan caused by selective Mg dissolution. In O2 saturated electrolyte, the EcZn values did not show a clear trend, likely due to the interplay with Al (i.e., NCE) and Mg.

In summary, this paper presents a new approach to element-resolved mixed potential analysis using AESEC-LSV curves. The electrochemical responses of multi-phase systems can be predicted through a bottom-up analysis starting from pure metals and individual phases. An element-specific electrochemical database, including EcZn, jsM, and ba, \({{\rm{j}}}_{{\rm{Zn}}}\) has been established for pure metals, intermetallic phases, and alloy coatings across a pH range of 8.4 ~12.8. This database enables more accurate corrosion rate prediction compared to conventional methods. Spontaneous elemental dissolution rates obtained from AESEC-OCP show a linear relationship with those obtained from AESEC-LSV across a relatively broad pH range and various chemical compositions and microstructure. This suggests that elemental corrosion rates can be estimated through relatively quick and simple AESEC-LSV measurements. Providing such element-specific data enhances the reliability of the ML-based corrosion resistant alloy design approach. Element-resolved electrochemistry also reveals important corrosion phenomena not detectable by conventional electrochemistry, such as cathodic dissolution, chemical dissolution, cathodic dealloying, negative correlation effects, and anomalous hydrogen evolution. These phenomena may play significant roles in corrosion processes and should be considered in the rate equations for numerical modeling.

Methods

The list of symbols and abbreviations used in this work is summarized in Table 2.

Materials

Nominally pure Zn (99.998%), Al (99.99%), and Mg (99.9%) metals obtained from Goodfellow were investigated in this work. Two ZnAl and one ZnAlMg commercial alloys were used in this work. The Zn-5 wt.% Al alloy (denoted as Zn5Al) has been reported to have a eutectic structure consisting of a dendritic η-phase of Zn interspersed within the lamella of the Zn-rich Al phase (β-phase of Al)63,64,65. The Zn-55 wt.% Al-1.6 wt.% Si alloy (denoted as Zn55Al) is generally composed of a dendritic Al-rich phase (α-phase of Al) and a Zn-rich interdendritic phase66,67,68,69. A commercial Zn-1.6 wt.% Al-1.6 wt.% Mg alloy coating exhibiting a microstructure comprising a dendritic η-phase of Zn, a Zn-MgZn2 binary eutectic, and a Zn-Al-MgZn2 ternary eutectic phase was used in this work70,71,72,73,74. Binary phases were obtained from the University of Chemistry and Technology in Prague. Detailed information on sample preparation and their characterization can be found elsewhere31,32,43,44.

Recent research on ZnAlMg alloy coatings focusing on chemical composition, microstructure, and the formation of surface oxides/hydroxide and their effects on corrosion properties is summarized in Table 3.

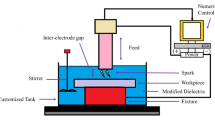

Atomic emission spectroelectrochemistry (AESEC)

The AESEC technique has been described in detail in our previous publications75,76. An Ultima 2CTM inductively coupled plasma–atomic emission spectrometer (ICP-AES, Horiba France) coupled with an electrochemical measurement system was used. A Gamry Reference 600TM potentiostat was used to perform electrochemical tests. A saturated calomel electrode (SCE) was used as the reference electrode in pH = 8.4 and 10.1 solutions, while a Hg/HgO electrode in 0.1 M NaOH was used as the reference electrode in the pH = 12.8 solution. All potential values presented in this work are referenced to SCE for ease of comparison. A Pt foil was used as the counter electrode. The intensity information of each element at its specific wavelength was converted into elemental concentration using conventional ICP-AES calibration methods. Elemental dissolution rates (vM) were then obtained from the elemental concentrations using an electrolyte flow rate (f) of 2.8 mL min−1 controlled by a peristaltic pump. It is often convenient to present vM as an equivalent elemental current density to facilitate comparison with the electrical current density:

where zM is the valence of the dissolved ion M, and F is the Faraday constant. In this work, zZn and zMg were taken as 2 and zAl was taken as 3 based on thermodynamic prediction shown in Fig. 1.

Data availability

Element-resolved electrochemical data are provided in the manuscript. Other datasets generated and/or analyzed during the current study are available from the corresponding author upon reasonable request.

References

Sur, D., Joress, H., Hattrick-Simpers, J. & Scully, J. R. A high throughput aqueous passivation testing methodology for compositionally complex alloys using a scanning droplet cell. J. Electrochem. Soc. 170, 081507 (2023).

Klemm, S. O., Schauer, J.-C., Schuhmacher, B. & Hassel, A. W. High throughput electrochemical screening and dissolution monitoring of Mg-Zn material libraries. Electrochim. Acta 56, 9627–9636 (2011).

Kollender, J. P., Voith, M., Schneiderbauer, S., Mardare, A. I. & Hassel, A. W. Highly customizable scanning droplet cell microscopes using 3D-printing. J. Electroanal. Chem. 740, 53–60 (2015).

Ghassemali, E. & Conway, P. L. J. High-throughput CALPHAD: a powerful tool towards accelerated metallurgy. Front. Mater. 9, 889771 (2022).

Van de Walle, A. & Asta, M. High-throughput calculations in the context of alloy design. MRS Bull. 44, 252–256 (2019).

Nyby, C. et al. Electrochemical metrics for corrosion resistant alloys. Sci. Data 8, 58 (2021).

Wagner, C. & Taud, W. Über die Deutung von Korrosionsvorgängen durch Überlagerung von elektrochemischen Teilvorgängen und über die Potentialbildung an Mischelektrode. Z. Elektroch. 44, 391–402 (1938).

Stern, M. & Geary, A. L. Electrochemical polarization: I. A theoretical analysis of the shape of polarization curves. J. Electrochem. Soc. 104, 56 (1957).

Liu, C. & Kelly, R. G. A review of the application of finite element method (FEM) to localized corrosion modeling. Corrosion 75, 1285–1299 (2019).

Saeedikhani, M. & Blackwood, D. J. Finite element method for thin film corrosion modelling: Where we advanced and where we would like to advance?. Corros. Mater. Degrad. 1, 273–281 (2020).

Thébault, F., Vuillemin, B., Oltra, R., Ogle, K. & Allely, C. Investigation of self-healing mechanism on galvanized steels cut edges by coupling SVET and numerical modeling. Electrochim. Acta 53, 5226–5234 (2008).

Thébault, F., Vuillemin, B., Oltra, R., Allely, C. & Ogle, K. Protective mechanisms occurring on zinc coated steel cut-edges in immersion conditions. Electrochim. Acta 56, 8347–8357 (2011).

Thébault, F., Vuillemin, B., Oltra, R., Allely, C. & Ogle, K. Modeling bimetallic corrosion under thin electrolyte films. Corros. Sci. 53, 201–207 (2011).

Dolgikh, O. et al. Corrosion protection of steel cut-edges by hot-dip galvanized Al(Zn, Mg) coatings in 1 wt% NaCl: Part II. Numerical simulations. Mater. Corros. 70, 1–13 (2018).

Dolgikh, O. et al. Corrosion protection of steel cut-edges by hot-dip galvanized Al(Zn,Mg) coatings in 1 wt% NaCl: Part I. Experimental study. Mater. Corros. 70, 768–779 (2018).

Prosec, T., Larché, N., Vlot, M., Goodwin, F. & Thierry, D. Corrosion performance of Zn-Al-Mg coatings in open and confined zones in conditions simulating automotive applications. Mater. Corros. 61, 412–420 (2010).

LeBozec, N., Thierry, D., Persson, D., Riener, C. K. & Luckeneder, G. Influence of microstructure of zinc-aluminium-magnesium alloy coated steel on the corrosion behavior in outdoor marine atmosphere. Surf. Coat. Tech. 375, 897–909 (2019).

Maniam, K. K. & Paul, S. Corrosion performance of electrodeposited zinc and zinc-alloy coatings in marine environment. Corros. Mater. Degrad. 2, 163–189 (2021).

Li, S. et al. Effects of magnesium on the microstructure and corrosion resistance of Zn-55Al-1.6Si coating. Constr. Build. Mater. 71, 124–131 (2014).

Bakhsheshi-Rad, H. R. et al. Fabrication of biodegradable Zn-Al-Mg alloy: mechanical properties, corrosion behavior, cytotoxicity and antibacterial activities. Mater. Sci. Eng. C 73, 215–219 (2017).

Venezuela, J. & Dargusch, M. S. The influence of alloying and fabrication techniques on the mechanical properties, biodegradability and biocompatibility of zinc: a comprehensive review. Acta Biomater. 87, 1–40 (2019).

Meng, Y., Jiang, G., Ju, X. & Hao, J. TEM study on the microstructure of the Zn-Al-Mg alloy. Mater. Char. 129, 336–343 (2017).

Wint, N. et al. The effect of microstructural refinement on the localized corrosion of model Zn-Al-Mg alloy coatings on steel. J. Electrochem. Soc. 166, C3147 (2019).

Yasakau, K. A., Kallip, S., Lisenkov, A., Ferreira, M. G. S. & Zheludkevich, M. L. Initial stages of localized corrosion at cut-edges of adhesively bondd Zn and Zn-Al-Mg galvanized steel. Electrochim. Acta 211, 126–141 (2016).

Dutta, M., Halder, A. K. & Singh, S. B. Morphology and properties of hot dip Zn-Mg and Zn-Mg-Al alloy coatings on steel sheet. Surf. Coat. Tech. 205, 2578–2584 (2010).

Lee, J.-W. et al. Mechanistic study on the cut-edge corrosion behaviors of Zn-Al-Mg alloy coated steel sheets in chloride containing environments. Corros. Sci. 160, 108170 (2019).

Krieg, R., Rohwerder, M., Evers, S., Schuhmacher, B. & Schauer-Pass, J. Cathodic self-healing at cut-edges: The effect of Zn2+ and Mg2+ ions. Corros. Sci. 65, 119–127 (2012).

Persson, D., Thierry, D., LeBozec, N. & Prosek, T. In situ infrared reflection spectroscopy studies of the initial atmospheric corrosion of Zn-Al-Mg coated steel. Corros. Sci. 72, 54–63 (2013).

Cao, Y., Zheng, D., Zhang, F., Pan, J. & Lin, C. Layered double hydroxide (LDH) for multi-functionalized corrosion protection of metals: A review. J. Mater. Sci. Tech. 102, 232–263 (2022).

Pourbaix, M. Atlas of Electrochemical Equilibria in Aqueous Solutions 2nd edn (National Association of Corrosion Engineers, 1974).

Han, J. & Ogle, K. The anodic and cathodic dissolution of α-phase Zn-68Al in alkaline media. Corros. Sci. 148, 1–11 (2019).

Han, J. & Ogle, K. Cathodic dealloying of α-phase Al-Zn in slightly alkaline chloride electrolyte and its consequence for corrosion resistance. J. Electrochem. Soc. 165, C334–C342 (2018).

Ogle, K., Serdechnova, M., Mokaddem, M. & Volovitch, P. The cathodic dissolution of Al, Al2Cu, and Al alloy. Electrochim. Acta 56, 1711–1718 (2011).

Tran, T. T. M., Tribollet, B. & Sutter, E. M. M. New insights into the cathodic dissolution of aluminium using electrochemical methods. Electrochim. Acta 216, 58–67 (2016).

Serdechnova, M., Volovitch, P. & Ogle, K. Atomic emission spectroelectrochemistry study of the degradation mechanism of model high-temperature paint containing sacrificial aluminum particles. Surf. Coat. Tech. 206, 2133–2139 (2012).

Vu, T. N., Mokaddem, M., Volovitch, P. & Ogle, K. The anodic dissolution of zinc and zinc alloys in alkaline solution II. Al and Zn partial dissolution from 5% Al-Zn coating. Electrochim. Acta 74, 130–138 (2012).

Jegdić, B., Popić, J., Bobić, B. & Stevanović, M. Chemical corrosion of metals and alloys. Zastita Mater. 57, 205–211 (2016).

Han, J. & Ogle, K. Hydrogen evolution and elemental dissolution by combined gravimetric method and atomic emission spectroelectrochemistry. J. Electrochem. Soc. 166, C3068–C3070 (2019).

Han, J. & Gharbi, O. Current state of electrochemical techniques and corrosion rate analysis for next-generation materials. Curr. Opin. Electrochem. 36, 101131 (2022).

Gharbi, O. et al. On the corrosion of additively manufactured aluminium alloy AA2024 prepared by selective laser melting. Corros. Sci. 143, 93–106 (2018).

Shkirskiy, V. et al. Observation of l-cysteine enhanced zinc dissolution during cathodic polarization and its consequences for corrosion rate measurements. Electrochim. Acta 184, 203–213 (2015).

Dou, B., Li, X., Han, J., Birbilis, N. & Ogle, K. Operando kinetics of hydrogen evolution and elemental dissolution II: a time resolved mass-charge balance during the anodic dissolution of magnesium with variable iron content. Corros. Sci. 217, 111095 (2023).

Han, J. & Ogle, K. Dealloying of MgZn2 intermetallic in slightly alkaline chloride electrolyte and its significance in corrosion resistance. J. Electrochem. Soc. 164, C952–C961 (2017).

Han, J., Vivier, V. & Ogle, K. Refining anodic and cathodic dissolution mechanisms: combined AESEC-EIS applied to Al-Zn pure phase in alkaline solution. npj Mater. Degrad. 4, 19 (2020).

Prosek, T. et al. Effect of the microstructure of Zn-Al and Zn-Al-Mg model alloys on corrosion stability. Corros. Sci. 110, 71–81 (2016).

Han, J. et al. Elementally resolved dissolution kinetics of a Ni-Fe-Cr-Mn-Co multi-principal element alloy in sulfuric acid using AESEC-EIS. J. Electrochem. Soc. 169, 081507 (2022).

Crowe, C. R. & Kasper, R. G. Ionic current densities in the nearfield of a corroding iron-copper galvanic couple. J. Electrochem. Soc. 133, 879 (1986).

Thébault, F., Vuillemin, B., Oltra, R., Ogle, K. & Allely, C. Reliability of numerical models for simulating galvanic corrosion processes. Electrochim. Acta 82, 349–355 (2012).

Huang, M. W., Allely, C., Ogle, K. & Orazem, M. E. A mathematical model for cathodic delamination of coated metal including a kinetic pH-porosity relationship. J. Electrochem. Soc. 155, C279 (2008).

Allahar, K. N., Orazem, M. E. & Ogle, K. Mathematical model for cathodic delamination using a porosity-pH relationship. Corros. Sci. 49, 3638–3658 (2007).

Oltra, R. et al. Simulation of pH-controlled dissolution of aluminium based on a modified scanning electrochemical microscope experiment to mimic localized trenching on aluminium alloys. Electrochim. Acta 56, 7038–7044 (2011).

Sorriano, C., Oltra, R., Zimmer, A., Vuillemin, B. & Borkowski, C. Microstructural corrosion of aluminium alloys: a predictive finite element model based on corrosion mimicking experiments. Surf. Inter. Anal. 45, 1649–1653 (2013).

Cui, F., Presuel-Moreno, F. J. & Kelly, R. G. Experimental and computational evaluation of the protection provided by an aluminum cladding to AA2024-T3 exposed at a seacoast environment. Corrosion 62, 251–263 (2006).

King, A. D., Lee, J. S. & Scully, J. R. Finite element analysis of the galvanic couple current and potential distribution between Mg and 2024-T351 in a Mg rich primer configuration. J. Electrochem. Soc. 163, C342 (2016).

Simillion, H., Dolgikh, O., Terryn, H. & Deconinck, J. Atmospheric corrosion modeling. Corros. Rev. 32, 73–100 (2014).

Van den Steen, N., Simillion, H., Dolgikh, O., Terryn, H. & Deconinck, J. An integrated modeling approach for atmospheric corrosion in presence of a varying electrolyte film. Electrochim. Acta 187, 714–723 (2016).

Sharland, S. M., Jackson, C. P. & Diver, A. J. A finite-element model of the propagation of corrosion crevices and pits. Corros. Sci. 29, 1149–1166 (1989).

Srinivasan, J., Liu, C. & Kelly, R. G. Geometric evolution of flux from a corroding one-dimensional pit and its implications on the evaluation of kinetic parameters for pit stability. J. Electrochem. Soc. 163, C694 (2016).

Marshall, R. S., Katona, R. M., Melia, M. A. & Kelly, R. G. Pit stability predictions of additively manufactured SS316 surfaces using finite element analysis. J. Electrochem. Soc. 169, 021506 (2022).

Hajializadeh, F. & Ince, A. Finite element-based numerical modeling framework for additive manufacturing process. Mat. Des. Process. Comm. 1, e28 (2019).

Moazzen, P. et al. Optimum corrosion performance using microstructure design and additive manufacturing process control. npj Mater. Degrad. 9, 10 (2025).

de Oca Zapiain, D. M. et al. Accelerating FEM-based corrosion predictions using machine learning. J. Electrochem. Soc. 171, 011504 (2024).

Elvins, J., Spittle, J. A. & Worsley, D. A. Microstructural changes in zinc aluminium alloy galvanizing as a function of processing parameters and their influence on corrosion. Corros. Sci. 47, 2740–5759 (2005).

Zhang, X., Leygraf, C. & Wallinder, I. O. Atmospheric corrosion of Galfan coatings on steel in chloride-rich environments. Corros. Sci. 73, 62–71 (2013).

Yadav, A. P. et al. Effect of Al on the galvanic ability of Zn-Al coating under thin layer of electrolyte. Electrochim. Acta 52, 2411–2422 (2007).

Qiu, P., Leygraf, C. & Wallinder, I. O. Evolution of corrosion products and metal release from Galvalume coatings on steel during short and long-term atmospheric exposures. Mater. Chem. Phys. 133, 419–428 (2012).

Moreira, A. R. et al. Zn/55Al coating microstructure and corrosion mechanism. Corros. Sci. 48, 564–576 (2006).

Lowe, T. A., Wallace, G. G. & Neufeld, A. K. Insights into the cut edge corrosion of 55% Al-Zn metal coating on steel from simultaneous electrochemical polarization and localised pH sensing experiments. Corros. Sci. 55, 180–186 (2012).

Mathew, R., Stoddart, P. R. & Nolan, D. Microstructural refinement of aluminium-zinc-silicon coated steels. Surf. Coat. Tech. 306B, 490–496 (2016).

Schürz, S. et al. Chemistry of corrosion products on Zn-Al-Mg alloy coated steel. Corros. Sci. 52, 3271–3279 (2010).

Volovitch, P., Vu, T. N., Allély, C., Aal, A. A. & Ogle, K. Understanding corrosion via corrosion product characterization: II. Role of alloying elements in improving the corrosion resistance of Zn-Al-Mg coatings on steel. Corros. Sci. 53, 2437–2445 (2011).

Stoulil, J. et al. Electrochemical properties of corrosion products formed on Zn-Mg, Zn-Al and Zn-Al-Mg coatings in model atmospheric conditions. Mater. Corros. 66, 777–782 (2015).

Commenda, C. & Pühringer, J. Microstructural characterization and quantification of Zn-Al-Mg surface coatings. Mater. Character 61, 943–951 (2010).

Jiang, L., Volovitch, P., Wolpers, M. & Ogle, K. Activation and inhibition of Zn-Al and Zn-Al-Mg coatings on steel by nitrate in phosphoric acid solution. Corros. Sci. 60, 256–264 (2012).

Ogle, K. Atomic emission spectroelectrochemistry: real-time rate measurements of dissolution, corrosion, and passivation. Corrosion 75, 1398–1419 (2019).

Sultan, B. B. M., Gharbi, O., Ogle, K. & Han, J. On-line inductively coupled plasma-atomic emission spectroelectrochemistry: Real-time element-resolved electrochemistry. Curr. Opin. Electrochem. 41, 101350 (2023).

Elvins, J., Spittle, J. A., Sullivan, J. H. & Worsley, D. A. The effect of magnesium additions on the microstructure and cut edge corrosion resistance of zinc aluminium alloy galvanised steel. Corros. Sci. 50, 1650–1658 (2008).

Li, B. et al. Investigation of the corrosion behaviors of continuously hot-dip galvanizing Zn - Mg coating. Surf. Coat. Technol. 206, 3989–3999 (2012).

Shimoda, N., Ueda, K. & Kubo, Y. Corrosion resistance of several Zn-Al-Mg alloy coated steels. Nippon Steel Sumitomo Met. Tech. Rep. 108, 14–17 (2015).

Li, K., Liu, Y., Tu, H., Su, X. & Wang, J. Effect of Si on the growth of Fe-Al intermetallic layer in Zn-11%Al-3%Mg coating. Surf. Coat. Tech. 306, 390–396 (2016).

Wint, N., Eaves, D., Williams, G. & McMurray, H. N. The effect of composition and thickness on the mechanism and kinetics of filiform corrosion occurring on zinc-aluminium-magnesium coated steel. Corros. Sci. 179, 109168 (2021).

Duchoslav et al. Structure and chemistry of surface oxides on ZnMgAl corrosion protection coatings with varying alloy composition. Surf. Coat. Tech. 368, 51–58 (2019).

Sullivan, J. et al. In situ monitoring of corrosion mechanisms nad phosphate inhibitor surface deposition during corrosion of zinc-magnesium-aluminium (ZMA) alloys using novel time-lapse microscopy. Faraday Discuss. 180, 361–379 (2015).

Duchoslav, J. et al. Nanoscopic view on the initial stages of corrosion of hot dip galvanized Zn-Mg-Al- coatings. Corros. Sci. 83, 327–334 (2014).

Truglas, T. et al. Correlative characterization of Zn-Al-Mg coating by electron microscopy and FIB tomography. Mater. Charact. 166, 110407 (2020).

Prosek, T., Nazarov, A., Goodwin, F., Šerák, J. & Thierry, D. Improving corrosion stability of Zn-Al-Mg by alloying for protection of car bodies. Surf. Coat. Technol. 306, 439–447 (2016).

Wint, N. et al. The ability of Mg2Ge crystals to behave as ‘smart release’ inhibitors of the aqueous corrosion of Zn-Al-Mg alloys. Corros. Sci. 179, 109091 (2021).

Gablacová, Z., Gogola, P., Kusý, M. & Suchánek, H. The effect of Sn addition on Zn-Al-Mg alloy; Part II: corrosion behaviour. Materials 14, 5290 (2021).

Britton, D. A. et al. Effect of antimony additions on the microstructure and performance of Zn-Mg-Al alloy coatings. npj Mater. Degrad. 8, 62 (2024).

Lee, J.-W., Son, I. & Kim, S. J. Newly designed surface control using Si addition in trace quantity for Zn-2Al-3Mg alloy coated steel sheet with improved corrosion resistance. Appl. Surf. Sci. 598, 153868 (2022).

Sung, Y. et al. Microstructural characterization of corrosion resistant Zn-15Al-6Mg-0.4Si galvanized coating. J. Mater. Res. Tech. 34, 738–747 (2025).

Duchoslav, J. et al. Evolution of the surface chemistry of hot dip galvanized Zn-Mg-Al and Zn coatings on steel during short term exposure to sodium chloride containing environments. Corros. Sci. 91, 311–320 (2015).

Salgueiro Azevedo, M., Allély, C., Ogle, K. & Volovitch, P. Corrosion mechanisms of Zn(Mg,Al) coated steel: 2. The effect of Mg and Al alloying on the formation and properties of corrosion products in different electrolytes. Corros. Sci. 90, 482–490 (2015).

Schuerz, S. et al. Corrosion behaviour of Zn-Al-Mg coated steel sheet in sodium chloride containing environment. Corros. Sci. 51, 2355–2363 (2009).

Ueda, K., Takahashi, A. & Kubo, Y. Investigation of corrosion resistance of pre-painted Zn-11% Al-3% Mg-0.2% Si alloy coated steel sheet through outdoor exposure test in Okinawa. Metal. Ital. 2, 13–19 (2012).

LeBozec, N. et al. Effect of carbon dioxide on the atmospheric corrosion of Zn-Mg-Al coated steel. Corros. Sci. 74, 379–386 (2013).

Diler, E. et al. Characterization of corrosion products of Zn and Zn-Mg-Al coated steel in a marine atmosphere. Corros. Sci. 87, 111–117 (2014).

Yao, C. et al. Effect of Mg content on microstructure and corrosion behavior of hot dipped Zn-Al-Mg coatings. J. Alloy. Compd. 670, 239–248 (2016).

Salgueiro Azevedo, M., Allély, C., Ogle, K. & Volovitch, P. Corrosion mechanisms of Zn(Mg, Al) coated steel in accelerated tests and natural exposure: 1. The role of electrolyte composition in the nature of corrosion products and relative corrosion rate. Corros. Sci. 90, 472–481 (2015).

Salgueiro Azevedo, M., Allély, C., Ogle, K. & Volovitch, P. Corrosion mechanisms of Zn(Mg, Al) coated steel: The effect of HCO3- and NH4+ ions on the intrinsic reactivity of the coating. Electrochim. Acta 153, 159–169 (2015).

Tokuda, S., Nishida, Y., Nishimoto, M., Muto, I. & Takahashi, T. Effect of precipitated Mg-containing corrosion products on the anodic behavior of steel in aqueous corrosion for Zn-Al-Mg coated steel. Corros. Sci. 239, 112372 (2024).

Holzner, T., Luckeneder, G., Strauß, B. & Valtiner, M. Corrosion protection of Zn-Al-Mg-coated steel by a layered double hydroxide conversion layer. Mater. Corros. 73, 1657–1665 (2022).

Tanguy, P. et al. On the effect of multiphase microstructure of ZnAlMg substrate on the Ti-based activation and phosphate conversion coating distribution. Surf. Coat. Tech. 369, 165–174 (2019).

Lostak, T. et al. Zr-based conversion layer on Zn-Al-Mg alloy coated steel sheets: insights into the formation mechanism. Electrochim. Acta 13, 65–74 (2014).

Ponomareva, M. et al. Effect of surface pretreatments on the formation of Zr-based conversion layers on Zn-Al-Mg alloy-coated steel. Mater. Corros. 109 https://doi.org/10.1002/maco.202414664 (2024).

Chen, T. et al. Effect of SO2 and NH3 on the corrosion failure of Zn-Al-Mg coatings. Surf. Coat. Tech. 493, 131244 (2024).

Acknowledgements

The authors would like to express our sincere gratitude to Dr. Jan Stoulil (University of Chemistry and Technology in Prague, Czech Republic) for supplying intermetallic phase samples. The authors would also like to express their appreciation to the coordinators: Prof. Tomáš Prošek (University of Chemistry and Technology in Prague, Czech Republic), Dr. Nathalie LeBozec and Dr. Dominique Thierry (Institut de la Corrosion), as well as the other partners of the project. This work was partially supported by the Research Fund for Coal and Steel, grant no. RFSR-CT-2015-00011. This work was also supported by the French government’s “France 2030” initiative through the PEPR-DIADEM (Priority Research Programs and Equipment–Integrated Devices for Accelerating the Deployment of Emerging Materials) program, managed by the French National Research Agency (Agence Nationale de la Recherche, ANR), no. ANR-23-PEXD-0006.

Author information

Authors and Affiliations

Contributions

J.H. carried out the AESEC experiments and performed analysis. J.H. and K.O. conceptualized the AESEC analysis. J.H. and K.O. contributed to write the paper and revision. J.H. and K.O. read and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Han, J., Ogle, K. Element-resolved electrochemical database: AESEC polarization curves of ZnAlMg alloy coating constituents. npj Mater Degrad 9, 94 (2025). https://doi.org/10.1038/s41529-025-00627-1

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41529-025-00627-1