Abstract

Carbon steel and low alloy steel coupons were immersed for 7–8 months in natural marine medium (Les Minimes seaport – Atlantic Ocean, La Rochelle, France) and in laboratory conditions, but using natural seawater sampled in the seaport. The corrosion processes were studied by open circuit potential and linear polarization resistance measurements whereas the corrosion product layers were characterized by µ-Raman spectroscopy and X-ray diffraction. Various steel grades with increasing Cr content (from less than 0.05 wt.% to 1.1 wt.%) were considered, some of them also containing various amounts of Al, Cu, Ni and/or Si. Polarization resistance measurements showed that the resistance to corrosion was significantly improved in seaport conditions only for the low alloy steel containing 1.1 wt.% Cr and 0.55 wt.% Al. In laboratory conditions, the low alloy steel containing 0.8 wt.% Cr but no Al also showed improved resistance to corrosion. The analysis of the corrosion product layers revealed significant differences between seaport and laboratory conditions. In seaport conditions, besides the specific presence of FeS due to bacterial activity, the formation of the sulfate green rust (Fe6(OH)12SO4 ∙ 8H2O) was favored with respect to that of magnetite (Fe3O4). Finally, the improved resistance to corrosion was associated with corrosion product layers enriched with FeOOH phases and (CrIII,FeII-III) spinel-like oxides.

Similar content being viewed by others

Introduction

Marine corrosion of carbon and low alloyed steel remains a topical and crucial research axis, in particular because of the rapid expected development of marine renewable energy (MRE) devices. In France, the current aim is to produce about 45 GW (i.e., 20% of the French production of electricity) by 2050 with off-shore wind farms. The durability of MRE devices is a key point but it faces the challenge of mitigating the intrinsic corrosivity of marine environments. Besides the optimization of anticorrosion processes and methods (organic and metallic coatings, cathodic protection, etc.) the elaboration of low alloyed steel with increased resistance to corrosion in seawater is an alternative and/or complementary solution.

In a review dealing with the influence of alloying elements, R. Melchers et al. highlighted the complexity of the problem1. First, synergistic effects are often involved and the combination of two elements may lead to beneficial effects while the presence of only one element may not have any influence. It was in particular demonstrated that the combination of Cr and Al led to an increased resistance to corrosion in seawater (with respect to carbon steel), even with low amounts of alloying elements, typically 1 wt.% of Cr and 0.5 wt.% of Al2.

The role of a given alloying element may vary over time, as the mechanism of the corrosion itself changes upon exposure duration3,4,5. During the early stages of the process (aerobic phase), the corrosion rate is controlled by the transport of oxygen from seawater to steel surface through the corrosion product layer (except at the very beginning of the corrosion process)3. For advanced stages (anaerobic phase), the mechanism is closely related to the influence of micro-organism and involves the available amount of nutrients and the transport of these nutrients through the corrosion product layer5.

It is then noticeable that, at both early and advanced stages, the corrosion product layer constitutes a physical barrier between the metal and the marine environment. Its properties (including phase composition, compacity and adhesion to the substrate) necessarily influences the resistance of the steel towards corrosion. As far as Cr is concerned, many works did address its influence on the corrosion product layer forming on low alloyed steel surfaces6,7,8,9,10,11,12,13,14,15,16. An enrichment in Cr at the steel surface/corrosion product layer was reported6,7,8,9,10,11,12, associated with the presence of (Cr,Fe) oxides12,13,14,15, Cr(OH)312,13 or Cr-substituted goethite (α-Fe1-xCrxOOH)8. In the specific case of low alloyed steel with Cr (1 wt.%) and Al (0.5 wt.%), (CrIII,FeII-III) spinel-like oxides were observed2.

More fundamental studies were devoted to the influence of Cr(III) species on the formation and transformation of iron corrosion products17,18,19. It was in particular showed that Cr(III) hindered the formation of green rust compounds (GR), i.e., Fe(II-III) layered double hydroxides, and favored the solid state transformation of Fe(OH)2 thus favoring the formation of goethite (α-FeOOH)19. This finding can be correlated with corrosion studies, as it was demonstrated that Cr promoted the formation of α-FeOOH (with respect to that of magnetite Fe3O4), which improved the resistance to atmospheric corrosion of 4–8 wt.% Cr-containing low alloyed steel16. Though demonstrated beneficial, the effects of the Cr and Al combination on marine corrosion of low alloy steel remained unexplained.

Another key point when dealing with marine corrosion is the necessity to take into account the influence of microorganisms, and, more generally, the influence of the biofilm, the living organisms it contains and the associated organic matter. For carbon steel and low alloyed steel, it is generally acknowledged that the most influential micro-organisms are sulfate-reducing bacteria (SRB)20,21. Consequently, the immersion of such steels in natural environments (mostly seaport environments in published data), always implies that, after a time sufficient for SRB to develop and be active, FeS is formed as a corrosion product on the steel surface22,23,24. Besides, the organic matter associated with biofilm and micro-organisms can have various effects. It was for instance shown that organic species, via their adsorption on the crystals of sulfate green rust GR(SO42-), favored the formation of this compound at the detriment of magnetite Fe3O4 and chloride green rust GR(Cl-)25.

Based on this analysis of current knowledge, the study presented here aims to investigate the synergistic effect of Cr and Al on the corrosion resistance of low alloyed steels in marine environments, with and without microbial activity, using both field (seaport) and laboratory exposures. For that purpose, various coupons of four steel grades were immersed for 252 days at low depth (~20 cm) in the marina of La Rochelle (North Atlantic Ocean) and for 227 days in the laboratory, at a similar depth (~10 cm) in tanks filled with the same seawater (stirred vigorously), i.e., seawater sampled in the seaport and carried to the lab. One carbon steel grade (CS1) was characterized by very low amounts of both Cr and Al, the second carbon steel grade (CS2) contained 0.15 wt.% Cr (and 0.15 wt.% Ni). One low alloyed steel grade (LA1) contained 0.8 wt.% Cr and less than 0.05 wt.% Al while the second one (LA2) contained 1.1 wt.% Cr and 0.55 wt.% Al (see the “Methods” section at the end of the article for details).

The corrosion behavior was studied by open circuit potential (OCP) and linear polarization resistance (LPR) measurements. The corrosion product layers were finally characterized by X-ray diffraction (XRD) and µ-Raman spectroscopy.

Results

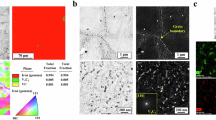

Images of the coupons were taken after 168 days. Those of coupons CS2 and LA2 immersed in both exposure conditions are shown as examples in Fig. 1.

First, Fig. 1a, c clearly show that the corrosion process is not really uniform for both CS and LA steels. Large parts of the surface are covered with brown/orange thick layers of corrosion products while other regions are covered with darker and thinner layers. This result is consistent with previous findings26,27. The thick layers cover the anodic areas, the thinner layers the cathodic areas of the steel surface. For LA2 steel (Fig. 1c), as for LA1, the anodic areas are smaller and more numerous than for CS1 and CS2 (Fig. 1a), indicating that the corrosion tends to be even less uniform for LA steel grades.

However, the main difference is not observed between the two steel grades but between the two exposure conditions. For laboratory conditions, the metal surface is covered with a (heterogeneous) layer of orange rust. The resin around the coupons remains clearly visible as a yellow frame. For seaport conditions, all the surface, metal and resin, appears covered with a greyish layer, i.e., a biofouling layer more likely including seabed sediments.

To conclude, these images clearly demonstrate that laboratory and seaport conditions are significantly different. The results obtained, described thereafter, highlight this difference.

OCP and LPR measurements

The OCP vs time curves obtained in both exposure conditions are displayed in Fig. 2. The OCP values are the average obtained for each steel grade. The discrepancy between the OCP values for 3 replicates of a given steel grade varied from one steel grade to another but was ±15 mV at worst.

In both conditions, the initial highest OCP values (days 1–10) are obtained for LA2. They decrease from LA1, CS2 and finally CS1. This clearly illustrates that the alloying elements have an influence on the behavior of the metal surface in contact with seawater.

In laboratory conditions (Fig. 2a), the OCP of LA2 decreases with time from day 1 to day 60 where it reaches a minimum of −649 mV/Ag-AgCl-3M. This decrease in OCP could correspond to a decrease in cathodic reaction rate, indicating that the growing corrosion product layer hinders more and more efficiently the transport of dissolved O2 from seawater to steel surface. The OCP of LA2 increases very slightly afterwards and finally stabilizes at −635 ± 5 mV/Ag-AgCl-3M. The same trend is observed for other steel grades. However, the initial decrease in OCP is less important while the subsequent increase is conversely more important. As an illustration, the final OCP value (day 227) is lower than the initial one (day 1) for LA2 while the final OCP value is similar to the initial one for other steel grades. The difference between the OCP values of the various steel grades is finally lower at day 227 (maximum difference = 19 mV) than at day 1 (maximum difference = 59 mV).

In seaport conditions (Fig. 2b), the OCP of LA2 decreases slowly with time. Conversely, for all other steel grades, the OCP increases rapidly with time during the first two months. It oscillates around a constant average value for CS1 and CS2 afterwards. For LA1, it remains constant at a maximum around -635 mV/Ag-AgCl-3M between day 60 and day 112 and decreases slightly, as for LA2, until the end of the experiment. The final OCP value (day 252) is the same for CS2, LA1 and LA2 (-654 mV/Ag-AgCl-3M, -657 mV/Ag-AgCl-3M and -653 mV/Ag-AgCl-3M, respectively), and slightly lower for CS1 (-667 mV/Ag-AgCl-3M). As already observed in laboratory conditions, the difference between the OCP values of the various steel grades decreases with time (maximum difference = 96 mV at day 1 and 14 mV at day 252).

The results of LPR measurements are displayed in Fig. 3. They highlight significant differences between laboratory (Fig. 3a) and seaport (Fig. 3b) conditions. The given Rp values are the average obtained for each steel, excepted for LA2 in seaport conditions where the discrepancy between the three replicates was too large. The discrepancy between the Rp values of the 3 replicates of each steel grade varied and was, at worst, equal to ±10% for LA1, ±15% for CS1 and CS2, and ±20% in laboratory conditions for LA2. The higher dispersion of Rp values for LA2 steel grade was already reported2. For LA2 in seaport conditions, the discrepancy was very important in some cases and thus the Rp vs time curves of two LA2 samples, called LA2_a and LA2_b, are shown as examples (Fig. 3b).

In both exposure conditions, the polarization resistance (Rp) values are initially (days 1–7) similar for all steel grades. In laboratory conditions, this initial value is about 1400 ± 200 Ω cm2, whereas in seaport conditions it is about 3000 ± 1000 Ω cm2. The initial discrepancy between the two exposure conditions can mainly be attributed to differences in hydrodynamic conditions and kinetics of biofilm formation.

In laboratory conditions, for all steel grades, Rp increases after the first week and reaches a maximum after 90–120 days. This increased resistance to corrosion is due to the progressive formation of a protective layer of corrosion products on the steel surface, as generally admitted3,28,29. However, the protective efficiency of this layer depends on the composition of the steel. For both carbon steel grades, the maximal Rp value is about 2300 Ω cm2. For LA1, the low alloy steel grade with 0.8 wt.% Cr and no Al, Rp reaches a maximum of 3730 Ω cm2 at day 84. Finally, for LA2, the low alloy steel grade with 1.1 wt.%Cr and 0.55 wt.% Al, the maximum is as high as 4450 Ω cm2 at day 84.

Rp decreases after day 150, i.e., 5 months after the launching of the experiments, for all steel grades. As the experiment was launched in December, this decrease began in May and the lower measured Rp values were all subsequently obtained in summer, when the temperature in the laboratory was significantly higher. This may explain the simultaneous decrease of all Rp values, as an increase in temperature in the 10 °C–40 °C range generally leads to an increase in corrosion rate4,30,31.

In seaport conditions, LA1 behaved as carbon steel coupons CS1 and CS2. The highest Rp values were observed at day 112, with a maximum of 4476 Ω cm2 for CS2. The experiments in the seaport were launched one month after the laboratory experiments so that the decrease in Rp observed after day 120 for LA1, CS1 and CS2 began in May as well. It may then be attributed to the increase in seawater temperature. It must also be noted that, once again, the initial Rp values are similar for all steel grades.

After day 60, however, the Rp of LA2 steel grade increases strongly, up to an average of 16220 Ω cm2. For sample LA2_a, a maximum of 17360 Ω cm2 is reached at day 196, while for sample LA2_b, the maximum is lower, with 15080 Ω cm2, and reached later on, at day 224. The resistance to corrosion of LA2 increases progressively with time, as a protective corrosion product layer forms on the steel surface. Actually, a drastic decrease in Rp occurs for both LA2 samples, after day 196 (LA2_a) or after 224 days (LA2_b). It is more rapid and more important than the decrease in Rp observed for other steel grades and does not occur at the same time. It cannot be attributed to the increase in temperature of the seaport water. Similar sharp changes in Rp were observed previously for LA2 steel grade and were attributed to local breakdowns of the protective corrosion product layer2, maybe due to the stress associated with the growth and increasing thickness of the protective layer. The damaged corrosion product layer may self-repair later on because it forms spontaneously in seawater, as also observed in the previous study2.

In conclusion, only LA2 demonstrated an increased resistance to corrosion, with respect to carbon steel, in both exposure conditions. In laboratory conditions, the Rp of LA2 was, at its maximum, twice as much as that of carbon steels CS1 and CS2, i.e., Rp(LA2)/Rp(CS1-2) = 2. In seaport conditions, the ratio Rp(LA2)/Rp(CS1-2) was higher, reaching an average of 6.3 for LA2_a and 6.2 for LA2_b at its maximum (days 196 and 224, respectively). Low alloy steel grade LA1 demonstrated an increased resistance to corrosion only in laboratory conditions, with a Rp(LA1)/Rp(CS1-2) ratio reaching 1.7 at its maximum (day 140).

XRD analysis of the corrosion product layers

Figures 4 and 5 display the XRD patterns of the corrosion products formed on the various steel grades in laboratory conditions.

For carbon steel grades CS1 and CS2 (Fig. 4), the main components of the corrosion product layer are unambiguously the sulfate green rust GR(SO42−) and magnetite Fe3O4. The diffraction peaks of the other identified corrosion products, namely lepidocrocite and carbonate green rust, are much less intense. The last identified compound is aragonite, one of the CaCO3 polymorph. These results are fully consistent with literature data22,23,26,32.

It is generally observed that the corrosion product layer is composed of two strata, an inner stratum mainly composed of GR(SO42−) and magnetite, and an outer stratum composed of FeOOH phases, mainly lepidocrocite γ-FeOOH for exposure times shorter than 12 months23. The sulfate green rust, with chemical formula FeII4FeIII2(OH)12SO4 ∙ 8H2O33, is the first solid phase to form from the Fe2+ ions produced by the anodic reaction (Fe → Fe2+ + 2e−)22,23,32, and its subsequent oxidation can lead, depending on numerous factors such as hydrodynamic conditions and aeration34, pH35, temperature36, organic matter concentration25, etc., to magnetite, goethite or lepidocrocite. The formation of the carbonate green rust GR(CO32−), with chemical formula FeII4FeIII2(OH)12CO3 ∙ 2-3H2O37,38, is favored in seawater by an increase in pH39, and thus mainly forms in cathodic zones of the steel surface26,27,39. Conversely, the formation of GR(SO42−) is favored in anodic zones with respect to that of GR(CO32−) and magnetite26. In cathodic zones, as observed on steel surfaces subjected to cathodic protection40,41, the increase in pH can also lead to the formation of aragonite26,39.

For both low alloy steel grades LA1 and LA2 (Fig. 5), lepidocrocite is one of the main components of the corrosion product layer, together with magnetite (LA1) or with both magnetite and GR(SO42-) (LA2). As proposed in a previous study2, the improved resistance to corrosion of these alloys may be, at least partially, attributed to the formation of an outer lepidocrocite layer, formed on top of an inner layer of GR and magnetite. This outer stratum of γ-FeOOH hinders the transport of dissolved O2.

An additional corrosion product, not present on carbon steel coupons, was identified for LA1 and LA2, however as a minor component. This compound is goethite α-FeOOH that may also have contributed to the protective efficiency of the corrosion product layer. Its formation is favored by Cr(III) species19, and, accordingly, the formation of goethite was reported to be favored by the presence of Cr in low alloy steel42,43.

Figures 6 and 7 display the XRD patterns of the corrosion products formed on the various steel grades in seaport conditions.

The main observed result is a clear difference between the composition of the corrosion product layer covering LA2 coupons and that of the corrosion product layers covering other coupons. For LA2, as observed in laboratory conditions, FeOOH phases, in this case both lepidocrocite and goethite, are the main components of the corrosion product layer, and GR compounds are not detected. Conversely, the main component is the sulfate GR in any other case, together with magnetite for LA1.

Comparing these results with those obtained in laboratory conditions, it appears that the formation of the sulfate GR is favored with respect to that of magnetite in seaport conditions (except for LA2). This finding is consistent with previous data obtained for carbon steel and was interpreted to be associated with the presence of an important amount of organic matter, typical of “natural” conditions where bacteria colonize and grow inside the corrosion product layer25. It can also be noted that goethite α-FeOOH was observed on all steel grades in seaport conditions, and as an important component of the corrosion product layer formed on LA2, while it was not observed (or as traces on LA1 and LA2) in laboratory conditions.

Finally, mineral phases coming from the marine environment were incorporated into the corrosion product layer, however in small amounts. These phases are α-quartz SiO2, i.e., sand (Fig. 6b), and calcite CaCO3, i.e., fragments of seashells (Fig. 6a and Fig. 7).

µ-Raman spectroscopy analysis of the coupons surface

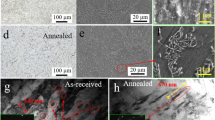

µ-Raman spectroscopy was used to identify the corrosion products present at the very surface of the metal, which were not scraped with the main part of the corrosion product layer, and remained as a discontinuous thin film on the steel coupons. The results proved similar for both carbon steel grades and typical Raman spectra are gathered in Fig. 8.

In laboratory conditions, only magnetite (Fig. 8a) and a green rust compound are identified (Fig. 8b). The GR compound is more likely GR(SO42-), the main GR compound according to the corresponding XRD analysis (Fig. 4) and previous works22,23,25,26,32. It must be recalled that GR(SO42−) and GR(CO32−), which were both identified by XRD, have similar Raman spectra44,45,46. In seaport conditions, besides magnetite (Fig. 8c) and GR(SO42−) (Fig. 8d), mackinawite FeS is identified as a third corrosion product present on the carbon steel surface (Fig. 8e). It is more precisely nanocrystalline mackinawite, as its Raman spectrum is characterized by two peaks at 207–209 cm−1 and 281–291 cm−147, which explains why it was not evidenced by XRD, as reported previously22,23,25,26.

The formation of FeS is the consequence of the metabolic activity of sulfide-producing microorganisms, mainly sulfate-reducing bacteria (SRB), as sulfide species are not normally present in seawater. Various studies carried out in seaport conditions demonstrated the link between the presence of FeS in the corrosion product layer and the colonization of this layer by SRB23,24. Actually, the formation of FeS clearly illustrates the specificity of natural conditions, e.g., seaport conditions, with respect to laboratory conditions. The present result moreover demonstrates that the use of natural seawater in the laboratory is not sufficient to reproduce the corrosion processes occurring in-situ.

Figure 9 displays the results of µ-Raman analysis for LA1 coupons. For the coupons immersed in laboratory conditions (Fig. 9a, b), the surface proved almost exclusively covered with a compound assumed to be a (CrIII,FeII-III) oxide. The Raman spectrum of this compound is mainly characterized by two rather broad peaks, located around 550–570 cm−1 and 680–700 cm−1. In Fig. 9b, two additional small peaks are seen, at 306 cm−1 and 425 cm−1, and may be attributed to the (CrIII,FeII-III) oxide too. This Raman spectrum was already reported in a previous study about marine corrosion of LA2 steel that contains both Cr (1.1 wt.%) and Al (0.55 wt.%)2. Based on similarities with the Raman spectrum of Cr2O3 (main peak at 550 cm-1)48 and the Raman spectrum of Fe3O4 (main peak at 670 cm−1)48,49, it was proposed that this compound could be a magnetite-like oxide, i.e., characterized by a spinel-like structure, but incorporating some Cr(III) cations. It would then be intermediate between magnetite, i.e., FeII1FeIII2O4, and chromite sensu stricto, i.e., FeII1CrIII2O4. The results obtained here for LA1, a low alloyed steel that does not contain Al, but Cr as the main alloying element (0.8 wt.%), confirm that the formation of this corrosion product is due to the presence of Cr in the low alloyed steel. Actually, (Fe-Cr) oxides were repeatedly identified in the corrosion product layers of Cr-containing low alloy steels6,13,14,15.

The predominance of this compound on the surface of LA1 coupons immersed in laboratory conditions indicates that the steel/corrosion product layer interface is enriched in Cr (with respect to the composition of the steel), in agreement with previous works6,7,8,9,10,11,12. According to the Raman study of (Cr,Fe) oxides48, spinel-like oxides with composition between Fe1.8Cr1.2O4 and Fe1.4Cr1.6O4 (i.e., FeII1FeIII0.8CrIII1.2O4 and FeII1FeIII0.4CrIII1.6O4) characterized by two peaks at 548–550 cm−1 and 674–679 cm−1, could correspond to the compound identified via the Raman spectra of Figs. 9a, b. Thus, this compound would contain similar Cr (40–53 at.%) and Fe (60–47 at.%) proportions.

For the LA1 coupons immersed in seaport conditions, the compounds present on the steel surfaces were different. As for carbon steel grades, only magnetite, GR(SO42−) and nanocrystalline mackinawite could be identified (Fig. 9c, d). In Fig. 9c, both typical Raman peaks of magnetite (671 cm−1)48,49 and GR(SO42−) (220 cm−1, 251 cm−1, 423 cm−1 and 510 cm−1)46 are seen. In Fig. 9d, the two characteristic peaks of mackinawite (206 cm−1 and 294 cm−1)47 are seen together with the main peak of gypsum (1008 cm−1)50,51. Gypsum, i.e., CaSO4 ∙ 2H2O, is the most important sulfate mineral in saline sediments52. The (CrIII,FeII-III) oxide covering the surface of LA1 coupons immersed in laboratory conditions could not be identified on LA1 coupons immersed in seaport conditions. As the LA1 steel grade showed an increased resistance to corrosion (with respect to carbon steel) only in seaport conditions, it can be forwarded that the thin film of (CrIII,FeII-III) oxide identified in laboratory conditions contributed to the protectiveness of the corrosion product layer.

The results obtained for LA2 steel grade, which contains both Cr (1.1 wt. %) and Al (0.55 wt.%), are displayed in Fig. 10. In laboratory conditions, in agreement with previous work2, both sulfate green rust (Fig. 10a) and (CrIII,FeII-III) oxide (Fig. 10b, c) were found at the steel surface. Various spectra were obtained for the (CrIII,FeII-III) oxide, with changing relative intensities for the two characteristic Raman peaks. The intensity of both peaks was in some cases similar (Fig. 10b) whereas the intensity of the peak at 558–568 cm−1 could be significantly higher than that of the peak at 697 cm−1 in other cases (Fig. 10c). The first spectrum can be attributed to a spinel-like (CrIII,FeII-III) oxide, as for LA1. However, a Raman spectrum such as the one displayed in Fig. 10c was not observed in the previous Raman study of (Cr,Fe) oxides48.

A first assumption would be that Al, present in LA2 steel grade but not in LA1 steel grade, could also be incorporated in the spinel-like oxide. A Raman study of (CrIII,AlIII,FeII-III) spinel-type oxides showed that the position of the two peaks varied between 529 and 601 cm-1 (peak 1) and between 678 and 727 cm−1 (peak 2) with the Cr and Al content53. However, the intensity of peak 2 remained in any case higher or similar to that of peak 153. The (Cr,Fe) oxide identified via the Raman spectrum of Fig. 10b may then be closer to chromine Cr2O3, which is characterized by a main Raman peak at 553 cm−148, than to a (Cr,Fe) spinel-like oxide.

In seaport conditions, the main phase identified on the LA2 coupons is GR(SO42−) as illustrated by Fig. 10d, e. In contrast to LA1 coupons, the (CrIII,FeII-III) oxide could be identified, but it was always associated with GR(SO42−), as displayed in Fig. 10e. More likely, the (CrIII,FeII-III) oxide is in contact with the metal surface and GR(SO42−) precipitates on top of the oxide film surface. Either way, the (CrIII,FeII-III) oxide appeared less abundant after exposure in seaport conditions, confirming, as clearly observed for LA1 coupons, that the specificities of the exposure in a natural site are unfavorable for the formation of (CrIII,FeII-III) oxides. This could be the consequence of processes that hinder the formation of such oxides, or the consequence of processes that favors the formation of another phase, for instance GR(SO42−), which proved to be favored with respect to magnetite through the influence of adsorbed organic species25.

Discussion

First, the present study highlights the role of the exposure conditions. It clearly demonstrates that the use of natural seawater in laboratory conditions is not sufficient to reproduce the processes taking place in real marine environments. The main evidence is the detection via µ-Raman spectroscopy of mackinawite FeS in seaport conditions on CS1, CS2 and LA1 coupons, while it could not be identified on any of the coupons immersed in laboratory conditions, even using natural seawater. FeS results from the metabolic activity of sulfide-producing bacteria (mainly SRB) and its absence on the coupons immersed in laboratory conditions clearly indicate that these conditions cannot be compared, in terms of bacterial growth and biological activity, to those met in natural sites. This particular point was illustrated by the visual aspect of the coupons (Fig. 1), which revealed the presence of a (visible) biofouling layer in seaport conditions only. Other significant differences were observed between both exposure conditions, as discussed thereafter.

Secondly, the obtained results highlight the antagonist roles of Cr and effect of organic matter. Both carbon steel grades CS1 and CS2 showed similar behavior. The amount of Cr (0.15 wt.%) and other alloying elements present in CS2 was not sufficient to ensure an improved resistance to corrosion in both experimental conditions considered here. However, looking closely to the XRD data obtained for the samples immersed in laboratory conditions, it appears that this small quantity of alloying elements favored magnetite with respect to GR(SO42−). This effect seems to be mainly due to Cr, because for LA1 steel (0.8 wt.%Cr), the proportion of magnetite, with respect to that of GR(SO42−), is even more important. To study the evolution of magnetite and GR(SO42−) proportions with Cr content, the ratio between the intensity of the main diffraction peak of magnetite and that of the main diffraction peak of GR(SO42−) was determined in each case. The intensity was determined via a computer fitting of the diffraction peaks, using a Gauss function for the (311) peak of magnetite and a Lorentz function for the (001) peak of GR(SO42−), set at low diffraction angles. This ratio, i.e., IM311/IGRS001, was then computed at 0.54 for CS1, 1.56 for CS2 and 5.96 for LA1 in laboratory conditions (Table 1).

This effect of Cr is consistent with a previous fundamental study devoted to the effects of Cr(III) species on the oxidation of Fe(OH)2, which demonstrated that Cr(III) hindered the formation of GR compounds19, thus favoring other phases, in the present case magnetite. However, this effect of Cr is strongly attenuated in seaport conditions, as it can be seen comparing the XRD patterns of Fig. 4 and Fig. 5a. More precisely, the IM311/IGRS001 ratio is 0.43 for CS1, 0.28 for CS2 and 0.81 for LA1 in seaport conditions (Table 1). The effect of Cr is even not observed for CS2 (0.15 wt.% Cr) and kept small for LA1 (0.8 wt.% Cr) if compared with laboratory conditions. Moreover, the IM311/IGRS001 ratio is, for each steel grade, smaller in seaport than in laboratory conditions. This result is consistent with previous works, as it was noted that exposure in “natural” conditions favored the formation of GR(SO42−) with respect to magnetite25. It was demonstrated that the adsorption of organic species on the crystals of GR(SO42−) prevented its subsequent transformation to magnetite25. The effects of Cr(III) species were similarly interpreted via mechanisms hindering the transformation of Fe(OH)2 particles to GR crystals19. It can then be forwarded that the inhibition of the influence of Cr(III) species in seaport conditions is due to a competitive process with the adsorption of organic species on the particles of iron corrosion products.

Thirdly, the increased resistance to corrosion in seawater proved linked to the composition of the corrosion product layer. For both low alloy steel grades LA1 and LA2, an improved resistance to corrosion was observed in laboratory conditions. The best results were observed with LA2 that contains Al (0.55 wt.%) and slightly more Cr (1.1 wt.%) than LA1 (0.8 wt.%). However, only LA2 showed an improved resistance to corrosion in seaport conditions. The improvement was even better than in laboratory conditions. Conversely, LA1 did not show any improved resistance to corrosion in seaport conditions. In any case, the improved resistance to corrosion was not observed at the beginning of the immersion, but appeared with time and increased during the first two months. This improved resistance to corrosion is then due to the protective ability of the corrosion product layer forming spontaneously when steel is immersed in seawater. The resistance to corrosion increases with the increasing thickness of the corrosion product layer, as this layer constitutes a more and more efficient barrier against dissolved O2 diffusion. In agreement with this result, the composition of the corrosion product layer proved significantly different for steel grades with improved resistance to corrosion, that is for LA2 in each considered condition and for LA1 in laboratory conditions. When the resistance to corrosion is increased, lepidocrocite γ-FeOOH is the main component of the corrosion product layer (Fig. 5, to be compared with Fig. 4), together with goethite α-FeOOH for LA2 in seaport conditions (Fig. 7). The FeOOH phases form an outer stratum (seawater side) in the corrosion product layer2,22,23,24,25,54, thus constitute a physical barrier between the marine environment and the inner stratum (metal side) that contains GR(SO42−), FeS (in seaport conditions) and Fe3O4. Both lepidocrocite and goethite are insulating compounds and can indeed constitute a physical barrier hindering the transport of dissolved O2. In contrast, both FeS and Fe3O4 are electronic conductors55,56 and may be cathodic sites for O2 reduction22,26.

µ-Raman spectroscopy however revealed another important difference. The improved resistance to corrosion is also associated with the formation, in this case in the most inner part of the corrosion product layer, i.e., on the metal surface, of spinel-like (CrIII,FeII-III) oxides (Fig. 9a, b and Fig. 10b, e) and in one case for LA2, of an oxide close to Cr2O3 (Fig. 10c). These oxides were the main compounds present on the surface of LA1 steel in laboratory conditions while they could not be identified for LA1 in seaport conditions. For this steel grade containing 0.8 wt.% Cr but no Al, the Raman spectra obtained in laboratory conditions were all typical of spinel-like (CrIII,FeII-III) oxides (with probable composition between FeII1FeIII0.8CrIII1.2O4 and FeII1FeIII0.4CrIII1.6O4), hence compounds similar to magnetite (FeII1FeIII2O4). Such oxides were not observed in seaport conditions, a result that can be compared to the decrease in magnetite proportion in seaport conditions observed for LA1, CS1 and CS2, with respect to laboratory conditions. The mechanisms may be the same as those forwarded for the increase in the GR(SO42−) to Fe3O4 abundance ratio, which are linked to the influence of organic matter that favors GR(SO42−). For LA2, the (Cr,Fe) oxides were observed in both exposure conditions, but always associated to GR(SO42−) in seaport conditions. Once again, the influence of organic matter can be forwarded.

The fourth important point is the beneficial effect of the combination of Cr and Al. For LA2, the improved resistance to corrosion, with respect to LA1 steel, is more likely the consequence of the presence of Al (0.55 wt.%), though the slightly higher proportion in Cr may also be beneficial (1.1 wt.% vs 0.8 wt.% for LA1). In laboratory conditions, where both LA1 and LA2 steels showed an improved resistance to corrosion with respect to carbon steel, the differences between the composition of the corresponding corrosion product layers were small. The proportion of magnetite was however higher for LA1, and those of GR(SO42−) and γ-FeOOH were higher for LA2 (Fig. 5). This enrichment in Fe3O4 may favor corrosion cells as Fe3O4 particles can act as cathodic sites if they are interconnected and connected to the metal surface. Actually, the XRD pattern of LA1 in laboratory conditions (Fig. 5a) was the only one showing a higher proportion of GR(CO32−) than GR(SO42−). The formation of GR(CO32−) is favored by an increase in pH39, and thus GR(CO32−) preferentially forms in cathodic sites of the steel surface26. The high proportion of GR(CO32−) for LA1 in laboratory conditions then confirmed that the high proportion of magnetite did favor corrosion cells, which may explain the lesser resistance to corrosion of LA1, if compared to LA2.

In seaport conditions, the corrosion product layers of LA1 and LA2 were conversely characterized by significantly different compositions (Figs. 6c and 7 for XRD and Figs. 9c, d and 10d, e for Raman spectroscopy). This result fully explains the corresponding differences between the corrosion behaviors of LA1 and LA2 in seaport conditions. The XRD of Fig. 7 showed that the corrosion product layer of LA2 was in this case enriched with FeOOH phases, while µ-Raman spectroscopy analysis identified (Cr,Fe) oxides on the steel surface. Possibly, for LA2, it could be (Cr,Al,Fe) oxides but there was no evidence from Raman analysis that this was indeed the case. However, it is only for LA2 in seaport conditions that an important goethite (α-FeOOH) proportion was observed (Fig. 7 to be compared with all XRD patterns). Strikingly, it was demonstrated that the addition of a small amount (5 at.%) of Al(III) species strongly favored the oxidation of GR(SO42−) to goethite (with respect to lepidocrocite) in marine environments57. This confirms that combined effects of Al and Cr are involved in the improved resistance of LA2 steel to marine corrosion.

As a conclusion, the main results can be summarized as follows:

-

First, this study highlights that the resistance to corrosion of Cr-containing low alloyed steel, such as LA1 steel grade, may be different depending on exposure conditions, i.e., laboratory or seaport conditions, due to the opposite effects of Cr and organic matter. To our knowledge, this is the first comparative study highlighting how Cr’s inhibition of GR formation, a beneficial effect in laboratory conditions, is suppressed in natural marine environments due to organic matter competition.

-

The combination of Cr and Al in LA2 steel grade leads to an improved resistance to corrosion in both laboratory and seaport conditions. This improved resistance to corrosion is due to changes in the corrosion product layer composition. The mechanisms involved in the effectiveness of Cr and Al combination still remained unclear and need further research studies to be elucidated.

-

The best corrosion performance was observed for LA2 steel grade in seaport conditions: the corrosion product layer was enriched in both goethite (α-FeOOH) and spinel-like (CrIII,FeII-III) oxides, leading, at the maximum, to Rp values six times higher than those of carbon steel after about 6–7 months of immersion.

-

The use of natural seawater in the laboratory is not sufficient to reproduce the corrosion processes taking place in real marine environments (seaport conditions). Results obtained in laboratory and seaport conditions thus differ, but laboratory studies remained necessary to provide the information related to the main electrochemical processes and interpret the origin of the discrepancy with “natural” conditions whatever its origin (influence of micro-organisms, organic matter, sediments, local variations of seawater composition, etc.).

-

Though further research is needed to fully understand the mechanisms and assess the efficiency of Cr and Al containing low alloy steels in various exposure zones (i.e., tidal zone, splash zone), the promising results described here confirm that corrosion resistant low alloy steels should be considered in the next future as a possible alternative to carbon steel for marine applications.

Methods

Materials and experimental setup

Four steel grades were considered for this study. Two of them were carbon steel (CS1 and CS2), two of them were low-alloy steel (LA1 and LA2), with a similar carbon content of 0.15 ± 0.01 wt.%. Their composition, restricted to the main alloying elements, is given in Table 2. Other elements (S, P, N, V, Mo, Nb, Ti and Sn), present with wt.% lower than 0.1 in all alloys, are omitted.

In Table 2, the various alloys are listed with increasing Cr content. From CS1 to LA2, the Cr content increases from less than 0.05 wt.% to 1.1 wt.%. Except for CS1 that contains a very small proportion of alloying elements (except Si and Mn) and for LA2 that contains 0.55 wt.% of Al, the proportion of alloying elements does not vary so importantly as the Cr content. The Si content remains between 0.2 wt.% and 0.4 wt.%, the Ni content between 0.1 wt.% and 0.2 wt.% and the Cu content between 0.2 wt.% and 0.4 wt.%.

Three coupons of each steel grade were immersed in natural seawater in the marina of La Rochelle (North Atlantic Ocean). Figure 11a shows the experimental platform where the coupons were immersed vertically at a depth of ~20 cm (measured from the upper edge of the coupons). The experimental platform floats on the sea surface and the immersion depth is then constant whatever the tide. Seawater temperature was measured before each electrochemical measurement campaign. It varied from an average of 9–10 °C in winter (January to March), and increased up to an average of 18–20 °C in summer (June to August).

The sample holders, each one carrying six coupons, were designed specifically for the study (Fig. 11b). Note that the study initially included two other carbon steel grades, hence the overall number of 18 coupons. The results obtained with these two grades were not significantly different from those obtained with CS1 and CS2 and are thus not described here. A copper wire was first welded on one side of each coupon to ensure the connection with the potentiostat used for electrochemical measurements. The coupons were then embedded in epoxy resin so that the weld could not be in contact with seawater and only the opposite side of the coupons was exposed to seawater (4.6 mm × 4.6 mm, i.e., active area of 21.16 cm2). This side was abraded with SiC paper, grade 180 (i.e., average particle size = 76 µm), to simulate a sandblasted surface. The previously formed oxide/rust layer was then totally removed from the metal surface to be exposed to seawater.

For laboratory experiments, two cylindrical tanks (diameter = 50 cm, height = 100 cm) were filled with vigorously stirred natural seawater sampled in the marina of La Rochelle. Therefore, the same seawater was used in both laboratory and seaport experiments. A sample holder (as displayed in Fig. 11b) was set in each tank so that the steel coupons were immersed at a depth of 10 cm. Seawater was entirely renewed monthly in each tank. To avoid important differences in temperature with seaport conditions, the laboratory experiments were carried out in a shed-like room not heated in winter and sheltered from the sun in summer. However, occasional temperature measurements revealed that the temperature of laboratory conditions was always a few degrees (°C) higher than that of seaport conditions.

The coupons were removed from seawater after 252 days (seaport conditions) or 227 days (laboratory conditions) and immediately set in a freezer (−20 °C) to avoid further corrosion of the metal and further oxidation of Fe(II)-based corrosion products (e.g., green rust compounds) before analysis2,22,23,26. The coupons immersed in La Rochelle marina were carried to the lab while still immersed in a tank filled with seawater.

Electrochemical measurements

All electrochemical measurements were performed with a Bio-Logic VSP potentiostat using a titanium grid as counter electrode and an Ag/AgCl/3 M reference electrode (E = +0.210 V vs SHE at 25 °C). OCP (open circuit potential) and LPR (linear polarization resistance) measurements were carried out on all coupons. For LPR measurements, the polarization was limited at OCP ± 15 mV with a low scan rate dE/dt = 0.1 mV s−1 to restrict capacitive effects. This range of E variation was chosen as a compromise between minimal number of required data and minimal perturbation of the corrosion system. The experimental sequence applied in each case consisted of an OCP measurement for 15 min, followed by LPR measurements. This 15 min duration was sufficient to determine whether the system has reached a steady state (constant OCP) or not (OCP varying with time). When needed, i.e., if the OCP was varying significantly when LPR measurement was performed, the measurement was repeated.

Characterization of the corrosion product layers

The corrosion product layers covering the coupons were entirely scraped for XRD analysis, except for a very thin adherent film remaining here and there on the surface. The remnants of this film that could not be scraped were subsequently analyzed by µ-Raman spectroscopy.

For XRD analysis, the corrosion products were mixed with glycerol, a procedure that sheltered from air the Fe(II)-based compounds such as green rusts (GRs)58, and then ground to obtain a homogeneous oily paste. The XRD analysis was carried out with a D8 Advance diffractometer (Bruker AXS GmbH, Karlsruhe, Germany) using the Cu-Kα radiation (λ = 0.15418 nm), with Bragg–Brentano geometry in the 2θ range of 6° to 65°. The 2θ angle was varied by steps of 0.0133° each 0.4 s, for an overall acquisition time of 30 min. The diffracted signal was acquired using the LYNXEYE XE-T silicon strip detector. The ICDD-JCPDS-PDF-2 database (ICDD, Newtown Square, PA, USA) was used to identify the crystalline phases and the peaks were indexed according to the corresponding file.

µ-Raman spectroscopy analysis was carried out with a Horiba High Resolution Raman spectrometer (LabRAM HR) equipped with an Olympus BX 41 microscope and a Peltier-based cooled charge coupled device (CCD) detector. Various zones (diameter of ~5 µm) of each coupon surface were analysed at room temperature through a ×50 long working distance objective. A minimum of 20 zones were considered in each case and typical spectra were recorded with a resolution of ~1 cm−1. Excitation was provided by a green laser diode (533 nm) whose power was reduced to 2.5% of the maximum (~0.5 mW) in order to prevent an excessive heating able to induce the transformation of the analysed Fe-compound into hematite (α-Fe2O3)49. The acquisition time was 1 min in most cases, but was increased up to 2 min to optimize the signal-to-noise ratio when necessary.

Data availability

The data that support the findings of this study are available in “figshare” with the identifier https://doi.org/10.6084/m9.figshare.29890340.

References

Melchers, R. E. Effect of small compositional changes on marine immersion corrosion of low alloy steels. Corros. Sci. 46, 1669–1694 (2004).

Refait, Ph., Jeannin, M., Urios, T., Fagot, A. & Sabot, R. Corrosion of low alloy steel in stagnant artificial or stirred natural seawater: role of Al and Cr. Mater. Corros. 70, 985–995 (2019).

Melchers, R. E. Mathematical modelling of the diffusion-controlled phase in marine immersion corrosion of mild steel. Corros. Sci. 45, 923–940 (2003).

Melchers, R. E. & Jeffrey, R. Early corrosion of mild steel in seawater. Corros. Sci. 47, 1678–1693 (2005).

Melchers, R. E. & Wells, T. Models for the anaerobic phases of marine immersion corrosion. Corros. Sci. 48, 1791–1811 (2006).

Li, J. et al. Corrosion behavior of low-carbon Cr micro-alloyed steel for grounding grids in simulated acidic soil. J. Iron Steel Res. Int. 25, 755–766 (2018).

Yamashita, M., Miyuki, H., Matsuda, Y., Nagano, H. & Misawa, T. The long term growth of the protective rust layer formed on weathering steel by atmospheric corrosion during a quarter of a century. Corros. Sci. 36, 283–299 (1994).

Nishimura, T. Rust formation mechanism on low alloy steels after exposure test in high Cl- and high SOx environment. Materials 10, 199 (2017).

Jiang, S., Chai & Yang, C. F. Influence of Cr on reduction behavior of rust formed on low alloy steels in flowing 3.5% NaCl solution. J. Iron Steel Res. 30, 251–258 (2018).

Wu, X.-J. et al. Initial corrosion behavior and electrochemical property evolution of 40CrNiMo steel in salt spray environment. Surf. Technol. 51, 234–244 (2022).

Ming, J., Zhou, X., Jiang, L. & Shi, J. Corrosion resistance of low-alloy steel in concrete subjected to long-term chloride attack: characterization of surface conditions and rust layers. Corros. Sci. 203, 110370 (2022).

Qi, X. et al. Corrosion resistance and mechanism of X100 pipeline steel laser-metal active gas hybrid welds with Cr containing welding wire in NS4 solution. Corros. Sci. 221, 111329 (2023).

Yang, J., Jiang, S. & Xu, F. Effect of Cr on the characteristic of rust layer formed on low alloy steels immersed in flowing 3.5%NaCl solution. J. Phys.: Conf. Ser. 1626, 012175 (2020).

Hao, X. et al. The microstructure and corrosion behavior of Cr-containing ferrite-pearlite steels in acidic environment, Anti-Corros. Methods Mater. 70, 218–226 (2023).

Park, J. S., Lee, S. C., Choi, J. K. & Kim, S. J. Advanced Hadfield steel with Cr-optimization resists against corrosion and erosion-corrosion. Appl. Surf. Sci. 637, 157875 (2023).

Sun, B., Zuo, X. & Li, X. The role of chromium content in the long-term atmospheric corrosion process. npj Mater. Degrad. 4, 37 (2020).

Liu, W. et al. Role of Cr in the anticorrosion ability of weathering steel based on the microcharacteristics of synthetic α-FeOOH in the presence of Cr(III). JOM 75, 3170–3182 (2023).

Inoue, K., Shinoda, K., Susuki, S. & Waseda, Y. Oxidation of green rust suspensions containing different chromium ion species. Corros. Sci. 52, 1421–1427 (2010).

Serjaouan, M., Rémazeilles, C. & Refait, Ph. Influence of Cr(III) on the formation and transformation of corrosion products of steel in marine environments. npj Mater. Degrad. 8, 4 (2024).

Little, B. J., Lee, J. S. & Ray, R. I. The influence of marine biofilms on corrosion: A concise review. Electrochim. Acta 54, 2–7 (2008).

Stipanicev, M. et al. Corrosion behavior of carbon steel in presence of sulfate-reducing bacteria in seawater environment. Electrochim. Acta 113, 390–406 (2013).

Refait, Ph., Grolleau, A.-M., Jeannin, M., Rémazeilles, C. & Sabot, R. Corrosion of carbon steel in marine environments: role of the corrosion product layer. Corros. Mater. Degrad. 1, 198–218 (2020).

Pineau, S. et al. Formation of the Fe(II-III) hydroxysulphate green rust during marine corrosion of steel associated to molecular detection of dissimilatory sulphite-reductase. Corros. Sci. 50, 1099–1111 (2008).

Lanneluc, I. et al. On the bacterial communities associated with the corrosion product layer during the early stages of marine corrosion of carbon steel. Int. Biodeter. Biodegrad. 99, 55–65 (2015).

Duboscq, J. et al. Influence of organic matter/bacteria on the formation and transformation of sulfate green rust. Corros. Mater. Degrad. 3, 1–16 (2022).

Refait, Ph., Grolleau, A.-M., Jeannin, M., François, E. & Sabot, R. Localized corrosion of carbon steel in marine media: galvanic coupling and heterogeneity of the corrosion product layer. Corros. Sci. 111, 583–595 (2016).

Refait, Ph., Jeannin, M., François, E., Sabot, R. & Grolleau, A.-M. Galvanic corrosion in marine environments: effects associated with the inversion of polarity of Zn/carbon steel couples. Mater. Corros. 70, 950–961 (2019).

Evans, U. R. The Corrosion and Oxidation of Metals: Scientific Principles and Practical Applications (Edward Arnold (Publishers) Ltd., 1960).

Jones, D. Principles and Prevention of Corrosion, 2nd ed. (Prentice-Hall, 1996).

Toloei, A., Atashin, S. & Pakshir, M. Corrosion rate of carbon steel under synergistic effect of seawater parameters including pH, temperature, and salinity in turbulent condition. Corros. Rev. 31, 135–144 (2013).

Chohan, I. M. et al. Effect of seawater salinity, pH, and temperature on external corrosion behavior and microhardness of offshore oil and gas pipeline: RSM modelling and optimization. Sci. Rep. 14, 16543 (2024).

Refait, Ph. et al. Electrochemical formation of green rusts in deaerated seawater-like solutions. Electrochim. Acta 56, 6481–6488 (2011).

Simon, L. et al. Structure of the Fe(II-III) layered double hydroxysulphate green rust two from Rietveld analysis. Sol. State Sci. 5, 327–334 (2003).

Gilbert, F., Refait, Ph., Lévêque, F., Remazeilles, C. & Conforto, E. Synthesis of goethite from Fe(OH)2 precipitates: influence of Fe(II) concentration and stirring speed. J. Phys. Chem. Solids 69, 2124–2130 (2008).

Olowe, A. A. & Génin, J.-M. R. The mechanism of oxidation of Fe(II) hydroxide in sulfated aqueous media: importance of the initial ratio of the reactants. Corros. Sci. 32, 965–984 (1991).

Olowe, A. A., Pauron, B. & Génin, J.-M. R. The influence of temperature on the oxidation of ferrous hydroxide in sulphated aqueous medium: activation energies of formation of the products and hyperfine structure of magnetite. Corros. Sci. 32, 985–1001 (1991).

Stampfl, P. P. Ein basisches Eisen(II,III)-Karbonat in Rost. Corros. Sci. 9, 185–187 (1969).

Drissi, S. H., Refait, Ph., Abdelmoula, M. & Génin, J.-M. R. Preparation and thermodynamic properties of Fe(II)-Fe(III) hydroxide-carbonate (green rust one), Pourbaix diagram of iron in carbonate-containing aqueous media. Corros. Sci. 37, 2025–2041 (1995).

Duboscq, J., Sabot, R., Jeannin, M. & Refait, Ph. Localized corrosion of carbon steel in seawater: processes occurring in cathodic zones. Mater. Corros. 70, 973–984 (2019).

Wolfson, S. L. & Hartt, W. H. An initial investigation of calcareous deposits upon cathodic steel surfaces in sea water. Corrosion 37, 70–76 (1981).

Yan, J.-F., Nguyen, T. V. & White, R. E. Mathematical modelling of the formation of calcareous deposits on cathodically protected steel in seawater. J. Electrochem. Soc. 140, 733–742 (1993).

Yuan, R., Wu, H. & Gu, Y. Effect of alloyed Cr on corrosion behavior of low-alloy steel in wet atmosphere. Mater. Corros. 73, 918–931 (2022).

Dong, B. et al. Optimize Ni, Cu, Mo element of low Cr-steel rebars in tropical marine atmosphere environment through two years of corrosion monitoring. Cem. Concr. Comp. 125, 104317 (2022).

Legrand, L., Sagon, G., Lecomte, S., Chaussé, A. & Messina, R. A Raman and infrared study of a new carbonate green rust obtained by electrochemical way. Corros. Sci. 43, 1739–1749 (2001).

Reffass, M. et al. Localised corrosion of carbon steel in NaHCO3/NaCl electrolytes: role of Fe(II)-containing compounds. Corros. Sci. 48, 709–726 (2006).

Sabot, R. et al. Influence of lactate ions on the formation of rust. Corros. Sci. 49, 1610–1624 (2007).

Bourdoiseau, J. A., Jeannin, M., Sabot, R., Rémazeilles, C. & Refait, Ph. Characterisation of mackinawite by Raman spectroscopy: effects of crystallisation, drying and oxidation. Corros. Sci. 50, 3247–3255 (2008).

McCarty, K. F. & Boehme, D. R. A Raman study of the systems Fe3-xCrxO4 and Fe2-xCrxO3. J. Solid State Chem. 79, 19–27 (1989).

De Faria, D. L. A., Silva, S. V. & Oliveira, M. T. D. Raman micro spectroscopy study of some iron oxides and oxyhydroxides. J. Raman Spectrosc. 28, 873–878 (1997).

Berenblut, B. J., Dawson, P. & Wilkinson, G. R. The Raman spectrum of gypsum. Spectrochim. Acta 27A, 1849–1863 (1971).

Brotton, S. J. & Kaiser, R. I. In situ Raman spectroscopic study of gypsum (CaSO4·2H2O) and epsomite (MgSO4·7H2O) dehydration utilizing an ultrasonic levitator. J. Phys. Chem. Lett. 4, 669–673 (2013).

Ichikuni, M. & Musha, S. Partition of strontium between gypsum and solution. Chem. Geol. 21, 359–363 (1978).

Kaliwoda, M. et al. Raman spectroscopy as a tool for the quantitative estimation of chromium aluminum oxide content in chromite. Spectroscopy 36, 18–23 (2021).

Duan, J. et al. Corrosion of carbon steel influenced by anaerobic biofilm in natural seawater. Electrochim. Acta 54, 22–28 (2008).

Enning, D. et al. Marine sulfate-reducing bacteria cause serious corrosion under electroconductive biogenic mineral crust. Environ. Microbiol. 14, 1772–1787 (2012).

Lopez Maldonado, K. L. et al. Effects of grain boundary width and crystallite size on conductivity and magnetic properties of magnetite nanoparticles. J. Nanopart. Res. 16, 2482 (2014).

Refait, Ph., Sabot, R. & Jeannin, M. Role of Al(III) and Cr(III) on the formation and oxidation of the Fe(II-III) hydroxysulfate Green Rust. Coll. Surf. A 531, 203–212 (2017).

Hansen, H. C. B. Composition, stabilisation, and light absorption of Fe(II)-Fe(III) hydroxycarbonate (green rust). Clay Miner. 24, 663–669 (1989).

Acknowledgements

The authors thank Bruno Péraudeau for his help in the design and making of the experimental setup.

Author information

Authors and Affiliations

Contributions

M.S.: Measurements, data analysis, methodology, visualization; A.S.: Measurements, methodology, data analysis; M.J.: Conceptualization, data analysis, methodology; P.G.: Measurements, data analysis; T.U.: Conceptualization, methodology, funding acquisition; C.R.: Conceptualization, data analysis, methodology; P.R.: Measurements, conceptualization, data analysis, visualization, methodology, writing, funding acquisition.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Serjaouan, M., Serres, A., Jeannin, M. et al. Marine corrosion of carbon and micro-alloyed steel: comparison between seaport and laboratory conditions. npj Mater Degrad 9, 112 (2025). https://doi.org/10.1038/s41529-025-00666-8

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41529-025-00666-8