Abstract

Cryopreservation is a widely employed method for processing and preserving food. However, conventional antifreeze agents often hard to mitigate the mechanical damage caused by ice recrystallization during freeze-thaw cycles. In this study, two ice-binding proteins (IBPs), COR15B and COR47, were identified from Raphanus sativus using bioinformatics and molecular biology techniques. Both IBPs exhibited significant ice recrystallization inhibition (IRI) and ice crystal morphology modification activity. A novel, high-yield Bacillus subtilis expression system was developed for the heterologous production of these IBPs, achieving approximately 50 μg/mL through response surface optimization. These proteins, even when used at thousandths of the ratio, retained their IRI activity. Notably, the heterologously expressed IBPs significantly reduced freeze-induced damage in flour-based products and improved yeast survival and fermentative capacity during repeated freeze-thaw cycles. These results highlight the considerable potential of radish-derived IBPs as cryoprotectants for enhancing food storage stability.

Similar content being viewed by others

Introduction

Freezing is a widely used method for food preservation, wherein temperatures are lowered to near or below the freezing point to improve food processing and storage. However, due to the high water content in most foods, cryopreservation and transportation often results in quality degradation including moisture loss, ice crystal damage, and protein denaturation1. Cell-based frozen foods, such as freeze-dried probiotics, are particularly vulnerable to mechanical damage from ice crystals, leading to reduced cell viability2,3. As a result, antifreeze agents are critical in frozen food applications. Despite rapid advancements in food freezing technologies, traditional antifreeze agents such as sugar-based and phosphate-based compounds still face challenges, including issues with concentration control, uneven distribution post-processing, and safety concerns4. Moreover, cell cryoprotectants like dimethyl sulfoxide (DMSO), glycerol, and 1,2-propanediol can interfere with cellular metabolism and require high concentrations that are often toxic to cells and tissues, potentially causing irreversible damage. This underscores the need for novel antifreeze agents. In this context, protein-based antifreezes have attracted significant attention due to their high efficacy, low required concentrations5, and safety1,6.

Ice-binding proteins (IBPs) are unique proteins that allow organisms to survive in subzero conditions7,8. The antifreeze activity of IBPs is manifests in three aspects: ice crystal morphology modification activity, thermal hysteresis activity, and recrystallization inhibition activity, making them valuable in various fields such as food preservation, agriculture, and cryobiology. Plant-derived IBPs, such as DrAFP2,TaEON3,RBCaB9 and LpIRI310, are naturally non-toxic to cells and exhibit strong recrystallization inhibition, effectively mitigating quality loss in food under freezing conditions. The mechanism of action of these proteins is kinetic in nature, enabling their activity at concentrations an order of magnitude lower than traditional chemical antifreezes5. Plant-derived IBPs have been approved in various national food additive standards, particularly in products like ice cream, highlighting their promise in the food industry6,11. While many plant-derived IBPs have been identified, most research has focused on their interactions with ice crystals and antifreeze functions in laboratory settings, with relatively limited application-oriented studies. One primary challenge is the low natural abundance of these proteins, coupled with the difficulties associated with their extraction, purification, and regeneration, which hinders large-scale production. Additionally, the diverse structural and function of cold-regulatory proteins complicate the understanding of their antifreeze mechanisms, adding complexity to their use and safety.

Raphanus sativus (radish) is one of the world’s oldest cultivated crops, widely consumed globally, with assured safety of its proteins. Although there are reports of active IBPs in R. sativus with significant potential in food, agriculture, medicine, and chemical industries9, there is a lack of comprehensive reports detailing their identity and properties. The extraction of IBPs from R. sativus remains challenging due to their low concentration in the plant. Heterologous protein expression in bacteria offers a promising approach to to overcome the limitations of natural protein production, such as low yield and high purification costs. Bacillus subtilis, known for its safety in industrial and pharmaceutical production12, rapid growth13, strong secretion capacity14, clear genetic background15,16, and availability of genetic engineering tools17,18,19,20,21,22, is an ideal host for the expression of antifreeze proteins. Notably, B. subtilis has been successfully used to express antifreeze proteins from fish and insects23,24, making it a suitable candidate for IBP production.

In this study, we identify highly active plant-derived IBPs from Raphanus sativus and explore their mass production in a cell-based system for application in frozen dough products. Two IBPs were identified using bioinformatics and genetic engineering approaches, both of which exhibited significant recrystallization inhibition and ice crystal morphology modification activity. An optimized expression system was developed using the B. subtilis strain WB800N, enabling mass production of these proteins for potential industrial application. The heterologous IBPs demonstrated antifreeze activity, maintaining the quality preservation of dough quality and enhancing yeast cell viability under freezing-thawing conditions. These finding provide a foundation for the future development and application of these proteins in food preservation.

Results

Selection of Raphanus sativus Varieties

Previous literature9 and patents have reported the presence of active IBPs in Japanese Raphanus sativus, but the identities of the IBPs remain largely known. Furthermore, it is unknown whether active IBPs exist in the R. sativus varieties available in China. In this study, we examined three common varieties of R. sativus—Xiangya Bai(XYB), Nanpan Zhou(NPZ), and Weixian Qin(WXQ)—for their ice crystal morphology modification activity and ice recrystallization inhibition (IRI) activity in protein extracts from seedlings. The extract from XYB exhibited notable ice crystal morphology modification activity, characterized by the formation of prominent hexagonal ice crystal, followed by extract from WXQ. In contrast, the NPZ extract showed minimal ice crystal morphology modification activity under our experimental conditions (Fig. 1A).

A ice crystal morphology modification activity of cold-induced extracts from different Raphanus sativus seedlings, WXQ, XYB and NPZ. Blank: ddH2O; Hexagonal ice crystals are highlighted in red. (B-C) Ice recrystallization inhibition activity of cold-induced extracts from different Raphanus sativus seedlings. The representative microscopic images of the samples were shown (B) and the ice crystal area distribution were measured (C). D The ratio of the average ice crystal area of extracts in cold-induced or non-cold-induced from different Raphanus sativus seedlings to the average ice crystal area of Blank.

All three Raphanus sativus seedlings extracts effectively inhibit ice crystals recrystallization, with the WXQ extract displaying the strongest IRI activity, followed by XYB extract (Fig. 1B, C). While the NPZ extract also demonstrated IRI activity, larger ice crystals were observed, suggesting worse IRI activity (Fig. 1B, C). This observation aligns with previous patent reports. Additionally, the IRI activity of the extracts from XYB and WXQ, though not that of NPZ, was significantly enhanced after cold treatment (Fig. 1D), indicating that the antifreeze activity may be induced or activate at low temperature25, consistent with the IBPs in the rye26. Based on these findings, and considering the requirements for germplasm and culture environment, WXQ was selected for further investigation.

Screening and identification of IBPs from Raphanus sativus

In the above study, the protein extract from WXQ seedlings, treated with 4°C for 2 d, demonstrated significant ice crystal morphology modification activity (Fig. 1A). Transcriptome analysis of WXQ seedlings treated with 4°C for 24 h revealed the differential expression of genes, with 5154 genes being up-regulated and 3819 genes down-regulated in response to low temperature (Fig. 2A). Further analysis of the up-regulated genes identified 548 genes that were continuously upregulated from 4 h to 24 h, and 414 genes that showed persistent upregulated from 12 h to 24 h (Fig. 2B). Using genome annotation from databases such as NR, Swiss-Prot, and Pfam, a total of 802 up-regulated genes were obtained.

A The different transcription level between 4°C-treated at 24 h or untreated WXQ seedlings. The horizontal coordinate is the multiple of the gene expression difference between the two samples, and the vertical coordinate is the statistical test value of the gene expression change. B The different transcription level of seedlings treated with 4°C at 0, 4, 12 and 24 h. The different colored circles represent the genes screened based on expression level in different treatments, and the numbers represent the common and unique genes in different treatments. C The expression change of the predicted IBPs over time in WXQ seedlings treated with 4°C.

Genes known to be involved in cold stress response, based on prior reports of their function at low temperatures, were selected and analyzed using Cryoprotect27 for potential classification within the AFP (Antifreeze Protein) family. Among the predicted IBPs, COR15B and COR47 were identified as strong candidates25,28,29. Therefore, COR15B and COR47 were selected for further investigation (Table 1, Supplementary Figs. 1 and 2C).

Recombinant COR15B and COR47 expressed heterologously in E. coli exhibit antifreeze activity

The DNA sequence and corresponding translated peptide sequences are provided in Supplementary Figs. 2 and 3. The recombinant plasmids pET28a-COR15B and pET28a-COR47 were introduced into E.coli BL21. Positive clones were identified by PCR, with target bands for COR15B at 408 bp and COR47 at 813 bp (Fig. 3A). The induced bacterial cultures were lysed by ultrasonication, and proteins were purified using His Beads. Expression was confirmed by SDS-PAGE and Western Blot (Fig. 3B, D). The purified protein solution was concentrated by ultrafiltration, with the final concentration of His-COR15B and His-COR47 reaching 250 μg/mL and 150 μg/mL, respectively.

A PCR detects positive clones in BL21. M: DNA marker DL5000; Monoclonal strain 1-3. B Expression and purification proteins assayed by coomassie blue staining. Input: E. coli lysate; Elution: solution adsorbed with His beads. Arrows point the target proteins. C Ice crystal morphology modification activity of purified COR15B and COR47. Hexagonal ice crystals are highlighted in red. D The purified proteins were detected by western blot. E, F Recrystallization inhibition activity assayed and the ice crystal area distribution in different concentrations of COR15B and COR47. Blank: ddH2O.

The hexagonal ice morphology (Fig. 3 C), and the significantly inhibited growth rate of ice crystals (Fig. 3E, F; Supplementary Fig. 4) were observed in the solution containing each of the two protein under a hot and cold stage and optical microscope. COR15B effectively inhibited recrystallization at concentrations greater than 12.5 μg/mL, a finding consistent with reported IBPs10,30. In contrast, COR47 could inhibit recrystallization at concentrations above 50 μg/mL, but promoted recrystallization when it was 25 μg/mL, which may be related to the Janus effect of IBPs31. These results confirm that COR15B from WXQ is indeed an excellent IBP, while COR47 is also an IBP, but slightly less active than COR15B.

Expression of Raphanus sativus IBPs in Bacillus subtilis and optimization of expression conditions

Due to challenges such as codon bias and endogenous expression, the expression levels of Raphanus sativus COR15B and COR47 in E. coli BL21 were suboptimal. To enhance their expression, the recombinant plasmids pHT43-COR15B and pHT43-COR47 were transformed into Bacillus subtilis WB800N. Positive recombinant B. subtilis strains were confirmed by PCR (Fig. 4A). Under the culture condition of 37°C, induction for 4 h by 1 mM IPTG in LB medium (pH 7.0), the total protein secreted by B. subtilis was approximately 80 μg/mL. Using specifically designed antibodies for Raphanus sativus COR15B and COR47, the purified GST-COR15B and GST-COR47 served as standards for semi-quantitative analysis (Supplementary Fig. 5). The expression of COR15B and COR47 in B. subtilis accounted for about 10% and 5% of the total secreted protein respectively.

Further antifreeze activity assays distinct hexagonal ice crystals in the fermentation broth of COR15B, while the ice crystals in the COR47 fermentation broth exhibited a tendency to form hexagonal shapes(supplementary Fig. 6A). The IRI activity of the COR15B fermentation broth was close to that of 150 μg/mL purified His-COR15B, and the IRI activity of the COR47 broth was close to that of 50 μg/mL purified His-COR47 (Supplementary Fig. 6B; Fig. 3E, F). These findings confirm that COR15B and COR47 from WXQ was successfully expressed in B. subtilis WB800N and exhibited strong antifreeze activity.

To further improve COR15B expression, we optimized the culture conditions for the PHT43-COR15B/WB800N strain. Initial optimization focused on single-variable factors, including strains, culture media, original bacterial age, seed liquid, inoculation amount, IPTG concentration, and fermentation time (Supplementary Figs. 7–11). The most influential factors including fermentation time, culture medium pH, and IPTG concentration were then selected for three-factor, three-level response surface optimization. The experimental design for response surface optimization is shown in Supplementary Table 1, with the analysis of variance provided in Table 2. The optimization response curve is depicted in Fig. 5A.

Based on the fitted results, a multivariate quadratic response surface regression model Eq. (1) for total COR15B protein was established:

The model’s R2 value of 0.98 indicates a good fit between the actual and predicted data. The model predicted that the maximum total protein would be obtained at pH 8.05 and IPTG concentration 0.281 mM after 6 h of fermentation. Experimental verification of these conditions resulted in a total protein concentration of 244 μg/mL, which closely matched the predicted value. Furthermore, according to Fig. 5A, the fermentation conditions within the pH range of 7.6-8.3, IPTG concentration of 0.22–0.3 mM, and a 6-hour culture period yielded total protein concentrations exceeding 200 μg/mL, with COR15B constituting the highest proportion of the total protein. Verification results (Fig. 5 B) shows that under such conditions, the total protein concentration of the recombinant strain increased 2.5-3 times, with COR15B’s proportion rising from 10% to approximately 20%. These optimized conditions resulted in a fivefold increase in the yield of the target protein.

Application of Bacillus-expressed Raphanus sativus IBPs in dough products

The Bacillus fermentative fluid, protein extracts from WXQ seedlings, and BSA aqueous solution were diluted to 10 µg/mL with sterile water and added to dough, which was then processed into noodles. These noodles were cooked after repeated freeze-thaw ten times at −20°C and 20°C, and the effect of COR15B and COR47 on noodle quality were assessed. The dH2O group (Blank) showed significantly deeper compared to other groups, along with marked reductions in hardness, gumminess, and tensile force, while exhibiting significant increases in adhesiveness, springiness, and chewiness (Fig. 6; supplementary Fig. 12, Table 2). This suggests that the dough subjected to repeated freeze-thaw cycles became softer and exhibited poorer texture. The texture data for the BSA group was closer to the dH2O group, while the WXQ group exhibited texture properties closer to those of the fresh noodle group (Control). Regarding all texture parameters, the group supplemented with COR15B exhibited a texture profile similar to the control, with cryoprotective effects decreasing as the concentration increased, indicating that COR15B had an excellent cryoprotective effect. The COR47 group also demonstrated some cryoprotective effects, slightly better than the blank group but inferior to the Control and WXQ groups (Fig. 6 B; supplementary Table 2).

A–C The noodles of different group were cooked after freezing-thawing 10 times at −20°C and 20°C. The appearance (A), the hardness (B) and the gumminess (C) of frozen-thawed noodles. Control: fresh dough without freezing-thawing; Blank: ddH2O; WXQ: The extract of WXQ seedlings diluted to 10 μg/mL; BSA: 10 μg/mL BSA aqueous solution.

To further assess the impact of bacillus-expressed COR15B and COR47 on fermented dough products, dough with yeast was subjected to 10 freeze-thaw cycles at -20°C and 20°C, followed by fermentation. The texture of the COR15B and COR47 groups closely resembled that of fresh dough in terms of expansion, hardness, chewiness, cohesiveness, and resilience (Fig. 7; Supplementary Fig. 13, Table 3). This suggests that COR15B and COR47 can protect yeast activity and reduce damage to dough products during freezing. The cryoprotective effect increased with the concentration of addition, approaching the characteristics of fresh fermented dough at 50 ng/g.

Freeze protection of yeast by Raphanus sativus COR15B

The cryoprotective effect of COR15B on fermented dough, as observed in the previous section, may be attributed to its ability to protect yeast from freezing. Using commercially available Angel yeast as a model, we investigated the cryoprotection of yeast by Bacillus-expressed COR15B and COR47 during repeated freeze-thaw cycles. As shown in Fig. 8, the yeast solution added with COR15B maintained over 50% survival after 8 d of repeated freeze-thaw cycles, demonstrating the effective cryoprotective action of COR15B. The addition of COR47 showed good protection at lower concentrations during shorter freeze-thaw cycles, but did not provide effective protection after 8 d. When COR15B and COR47 were mixed, a small amount of COR47 added to COR15B significantly enhanced the protective effect on yeast viability. However, as the concentration of COR47 increased, the cryoprotective activity of the mixture became comparable to or even weaker than that of COR15B alone at the same concentration (Fig. 8, supplementary Fig. 14). These results suggest that different concentrations or ratios of antifreeze proteins exert varying cryoprotective effects on cells, likely due to distinct underlying mechanisms.

Discussion

Plant-derived IBPs are increasingly considered the most promising cryoprotectants in the food industry. This is due to their numerous advantages including high safety, low required dosages, high antifreeze activity, and easy metabolism by the human body. However, challenges in identifying and mass-producing IBPs from plants have limited their widespread application.

Previous studies have demonstrated that the ice recrystallization inhibition (IRI) activity and thermal hysteresis activity of IBPs are generally not compatible. IBPs from fish and insects typically exhibit high thermal hysteresis activity and low IRI activity, while plant-derived IBPs usually display higher IRI activity and lower thermal hysteresis activity32. The regulatory effect of IBPs on ice crystals follows the “Janus” effect, which involves two distinct faces: the non-ice-binding face (NIBF) and the ice-binding face (IBF). The IBF, characterized by the ordered arrangement of methyl and carboxyl groups, facilitates the binding of the protein to the ice crystal surface. The NIBF, with its disordered arrangement of charged and hydrophobic side chains, inhibits the formation of a stable ice crystal lattice. IBPs adsorb onto the ice crystal growth interface, with the NIBF exposed in water, disrupting the orderly arrangement of water molecules and preventing the formation and growth of ice crystals during freezing8,31,33. Based on the observed ice crystal structural characteristics and helical conformation with addition of COR15B and COR47 protein (Fig. 3E, F), we hypothesize that these proteins may also exhibit the “Janus” effect34. Additionally, both COR15B and COR47 significantly alter the shape of ice crystals (Fig. 3C) and inhibit ice recrystallization (Fig. 3E, F), suggesting that Raphanus sativus COR15B and COR47 exert antifreeze effects by adsorbing to the ice crystal growth interface.

Homologous proteins of Raphanus sativus COR15B, such as COR15A and COR15B from Arabidopsis, have been shown to undergo ave been shown to undergo conformational changes that enable them bind to the membrane system, stabilizing the biological membrane system and reducing damage caused by low temperatures25. In our study, we found that that COR15B significantly protected yeast from freeze-thaw damage, whereas COR47 showed weaker effects, even at several times higher concentrations. Interestingly, when a small amount of COR47 was added to COR15B, the cryoprotective effect on yeast viability was significantly enhanced (Fig. 8). These finding suggest that the antifreeze activity of cells in nature may be coordinated by a combination of different antifreeze proteins.

Protein extracts from all tested Raphanus sativus seedlings subjected to low-temperature induction exhibited ice crystal morphology modification activity, although the IRI activity varied among different varieties (Fig. 1). The extract from WXQ, despite having very low levels of COR15B and COR47, still exhibited excellent antifreeze activity. This suggests that the observed activity may result from the synergistic action of multiple antifreeze proteins and/or other cryoprotective substances present in the plant cells. However, the specific molecular mechanisms underlying this effect require further investigation.

In summary, we successfully isolated and identified two IBPs, COR15B and COR47, from Raphanus sativus using bioinformatics, transcriptomics, and proteomics approaches. A heterologous expression system in Bacillus subtilis was developed for large-scale-production of these proteins. Our results demonstrated that both COR15B and COR47 have the ability to modify ice crystals, inhibiting ice crystal growth. Moreover, these proteins exhibited excellent cryoprotective effects on frozen dough products. Notably, COR15B significantly enhanced yeast survival and fermentative capability in dough products, although the exact mechanisms of action remain to be fully elucidated. These findings highlight the significant potential of Raphanus sativus IBPs as cryoprotectants in food storage and provide a foundation for their future industrial-scale production and application.

Methods

Materials and reagents

Raphanus sativus

Xiangya Bai(XYB) and Nanpan Zhou (NPZ) are commercially available. Weixian Qing(WXQ) is a homozygous line variety purchased from the Shandong Academy of Agricultural Sciences.

Plasmids pGXE-4T-1, pET28a, pHT43, and E. coli Top10, E.coli BL21, B. Subtilis WB800N, B. Subtilis DB103, B. Subtilis 168 are preserved in our laboratory.

Restriction enzymes were ordered from Takara Bio Company (Shanghai, China), DNA purification kit from TianGen Biotech (Beijing, China), yeast powder from Angel Yeast Co., Ltd., high-gluten wheat flour from Weifang Kite Flour Co., Ltd. Yeast powder was commercially available from Angel Yeast. Other detection and analytical reagents were purchased from Sinopharm Chemical Reagent Co., Ltd.

Extraction of Raphanus sativus ice-binding proteins

Raphanus sativus seeds were disinfected in a 0.8% sodium hypochlorite solution, then soaked in distilled water for 48 hours, spread on filter paper, and incubated in a dark environment at 28°C for 48 hours. They were then transferred to 25°C incubator with a photoperiod of light/ dark (16 h /8 h), and cultured for 4-5 days. Some of the seedlings were then transferred to a 4 ± 2°C incubator with the same photoperiod for further 4 days. The seedlings kept in the 25°C incubator were considered as control group. The seedlings were mixed with Tris buffer at a 1:1 mass ratio, ground at low temperature at 4°C for 10 minutes, centrifuged at 12,000 rpm for 10 minutes, and the supernatant was collected as the total protein extract.

Detection of ice crystal morphology modification activity

The sandwich assay was employed35. Briefly, 20 μL of sample solution or ddH2O (negative control) was mixed with 46% sucrose at a 1:1 mass ratio. One microliter of the mixture was dropped onto a slid. After being covered with a glass lid, the mixture was then transferred to the thermal stage (Model THM 600, Linkham Instruments, Surrey, UK). The temperature of the stage, which was controlled by the connected programming unit (Model TMS 90, Linkham Scientific Instruments, Surrey, UK), was set as follows: lowered first to 0°C at the rate of 10°C/min, secondly to −40°C at the rate of 80°C/min, then raised to − 5°C at the same rate, next raised to − 2.5°C at the rate of 10°C/min, finally lowered to -20°C at the rate of 0.1°C/min. Under an optical microscope (Olympus BH, Tokyo, Japan), microscopic images of the samples were captured when the ice crystals appear as hexagons or to -20°C.

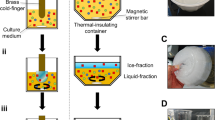

Detection of recrystallization inhibition activity

The sandwich assay was employed to evaluate the IRI activity of IBPs35. Briefly, 20 μL of sample solution or ddH2O (negative control) was mixed with 46% sucrose at a 1:1 mass ratio. One microliter of the mixture was dropped onto a slid. After being covered with a glass lid, the mixture was then transferred to the thermal stage (Model THM 600). The temperature of the stage, which was controlled by the connected programming unit (Model TMS 90), was set as follows: lowered first to 0°C at the rate of 10°C/min, then to − 40°C at the rate of 80°C/min, finally raised to − 6°C at the same rate and maintained the temperature for 30 min. Under an optical microscope (Olympus BH), images of the samples were captured. The detection was repeated three times and three fields view were randomly selected for counting each time under the condition that the parameters of the microscope were consistent. Image Pro Plus software (Media Cybernetics) was used to count and measure the number and size of ice crystals.

mRNA-sequencing snalysis

Total RNA was extracted from 14 d Weixianqing seedlings treated with 4°C for 0 days and 4 days by using MJzol total RNA extraction kit (Majorbio) following the manufacturer’s instructions. The RNA-seq transcriptome library was prepared following Illumina® Stranded mRNA Prep, Ligation (San Diego, CA) using 1 μg of total RNA. mRNA-sequencing was conducted using the high-throughput Genomics Core facility at Majorbio (www.majorbio.com)36,37,38. To identify DEGs (differential expression genes) between two different samples, the expression level of each transcript was calculated according to the transcripts per million reads (TPM) method. RSEM37 was used to quantify gene abundances. Essentially, differential expression analysis was performed using the DESeq238. DEGs with |log2FC | ≧1 and FDR < 0.05 were considered to be significantly different expressed genes. In addition, functional-enrichment analysis including GO and KEGG were performed to identify which DEGs were significantly enriched in GO terms and metabolic pathways at Bonferroni-corrected P-value < 0.05 compared with the whole-transcriptome background. GO functional enrichment and KEGG pathway analysis were carried out by Goatools and Python scipy software, respectively. In the end, the sequences of these gene were predicted using the software Cryoprotect.

Construction of recombinant E.coli BL21 and Bacillus subtilis WB800N

The cDNA sequence COR15B and COR47 was amplified from WXQ seedlings and cloned them into the pET28a vector respectively, which was renamed pET28a-COR15B and pET28a-COR47. The recombinant constructs were transformed into BL21 via heat shock. The two genes were sub-cloned in the pHT43 vector between XbaI and SmaI sites respectively, which were renamed as pHT43-COR15B and pHT43-COR47. The recombinant constructs were transformed into WB800N via chemical transformation39. All the generated constructs were verified by sequencing.

Expression of recombinant E.coli BL21 or recombinant Bacillus subtilis WB800N

The stored recombinant bacteria or bacillus were inoculated in LB (1 mL) for 12 h at 37 °C, and then transferred to 50 mL of LB supplemented with 50 μg/mL kanamycin (bacteria) or 34 μg/mL chloroamphenicol (bacillus) for further culture. When the OD600 reached 0.8–1.0, the target proteins were induced by 1 mM IPTG for 4 h. Cells were collected by centrifugation (3000 × g, 4 °C, 20 min), lysed in buffer, centrifuged and the protein extract recovered in the supernatant. The proteins were analyzed by SDS-PAGE and western blot.

Purification of recombinant COR15B and COR47

The recombinant target protein was purified by affinity versus His-tag on Ni2+ resin (Beyotime). Briefly, a slurry of affinity versus His-tag was packed in a Ni2+ resin column (10 × 2.5 cm) and equilibrated with 5-column volume of equilibrating buffer and TBS buffer (20 mM Tris-HCl, 150 mM NaCl, pH 7.5). 50 mL culture medium was loaded into the column. The column was washed 3 times with TBS buffer with 0, 25, and 50 mM imidazole. The bound proteins were eluted using gradient elution with the same buffer containing 200 mM imidazole at a flow rate of 0.5 mL/min. The eluate protein was analyzed by SDS-PAGE and quantitatively by Bradford Protein Assay Kit (Sangon Biotech).

Expression optimization of recombinant Bacillus subtilis WB800N

Following the above methods, experiments were conducted by changing a single variable to obtain the optimal solution for each single variable. At the same time, the three most influential factors were selected, and a three-level, three-factor Box-Benhnken optimization study was designed and analyzed using the statistical software Design-Exper, focusing on total protein concentration and target protein ratio as the assessment indicators, and predicting possible mathematical models Eq. (2):

Application of Raphanus sativus ice-binding proteins in dough

All add solution, such as bacillus fermentative fluid, protein extracts from WXQ seedlings and BSA aqueous solution, were diluted to 10 µg/mL with sterile water and added to dough, which was then processed into noodles. Samples were mixed with flour and water, mixed using a dough mixer until the flour gathered into a mass, program number 16. After freezing at -20°C for 16 hours and thawing at 20°C for 8 hours, repeated freeze-thaw cycles were performed. The texture analysis was performed as described by Fan40 by using a texture analyzer equipped with a P50 cylindrical organic glass probe (diameter 50 mm) (TA.XT plus, Stable Micro Systems, UK). The Dough compressed at a compression degree of 70% with both the pre-test and post-test speed set at 3 mm/s and the test speeds set at 1 mm/s. The trigger type was set to auto with a 5.0 g trigger force. Each sample was measured ten times.

In the application experiment of non-fermented dough, samples were mixed according to Table 3. Noodles were formed using a mold and cooked in water. Bovine serum albumin (BSA) addition and no protein addition (Blank) were used as negative control, and WXQ extract was used as a positive control.

In the application experiment of fermented dough, samples were mixed according to Table 4. The dough was fermented in a 30°C incubator for 30 minutes and steamed in a steamer. No protein addition (blank) was used as a negative control.

Application of Raphanus sativus ice-binding proteins in yeast freeze protection

Different concentrations of Raphanus sativus COR15B and COR47 solutions were mixed with yeast broth (OD600 = 1) at a 1:9 volume ratio, and the number of live yeast in the broth (AFU/mL) was counted. The remaining mixed solution was frozen at -20°C for 23 hours and thawed at room temperature for 1 hour, repeated freeze-thaw cycles were performed. The number of live yeast (AFU/mL) was measured again on days 2, 4, 6, and 8.

Data availability

No datasets were generated or analysed during the current study.

References

Tian, Y., Zhu, Z. & Sun, D.-W. Naturally sourced biosubstances for regulating freezing points in food researches: Fundamentals, current applications and future trends. Trends Food Sci. Technol. 95, 131–140 (2020).

Provesi, J. G. et al. Extraction of antifreeze proteins from cold acclimated leaves of Drimys angustifolia and their application to star fruit (Averrhoa carambola) freezing. Food Chem. 289, 65–73 (2019).

Chow-Shi-Yée, M. et al. Inhibition of ice recrystallization and cryoprotective activity of wheat proteins in liver and pancreatic cells. Protein Sci. 25, 974–986 (2016).

Gaukel, V. & Leiter, A. SPIESS W E L. Synergism of different fish antifreeze proteins and hydrocolloids on recrystallization inhibition of ice in sucrose solutions. J. Food Eng. 141, 44–50 (2014).

Haji-Akbari, A. Rating antifreeze proteins: Not a breeze. Proc. Natl Acad. Sci. 113, 3714–3716 (2016).

Zhang, Y. et al. Purification and identification of antifreeze protein from cold-acclimated oat (Avena sativa L.) and the cryoprotective activities in ice cream. Food Bioprocess Technol. 9, 1746–1755 (2016).

Harding, M. M., Ward, L. G. & Haymet, A. D. J. Type I ‘antifreeze’ proteins - Structure-activity studies and mechanisms of ice growth inhibition. Eur. J. Biochem 264, 653–665 (1999).

Davies, P. et al. Determining the ice-binding planes of antifreeze proteins by fluorescence-based ice plane affinity. J. Visualized Exp. 83, e51185 (2014).

Osuda, H., Sunano, Y. & Hara, M. An intrinsically disordered radish vacuolar calcium-binding protein (RVCaB) showed cryoprotective activity for lactate dehydrogenase with its hydrophobic region. Int. J. Biol. Macromolecules 182, 1130–1137 (2021).

Sidebottom, C. et al. Phytochemistry - Heat-stable antifreeze protein from grass. Nature 406, 256 (2000).

Zhang, Y. et al. Thermal, rheological properties and microstructure of hydrated gluten as influenced by antifreeze protein from oat (Avena sativa L.). J. Cereal Sci. 93, 102934 (2020).

Nguyen, H. D. & Phan, T. T. P. A protocol to enhance soluble protein expression in the cytoplasm of Bacillus subtilis. Methods Mol. Biol. (Clifton, NJ) 2406, 233–243 (2022).

Schumann, W. Production of recombinant proteins in Bacillus subtilis. Adv. Appl. Microbiol. 62, 137–189 (2007).

Harwood, C. R. & Cranenburgh, R. Bacillus protein secretion:: an unfolding story. Trends Microbiol. 16, 73–79 (2008).

Kunst, F. et al. The complete genome sequence of the Gram-positive bacterium Bacillus subtilis. Nature 390, 249–256 (1997).

Morimoto, T. et al. Enhanced recombinant protein productivity by genome reduction in Bacillus subtilis. DNA Res 15, 73–81 (2008).

Wu, X. C. et al. Engineering a Bacillus subtilis expression-secretion system with a strain deficient in six extracellular proteases. J. Bacteriol. 173, 4952–4958 (1991).

Kang, Z. et al. Molecular engineering of secretory machinery components for high-level secretion of proteins in Bacillus species. J. Ind. Microbiol Biot. 41, 1599–1607 (2014).

Wang, Y. et al. Deleting multiple lytic genes enhances biomass yield and production of recombinant proteins by Bacillus subtilis. Microb. Cell Fact. 13, 129 (2014).

Sauer, C. et al. Exploring the nonconserved sequence space of synthetic expression modules in Bacillus subtilis. ACS Synth. Biol. 7, 1773–1784 (2018).

Lu, Z. et al. CRISPR-assisted multi-dimensional regulation for fine-tuning gene expression in Bacillus subtilis. Nucleic Acids Res. 47, e40–e40 (2019).

Krüger, A. et al. A host-vector toolbox for improved secretory protein overproduction in Bacillus subtilis. Appl. Microbiol. Biotechnol. 106, 5137–5151 (2022).

Yeh, C. M., Kao, B. Y. & Peng, H. J. Production of a recombinant type 1 antifreeze protein analogue by L. lactis and its applications on frozen meat and frozen dough. J. Agric. Food Chem. 57, 6216–6223 (2009).

Yeh, C. M., Wang, J. P. & Su, F. S. Extracellular production of a novel ice structuring protein by Bacillus subtilis -: A case of recombinant food peptide additive production. Food Biotechnol. 21, 119–128 (2007).

Thalhammer, A. et al. Disordered cold regulated15 proteins protect chloroplast membranes during freezing through binding and folding, but do not stabilize chloroplast enzymes in vivo. Plant Physiol. 166, 190–201 (2014).

Griffith, M. & Yaish, M. W. F. Antifreeze proteins in overwintering plants: a tale of two activities. Trends Plant Sci. 9, 399–405 (2004).

Pratiwi, R. et al. CryoProtect: a web server for classifying antifreeze proteins from nonantifreeze proteins. J. Chem. 2017, 15 (2017).

Bremer, A. et al. Folding of intrinsically disordered plant LEA proteins is driven by glycerol‐induced crowding and the presence of membranes. FEBS J. 284, 919–936 (2017).

Popova, A. V. et al. The intrinsically disordered protein LEA7 from Arabidopsis thaliana protects the isolated enzyme lactate dehydrogenase and enzymes in a soluble leaf proteome during freezing and drying. Biochimica et. Biophysica Acta (BBA) - Proteins Proteom. 1854, 1517–1525 (2015).

Ma, Q., Shibata, M. & Hagiwara, T. Ice crystal recrystallization inhibition of type I antifreeze protein, type III antifreeze protein, and antifreeze glycoprotein: effects of AF(G)Ps concentration and heat treatment. Biosci., Biotechnol., Biochem. 86, 635–645 (2022).

Liu, K. et al. Janus effect of antifreeze proteins on ice nucleation. P Natl Acad. Sci. USA 113, 14739–14744 (2016).

Gruneberg, A. K. et al. Ice recrystallization inhibition activity varies with ice-binding protein type and does not correlate with thermal hysteresis. Cryobiology 99, 28–39 (2021).

Hudait, A. et al. Ice-nucleating and antifreeze proteins recognize ice through a diversity of anchored clathrate and ice-like motifs. J. Am. Chem. Soc. 140, 4905–4912 (2018).

Thalhammer, A. & Hincha, D. K. A mechanistic model of COR15 protein function in plant freezing tolerance: integration of structural and functional characteristics. Plant Signal. Behav. 9, e977722 (2014).

Qin, L. J. et al. Effects of polysaccharides autoclave extracted from Flammulina velutipes mycelium on freeze-thaw stability of surimi gels. Lwt-Food Sci. Technol. 169, 113941 (2022).

Chen, S. et al. fastp : an ultra-fast all-in-one FASTQ preprocessor. Cold Spring Harbor Lab. 15, 884–890 (2018).

Li, B. & Dewey, C. N. RSEM: accurate transcript quantification from RNA-Seq data with or without a reference genome. BMC Bioinforma. 12, 16 (2011).

Love, M. I., Huber, W. & Anders, S. Moderated estimation of fold change and dispersion for RNA-seq data with DESeq2. Genome Biol. 15, 38 (2014).

Li, R. et al. Competent preparation and plasmid transformation of Bacillus subtilis. Biotechnol. Bull. 50, 227–230 (2011).

Fan, M. C. et al. Gel properties of myofibrillar protein as affected by gelatinization and retrogradation behaviors of modified starches with different crosslinking and acetylation degrees. Food Hydrocolloid 96, 604–616 (2019).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (No. 31670271) and Beijing Life Science Academy (BLSA) (No.2024400CB0050).We thank Prof. Jing Huang (East China Normal University) for kindly supplying the plasmids pET28 and pHT43, B. Subtilis WB800N, DB103, and 168. We thank the Instruments Sharing Platform of School of Life Sciences, East China Normal University.

Author information

Authors and Affiliations

Contributions

Shu Z, and JT performed experiments. Other authors assisted in experiments and discussed the results. Xiao L and De J designed the experiment, supervised the study, analyzed the data. Shu Z and Xiao L wrote the paper.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhao, SH., Tan, J., Zhang, W. et al. Identification of ice-binding proteins from Raphanus sativus and application in frozen dough. npj Sci Food 9, 58 (2025). https://doi.org/10.1038/s41538-025-00420-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41538-025-00420-z