Abstract

Conventional flow-electrode capacitive deionization (FCDI) often exhibits performance constraints stemming from elevated ion migration resistance associated with diminished conductivity within the desalination chamber, particularly under complex aqueous matrices. This investigation introduces a symmetric anion-exchange membrane (AEM) configuration engineered to circumvent these conductivity limitations and enhance arsenic removal efficacy. Relative to conventional designs, the symmetric-AEM configuration demonstrated an approximate 19.4% enhancement in arsenic removal efficiency. For influent streams with initial arsenic concentrations of 1000 μg·L⁻¹, effluent concentrations were diminished below the analytical detection limit (0.02 μg·L⁻¹) employing a two-stage sequential process. This configuration sustains or potentially enhances desalination-chamber conductivity by optimizing ion migration pathways and facilitating anion compensation via highly mobile chloride ions. The contributions of chloride ions as supporting electrolytes and the transformations of arsenic valence states were interrogated, providing mechanistic insights into the observed performance improvements. Our findings signify a practical advancement in FCDI, presenting a potentially robust and efficacious strategy for arsenic remediation in contaminated groundwater. Thus, the symmetric-AEM configuration represents a significant advancement toward the broader implementation and practical application of FCDI systems for potable water production.

Similar content being viewed by others

Introduction

Elevated arsenic concentrations in groundwater represent a critical environmental challenge, attracting significant governmental and public concern due to the severe health risks intrinsically linked to arsenic exposure1,2. The development of efficacious methods for treating arsenic-contaminated groundwater to meet stringent drinking water quality standards is imperative for safeguarding public health. The World Health Organization (WHO) recommends a guideline value of 10 μg·L⁻¹ for arsenic in drinking water3. However, in various regions, groundwater arsenic concentrations exhibit wide variability, often ranging from 5 to 500 μg·L⁻¹ 4, with extreme instances surpassing 1000 μg·L⁻¹5,6. For example, groundwater arsenic contamination in the alluvial plain of northern Henan Province, China, downstream of the Yellow River, reaches levels of 190 μg·L⁻¹, while concentrations in the Mekong and Red River Deltas in Vietnam can ascend to 1610 μg·L⁻¹. Such high concentrations present substantial challenges for conventional water-treatment modalities7,8. Remediating groundwater arsenic to meet potable water standards directly aligns with Sustainable Development Goal 6 (SDG 6) – Clean Water and Sanitation.

Conventional arsenic removal technologies (e.g., coagulation, adsorption, sand filtration) encounter substantial limitations, including high chemical or energy demands, inconsistent removal efficiencies, and the potential generation of secondary pollutants9,10,11,12. In contrast, capacitive deionization (CDI) technologies, encompassing membrane CDI (MCDI) and flow-electrode CDI (FCDI), have emerged as promising, potentially cost-effective and efficient alternatives for the treatment of arsenic-contaminated groundwater13,14. Nonetheless, existing CDI research has predominantly centered on electrode material optimization or surface modifications, while optimization of operational modes and elucidation of ion migration pathways have received comparatively less attention. This knowledge gap limits the broader applicability and sustained long-term performance of CDI systems, particularly under variable groundwater compositions and during extended operation. Consequently, optimizing CDI operational modes and comprehensively understanding the intricate ion-transport mechanisms are critical for advancing this technology and overcoming prevailing performance barriers.

Flow-electrode capacitive deionization (FCDI) is regarded as a promising technology for heavy metal removal owing to its potential for high efficiency and low energy consumption. However, conventional FCDI configurations frequently exhibit performance degradation linked to diminished conductivity within the desalination chamber, especially during prolonged operation or when treating complex groundwater matrices. Typically, FCDI systems employ an anion-exchange membrane (AEM) adjacent to the anode and a cation-exchange membrane (CEM) adjacent to the cathode. This standard membrane arrangement can inadvertently impede efficient ion transport by increasing migration resistance, consequently leading to reduced contaminant removal efficiency, particularly during later operational phases.

Previous investigations have demonstrated the capability of FCDI systems to reduce As(III) concentrations in effluent to meet the 10 μg·L⁻¹ drinking water standard under precisely controlled laboratory settings15. However, the broader applicability and consistent performance of these promising results under diverse, real-world groundwater conditions remain insufficiently characterized. Specifically, achieving consistently low effluent arsenic concentrations across varied geochemical conditions and during extended operational periods presents an ongoing challenge, as previously reported outcomes often closely approach regulatory thresholds even under idealized scenarios. Therefore, further investigation is imperative to enhance the stability and reliability of FCDI systems for practical, large-scale deployment.

To surmount these limitations, this study introduces a novel symmetric-AEM configuration engineered to stabilize or potentially enhance conductivity within the desalination chamber, thereby mitigating the elevated ion migration resistance observed in conventional systems. By substituting the cathode-side CEM with an additional AEM, the proposed configuration optimizes ion-transport pathways and promotes stable desalination-chamber ionic conditions, significantly augmenting arsenic removal efficiency, particularly during the later stages of system operation. Anion-exchange membranes (AEMs) are essential for effectively removing negatively charged arsenic oxyanions from water, despite being more expensive than cation-exchange membranes (CEMs). CEMs are inherently unsuitable for this application because they impede the transport of negatively charged species. Although the current higher cost of AEMs presents an economic challenge, ongoing developments in membrane materials and potential reductions in manufacturing costs through economies of scale may gradually improve the economic viability of symmetric-AEM configurations in the future. The efficacy of this modified configuration, alongside its underlying mechanisms—including the roles of supporting electrolytes (e.g., chloride ions) and arsenic valence transformations—are systematically investigated to establish a robust foundation for enhancing the long-term consistency and applicability of FCDI technology in the remediation of arsenic-contaminated groundwater.

Investigating the mechanisms and efficiency of FCDI under the symmetric-AEM configuration for purifying arsenic-laden groundwater addresses critical challenges associated with long-term operation in practical electrochemical remediation scenarios. Furthermore, this study validates system performance using authentic groundwater samples sourced from arsenic-contaminated regions, thereby ensuring practical relevance.

Results

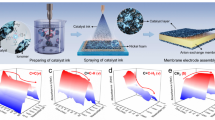

Comparative performance and mechanistic elucidation

The efficacy of the symmetric-AEM FCDI configuration was directly compared against a conventional FCDI setup (AEM at anode, CEM at cathode) for arsenic removal. As depicted in Fig. 1a, the symmetric-AEM FCDI exhibited superior removal efficiency; operating for a single 240-min cycle, it reduced the influent arsenic concentration from 1000 μg·L⁻¹ to 73.7 µg·L⁻¹, whereas the conventional FCDI achieved only 198.7 µg·L⁻¹ under identical conditions. This enhanced performance is primarily attributed to the capacity of the symmetric-AEM configuration to maintain higher operational current and stabilize conductivity within the desalination chamber.

a Temporal change in arsenic concentration in the desalination chamber for the symmetric anion-exchange membrane (AEM) system and the conventional system over a 240-min operation. b Corresponding operational current over time for both systems. c Conductivity changes within the desalination chamber for both configurations. d Electrochemical impedance spectroscopy (EIS) Nyquist plots for both systems were measured before and after the 4-h treatment. The inset shows the equivalent circuit model used for fitting, where R1 is the combined electrolyte and interface resistance, R2 and Q1 are the charge-transfer resistance and constant-phase element at the flow electrode/collector interface, and R3 and Q2 represent the resistance and constant-phase element for ion adsorption/transport at the electrode/membrane interface. Data for the symmetric-AEM system (for example, solid lines or circle symbols) are compared against the conventional system (for example, dashed lines or square symbols). Data shown are from a representative experiment. Data points represent the mean ± SD from n = 3 independent experiments.

Correspondingly, the symmetric-AEM FCDI sustained a higher and more stable operational current throughout the cycle (Fig. 1b), stabilizing around 33 mA, while the current in the conventional FCDI decayed rapidly, diminishing to 1.2 mA after 100 min. Furthermore, conductivity measurements within the desalination chamber (Fig. 1c) indicated stable, and even slightly increasing, conductivity over the 240-min period for the symmetric-AEM system. Conversely, the conventional system showed a marked decrease in conductivity.

To further probe the electrochemical characteristics and elucidate the origins of the enhanced performance, electrochemical impedance spectroscopy (EIS) was employed before and after the 4-h treatment period for both configurations. The impedance data were modeled using an equivalent circuit (Fig. 1d), where R1 represents the combined electrolyte and interface resistance, R2 and Q1 correspond to the charge-transfer resistance and constant-phase element at the flow electrode/collector interface, and R3 and Q2 represent the resistance and constant-phase element associated with ion adsorption/transport processes at the electrode/membrane interface16,17,18.

Analysis of the EIS data (Fig. 1d) revealed significantly lower initial resistances (R1 = 1.16 Ω, R2 = 16.10 Ω, R3 = 15.31 Ω) for the symmetric-AEM system compared to the conventional system (R1 = 2.02 Ω, R2 = 22.62 Ω, R3 = 15.64 Ω). Crucially, after 4 h of operation, the resistances in the symmetric-AEM system decreased substantially (R1 = 0.32 Ω, R2 = 11.10 Ω, R3 = 3.22 Ω), whereas they markedly increased in the conventional system (R1 = 4.33 Ω, R2 = 46.56 Ω, R3 = 14.65 Ω). This observed reduction in system impedance within the symmetric configuration correlates well with the sustained current and enhanced ion removal performance, suggesting facilitated ion transport.

The symmetric-AEM FCDI configuration demonstrates a distinctive strategy for managing system resistance. Firstly, any localized decrease in cathode-chamber conductivity—caused by Cl⁻ migration—is effectively mitigated by rapid circulation and continuous homogenization of the electrode suspension, where Cl⁻-depleted catholyte is promptly mixed with Cl⁻-enriched anolyte. Consequently, stable bulk conductivity within the electrode circuit is maintained (Fig. S7).

More importantly, this internal circulation simultaneously addresses the primary resistance bottleneck of conventional FCDI systems—the low-conductivity desalination chamber. By strategically introducing highly mobile chloride ions into the desalination chamber, its conductivity substantially increases, significantly reducing its resistance. Given that desalination-chamber resistance constitutes the dominant component of overall system impedance, this mechanism markedly reduces total solution resistance (R1). Additionally, the increased ionic strength mitigates concentration polarization at membrane interfaces, further lowering charge-transfer resistance (R2) and ion-transport resistance (R3).

Transitioning from electrochemical impedance, the influence of ion migration dynamics, particularly that of chloride ions, was investigated. Figure 2a, b illustrates the temporal changes in chloride ion concentration within the desalination chambers of both systems operating in isolated closed-cycle (ICC) mode. The ICC mode is employed to simulate the ion migration pathways and behavior between the electrode chambers and the desalination chamber under short-circuit closed-loop (SCC) conditions. In the symmetric-AEM FCDI (Fig. 2a), the Cl⁻ concentration progressively increased during the cycle. In stark contrast, Cl⁻ became undetectable in the conventional FCDI’s desalination chamber after approximately 80 min (Fig. 2b). This divergence originates from the distinct membrane configurations (Fig. 9). The symmetric-AEM setup facilitates the migration of Cl⁻ from the catholyte suspension (acting as a reservoir) into the desalination chamber, driven by both the electric field and concentration gradients. This influx sustains a higher Cl⁻ concentration and, consequently, higher ionic conductivity in the desalination chamber, which acts as a supporting electrolyte, thereby enhancing arsenic (arsenate/arsenite anion) electromigration and removal19.

Temporal changes in chloride ion concentration within the anolyte, catholyte, and desalination chambers operating in isolated closed-cycle (ICC) mode. a Chloride migration in the symmetric-AEM flow-electrode capacitive deionization (FCDI) system, showing an increase in the desalination chamber. b Chloride migration in the conventional FCDI system, showing depletion in the desalination chamber. The ICC mode was used to analyze ion migration pathways between the electrode and desalination chambers. Data points represent the mean ± SD from n = 3 independent experiments.

A key feature of the symmetric-AEM configuration is its strategic management of system resistance. Although migration of chloride ions from the electrode suspension to the desalination chamber leads to slight dilution of the electrode suspension, this dilution is quantitatively negligible, accounting for only approximately 4.8% of the total chloride ion concentration after 4 h of continuous operation. More importantly, this minor dilution effect is significantly outweighed by a substantial enhancement in the conductivity of the desalination chamber. Acting as an internal electrolyte reservoir, the electrode suspension continuously replenishes chloride ions into the desalination chamber, thereby markedly reducing its resistance—which is the primary contributor to total system impedance in conventional FCDI systems. Experimental evidence clearly demonstrates that the overall system impedance substantially decreases (Fig. 1d), maintaining a stable electric field and ensuring consistent arsenic removal. Furthermore, extended experiments conducted over 12 continuous hours—three times longer than typical operational cycles—confirmed sustained performance without observed degradation (Fig. S6). These results robustly validate the viability and practicality of our symmetric-AEM configuration for real-world water-treatment applications. In the SCC mode, the key to maintaining ionic stability lies in the use of a single, continuously mixed flow-electrode suspension shared by both anode and cathode chambers.

This configuration establishes a dynamic equilibrium: chloride ions migrating from the suspension into the desalination chamber at the cathode are continuously replenished by chloride ions entering the suspension at the anode side. Due to rapid homogenization, these opposing ion fluxes effectively balance out across the entire system. Consequently, the electrode suspension functions as a large, self-sustaining “ion buffer pool,” maintaining a stable bulk chloride concentration. This mechanism is clearly validated by experimental data (Fig. S7), which demonstrate consistent chloride concentration during operation. Ultimately, such a stable ionic environment supports continuous chloride flux for sustained deionization, preventing electrode-solution depletion and ensuring long-term stable system performance.

This symmetric configuration establishes pathways for continuous anion exchange between the electrode suspensions and the desalination chamber, effectively replenishing anions in the desalination chamber, unlike the conventional FCDI, where depletion occurs. During the extended operation of conventional FCDI, the electromigration of both anions (toward the anode) and cations (toward the cathode) leads to significant ion depletion within the central desalination chamber. This depletion elevates both charge-transfer and ion migration resistances and diminishes the effective driving force for desalination by altering the electric field distribution. Altering ion concentration influences the Debye length and the thickness of the electrical double layer, thereby affecting the electric field gradient. In an FCDI device, the anode attracts target anions, facilitating their transport across the membrane to achieve pollutant removal. In conventional devices, however, the cathode merely serves to balance the charge. In contrast, within the symmetric-AEM FCDI, the cathode not only balances charge but also acts as a primary reservoir supplying ions—particularly chloride ions (Cl⁻)—to maintain high ionic concentrations in the desalination chamber. This mechanism effectively mitigates resistance increases caused by ion depletion, preventing the formation of low-conductivity, high-resistance zones, and thus represents an essential feature of the symmetric-AEM configuration. Ultimately, this stable replenishment of ions sustains high arsenic removal efficiencies.

The superior arsenic removal efficiency observed in the symmetric-AEM FCDI configuration can be attributed to a synergistic interplay of three primary mechanisms:

(i) Enhanced Anion-Selective Electrosorption Capacity: In conventional FCDI, the total charge passed is utilized for the removal of both anions and cations. The symmetric-AEM configuration, by employing AEMs at both electrode interfaces, effectively excludes cation removal. This dedicates the entirety of the system’s electrosorptive capacity to anions, thereby maximizing the potential for arsenate/arsenite removal by eliminating competition from cations for charge compensation.

(ii) Reduced Ion Migration Resistance: Conventional FCDI suffers from increasing concentration polarization and solution resistance as ions are depleted from the desalination chamber. The symmetric-AEM configuration mitigates this effect. The influx of chloride anions from the catholyte into the desalination chamber compensates for the efflux of arsenate/arsenite anions, maintaining or even increasing the ionic conductivity of the central chamber (Fig. 1c). This sustained conductivity significantly lowers the overall ion migration resistance compared to the conventional setup, facilitating more efficient ion transport under the applied potential.

(iii) Mitigation of Concentration Polarization: Concentration polarization, the buildup or depletion of ions near membrane surfaces, can limit transport rates. The facilitated bidirectional anion movement in the symmetric-AEM system (arsenate/arsenite toward the anode, chloride toward the desalination chamber from the cathode side) helps to stabilize ion concentration profiles near the membranes compared to the unidirectional depletion seen in conventional systems. This mitigation of severe concentration polarization contributes to maintaining stable and efficient ion transport.

Collectively, these mechanisms—focused anion electrosorption, sustained desalination-chamber conductivity reducing migration resistance, and mitigated concentration polarization—synergistically enhance arsenic removal performance, rendering the symmetric-AEM FCDI configuration particularly advantageous for sustained water purification applications.

Influence of operational parameters (voltage, activated carbon mass fraction, pH, co-existing ions, long-term operation) on symmetric-AEM FCDI performance

The influence of applied voltage on arsenic removal performance within the symmetric-AEM FCDI system was systematically evaluated across a range of 0.8–2.0 V. As illustrated in Fig. 3, the electromigration driving force intensified with increasing voltage, resulting in augmented arsenic removal efficiency20. Below 1.2 V, charge percolation within the flow electrodes likely relies significantly on interparticle collisions. Above 1.6 V, the enhancement in removal efficiency is primarily ascribed to the increased electromigration driving force21,22. However, operating FCDI at voltages exceeding approximately 1.2–1.6 V risks inducing water electrolysis (hydrolysis), leading to gas evolution with complex effects on the arsenic removal process23. Simultaneously, bubble-induced turbulence may enhance mass transport and reduce concentration polarization. Conversely, electrolysis consumes energy inefficiently (reducing ENRS), and gas bubble adhesion onto electrode surfaces can passivate active sites, increase system resistance, and potentially hinder arsenic removal23,24 Reflecting these factors, the average salt removal rate (ASRR) increased from 1.18 to 1.48 μg·cm⁻²·min⁻¹ as voltage increased from 0.8 V to 2.0 V (Fig. 3b). The arsenic removal efficiency improved markedly, from 84.8% at 0.8 V to 99.8% at 2.0 V (Fig. 3a). However, practical application necessitates consideration of energy consumption. The normalized energy consumption for salt removal (ENRS) decreased (indicating lower energy efficiency) from 2.7 μmol·J⁻¹ at 0.8 V to 0.5 μmol·J⁻¹ at 2.0 V (Fig. 3b), highlighting the inherent trade-off between removal efficacy and energy expenditure25. Optimal voltage selection, therefore, requires balancing performance targets with operational economics. Based on achieving >90% removal with reasonable energy efficiency, 1.2 V was selected for subsequent experiments unless otherwise specified.

a Arsenic removal efficiency over time at different applied voltages ranging from 0.8 V to 2.0 V. b The average salt removal rate (ASRR) and normalized energy consumption for salt removal (ENRS) were calculated for each applied voltage. The data illustrate the trade-off between removal efficiency and energy consumption. Data points represent the mean ± SD from n = 3 independent experiments.

Increasing the mass fraction of activated carbon in the flow electrode can enhance charge percolation pathways and improve electrical conductivity via increased interparticle contact frequency, thereby promoting charge transfer26,27,28. However, excessively high carbon loadings can lead to increased suspension viscosity and potential clogging of flow channels, particularly given the hydrophobic nature of carbon particles26,27,28,29,30. The effect of activated carbon mass fraction (3, 6, and 9 wt%) was evaluated. Results indicated that arsenic removal efficiency exhibited an initial increase followed by a plateau or slight decrease as the carbon fraction increased (Fig. 4a). After 240 min, removal efficiencies were 89.5%, 94.3%, and 92.2% for 3, 6, and 9 wt% carbon, respectively. Increasing the activated carbon mass fraction to 9 wt% elevates the particle concentration, thereby increasing the frequency of particle collisions with the membrane interface. Activated carbon slurries are non-Newtonian fluids, often exhibiting shear-thinning behavior, meaning viscosity decreases at higher flow rates. The performance difference between 6 wt% and 9 wt% was marginal (Fig. 4a). Considering practical aspects, including material costs and potential operational issues associated with higher viscosity, increasing the carbon fraction beyond 6 wt% offered diminishing returns. Therefore, 6 wt% was deemed optimal for this system.

a The effect of activated carbon mass fraction (3, 6, and 9 weight percent) in the flow-electrode suspension on the arsenic removal efficiency over 240 min. b The effect of initial feed water pH (adjusted to 3, 5, 7, and 9) on the arsenic removal efficiency. Data points represent the mean ± SD from n = 3 independent experiments.

Aqueous arsenic speciation is strongly dependent on redox potential and pH31. For As(V) (arsenate), the dominant species are H₃AsO₄ (pH < 2), H₂AsO₄⁻ (pH 2–6), HAsO₄²⁻ (pH 6–11), and AsO₄³⁻ (pH > 11). For As(III) (arsenite), the predominant forms are H₃AsO₃ (pH < 9.2), H₂AsO₃⁻ (pH 9.2–12.1), and HAsO₃²⁻ (pH > 12.1). To assess the influence of initial feed water pH on ion electrosorption and arsenic removal efficiency, experiments were conducted with initial pH adjusted to 3, 5, 7, and 9. As shown in Fig. 4b, optimal arsenic removal efficiency (~93.9%) was observed at an initial pH of 5. At pH < 5, efficiency decreased, likely due to increased competitive electrosorption between anionic arsenate (predominantly H₂AsO₄⁻) and the abundant Cl⁻ background ions, as well as potential protonation effects on the carbon surface. Efficiency also decreased at pH > 5 compared to pH 5. This is likely attributable to the shift in dominant arsenic speciation toward the divalent HAsO₄²⁻ and increased competition from hydroxide (OH⁻) ions at higher pH. Compared to H₂AsO₄⁻, HAsO₄²⁻ exhibits reduced transmembrane transport capability due to its higher negative charge density, larger hydrated ionic radius, and consequently lower mobility, thereby limiting its removal efficiency32.

Natural groundwater matrices typically contain diverse co-existing ions that can compete with target contaminants for electrosorption. Therefore, evaluating the impact of common co-solutes on arsenic removal is essential. The influence of several common ions (CO2−3, SO2−4, Ca²⁺, and K⁺) was investigated at three ionic strengths (adjusted by adding Na₂CO₃, Na₂SO₄, CaCl₂, or KCl to achieve approximate competitor concentrations of 0.5, 1.0, and 1.5 mmol·L⁻¹, assuming the background NaCl dominates ionic strength – clarify concentration basis). As shown in Fig. 5, all tested co-existing ions exhibited an inhibitory effect on arsenic removal efficiency to varying extents, and this inhibition intensified with increasing co-solute concentration. The observed order of inhibition was CO2−3 > SO2−4 > Ca²⁺ > K⁺. Carbonate exerted the most significant inhibitory effect, potentially attributed to direct competition for adsorption sites and its influence on solution pH and electrode surface charge. Sulfate, another divalent anion, also showed considerable competition. Among the evaluated background electrolyte ions, cations (Ca²⁺ and K⁺) showed minimal interference with arsenic removal efficiency, consistent with expectations for an anion-selective removal system utilizing AEMs.

Final arsenic removal efficiency after 240 min of treatment in the presence of various co-existing ions (carbonate, sulfate, calcium, and potassium) at three different concentrations (0.5, 1.0, and 1.5 millimoles per liter). The results show the inhibitory effect of competing ions on arsenic removal. Experiments were conducted once (n = 1) to assess the performance under these specific conditions.

The long-term operational stability of the symmetric-AEM FCDI system was assessed through extended cyclic operation (7 cycles of 240 min each, total 28 h, replacing feed water but not electrode suspension). As shown in Fig. S3, the system exhibited a progressive decline in arsenic removal efficiency over successive cycles, failing to maintain stable long-term performance under these conditions. The efficiency decreased from >95% initially to ~85% after 7 cycles and continued to decline. This degradation likely stems from factors including back-diffusion, progressive saturation of adsorption sites on the activated carbon, and/or potential membrane fouling or scaling, especially considering the accumulation of cations near the cathode-side AEM. Ion migration within the FCDI system is driven by both the applied electric field (electromigration) and concentration gradients (diffusion). While the electric field is the primary driver for the low-concentration arsenic, as cycles progress and arsenic accumulates in the electrode suspensions, back-diffusion or electromigration toward the desalination chamber may become more significant, contributing to the reduced net removal33,34. Further optimization, potentially involving periodic electrode regeneration or alternative electrode materials, is required to enhance long-term stability. Enhancing the adsorption capacity of activated carbon or introducing iron-based strategies may mitigate this effect. Specifically, the addition of iron compounds, particularly Fe²⁺, can promote the formation of stable arsenic complexes, thereby hindering arsenic migration and facilitating beneficial redox reactions. These processes collectively may help reduce arsenic back-diffusion and enhance overall removal efficiency.

Migration and transformation of As(III) and As(V) species

To investigate potential redox transformations of arsenic during FCDI operation, cyclic voltammetry (CV) was performed on the feed water (Fig. S1a). Distinct redox peaks observed in the presence of arsenic, absent in the blank electrolyte (Fig. S1b), suggest redox activity of arsenic species under the applied potential window (1.2 V). Further CV analysis of solutions containing only As(V) or As(III) at varying concentrations (Fig. S1c, d) supports the hypothesis that As(V) can be reduced to As(III) and As(III) can be oxidized to As(V) within this potential range.

Experiments were conducted using initial solutions containing either 1000 μg·L⁻¹ As(V) or 1000 μg·L⁻¹ As(III) to evaluate the system’s efficacy for removing these species independently. The system demonstrated higher removal efficiency for As(V) compared to As(III) (Fig. S2), potentially due to the anionic nature of As(V) species (H₂AsO₄⁻/HAsO₄²⁻) facilitating electromigration toward the anode, whereas As(III) exists primarily as the neutral H₃AsO₃ molecule under mildly acidic to neutral pH, hindering direct electrostatic removal.

The data suggest that As(III) removal occurs via two distinct pathways: direct electrosorption, which is presumably less efficient due to the neutral charge of As(III), and an oxidation-electrosorption pathway, wherein As(III) is first oxidized to the more readily adsorbed As(V) anions. Figure 6 details arsenic speciation and distribution during FCDI treatment starting with 1000 μg·L⁻¹ As(III). Arsenic removal involves both electrosorption onto the activated carbon surface and retention within the bulk electrode suspension (anolyte and catholyte). At the end of the experiment (240 min), approximately 53.4% of the removed arsenic was found adsorbed onto the carbon (estimated by mass balance difference or direct measurement), with the remaining ~46.6% residing in the electrode suspensions. In the absence of applied voltage, the arsenic removal efficiency was limited to approximately 14.9%, indicating minimal adsorption via passive diffusion. Under otherwise identical conditions, applying voltage substantially increased the removal efficiency to approximately 50%. This notable improvement suggests that the applied voltage significantly enhanced As(III) removal, primarily through its oxidation to As(V), a species more amenable to adsorption. Hence, our results indicate that both oxidation followed by adsorption and direct adsorption followed by possible oxidation at the electrode surface may simultaneously occur. The enhanced removal efficiency upon voltage application predominantly suggests that oxidation of As(III) to As(V) occurs first, facilitating subsequent adsorption. However, a minor fraction of molecular As(III) might directly diffuse through the membrane and adsorb onto the electrode surface, potentially undergoing subsequent oxidation.

a Arsenic removal efficiency and b distribution of removed arsenic (adsorbed on carbon versus in suspension) and speciation ratio (As(V) to As(III)) over time when the initial feed contained 1000 micrograms per liter of As(III). c Arsenic removal efficiency and d arsenic distribution and speciation ratio over time when the initial feed contained a 1-to-1 mixture of As(V) and As(III) (totaling 1000 micrograms per liter). Experiments were conducted once (n = 1) to assess the performance under these specific conditions.

Electrochemical oxidation of As(III) to As(V) appears kinetically more favorable compared to direct electromigration or adsorption of neutral As(III). Consequently, as As(V) is continuously generated and subsequently removed, its relative proportion initially increases, suggesting that oxidation followed by electrosorption is the predominant removal mechanism during the early stage. In the initial phase (first 20 min), ~9.8% of the total arsenic was removed. Analysis of the electrode suspension revealed a higher concentration of As(V) than As(III) (ratio ~3.6:1), despite starting with only As(III). Under the slightly alkaline pH observed in the electrode suspension (Fig. S4a), As(V) exists predominantly as anionic H₂AsO₄⁻/HAsO₄²⁻, while As(III) exists primarily as neutral H₃AsO₃. Electrosorption favors charged species. Ion migration faces internal resistance, charge-transfer resistance, and adsorption resistance; charge-transfer resistance is often lowest35,36.

In the middle phase (around 80 min), the As(V):As(III) ratio in the electrode suspension decreased to ~1:1.2, suggesting that as the overall As(III) concentration diminishes, the rate of direct migration/adsorption, though less efficient, may become relatively more significant compared to the oxidation rate. As the experiment progresses further and total arsenic concentration decreases, the redox processes likely slow down, but the interplay continues.

During operation, the pH of the feed solution exhibited a discernible increase (Fig. S4a), accompanied by an increase in conductivity (Fig. S4b). This is consistent with the migration of hydroxide (OH⁻) and chloride (Cl⁻) anions from the electrode suspensions (where they are exchanged for arsenate or are present initially) through the AEMs into the desalination chamber. The pH increase could potentially shift As(III) speciation slightly toward anionic forms (H₂AsO₃⁻ becomes relevant above pH 9.2) but primarily influences As(V) speciation and potentially electrode surface chemistry, possibly enhancing overall arsenic removal under certain conditions.

Figure 6c, d presents results starting with a 1:1 mixture of As(V) and As(III) (totaling 1000 μg·L⁻¹). In this scenario, approximately 30% of the removed arsenic was adsorbed onto the carbon, with ~70% remaining in the electrode suspensions. This difference in distribution compared to the As(III)-only start might relate to the initial presence of readily adsorbable As(V) anions, saturating sites differently, or influencing suspension pH37. Notably, after 20 min, the total amount of As(V) measured (in feed + electrode suspensions) was ~2.8% higher than initially added, while As(III) decreased by ~8.9%. This confirms that As(III) oxidation occurs, and although As(V) reduction to As(III) is thermodynamically possible and suggested by CV (Fig. S1), the net process favors As(III) oxidation under these operating conditions. Furthermore, the removal of As(V) from the feed (~18.0% of total As removed in the first 20 min) significantly exceeded the net amount of As(V) generated (~2.8%), indicating that direct electrosorption was the primary removal pathway for the initially present As(V). As the experiment continued, arsenic concentration decreased, redox reactions likely weakened, but the overall removal rate remained significant, suggesting that for the removal of As(V), the dominant mechanisms are direct electromigration through the membrane and adsorption onto activated carbon surfaces, rather than oxidation-reduction processes.

Application of symmetric-AEM FCDI for real groundwater arsenic removal

To evaluate the practical applicability of the optimized symmetric-AEM FCDI system, groundwater samples were collected from five sites in a known arsenic-affected region: Tongyu County, Jilin Province, China (approx. 120°02′E, 44°12′N). Water quality parameters for these samples are detailed in Table S3. The highest arsenic concentration was detected in the sample from Xiaili Village (122°81′E, 44°99′N), reaching approximately 110 μg·L⁻¹, significantly exceeding the Chinese national drinking water standard (10 μg·L⁻¹, GB 5749-2022) and posing a considerable public health risk.

Using the optimized operating parameters determined from feed water experiments (1.2 V, 6 wt% carbon, 20 mL·min⁻¹ flow rate, initial pH unadjusted), the five groundwater samples were treated using the symmetric-AEM FCDI system after filtration (0.45 μm) to prevent potential clogging. The arsenic removal performance for each sample is presented in Fig. 7.

Arsenic concentration profiles over a 240-min treatment period for five different real groundwater samples collected from Tongyu County, Jilin Province, China. The experiments were conducted using the optimized symmetric-AEM FCDI system. The dashed horizontal line indicates the World Health Organization drinking water guideline of 10 micrograms per liter. Experiments were conducted once (n = 1) to assess the performance under these specific conditions.

After 240 min of treatment, the arsenic concentrations in the samples from Xiaili Village (122°81′E, 44°99′N), Sichizi Township (122°80′E, 44°90′N), and Xinxing Township (122°72′E, 44°73′N) were reduced to below the analytical detection limit of the AFS instrument (≤0.02 μg·L⁻¹). The arsenic concentrations in the treated samples from Lühai Village (123°08′E, 45°05′N) and Wulanhua Township (122°65′E, 44°71′N) were approximately 3.8 μg·L⁻¹ and 3.1 μg·L⁻¹, respectively, both well below the 10 μg·L⁻¹ drinking water standard. These results demonstrate the high efficacy of the symmetric-AEM FCDI configuration for treating real arsenic-contaminated groundwater with varying initial concentrations and background matrices.

Two-stage operation, ion selectivity, and back-diffusion

A supplementary two-stage experiment was conducted at an applied voltage of 1.2 V, a flow rate of 20 mL·min⁻¹, and an activated carbon electrode suspension of 6 wt%, with each stage lasting 4 h. After the first stage, approximately 1.5% of the initial arsenic remained in solution (~16.2 μg·L⁻¹). During the subsequent second-stage treatment, the arsenic concentration further decreased to approximately 7.5 μg·L⁻¹ within 1 h, meeting both the Chinese national drinking water standard (10 μg·L⁻¹) and the World Health Organization’s recommended guideline (10 μg·L⁻¹). Notably, from the second hour onward in the second stage, arsenic concentrations consistently remained below the analytical detection limit (0.02 μg·L⁻¹), clearly demonstrating the high efficacy of the two-stage sequential treatment.

The selective ion migration capability of the device demonstrates its effectiveness in removing targeted pollutants while avoiding unnecessary energy expenditure on non-target or beneficial ions, thereby enhancing both economic and environmental benefits. As depicted in Fig. S5, arsenic removal efficiency remained relatively stable despite increasing chloride ion concentrations in the feed water. However, the migration efficiency of chloride ions gradually decreased as their initial concentration increased, leading to a reduced chloride ion requirement for removing a given amount of arsenic. Correspondingly, calculated charging efficiencies were 6.23 × 10⁻³%, 6.15 × 10⁻³%, and 3.88 × 10⁻³% at ascending chloride concentrations, indicating a declining trend in charging efficiency with increased chloride content. Therefore, the selection of chloride ion concentration in feed water should balance not only the arsenic removal efficiency but also the charging efficiency to achieve optimal system performance.

The performance characteristics of the symmetric-AEM FCDI in SCC mode are specifically tailored for the robust and continuous removal of trace-level contaminants. Within this framework, the observed low charge efficiency is neither a flaw nor an imbalance; rather, it is an intentional and necessary consequence of our design strategy. The gradual increase in effluent conductivity provides direct experimental evidence supporting our intended ion-exchange mechanism. This controlled migration of Cl⁻ ions into the desalination chamber is essential to counteract the resistance increase that typically stalls conventional CDI systems when treating low-conductivity water.

Specifically, the relatively high background current (~33 mA), primarily carried by chloride ions, performs a critical function by sustaining a stable, strong electric field across the desalination chamber. This field stability is indispensable for continuously driving the migration and removal of sparsely distributed arsenate ions over extended operational periods. Consequently, our “low-efficiency, high-robustness” strategy represents a pragmatic trade-off, deliberately sacrificing traditional metrics (such as charge efficiency) to substantially enhance a more critical parameter: sustained, long-term operational stability in trace-contaminant remediation.

Back-diffusion could negatively impact the device’s arsenic removal efficiency during prolonged operation. To verify that severe back-diffusion would not occur in the later stages within the symmetric-AEM FCDI system, we conducted additional experiments. Notably, pollutant re-release phenomena—such as BOD rebound observed in activated-sludge adsorption–regeneration processes—are common engineering challenges in water-treatment systems. Although fundamentally different in mechanism (biophysical adsorption saturation versus ion back-diffusion driven by concentration gradients), such issues consistently present the practical challenge of maintaining stable treatment performance.

In biological wastewater treatment processes, mature engineering solutions, including periodic sludge regeneration and operational adjustments, have been successfully developed to manage these re-release issues. However, ion back-diffusion in Flow-Electrode Capacitive Deionization (FCDI) systems remains a significant and persistent technical limitation. Nevertheless, the success in managing analogous issues within biological wastewater treatment highlights promising strategies that could potentially be adapted to FCDI systems. Future research could beneficially incorporate established water-treatment strategies—such as periodic electrode regeneration, polarity reversal, or operational optimization—to mitigate or manage back-diffusion effects effectively. Therefore, arsenic back-diffusion in FCDI systems is not an insurmountable obstacle but rather a manageable engineering issue. As shown in Fig. S6, the arsenic removal efficiency reached approximately 96.1% after 4 h, followed by minor fluctuations—initially rising to 99.1%, and subsequently varying between 95.6% and 99.1% throughout the remaining duration. Notably, during extended operation, temporary increases in arsenic concentration indicated occasional arsenic crossover from the electrode chambers back into the desalination chamber. However, these increases were consistently offset by subsequent enhanced forward migration, restoring efficient arsenic removal. Ultimately, a dynamic equilibrium was established, effectively preventing persistent arsenic accumulation within the desalination chamber.

Discussion

This study demonstrates a potentially feasible and highly effective approach for arsenic remediation using a symmetric-AEM FCDI configuration, particularly relevant for regions confronting arsenic contamination in groundwater, including developing and underdeveloped nations requiring low-pressure membrane, low-voltage driven solutions.

The symmetric-AEM configuration consistently enabled effluent arsenic concentrations to meet stringent drinking water standards. This design enhanced arsenic removal efficiency by approximately 19.4% compared to conventional FCDI, while significantly improving and stabilizing conductivity within the desalination chamber. This feature effectively mitigates conductivity limitations and associated ion-transport resistances commonly observed in conventional FCDI systems during extended operation. Notably, for influent arsenic concentrations as high as 1000 μg·L⁻¹, a two-stage sequential treatment reduced effluent arsenic levels below the analytical detection limit (0.02 μg·L⁻¹). Moreover, the treatment of real groundwater samples with typical arsenic levels (~110 μg·L⁻¹) consistently achieved concentrations below both Chinese national and WHO drinking water standards, often below detection limits. Although the SCC operation mode employed may exhibit lower theoretical energy efficiency compared to SCSC modes, the demonstrated high removal efficacy under continuous operation is acceptable and practically valuable for arsenic-affected regions prioritizing water safety. Rather than pursuing conventional charge efficiency, this study adopts a ‘low-efficiency, high-robustness’ design philosophy to ensure stable electric field conditions and uninterrupted removal of trace arsenic contaminants, providing a viable strategy for long-term drinking water safety.

However, several limitations remain to be addressed. Long-term cycling experiments indicated a gradual decline in removal efficiency, potentially arising from electrode saturation, membrane fouling or scaling, and ion accumulation near the cathode-side AEM. Future studies should focus on systematically exploring electrode regeneration methods, alternative electrode materials, and membrane antifouling strategies to improve system durability and long-term operational stability. Furthermore, although the symmetric-AEM configuration demonstrated excellent arsenic removal capability, the charge efficiency was relatively low (~6 × 10⁻³%). Future work should aim to enhance charge efficiency by optimizing electrode materials or adjusting operational parameters.

Overall, this work represents a significant step toward translating FCDI technology from laboratory-scale research to practical application, showcasing the potential of the symmetric-AEM configuration as a robust solution for producing safe drinking water from arsenic-contaminated sources.

Methods

FCDI device structure and configuration

The FCDI device was constructed utilizing two identical acrylic end plates, six silicone gaskets, two anion-exchange membranes (AMV, AGC Inc., Japan), and two graphite current collectors, all precisely aligned to facilitate optimal ion transport and ensure device stability (Fig. 8). The acrylic plates (100 mm × 90 mm, 15 mm thickness) served as end plates, securing the device assembly. The silicone gaskets possessed matching lateral dimensions and a thickness of 0.5 mm. The central portion of the end plates (50 mm × 40 mm) was excised to accommodate the IEMs and reaction chambers.

An exploded-view schematic diagram illustrating the components and assembly of the flow-electrode capacitive deionization (FCDI) device. The key components include acrylic end plates, silicone gaskets, graphite current collectors, and ion-exchange membranes, which form the desalination and electrode chambers.

The IEMs, with dimensions of 5.7 cm × 4.7 cm, yielding an effective membrane area of 10.9 cm², were selected to enable selective anion transport while minimizing co-ion leakage. The graphite plates served as current collectors, each incorporating 13 serpentine flow channels (2 mm width, 2 mm depth) designed for the electrode suspension flow. Eight 10 mm diameter apertures in the acrylic plates and silicone gaskets facilitated device assembly using M6 screws, ensuring a tight seal. Additionally, three 5 mm diameter ports were symmetrically positioned on the front face of each acrylic end plate to function as inlets and outlets for the feed water and electrode suspension. During assembly, 10 cm long M6 stainless steel screws were employed to fasten and secure all components, adhering to the validated assembly protocol established in our prior work on conventional FCDI systems38. A schematic comparison of the conventional and symmetric-AEM configurations is presented in Fig. 9.

Schematic diagrams illustrating the principle of operation and key ion migration pathways. a The symmetric-AEM configuration, which uses two anion-exchange membranes, facilitates anion (arsenate and chloride) transport. b The conventional FCDI configuration uses one anion-exchange membrane and one cation-exchange membrane. c Schematic diagram of equipment operation in SCC mode.

Preparation of flow electrodes and feed water

The FCDI system was operated in short-circuit closed-loop (SCC) mode, following established methodologies39. While the short-circuit open-circuit cycling (SCSC) mode often yields superior energy efficiency by alternating between adsorption and desorption phases, continuous operation under the SCC mode was selected for this investigation. This mode provides a stable, continuous electric field, essential for the systematic investigation of arsenic species migration and transformation, particularly under the symmetric-AEM configuration where precise analysis of ion-transport pathways and conductivity stability is paramount. Furthermore, continuous SCC operation mitigates the concentration fluctuations inherent in cyclic modes, thereby maintaining consistent ionic conditions and enabling clearer elucidation of arsenic removal mechanisms and long-term operational stability. For SCC mode operation, prior to each experiment, 1 L of 5 g·L⁻¹ sodium chloride (NaCl) solution was prepared, from which 180 mL was utilized. Activated carbon (6 wt%, YEC-8A, Fuzhou Huan Carbon Co., LTD) and carbon black (1 wt%, Super P Li, Fuzhou Huan Carbon Co., LTD) were weighed according to the desired mass fractions. These carbon materials were dried in a vacuum oven at 105 °C for 1 h. Post-drying, they were dispersed into the 180 mL NaCl solution to formulate the flow-electrode suspension. The suspension was continuously stirred for 4 h using a mechanical stirrer, followed by continuous agitation on a magnetic stirrer throughout the experiments to ensure homogeneity.

Given the wide range reported for high-arsenic groundwater40, a representative maximum concentration of approximately 1 mg·L⁻¹ (specifically, 1000 μg·L⁻¹) was selected for experimental simulations. The 1 mg·L⁻¹ arsenic stock solution was prepared by diluting a certified 1000 μg·mL⁻¹ arsenic standard solution (National Center for Analysis and Testing of Nonferrous Metals and Electronic Materials) with deionized water. NaCl (400 mg·L⁻¹) was added as the background electrolyte. The initial pH of the feed water was adjusted as required using dilute HCl (0.1% v/v) or NaOH (0.1 mol·L⁻¹). All chemical reagents were of analytical grade unless specified otherwise. Unless stated otherwise, experiments were conducted under constant voltage operation. Standard operating conditions involved an applied voltage of 1.2 V, a feed water flow rate of 20 mL·min⁻¹, and an identical flow rate for the activated carbon suspension.

Analytical and electrochemical methods

Dissolved arsenic concentrations were quantified using atomic fluorescence spectroscopy (AFS-8530, Haiguang Instrument Co., China). For As(III) determination, the reaction medium consisted of 1.5% HCl and a reducing agent solution of 1.5 wt% KBH₄ + 5 wt% KOH. For total arsenic (T-As) determination, thiourea (5 wt%) and ascorbic acid (5 wt%) were employed as masking and reducing agents, respectively, with an eluent comprising 5% HCl and a reductant of 2 wt% KBH₄ + 5 wt% KOH. The concentration of As(V) was calculated as the difference between T-As and As(III) concentrations. Chloride (Cl⁻) concentration was determined via ion chromatography (ICS-2100, Dionex). pH variations in the desalination chamber were monitored using a calibrated pH meter (pHB-5, Shanghai Skill Scientific Instrument Co., Ltd).

An in situ three-electrode FCDI system was adapted and constructed based on the methodology reported by Luo et al.41. An Ag/AgCl reference electrode was inserted into a custom-machined reference port. Apertures were created at corresponding locations on the graphite plate and the acrylic end plate to accommodate the reference electrode assembly. The reference electrode (4 mm diameter) tip was positioned approximately 0.2 mm from the current collector surface to minimize ohmic drop artifacts. Cyclic voltammetry (CV) tests were performed using an electrochemical workstation (CHI760E, Shanghai Chenhua Instrument Company) at a scan rate of 10 mV·s⁻¹ within the three-electrode FCDI system, employing the graphite collector as the working electrode, the opposing collector as the counter electrode, and Ag/AgCl as the reference electrode. Electrochemical impedance spectroscopy (EIS) measurements of the flow electrodes were conducted under realistic FCDI operating conditions with a perturbation amplitude of 10 mV over a frequency range from 10⁵ Hz to 0.01 Hz. Specifications for apparatus and reagents are detailed in Tables S1 and S2 (Supporting Information).

At each sampling interval, two aliquots of the feed solution were simultaneously collected. One aliquot was treated with a thiourea-ascorbic acid solution to determine total arsenic concentration, while the other aliquot was left untreated for direct measurement of As(III). The concentration of As(V) was subsequently calculated from the difference between these two measurements.

Similarly, at identical sampling intervals, two aliquots (1 mL each) of the electrode suspension were carefully withdrawn to minimize disturbance to the activated carbon suspension. These aliquots were immediately filtered to obtain clear solutions and analyzed for arsenic species following the procedure described above.

Considering each sample’s small volume (~1% of the total suspension), this sampling approach did not appreciably alter the composition of the electrode suspension or compromise the stability of the activated carbon electrode.

Performance evaluation

The performance of the FCDI system for arsenic removal was quantified using the following parameters42:

Average salt removal rate (ASRR, μg·cm−2· min−1):

where C0 is the initial arsenic concentration of the influent (mg·L−1), Ct is the concentration of the effluent at time t, vd is the flow rate of the influent (mL·min−1), Aeff is the effective area between the flow electrode and the IEM (cm2), and M is the molar mass of arsenic (g·mol−1). The following applications of this equation all calculate the average rate of arsenic removal, where C0 and Ct refer to the concentration of arsenic.

(2) Removal Efficiency (RE) (%):

(3) Removal Rate (mg·L−1·min−1):

(4) Normalized Energy Consumption for Salt Removal (ENRS, μmol·J−1):

Where Vs is the sample volume, I is the current (A), and U is the voltage (V), M is the relative atomic mass, and the unit for Vs is sample volume.

(5) The selectivity between As and Cl− was calculated as the ratio of their removal efficiency (η):

(6) charge efficiency (CE, %):

where C0 is the initial concentration of the Cl–, Ct is the concentration at time t, F is Faraday’s constant (96485 C • mol–1), Vs is the volume of solution; M is the molar mass of Cl–; I is the current at time t。C0 - Ct is expressed in terms of migration volume.

Data availability

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation, upon reasonable request.

Abbreviations

- AEM:

-

Anion-exchange membrane

- ASRR:

-

Average salt removal rate

- CDI:

-

Capacitive deionization

- CV:

-

Cyclic voltammetry

- EIS:

-

Electrochemical impedance spectroscopy

- ENRS:

-

(Normalized) Energy consumption for salt removal

- FCDI:

-

Flow-electrode capacitive deionization

- ICC:

-

Isolated closed-cycle

- IEM:

-

Ion-exchange membrane

- MCDI:

-

Membrane capacitive deionization

References

Rodríguez-Lado, L. et al. Groundwater arsenic contamination throughout China. Science 341, 866–868 (2013).

Podgorski, J. & Berg, M. Global threat of arsenic in groundwater. Science 368, 845–850 (2020).

Raju, N. J. Arsenic in the geo-environment: a review of sources, geochemical processes, toxicity and removal technologies. Environ. Res. 203, 111782 (2022).

Postma, D. et al. Groundwater arsenic concentrations in Vietnam controlled by sediment age. Nat. Geosci. 5, 656–661 (2012).

Benner, S. G. & Fendorf, S. Arsenic in South Asia groundwater. Geogr. Compass 4, 1532–1552 (2010).

Chakraborti, D. et al. Groundwater arsenic contamination in the Ganga River Basin: a future health danger. Int. J. Environ. Res. Public Health 15, 180 (2018).

Reddy, R. R. et al. Evaluation of arsenic field test kits for drinking water: Recommendations for improvement and implications for arsenic affected regions such as Bangladesh. Water Res. 170, 115325 (2020).

Ramsay, L. et al. Drinking water criteria for arsenic in high-income, low-dose countries: the effect of legislation on public health. Environ. Sci. Technol. 55, 3483–3493 (2021).

Nikić, J., Watson, M., Tenodi, K. Z., Dalmacija, B. & Agbaba, J. Pilot study on arsenic removal from phosphate rich groundwater by in-line coagulation and adsorption. J. Hazard. Mater. Adv. 10, 100280 (2023).

Annaduzzaman, M., Rietveld, L. C., Hoque, B. A., Bari, M. N. & van Halem, D. Arsenic removal from iron-containing groundwater by delayed aeration in dual-media sand filters. J. Hazard. Mater. 411, 124823 (2021).

Ge, J. et al. Challenges of arsenic removal from municipal wastewater by coagulation with ferric chloride and alum. Sci. Total Environ. 725, 138351 (2020).

Sandoval, M. A., Fuentes, R., Thiam, A. & Salazar, R. Arsenic and fluoride removal by electrocoagulation process: A general review. Sci. Total Environ. 753, 142108 (2021).

Zhu, Y. et al. Brackish groundwater desalination by constant current membrane capacitive deionization (MCDI): results of a long-term field trial in Central Australia. Water Res. 254, 121413 (2024).

Yang, F. et al. Flow-electrode capacitive deionization: a review and new perspectives. Water Res. 200, 117222 (2021).

Yin, H., Liu, L., Ma, J., Zhang, C. & Qiu, G. Efficient removal of As(III) from groundwaters through self-alkalization in an asymmetric flow-electrode electrochemical separation system. Water Res. 246, 120734 (2023).

Li, Y. et al. Carbon felt (CF) acted as an “ionic capacitor” to enhance flow electrode capacitive deionization (FCDI) desalination performance. Desalination 575, 117341 (2024).

Dennison, C. R. The Electrochemical Flow Capacitor: Capacitive Energy Storage in Flowable Media. PhD dissertation, Drexel University, ProQuest LLC (2014).

Sarac, A. S., Ates, M. & Kilic, B. Electrochemical impedance spectroscopic study of polyaniline on platinum, glassy carbon and carbon fiber microelectrodes. Int. J. Electrochem. Sci. 3, 777–786 (2008).

Wu, H. et al. Selective chromium and copper recovery from wastewater using flow-electrode capacitance deionization: In-situ reduction mechanism regulating metal charging characteristics. Sep. Purif. Technol. 328, 124970 (2024).

Tang, K., Zheng, H., Du, P. & Zhou, K. Simultaneous fractionation, desalination, and dye removal of dye/salt mixtures by carbon cloth-modified flow-electrode capacitive deionization. Environ. Sci. Technol. 56, 8885–8896 (2022).

Luo, K. et al. Desalination behavior and performance of flow-electrode capacitive deionization under various operational modes. Chem. Eng. J. 389, 124051 (2020).

Xu, L. et al. Can flow-electrode capacitive deionization become a new in-situ soil remediation technology for heavy metal removal?. J. Hazard Mater. 402, 123568 (2021).

Doornbusch, G., Dykstra, J., Biesheuvel, P. & Suss, M. Fluidized bed electrodes with high carbon loading for water desalination by capacitive deionization. J. Mater. Chem. A 4, 3642 (2016).

Nativ, P., Badash, Y. & Gendel, Y. New insights into the mechanism of flow-electrode capacitive deionization. Electrochem. Commun. 76, 24 (2017).

Ma, J., He, C., He, D., Zhang, C. & Waite, T. D. Analysis of capacitive and electrodialytic contributions to water desalination by flow-electrode CDI. Water Res. 144, 296 (2018).

Zhang, J. et al. Removal and recovery of phosphorus from low-strength wastewaters by flow-electrode capacitive deionization. Sep. Purif. Technol. 237, 116322 (2020).

Dahiya, S., Singh, A., Tripathi, A. & Mishra, B. K. Understanding behaviour and performance of flow electrode capacitive deionization (FCDI) during simultaneous selective removal of chromium (Cr (VI)) and fluoride from brackish wastewater. J. Water Process Eng. 69, 106864 (2025).

Dahiya, S. & Mishra, B. K. Enhancing understandability and performance of flow electrode capacitive deionisation by optimizing configurational and operational parameters: a review on recent progress. Sep. Purif. Technol. 240, 116660 (2020).

Lim, J., Shin, Y.-U., Son, A., Hong, S. W. & Hong, S. TiO2 nanotube electrode for organic degradation coupled with flow-electrode capacitive deionization for brackish water desalination. npj Clean Water 5, 7 (2022).

Mansoor, N. E. et al. Removal and recovery of ammonia from simulated wastewater using Ti3C2Tx MXene in flow electrode capacitive deionization. npj Clean Water 5, 26 (2022).

Nazari, A. M., Radzinski, R. & Ghahreman, A. Review of arsenic metallurgy: treatment of arsenical minerals and the immobilization of arsenic. Hydrometallurgy 174, 258–281 (2017).

Dong, Y. et al. Effective and continuous removal of Cr(VI) from brackish wastewater by flow-electrode capacitive deionization (FCDI). J. Clean Prod. 326, 129417 (2021).

Liu, W. et al. Direct conversion of monopotassium L-aspartate by electrodialysis metathesis: Stack resistance, co-ion transport, and concentration polarization. Chem. Eng. Sci. 294, 120113 (2024).

Wang, J. et al. The optimized flow-electrode capacitive deionization (FCDI) performance by ZIF-8 derived nanoporous carbon polyhedron. Sep. Purif. Technol. 281, 119345 (2022).

Huang, Y. & Matsumoto, M. Effects of electric double layer on nanoscale boiling: molecular dynamics approach. Colloids Surf. A Physicochem. Eng. Asp. 695, 134253 (2024).

Kim, N., Park, J., Cho, Y. & Yoo, C.-Y. Comprehensive electrochemical impedance spectroscopy study of flow-electrode capacitive deionization cells. Environ. Sci. Technol. 57, 8808–8817 (2023).

Kanel, S. R., Manning, B., Charlet, L. & Choi, H. Removal of arsenic(III) from groundwater by nanoscale zero-valent iron. Environ. Sci. Technol. 39, 1291–1298 (2005).

Zhou, R. et al. Enhanced capacitive deionization for Cr(VI) removal from electroplating wastewater: efficacy, mechanisms, and high-voltage flow electrodes. J. Environ. Chem. Eng. 12, 113178 (2024).

Jiang, H. et al. Effective fluoride removal from brackish groundwaters by flow-electrode capacitive deionization (FCDI) under a continuous-flow mode. Sci. Total Environ. 804, 150166 (2022).

Hamidian, A. H., Razeghi, N., Zhang, Y. & Yang, M. Spatial distribution of arsenic in groundwater of Iran, a review. J. Geochem. Explor. 201, 88–98 (2019).

Luo, L. et al. Indirect charging of carbon by aqueous redox mediators contributes to the enhanced desalination performance in flow-electrode CDI. Water Res. 220, 118688 (2022).

Zhang, C. et al. Flow Electrode Capacitive Deionization (FCDI): Recent Developments, Environmental Applications, and Future Perspectives. Environ. Sci. Technol. 55, 4243–4267 (2021).

Acknowledgements

This work received support from the National Key Research and Development Program of China (grant number 2022YFC3702200) and the National Natural Science Foundation of China (grant number 42107483). The authors express their gratitude to all individuals who provided technical assistance. Manuscript review and editing support from Enago (www.enago.cn) is acknowledged.

Author information

Authors and Affiliations

Contributions

S. Z.: Data Curation, Conceptualization, Methodology, Investigation, Formal analysis, Writing–original draft. P. W.: Formal analysis, Investigation, methodology, Writing–original draft. W. X.: Formal analysis, Writing–review & editing. W. Z.: Visualization, Writing–review & editing. F. L.: Supervision. C. Y.: Writing–review & editing. H. L.: Writing–review & editing. Y. Z.: Writing–review & editing. Z. Z.: Writing–review & editing. C. Z.: Conceptualization, Funding acquisition, Investigation, Methodology, Project administration, Supervision, Writing–review & editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zhang, S., Wang, P., Xue, W. et al. Symmetric anion exchange membranes enhance arsenic removal and overcome conductivity limitations in FCDI systems. npj Clean Water 8, 70 (2025). https://doi.org/10.1038/s41545-025-00503-0

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41545-025-00503-0