Abstract

Mechanical metamaterials exhibit interesting properties such as high stiffness at low density1,2,3, enhanced energy absorption3,4, shape morphing5,6,7, sequential deformations8,9,10,11, auxeticity12,13,14 and robust waveguiding15,16. Until now, metamaterial design has primarily relied on geometry, and materials nonlinearities such as viscoelasticity, fracture and plasticity have been largely left out of the design rationale. In fact, plastic deformations have been traditionally seen as a failure mode and thereby carefully avoided1,3,17,18. Here we embrace plasticity instead and discover a delicate balance between plasticity and buckling instability, which we term ‘yield buckling’. We exploit yield buckling to design metamaterials that buckle sequentially in an arbitrary large sequence of steps whilst keeping a load-bearing capacity. We make use of sequential yield buckling to create metamaterials that combine stiffness and dissipation—two properties that are usually incompatible—and that can be used several times. Hence, our metamaterials exhibit superior shock-absorption performance. Our findings add plasticity to the metamaterial toolbox and make mechanical metamaterials a burgeoning technology with serious potential for mass production.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$32.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to the full article PDF.

USD 39.95

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All the codes and data supporting this study are available on the public repository https://zenodo.org/records/12724185 (ref. 64). Source data are provided with this paper.

Code availability

All the codes and data supporting this study are available on the public repository https://zenodo.org/records/12724185 (ref. 64).

References

Schaedler, T. A. et al. Ultralight metallic microlattices. Science 334, 962–965 (2011).

Zheng, X. et al. Ultralight, ultrastiff mechanical metamaterials. Science 344, 1373–1377 (2014).

Meza, L. R., Das, S. & Greer, J. R. Strong, lightweight, and recoverable three-dimensional ceramic nanolattices. Science 345, 1322–1326 (2014).

Tancogne-Dejean, T., Spierings, A. B. & Mohr, D. Additively-manufactured metallic micro-lattice materials for high specific energy absorption under static and dynamic loading. Acta Mater. 116, 14–28 (2016).

Meeussen, A. & van Hecke, M. Multistable sheets with rewritable patterns for switchable shape-morphing. Nature 621, 516–520 (2023).

Choi, G. P., Dudte, L. H. & Mahadevan, L. Programming shape using kirigami tessellations. Nat. Mater. 18, 999–1004 (2019).

Gao, T., Bico, J. & Roman, B. Pneumatic cells toward absolute Gaussian morphing. Science 381, 862–867 (2023).

Coulais, C., Sabbadini, A., Vink, F. & van Hecke, M. Multi-step self-guided pathways for shape-changing metamaterials. Nature 561, 512–515 (2018).

Florijn, B., Coulais, C. & van Hecke, M. Programmable mechanical metamaterials. Phys. Rev. Lett. 113, 175503 (2014).

Shan, S. et al. Multistable architected materials for trapping elastic strain energy. Adv. Mater. 27, 4296–4301 (2015).

Restrepo, D., Mankame, N. D. & Zavattieri, P. D. Phase transforming cellular materials. Extreme Mech. Lett. 4, 52–60 (2015).

Lakes, R. Foam structures with a negative Poisson’s ratio. Science 235, 1038–1040 (1987).

Bertoldi, K., Reis, P. M., Willshaw, S. & Mullin, T. Negative Poisson’s ratio behavior induced by an elastic instability. Adv. Mater. 22, 361–366 (2010).

Babaee, S. et al. 3D soft metamaterials with negative Poisson’s ratio. Adv. Mater. 25, 5044–5049 (2013).

Jin, L. et al. Guided transition waves in multistable mechanical metamaterials. Proc. Natl Acad. Sci. 117, 2319–2325 (2020).

Deng, B., Wang, P., He, Q., Tournat, V. & Bertoldi, K. Metamaterials with amplitude gaps for elastic solitons. Nat. Commun. 9, 3410 (2018).

Bauer, J., Kraus, J. A., Crook, C., Rimoli, J. J. & Valdevit, L. Tensegrity metamaterials: toward failure-resistant engineering systems through delocalized deformation. Adv. Mater. 33, 2005647 (2021).

Dykstra, D. M., Lenting, C., Masurier, A. & Coulais, C. Buckling metamaterials for extreme vibration damping. Adv. Mater. 35, 2301747 (2023).

Bertoldi, K., Vitelli, V., Christensen, J. & Van Hecke, M. Flexible mechanical metamaterials. Nat. Rev. Mater. 2, 17066 (2017).

Jiao, P., Mueller, J., Raney, J. R., Zheng, X. & Alavi, A. H. Mechanical metamaterials and beyond. Nat. Commun. 14, 6004 (2023).

Djellouli, A. et al. Shell buckling for programmable metafluids. Nature 628, 545–550 (2024).

Lubbers, L. A., van Hecke, M. & Coulais, C. A nonlinear beam model to describe the postbuckling of wide neo-Hookean beams. J. Mech. Phys. Solids 106, 191–206 (2017).

Chen, Y. & Jin, L. Reusable energy-absorbing architected materials harnessing snapping-back buckling of wide hyperelastic columns. Adv. Funct. Mater. 31, 2102113 (2021).

Dykstra, D. M. J., Janbaz, S. & Coulais, C. The extreme mechanics of viscoelastic metamaterials. APL Mater 10, 080702 (2022).

Bossart, A., Dykstra, D. M., van der Laan, J. & Coulais, C. Oligomodal metamaterials with multifunctional mechanics. Proc. Natl Acad. Sci. 118, e2018610118 (2021).

Janbaz, S., Narooei, K., van Manen, T. & Zadpoor, A. Strain rate–dependent mechanical metamaterials. Sci. Adv. 6, eaba0616 (2020).

Janbaz, S. & Coulais, C. Diffusive kinks turn kirigami into machines. Nat. Commun. 15, 1255 (2024).

Evans, A. G. et al. Concepts for enhanced energy absorption using hollow micro-lattices. Int. J. Impact Eng. 37, 947–959 (2010).

Rafsanjani, A. & Bertoldi, K. Buckling-induced kirigami. Phys. Rev. Lett. 118, 084301 (2017).

Zhang, F. et al. Shape morphing of plastic films. Nat. Commun. 13, 7294 (2022).

Hwang, D., Barron III, E. J., Haque, A. T. & Bartlett, M. D. Shape morphing mechanical metamaterials through reversible plasticity. Sci. Robot. 7, eabg2171 (2022).

Ren, X., Shen, J., Ghaedizadeh, A., Tian, H. & Xie, Y. M. Experiments and parametric studies on 3D metallic auxetic metamaterials with tuneable mechanical properties. Smart Mater. Struct. 24, 095016 (2015).

Ghaedizadeh, A., Shen, J., Ren, X. & Xie, Y. M. Tuning the performance of metallic auxetic metamaterials by using buckling and plasticity. Materials 9, 54 (2016).

Bažant, Z. P. & Cedolin, L. Stability of Structures: Elastic, Inelastic, Fracture and Damage Theories (World Scientific, 2010).

Frenzel, T., Findeisen, C., Kadic, M., Gumbsch, P. & Wegener, M. Tailored buckling microlattices as reusable light-weight shock absorbers. Adv. Mater. 28, 5865–5870 (2016).

Rafsanjani, A., Jin, L., Deng, B. & Bertoldi, K. Propagation of pop ups in kirigami shells. Proc. Natl Acad. Sci. 116, 8200–8205 (2019).

Melancon, D., Forte, A. E., Kamp, L. M., Gorissen, B. & Bertoldi, K. Inflatable origami: multimodal deformation via multistability. Adv. Funct. Mater. 32, 2201891 (2022).

Bense, H. & van Hecke, M. Complex pathways and memory in compressed corrugated sheets. Proc. Natl Acad. Sci. 118, e2111436118 (2021).

Guo, X., Guzmán, M., Carpentier, D., Bartolo, D. & Coulais, C. Non-orientable order and non-commutative response in frustrated metamaterials. Nature 618, 506–512 (2023).

Yasuda, H. et al. Mechanical computing. Nature 598, 39–48 (2021).

Kwakernaak, L. J. & van Hecke, M. Counting and sequential information processing in mechanical metamaterials. Phys. Rev. Lett. 130, 268204 (2023).

Novelino, L. S., Ze, Q., Wu, S., Paulino, G. H. & Zhao, R. Untethered control of functional origami microrobots with distributed actuation. Proc. Natl Acad. Sci. 117, 24096–24101 (2020).

Fu, H. et al. Morphable 3D mesostructures and microelectronic devices by multistable buckling mechanics. Nat. Mater. 17, 268–276 (2018).

Zhang, Y., Velay-Lizancos, M., Restrepo, D., Mankame, N. D. & Zavattieri, P. D. Architected material analogs for shape memory alloys. Matter 4, 1990–2012 (2021).

Fancher, R. et al. Dependence of the kinetic energy absorption capacity of bistable mechanical metamaterials on impactor mass and velocity. Extreme Mech. Lett. 63, 102044 (2023).

Overvelde, J. T. B., Shan, S. & Bertoldi, K. Compaction through buckling in 2D periodic, soft and porous structures: effect of pore shape. Adv. Mater. 24, 2337–2342 (2012).

Overvelde, J. T. & Bertoldi, K. Relating pore shape to the non-linear response of periodic elastomeric structures. J. Mech. Phys. Solids 64, 351–366 (2014).

van Mastrigt, R., Dijkstra, M., Van Hecke, M. & Coulais, C. Machine learning of implicit combinatorial rules in mechanical metamaterials. Phys. Rev. Lett. 129, 198003 (2022).

van Mastrigt, R., Coulais, C. & van Hecke, M. Emergent nonlocal combinatorial design rules for multimodal metamaterials. Phys. Rev. E 108, 065002 (2023).

Deng, F., Nguyen, Q.-K. & Zhang, P. Liquid metal lattice materials with simultaneously high strength and reusable energy absorption. Appl. Mater. Today 29, 101671 (2022).

Papka, S. D. & Kyriakides, S. Experiments and full-scale numerical simulations of in-plane crushing of a honeycomb. Acta Mater. 46, 2765–2776 (1998).

Deshpande, V., Ashby, M. & Fleck, N. Foam topology: bending versus stretching dominated architectures. Acta Mater. 49, 1035–1040 (2001).

Guell Izard, A., Bauer, J., Crook, C., Turlo, V. & Valdevit, L. Ultrahigh energy absorption multifunctional spinodal nanoarchitectures. Small 15, 1903834 (2019).

Tancogne-Dejean, T. & Mohr, D. Stiffness and specific energy absorption of additively-manufactured metallic BCC metamaterials composed of tapered beams. Int. J. Mech. Sci. 141, 101–116 (2018).

Rafsanjani, A., Zhang, Y., Liu, B., Rubinstein, S. M. & Bertoldi, K. Kirigami skins make a simple soft actuator crawl. Sci. Robot. 3, eaar7555 (2018).

Hwang, D., Barron, E. J. III, Haque, A. B. M. T. & Bartlett, M. D. Shape morphing mechanical metamaterials through reversible plasticity. Sci. Robot. 7, eabg2171 (2022).

Shi, Y. et al. Plasticity-induced origami for assembly of three dimensional metallic structures guided by compressive buckling. Extreme Mech. Lett. 11, 105–110 (2017).

Stern, M., Pinson, M. B. & Murugan, A. Continual learning of multiple memories in mechanical networks. Phys. Rev. X 10, 031044 (2020).

Pashine, N., Hexner, D., Liu, A. J. & Nagel, S. R. Directed aging, memory, and nature’s greed. Sci. Adv. 5, eaax4215 (2019).

Euler, L. Methodus Inveniendi Lineas Curvas Maximi Minimive Proprietate Gaudentes, Sive Solutio Problematis Isoperimetrici Latissimo Sensu Accepti Vol. 1 (Springer, 1952).

Shanley, F. R. Inelastic column theory. J. Aeronaut. Sci. 14, 261–268 (1947).

Hutchinson, J. W. Plastic buckling. Adv. Appl. Mech. 14, 67–144 (1974).

Cimetière, A., Leger, A. & Pratt, E. On the coupling of large deformations and elastic-plasticity in the mechanics of a simple system. J. Mech. Phys. Solids 128, 239–254 (2019).

Liu, W. Leveraging plasticity to design sequential metamaterials with ideal shock absorption. Zenodo https://doi.org/10.5281/zenodo.10074741 (2024).

Resch, R. D. Geometrical device having articulated relatively movable sections. US patent 3,201,894 (1965).

Coulais, C., Kettenis, C. & van Hecke, M. A characteristic length scale causes anomalous size effects and boundary programmability in mechanical metamaterials. Nat. Phys. 14, 40–44 (2018).

Czajkowski, M., Coulais, C., van Hecke, M. & Rocklin, D. Conformal elasticity of mechanism-based metamaterials. Nat. Commun. 13, 211 (2022).

Acknowledgements

We thank K. Danas, E. Atzema, I. Pons, S. Neukirch, C. Maurini, J. van de Groep and M. van Hecke for insightful discussions and suggestions and D. Giesen, C. Ederveen Janssen and J. Heine for technical assistance. We acknowledge financing from the European Research Council under grant agreement 852587 and the Netherlands Organisation for Scientific Research under grant agreement NWO TTW 17883.

Author information

Authors and Affiliations

Contributions

W.L. and C.C. conceptualized and guided the project. W.L. designed the samples and experiments. W.L. and S.J. carried out the experiments. W.L. carried out the theories and the numerical simulations. All authors contributed extensively to the interpretation of the data and the production of the manuscript. W.L., B.E. and C.C. wrote the main text. W.L. created the figures and videos. All authors contributed to the writing of Methods and the Supplementary Information.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature thanks the anonymous reviewers for their contribution to the peer review of this work. Peer reviewer reports are available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data figures and tables

Extended Data Fig. 1 Buckling behaviours of the unit cell with elastoplastic material.

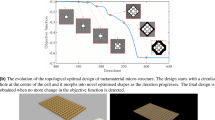

a, Sketch of a buckling unit cell. b–d, Three regimes of buckling are described by force, deflection and plastic strain. The normalized force F/Fy is used to determine the stiffness at the buckling point and the postbuckling stiffness S (black curve), the normalized deflection w/ℓ is used to determine the buckling point (blue curve) and the plastic strain εp is used to determine the onset of plasticity at the ligaments (red curve). The blue shading denotes the buckled regime, the salmon filling denotes the regime of plastic deformations and the magenta filling denotes the combined regime with both buckling and plastic deformations. b, Elastic buckling. c, Plastic buckling. d, Yield buckling. e, Postbuckling stiffness S versus aspect ratio of the unit cell t/ℓ and ratio between yield stress and Young’s modulus σy/E. The red triangles denote the yield-buckling regime defined by S < 0 and Fsc < Fcr.

Extended Data Fig. 2 Stress distribution, imperfection study and sequential buckling for the three regimes of buckling.

a–c, The strain contour at the onset of elastic, plastic and yield buckling with the same geometry and different material models. d–f, The stress distribution along the cross-section of the middle ligament from the buckling moment to a postbuckling moment. g–i, Imperfection sensitivity analysis of the three regimes of buckling. Force (black lines) and lateral deflection (coloured lines) versus displacement u/ℓ. The force is normalized by the buckling load of the unit cell with the smallest imperfection. j–l, Force (top) and lateral deflection (bottom) versus displacement u/(2ℓ). The force is normalized by the initial buckling load of the structure. Inset, the buckling snapshot of the two lumped unit cells of the three regimes of buckling.

Extended Data Fig. 3 Yield buckling in large-scale metamaterials.

a, A metamaterial consisting of N × N unit cells. b–d, Buckling mode versus aspect ratio t/ℓ and metamaterial size N in the elastic (b), plastic (c) and yield-buckling (d) regimes from simulations. Grey squares denote a global counter-rotating square mode65,66,67 in a single step, green and blue circles denote simultaneous buckling of line modes without self-contact (see insets of panels b and c), red circles denote sequential buckling of the line modes with self-contact (see insets of panel d) and grey squares denote a global shear mode46. e,f, Snapshots of metamaterials with 7 × 7 unit cells under compression. Metamaterial in e is 3D printed with elastic rubber and metamaterial in f is printed with 316L stainless steel. Scale bar, 15 mm.

Extended Data Fig. 4 Geometry design of sequential metamaterials.

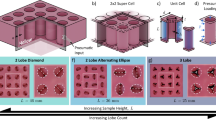

a, A metamaterial with a 4 × 4 orthogonal line-mode pattern and the represented unit cell of size 2ℓ. The ligament in the centre of the unit cell has an angle α = 45° and size t2, and the rest of the straight ligaments have size t1. b, A 3D unit cell with three orthogonal layer modes in the X, Y and Z directions and the represented components. The ligament in the centre of the components has an angle of 45° and diameter d2. The rest of the straight ligaments have diameter d1. c, A cylindrical line-mode metamaterial of radius R, thickness T and length L and the represented unit cell of size 2ℓ. There are six unit cells in the length direction and eight unit cells in the circular direction. d, A cylindrical metamaterial revolved from a 12-layer beam structure with aspect ratio t/ℓ and the represented cross-section.

Extended Data Fig. 5 Material calibration and sample fabrication.

a, Stress–strain curve of 3D-printed 316L steel, for which we linear fit the elastic modulus and tangent modulus. The fits provide measurements for Young’s modulus E ≈ 200 GPa, yield stress σy ≈ 500 MPa, and tangent modulus Et ≈ 500 MPa. b, 3D-printed metamaterial with 316L stainless steel. Supports are added at the overhang edges along the printing direction (left) and are removed after printing (right). c, Milled metamaterial from a 316L stainless steel tube.

Extended Data Fig. 6 Metamaterials with more density of line modes.

a, A unit cell with single line mode (top) is adjusted to a unit cell with two line modes (bottom). b, Snapshots of a metamaterial with ten line modes under compression. c, Force–displacement curves of the metamaterial with ten line modes (red solid line) and the metamaterial with six line modes (blue dashed line).

Extended Data Fig. 7 Out-of-axis compression of the metamaterials with six line modes.

a–e, Snapshots of the metamaterials at rest (top) and compressed (bottom) at oblique angles from 3° to 30°. f–i, The force F versus compressive stroke u/L and the number of buckled line modes Nbuckled versus compressive stroke u/L of the metamaterials at angles from 3° to 9° (f and g) and from 9° to 30° (h and i).

Extended Data Fig. 8 Multiple impacts.

a,b, Snapshot comparisons at each impact of the sequential metamaterial and the crash can with the same stiffness and strength. Each impact has a speed of 3.2 m s−1 and a weight of 5.5 kg. c,d, The impact speed V versus impact time at each impact of the metamaterial (c) and the crash can (d). e,f, The deceleration (Dec.) versus compressive stroke under six impacts of the metamaterial (e) and the crash can (f).

Extended Data Fig. 9 Yield buckling in several directions.

a–c, A metamaterial exhibits 8 × 8 orthogonal line modes along the vertical and horizontal directions. Metamaterial at rest (a) and under horizontal and vertical compression (b) in simulations. c, Corresponding force–displacement curves. d,e, 3D unit cell with three orthogonal buckling modes localized along surfaces. Structure at rest (d) and in linear buckling stability analysis along three directions (e) (see Supplementary Video 5).

Extended Data Fig. 10 Yield buckling of beams and metacrashcans.

a, Sketch of a buckling beam. b, Postbuckling stiffness S versus aspect ratio t/ℓ and moduli ratio Et/E. The red triangles denote the yield-buckling regime defined by S < 0 and Fsc < Fcr. c,d, Buckling behaviour of a six-layer beam structure with sliding constraints on its side. c, Snapshots at selected buckling steps. The colours denote the horizontal displacement field. d, Corresponding force–displacement curve. The reaction force is normalized by the initial yield-buckling load, Fcr = σyt. e, A metacrashcan made by revolving five layers of beams with t/ℓ = 0.03 at rest and selected buckling steps under compression at which each layer enables two steps of folding. f, Corresponding force–displacement curve.

Supplementary information

Supplementary Information

This PDF file contains Supplementary text; Supplementary Figs. 1 and 2; captions for Supplementary Videos 1–8 and references for Supplementary Information reference citations.

Supplementary Video 1

Summary. We summarize the regime of yield buckling and the function of triggering clean sequential buckling in metamaterials that can be used as ideal shock absorbers with load bearing and stable energy dissipation at the same time.

Supplementary Video 2

Yield buckling. We introduce the regime of yield buckling in a pair of rotating squares. We illustrate the difference between elastic, plastic and yield buckling and demonstrate that yield buckling allows separating the buckling mode in a two-layer structure of squares and achieving clean multistep sequential buckling in a six-layer structure of rotating squares.

Supplementary Video 3

Yield buckling in line-mode metamaterials. We introduce yield buckling into a metamaterial pattern with line modes (zero energy modes). The line-mode pattern can postpone the force drop of yield buckling and the yield buckling enables a large number of sequential buckling steps in line-mode metamaterials. By contrast, elastic and plastic buckling can only have a single step of global buckling mode in metamaterials with a large number of line modes.

Supplementary Video 4

Sequential yield buckling for shock absorption. In this video, we demonstrate that sequential metamaterials with line modes and yield buckling can be used as shock absorbers that are tunable over a large range of plateau stress, robust over a large range of impact speeds and usable several times. The metamaterials are tunable: the metamaterials with six line modes show six steps of sequential buckling, which correspond to a high stiffness before buckling and a stable plateau strength after buckling. The plateau strength of the metamaterials can increase two times when the thickness of the ligaments in metamaterials increases from 0.4 to 0.6 mm. Sequential yield buckling is robust: the sequential line-mode buckling is well delineated in the metamaterials over a large range of impact speeds from 0.1 to 10.0 m s−1. In the case of 10.0 m s−1, the first two line modes buckle in a less clear sequence before self-contact happens—we suspect this to be because of the viscoplasticity of steel at large strain rates. After that, the rest of the line modes show clear sequential buckling again. The sequential metamaterials can be used several times: the metamaterial can retain its initial stiffness and strength after a six-round static loading and unloading compression and have the same deceleration with impact of speed 3.2 m s−1 and weight 5.5 kg.

Supplementary Video 5

Multidirectional yield buckling. We modify the design of the line-mode pattern to host line modes in two orthogonal directions. We confirm such a design with simulations in a metamaterial with 8 × 8 line modes and with experiments in metamaterials with 4 × 4 line modes. Both simulations and experiments show the same wiggly plateaus in both directions. We expand this strategy into three dimensions with three orthogonal layer modes and prove it with the linear buckling mode in simulation.

Supplementary Video 6

Sequential yield buckling in out-of-axial compression. In this video, we demonstrate a robust sequential yield buckling of metamaterials with six parallel line modes under compression of five different oblique angles from 3° to 30°. Except for the case of 30°, all of the metamaterials have six full steps of sequential buckling. The metamaterial with 30° angle shows part sequential buckling until step three and a global shearing mode comes after that.

Supplementary Video 7

Metamaterials with high density of line mode. We modify the unit cell with a single line mode to a unit cell with two line modes within a similar volume. This new line-mode unit cell allows the design of a metamaterial with more steps of buckling and larger compressing stroke. We demonstrate a metamaterial with ten line modes showing ten steps of buckling under compression with a speed of 0.1 m s−1.

Supplementary Video 8

Metacrashcan. We generalize the yield buckling into beam architectures, which show the same negative buckling stiffness and six-step sequential buckling in a six-layer beam structure as the pairs of rotating squares in Supplementary Video 2. The multilayer beam structure can be revolved into a metacrashcan. We experimentally prove it in a metacrashcan with 12 buckling layers with aspect ratio t/ℓ = 0.1 and showcase a 12-step sequential buckling corresponding to a stabilized force plateau over a large stroke until 0.522. We then demonstrate that an even larger stroke with 0.72 can be achieved with a smaller aspect ratio t/ℓ = 0.03 in a five-layer metacrashcan.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, W., Janbaz, S., Dykstra, D. et al. Harnessing plasticity in sequential metamaterials for ideal shock absorption. Nature 634, 842–847 (2024). https://doi.org/10.1038/s41586-024-08037-0

Received:

Accepted:

Published:

Version of record:

Issue date:

DOI: https://doi.org/10.1038/s41586-024-08037-0

This article is cited by

-

Multi-Polarization Vibration Modes and Bandgap Regulation Mechanism of the Multi-Bandgap Lightweight Plate-Truss Hybrid Structures

Acta Mechanica Solida Sinica (2026)

-

Symmetry-driven artificial phononic media

Nature Reviews Materials (2025)

-

Dual-bond fracture metamaterials with full-field extrinsic toughening

Nature Communications (2025)

-

Static nonreciprocity in mechanical metamaterials enabled by symmetry breaking: a perspective

npj Metamaterials (2025)

-

Chiral multi-curved shell metamaterials integrating compression-torsion and buckling mechanisms for ideal energy absorption

Nature Communications (2025)