Abstract

The natural circulation loop (NCL) is a highly reliable and noise-free heat transfer device due to the absence of moving components. Working fluid used in the natural circulation loop plays an important role in enhancing the heat transfer capability of the loop. This experimental study investigates the subcritical and supercritical heat transfer performance of a natural circulation loop (NCL) with CO2 as the working fluid. Operating pressures and temperatures are varied in such a way that the loop fluid should remain in the specified state (subcooled liquid, two-phase, superheated vapor, supercritical). Water and methanol are used as external fluids in cold and hot heat exchangers for temperatures above zero and below zero (in °C) respectively, depending on operating temperature. For loop fluids, the performance of CO2 is compared with water for above zero and with brine solution for the subzero case. Further, the impact of loop operating pressure (35–90 bar) on the performance of the system is also studied. For hot heat exchanger inlet temperature (5 to 70 °C) and cold heat exchanger inlet temperature (−18 to 32 °C), it was observed that the maximum heat transfer rates in the case of subcritical vapor, subcritical liquid, two-phase and supercritical CO2 based systems are 400%, 500%, 900%, and 800% higher than the water/brine-based system respectively.

Similar content being viewed by others

Introduction

The heat transfer loops (secondary loops) are classified as forced circulation loop (FCL) and the natural circulation loop (NCL). Forced circulation loop is an active system which requires pump or compressor to drive the fluid flow, whereas natural circulation loop (NCL) is a simple system in which fluid flow takes place due to the density gradient caused by an imposed temperature difference.

In an NCL, the heat sink is situated at a higher elevation than the heat source. This establishes a density gradient in the system, due to which, lighter (warmer) fluid rises up and heavier (cooler) fluid moves down. Hence thermal energy can be transported from a high temperature source to a low temperature sink without direct contact with each other and also without using any prime mover.

NCL is preferred over forced convection loop where safety is the foremost concern. It also provides noise free and maintenance free operations. NCL is a promising option in many engineering applications such as nuclear reactors1, chemical extraction2,3 electronic cooling system4, solar heaters5,6,7,8,9,10, geothermal applications11,12, cryogenic refrigeration systems13, turbine blade cooling14, thermosyphon reboilers15,16, and refrigeration and air conditioning17, etc. Compared to forced convection systems, heat transfer rates in natural convection systems are on the lower side, and enhancement of the same is a challenging task. Researchers are trying different ways for the improvement of heat transfer rate such as by using various working fluids/nanofluids. Misale et al.18 and Nayak et al.19 experimentally reported a 10–13% enhancement in heat transfer rate with nano-fluid (Al2O3 + water) compared to water based NCL.

The selection of working fluids for NCL is typically carried out based on some favorable thermophysical properties. Commonly used working fluids can be divided into aqueous and non-aqueous category. Aqueous solutions are generally either salt based or alcohol based products. These are having one or more non-favorable effects like corrosiveness, toxicity, high pH value, etc. Non-aqueous solutions are commercially available chemicals.

In recent years, CO2 has gained popularity as a loop fluid in NCL due to its excellent thermophysical properties and environment benignity (no ozone depletion potential and negligible global warming potential) and has been employed for various applications such as solar thermal collector20, heat pump21, geothermal system22, etc. Suitability of CO2 as a loop fluid has been studied by Kiran Kumar et al.23 for NCL, and by Yadav et al.24 for forced circulation loop.

Any fluids operating near-critical region, show very good heat transfer and fluid flow characteristics due to its favorable thermophysical properties. Carbon dioxide has an advantage of low critical temperature (~ 31 °C) and quite reasonable critical pressure (73.7 bar).

Swapnalee et al.25 carried out experimental investigations to study the static instability of supercritical CO2 and water-based NCLs with heater as a heat source. Kiran et al.26 conducted experiments and studied the heat transfer behavior of NCL using subcritical CO2 with limited temperature and pressure range.

Although, the availability of experimental studies is very scant due to the risk involved in handling high operating pressure of CO2, a quite good number of numerical studies on the heat transfer behavior of CO2 based NCLs are available in open literature27,28,29.

Kiran Kumar et al.27 carried out a numerical study on steady-state analysis of single-phase rectangular NCL with parallel flow, tube-in-tube type heat exchangers. Yadav et al.28 carried out transient analysis of carbon dioxide-based natural circulation loop (NCL) with end heat exchangers. Basu et al.29 carried out, aims at the development of a theoretical model to simulate the steady-state performance of a rectangular single-phase natural circulation loop and to investigate the role of different geometric parameters on the system behavior. Yadav et al.30 carried out three dimensional CFD study and claimed ~700% higher heat transfer rate in the case of subcritical liquid as well as supercritical CO2 compared to water. Two-dimensional analysis at 90 bar for various heat source temperatures reported the instabilities associated with supercritical flow31,32.

Ample numerical studies27,28,29 on CO2 based NCL with different configurations are available. However, very few experimental studies are reported in the literature on account of the risk involved in handling CO2 at higher operating pressure. As in most of the engineering studies pertaining to practical relevance, experimental studies form the benchmark. The experimental studies on NCLs employing supercritical/subcritical CO2 with end heat exchangers over a wide range of temperatures covering the subzero temperature are limited. To fill in that critical void, this experimental study presents an investigation on the heat transfer behavior of subcritical/supercritical CO2 based NCL with end heat exchangers for the wide applications ranging from subzero (−18 °C) to above zero (70 °C) temperatures. The study also includes the heat transfer phenomenon in a single phase (liquid and vapor) and two-phase CO2 based NCL. Further heat transfer rates of water (for above zero temperature) and brine solution (for subzero temperature) in NCL are compared.

The Experimental details

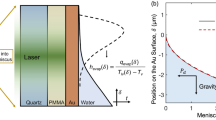

A complete representation of the test facility is in Fig. 1. The test facility comprises of a CO2 reservoir, tube-in-tube heat exchangers (hot and cold) with vertical tubes (riser and downcomer).

T-type thermocouples of appropriate length are connected to measure temperature of the loop fluid (CO2/water/brine solution) and external fluid (water/methanol) that flows inside the inner tube and the annulus, respectively as depicted in Fig. 1.

The photographic view of the employed facility is shown in Fig. 2. Natural circulation loop of 2 × 2 m is made up of stainless steel (SS-316) having outer diameter 32 mm, inner diameter 26 mm, thickness 3 mm and it withstands pressure up to 250 bar. To control heat transfer from loop to ambient, the entire loop is insulated with asbestos rope and foam tape insulating material of 3 mm thick each. The heat exchangers of length of 1600 mm, outer diameter 51 mm, and having thickness 3 mm.

Two thermostatic baths (Thermo scientific PC200) having a heating/cooling capacity of 2 kW supplies external fluid (water/methanol) at fixed temperature to the heat exchangers. Mass flow rate of external fluids is measured using two calibrated rotameters (2–20 LPM range) with valve arrangement, connected separately to HHX and CHX.

A bourdon pressure gauge range of 0–150 bar is connected to measure loop line pressure at the center of the right leg. Six T-type thermocouples are used to monitor the temperature of CO2 at various locations along the loop, thermocouples are connected in direct connection with the internal loop fluid CO2 as shown in Fig. 1 of enlarged portion of nut and ferrule arrangement. A data acquisition system (DAQ, Keighley - Model 2700) is employed to record various temperatures of the loop. The geometrical specifications of the test rig are specified in Table 1. The operating variables and its operating range is presented in Table 2 for the entire experiment.

Methodology

The cold and hot heat exchangers are tested for leakages up to 10 bar pressure, and the loop is tested for leaks at 150 bar. Later, entire natural circulation loop is evacuated, and required amount of CO2 is charged to the loop from CO2 cylinder. Charging of CO2 is stopped once the loop fluid pressure reaches required operating condition. External fluid is made to flow inside annular tube of both heat exchangers at specified mass flow rate and temperatures. When external fluid starts flowing, loop temperature starts varying with small variation in loop pressure. To maintain specified operating pressure, CO2 is transferred to/from the cylinder which is kept at operating pressure. This practice continues until the loop reaches steady state. The loop is said to be reached steady state if the transient variation in all temperatures and pressures are less than 0.5%.

At specified operating pressure, the state of CO2 is confirmed by monitoring the temperature at all locations of the loop (single-phase, two-phase or supercritical phase). Once the complete system reaches a steady-state, results are recorded. To compare the results of CO2 as loop fluid, a brine solution is used as loop fluid for lower temperature applications, whereas water is used for above zero temperature applications. Methanol is used as an external fluid for lower temperature (below 0 °C) applications and water as an external fluid for higher temperature (above 0 °C) applications.

To ensure turbulent flow conditions for the external fluid, a mass flow rate of 0.083 kg/s (5 liters/min) is maintained in CHX as well as in HHX.

Heat transfer rate (Q) is calculated by

where, m = mass flow rate of external fluid in kg/s

cp–HHX = specific heat of HHX in J/kg-K

cp–CHX = specific heat of CHX in J/kg-K

ΔTHHX = HHX temperature difference between inlet and outlet

ΔTCHX = CHX temperature difference between inlet and outlet

Average temperature is calculated by

where,TC = CHX inlet temperature in °C

TH = HHX inlet temperature in °C

Results and Discussion

This experimental study covers wide applications ranging from −18 °C to 70 °C temperatures and operating pressure from 35 bar to 90 bar. Heat transfer rate, pressure drop and temperature distribution of single phase (supercritical, liquid and vapor) and two-phase CO2 based NCL compared with water/brine based natural circulation loop at same operating temperatures. The operating pressure for water and brine as loop fluid is kept at 1 atm pressure as the variation of thermophysical properties of water with operating pressure is insignificant (less than 1%), which in turn does not affect the heat transfer rate significantly33.

Supercritical CO2 as loop fluid

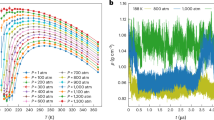

In CHX and HHX, water is the external fluid. For a fixed inlet temperature of water (just above the critical temperature of CO2 ~31.2 °C), HHX inlet temperature is varied from 40 °C to 70 °C in steps of 10 °C. Figure 3(a) shows the temperature variation throughout the loop at 90 bar. The temperature variation is also recorded for all operating pressures to make sure the loop fluid is in supercritical state throughout the loop.

For Supercritical CO2: (a) Temperature at different points along the loop, (b) Variation of heat transfer rate for water and CO2 at different pressures, (c) Pressure drop comparison of water and CO2 at different pressures, (d) Temperature difference between left and right legs v/s operating pressure.

The effect of CO2 pressure on the heat transfer rate and pressure drop is studied by varying it from 75 to 90 bar in a supercritical zone as shown in Fig. 3(b,c). Heat transfer rate is compared with widely used loop fluid i.e., water at atmospheric pressure (1 atm) under the same HHX and CHX temperatures. Figure 3(d) shows the effect of pressure on the loop fluid temperature difference between the left leg center and right leg center. Results clearly show that as pressure increases, temperature difference decreases, which occurs due to an increase in specific heat at higher pressure at particular average operating temperature (Tavg = 46 °C, TH = 60 °C) as shown in Table 3. At higher temperatures, decrease in viscosity leads to lower pressure drop in the loop (Fig. 3(c)). Uncertainty (error) analysis has been carried out (shown after results and discussion part), and errors are incorporated in heat transfer calculation for all the cases.

The effect of operating pressure on the heat transfer rate at different HHX inlet temperatures (TH) for a fixed TC is depicted in Fig. 3(b). The heat transfer rate is found to be maximum for the operating pressure of 90 bar. Average operating temperature (~loop fluid temperature) of 41 °C (obtained in this case) is near to the pseudo critical point (40.2 °C) of CO2 at 90 bar, which leads to a maximum heat transfer rate at this pressure because of a very high volumetric expansion coefficient of CO2 compared to water (~240 times). Experiments are also carried out for average operating temperatures of 46 °C and 51 °C.

In this case, the maximum heat transfer rate of CO2 based NCL yields ~8 times (800%) higher than water-based NCL as shown in Fig. 3(b). At higher HHX inlet temperature, buoyancy effect predominates increasing the heat transfer rate.

Subcritical vapor CO2 as loop fluid

With water as the external fluid in both CHX and HHX, for a fixed inlet temperature in CHX (=32 °C), the inlet temperature in HHX is varied from 40 °C to 70 °C for incremental values of 10 °C. For varying operating pressures of CO2 (40 to 70 bar), data is collected. Figure 4(a–d) shows the temperature variation along the loop, impact of operating pressure on the heat transfer rate, pressure drop v/s operating pressure, and temperature difference between left and right legs v/s operating pressure for subcritical vapor case. Figure 4(a) shows the temperature variation throughout the loop at 60 bar. It is observed that with increase in hot fluid inlet temperature heat transfer rate increases due to an increase in the temperature gradient between CO2 and water in HHX. With the increase in system pressure, the heat transfer rate also increases. In this case, the maximum heat transfer rate of CO2 based NCL yields ~4 times (400%) higher than water-based NCL (1 atm) for the same operating temperatures as shown in Fig. 4(b). The difference in pressure drop is found to be insignificant for the operating pressure between 40–70 bar as shown in Fig. 4(c) which occurs due to constant viscosity ratio (shown in Table 4). Results show the decrease in temperature difference between left and right legs as operating pressure increases as depicted in Fig. 4(d).

Subcritical liquid CO2 as loop fluid

This experimental study is mainly focused on low temperature (below 0 °C) applications such as refrigerators, solar water heater for cold weather, etc. In CHX and HHX, methanol is used as the external fluid as water becomes solid at sub-zero temperature. The inlet temperature of CHX is maintained constant and HHX temperature is varied. To compare the heat transfer rate of liquid CO2 based NCL, we conducted experiments using brine solution (a widely used fluid for sub-zero temperature) as loop fluid. Figure 5(a–d) shows the temperature variation along the loop, the heat transfer rate for different operating pressure, pressure drop v/s operating pressure, and temperature difference between left and right legs v/s operating pressure for subcritical liquid case. To ensure the liquid phase (of CO2) throughout the loop, temperatures at different locations are recorded as shown in Fig. 5(a). Since brine viscosity is higher than water, we will certainly get a lower heat transfer rate with brine. However, we achieved the maximum 500% higher heat transfer rate in this case of liquid CO2 compared to brine-based NCL as shown in Fig. 5(b). As explained earlier Fig. 5(c,d) shows similar trends of pressure drop and temperature difference for an increase in operating pressure respectively. Table 5. shows the comparison of the properties of subcritical liquid CO2 at different pressures with brine at atmospheric pressure for different operating temperatures, there is not much variation in viscosity ratio of CO2 and brine.

Two-phase CO2 as loop fluid

In this study, methanol is employed as the external fluid in both CHX and HHX to achieve two-phase at lower temperatures (sub-zero temperature). The operating parameters considered to conduct the experiments are shown in Table 6. For different operating pressures of CO2, i.e., 50, 55, 60, and 65 bar, results are obtained. Similar to the liquid case, we carried out experiments using brine solution as loop fluid to compare the heat transfer rate of two-phase CO2 based NCL. Figure 6(a–d) shows the temperature variation along the loop, the heat transfer rate for different operating pressure, pressure drop v/s operating pressure, and temperature difference between left and right legs v/s operating pressures for two-phase CO2 case (liquid + vapor). In this case, achieving two-phase inside the loop maintained at high pressure is quite difficult. With the continuous record of temperatures at different locations in the loop, we achieved two-phase CO2 by comparing saturation temperature at a given pressure (shown in Fig. 6(a)).

As the loop moves into the two-phase region, a large buoyancy effect gets generated causing an increase in the mass flow rate of CO2 and which in turn enhances the heat transfer coefficient. In this case, the maximum heat transfer rate of CO2 based NCL yields 9 times (900%) higher than the brine solution based NCL for the same operating temperatures as shown in Fig. 6(b). Figure 6(c) show the pressure drop variation at different operating pressures and different temperatures. It is interesting to see the effect of operating pressures on the temperature gradient in the left and right legs as shown in Fig. 6(d). As pressure decreases, the latent heat of vaporization increases which causes a decrease in temperature difference.

Error analysis

Heat transfer rate, mass flow rate and temperature are the various performance parameters for functional dependency (specific heat of external fluid is considered to be constant), the relation is given as:

If M is a certain measuring parameter, its functional relationship with the independent variables as represented by M = f(y1, y2, y3, y4,…… + yn) then uncertainty in various parameter is given as:

where u1, u2, u3, ………, un be the uncertainties in the independent variables.

With a rotameter of least count (0.2 LPM), minimum flow rate recorded is 5LPM.

Uncertainty associated with mass flow rate is

Minimum operating temperature recorded is −18 °C and accuracy for T-type thermocouple is 0.25 °C.

Maximum uncertainty in temperature measurement is

Heat transfer rate with considering uncertainty is calculated by

Conclusion

Steady-state behavior of a CO2 based NCL is experimentally analyzed. Subcritical (liquid, vapor, and two-phase) and supercritical phases of the CO2 are studied for 35–90 bar and −18 to 70 °C. The heat transfer rate of CO2 based NCL is compared with widely used loop fluid i.e., water (for above 0 °C) and brine (for below 0 °C). Conclusions from the test results can be enumerated as follows:

-

In the case of supercritical CO2 as loop fluid, the maximum increase in heat transfer rate is 800% higher compared to water as loop fluid.

-

In the case of subcritical vapor CO2 as loop fluid, the maximum increase heat transfer rate is 400% higher compared to water as loop fluid.

-

For low-temperature applications (below 0 °C), subcritical liquid CO2 yields a maximum 500% higher heat transfer rate compared to brine solution as loop fluid.

-

Much higher heat transfer rate (maximum 900%) is obtained in the case of two-phase CO2 based NCL compared to brine-based NCL. This study is carried out for low-temperature applications (below 0 °C).

The present study will be useful in designing compact heat transfer devices for electronic cooling, refrigeration, and air conditioning, solar thermal collector, etc.

Data availability

The datasets generated and/or analyzed during the current study are available with the corresponding author on reasonable request.

References

Dostal, V., Hejzlar, P. & Driscoll, M. J. The supercritical carbon dioxide power cycle comparison to other advanced power cycles. Nuclear Technology 154, 283–301 (2006).

Bondioli, P., Mariani, C., Mossa, E., Fedelli, A. & Muller, A. Lampante olive oil refining with supercritical carbon dioxide. Journal of American Oil Chemical Society 69, 477–480 (1992).

Fourie, F. C. V. N., Schwarz, C. E. & Knoetze, J. H. Phase equilibria of alcohols in supercritical fluids Part I. The effect of the position of the hydroxyl group for linear C8 alcohols in supercritical carbon dioxide. Journal of Supercritical Fluids 47, 161–167 (2008).

Kim, D. E., Kim, M. H., Cha, J. E. & Kim, S. O. Numerical investigation on thermal-hydraulic performance of a new printed circuit heat exchanger model. Nuclear Engineering 238, 3269–3276 (2008).

Close, D. J. The Performance of Solar Water Heaters with Natural Circulation. Solar Energy 6, 30–40 (1962).

Ong, K. S. A finite-difference method to evaluate the thermal performance of a solar water heater. Solar Energy 16, 137–147 (1974).

Zvirin, Y., Shitzer, A. & Grossman, G. The natural circulation solar heater-models with linear and nonlinear temperature distributions. International Journal of Heat Mass Transfer 20(9), 997–999 (1977).

Shitzer, A. & Kalomonviz, D. Experiments with a flat plate solar water heating system in thermo symphonic flow. Solar Energy 22, 27–35 (1979).

Mertol, A., Place, W., Webster, T. & Greif, R. Detailed loop model (DLM) analysis of liquid solar thermosiphons with heat exchangers. Solar Energy 27, 367–386 (1981).

Huang, B. J. Similarity theory of solar water heater with natural circulation. Solar Energy 25, 105–116 (1980).

Kreitlow, D. B. & Reistad, G. M. Themosyphon models for downhole heat exchanger application in shallow geothermal systems. Journal of Heat Transfer 100, 713–719 (1978).

Torrance, K. E. Open-loop thermosyphons with geological application. Journal of Heat Transfer 100, 677–683 (1979).

Yamaguchi, H., Zhang, X. R. & Fujima, K. Basic study on new cryogenic refrigeration using CO2 solid-gas two-phase flow. International Journal of Refrigeration 31, 404–410 (2008).

Cohen, H. & Bayley, F. J. Heat Transfer Problems of Liquid Cooled Gas Turbine Blades. Proceedings of Institution of Mechanical Engineers 169, 1063–1080 (1955).

McKee, H. R. Thermosyphon reboilers: A review. Industrial and Engineering Chemistry Process Design and Devlopment 62, 76–82 (1970).

Sarma, N. V. L. S., Reddy, P. J. & Murti, P. S. A computer design method for vertical thermosyphon reboilers. Industrial and Engineering Chemistry Process Design and Devlopment 12, 278–290 (1973).

Kaga, S., Nomura, T., Seki, K., & Hirano, A. Development of compact inverter refrigerating system using R600a/CO2 by Thermo-siphon. Proceedings of the 8th Gustav Lorentzen Conference on Natural Working Fluids, Copenhagen, Denmark, 3–04 (2008).

Misale, M., Devia, F. & Garibaldi, P. Experiments with Al2O3 nanofluid in a single-phase natural circulation mini-loop: Preliminary results. Applied Thermal Engineering 40, 64–70 (2012).

Nayak, A. K., Gartia, M. R. & Vijayan, P. K. An experimental investigation of single-phase natural circulation behavior in a rectangular loop with Al2O3 nanofluids. Experimental Thermal and Fluid Science 33, 184–189 (2008).

Zhang, X. R. & Yamguchi, H. An experimental study on evacuated tube solar collectors using supercritical CO2. Applied Thermal Engineering 28, 1225–1233 (2007).

Rieberer, R. Naturally circulation probes and collectors for ground-coupled heat pumps. International Journal of Refrigeration 28, 1308–1315 (2005).

Pruess, K. Enhanced geothermal systems (EGS) using CO2 as working fluid A novel approach for generating renewable energy with simultaneous sequestration of carbon. Geothermics 35, 351–367 (2006).

Kiran Kumar, K. & Ram Gopal, M. Carbon dioxide as secondary fluid in natural circulation loops. Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering 223, 189–194 (2009a).

Yadav, A. K., Bhattacharyya, S. & M., R. G. On the suitability of carbon dioxide in forced circulation type secondary loops. International Journal of Low-Carbon Technologies 9, 85–90 (2014).

Swapnalee, B. T., Vijayan, P. K., Sharma, M. D. & Pilkhwal, S. Steady-state flow and static instability of supercritical natural circulation loops. Nuclear. Engineering 245, 99–112 (2012).

Kiran Kumar, K. & Ram Gopal, M. Carbon dioxide as secondary fluid in natural circulation loops. Journal of Process Mechanical Engineering 223, 189–194 (2009).

Kumar, K. & Ramgopal, M. Steady-state analysis of CO2 based natural circulation loops with end heat exchangers. Applied Thermal Engineering 29, 1893–1903 (2009).

Yadav, A. K., Ramgopal, M. & Bhattacharyya, S. Transient analysis of subcritical/supercritical carbon dioxide-based natural circulation loops with end heat exchangers: Numerical studies. International Journal of Heat and Mass Transfer 79, 24–33 (2014).

Basu, D. N., Bhattacharyya, S. & Das, P. K. Effect of geometric parameters on the steady-state performance of single-phase NCL with heat loss to ambient. International Journal of Thermal Sciences 47(10), 1359–1373 (2008).

Yadav, A. K., Ramgopal, M. & Bhattacharyya, S. CO2 based natural circulation loops: new correlations for friction and heat transfer. International Journal of Heat Mass Transfer 55, 4621–4630 (2012).

Zhang, X., Chen, L. & Yamaguchi, H. Natural convective flow and heat transfer of supercritical CO2 in a rectangular circulation loop. International Journal Heat and Mass Transfer 53, 4112–4122 (2010).

Chen, L., Zhang, X., Yamaguchi, H. & Liu, Z. Effect of heat transfer on the instabilities and transitions of supercritical CO2 flow in a natural circulation loop. International Journal Heat and Mass Transfer 53, 4101–4111 (2010).

NIST Standard Reference Database-REFPROP, Version 9.1 (2013).

Acknowledgements

The present work is carried out under a project sponsored by the Science and Engineering Research Board, Department of Science and Technology, Government of India (Sanction order No. SB/FTP/ETA-443/2013). The financial support offered by DST-SERB is gratefully acknowledged. Authors also like to acknowledge the suggestions given by Professor M. Ramgopal and Professor Souvik Bhattacharyya, Department of Mechanical Engineering, IIT Kharagpur, India, to carry out the experimental work.

Author information

Authors and Affiliations

Contributions

Ajay Kumar Yadav has designed the experiments. Thippeswamy L.R. and Ajay Kumar Yadav have fabricated the setup and performed experiments. Both authors have analyzed the results and contributed to the paper writing, editing and revisions.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Thippeswamy, L.R., Kumar Yadav, A. Heat transfer enhancement using CO2 in a natural circulation loop. Sci Rep 10, 1507 (2020). https://doi.org/10.1038/s41598-020-58432-6

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-020-58432-6