Abstract

The study focuses on synthesizing wollastonite using bypass and silica fume waste materials as starting materials. The novelty of this work is the utilization of temperature-induced forming technique for the synthesis of wollastonite. Bypass and silica fume are mixed with various CaO/SiO2 ratios and then cast and fired at temperatures ranging from 900 to 1200 °C. Rheological properties and zeta potential are characterized for the slurries to optimize the dispersant percentage. The fired samples' phase composition, structure properties, apparent porosity, linear shrinkage, and compressive strength are characterized. Results show that the sample with a CaO: SiO2 ratio of 1:1.45 is the optimum composition for forming mainly pure β-wollastonite at 1100 °C, which changed into pseudo-wollastonite at about 1150 °C. The best physical and mechanical properties are obtained at 1170 °C, including apparent porosity of 8%, bulk density of 2.2 g/cm3, linear shrinkage of 13%, and compressive strength of 40 MPa, which widens its ceramic applications.

Similar content being viewed by others

Introduction

Waste is described as an unwanted or undesired material, depending on the type of material, and might include materials left over from production processes or family and community activities1. Recycling manufacturing wastes is well thought out to be a big concern, both financially and environmentally. The rapid population development and rise in human prosperity have led to increased industrial waste, becoming a significant social and environmental issue. Managing industrial waste has become the most important environmental concern in many developing nations. Human activity mostly produces solid waste, including construction and technological advancement. These wastes result in various intricate issues about storage, transportation, and contamination of the environment or atmosphere. The key to having a clean and safe environment will be using manufacturing waste to create useful resources using green chemical techniques2,3,4.

Wollastonite emerged to overcome waste buildup and create an appropriate precursor for the tile sector. Natural wollastonite has the unique property of minimizing changes in dimensions in ceramic goods' firing and drying processes. Wollastonite finds applications in making heat-insulating ceramics, packaging, lining for foundries, and filling paints and polymers in the metallurgical and automotive industries5. Wollastonite is currently in high demand worldwide, especially in areas where asbestos has been replaced, which is detrimental to human health. It is used in the ceramics industry to create hygienic porcelain, earthenware, and special electrotechnical porcelain with minimal dielectric losses. Wollastonite is used novelly in the bioactive ceramic industry, functioning as a bioglass for bone replacement and covering applications5,6,7.

Wollastonite is characterized by a theoretical composition of 52 weight percent SiO2 and 48 weight percent CaO, and it is identified as calcium metasilicate with the chemical formula CaSiO38,9,10. Wollastonite is rarely discovered in its pure form and has trace amounts of titanium oxide, manganese oxide, magnesium oxide, iron oxide, and other hazardous contaminants. It is most frequently found as a metamorphic deposit in contact between limestone and garnet, igneous rocks, calcite, diopside, quartz, and epidote8,11,12.

Wollastonite exhibits three distinct polymorphic forms: the low-temperature triclinic form [1T], the monoclinic form, commonly referred to as para-wollastonite [2M], and the high-temperature pseudo-wollastonite, which occasionally occurs in its pseudo-hexagonal form in nature. The transformation from low-temperature to high-temperature forms occurs at 1125 °C5,8,13,14.

Much work has been done recently to create synthetic wollastonite by solid-state reaction with biowaste as the raw material15. For instance, Phutthawong et al.16 discovered that the formation of wollastonite increases with grinding time, with the ideal duration being 7 h at a calcination temperature of 1000 °C for 2 h. Wollastonite combines 1:1 molar ratios of silica, rice husk ash, and snail shells (Pomacea canaliculata). Rashid et al.17 also employed the same procedure, using 99.56 weight percent silica sand and CaO from limestone to create the β-CaSiO3 phase at 1050 °C sintering temperature, subsequently converting this phase to α-CaSiO3 at 1150 °C sintering temperature. Sintering at 950 °C and 1200 °C produced single-phase β-CaSiO3 and α-CaSiO3 with an average particle size of 29–50 nm using calcium nitrate and fumed silica as raw materials, synthesized using the solid-state technique18. Meanwhile, β-CaSiO3 and α-CaSiO3 are the wollastonite crystals that develop around 1100 °C and 1300 °C, respectively, according to a study by Nizami19. Furthermore, using the solid reaction method, wollastonite crystals with a density of 1.98 g/cm3 and a sintering temperature of 1250 °C were produced20.

Cement is one of the most astounding binding substances. Over the world, it is manufactured in vast amounts. One industry that generates a substantial amount of solid waste is cement manufacturing. These wastes must be controlled to create a secure and hygienic environment2,3,4,5,6,7,8,9,10,11,12,13,14,21. Egypt has many cement factories that make a lot of waste. The composition of the source material, gas flow rate, and technique type significantly influence the chemical composition of the bypass byproduct. Bypass frequently contains alkali sulfates, halides, clinker dust, unreacted raw feed, and other volatile components2,22,23,24,25. About one million tonnes of bypass cement kiln dust (BCKD) are produced annually from the cement industry in Egypt. Recycling these wastes is advised rather than disposing of them in landfills that pollute the land, water, and air. The various wastes used to make roof tiles in place of certain clay are displayed at the following points26: A byproduct of the production of elemental silicon, silica fume, is produced in electric arc furnaces by a carbothermic reduction process. When temperatures rise above 1800 °C, silicon monoxide gas escapes and oxidizes in the atmosphere to produce thin, amorphous silica particles. A gas cleaning system gathers condensed silica with dust and other phases27,28,29,30,31. Silica fume is an amorphous SiO2 with a chemical composition of > 90% silica and a particle size of 0.1 microns32,33. Around 18,000 tonnes of silica fume are generated yearly in Egypt as a waste byproduct34.

In this work, wollastonite production is performed by using the bypass and silica fume to reduce the final product's cost and eliminate the negative effects of these wastes on the environment. Wollastonite has been prepared using a variety of techniques, such as the solid reaction method1,17,35, the sol–gel method36, microwave methods37, and hydrothermal methods37,38,39. The most common technique is the solid-state reaction method, which yields samples with large grain sizes40 and necessitates a long reaction time and high calcination temperature. Despite this, the solid-state reaction method is the most straightforward way to obtain wollastonite material in the ceramic industry.

Using the solid-state method combined with colloidal forming techniques for ceramics offers significant advantages over dry processing techniques due to the potential reduction in defect size. For the near-net-shape forming of intricate ceramic objects, novel forming technologies based on colloidal processing have been created41,42,43,44. Colloidal forming techniques made it possible to manufacture complex components without machining directly, and it was possible to enjoy homogenous green microstructures and excellent particle packing45.

A colloidal technique made ceramic green bodies for slip, tape, and drain casting. Slip casting still needs to be done many more times, and the green body's strength needs to be increased46. Numerous near-net shape-forming techniques, such as direct coagulating methods, salt-induced plasticity or short-range steric force, temperature-induced forming, and gel casting, have recently been developed and studied due to the importance of productivity, reliability, economy, and fabricability46. To make the process of filling the mold easier, each approach requires a well-dispersed, highly concentrated suspension mold with a manageably low viscosity45.

Temperature-induced forming techniques46 are among the several approaches for creating wollastonite by solid-state reaction47, including freeze casting48,49, replication technique50,51, and three-dimensional (3D) printing52. Temperature-induced formation is less expensive and more accessible than the other techniques; it doesn't require air control, and ess than 0.5% of the organic additives' weight is compared to the ceramic powder's weight46.

In temperature-induced forming (TIF), to achieve stability at room temperature, concentrated aqueous suspensions combine a higher molecular weight polymer, specifically polyacrylic acid, with a lower molecular weight dispersion, such as ammonium citrate. Increasing the temperature enhances the dissolution of ceramic particles, facilitating the suspensions to undergo bridging flocculation53.

Using a dispersant, the TIF approach stabilizes the ceramic slurry through an electric double layer at room temperature. When added, the polymer forms a bridging network (gel), and the temperature is raised54,55,56,57. Yang et al. investigated the gelation behavior of the Al2O3 aqueous suspension during TIF. They discovered that adding polyacrylic acid (PAA) caused the viscosity of the alumina suspension to rise with temperature58. In a different investigation, the same authors used the TIF approach with 0.03 weight percent PAA and 0.4 weight percent ammonium citrate tribasic (ACT) to successfully shape complicated alumina pieces with a satisfactory surface polish and green density of 65%57. Zirconia green bodies with 0.4 weight percent ACT were prepared by Ewais et al. using TIF. The TIF green bodies had a homogeneous microstructure and good compaction46.

Thus, this work concerns preparing wollastonite ceramic materials using bypass and silica fume based on an advanced method called temperature-induced forming. Then, the rheological behaviors, phase composition, microstructure, and physical and mechanical properties are studied to prepare wollastonite with good technological properties. The obtained wollastonite can be used to substitute granite and natural marble in various applications, such as ceramics, architecture, and construction materials like floor materials59. The obtained wollastonite can be used in various applications, such as ceramics, architecture, and construction materials like floor materials, as a substitute for granite and natural marble59.

Materials and experimental method

Starting materials

Alexandria Refractories supplied the starting materials for this work for bypass, while the silica fume was provided by the Egyptian Ferro-alloys company located in Edfu, Aswan, Egypt. The chemicals utilized in this study included ammonium citrate tribasic (dispersant, ACT, Alfa Aesar; USA, 97) and polyacrylic acid (binder, PAA, Alfa Aesar; USA, polyacrylic acid 25% sol. in water). XRF determines the chemical composition of the silica fume and bypass material. The phase compositions, particle sizes, and microstructures are determined by X-ray diffraction (XRD), transmission electron microscope (TEM), and scanning electron microscope (SEM), respectively. A sieving analysis was carried out to determine the silica fume and bypass particle size distribution.

Experimental method and characterizations

Rheological and Zeta potential measurement of ceramic slurries

Before casting the ceramic samples, the ceramic slurries' zeta potential and rheological behavior are assessed to determine the ideal slurry composition. Zeta potential was measured by Zeta Sizer 2000, Malvern (Germany). 5 vol.% solid loading of powders with various percentages of the dispersant (ACT) (0, 0.3, 0.6, 1, and 1.5 wt% based on powder) were used to assess the zeta potential (based on powder) and represented as (w, w0.3 ACT, w0.6 ACT, w1 ACT and w1.5 ACT). For 24 h, the slurry was continuously stirred. This slurry was diluted from 0.4 to 200 mL; as a result, the measurement's solid loading was 0.01 vol.%.

Viscosity measurements were used to determine the rheological characteristics. The viscosity measurement was carried out with MCR301 viscometer with a shear rate varying from 0.05 to 100 s−1. Tables 1 and 2 show the composition of samples used to study the rheological behavior, measure shear stress, and measure viscosity at a shear rate of 100 s−1. As depicted in Tables 1 and 2, shear stress and viscosity measurements were taken on eight samples. These slurries include metal oxides with weight percentages ranging from 55 to 70%, water contents from 44 to 30 wt%, two dispersants (0.6 and 1 weight percent based on powder), and a small amount of polyacrylic acid (0.06 weight percent) to optimize the dispersant percentage.

Preparation of samples by temperature-induced forming (TIF) method

According to the viscosity measurement and zeta potential that are shown later in section "Results and discussion", the optimum weight percentage of selected ceramic oxide is 65 wt% with 0.6 wt% of ACT. The ceramic powder mixes were shaped using the temperature-induced forming (TIF) process (Fig. 1). Usually, to create an aqueous ceramic slurry, 65 weight percent of the ceramic powder mixture (18.85 wt% of silica fume and 46.10 wt% of bypass) was added to 35 wt% water, along with ammonium citrate tribasic (ACT = 0.6 wt%, depending on powder), and poly acrylic acid (PAA = 0.06 wt%). The slurry was then mechanically mixed with a Daihan Scientific mixer at 200 rpm at room temperature for 2 h. During the procedure, the gelling agents and dispersant were absorbed onto the surface of the ceramic slurry, resulting in the formation of an electrical double-layer (EDL) that had a steric impact60. After casting the composite slurries in an acrylic mold with 1.5 cm × 1.5 cm × 1.5 cm, the temperature was raised to 80 ºC for 15 h to induce gel formation and consolidate the green bodies. To reduce the inhomogeneous shrinkage, plastic sheets were used to cover the molds, slowing down the evaporation of water. After the forming process, the samples were dried at room temperature for 24 h. The samples were then fired for 1 h at 900, 1000, 1050, 1100, 1150, 1170, and 1200 ºC to track the phase compositions. The heating rates are divided into three stages. The temperature is raised from 0 to 300 °C in 20 min to prevent hydration of CaO, followed by an increase in the temperature from 300 to 700 °C over 3 h to burn out the organic matter slowly. Finally, the temperature is raised to the final firing temperature (900, 1000……1200 °C) in 1 h. Then, the furnace was switched off, and the samples were permitted to cool inside it to room temperature.

The other three slurry compositions containing excess silica, as seen in Table 3, are prepared. These slurries are designed according to the same procedure as the above slurry by TIF by changing the weight percentage of the CaO and SiO2 ratios to optimize the wollastonite formation. The three mixes were fired at various temperatures ranging from 900 ºC to 1170 ºC.

Characterization methods of the starting materials and fired samples

The chemical composition of the representative starting materials was quantitatively assessed using wavelength-dispersive X-ray fluorescence (AXIOS, WD-XRF Sequential Spectrometer from Panalytical, 2005). The X-ray powder diffraction (XRD) technique was employed to examine the phase composition of both the starting materials and fired samples. The analysis was conducted at room temperature using a diffractometer (Bruker D8 Advance, Germany) equipped with a Ni filter and Cu Kα radiation, with a scan speed of 0.5 min−1. The microstructure of both the starting materials and fired samples was analyzed using a Philips XL 30 scanning electron microscope (SEM) instrument from the UK. Transmission electron microscope (TEM) JEM-2100 was used to examine the particle size of the starting materials. The thermogravimetric analysis was performed using BEL-Sorb Max equipment made in Japan.

The apparent porosity and bulk density were assessed through the Archimedes water displacement method, following the guidelines outlined in the American Society for Testing and Materials (ASTM C373-88)61. Water is added to three test samples, which are then boiled for two hours. After submerging in water (WI), the saturated samples were weighed again in the air (WS). After being left overnight at 110 °C, the samples were dry-weighted (Wd). The test samples' bulk density (BD) and apparent porosity (AP) were determined using the following formulas (1 and 2):

Where \(\upgamma \) is density.

The compressive strength (CCS) of the three fired samples was measured using a hydraulic testing machine (Seidner model, Riedlinger, Germany) with a maximum load capacity of 600 KN (ASTM C133-97)62. The compressive strength (CCS) of the test samples was calculated using the formula below (3):

Results and discussion

Characterization of the starting materials

Table 4 illustrates the chemical composition of silica fume and bypass determined using the XRF method. According to Table 4, silica accounts for more than 92% of the main oxide compositions in silica fume. The predominant phase in the bypass is made primarily of silica and CaO.

The XRD was utilized to analyze the phase compositions of these materials. The amorphous phase of silica is easily visible for silica fume particles since there are no crystalline peaks other than a faint and extremely broad hump about 21.8, as can be shown in Fig. 2a 63. In the case of bypass, the lime (CaO) and hydrated lime (Ca(OH)2) were the most prevalent components percentage in bypass dust, followed by Larnite Ca2SiO4, as shown in Fig. 2b. Other small components such as calcite, quartz, periclase, MgO, and Al2O3 were also present. The secondary phases, quartz, and calcite, are derived from untreated raw materials.

Figure 3 displays the SEM of silica fume and bypass. The spherical particles of silica fume (Fig. 3a) range in average diameter from 0.2 µm to around 2 µm. The SEM of bypass (Fig. 3b) is a heterogeneous combination of particles with different morphologies, including large and tiny particles. Small dust particles are typically grouped in clusters of 1–3 µm (Fig. 3b). The charges cause some small particles to adhere to the surfaces of the giant particles. The size of the little particles joined to the giant particles varies. Still, they are often sub-micron-sized (Fig. 3b). The little brightness that can be seen in the SEM micrographs of the microscopic particles is a result of electron charging during imaging. The fact that these particles are charged suggests that they have an electrical charge that enables them to adhere to the giant particles64.

Figure 4 displays the raw materials' TEM characterization. According to the TEM investigation (Fig. 4a), silica fume still has its original spherical shape. According to TEM results for bypass (Fig. 4b), the diameters of the particles in those samples, which were shaped like plates, ranged from 10 to 95 nm.

Sieving analysis was conducted to determine the particle size distribution for silica fume and bypass, as shown in Table 5. It was found that the bypass is finer than silica fume. As seen in Table 5, the highest percentage of particles at the 200 micron size is for silica fume, while the highest percentage of particles in the 75–100 micron size range is for bypass.

Zeta potential

The zeta potential measurements for the suspended liquids with various amounts of ACT are shown in Fig. 5. It is observed that the suspension of the powder without dispersant shows a low zeta potential value. A low zeta potential value shows that the powder does not disperse well without a dispersant. The zeta potential significantly increases with the addition of ACT. The iso-electric point (IEP) shifts to the positive region, resulting in a higher zeta potential (3.35 mV). It is indicated that the addition is necessary for stabilizing the powder.

The stabilization mechanism can be illustrated as follows: the dissociation of dispersant agents in water containing carboxyl and ammonium groups occurred. This produces a positive charge (ammonium group) and a negative charge (carboxyl group). The negative charge of the carboxyl group is absorbed on the positively charged calcium oxide surface. In contrast, the positive charge of the ammonium group is adsorbed on the negatively charged silica surface, leading to good stabilization of the slurry.

Viscosity

According to the results of the zeta potential, two percentages of dispersant 0.6 and 1 wt% based on powders are selected to show the effect of each percentage value of dispersant on the ceramic slurry, as seen in Fig. 6. It is noted that the viscosity rises with the increase in weight percentage of ceramic oxides from 55 to 70 wt%. The suspensions approach a constant viscosity at high shear rates and exhibit shear thinning behavior. When the amount of ceramic oxides increases up to 65 weight percent, both the degree of shear thinning and the viscosity at high shear rates rise. Because thermal motion outweighs viscous forces at low shear rates, the suspension structure approaches the equilibrium structure at rest. Shear thinning happens at greater shear rates because the viscous forces act more strongly on the suspension structure65. It was found that certain regions showed shear thickening when the ceramic oxide level was raised to 70%. watery.

At low shear rates, colloidally stable suspensions exhibit a rather robust shear thinning behavior. This is followed by discontinuous shear thickening at ceramic oxide concentrations of 70%. The shear thickening can be explained as the result of a particle structural order–disorder transition. At the critical shear rate, the ordered layers that emerge in the shear thinning zone disintegrate into a less ordered structure. Because of particle “jamming,” this less ordered structure loses more energy during flow, increasing viscosity. Most scientists believe that shear thickening only happens in concentrated suspensions of solid particles that don't aggregate65,66,67. It has been discovered that variables such as the medium's viscosity, tile particle size, and the strength of the interparticle repulsion regulate when shear thickening begins65,66,67. Shear thickening may be linked to the creation of clusters due to hydrodynamic forces, according to a recent study that integrated rheology with suspension structure analysis65.

According to Xu et al., the viscosity required for colloidal forming must be less than 1 Pa s at a shear rate of 100 s−1. This viscosity is low enough for casting and degassing67. Therefore, a powder percentage of 65 wt% is chosen in subsequent experiments. In comparison with the slurry containing 1 wt% of dispersant, it is observed that these slurries are more viscous, especially at 0 s−1 shear rate. This means an excess amount of dispersant that does not adsorb onto the particle's surface. Thus, 0.6 wt% of dispersant is suitable for slurry preparation.

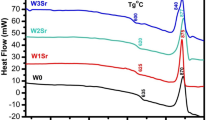

DTG and TG analysis

Figure 7 displays the green sample's profiles for differential thermal analysis (DTG) and thermogravimetric analysis (TG). It was noted that there are distinct stages of thermal breakdown. The DTG analysis reveals two distinct peaks, one between 35 and 145 °C and the other between 400 and 500 °C. Additionally, there is a 38% decrease in weight, explained by the vaporization of certain organic debris, interior water, and absorbed water. After that, a sharp increase between 510 and 780 °C in the DTG analysis shows a continual weight loss of 37% upon heating to 780 °C. The delayed elimination of chemically absorbed water, PAA, and TAC is the reason for this34. In DTG, a peak appears between 930 and 1030 °C, indicating slow weight loss, evident after 800 °C and reaching 10%. The reason for this is that β-wollastonite is forming. Owing to the transformation of β-wollastonite into α-wollastonite, the steady state is reached after 1030 °C15,34.

XRD of fired samples

The XRD results in Fig. 8, depicting the work to synthesize wollastonite from bypass waste and silica fumes, show that the stoichiometric composition of lime and silica (CaO/ SiO2 ratio = 1:1) gave a mixture of larnite (PDF card No.#77-0388) and wollastonite (PDF card No. 76-1846) for the samples fired at 900, 1000 and 1050 ºC. Moreover, above 1050 ºC, the larnite started to disappear, and the wollastonite phase intensity peaks decreased. Both phases changed into rankinite (PDF card No. 76-0623) for the samples fired at 1150, 1170, and 1200 ºC, as seen in Fig. 8.

The mechanism of the reaction can be explained as follows (Eqs. 4–11)68: when a sample is fired between 900 and 1000 °C

The proportions of unreacted CaO and silica reduced with the further development of larnite (C2S) and wollastonite (CS) when the calcination temperature was raised to 1050 °C. At the same time, the formation of akermanite and bredigite Ca7Mg(SiO4)4 may have begun earlier, at 900 °C.

Akermanite formation is thought to occur in the MgO-CaSiO3 (pseudo) binary system69. On the other hand, transitional intermediate compounds like wollastonite, larnite, merwinite, and calcium magnesium silicate70 are formed during the bredigite formation process. Considering their small presence in the finished product, these Ca and Mg silicates shouldn't impact the final material's characteristics, even though they were created due to the initial mixture's relatively high magnesium content. With increasing the firing above 1050 °C, rankinite (Ca3Si2O7) formation is starting to develop. A further increase of the calcination temperature up to 1200 °C led to full recrystallization of CS and C2S to rankinite (C3S2) (Fig. 9).

Wollastonite can only form in pure systems under hydrothermal conditions or when mineralizers are present. Despite the attempt in the current study using bypass and silica fume, pure wollastonite could not be obtained, even when subjected to high firing temperatures of 1200 ºC, as in Ref.5. This is consistent with the findings of Balkevich et al.71, who found that siliceous limestone at 850 ºC can form wollastonite. They attributed its formation to the fine particle size of the components and intimate mixing. Furthermore, Kotsis and Balogh72 documented the formation of wollastonite from silica gel and limestone at 1300 ºC. However, they did not clarify whether the presence of impurities in the limestone was the cause of its existence.

According to Nour et al.5 the existence of impurities such as magnesia, alkali (Na2O and K2O), aluminum oxides, and iron in both wastes promoted the early formation of wollastonite at 900 °C and a liquid phase at approximately 1100 ºC. According to the phase diagram of CaO-SiO2, wollastonite formation is expected to occur at around 1450 ºC73. However, at around 1100 °C, the liquid phase is formed early because of feldspars' creation and iron oxide's presence during the firing process74,75. Since feldspars supply alkaline oxides like Li2O, Na2O, and K2O that help create a low-viscosity liquid at high firing temperatures, they are regarded as fluxing agents75.

In general, the stoichiometric composition of the materials contains impurities that exceed approximately 4%, which is even higher than the recommended amount of 3.6% by various authors for the formation of wollastonite72. These impurities and the required amount of silica contributed to the formation of a melt, thereby reducing the stoichiometric ratio of 1:1 necessary for forming pure wollastonite as the sole phase. As a result, the crystallization of rankinite occurred alongside very small amounts of pseudo-wollastonite in samples fired at temperatures of 1150, 1170, and 1200 ºC, Fig. 8. To address this issue, it was necessary to increase the proportion of silica to provide the required amount for wollastonite formation. According to Nour et al.5, the CaO/SiO2 ratio of 1:1.125 was identified as the most suitable, as the two higher ratios, 1:1.166 and 1:1.25, led to the presence of cristobalite. In line with Balkevich et al.71, the stoichiometric composition decreased alongside the formation of (belite) β-2CaO-SiO2. However, in the current study, larnite Ca2SiO4 was formed. An excess of silica is essential to shift the reaction towards wollastonite formation (CaSiO3). In this situation, silica reacts directly with the larnite, lime, or rankinite formed, transforming it into wollastonite.

Thus, from the above, three other slurries with different CaO: SiO2 ratios are prepared, i.e., 1:1.17, 1:1.25, and 1.45, and then the obtained green samples are fired at temperatures ranging from 900 to 1170 ºC. The XRD patterns are shown in Figs. 10, 11, and 12. For samples containing CaO: SiO2 ratio of about 1: 1.17, the mixture of larnite and wollastonite was formed after firing at 900, 1000, 1050, and 1100 ºC as seen in Fig. 10. The larnite amount increased with the rise in firing temperature at the expense of wollastonite. Upon raising the temperature above 1100, the wollastonite changes into pseudo-wollastonite, and larnite amounts are increasing continuously until reaching 1170 °C.

With increasing the CaO: SiO2 ratio to 1:1.25, as seen in Fig. 11, the larnite content is still high with wollastonite and pseudo-wollastonite at different firing temperatures. However, the wollastonite intensity peaks are higher than the samples of CaO: SiO2 ratio of 1:1.17 (Fig. 10), as seen for samples fired at 1100°C.

The best result for well wollastonite formation is indicated after using a CaO: SiO2 ratio of about 1:1.45, as seen in Fig. 12. The highest amount of wollastonite is indicated after firing at 1100°C with the least amount of larnite. When the firing temperature is increased above 1100 °C, the wollastonite is converted to pseudo-wollastonite. The pseudo-wollastonite formation increases with increasing firing temperatures to 1170°C. At this firing temperature, pseudo-wollastonite is the main phase, besides the least amount of larnite.

The highly active excess amorphous nano-SiO2 and the active CaO derived from the silica fume and bypass exhibit a higher potential for reacting with each other through diffusion reactions. This results in the formation of a pure wollastonite phase in these samples. The pseudo-wollastonite, i.e., α-wollastonite phase, is mostly achieved in samples fired at 1170 °C. When the temperature rises above 1100 °C, a polymorphic transformation reaction occurs in the wollastonite phase, transforming from a low-temperature phase called β-wollastonite to a high-temperature phase called α-wollastonite. The eutectic invariant point in the CaO-SiO2 binary system typically occurs around 1500 °C for a 1:1 molar ratio of CaO and SiO2. On the other hand, in this study, silica fume and bypass melted at a temperature lower than the eutectic point. This is attributed to both containing more active CaO and SiO2 (in amorphous form) than conventional sources. Moreover, the constituents' fineness significantly affects the material's melting temperature. So, the use of micro calcium oxide and nano-silica fume may accelerate the reaction, causing it to melt at a lower temperature than the eutectic invariant point5,76,77,78.

Compare this study to Sk S. Hossain et al.79, who create synthetic wollastonite using a cost-effective solid-state method using rice husk ash and chicken eggshells. The peaks of unreacted cristobalite (SiO2), minor quantities of larnite (Ca2SiO4), and β-wollastonite are seen at 1000 °C. After being calcined at 1100 °C, single-phase β-wollastonite is obtained, and larnite and cristobalite are removed through mutual reaction. Furthermore, at high temperatures, the β-wollastonite changes into its polymorphic form, or pseudo-wollastonite, which is the α-wollastonite. The calcined powder consists primarily of the pseudo wollastonite phase at 1200 °C, with the collaborative α and β-wollastonite phases present at 1150 °C.

SEM of the fired samples

SEM for samples fired at various temperatures are seen in Fig. 13. It was found that the samples with CaO: SiO2 ratio 1:1 exhibit various morphologies after firing at different temperatures. As seen in Fig. 13a, wollastonite appeared in needle shape at 900 ºC, like in morphology as Reference80, and larnite occurred as subspherical grains. As the firing temperature increases to 1050 ºC, the wollastonite content increases and more needle shapes appear with larnite, as seen in Fig. 13b and c. The needle shapes of wollastonite started to disappear at 1100 and 1150 ºC. Moreover, anhedral particle shapes have appeared that are related to the starting of crystallization of rankinite, as seen in Fig. 13d and e. The good crystallization of rankinite as mainly sole phase appeared at 1170 and 1200 °C (Fig. 13f and g), which appeared as gray polygonal shapes like Ref.68 in between some rankinite phases appeared in the form of cubic phase. It was observed that the pinholes decreased with the increase in firing temperatures.

SEM images of some selected samples with varying ratios of CaO/SiO2 and fired at 1050 and 1150°C are seen in Fig. 14. It was observed that the samples with CaO/SiO2 = 1:1.17 and CaO/SiO2 = 1:1.25 are still having larnite (gray cubic shapes) embedded between the needle grains of wollastonite after firing at 1050°C as seen in Fig. 14a and b. Upon raising the CaO/SiO2 ratio to 1:1.45 (Fig. 14c), larnite mostly disappeared, and the needle wollastonite grains were the main constituent of the samples. For the samples fired at 1150°C, it was observed that wollastonite disappeared and was replaced by pseudo-wollastonite. Irregular elongated grains are determined for pseudo-wollastonite. Larnite is enlarged and accumulated together, as seen in Fig. 14 (d and e). The larnite is still embedded between the pseudo-wollastonite for CaO/SiO2 ratios 1:1.17 and 1:1.25. The pseudo-wollastonite appeared as the main phase with the disappearance of the wollastonite in Fig. 14f. The high compaction and less porosity are observed for samples fired at 1150 °C.

Physical properties

Physical properties of apparent porosity (AP) and bulk density (BD) are shown in Fig. 15 for samples with CaO/SiO2 = 1:1 and fired at various temperatures. It was observed that apparent porosity decreases and bulk density increases with increasing the firing temperature. This finding can be primarily attributed to the similar linear shrinkage observed with the increase in firing temperatures, as seen in Fig. 16. Linear shrinkage was raised from 0% to around 15% when the firing temperature increased from 900 to 1200 °C. The pores in ceramic bodies get filled through ceramic processing as the grains grow throughout the body. The low temperature utilized in this case was insufficient to achieve densification, and consequently, it did not lead to significant closure of the porosity3981. Thus, the rise in firing temperature has also led to pore closure and improved particle interaction, which increases the shrinkage percentage82. In addition, using fine particles expedites the densification process, leading to a reduction in open porosity. This is due to the formation of liquid phases such as calcium aluminosilicates that contain a smaller quantity of liquid phase during firing, consequently decreasing porosity83.

Up to 1000 °C, no appreciable shrinkage or expansion behavior is seen for CaO: SiO2 = 1:1. However, the graph indicates that the densification of the compacted powders starts at about 1050 °C and that the rate of shrinking rises as the temperature rises. Wollastonite exhibits sintering behavior similar to what was seen in earlier research79,84,85. The linear shrinkage values of wollastonite are 0.82, 3.9, and 6.27% for 1100, 1200, and 1250 °C were obtained by79. The high powder verification may cause these increases in shrinkage values compared with Hossain et al.79.

Various calcium-containing materials are one approach for controlling firing shrinkage57. Figures 17, 18, and 19 illustrate samples' bulk density and apparent porosity with various CaO/SiO2 ratios fired at various temperatures. The linear shrinkage of these samples was observed in Fig. 16 after firing at various temperatures. It was observed that there is an increase in shrinkage and density and a decrease in apparent porosity with increasing the CaO/ SiO2 ratios up to 1:1.45.

These results are due to the formation of more wollastonite observed by increasing the silica content in the samples. By developing a greater amount of liquid phase, Wollastonite leads to the closing of pores in samples of CaO/SiO2 ratio 1:1.45 than the other samples86. This sample exhibits mainly the formation of pseudo-wollastonite (α-wollastonite) with porosity of about 8%, density of about 2.2 g/cm3, and linear shrinkage of about 13% at 1170°C. The increased firing temperature has also enhanced linear shrinkage, attributed to pore closure and improved particle interaction46.

In general, a high drop in the apparent porosity is observed after firing above 1150 °C for all samples is due to the presence of impurities such as iron and alkali (Na2O and K2O) oxides in the bypass and silica fume. This amount of alkali leads to the formation of feldspar, which tends to form in the liquid phase above 1100 °C. This liquid phase fills the open pores between the grain boundaries, enhances the densification parameters, and changes the sample's color from light to dark brown at high temperatures5,74,75, as seen in Figs. 20 and 21.

Wollastonite was made by Rashita Abd Rashid et al.80, utilizing a solid-state reaction with limestone and silica sand. The samples were burned at 1450 °C with limestone to silica sand ratios of 1:1, 2:1, and 3:1. It was found that wollastonite is visible at an early ratio for a 1:1 fire at 1450 °C. However, additional phases, such as olivine and larnite, were noted in 2:1 and 3:1 ratios. According to Chen et al.87 and Wesselsky and Jensen88, the phases exist at greater molar ratios of silica sand to limestone, specifically 2:1 and 3:1. The wollastonite phase was absent at the 2:1 and 3:1 molar ratio. The sintering temperature and raw material purity had a significant impact on the density of the colored products at a molar ratio of 1:1. Wollastonite was generated at a temperature close to its usual density of 2.86–3.09 g cm−3, following sintering at 1450 °C.

Compressive strength

Figure 22 illustrates the compressive strength of samples at different firing temperatures for different CaO/SiO2 ratios. An increase in silica content in the samples was observed to increase compressive strength to reach 40 MPa for the samples with a CaO/SiO2 ratio of 1:1.45. Among the samples, the samples with CaO/SiO2 = 1:1 had the lowest strength at 1170 °C compared to other samples. Furthermore, it was observed that the increase in firing temperature decreased porosity because of improved particle interaction, leading to an enhancement of the compressive strength with firing temperature81,83. Numerous researchers concurred that porosity, influenced by particle size and distribution, is directly related to compressive strength81,89. A similar discovery suggested that a finer particle size could increase compressive strength (or decrease porosity)81,90. The grains grow between the fine particles and eventually bond them together under the impact of particle dissolving action and high temperature. Pores are sealed off, and porosity gradually diminishes as grain boundaries expand. Furthermore, the increased formation of vitreous phases, which close the pores and improve the samples' strength and density, reduced porosity and a higher degree of calcic phases (wollastonite)91.

The maximum strength obtained in this work is like of Srinath Palakurthy et al.92, who prepared β-wollastonite by using natural waste materials such as rice husk ash (RHA) and eggshells based on using sol–gel method and sintered the sample at 850 °C. It is demonstrated that the mechanical properties revealed excellent compressive strength (40.77 ± 2.46 MPa).

Table 6 compares the results for apparent porosity, bulk density, and compressive strength from the current study with those from previous studies in the literature.

Conclusion

-

Pure systems, utilizing a composition with a CaO/SiO2 ratio of 1:1, failed to produce wollastonite at all temperatures ranging from 900 to 1200 °C.

-

The presence of impurities in alkalis, Fe2O3, and MgO in both bypass and silica fume wastes resulted in larnite and rankinite, with a small amount of wollastonite.

-

To obtain wollastonite as the single phase, the silica content needs to be increased beyond the stoichiometric composition. The most favorable molar ratio of CaO/SiO2 for the current wastes is determined to be 1:1.45.

-

The composition with CaO/SiO2 of 1:1.17 and 1:1.25 still had larnite beside the wollastonite formation up to 1100 °C.

-

Increasing the firing temperature above 1100 °C to 1170 °C for composition of CaO/SiO2 molar ratios of 1:1.17 and 1:1.25 showed the formation of pseudo-wollastonite with larnite.

-

When the CaO/SiO2 ratio is increased to 1:1.45, primarily pure wollastonite is observed, with minimal larnite, especially as the firing temperature is raised to 1100 °C.

-

Wollastonite changed into pseudo-wollastonite after firing above 1100 °C for a CaO/SiO2 ratio of 1:1.45.

-

Increasing the silica content in the stoichiometric composition for wollastonite formation, the decrease in the apparent porosity and the increase in the bulk density was observed to reach 8% and 2.2 g/cm3 for CaO: SiO2 of 1:1.45 at 1170 °C respectively. Increasing the silica content in the stoichiometric composition for wollastonite formation resulted in a decrease in apparent porosity and an increase in bulk density, reaching 8% and 2.2 g/cm3, respectively, for a CaO: SiO2 ratio of 1:1.45 at 1170 °C.

-

The maximum compressive strength of about 40 MPa was obtained for samples with high silica contents at 1170 °C.

-

The present study produced mainly pure wollastonite ceramic bodies by increasing the silica content to overcome impurities in the utilized wastes. As a result, this expansion enhances the potential applications of ceramic products, including their use in heat-insulating ceramics, packaging, foundry lining, and as a filler in paints and polymers within the metallurgy and automotive industries.

Data availability

The data sets generated and/or analyzed during the current study are not publicly available because they are for authors but are available from the corresponding author on reasonable request.

References

Noor, A. H. M. et al. Synthesis and characterization of wollastonite glass-ceramics from eggshell and waste glass. JSST 16(1–2), 1–5 (2015).

Khater, G. A., El-Kheshen, A. A. & Farag, M. M. Synthesis and characterization of cordierite and wollastonite glass-ceramics derived from industrial wastes and natural raw materials. Materials 15(10), 3534 (2022).

Awuchi, C. G., Hannington, T., Awuchi, C. G., Igwe, V. S. & Amagwula, I. O. Industrial waste management, treatment, and health issues: Wastewater, solid, and electronic wastes. EAR 8(2), 1081–1119 (2020).

Fagariba, C. J. & Song, S. Assessment of impediments and factors affecting waste management: A case of Accra Metropolis, (2016).

Nour, W. M. N., Mostafa, A. A. & Ibrahim, D. M. Recycled wastes as precursor for synthesizing wollastonite. Ceram. Int. 34(1), 101–105 (2008).

Hench, L. L. Bioceramics: From concept to clinic. J. Am. Ceram. Soc. 74(7), 1487–1510 (1991).

Long, L. H., Chen, L. D. & Chang, J. Low temperature fabrication and characterizations of β-CaSiO3 ceramics. Ceram. Int. 32(4), 457–460 (2006).

Obeid, M. M. Crystallization of synthetic wollastonite prepared from local raw materials. Int. J. Mater. Chem. 4(4), 79–87 (2014).

Podporska, J., Błażewicz, M., Trybalska, B. & Zych, Ł. A novel ceramic material with medical application. Process. Appl. Ceram. 2(1), 19–22 (2008).

Zhu, L. Z., Sohn, H. Y. & Bronson, T. M. Flux growth of 2M-wollastonite crystals for the preparation of high aspect ratio particles. Ceram. Int. 40(4), 5973–5982 (2014).

Yazdani, A., Rezaie, H. R. & Ghassai, H. Investigation of hydrothermal synthesis of wollastonite using silica and nano silica at different pressures. J. Ceram. Process. Res. 11(3), 348–353 (2010).

Volochko, A. T., Podbolotov, K. B. & Zhukova, A. A. Preparation of porous ceramic materials based on wollastonite using silicon-containing components. Refract. Ind. Ceram. 52(3), 186–190 (2011).

Shukur, M. M., Al-Majeed, E. A. & Obied, M. M. Characteristic of wollastonite synthesized from local raw materials. Int. J. Eng. Technol 4(7), 426–429 (2014).

Tangboriboon, N., Khongnakhon, T., Kittikul, S., Kunanuruksapong, R. & Sirivat, A. An innovative CaSiO3 dielectric material from eggshells by sol–gel process. JSST 58, 33–41 (2011).

Mardina, D., Asmi, D., Badaruddin, M. & Syahrial, A. Z. Preparation of synthetic β-wollastonite produced from amorphous SiO2 bamboo leaf ash and Meretix meretix shell. MSF 1029(9), 167–173 (2021).

Phuttawong, R., Chantaramee, N., Pookmanee, P. & Puntharod, R. Synthesis and characterization of calcium silicate from rice husk ash and shell of snail Pomacea canaliculata by solid state reaction. Adv. Mater. Res. 1103, 1–7 (2015).

Rashid, R. A., Shamsudin, R., Hamid, M. A. A. & Jalar, A. Low temperature of wollastonite from limestone and silica sand through solid state reaction. J Asian Ceram. Soc. 2, 77–81 (2014).

Chakradhar, R. P. S., Nagabhushana, B. M., Chandrappa, G. T., Ramesh, K. P. & Rao, J. L. Solution combustion derived nanocrystalline macroporous wollastonite ceramics. Mater. Chem. Phys. 95(1), 169–175 (2006).

Nizami, M. Characterization of a material synthesized by availing silica from plant source. J. Mater. Sci. Technol. 19(6), 599–603 (2003).

Shukur, M. M., Elham, A. A. & Mohammed, M. O. Characteristic of wollastonite synthesized from local raw materials. Int. J. Eng. Technol. 04, 426–428 (2014).

El-Attar, M. M., Sadek, D. M. & Salah, A. M. Recycling of high volumes of cement kiln dust in bricks industry. J. Clean. Prod. 143, 506–515 (2017).

El-Sayed Seleman, M. M., El-kheshen, A. A., Kharbish, S. & Ebrahim, W. R. Utilization of cement kiln dust for the preparation of borosilicate glass. Int. Ceram. Rev. 69, 26–33 (2020).

Abid, K. N., Yasse, R. S. & Salih, S. J. Use of bypass cement dust from Al-Kufa cement factory for production of glass ceramic material. Al Qadisiyah J. Eng. Sci 12, 118–126 (2019).

Srivastava, L., Paramkusam, B. & Prasad, A. Stabilization of engine oil contaminated soil using cement kiln dust. Indian Geotech. Conf. 18, 389–392 (2010).

Hamann, B., Schulz, M. & Schneider, C. Use of alkaline process dusts from the cement industry in glass production processes. Veröffentlichung_DGG J. (2008).

ElNaggar, K. A. M., Ahmed, M. M., Abbas, W. & Abdel Hamid, E. M. Recycling of bypass cement kiln dust in the production of ecofriendly roof tiles. Mater. Res. Express 10, 065505 (2023).

Siddique, R. & Chahal, N. Use of silicon and ferrosilicon industry byproducts (silica fume) in cement paste and mortar. Resour. Conserv. Recycl. 55, 739–774 (2011).

Mostafa, N. Y., El-Hemaly, S. A. S., Al-Wakeel, E. I., El-Korashy, S. A. & Brown, P. W. Characterization and evaluation of the pozzolanic activity of Egyptian industrial by-products I: Silica fume and dealuminated kaolin. Cement Concr. Res. 31, 467–474 (2001).

Khattab, R. M., El-Rafei, A. M. & Zawrah, M. F. In situ formation of sintered cordierite–mullite nano–micro composites by utilizing of waste silica fume. Mater. Res. Bull. 47, 2662–2667 (2012).

Khattab, R. M., Sadek, H. E. H., Taha, M. A. & El-Rafei, A. M. Recycling of silica fume waste in the manufacture of β-eucryptite ceramics. Mater. Char. 171(5), 110740 (2022).

Barati, M., Sarder, S., McLean, A. & RoyKj, R. Recovery of silicon from silica fume. J. Non-Cryst. Solids 357, 18–23 (2011).

Nilforoushan, M. R. The effect of micro silica on permeability and chemical durability of concrete used in the corrosive environment. Iran. J. Chem. Chem. Eng. 24(2), 31–37 (2005).

Janca, M., Siler, P., Opravil, T. & Kotrla, J. Improving the dispersion of silica fume in cement pastes and mortars. In IOP Conf. Ser.: Mater. Sci. Eng., Vol. 583, 012022 (IOP Publishing, 2019).

El-Rafei, A. M. Preparation and characterization of mesoporous amorphous nano-silica and nano-cristobalite for value enhancement of low-cost Egyptian waste materials. Ceram. Int. 48(21), 32185–32195 (2022).

Singh, S. P. & Charmakar, B. Mechanochemical synthesis of nano calcium silicate particles at room temperature. New J. Glass Ceram. 1, 49–52 (2011).

Meiszterics, A. & Sinko, K. Sol-gel derived calcium silicate ceramic. Colloids Surf. A Physicochem. Eng. Aspects. 319, 143–148 (2008).

Wang, H., Zhang, Q., Yang, H. & Sun, H. Synthesis and microwave dielectric properties of CaSiO3 nano powder by the sol-gel process. Ceram. Int. 34(6), 1405–1408 (2008).

Lin, K., Chang, J. & Lu, J. Synthesis of wollastonite nanowires via hydrothermal microemulsion methods. Mater. Lett. 60(24), 3007–3010 (2006).

Puntharod, R., Sankram, C., Chantaramee, N., Pookmanee, P. & Haller, K. J. Synthesis and characterization of wollastonite from egg shell and diatomite by the hydrothermal method. J. Ceram. Proc. Res. 14(2), 198–201 (2013).

Lin, K., Chang, J., Zheng, Y. & Qian, W. Preparation of macroporous calcium silicate ceramics. Mater. Lett. 58(15), 2109–2113 (2004).

Xu, X., Fu, R. L. & Ferreira, J. M. F. A Novel Temperature induced gelation forming method. Key Eng. Mater. 368, 669–671 (2008).

Lange, F. F. Powder processing science and technology for increased reliability. J. Am. Ceram. Soc. 72(1), 3–15 (1989).

Sigmund, W. M., Bell, N. S. & Bergström, L. Novel powder-processing methods for advanced ceramics. J. Am. Ceram. Soc. 83(7), 1557–1574 (2000).

Lewis, J. A. Colloidal processing of ceramics. J. Am. Ceram. Soc. 83(10), 2341–2359 (2000).

Bergström, L. & Sjöström, E. Temperature induced gelation of concentrated ceramic suspensions: Rheological properties. J. Eur. Ceram. 19(12), 2117–2123 (1999).

Ewais, E., Zaman, A. A. & Sigmund, W. Temperature induced forming of zirconia from aqueous slurries: Mechanism and rheology. J. Eur. Ceram. 22(16), 2805–2812 (2002).

Ismail, H., Zakri, M. N. Z. & Mohamad, H. A comparative study of physicomechanical and in vitro bioactivity properties of β-wollastonite/cordierite scaffolds obtained via gel casting method. Ceram. Int. 48, 25495–25505 (2022).

Gaudillere, C. & Serra, J. M. Freeze-casting: Fabrication of highly porous and hierarchical ceramic supports for energy applications. Bol. La Soc. Esp. Ceram. y Vidr. 55(2), 45–54 (2016).

Deville, S. Freeze-casting of porous biomaterials: Structure, properties and opportunities. Materials 3, 1913–1927 (2010).

Kumar, P. et al. Fabrication and characterization of silver nanorods incorporated calcium silicate scaffold using polymeric sponge replica technique. Mater. Des. 195, 109026 (2020).

Mehatlaf, A. A., Farid, S. B. H. & Atiyah, A. A. Fabrication and investigation of bioceramic scaffolds by a polymer sponge replication technique. IOP Conf. Ser. Mater. Sci. Eng. 1076, 012080 (2021).

Alharbi, N., Khan, S. F., Bretcanu, O. & Dalgarno, K. W. Processing of apatite-wollastonite (AW) glass-ceramic for three-dimensional printing (3DP). Appl. Mech. Mater. 754(755), 974–978 (2015).

Yang, Y. & Sigmund, W. M. Expanded percolation theory model for the temperature induced forming (TIF) of alumina aqueous suspensions. J. Eur. Ceram. 22(11), 1791–1799 (2002).

Hessien, M. A., Khattab, R. M., Taha, M. A. & Sadek, H. E. H. Fabrication of porous Al2O3–MgO–TiO2 ceramic monoliths by the combination of nanoemulsion templating and temperature-induced forming. J. Eur. Ceram. Soc. 41(2), 1514–1523 (2020).

Zhang, M. et al. High strength macro-porous alumina ceramics with regularly arranged pores produced by gel-casting and sacrificial template methods. J. Mater. Sci. 54, 10119–10129 (2019).

Xu, X. & Ferreira, J. M. F. Temperature-induced gelation of concentrated sialon suspensions. J. Am. Ceram. Soc. 88, 593–598 (2005).

Yang, Y. & Sigmund, W. M. Preparation, characterization, and gelation of temperature-induced forming (TIF) alumina slurries. J. Mater. Synth. Process. 9, 7 (2001).

Yang, Y. & Sigmund, W. M. Effect of particle volume fraction on the gelation behavior of the temperature induced forming (TIF) aqueous alumina suspensions. J. Am. Ceram. Soc. 84, 2138–2140 (2004).

Almasri, K. A., Matori, K. A. & Zaid, M. H. M. Effect of sintering temperature on physical, structural and optical properties of wollastonite based glass-ceramic derived from waste soda lime silica glasses. Results Phys. 7, 2242–2247 (2017).

Sadek, H. E. H., Hessien, M. A., Abd El-Shakour, Z. A., Taha, M. A. & Khattab, R. M. The effect of sintering on the properties of magnesia-granite sludge ceramics shaped by temperature-induced forming. JMR&T 11, 264–273 (2021).

ASTM C 373-88, 2006 standard test method for water absorption, bulk density, apparent porosity and apparent specific gravity.

ASTM C133-97, 2015 standard test methods for cold crushing strength and modulus of rupture of refractories.

Khattab, R. M., Sadek, H. E. H., Taha, M. A. & El-Rafei, A. M. Recycling of silica fume waste in the manufacture of β-eucryptite ceramics. Mater. Charact. 171, 110740 (2021).

Yilbas, B. S. et al. Influence of dust and mud on the optical, chemical and mechanical properties of a pv protective glass. Sci. Rep. 5(1), 15833 (2015).

Bergstrom, L. Shear thinning and shear thickening of concentrated ceramic suspensions Collid Surf. A-Physicochem. Eng. Asp. 133, 151–155 (1998).

Barnes, H. A. B. Shear-thickening (“Dilatancy”) in suspensions of nonaggregating solid particles dispersed in Newtonian liquids. J. Rheol. 33(2), 329–366 (1989).

Xu, J. et al. Enhanced piezoelectric properties of PZT ceramics prepared by direct coagulation casting via high valence counterions (DCC–HVCI). Ceram. Int. 42(2), 2821–2828 (2016).

Šmigelskytė, A. Synthesis, Properties, and Application of Rankinite in the Production of CO2 Cured Concrete, Doctoral Dissertation (Kaunas University of Technology, Faculty of Chemical Technology, 2019).

Joachim, B., Gardes, E. & Abart, R. Experimental growth of akermanite reaction rims between wollastonite and monticellite: Evidence for volume diffusion control. Contrib. Mineral. Petrol. 161(3), 389–399 (2010).

Mirhadi, S. M., Tavangarian, F. & Emadi, R. Synthesis, characterization and formation mechanism of single-phase nanostructure bredigite powder. Mater. Sci. Eng. C 32(2), 133–139 (2012).

Balkevich, V. L., Peres, F. S., Kogos, A. Y., Kliger, A. B. & Fishman, M. A. Synthesizing wollastonite from natural siliceous carbonate compositions. Glass Ceram. 42, 40–43 (1985).

Kotsis, I. & Balogh, A. Synthesis of wollastonite. Ceram. Int. 15(2), 79–85 (1989).

Philip, B. & Muan, A. Phase diagram of CaO–SiO2. J. Am. Ceram. Soc. 414 (1959).

Locks, M. et al. Effect of feldspar substitution by basalt on pyroplastic behaviour of porcelain tile composition. Materials 14(14), 3990 (2021).

Beyene, E., Tiruneh, S. N., Andoshe, D. M., Abebe, A. M. & Tullu, A. M. Partial substitution of feldspar by alkaline-rich materials in the electrical porcelain insulator for reduction of processing temperature. Mater. Res. Express 9, 065201 (2022).

Hossain, S. S. et al. A comparative study of physico-mechanical, bioactivity and hemolysis properties of pseudo-wollastonite and wollastonite glass-ceramic synthesized from solid wastes. Ceram. Int. 46(1), 833–843 (2020).

Taylor, J. R. & Dinsdale, A. T. Thermodynamic and phase diagram data for the CaO-SiO2 system. Calphad 14(1), 71–88 (1990).

Singh, M., Lara, S. O. & Tlali, S. Effects of size and shape on the specific heat, melting entropy and enthalpy of nanomaterials. J. Taibah Univ. Sci. 11(6), 922–929 (2017).

Hossain, S. K. S. & Roy, P. K. Study of physical and dielectric properties of bio-waste-derived synthetic wollastonite. J. Asian Ceram. Soc. 6(3), 289–298 (2018).

Abd Rashid, R., Shamsudin, R., Abdul Hamid, M. A. & Jala, A. Low temperature production of wollastonite from limestone and silica sand through solid-state reaction. J. Asian Ceram. Soc. 2, 77–81 (2014).

Getem, C. & Gabbiye, N. Synthesis and characterization of β-wollastonite from limestone and rice husk as reinforcement filler for clay based ceramic tiles. In Advances of Science and Technology: 7th EAI International Conference, ICAST 2019, Bahir Dar, Ethiopia, August 2–4, Proceedings, Vol. 7, 695–706 (Springer International Publishing, 2019).

Lira, C., Fredel, M. C., da Silveira, M. D. & Alarcon, O. E. Effect of carbonates on firing shrinkage and on moisture expansion of porous ceramic tiles. V World Congress on Ceramic Tile Quality-Qualicer 98, 101–106 (1998).

Das, S. K., Dana, K., Singh, N. & Sarkar, R. Shrinkage and strength behaviour of quartzitic and kaolinitic clays in wall tile compositions. Appl. Clay Sci. 29(2), 137–143 (2005).

Karamanov, A. & Pelino, M. Induced crystallization porosity and properties of sintered diopside and wollastonite glass-ceramics. J. Eur. Ceram. Soc. 28, 555–562 (2008).

Cannillo, V., Pierli, F. & Sampath, S. Thermal and physical characterization of apatite/wollastonite bioactive glass–ceramics. J. Eur. Ceram. Soc. 29, 611–619 (2009).

Turkmen, O., Kucuk, A. & Akpinar, S. Effect of wollastonite addition on sintering of hard porcelain. Ceram. Int. 41(4), 5505–5512 (2015).

Chen, J. J., Thomas, J. J., Taylor, F. W. & Jennings, H. M. Solubility and structure of calcium silicate hydrate. J. Cement Concr. Res. 34, 1499–1519 (2004).

Wesselsky, A. & Jensen, O. M. Synthesis of pure Portland cement phases. J. Cement Concr. Res. 39, 973–980 (2009).

Isabella, C., Lukey, G. C., Xu, H. & van Deventer, J. S. The effect of aggregate particle size on formation of geopolymeric gel. Adv. Mater. Construct. Bridges Build. 9 (2003).

Spath, S., Drescher, P. & Seitz, H. Impact of particle size of ceramic granule blends on mechanical strength and porosity of 3D printed scaffolds. Materials 8(8), 4720–4732 (2015).

González-Barros, M. R., García-Ten, J. & Alonso-Jiménez, A. Synthesis of wollastonite from diatomite-rich marls and its potential ceramic uses. Bol. Soc. Esp. Ceram. Vidr. 61(6), 585–594 (2022).

Palakurthy, S., Reddy, K. V. G., Samudrala, R. K. & Azeem, A. In vitro bioactivity and degradation behaviour of β-wollastonite derived from natural waste. Mater. Sci. Eng. C. 98, 109–117 (2019).

Vichaphund, S., Kitiwan, M., Atong, D. & Thavorniti, P. Microwave synthesis of wollastonite powder from eggshells. J. Eur. Ceram. Soc. 31(14), 2435–2440 (2011).

Ewais, E. M. M., Ahmed, Y. M. Z., El-Amir, A. A. & El-Didamony, H. Cement kiln dust/rice husk ash as a low temperature route for wollastonite processing. JSBCM 66(3), 69–80 (2014).

Owoeye, S. S., Abegunde, S. M., Folorunso, D. O., Adigun, B. O. & Kingsley, U. Microstructure, phase and physical evaluation of non-bioactive wollastonite glass–ceramic prepared from waste glass by sintering method. Open Ceram. 5, 100062 (2021).

Acknowledgements

The authors would like to thank National Research Centre (NRC), Cairo, Egypt for financial support under grant (13010412).

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Contributions

H.H. Abo-almaged: project administration; conceptualization; review and editing. Rehab E.A. Ngida: data curation; formal analysis; conceptualization; methodology, review and editing. N.A. Ajiba: formal analysis, conceptualization, data curation; methodology, review and editing. H.E.H. Sadek: resources; software; conceptualization; review and editing. R.M. Khattab: supervision; validation; writing-original draft; review and editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Abo-Almaged, H.H., Ngida, R.E.A., Ajiba, N.A. et al. Utilization of industrial waste materials for the preparation of wollastonite by temperature-induced forming technique. Sci Rep 14, 21752 (2024). https://doi.org/10.1038/s41598-024-71243-3

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-71243-3