Abstract

Examining Irish ivy extract’s (IIE) potential as a novel corrosion inhibitor to preserve C-steel in 2.0 M H2SO4 solution under dynamic conditions is the main goal of this work. Investigations on weight loss, surface morphology, thermodynamics, electrochemistry (polarization and impedance), and adsorption isotherms all contributed to the achievement of this goal. The results demonstrated that the IIE extract’s inhibitory effectiveness increases with concentration, reaching a maximum of 94.2% at 0.5 g L-1. The approach that most nearly matched the experiment’s results was the Langmuir adsorption isotherm. The activation energy rises to 61.4 kJ mol-1 when IIE extract is added, compared to 46.9 kJ mol-1 (2.0 M H2SO4). The mixed type behavior of the IIE extract was confirmed by electrochemical method. The IIE extract effectively adsorbed on the C-steel, as confirmed by the FT-IR and SEM examinations. Many compounds, including α-hederin, hederacoside C, hederacoside D, and chlorogenic acid, which may operate as the main agents of corrosion control, were found by HPLC analysis of the IIE extract.

Similar content being viewed by others

Introduction

Carbon steel pipework and components are commonly used in the execution of desalination due to their good durability against corrosion and cost1. Carbon steel is susceptible to corrosion in desalination plants via acid cleaning procedures if proper safety precautions are not taken. Acid cleaning is the process of removing oxides and scale from the interior of equipment utilizing acidic solutions, including sulfuric or hydrochloric acid2. Corrosion inhibitors are capable of helping protect structures and components in desalination plant towards corrosion3,4,5. Chemicals referred to as corrosion inhibitors can be incorporated in the circulation of acid cleaning systems or operations to aid in slowing the rate at which metals corrosion by covering their surfaces with a protective layer6,7,8. Inhibitors like these help to reduce the acid’s destructive influence on the substrate surfaces during cleaning. When selecting corrosion inhibitors, it is necessary to consider the metals in the parts of the system, the specific chemistry of the water, and how effectively they function with other types of chemicals9. Saltwater desalination plants do not yet use natural corrosion inhibitors. The majority of corrosion inhibitors used in desalination facilities is organic compounds that are specifically developed to provide effective corrosion prevention10,11,12,13. Organic inhibitors for corrosion possess a variety of disadvantages, including expensive pricing, dangerous conditions, weak degradation, and rapid impact on the environment.

A significant amount of study has already been conducted regarding corrosion inhibitors derived from plant material as a viable alternative to traditional toxicity inhibitors. Natural inhibitors of corrosion derived from biodegradable extract molecules include both chemical components containing polar groups and organic components having unpaired electron elements, such as O, N, S, and P14,15,16.

Such substances from nature coat the metal’s surface upon adsorption, shielding it from corrosion. Aloe vera extract, Green tea extract, Neem extract, and Moringa oleifera extract represent examples of common and possibly efficient plant extracted-based corrosion inhibitors17,18. They include a combination of poly phenolic compounds, and organic acids. It is worth noting that the use of plant extract-based corrosion inhibitors in desalination processes is still in its early phases and may vary depending on the specific system as well as surrounding conditions. Additional studies and experiments are needed to determine their ongoing effectiveness, compatibility with various treatment chemicals, and reliability in desalination applications.

This study examines the effectiveness of Irish ivy extract (IIE) as a sustainable corrosion inhibitor for some desalination metallic construction (C-steel) in an acid clearing solution (2.0 M H2SO4) solution under dynamic environments. Adsorption isotherms, surface morphology, chemical, electrochemical, and thermodynamic investigations are all included in this research.

Irish ivy extract, derived from the leaves of the Hedera helix plant (commonly known as English ivy or Irish ivy), is recognized for its various health benefits and applications. Irish ivy extract has garnered interest as a potential corrosion inhibitor due to its natural compounds that may help protect metals from corrosion.

Experimental part

Materials and solutions

An Egyptian desalination services provided the C-steel (0.26% C, 0.03% P, 0.25% Si, 1.2% Mn, 0.028% S, and the remaining Fe). Shortly before being examined, the C-steel sample had been cleaned using SiC sandpaper sheets with 320, 800, and 1200 grit, respectively, and then washed with distilled water and an ethanol solution19.

After exposure to the 2.0 M H₂SO₄ solution, the samples were thoroughly cleaned to remove any corrosion products and residual extract components. The cleaning process involved:

(i) The samples were rinsed with distilled water to remove soluble contaminants. (ii) An ultrasonic cleaner was used for a brief period to ensure that any adhered corrosion products or debris were dislodged from the surface. (iii) The samples were again rinsed with distilled water and then dried using a soft lint-free cloth to prevent any water spots or residues.

Using 98% sulfuric acid (Merck) and deionizing water, 2.0 M H2SO4 solutions were produced for every experiment.

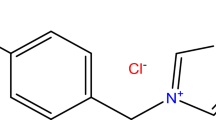

Irish ivy extract (IIE) was acquired from Symrise. The extract used in our experiments is a crude extract obtained from the Hedera helix plant. It is an aqueous glycolic preparation obtained from the plant Hedera. HPLC (Agilent) has been employed to identify the primary ingredients of IIE. The primary constituents of the IIE that have been discovered include rutin, α-hederin, hederacoside C, hederacoside D, and chlorogenic acid. The IIE extract dissolved entirely in 2.0 M H2SO4 solutions and water.

The retention times and UV–Vis spectra obtained were compared with data available in the literature for similar extracts or known compounds. This comparative analysis allowed us to infer the presence of specific phytochemicals in IIE extract.

Electrochemical and chemical methods

For weight loss (WL) assessment, 3.2 cm × 1.4 cm rectangular C-steel test specimens with a hole and 0.6 cm thickness are used. We performed WL testing in accordance with NACE-TM0169/G31–21. For WL tests, a glass vial of a suitable capacity (usually 500 ml) equipped with a temperature-regulating engine is typical devices for testing. During the 72-h immersion, each WL vial was placed on a stirred hot plate that was set to rotate at 500 rpm. The following formula has been applied for estimating the corrosion rate (CR) of C-steel20:

(W: weight loss (mg), A: surface area of the steel (cm2), t: exposure duration (h)).

The electrochemical testing was performed in accordance with G3-89 (2010). Using a potentiostat/3000-Gamry, the electrochemical measurement was established. The testing was done in a cell with two walls. A C-steel with a surface area of effective use of 0.407 cm2, a platinum strip serving as a counter, and a saturated calomel electrode (SCE) serving as a reference were used in the studies. Electrochemical impedance spectroscopy (EIS) investigations were conducted between the frequency range of 30 kHz to 0.01 Hz based on 10 mV amplitude AC voltage at the open circuit potential (OCP), which was recorded for a duration of 60 min. At a scanning rate of 0.125 mV s-1, potentiodynamic polarization has been measured at ± 0.250 V/SCE vs. OCP. Gamry Echem Analyst software was used fit fitting data and the construction of the equivalent electrical circuit.

The mean (M) and standard deviations (SD) of the three replicated investigations were computed.

Surface characterization

The surface morphological features of the C-steel specimens submerged in 2.0 M H2SO4 solution with or without a sufficient amount of the IIE extract as a corrosion inhibitor were examined using scanning electron microscopy (SEM) ( ZEISS-EVO). The scratched film generated on a C-steel surface in 2.0 M H2SO4 solution treated with 0.5 g L-1 IIE extract was investigated by FT-IR (PerkinElmer -Spectrometer).

Results and discussion

Electrochemical studies

Evaluating C-steel’s open circuit potential (OCP) in 2.0 M H2SO4 both with and without IIE extract will reveal important insights into how well the extract works to reduce corrosion. For a period of 60 min, the OCP evaluations for C-steel in 2.0 M H2SO4 were conducted both with and without the addition of IIE extract. The resulting curves are displayed in Fig. 1. A remarkably constant potential was obtained after 20 min of OCP scanning. The figure also shows that the OCP moves to higher positive values in the presence of IIE extract, but is more stable in the blank solution at about − 562 mV. At 0.1, 0.2, 0.3, 0.4, and 0.5 g/L of IEE, the steady OCP values of solutions containing IIE extract were about -544, -552, -550, 548, and -558 mV, respectively. IIE extract can influence the system’s electrochemical behavior and have an impact on C-steel’s OCP in 2.0 M H2SO4. Adsorption of the IIE extract onto the C-steel surface has the potential to produce a layer of protection or modify the electrochemical processes taking place at the point of contact. This result in the OCP shifting to a more positive value, indicating a decrease in the tendency for corrosion and demonstrating that the IIE extract slows the anodic dissolution of the C-steel21,22.

EIS tests were conducted to expand on the impact of IIE extract on the corrosion behavior of C-steel in 2.0 M H2SO4. Figure 2 (a, b, and c) displays the stated findings (Nyquist, Bode-module, and Bode-phase angle plots diagram). The Nyquist plot (see Fig. 2a) shows that there is one deformed semicircle in 2.0 M H2SO4. The plot includes a semicircle in the complex impedance plane, representing the charge transfer resistance associated with the steel-electrolyte interface23. The Nyquist and Bode-module plots (see Fig. 2 a and c) demonstrate that the semicircle’s diameter grows in proportion to the IIE extract concentration. This results in a decrease in the rate of corrosion24. The only one time constant was observed in the Bode diagrams. This demonstrates that the corrosion process is mainly determined by the charge transfer process.

The Bode-phase angle plot (see Fig. 2b) represents the phase shift between the input and output signals of a system across a range of frequencies. The phase angle map of the Bode plot shows one large peak, indicating the possibility of a single charge transfer mechanism during the oxidation of C-steel in 2.0 M H2SO4. Additionally, compared to the blank solution, the maximum height of phase angle levels elevated in the presence of IIE extract, suggesting a stronger capacitive behavior of the C-steel/H2SO4 interface25.

The frequency at which the maximum phase angle (fmax) of the IIE extract at concentrations of 0.4 and 0.5 g L-1 shifts away from the centre and towards the low frequency in comparison to the other systems. The behavior of the extract varies with IIE concentration. The interaction between the IIE extract components and the substrate may differ at these concentrations, influencing the overall impedance characteristics and leading to a shift of fmax towards lower frequencies.

A hypothetical equivalent circuit (EC) that was constructed to understand and display the Nyquist plots, is seen in Fig. 3. EC consists of the solution resistance (Rs), the charge transfer resistance (Rct), and the constant phase element (Qdl). The Qdl is often used instead of a simple ideal capacitor in electrochemical impedance models to account for deviations from ideal. The double layer capacitance (Cdl) is closely related to the Qdl and dielectric constant.

The EIS parameters that have been identified by fitting and exhibited by the Nyquist curve are shown in Table 1. Accurate fitting data are indicated by the comparatively low goodness of fit (χ2)26.

The inhibition of electron transport at the C-steel-H2SO4 solution interface, which is commonly linked to the corrosion action, is represented by the symbol Rct. The Rct value rises when IIE extract is present. An elevated Rct implies that the IIE extract creates a shield that serves to avoid corrosion and lower the electron transport rate on the C-steel surface. The usual behavior of Rs is not markedly affected by the existence of IIE extract. This demonstrates that the IIE extract has no discernible effect on the electrolyte’s conductivity. Table 1 demonstrates that heterogeneity factor (n) values rise upon the addition of IIE extract.

As IIE extract is added, the rise in (n) values suggests that the adsorption of the extract improves surface uniformity. This can occur due to the formation of a more homogeneous protective layer on the metal surface27. As the concentration of IIE increases beyond 0.1 g L-1, it is possible that the available adsorption sites on the steel surface become saturated. Once these sites are fully occupied, additional increases in concentration may not lead to further increases in n values.

Moreover, the value of Cdl decreased as the IIE extract content increased. This is related to the fact that IIE extract molecules adhere to the C-steel surface, minimizing the amount of contact between the surface and the H2SO4 solution28. As IIE extract concentration is raised, more water molecules having a higher dielectric constant are substituted by larger and more numerous IIE extract molecules, thickening the double electrical layer and lowering the Cdl.

The formula that’s given below has been utilized to assess the inhibitory effectiveness (ηR%) of the IIE extract29:

where Rct and Rcto are the charge transfer resistance with and without IIE extract solutions.

The calculated inhibitory efficiencies (ηR%) are outlined in Table 1. The ηR% of IIE extract achieves its full extent (94.2%) at 0.5 g L-1.

The Tafel polarization pattern of C-steel in 2.0 M H2SO4 at 298 K under dynamic conditions can be seen in Fig. 4 with varying IIE extract concentrations. Anodic and cathodic curves are changed when a given quantity of IIE extract is increased, according to polarization study results. The Tafel polarization findings are shown in Table 2.

Determine whether the 85 mV shift in Ecorr is towards more positive or negative values, as it indicates whether the inhibitor predominantly affects the anodic or cathodic reactions. An 85 mV shift is considered a substantial change in Ecorr and suggests a notable impact of the corrosion inhibitor on the corrosion potential of the system. The mixed type attitude of the IIE extract was confirmed by the difference in Ecorr values comparing the presence and absence of IIE extract, which was less than 85 mV30. Upon adding the IIE extract, there was a detectable positive shift in the Ecorr value. Because the IIE extract did not significantly change the Tafel slopes (βc and βa), it is clear that the anodic and cathodic operating processes were unaffected by its addition to the corrosion solution31. The corrosion current density (jcorr) declined substantially upon the use of IIE extract. It means that in 2.0 M H2SO4 solutions, IIE extract inhibits corrosion of the C-steel anode. The formula that’s given below has been utilized to assess the inhibitory effectiveness (ηj%) of the IIE extract32:

where jcorr and jcorr(0) are the corrosion current density with and without IIE extract solutions.

The IIE extract’s inhibitory effectiveness increases with concentration, reaching a maximum of 91.7% at 0.5 g L-1. These results validate the strong inhibitory effect of IIE extract on C-steel corrosion in 2.0 M H2SO4.

Weight loss studies

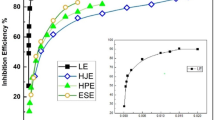

Corrosion performance of materials and the efficacy of IIE extract are frequently evaluated using WL and corrosion rate tests. The WL tests were used to assess the corrosion rate (CR) and percentage of corrosion inhibition ηW% for C-steel in 2.0 M H2SO4 solution containing IIE extract at 298 K during dynamic settings. Table 3 shows the acquired data.

The formula that’s given below has been utilized to assess the inhibitory effectiveness (ηW%) of the IIE extract33:

Where CR and CR0 are the corrosion rate with and without IIE extract solutions.

Table 3 illustrates the CR and ηW% at different IIE extract amounts and demonstrates that the mean CR declines as IIE extract concentration rises. The decrease in CR with increasing IIE extract dosage indicates a tendency towards increased C-steel surface covering assisted by IIE extract molecules. A key approach for inhibiting corrosion in C-steel is the adsorption of IIE extract components over the surface34. Increased IIE extract component concentrations often result in increased adsorption strengths. More IIE extract compounds are accessible for adsorption at higher concentrations, which improves corrosion inhibition and increases the overall coverage of C-steel. The maximum inhibitory efficiency (ηW% = 90.3) was found at 0.5 g L-1 of IIE extract.

Adsorption isotherm studies

Adsorption isotherm studies are common approaches used in corrosion research to understand the behavior and mechanisms of corrosion inhibitors. According to the specifics of how adsorption works and the hypotheses that have been made, several adsorption isotherm form, including Freundlich, Temkin, Langmuir isotherms, can be investigated (see Eqs. 5–7)35.

Identify which adsorption isotherm forms matches the experimental results and extract the applicable parameters by fitting the data to the model. Using the surface coverage (θ) obtained from WL data and the amount of the IIE extract (Cinh) in 2.0 M H2SO4 solution, numerous adsorption isotherm models have been fitted (Fig. 5). In accordance with the regression coefficient (R2) value, the best-fitting adsorption isotherm is chosen36. For the Langmuir, Temkin, and Freundlich isotherms, the corresponding R2 values are 0.9957, 0.2923, and 0.9722. With an R2 of 0.9957, the Langmuir adsorption isotherm method was the model that most closely fit the experiment’s data, as shown in Fig. 5a. The Langmuir adsorption isotherm is a commonly used model to describe the adsorption behavior of IIE extract onto C-steel in 2.0 M H2SO4 surfaces. It assumes that adsorption occurs through monolayer coverage of IIE extract on the C-steel surface35. The extent of adsorption between the IIE extract components and the C-steel surface is represented in Kads' data. It measures the degree of equilibrium between the component concentration in the solution and the amount of the adsorbed component. A stronger attraction between the IIE extract molecules and the C-steel surface is demonstrated by a larger value of Kads (Kads = 20.5 L/g), which suggests a more advantageous adsorption process37.

Temperature effect

The common approach for conducting thermodynamic research is to measure the behavior of IIE extract at various temperatures (298 K–333 K) and then use Arrhenius and transition-state equations (Eqs. 8 and 9) to analyze the results38.

(A = constant, h = 6.6261 10−34 m2 kg s−1, N = Avogadro’s constant, and R = universal gas constant).

Table 4 shows the temperature-dependent parameters (CR and ηW%) for C-steel in 2 M H2SO4 solution, both with and without IIE extract (0.5 g L-1). The analysis shows that as temperature rises, the CR of C-steel in acid solution, with or without IIE extract, keeps rising. Elevating the temperature often causes C-steel to corrode more quickly in acidic solutions. The velocity of chemical reactions, such as the oxidation and reduction activities associated with corrosion operations; speed up at higher temperatures39. The rate of corrosion increases as a result of this higher response rate.

The velocity of ions inside the electrolyte liquid rises concurrently at temperatures going up. Higher corrosion rates result from ions’ easier access to the C-steel surface and ability to engage in electrochemical processes due to their improvements in mobility. Furthermore, the passive C-steel surface layers may become less stable at elevated a temperature, which increases the risk to corrosion39. The ηW% significantly decreases from 90.3% to 82.5% when the temperature rises (see Table 4). It implies that the inhibitor’s effectiveness may be diminished at high temperatures due to decreased adsorption. The inhibitive activities of IIE extract may marginally diminish at elevated temperatures due to its small susceptibility to desorption. Additionally, this validates their physisorption process40. It is possible to determine the specific kind and method of the inhibition of corrosion process by computing thermodynamic parameters, such as activation energy (Ea), enthalpy change (∆H*), and entropy change (∆S*).

The Ea was calculated identified through an Arrhenius curve (Fig. 6), with or without the 0.5 g L-1 IIE extract. With the use of IIE extract, the Ea increases to 61.4 kJ mol-1 versus 46.9 kJ mol-1 (2.0 M H2SO4 solution). Considerably higher activation energy inhibits C-steel corrosion once IIE extract is added. The width of the double layer increases as a result of the adsorption of IIE extract over the C-steel surface, raising the energy barrier required to start the corrosion process. The IIE extract’s components’ appropriate physical adsorption was linked to this phenomenon40. The values of ΔH* and ΔS* have been determined using the transition transition-state figure (Fig. 7). The addition of IIE extract increased the ΔH* from 44.3 kJ mol-1 (2.0 M H2SO4 solution) to 58.8 kJ mol-1. The reference to the positive magnitude of ΔH* as reflecting the endothermic nature of oxidation may suggest a more complex interaction41. While the primary mode of adsorption may be physisorption, we recognize that there could be elements of chemisorption involved, particularly when the extract components interact more strongly with the surface at a molecular level. Some components may engage in chemisorption, particularly in the context of the endothermic reactions observed.

A small variation was seen in the ΔS*, which changed from -97.4 J mol−1 K−1 (in the 2.0 M H2SO4 solution) to -50.3 J mol−1 K−1 (with IIE extract present). Furthermore, it is likely that the presence of IIE extract causes an increase in H2O entropy due to H2O de-sorption on the C-steel surface, which is responsible for the decline in negative values of ΔS* in the extract solution42.

Surface morphology studies

A SEM picture of C-steel at 298 K and 2.0 M H2SO4 immersion for 72 h is shown in Fig. 8. The surface picture of C-steel in 2.0 M H2SO4 (Fig. 8a) reveals extensive surface cracking and flaws due to serious harm to the top layer of the C-steel. The 2.0 M H2SO4 solution’s corrosive properties were significantly decreased and the C-steel surface was shielded from corrosion by the addition of 0.5 g L-1 of IIE extract (Fig. 8b). This was shown by the C-steel surface being remarkably pristine and almost entirely covered with IIE extract components.

Figure 9 displays the FTIR spectrum of the IIE extract and the IIE extract adsorption on C-steel following a 72-h immersion in 2.0 M H2SO4 at 298 K. The O–H stretching vibration was identified as the cause of the band at 3435 cm−1. At 2940 cm−1, the stretching vibration of C–H was seen. The C = O band was allocated to 1763 cm−1. The stretching vibration of aromatic C = C might be the cause of the absorption at 1684 cm−1. The C–O groups were responsible for the peak at 1253 cm−1. The lengthy chain band was identified as the cause of the peak at 795 cm−1. These results demonstrated that the functional groups (O–H, C = O, or C–O) in the IIE extract included oxygen. Following immersion in a 2 M H2SO4 solution containing 0.5 g L-1 of IIE extract, the FTIR spectra of the compounds produced by corrosion onto C-steel is displayed in Fig. 9. The absorption peaks of O–H, C = O, C = C, and C–O occurred at 3487 cm−1, 1832 cm−1, 1770 cm−1, and 1288 cm−1, respectively.

The spectrum for the C-steel after immersion indicates shifts in peak positions or changes in intensity, which suggest interaction between the IIE extract and the steel surface. These changes can be attributed to the adsorption of extract components, indicating their role in corrosion inhibition. These findings implied that the surface of C-steel became saturated with IIE extract.

The mechanism of IIE extract as corrosion inhibitor

The IIE extract has organic ingredients that can adsorbed to the C-steel surface, including rutin, α-hederin, hederacoside C, hederacoside D, and chlorogenic acid (as shown in Fig. 10). These natural compounds can adhere to C-steel surfaces by means of functional groups like hydroxyl groups43,44,45. Furthermore, their connection with the C-steel surface is improved by having number of aromatic rings. The oxygen atom’s lone pair of electrons enables metal ions to form coordination bonds with it, which results in the adsorption of IIE extract compounds46,47. The functional groups found in IIE extract allow for hydrogen bonding, coordination, ionisation, and π-π bonds with the C-steel surface. These associations help the compounds of the IIE extract adsorb onto the surface of the C-steel, creating a layer of protection that inhibits corrosion. IIE extract can adsorb to both cathodic and anodic locations on the surface of C-steel. It is most probable to anodic adsorb because of electrical coupling with the partially-filled d-orbitals of Fe2+. Table 548,49,50,51,52 compares the efficacy of IIE extract with several other known natural extracts in reducing corrosion of steel in H2SO4 solutions. Table 5 demonstrates that IIE extract considerably reduces C-steel corrosion in H2SO4 solutions in comparison with different extract components in solutions of acids.

Conclusions

Investigating Irish ivy extract’s (IIE) potential as a novel corrosion inhibitor for protecting C-steel in 2.0 M H2SO4 solution is the main goal of this work., electrochemical (polarization and EIS), weight loss, adsorption, thermodynamic, and surface morphology investigations all supported this goal. The results demonstrated that the highest inhibitory efficiency (94.2%) was found at 0.5 g L-1 of IIE extract. The Langmuir adsorption isotherm is a commonly used model to describe the adsorption behavior of IIE extract. It assumes that adsorption occurs through monolayer coverage of IIE extract on the C-steel surface. At high temperatures, IIE extract are likely to be a little desorbed, which would support its physisorption function and result in a little reduction in its inhibitory properties. Enhanced activation energy significantly slows down the corrosion of C-steel once IIE extract is added. The positive magnitude of ΔH* represents the endothermic oxidation of C-steel in 2.0 M H2SO4. The mixed sort activity of the IIE extract was confirmed by the difference in Ecorr values between the presence and absence of the extract that were less than 85 mV. The capacity for contacts and creation of bonds between C-steel and IIE extract has been revealed by SEM and FT-IR studies. Plant extracts are a desirable alternative since the future of corrosion inhibition is probably going to be about creating environmentally friendly and sustainable alternatives.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Hodgkiess, T., Al-Omari, K. H., Bontems, N. & Lesiak, B. Acid cleaning of thermal desalination plant: do we need to use corrosion inhibitors?. Desalination 183, 209–216 (2005).

Malik, A.U., Ahmad, S., Andijani, I., Asrarm N. Acid Cleaning of Some Desal units at Al-Jubail plant. Technical Report No. TR3804/APP95007 (February 1997).

Al-Hamzah, A. A. & Fellows, C. M. A comparative study of novel scale inhibitors with commercial scale inhibitors used in seawater desalination. Desalination 359, 22–25 (2015).

Deyab, M. A. Enhancement of corrosion resistance in MSF desalination plants during acid cleaning operation by cationic surfactant. Desalination 456, 32–37 (2019).

Deyab, M. A. & Guibal, E. Enhancement of corrosion resistance of the cooling systems in desalination plants by green inhibitor. Sci. Rep. 10, 4812 (2020).

Frenier, W.W. Development and testing of a low-toxicity acid corrosion inhibitor for industrial cleaning applications. The NACE International Annual Conference and Exposition (1996) Paper No. 152.

Singh, D. D. N. & Gaur, B. Improving the inhibitive performance of dibenzyl sulfoxide for pickling of steel in sulfuric acid. Corrosion 51, 593–601 (1993).

Deyab, M. A. Understanding the anti-corrosion mechanism and performance of ionic liquids in desalination, petroleum, pickling, de-scaling, and acid cleaning applications. J. Mol. Liq. 309, 113107 (2020).

Shokri, A. & Fard, M. S. Corrosion in seawater desalination industry: A critical analysis of impacts and mitigation strategies. Chemosphere 307, 135640 (2022).

Lv, J. et al. Effect and mechanism of pyrophosphoric acid anodizing technological parameters on the superhydrophilicity coupled corrosion resistance of aluminum alloy distillation desalination tubes. Surf. Coat. Technol. 465, 129581 (2023).

Singh, A. et al. Corrosion and bacterial growth mitigation in the desalination plant by imidazolium based ionic liquid: Experimental, surface and molecular docking analysis. J. Environ. Chem. Eng. 11, 109313 (2023).

Deyab, M. A., Abd El-Rehim, S. S., Hassan, H. H. & Shaltot, A. M. Impact of rare earth compounds on corrosion of aluminum alloy (AA6061) in the marine water environment. J. Alloys Compd. 820, 153428 (2020).

Deyab, M. A., Fouda, A. S., Osman, M. M. & Abdel-Fattah, S. Mitigation of acid corrosion on carbon steel by novel pyrazolone derivatives. RSC Adv. 7, 45232–45240 (2017).

Gabsi, M. et al. The curious case of polyphenols as green corrosion inhibitors: a review on their extraction, design, and applications. Environ. Sci. Pollut. Res. 30, 59081–59105 (2023).

Okafor, P. C. et al. Inhibitory action of Phyllanthus amarus extracts on the corrosion of mild steel in acidic media. Corros. Sci. 50, 2310–2317 (2008).

Haque, J. et al. Alocasia Odora extract as environmentally benign corrosion inhibitor for aluminum in HCl. Moroccan J. Chem. 11, 11–14 (2023).

Kahlouche, A. et al. Molecular insights through the experimental and theoretical study of the anticorrosion power of a new eco-friendly Cytisus multiflorus flowers extract in a 1 M sulfuric acid. J. Mol. Liq. 347, 118397 (2022).

Benzidia, B. et al. Aloe vera mucilage as an eco-friendly corrosion inhibitor for bronze in chloride media: Combining experimental and theoretical researches. J. King Saud Univ. 35, 102986 (2023).

Chowdhury, M. A. et al. Tulsi and green tea extracts as efficient green corrosion inhibitor for the corrosion of aluminum alloy in acidic medium. Res. Eng. 17, 100996 (2023).

Deyab, M. A. & Mohsen, Q. Inhibitory influence of cationic Gemini surfactant on the dissolution rate of N80 carbon steel in 15% HCl solution. Sci. Rep. 11, 10521 (2021).

Deyab, M. A. Sulfonium-based ionic liquid as an anticorrosive agent for thermal desalination units. J. Mol. Liq. 296, 111742 (2019).

Solomon, M. M. & Umoren, S. A. In-situ preparation, characterization and anticorrosion property of polypropylene glycol/silver nanoparticles composite for mild steel corrosion in acid solution. J. Colloid Interface Sci. 462, 29–41 (2016).

Deyab, M. & Awadallah, A. E. Advanced anticorrosive coatings based on epoxy/functionalized multiwall carbon nanotubes composites. Prog. Org. Coat. 139, 105423 (2019).

Altunbaş Şahin, E. et al. Inhibitive effect of 4-amino-N-benzylidene-benzamide Schiff base on mild steel corrosion in HCl solution. J. Adhes. Sci. Technol. 34, 135–152 (2020).

Deyab, M. & Mele, G. Polyaniline/Zn-phthalocyanines nanocomposite for protecting zinc electrode in Zn-air battery. J. Power Sources 443, 227264 (2019).

Madaci, A. et al. Experimental and theoretical study of polysaccharides extracted from prickly pear nopales Pulp (PPUN) of Opuntia ficus-indica as corrosion inhibitors. J. Mol. Liq. 384, 122272 (2023).

Usman, B. J. et al. Eco-friendly 2-Thiobarbituric acid as a corrosion inhibitor for API 5L X60 steel in simulated sweet oilfield environment: Electrochemical and surface analysis studies. Sci. Rep. 9, 830 (2019).

Singh, A., Ansari, K. R., Kumar, A., Liu, W. & Songsong, C. Lin, Y Electrochemical, surface and quantum chemical studies of novel imidazole derivatives as corrosion inhibitor for J55 steel in sweet corrosive environment. J. Alloys Comp. 76, 61–13 (2017).

Tang, C. et al. Novel biosurfactants for effective inhibition of gas hydrate agglomeration and corrosion in offshore oil and gas pipelines. ACS Sustain. Chem. Eng. 11, 353–367 (2022).

Deyab, M. A., Essehli, R. & El Bali, B. Performance evaluation of phosphate NaCo(H2PO3)3.H2O as a corrosion inhibitor for aluminum in engine coolant solutions. RSC Adv. 5, 48868–48874 (2015).

Boughoues, Y., Benamira, M., Messaadia, L. & Ribouh, N. Adsorption and corrosion inhibition performance of some environmental friendly organic inhibitors for mild steel in HCl solution via experimental and theoretical study. Colloids Surf. Physicochem. Eng. Aspects 593, 124610 (2020).

Didouh, H. et al. Investigating the use of Moringa Oleifera leaf extract as an environment-friendly corrosion inhibitor for API 5L X52 steel in 1 M HCl. J. Mol. Liq. 390, 122910 (2023).

Deyab, M. A., Mohsen, Q. & Guo, L. Aesculus hippocastanum seeds extract as eco-friendly corrosion inhibitor for desalination plants: Experimental and theoretical studies. J. Mol. Liq. 361, 119594 (2022).

Tan, B. et al. Investigation of the inhibition effect of Montelukast Sodium on the copper corrosion in 0.5 mol/L H2SO4. J. Mol. Liq. 248, 902–910 (2017).

Qiang, Y., Zhang, S., Tan, B. & Chen, S. Evaluation of Ginkgo leaf extract as an eco-friendly corrosion inhibitor of X70 steel in HCl solution. Corros. Sci. 133, 6–16 (2018).

Adamson, A. W. & Gast, A. P. Physical chemistry of surfaces 6th edn. (Wiley-Interscience, 1997).

Bentiss, F., Lebrini, M. & Lagrenée, M. Thermodynamic characterization of metal dissolution and inhibitor adsorption processes in mild steel/2,5-bis(n-thienyl)-1,3,4- thiadiazoles/hydrochloric acid system. Corros. Sci. 47, 2915 (2005).

Deyab, M. A., Ouarsal, R., Lachkar, M., Bali, B. E. & Essehli, R. Phosphites compound: Novel corrosion inhibitor for radioactive waste container (carbon steel) in simulated Callovo-Oxfordian (COx) groundwater. J. Mol. Liq. 219, 994–999 (2016).

Popova, A. Temperature effect on mild steel corrosion in acid media in presence of azoles. Corros. Sci. 49, 2144 (2007).

Deyab, M. A. M. Corrosion inhibition and adsorption behavior of sodium lauryl ether sulfate on L80 carbon steel in acetic acid solution and its synergism with ethanol. J. Surfact Deterg. 18, 405–411 (2015).

Khan, G. et al. Electrochemical investigation on the corrosion inhibition of mild steel by Quinazoline Schiff base compounds in hydrochloric acid solution. J. Colloid Interface Sci. 502, 134–145 (2017).

Zarei, A., Dehghani, A., Guo, L. & Ramezanzadeh, B. Pepper extract effectiveness as a natural inhibitor against corrosion of steel samples (SS) in 1 M hydrochloric acid; Theoretical (DFT calculation – MD simulation), thermodynamic, and electrochemical-surface studies. Ind. Crops Prod. 189, 115839 (2022).

Deyab, M. A. & Keera, S. T. On corrosion and corrosion inhibition of carbon steel in stored biodiesel: electrochemical (AC and DC) studies. J. Taiwan Inst. Chem. Eng. 68, 187–191 (2016).

Mo, S., Luo, H.-Q. & Li, N.-B. Plant extracts as “green” corrosion inhibitors for steel in sulphuric acid. Chem. Papers 70, 1131–1143 (2016).

Verma, C., Ebenso, E. E., Bahadur, I. & Quraishi, M. A. An overview on plant extracts as environmental sustainable and green corrosion inhibitors for metals and alloys in aggressive corrosive media. J. Mol. Liq. 266, 577–590 (2018).

Pushpanjali, N., Rao, S. A. & Rao, P. Corrosion inhibition and adsorption behavior of Murraya koenigii extract for corrosion control of aluminum in hydrochloric acid medium. Surf. Eng. Appl. Electrochem. 53, 475–485 (2017).

Assad, H. & Kumar, A. Understanding functional group effect on corrosion inhibition efficiency of selected organic compounds. J. Mol. Liq. 344, 117755 (2021).

Rathod, M. R., Minagalavar, R. L. & Rajappa, S. K. Effect of Artabotrys odoratissimus extract as an environmentally sustainable inhibitor for mild steel corrosion in 0.5 M H2SO4 media. J. Indian Chem. Soc. 99, 100445 (2022).

Saxena, A., Prasad, D., Haldhar, R., Singh, G. & Kumar, A. Use of Saraca ashoka extract as green corrosion inhibitor for mild steel in 0.5 M H2SO4. J. Mol. Liq. 258, 89–97 (2018).

Oyewole, O., Abayomi, T. S., Oreofe, T. A. & Oshin, T. A. Anti-corrosion using rice straw extract for mild steel in 1.5 M H2SO4 solution. Res. Eng. 16, 100684 (2022).

Wang, Y., Qiang, Y., Zhi, H., Ran, B. & Zhang, D. Evaluating the synergistic effect of maple leaves extract and iodide ions on corrosion inhibition of Q235 steel in H2SO4 solution. J. Ind. Eng. Chem. 117, 422–433 (2022).

Priya, K. S., Prathibha, B., Vasudha, V. G. & Nagaswarupa, H. P. Spathodea Campanulata as a Corrosion Inhibitor for Mild Steel in 1N H2SO4 Media. Mater. Today Proc. 5, 22595–22604 (2018).

Author information

Authors and Affiliations

Contributions

M. A. Deyab and Q. Mohsen. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Deyab, M.A., Mohsen, Q. An eco-friendly corrosion inhibitor for steel used in desalination systems during acid cleaning: Irish ivy extract. Sci Rep 14, 30505 (2024). https://doi.org/10.1038/s41598-024-82263-4

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-82263-4