Abstract

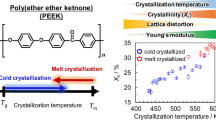

The crystallisation behaviour of carbon fiber reinforced polyetheretherketone composite (CF/PEEK) is affected by temperature changes during moulding and reprocessing, which ultimately affects their mechanical properties. Current studies do not consider the comprehensive effects of maximum temperature and cooling rate on crystallinity, and they lack prediction models. Therefore, the crystallinity and tensile properties of PEEK under different temperatures and cooling rates were obtained through DSC tests and quasi-static tensile tests, respectively. The influence of processing parameters on crystallisation and mechanical properties was also analysed. In addition, mathematical models for predicting the crystallinity and mechanical properties of PEEK and CF/PEEK were established, and the accuracy of the models was verified by a series of experiments. The results showed that the maximum temperature close to the melting point and the lowest cooling rate resulted in higher crystallinity, optimal mechanical properties and energy-saving. Under the same processing parameters, the crystallinity of the composite was approximately 1.07 times higher than that of the resin. The error of all theoretical calculated values from the prediction models falls within 11.03%, and the crystallinity of the resin can be directly used to predict the mechanical properties of the composites.

Similar content being viewed by others

Introduction

Polyetheretherketone (PEEK) has excellent high-temperature mechanical properties and biocompatibility1,2,3 and can be used to prepare thermoplastic composite materials with excellent heat resistance, high specific modulus, high specific strength, light weight, repairability, and recyclability. It has potential applications in the aerospace, construction, medical, and automotive fields4,5,6. PEEK and its composites typically undergo temperature changes during manufacturing processes such as moulding or three-dimensional (3D)-printing design and manufacturing, which requiring materials to be heated to a near-fluid temperature (approximately 400 °C). Gao et al.7 found that when drilling holes in PEEK components, heat accumulates along the axial, and local high temperatures (above the melting point) tend to form near the exit hole. At the same time, Hou et al.8 proved that this will affect the stress distribution around the hole and the safety performance and lifetime of the component. Regis et al.9 found that the change in temperature causes the resin matrix to undergo two changes in three mechanical states, which manifest microscopically as the thawing and rearrangement (recrystallisation) of molecular chains. The crystallinity of PEEK can range from almost completely amorphous (0%) to optimal (approximately 48%), and Rae et al.10 have long demonstrated that the crystallisation behaviour of the material is closely related to its macroscopic thermodynamic properties. Therefore, the influence of process parameters on the crystallinity, mechanical properties, and product quality of PEEK and its composites is currently a research hotspot, and some results have been obtained in both applied research and fundamental theoretical research fields.

In the field of applied research, Gao and Kim11 conducted a study on the effect of crystallinity on the mechanical properties of CF/PEEK during moulding, and showed that the crystalline phase is beneficial for improving the stiffness and strength of CF/PEEK, whereas the amorphous phase plays a positive role in absorbing impact energy, thereby enhancing the impact strength of the material. Mclauchlin et al.12 studied the reprocess ability of PEEK in the injection moulding process, and compared the effect of repeated reuse on mechanical properties. Xu et al.13 employed fused deposition modeling (FDM) for the additive manufacturing of continuous carbon fiber reinforced composites (CCFRC), investigating the influence of various HIP parameters, including temperature, pressure, and post-processing time, on interlayer shear strength (ILSS) and tensile strength. Yang et al.14 showed the influence of thermal processing conditions, including ambient temperature, nozzle temperature, and heat treatment methods, on the crystallinity and mechanical properties of PEEK by utilizing a temperature-controlled 3D printing system. Wang et al.15 study the effects of various printing parameters (the printing temperature, printing speed, and printing layer thickness) on the mechanical properties, microstructure, and surface quality of printed PEEK parts. Li et al.16 achieved high-quality processing of CFRP composites, featuring a considerable depth-to-width ratio and limited heat-affected zone (HAZ) width, by determining the ablation thresholds of the resin and carbon fiber and analyzing the influence of picosecond laser processing parameters on ablation depth and HAZ width. Ahmad et al.17 studied the impact of hole-drilling parameters on the stress distribution around the holes and the quality of the component. They showed that the thermal conductivity of the thermoplastic matrix was lower than that of the thermoset matrix, resulting in poor heat-dissipation performance when drilling holes. Yao et al.18 showed that the excessive cooling rate during the drilling of CF/PEEK materials is the main reason for the significant decline in the crystallinity of PEEK and the strength of CF/PEEK components; Qi et al.19 then proposed and validated a new process method for actively controlling temperature and delaying cooling after drilling holes.

In the field of fundamental theoretical research on polymer crystallisation kinetics, many in-depth studies have been conducted on the crystallisation kinetics and mechanisms of polymer moulding processes to clarify the intrinsic nature of material crystallisation behaviour and further understand the mechanism of the influence of process parameters on material crystallinity and mechanical properties to guide production and manufacturing. Motz and Schultz20 observed that both the initial crystallisation temperature and crystallinity were constrained by the cooling rate, particularly when the cooling rate was greater than the crystallisation rate of the polymer, resulting in a significant decrease in the crystallinity and changes in the crystal morphology. Cherri et al.21 clarified the role of the cooling rate on the crystallisation behaviour of materials. They also showed that the cooling rate is a key factor affecting material properties and can directly determine the crystallinity, crystal size, and crystal structure of materials. Gao and Kim22,23 confirmed the above viewpoint when studying the impact of the cooling rate on the crystallinity, interfacial-bond strength, and fracture toughness of thermoplastic composites during moulding. They observed that as the cooling rate increased, the crystallinity and spherulitic crystal size of the material decreased, ductility increased, tensile strength and tensile modulus decreased, and the overall mechanical properties decreased. Jonas and Legras24 studied the effect of thermal history on the non-isothermal crystallisation behaviour and mechanical properties of PEEK, and found that the quality and quantity of the crystalline regions depend on the cooling kinetics and can be altered by inclusions such as fibres, or by self-nucleation. This was consistent with the observations by Lee and Porter25, who used a polarized microscope to show that CF has a strong nucleation effect, and with the findings of Regis et al.26, who discovered that CF can promote the crystallization of PEEK.

In summary, current research has clearly demonstrated the effects and mechanisms of the cooling rate on the crystallinity and mechanical properties of materials, but neglect the impact of the maximum temperature reached by the material on the crystallisation. Moreover, quantitative research is generally limited, making it impossible to predict the crystallinity and mechanical properties under a certain processing parameter.

Therefore, this study aims to explore the effect of processing parameters (the maximum crystallisation temperature and cooling rate) on crystallisation and mechanical properties of PEEK and CF/PEEK, additionally, establish the relationship between them and develop mathematical models to control and optimize product quality. This study first simulates non-isothermal experimental conditions in actual production and discusses the crystallization behaviour of PEEK and CF/PEEK under different maximum temperatures and cooling rates. Furthermore, we analyse the mechanism of processing parameters affecting crystallisation and mechanical properties, and establish mathematical models for predicting crystallinity and mechanical properties of PEEK and CF/PEEK. The accuracy of the models is verified through Differential Scanning Calorimetry (DSC) experiments, tensile test and shear test, which provide good references and suggestions for the selection of the processing parameters for PEEK, CF/PEEK and other composites.

Experiment

Materials and preparation

PEEK 5600G was purchased from Jiangsu Junhua Special Plastics Co., Ltd. The unidirectional CF/PEEK composite laminate was fabricated using T800 carbon fibers and PEEK5600G film, with a fiber volume fraction of 58%, a ply stacking sequence of [0]20, and a thickness of 3.35 mm. The molding method referenced from literature18.

Differential scanning calorimetry (DSC)

Testing conditions

The DSC tests were conducted with sample masses of 5–10 mg under nitrogen protection at 40 mL/min. The sample was heated at 30 °C/min to different maximum temperatures and maintained for 10 min to fully heat the sample and eliminate the effects of thermal history on the sample, then cooled to 25 °C at a specified rate. Crystallinity during rapid cooling (> 200 °C/min) was determined via melting enthalpy measurements. Samples were sectioned from mechanical test specimens (Sect. 2.3), with three replicates per condition.

Studies25,26,28 have found that improving the wettability of the fiber surface and arranging the fibers reasonably can promote the crystallization of the matrix. However, the instability of the resin content during the sampling of CF/PEEK will bring a high degree of randomness to the test results of the crystallinity of the composite material. To address this problem, a crystallinity relationship Xc−CF/PEEK ≈ ζ*Xc−PEEK was proposed and validated against literature.

Temperature and cooling rates selection

Three maximum temperatures were selected. 360 °C: Minimum complete melting temperature for PEEK (DSC-confirmed). 400 °C: Fluid state temperature where crystallization becomes temperature-independent27. 380 °C: Intermediate value. Cooling rates were combined from literature-reported11,20 ranges (2–200 °C/min) and CFRP drilling-process measurements19 (300–2700 °C/min), forming a two-factor orthogonal experiment (Table 1).

Mechanical parameter testing

Testing methodology

Considering the parameters in certain directions of CF/PEEK are difficult to obtain, the mechanical parameters of CF/PEEK are derived by obtaining fibre parameters (referring to literature) and resin parameters (experimental acquisition). Then, the mechanical parameters of CF/PEEK materials are measured to verify and revise the derived values. The process for obtaining the material parameters is as follows.

Step 1: PEEK tensile specimens were prepared according to ASTM D638-10 standard29 using a WL2030BA water-jet cutter. Specimens were placed in a customized stainless-steel mold and heat-treated under DSC-matched thermal conditions (Table 1), with three replicates.

Step 2: Elastic modulus and Poisson’s ratio of PEEK were experimentally determined and combined with literature-derived fiber properties to calculate CF/PEEK parameters.

Step 3: According to ASTM D638-10 standard, ASTM D3039/D3039M-08 standard30 and ASTM D5379-19 standard31, crystallinity and mechanical parameters of PEEK and CF/PEEK were evaluated under four processing conditions (Table 2). The total number of PEEK and CF/PEEK samples shall not be less than 111 and 48 respectively.

Cooling protocols

Control the cooling rate of the samples through different cooling strategies. Φ ≤ 200 °C/min: Oven-controlled cooling. 300 ≤ Φ ≤ 1800 °C/min: Cold-air/liquid nitrogen guns (3.5 MPa), which are controlled by adjusting the wind speed and flow rate and the mass flow rate of the fluid. Φ = 2700 °C/min: Direct liquid nitrogen immersion. Temperature profiles were monitored using infrared thermal imaging and K-type thermocouples. All samples were dried at 60 °C for 12 h pre-testing.

Equipment

The heat treatment equipment and the mechanical properties measurement were illustrated in Fig. 1. The samples were placed in a customized stainless-steel mold to prevent thermal deformation, and heat-treated in a HE-150 L-500 oven (Fig. 1a). The DSC test was performed using a modulation differential scanning calorimeter (TA-Q20). The Infiray-ATS600 infrared thermal imager and a high-precision K-type thermocouple are used to capture the changes of temperature during the rapid cooling process. The tensile tests were performed on an Intons 8032 tensile machine, and the shear tests were performed on a GDW-100 compression machine manufactured by Baoda Instruments. The DMYB1808 dynamic and static resistance strain gauge produced by DANMO Electric and the BMB120-5AA-P300-W resistance strain gauge produced by Chengdu Chuanke were adopted to test the mechanical parameters of PEEK (Fig. 1b). The mechanical parameter verification experiments utilized the 3D-DIC system produced by Correlation Solutions Inc. (CSI) to perform three-dimensional measurements of strain fields and displacement fields on the material’s surface (Fig. 1c).

Results and discussion

Non-isothermal crystallization and tensile behavior of PEEK

The crystallinity of PEEK during conventional cooling (Φ ≤ 200 °C/min) can be obtained by measuring its crystallization enthalpy (Fig. 2a–c). While during rapid cooling (Φ ≥ 300 °C/min) can be obtained by measuring its melting enthalpy and cold crystallization enthalpy (Fig. 2d). To simplify the process, we ignored the errors caused by different detection methods. The crystallinity (Xc) is calculated from Eqs. (1) and (2).

where ΔHf, ΔHm and ΔHc are the crystallisation enthalpy, melting enthalpy and cold crystallisation enthalpy, respectively. ΔHfo is the melting enthalpy of PEEK at 100% crystallinity, which is 130 J/g. wf is the weight fraction of fibers in the sample.

Based on the stress-strain curve in Fig. 3, the Tensile strength (σbm), Elastic modulus (Em) and Poisson’s ratio (vm) of PEEK under different non-isothermal processing parameters can be calculated, and the Shear modulus (Gm) can be derived from Eq. (3).

The Xc and mechanical parameters of PEEK under different non-isothermal processing parameters were calculated and the relevant values are listed in Table 3. Figure 2; Table 3 show that under the synergistic effect of T and Φ, the width of the crystallisation peak, Ts (the starting crystallization temperature) and Tp (the crystallisation peak temperature) of PEEK all change. Ts and Tp decrease significantly with an increase in Φ (towards the lower temperatures), and the width of the crystallisation peak increases with an increase in Φ, which is consistent with the conclusions of previous research. Moreover, the influence of T on Ts and Tp increases with an increase in Φ, which becomes clearer when Φ is 200 °C/min. As shown in Fig. 3, when PEEK crystallizes at a rapid cooling rate, a cold crystallization peak appears during the melting process, and the intensity of the cold crystallization peak increases continuously with Φ and T, while the melting peak decreases continuously with them. Similarly, as shown in Fig. 3 the mechanical parameters of PEEK vary with non-isothermal processing parameters, the variation trend of Em and Gm is consistent with that of Xc, while vm is opposite. In addition, σbm gradually decreases as Φ or T increases, and we believe that changes in crystallinity are responsible for these results. In general, the crystallinity and mechanical parameters data related to the cooling rate measured in this study roughly in line with the data distribution trend studied by Gao and Kim11.

In the process of CF/PEEK hole drilling, due to the heat source such as the blade is pulled out, therefore, the actual Φ of the material around the holes is generally in the rapid-cooling range. Qi et al.19 showed that the recrystallisation behaviour of matrix PEEK around the hole is considerably affected by Φ when cooling is too fast. This may be because when Φ is too high, the molten polymer crystallises at a large degree of undercooling. This causes a sharp decrease in the Gibbs free energy of the molecular chain, resulting in a crystal-arrangement motion that always lags behind Φ when the molecular chain in an amorphous region progresses towards an ordered-crystalline region. In addition, the larger Φ always forces the nucleation and growth rates of the crystal to increase, thereby shortening the crystallisation time. The acceleration of the crystallisation process renders many crystals unable to grow or form well after nucleation, ultimately leading to a decrease in Xc.

Compared to the rapid cooling during drilling, the cooling rate of PEEK and its composites during moulding or 3D printing is within the conventional cooling range owing to the presence of heat sources such as moulds (Φ ≤ 100 °C/min). From Table 3, we can predict that at the same T, the Ts, Tp, and Xc of the material surrounding the holes after drilling will be considerably lower than the values obtained during moulding or 3D printing. Notably, Xc is affected by both T and Φ.

In 3D printing, researchers tend to design the shape of a material using its fluid temperature, which is considerably higher than the melting point of the material. However, this experiment showed that as T increases, the crystallisation-peak curve gradually lags behind Φ, and Xc gradually decreases, especially when T is 400 °C. This is because the crystallisation behaviour of polymers is related to the density of their crystal nuclei before crystallisation. When PEEK reaches a temperature near the liquidus temperature (T = 400 °C), the internal structural thermal motion of the material intensifies, and the kinetic energy and motion amplitude of the molecular chain significantly increase. With increasing interchain distances and self-rotation, the intermolecular forces (van der Waals forces), electrostatic interactions, and π-π interaction with higher bond energy between chains gradually disappears, resulting in a highly disordered arrangement and the overly loose packing of molecular chains. In addition, the initial crystal melt is subjected to high-temperature impacts, resulting in almost no remaining tiny grains. That is, when T is 360 °C, PEEK has more nucleation sites during isothermal crystallisation, enabling both homogeneous and heterogeneous nucleation to occur simultaneously. Thus, the increase in nucleation rate ultimately improves the Xc value of the material.

Xc is closely related to the performance of materials, and an excessively high T can cause secondary damage, such as aging. Therefore, when heat treating materials, using a lower T is preferable to achieve the best performance.

Non-isothermal crystallisation kinetics

During drilling, moulding, and 3D printing polymers and its composites, selecting the optimal process parameters based on the non-isothermal crystallisation behaviour of the materials is necessary. To clarify the mechanism of T and Φ on the non-isothermal crystallisation of PEEK, this study uses the Avrami equation32 modified by Jeziorny33 and the equation proposed by Motz and Schultz20 to analyse the non-isothermal crystallisation kinetics of PEEK.

the relative crystallinity (Xt) of PEEK can be obtained by calculating the ratio between the heat-releasing peak area at time (t) in the DSC curve and the entire peak area at the time of completion of crystallisation. The Xt is calculated from Eq. (4).

where t0 is the onset crystallisation time, t is the measurement time, and dH/dt is the crystallisation heat-flow rate.

As shown in Fig. 4, the change rule of relative crystallinity over time is as follows: rapid change at the initial stage of crystallisation and a sudden decrease and slowing at the later stage. This indicates that nucleation occurs rapidly in the early stage of crystallisation, whereas growth slows at the later stage. Furthermore, the crystallisation process gradually accelerates as Φ increases, the crystallisation time and temperature also gradually decrease.

Avrami equation modified by Jeziorny

Jeziorny modified the Avrami model by correcting the isothermal crystallisation rate constant K for the cooling rate Φ and obtaining the non-isothermal crystallisation rate constant Kc, which can be calculated from Eqs. (5) and (6).

where, n is the Avrami index reflecting the dimensionality of the crystallisation process. The value of n is determined by the nucleation mechanism and growth mode of the crystals. K is the crystallisation rate constant; Kc is the non-isothermal crystallisation rate constant of the polymer.

Figure 5 shows the plots of lg[-ln(1-Xt)] versus lg t, and linear fitting is performed on the linear part of the initial-crystallisation stage. Similar to the results of Liu et al.34, it shows that the curves of other crystallisation stages deviate from the original path, except for the initial stage, which maintains a good linear relationship. This indicates that the modified Avrami equation is suitable only for describing the crystallisation behaviour of polymers in the initial stages (crystal nucleation and nucleation growth, but without contact and collision). However, as the crystallisation progresses, the size and quantity of the crystals gradually increase, the distance between the crystals gradually decreases, and the previously formed crystals begin to contact and collide with each other. This stage is considered as the secondary crystal growth stage, which is represented by a curve that begins to deviate from linearity in the modified Avrami equation curve diagram.

The crystallisation half-time (t1/2), the time taken to reach maximum crystallinity (tmax), and the crystallisation rate (G) can be calculated from Eqs. (7)-(9)34. The calculated values are listed in Table 4.

All the n1 values in Table 4 (the initial stage of crystallisation) are not integer values, manifesting the non-isothermal crystallization of PEEK exhibits time-dependent initial nucleation, and the nucleation mode of the main crystallisation process involves both homogeneous and heterogeneous nucleation. The growth mode of the crystal nuclei is no longer simply a blend of crystals with different dimensions and morphologies, and the changes in the nucleation mode and secondary crystallisation effects are more pronounced. For example, when Φ is 2 °C/min, the values of n1 are close to 3, indicating that a small amount of 3D spherical crystals have already appeared at the initial stage of crystallisation. Furthermore, except when Φ is 150 °C/min and 200 °C/min, the n2 values are greater than 3, indicating that most crystals develop into 3D spherical crystals during the later stages of crystallisation.

Table 4 shows that n1 decreases as T or Φ increase, indicating that the nucleation mode and crystal morphology of PEEK are closely related to these values. The influence of Φ is more significant. For example, when T is 360 °C, n1 decreases from 2.99 to 1.54. This shows that when Φ > 25 °C/min, the crystallisation process is dominated by homogeneous nucleation and supplemented by heterogeneous nucleation; the growth mode comprises 1D needle crystals and a small amount of 2D flake crystals. With an increase in Φ, the dominance of 1D needle crystals becomes increasingly evident. When Φ < 25 °C/min, the growth mode of the crystals changes significantly, with 1D needle crystals no longer dominating, and the number of 2D flake crystals increasing. Furthermore, as Φ gradually increases, the trend towards the development of 2D flake crystals into 3D spherical crystals increases.

From this, we can conclude that at the initial stage of non-isothermal crystallisation, as Φ increases, the nucleation mode of the main crystallisation process of PEEK changes accordingly (the proportion of heterogeneous nucleation gradually decreases), the growth mode of PEEK develops from complex and diverse crystals blending to 1D needle crystals, which is main reason why the Xc of PEEK gradually decreases as Φ increase.

Mo model

In the process of non-isothermal crystallisation, when the cooling rate of polymer is Φ, there is a certain relationship between time (t) and temperature (Tt). Ozawa35 modified the Avrami equation based on Evans’ theory, and obtained the Ozawa equation. Then, Motz and Schultz20 combined the Avrami equation with the Ozawa equation and proposed a model that is more suitable for studying non-isothermal crystallisation kinetics, which can be expressed as Eqs. (10)-(12).

where Tt is the temperature at time t. KT is the cooling factor at temperature Tt and m is the Ozawa index. F(T) is the cooling rate required for the polymer to reach a particular relative crystallinity within a unit of time, which can be expressed as F(T)=(KT/K)1/m. Additionally, α = n/m, where n is the Avrami index.

Table 5. was obtained by plotting lg Φ versus lg t, which showed that F(T) increases significantly with an increase in Xt. This may be attributed to the crystal-growth mode at the late stage, which begins to develop from 2D to 3D. This gradually reduces the distance between the spherulites and intensifies the contact between the crystals, making crystal growth more difficult. The crystallisation behaviour tends to saturate when the material reaches a high Xc, which further proves surpassing the currently reported optimal Xc (approximately 48%) is challenging.

In addition, for the entire non-isothermal crystallisation process, α is always between 1.291 and 1.546, it generally decreases with an increase in T, and changes slowly with Xt. This indicates that the proportion of heterogeneous nucleation is higher at lower T and indirectly proves that a lower T can cause a fraction of tiny crystallites to remain in the molten material, which enables simultaneous homogeneous and heterogeneous nucleation during the crystallisation process.

Non-isothermal crystallisation activation energy (ΔE)

Kissinger36 proposed that the non-isothermal crystallisation activation energy (ΔE) can be expressed as Eq. (13).

where Tp is the crystallisation peak temperature, R is the universal gas constant, and its value is approximately 8.314 J/(mol K).

By plotting ln(Φ/Tp2) against 1/Tp (Fig. 6), the ΔE of PEEK at different temperatures can be calculated. The values are 253.92 kJ mol− 1, 236.54 kJ mol− 1, 222.64 kJ mol− 1, which decreases as T increases, indicating that the nucleation process is greater than the crystal-growth process. Additionally, a higher T can facilitate non-isothermal crystallisation behaviour; however, it also induces many adverse factors in the crystallisation movement and crystal growth of the polymer. In contrast, a lower T provides a relatively good crystallisation environment for PEEK. Therefore, when processing semi-crystalline polymer and its composites, T should be controlled near the melting point of the materials, and auxiliary insulation measures should be used to control Φ within 10 °C/min.

Morphological analysis

Figure 7 shows some representative samples. Among these samples, the ones in Fig. 7a will be used to obtain the mechanical parameters through the DMYB1808 strain gauge, and the ones in Fig. 7b–d will be used to verify the mechanical parameters of the material through the 3D DIC system. In Fig. 7, PEEK and CF/PEEK can maintain good morphology after hot treatment under the protection of the mold. However, as T increases, the color of the PEEK material gradually deepens. Through tensile and shear tests, the fracture elongation of the samples gradually decreases with T and Φ, indicating that the elastic-plasticity of the material is gradually replaced by brittleness.

The micro-morphology of the specimens was observed by the RH2000 ultra-depth scanning microscope produced by HiROX. In Fig. 8, as Φ increases, the diameter and density of pores on the surface of the material gradually increase, and even layering phenomena appear. Increasing T not only causes overheating and aging of the material, but also increases the porosity and pore diameter inside the material, resulting in significant differences in the morphology of the fracture surface. The sample with a larger Φ has local cracks in the tensile direction, indicating that as Xc decreases, the bonding force inside the material becomes weaker, making it easier for cracks to occur and directly lead to fracture.

In Fig. 9, when Φ is small, the resin distribution on the surface of CF/PEEK is relatively uniform (Fig. 9a(1)). As Φ increases, the resin distribution on the surface gradually becoming uneven and bumpy (Fig. 9c(1)). When T is large, the internal resin bleeds out, resulting in local depressions (Fig. 9d(1)). The fracture morphology of the tensile test precisely proves that the internal structure of the material is consistent with the surface layer, which is characterized by smooth fracture Fig. 9a(2), decreased flatness Fig. 9b(2), fiber pull-out Fig. 9c(2), and uneven fracture due to the resin overflow and aging Fig. 9d(2).

Upon comparison, the fracture morphology of the shear test closely resembles that of the tensile test. Specifically, the fracture in Fig. 9a(3) is concentrated and flat, with uniform distribution of fiber and resin. However, in Fig. 9b(3), both the smoothness of the fracture and the uniformity of the fibre and resin distribution are decreased. In Fig. 9c(3), there are numerous and large fractures, exhibiting unevenness and significant detachment of fibres and resin. The fracture in Fig. 9d(3) is concentrated but uneven, with a very uneven distribution of fiber and resin, and obvious signs of aging.

Mathematical models for predicting crystallinity and mechanical properties

The prediction of the effects of molding/reprocessing for PEEK

Previous researchers18,19,37 have used linear or quadratic equations to establish correlation models between mechanical parameters and crystallinity, as well as between crystallinity and cooling rate. Comparisons show that the quadratic equation for the correlation between mechanical parameters and crystallinity obtained in this paper provides a better fit. However, when correlating mechanical parameters and crystallinity with the cooling rate using either a linear or a quadratic equation, the fitting degree is poor. By comparing and analyzing the data in this paper and the literature, it is found that linear-equation fitting is suitable when the cooling rate is small (Φ ≤ 30 °C/min), and quadratic-equation fitting is suitable when the cooling rate is large (30 °C/min ≤ Φ ≤ 500 °C/min). Since the cooling rate range in this paper is too large (1–2700 °C/min), neither the linear nor the quadratic equation is applicable any more, and the more appropriate fitting equation is the Log3P1 equation.

Based on Table 3, a mathematical model can be established to predict the mechanical properties of PEEK based on processing parameters by plotting Xc, Em, vm, Gm and σbm against Φ (Fig. 10a–e, Eq. (8)). Additionally, another mathematical model can be developed to predict the mechanical properties of PEEK based on crystallinity by plotting Em, vm, Gm and σbm against Xc, respectively (Fig. 10f, Eq. (9)). After fitting the curves, it is observed that the variations of Xc, Em, vm, Gm and σbm with Φ conform to the Log3P1 equation of the logarithm model, while the variations of Em, vm, Gm and σbm with Xc adhere to the univariate quadratic equation in the polynomial model. The R2 values of the fitting equations are close to 1, indicating that the fitting models have high accuracy.

Where a, b, and c are linear equations related to temperature, the values of them are list in Table 6.

Where the values of a, b, and c are list in Table 7.

As can be seen from Table 6, Xc and mechanical parameters are less affected by temperature, especially vm and Gm, which also show a very sluggish response to changes in Xc in Table 7. According to Eqs. (14) and (15) respectively, Xc, Em, vm, Gm and σbm of PEEK under different processing parameters and crystallinities can be calculated. According to the ASTM D638-10 standard, DSC experiments (Fig. 11a) and tensile tests (Fig. 11b) were conducted on PEEK specimens after hot treatment. Figure 11c shows the tensile fracture specimen of PEEK and its image presented in the 3D-DIC system. The comparison of experimental values and theoretical calculations is shown in Table 8. This verifies that the crystallinity and mechanical properties calculated by the mathematical model of processing parameters have certain reliability. At the same time, it also has high reliability to predict mechanical properties based on experimental values or theoretical calculations of crystallinity.

The melting curve of PEEK indicates that 360 °C is the critical temperature for its complete melting. When the temperature is higher than 400 °C, the crystallization behavior of PEEK no longer changes with the processing temperature27. Therefore, the temperature range of the fitting equation established in this paper is from 360 to 400 °C. When the cooling rate is 1 °C/min, the experimental values of the crystallinity and mechanical parameters are close to the theoretical values. When the cooling rate approaches 0 °C/min, the theoretical crystallinity is 46.2%, which is still lower than the value in the literature10 (about 48%). When the cooling rate is higher than 2700 °C/min, how the crystallinity and mechanical parameters of PEEK change with the cooling rate deserves further in-depth study in the future. Therefore, the cooling rate range applicable to Eqs. (14) and (15) should be less than 2700 °C/min, and the range of crystallinity is between the lowest experimental value (10.93%) and the highest theoretical value of 46.2%.

The prediction of the effects of molding/reprocessing for CF/PEEK

Combining the crystallinity and mechanical properties of PEEK under different processing parameters (Table 3), based on the fiber mechanical parameters in literature38 and the relationship between the mechanical properties of fiber-reinforced composites and the matrix phase and reinforcement phase (Eq. (16)38), the mechanical properties of CF/PEEK under different processing parameters can be calculated. According to the DSC melting curves of CF/PEEK under the four processing parameters shown in Fig. 13a, through calculation, the experimental values of the crystallinity of PEEK and CF/PEEK under four processing parameters are shown in Table 9. The average value of ζ is 1.07, so by setting Xc−CF/PEEK ≈1.07 * Xc−PEEK, the theoretical values of the crystallinity of CF/PEEK under the corresponding processing parameters can be obtained according to Table 3.

where Eij is elastic modulus (f represents fibre, m represents matrix, i and j represent different directions, i, j = l, 2, 3). Gij is shear elastic modulus (f represents fibre, m represents matrix). vij is Poisson’s ratio (f represents fibre, m represents matrix). vf is the fibre volume fraction in CF/PEEK.

By plotting the obtained parameters against Φ and Xc respectively and fitting the curves (Fig. 12), we can establish mathematical models based on processing parameters and crystallinity for CF/PEEK (Eqs. (17) and (18)). Specifically, the variations of Xc, E, v, G, σb and Shear Strength (τ) with Φ follow the Log3P1 equation of the logarithm model (Fig. 12a–d), while the changes of E, v, G, σb and τ with Xc conform to the quadratic equation of the polynomial model (Fig. 12e–f). The R² values of the fitted equations are very close to 1, indicating a high accuracy for mathematical prediction models.

Where a, b, and c are linear equations related to temperature, the values are list in Table 10.

Where i and j represent different directions, i, j = 1, 2, 3. Eij is elastic modulus, Gij is shear elastic modulus, Vij is Poisson’s ratio, σbij is tensile strength, τij is shear strength. The values of a, b, and c are list in Table 11.

Similarly to Table 7, the Vij and Gij in Table 11 show the smallest variation with changes in crystallinity. Tensile tests and shear tests were conducted on CF/PEEK specimens with various processing parameters in both the longitudinal (0°) and transverse (90°) directions, following the standards specified in ASTM D3039/D3039M-08 and ASTM D5379-19 (Fig. 13b–d). Figure 13e and f respectively shows the tensile fracture and shear fracture images of the CF/PEEK sample presented in the 3D-DIC system, as well as the corresponding physical objects. A detailed comparison between the experimental values and theoretical calculations is presented in Table 12.

The DSC curve (a) of CF/PEEK, tensile stress-strain curve (b, c) and shear test curve (d) in the longitudinal (0°) and transverse (90°) directions, the tensile fracture (e) and shear fracture (f) images of the CF/PEEK sample presented in the 3D-DIC system, as well as the corresponding physical objects.

Upon validation of Table 12, we found that it is feasible to approximate the crystallinity of the composite and resin as Xc−CF/PEEK ≈ 1.07 * Xc−PEEK. Overall, the error of all theoretical calculated values falls within 11.03%, indicating that the mathematical models possess high credibility. In addition, we also found that the mechanical properties of CF/PEEK predicted based on the crystallinity of PEEK are very close to those predicted based on the crystallinity of CF/PEEK. Therefore, to simplify the process, the crystallinity of the resin can be directly used to calculate the mechanical properties of the composites.

Conclusions

In this study, the crystallisation of PEEK at different processing parameters (T and Φ) was measured using DSC. The influence of various parameters on the crystallisation behaviour of PEEK was systematically analysed, and the optimal processing parameters were obtained. Mathematical models have been established to predict the crystallinity and mechanical properties of PEEK and CF/PEEK based on processing parameters, as well as to predict mechanical properties based on crystallinity. The accuracy of these models has been validated. The following conclusions are drawn:

-

1.

The non-isothermal crystallisation kinetics of PEEK were revealed. The non-isothermal crystallisation behaviours of PEEK were analysed using the Avrami model modified by Jeziorny and Mo model. The results show that there is a time-dependent initial nucleation in the crystallisation processes, with both homogeneous and heterogeneous nucleation occurring simultaneously. The growth pattern in the early stages of crystallization is complex, diverse, and variable. The proportion of heterogeneous nucleation, crystal-growth mode, and the number of multi-dimensional crystals are related to the processing parameters. In addition, a secondary crystallisation effect occurs during the late stages of crystallisation.

-

2.

The influence of the processing parameters on the crystallinity and mechanical properties of PEEK and CF/PEEK were clarified. (1) Overall, Xc, E, G, σb and τ decreases as T increases, while the v is opposite. Although a higher T can reduce ΔE, making crystallization more likely, it also aggravated the thermal motion of PEEK molecular chains, causing the intermolecular force (Van der Waals force), electrostatic interaction, and π-π force with higher interchain bond energy to gradually disappear. These hinderers the transition of the amorphous molecular chain in the amorphous region into an orderly crystal region, reducing the number of nucleation sites. Moreover, the growth of the crystal is insufficient at the late stage. However, a lower T enables the PEEK molecular chain arrangement to remain relatively ordered. Due to the small number of residual crystal particles in the melt, both homogeneous and heterogeneous nucleation occur simultaneously, resulting in increased nucleation and crystal growth rates. (2) Xc, E, G, σb and τ decreases as Φ increases, while the v is opposite and the decreasing rates diminish gradually. Excessive Φ makes the movement of the molecular chain lag behind the cooling rate as it progresses towards an ordered crystalline region, which results in a shortened crystallisation time and hinders nucleation and crystal growth. Therefore, the T used in the traditional process (approximately 390 °C or even higher) should be broken and recommended to be marginally higher than the melting point of the material, resulting in better results and energy-saving. Auxiliary thermal-insulation measures should be used to reduce Φ, controlled within 10 °C/min, during the non-isothermal processing.

-

3.

The mathematical models for predicting the crystallinity and mechanical properties of PEEK and CF/PEEK were established. The mathematical models for predicting crystallinity and mechanical properties based on processing parameters were the Log3P1 equation of the logarithmic model, while the mathematical models for predicting mechanical properties based on crystallinity conform to the quadratic equation of the polynomial model. The DSC test, tensile test and shear test verified the accuracy of these mathematical models, the error of all theoretical calculated values falls within 11.03%. Additionally, there is a multiple relationship between the crystallinity of the composite material and that of the resin (approximately 1.07 times). This provides valuable references and recommendations for selecting appropriate process parameters for PEEK, CF/PEEK, and other composites.

Data availability

No datasets were generated or analysed during the current study.

Abbreviations

- T :

-

Processing temperature

- ΔH f :

-

Crystallisation enthalpy

- ΔH c :

-

Cold crystallisation enthalpy

- ΔH m :

-

Melting enthalpy

- ΔH fo :

-

Melting enthalpy of PEEK at 100% crystallinity

- Φ :

-

Cooling rate

- w f :

-

Weight fraction of fibers

- X c :

-

Crystallinity

- T s :

-

Starting crystallization temperature

- σ bm :

-

Tensile strength

- T p :

-

Crystallisation peak temperature

- E m :

-

Elastic modulus

- t 0 :

-

Onset crystallisation time

- v m :

-

Poisson’s ratio

- n 1 :

-

Avrami index (initial stage)

- G m :

-

Shear modulus

- n 2 :

-

Avrami index (later stage)

- X t :

-

Relative crystallinity

- K :

-

Crystallisation rate constant

- t :

-

Measurement time

- K c :

-

Non-isothermal crystallisation rate constant

- n :

-

Avrami index

- t 1/2 :

-

Crystallisation half-time

- G :

-

Crystallisation rate

- t max :

-

Time to reach maximum crystallinity

- T t :

-

Temperature at time t

- K T :

-

Cooling factor at temperature Tt

- m :

-

Ozawa index

- ΔE :

-

Non-isothermal crystallisation activation energy

- a :

-

Ratio of n to m

- R :

-

Universal gas constant

- Ζ:

-

Multiple relationship between crystallinity of composites and resins

- F(T):

-

Cooling rate required for the polymer to reach a particular relative crystallinity within a unit of time

References

Villar, M., Garnier, C. & Chabert, F. In-situ infrared thermography measurements to master transmission laser welding process parameters of PEKK. Opt. Laser Eng. 106, 94–104 (2018).

Zhang, Y. et al. Hole Morphology and Keyhole Evolution during Single Pulse Laser Drilling on Polyether-Ether-Ketone (PEEK). Materials. 15 (2022).

Liu, T., Liu, X. & Feng, P. A comprehensive review on mechanical properties of pultruded FRP composites subjected to long-term environmental effects. Compos. Part. B-Eng. 191, 107958 (2020).

Hassan, E. et al. Enhancing CF/PEEK composites by CF decoration with polyimide and loosely-packed CNT arrays. Compos. Part. A-Appl S. 127, 105613 (2019).

Hassan, E. et al. Synergistic effect of hydrogen bonding and π-π stacking in interface of CF/ PEEK composites. Compos. Part. B-Eng. 171, 70–77 (2019).

Zhu, S. et al. Enhanced interfacial interactions by PEEK-grafting and coupling of acylated CNT for GF/PEEK composites. Compos. Commun. 18, 43–48 (2020).

Gao, X. et al. Higher mechanical performances of CF/PEEK composite laminates via reducing interlayer porosity based on the affinity of functional s-PEEK. Polym. Compos. 40 (2019).

Hou, G. et al. Analysis of exit-ply temperature characteristics and their effects on occurrence of exit-ply damages during UD CFRP drilling. Compos. Struct. 231, 111456 (2019).

Ge, J. et al. Temperature field evolution and thermal-mechanical interaction induced damage in drilling of thermoplastic CF/PEKK-A comparative study with thermoset CF/epoxy. J. Manuf. Process. 88, 167–183 (2023).

Rae, P., Brown, E. & Orler, E. The mechanical properties of poly(ether-ether-ketone) (PEEK) with emphasis on the large compressive strain response. Polymer 48, 598–615 (2007).

Gao, S. & Kim, J. Cooling rate influences in carbon Fibre/PEEK composites. Part 1. Crystallinity and interface adhesion. Compos. Part. A-Appl S. 31, 517–530 (2000).

Mclauchlin, A., Ghita, O. & Savage, L. Studies on the reprocessability of poly(ether ether ketone) (PEEK). J. Mater. Process. Tech. 214, 75–80 (2014).

Xu, Z., Zou, B., Ding, S., Zhuang, Y. & Wang, X. Study on the hot isostatic pressing post-treatment of FDM-3D printed continuous carbon fiber reinforced composites. J. Manuf. Process. 104, 205–217 (2023).

Yang, C. et al. Influence of thermal processing conditions in 3D printing on the crystallinity and mechanical properties of PEEK material. J. Mater. Process. Tech. 248, 1–7 (2017).

Wang, P., Zou, B., Xiao, H., Ding, S. & Huang, C. Effects of printing parameters of fused deposition modeling on mechanical properties, surface quality, and microstructure of PEEK. J. Mater. Process. Tech. 271, 62–74 (2019).

Li, J. et al. Investigations on 355 Nm picosecond laser machining of carbon fiber reinforced polymer composites. J. Manuf. Process. 101, 854–866 (2023).

Ahmad, F., Manral, A. & Bajpai, P. Mach. Thermoplastic Compos. 107–123 (2019).

Yao, C., Qi, Z., Chen, W. & Zhang, C. Experimental study on CF/PEEK thermoplastic fastener: effects of fastener matrix crystallinity and fibre content on the strength of single-lap joint. Compos. Part. B-Eng. 213, 108737 (2021).

Qi, Z., Xu, Z., Li, F. & Yao, C. Effect of cooling strategy on the bearing capacity of CF/PEEK composite hole. Compos. Part. B-Eng. 250, 110406 (2023).

Motz, H. & Schultz, J. The solidification of PEEK. Part II: kinetics. J. Thermoplast Compos. 2, 267–280 (1989).

Cherri, A. et al. Thermal and crystallization properties of the alternated Tere/Iso PEKK copolymer: importance in High-Temperature laser sintering. Acs Appl. Polym. Mater. 4, 2806–2818 (2022).

Gao, S. & Kim, J. Cooling rate influences in carbon Fibre/PEEK composites. Part II: interlaminar fracture toughness. Compos. Part. A-Appl S. 32, 763–774 (2001).

Gao, S. & Kim, J. Cooling rate influences in carbon fibre/PEEK composites.Part III: impact damage performance. Compos Part A-Appl S. 32, 775–785 (2001).

Jonas, A. & Legras, R. Thermal-stability and crystallization of Poly(aryl ether ether Ketone). Polymer 32, 2691–2706 (1991).

Lee, Y. & Porter, R. Crystallization of poly(etheretherketone) (PEEK) in carbon fiber composites. Polym. Eng. Sci. 26, 633–639 (2010).

Regis, M., Zanetti, M., Pressacco, M. & Bracco, P. Opposite role of different carbon fiber reinforcements on the non-isothermal crystallization behavior of poly(etheretherketone). Mater. Chem. Phys. 179, 223–231 (2016).

Lee, Y. & Porter, R. Effects of thermal history on crystallization of poly(ether ether ketone) (PEEK). Macromolecules 21, 2770–2776 (1988).

Yuan, Q., Bateman, S. & Friedrich, K. Thermal and mechanical properties of PAN and pitch-based carbon fiber reinforced PEEK composites. J. Thermoplast Compos. 21, 323–336 (2008).

ASTM D638-10. Standard Test Method for Tensile Properties of PlasticsVol.0801 (ASTM International, 2010).

ASTM D3039/D3039M-08. Standard test method for tensile properties of polymermatrix composite materials. ASTM International, Composite Materials Vol.15.03. (2008).

ASTM D5379/D5379M-19. Standard test method for shear properties of composite materials by the V-Notched beam method. ASTM International, Composite Materials Vol.15.03. (2019).

Avrami, M. Kinetics of phase change. I general theory. J. Chem. Phys. 7, 1103–1112 (1939).

Jeziorny, A. Parameters characterizing the kinetics of the non-isothermal crystallization of poly(ethylene terephthalate) determined by D.s.c. Polymer 19, 1142–1144 (1978).

Liu, M. et al. Melting behaviors, isothermal and non-isothermal crystallization kinetics of nylon 1212. Polymer 44, 2537–2545 (2003).

Ozawa, T. Kinetics of non-isothermal crystallization. Polymer 12, 150–158 (1971).

Kissinger, H. Variation of peak temperature with heating rate in differential thermal analysis. J. Res. NIST. 57, 217–221 (1956).

Talbott, M., Springer, G. & Berglund, L. The effects of crystallinity on the mechanical properties of PEEK polymer and graphite fiber reinforced PEEK. J. Compos. Mater. 21, 1056–1081 (1987).

Qi, Z., Liu, Y. & Chen, W. An approach to predict the mechanical properties of CFRP based on cross-scale simulation. Compos. Struct. 210, 339–347 (2019).

Acknowledgements

The authors acknowledges the financial support from the National Natural Science Foundation of China (52275434), the National Commercial Aircraft Manufacturing Engineering Technology Research Center Innovation Foundation (COMAC-SFGS-2024-845), the Engineering Projects of Shandong Province (2023TSGC0303), and the Science and Technology Projects of Changzhou (CE20230019).

Funding

The National Natural Science Foundation of China (52275434), the National Commercial Aircraft Manufacturing Engineering Technology Research Center Innovation Foundation (COMAC-SFGS-2024-845), the Engineering Projects of Shandong Province (2023TSGC0303), and the Science and Technology Projects of Changzhou (CE20230019).

Author information

Authors and Affiliations

Contributions

Pingping Xiong: Conceptualization, Investigation, Formal analysis, Methodology, Funding acquisition, Writing-original draft. Yangwei Zhou: Investigation, Methodology, Project administration, Data curation, Writing-review and editing. Laishui Zhou: Supervision. Zhenchao Qi: Software, Supervision, Validation, Visualization, Writing-review and editing.

Corresponding author

Ethics declarations

Competing interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Xiong, P., Zhou, Y., Zhou, L. et al. The prediction of the effects of non-isothermal molding/reprocessing on the crystallinity and mechanical properties of PEEK and CF/PEEK. Sci Rep 15, 16370 (2025). https://doi.org/10.1038/s41598-025-01018-x

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-01018-x