Abstract

Friction Stir Welding (FSW), a solid-state welding process, is used to weld AA 1100 alloy plates together, varying weld parameters such as spindle speed, feed rate, and axial load. The Taguchi L27 orthogonal array is employed to study the effects of multiple factors with minimal test runs. Tensile tests are conducted on welded samples to determine the time of failure. Using the Signal to Noise (S/N) Ratio to maximise the tensile strength, the influencing parameters and their effect are determined. Weibull analysis is used to calculate weld reliability. Soft computing techniques, such as Adaptive Neuro-Fuzzy Inference Systems (ANFIS) and Artificial Neural Networks (ANN), have been developed to predict weld reliability based on parameters. The ANFIS model demonstrates superior performance, with an average percentage error of 4.61% compared to 19.95% for ANN and a Root Mean Square Error (RMSE) of 0.002 versus 0.008 for ANN. Optimal FSW parameters for maximising joint reliability are 1200 rpm spindle speed, 18 mm/min feed rate, and 7 kN axial load, resulting in a predicted reliability of 0.87. The study highlights the potential of ANFIS as an effective tool for predicting and optimising FSW joint reliability in AA 1100 aluminium alloys.

Similar content being viewed by others

Introduction

Friction Stir Welding (FSW) is one of the most innovative and revolutionary solid-state joining processes, patented in 1991 by the UK-based Welding Institute (TWI). The method transformed the welding of metals, especially those considered “difficult-to-weld,” such as alloys of aluminium, magnesium and dissimilar materials where the weldment does not melt at the weld. Since its inception, the automotive, aerospace, maritime, and even railway industries have utilised FSW extensively. FSW focuses on energy efficiency, environmental safety, and producing high-quality welds1,2,3. FSW stands out from the traditional fusion welding techniques as it does not touch the melting point of the processed materials, reducing problems such as porosity, brittleness, and cracking that arise in the traditional methods4. As a result, FSW has received much research attention, with ongoing efforts to optimise process parameters and evaluate its versatility for use in various alloys and material systems. The literature review deeply delves into the various advancements in FSW over time, including optimising welding parameters, using advanced computational tools, and escalating challenges. Further, the gaps in the current research landscape and potential methods to enhance efficiency and improve the application of FSW processes are identified. These are achieved through the following research questions.

RQ1

What parameters of FSW can maximise reliability in the AA 1100 aluminium alloy plate?

RQ2

How is the weld reliability of Adaptive Neuro-Fuzzy Inference Systems (ANFIS) compared with that of Artificial Neural Networks (ANN)?

These questions have enabled us to adopt multiple techniques to determine the effective tool for predicting and optimising FSW joint reliability in AA 1100 aluminium alloys. The remainder of the paper is organised as follows: Section two explains the various dimensions of relevant literature explored, followed by the gap identified. It is followed by the experimental analysis section, which defines the design, process settings, and various tools and analyses employed to test the performance and optimisation. The effects of Process Parameters on the Performance of AA 1100 FSW Joints are presented in section four. It is followed by determining the reliability using various techniques in section five. Section six explains the contribution of the study to literature and practice. Section seven summarises the study and presents the limitations and scope for future research. The next section presents an exhaustive review of various themes of literature to identify the explored areas and potential research gaps that could be bridged to improve the performance of various techniques employed in predicting the weld reliability of FSW in AA 1100 aluminium alloys.

Friction stir welding process

The FSW process uses a non-consumable rotating tool that travels along a contact line between two metals to soften an alloying material through frictional heat. At the weld interface, this softened alloying material allows for plastic deformation and mechanical mixing of the two metals. The final bond’s mechanical properties are high strength and excellent, making FSW an attractive choice for many industries that require lightweight yet strong components. FSW’s growing attractiveness stems primarily from its capability to weld materials that are difficult to join, such as aluminium alloys and other non-ferrous metals. FSW’s ability to preserve original material properties without developing large heat-affected zones (HAZ) and defects has made it popular5. The tool movement and material flow of stages involved in welding are shown in Fig. 16.

Schematic representation of the FSW process6.

'

Parametric study in friction stir welding

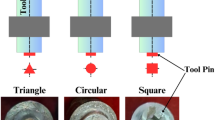

The FSW process produces weld quality dependent on critical parameters like speed, welding speed, axial force, tool geometry, and tilt angle7. The effects are discussed below to achieve defect-free, high-quality joints. FSW can help improve the material mechanics of Fine-grained AA1050 aluminium alloys. Optimising rotational and welding speed for a high-quality weld can enhance strength and ductility8. It signifies the importance of process parameters in determining the weld quality. Studies have emphasised attaining the desired accuracy for tool rotation and axial force to minimise the entry of defects such as voids and cracks9,10,11. FSW of AA6061 aluminium alloy in annealed and T6 conditions can fetch superior welds in high-strength aerospace alloys by optimising rotational speed, welding speed, and axial force12. Interaction of these parameters is essential for defect-free welds in materials and is difficult to join via conventional methods13. Tool designs and profiles also dramatically influence the welds’ mechanical properties, microstructure, hardness and structural strengths14.

Parametric optimisation techniques in friction stir welding process

Understanding the capabilities of the FSW process, researchers became interested in using various optimisation techniques to achieve quality welds and enhance process efficiency. Comparison of different methods such as Probability Weighted Moments (PWMs), Maximum Likelihood Methods (MLMs), Method of Moments (MoM), and Least Square Method (LSM) for estimating the parameters of the Weibull distribution proved the MLM to be the most accurate one15. The mutual association between the rotational speed and welding speed and their role in determining the weld quality can be understood by Taguchi-based grey relational analysis to multi-objective optimisations and similar soft computing techniques16. Mathematical modelling techniques expose the strengths and limitations of the various parameters and process settings17. Fuzzy logic improves efficiency and decision-making18, and fuzzy Taguchi helps optimise parameters to attain high-quality welds19. Studies have also focused on summarising the various strategies used to optimise the welding processes to lay a foundation for prospects20.

Meanwhile, optimising FSW parameters for dissimilar materials remains a challenge. Isa et al.21 reviewed recent improvements in the FSW of dissimilar metals, which included aluminium and copper. The research indicated the need for further investigation to optimise the process parameters and application of various techniques. Several works have been performed to improve the welding process for dissimilar materials owing to their practical significance. Double-side friction stirs Z shape butt-lap welding (DS-FSZW) improved FSW’s joint quality and reliability in Ti/Al dissimilar joints22. Integration of the Response Surface Method (RSM) and a Teaching-Learning-Based Optimisation (TLBO) algorithm enhanced reliability in predicting the weld of dissimilar Magnesium alloys, leading to better mechanical properties and weld quality23. Dialami et al.24 developed an advanced friction model of FSW by considering non-uniform pressure to improve the simulation of temperature, forces, and torque, with experimental analysis for validation. It was revealed that optimising the environmental parameters is a key to achieving better prediction and welds. Toorajipour et al.25 proposed a multi-objective dragonfly algorithm optimised toward the parameters of FSW. Despite the proven potential of the dragonfly algorithm, bio-inspired algorithms remain a less explored area in enhancing the FSW process.

Application of artificial intelligence techniques in FSW

Recent advances in soft computing and Artificial Intelligence (AI) have opened up new avenues for optimising FSW processes. We applied soft computing models like fuzzy logic and ANN to predict weld quality and optimise FSW processes. Considering the explosive growth in the application of AI and ML, Kumar et al.26 conducted an extensive discussion on their applications in FSW operations. Using the framework based on the structure of ANN, the researchers could predict the effect of heat generation on the mechanical properties of the materials welded under real-time process monitoring with AI. Okuyucu et al.27 demonstrated that ANNs can effectively correlate FSW welding parameters such as weld speed and tool rotation speed with properties like tensile strength, yield strength, elongation, and hardness of the weld metal and HAZ. These models can describe weld characteristics using real-time data. These advancements showcase the increasing intelligence of the welding systems in handling dynamic conditions. However, these AI models must be capable of working under challenging conditions and constraints to ensure the production of promising joints for real-time application with long-term durability28. The ANFIS demonstrates successful applications for modelling and optimising performance in FSW processes. Research demonstrates that ANFIS systems combined with Genetic Algorithm (GA) and Particle Swarm Optimization (PSO) or Harris Hawks Optimization (HHO) produce reliable Ultimate Tensile Strength (UTS) predictions for FSW processes when operating with welding speed, tool rotational velocity, and axial force parameters29,30. Analysis of FSW joint properties by ANFIS models produces better results than traditional RSM, according to Shehabeldeen et al.31. The Taguchi method establishes optimal FSW parameters, and ANFIS applications achieve advanced accuracy in experimental result predictions32. Simulation-based research demonstrates how ANFIS modelling supports FSW process optimisation, which can lead to automated operations and enhanced intermetallic bonding in multiple industrial applications.

The fatigue behaviour of friction stir butt-welded aluminium alloys has been, and design curves have been analysed to avoid fatigue in real-life applications33. Optimum conditions have been determined across diverse areas of FSW: mathematical techniques in AA8011-6062 alloys34, tribological properties of Cu–Ni–Sn alloys35, soft computing techniques for cutting tools36, fuzzy logic-based software reliability quantification framework to test the robustness of the software37, AI in manufacturing and welding operations38, etc. The study on friction stir-welded copper canisters of nuclear waste containment by Cederqvist and Öberg39 holds enormous importance for the long-term reliability of FSW joints. There is an overwhelming need to investigate the functioning of the FSW joints under changing environmental conditions, particularly in critical applications like aerospace and nuclear energy. Optimising FSW for dissimilar materials will always be an active challenge and requires further development of advanced tool designs and process parameters. Lastly, establishing consistent quality and reliability of FSW joints in industrial applications requires integrating AI-based real-time control systems and developing advanced temperature monitoring techniques. These discoveries reveal that much-unexplored territory remains despite significant advancements in FSW. The investigators will continue to improve the FSW process and expand its application to a wide range of industries, such as aerospace and automotive, reaching out to even more industrial companies.

In this work, ANN and ANFIS methods are utilised to predict the reliability of FSW joints. ANN demonstrates distinguished performance in analysing unclear patterns via an automated learning process, which works well with extensive dataset applications. ANFIS combines neural network learning functions with fuzzy logical reasoning to process complex parameter interactions while improving its ability to address uncertainties in data. The order-based design delivers improved interpretability among the system’s structural elements. Evidently, the prediction reliability depends on several aspects of the FSW process. The results of the studies confirm the necessity of utilising the capabilities of various techniques and considering the holistic optimisation of FSW. Integrating AI algorithms and machine learning into process monitoring would imply real-time feedback and adaptability to the welding process. Table 1 shows the sources summary, highlighting the research question’s relevance, contributions, and insights and identifying gaps in the literature.

Research gaps

FSW, a newly developed metallic joining process, offers several advantages over fusion welding processes. In recent years, much work has been done to improve FSW parameters and weld quality concerning high-strength material applications, particularly aluminium alloys. Despite the significant advancements in FSW process optimisation and weld quality enhancement, some gaps still require attention. The most significant gap remains in integrating AI and advanced computational models with real-time process control. ANN and fuzzy logic models have produced promising results for weld quality prediction, but their industrial implementation is still in its infancy. Advanced research is demanded to guarantee the scalability and efficient operation of these models in dynamic, real-world environments. Another area of research interest is the long-term reliability of FSW joints, especially in harsh environmental conditions.

Materials and methods

Materials

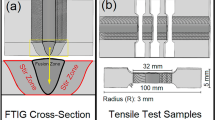

The FSW is performed on aluminium alloy of AA 1100 plates with a 100 mm × 100 mm × 3 mm dimension. Specimens were machined to the required dimensions through a wire Electric Discharge Machining process. The chemical composition of the aluminium AA 1100 is determined through an Optical Emission Spectrometer; the summary is shown in Table 2. The yield strength of the alloy varies from 34 to 115 MPa, ultimate tensile strength varies from 90 to 165 MPa and hardness from 23 to 44 HB, depending on the temper.

Methodology

The study focussed on the FSW of AA 1100 aluminium alloy plates. An experiment design is generated using the Taguchi L27 orthogonal array, with spindle speed, feed rate, and axial load as the welding parameters. The FSW process is performed by varying these parameters. Tensile tests are conducted to measure the time to failure for each welded sample. The results are then analysed using Weibull distribution to estimate reliability. Soft computing models, including ANN and ANFIS, are developed to predict reliability. The models are trained, and their performance is compared, followed by optimisation of the FSW parameters and validation of the results. The methodology followed in the current study is presented in Fig. 2.

The most influencing FSW parameters based on the literature chosen in this study are spindle speed (rpm), feed rate (mm/min) and axial load (kN). In FSW, selecting appropriate process parameters is important for optimising weld quality and efficient operation. The factors, along with their respective levels, of spindle speed, feed rate, and axial load are chosen with such care as to produce a balance between the generation of heat, material flow, tool durability, and prevention of defects. The spindle speed, ranging between 1100 and 1300 RPM, is necessary to ensure frictional heat generated from the rotary tool that should plasticise the material. It also ensures enough heat input without overheating and over-the-tool wear. Feed rates, set at between 15 and 21 mm/min, also control the traverse speed of the tool. It provides a proper mix of the material and prevents defects like pores or inadequate penetration due to maintaining a balance between the heat generated and the movement speed. Lastly, axial load, which ranges from 5 to 9 kN, gives sufficient downward pressure for material consolidation without excessive forces that would cause damage to the tool or workpiece. These parameters match the standard industrial requirements for FSW processes and have been devised to achieve broad applicability to various materials, including aluminium alloys and mild steel, while reducing the risks of process failure such as flash, voids, or incomplete welds. The Taguchi method is utilised for designing experiments to explore the influence of different parameters on the average and variability of a process performance indicator, which determines the effectiveness of the process. Taguchi method involves reducing process variation through robust Design of Experiments (DoE)16.

Optimisation and prediction of FSW joints are carried out using the Taguchi approach, ANN, and ANFIS. The integrated approach provides a structured methodology to design experiments, optimise parameters, and predict modelling for reliable welds with performance. The Taguchi method represents a commonly applied optimisation method that optimises product quality and process execution through noise variability reduction. Through robust design methodology, a system designs itself to ignore external forces while maintaining peak operational effectiveness. Taguchi method’s experimental design performs efficient factor exploration by conducting minimum experiments through orthogonal arrays. Central to this approach lies the signal-to-noise ratio that enables the selection of the optimal parameters by using the larger-is-better approach for maximum response outcomes, including tensile strength. The Signal to Noise (S/N) ratio is calculated using Eq. (1):

where \(y_{i}\) represents the observed values, and n denotes the number of experiments. A part of this approach evaluates process parameter significance and their interaction effects through Analysis of Variance (ANOVA). The logarithmic structure of S/N ratios shows that process enhancement requires minimised variability and maximised performance output. Higher performance outcomes are more efficiently achieved when using the Taguchi method in scenarios that demand strong increments of efficiency or strength. The Taguchi approach maximises the S/N ratio to find optimal FSW parameters that increase weld reliability. However, the Taguchi approach does not consider the complex non-linear relationship between input variables and the output weld quality, although it provides an efficient means of optimising process parameters.

The ANN approach is presented to model and predict FSW performance using a machine learning approach to overcome this limitation. ANN draws inspiration from the brain’s anatomy with layers of neurons connected and capable of learning complex inter-relations between the input parameters such as spindle speed, feed rate, and axial load, and the output response like tensile strength and reliability. The basic operation in an ANN is a combination of weighted transformations with activation functions, represented by Eq. (2):

where \(w_{i} , x_{i} , b\) and \(f\) stand for the weights, input variables, bias, and activation function, respectively. The ANN model will be trained using backpropagation to adjust its weights for minimum prediction error. Although ANN can capture non-linear relationships, it does not possess interpretability. It suffers from low datasets, which makes it difficult to generate insights on the influence of the individual parameters of FSW.

The ANFIS is integrated as a hybrid approach, which combines the advantages of ANN and fuzzy logic to overcome these shortcomings. ANFIS uses fuzzy if–then rules to model uncertain and imprecise relationships, thus better allowing for interpretability while exploiting the learning capability of ANN. A standard ANFIS system consists of a fuzzy layer that gives input membership functions, a rule layer that applies fuzzy logic rules to the inputs, and an output layer that provides predictions based on a linear function. The process of fuzzy inference does follow the Sugeno-type model wherein the rule is expressed by Eq. (3):

where \(p\), \(q\), and \(r\) are parameters adjusted during training. The final output is then computed by Eq. (4):

where \(w_{i}\) represents for the rule activation strength. Hybrid learning is implemented in the training of the ANFIS model, using the gradient descent combined with the least squares method to adjust the parameters step by step. It makes ANFIS powerful in modelling complicated non-linear interactions of FSW parameters while still being interpretable from its rule-based structure. This study systematically optimises, models, and predicts the reliability of FSW joints by integrating the Taguchi approach, ANN, and ANFIS. Taguchi method introduces a structured experimental design and establishes optimal welding parameters, while ANN enhances prediction accuracy by learning complex relationships. ANFIS further refines these predictions through fuzzy logic for better reliability and interpretability. This multi-method approach ensures that FSW process optimisation is statistically robust and computationally efficient to enhance joint performance and reliability.

The levels of spindle speed chosen in this study are 1100 rpm, 1200 rpm and 1300 rpm. For feed rates, 15 mm/min, 18 mm/min and 21 mm/min and an axial load of 5 kN, 7 kN and 9 kN are considered for the current study as detailed in Table 3. The design of experiments was generated using Taguchi L27 orthogonal array with the three levels of three welding parameters as discussed above.

The FSW setup is shown in Fig. 3. The machine was developed by modifying a milling machine, and load is applied through the hydraulic circuits. The FSW fixture setup includes a clamping system that securely holds the aluminium plates during welding. Considering the applied loads and heat during welding, the fixture does not allow the workpieces to deform or warp. In addition, the fixture has adjustable clamps and accommodating plates of all sizes for uniform contact between the tool and workpiece. The FSW tool consists of a shoulder and a probe and is made from hardened steel to accommodate the high forces of the process. An L27 orthogonal array-based design of the experiment plan was developed based on the weld parameters and their levels.

Experimental analysis of FSW

The macroscopic image of the friction weld sample is presented in Fig. 4. The tensile specimens are prepared based on ASTM E8 standard. The tensile specimen with dimension s and samples are machined out through the wire EDM process from the welded sample, as depicted in Figs. 5 and 6.

Results and discussions

The tensile strength and time to failure are recorded for every specimen. The time to failure is the response to performing reliability analysis40. The statistical distribution chosen for the reliability analysis in this study is Weibull. The obtained results are outlined in Table 4.

Effects of process parameters on the performance of AA 1100 FSW joints

The effects of spindle speed, feed rate, and axial load on the performance of FSW joints in AA 1100 aluminium alloy exhibit complex, non-linear interactions. Lower spindle speeds, specifically 1100 rpm, consistently produced superior results, achieving tensile strengths up to 61.60 MPa and failure times of 162.08 s under optimal conditions. The spindle speed of 1200 rpm generally underachieved, while 1300 rpm was sometimes similar to 1100 rpm. The interaction between feed rate and spindle speed was very strong, with 18 mm/min always producing the highest tensile strengths and longest failure times, especially at 1100 rpm and 1300 rpm. The most significant 21 mm/min feed rate also produced exceptional results in certain configurations. Axial load was inconsistent, where the lower load of 5 kN often surpassed higher loads, especially at spindle speeds of 1100 rpm and 1300 rpm. The best parameter combination that yielded the highest tensile strength and longest failure time was found to be spindle speed at 1100 rpm, feed rate at 21 mm/min, and axial load at 7 kN, implying that low heat input and moderate forging pressure are advantageous for AA 1100 FSW joints (Fig. 7).

The superior performance observed at low spindle speeds, for instance, 1100 rpm, could be due to a better microstructure, which results from sufficient heat input to effect plasticisation without causing undue grain growth. Such a balance between dynamic recrystallisation and grain growth would naturally lead to a fine-grained structure with good mechanical properties. Higher spindle speeds, like 1200–1300 rpm, resulted in overheating, extreme grain growth, and sometimes partial melting, greatly degrading the mechanical property. The spindle speed and feed rate interaction determine the heat input per unit length. Thus, the optimal results are 1100 rpm and 21 mm/min, wherein the balance of heat generation and dissipation exists, allowing enough material flow and preserving an ideal microstructure. This increased strength could result from a higher cooling rate, yielding finer grains.

In contrast, process parameters such as spindle speed and feed rate play a critical role in determining material flow and the quality of the weld joint. For example, a low spindle speed (1100 rpm) exhibited superior performance at higher feed rates of 21 mm/min by allowing effective transportation of materials and consolidation without defects. Instead, higher axial loads of up to 9 kN resulted in turbulent flow and incomplete fusion, leading to lower performance. Therefore, the process parameters were found at 1100 rpm, 21 mm/min, and 7 kN. From the analysis of the response table for means in Table 5, it is evident that spindle speed, feed rate, and axial load all have different effects on performance, with spindle speed being the most significant factor. The best performance is obtained at spindle speed level 1100 RPM (Level 1) with a mean response of 41.96, while the worst is obtained at 1200 RPM (Level 2). The Delta value for spindle speed is 12.70, meaning the spindle speed is the dominant factor influencing the response. The feed rate also comes in at a significant level, 21 mm/min, Level 3, showing the best performance at 41.10. The Delta value for feed rate is 12.33, which shows it as the second highest influence factor. Axial load is the least influential of the factors, with Level 2 at 7 kN being the best performance at 40.90. Higher axial loads of 9 kN (Level 3) only yield lower performance (Fig. 8).

The optimum parameters for maximum performance are the spindle speed at 1100 RPM, feed rate at 21 mm/min, and an axial load of 7 kN. This combination of optimum levels of the parameters, with spindle speed being the most critical in the performance of FSW joints, is likely to yield the best performance, as depicted in Table 5. The outcome shows that spindle speed, RPM, has the most significant effect on output, followed by feed rate, mm/min. Axial load, kN, contributes the least. While no factor is statistically significant at p < 0.05 level, spindle speed has the highest variability impact, hence the most influential. The calculated Delta values further support this ranking, and it thus follows that optimisation of spindle speed and feed rate can yield effective output control.

Three confirmation tensile tests have been conducted under the optimum combination of factors obtained based on the Taguchi design to determine the confirmatory tensile test values of 52.4 MPa, 53.1 MPa, and 53.6 MPa (Fig. 9). These values are within the 95% confidence interval (45.60–57.40 MPa) predicted for tensile strength, validating the optimisation process.

The experimental results match closely with the theoretical predicted value of 51.50 MPa, proving that the chosen parameter settings effectively improve tensile strength. Deviations observed within the range are expected for processes and, therefore, do not diminish the robustness of the selected conditions. This validation establishes that the optimised parameters by the Taguchi approach are effective and can be confidently applied to improving tensile strength in similar experimental setups.

Determination of reliability

Reliability was estimated using the Weibull distribution, with the Median Rank Method (MRM) and MoM being statistical techniques used to estimate probability distributions’ shape and scale parameters. The welding parameters are input, and reliability estimated using Weibull distribution are given as targets in ANFIS and ANN in Matlab Software. ANFIS and ANN are soft computing techniques used to determine reliability, validate the results with experimental results, and find errors.

The following terms are used for the reliability calculation:

-

1.

Time of failure → t

-

2.

Shape factor → m

-

3.

Scale factor → η

Reliability with respect to time [R(t)] is given by Eq. (5):

Since the shape factor and scale factor should be calculated to estimate reliability, two methods, the MRM and MoM, are used and compared to determine the best method to find the reliability15.

Median rank method

The Weibull distribution’s median rank technique estimates unreliability values using the binomial distribution of cumulative data and failure order number. The cumulative binomial formula; i.e., Eq. (6), can be used to get the rank for every percentage point larger than zero and less than one:

where j is the failure serial number and n is the total number of samples. From Isa, Moghadasi et al. (2021), this can be linearised as Eq. (7):

Equation (7) forms in y = m(x) + b equation format, where m is the slope and b is the intercept. These values will be validated with the predicted values of a soft computed model, namely, an ANN and ANFIS System.

Method of moments

An approach for estimating population parameters is the MoM. It begins by describing the population moments as functions of the important parameters. The distribution mean and sample mean are matched using the MoM. Eqs. (8) and (9) are the formulas to calculate shape and scale parameters, respectively15:

Comparison of the methods in determining the reliability

Shape and scale parameters are calculated using the MRM and MoM. Then parameters are substituted for in reliability Eq. (5). The reliability values obtained from the MRM and MoM are shown in Table 6. These methods prove that the best method for estimating the two-parameter Weibull distribution is to consider the total deviation as a measure of comparison. Therefore, reliability values obtained using the MoM for the respective weld parameters are shown in Table 7, and the results are used as a reference for comparing the predicted values.

Reliability values using ANN

A collection of computational methods based on AI (human-like decision) and natural selection are known as soft computing techniques. They are designed to solve exceedingly complicated problems quickly and affordably in the absence of analytical formulations. The two soft computing techniques used in the present study are ANFIS and ANN. ANN instructs computers to analyse data like a human brain. Deep learning is a type of machine learning that uses linked neurons in a layered framework to simulate the human brain. The ANN Model structure employed in the current study is shown in Fig. 9. The ANN training data used in the present study is given in Table 8.

In Figure 10, input, output, and hidden refer to weld parameters, experimental results, and rules. The simulation of trial set values from the ‘input’ and the ‘target’, as well as the ‘sample’, is used to determine how efficient the neural network is in predicting the reliability of welded joints41. The Matlab software simulates the trial values, and this tool is efficient enough to consider the number of iterations required to bring regression values of training, validation, and testing to the highest percentage. The reliability values are obtained through an ANN, and the steps are followed using Matlab software. The obtained reliability values predicted through the ANN method are displayed in Table 9.

ANN model structure42.

The ANN model used a sigmoid transfer function given in Eq. (10), indicated by the map inputs within a range of 0–1, efficiently responding to non-linear relationships. The learning algorithm applied was backpropagation with gradient descent. This algorithm adjusts the weights and biases iteratively to minimise prediction error through error calculation, gradient computation, and, finally, weight updates. Such an approach improves the capability of the model to capture complex FSW parameter interactions.

The comparison of the experimental results against the reliability values computed through the ANN method is plotted in Fig. 11.

Reliability values using ANFIS

The ANFIS model is a good combination of ANN and the Fuzzy Inference System (FIS). It is a hybrid AI model that integrates fuzzy and ANN. The ‘antisemite’ accesses the ANFIS application in Matlab. It is possible to train the ANFIS model without exclusively depending on expert information necessary for a fuzzy logic model. ANFIS model has the benefit of having both language and number knowledge. ANFIS also utilises the ANN’s capacity to categorise data and spot patterns. The ANFIS structure used in the present study is shown in Fig. 12.

ANFIS model structure41.

Input parameters and corresponding target data are stored in separate Excel sheets. The “Load data” function is utilised to import input and cluster data by selecting the FIS. The system generates a network structure based on the imported data. ANFIS trains the model by analysing the data, similar to ANN, to create a fuzzy model that captures the input–output relationships. The trained ANFIS model is saved in .fis format. The saved model is accessed in the FIS, where input parameters, experimental outputs, and rules are configured. The established rules are checked within the FIS environment. The rules defined in the FIS (Table 10) are employed to derive reliability values through the FIS for the respective weld parameters.

The rules set through ANFIS in the FIS are illustrated in Fig. 13. The results checking using the rule viewer are displayed in Fig. 14.

The reliability values predicted through ANFIS are outlined in Table 11, and a comparison of the experimental values with those predicted through ANFIS is displayed in Fig. 15. The comparison of reliability values acquired through ANFIS with experimental results is also shown in Table 11.

Estimating reliability using ANN and ANFIS Systems is done, and values of ANN and ANFIS are compared with experimental results, and percentage error and Root Mean Square Error (RMSE) are calculated for both ANN and ANFIS. It was understood that ANFIS was more efficient in predicting reliability percentage than ANN. Percentage error and RMSE are much lower for ANFIS than for ANN.

Percentage error and RMSE are calculated using Eqs. (11) and (12) and outlined in Table 12:

The average percentage error and RMSE values of the ANFIS and ANN methods are shown in Table 13. The comparison of the reliability values of both methods is displayed in Fig. 16.

The optimisation process led to identifying the ideal design parameters for ANN and ANFIS models, as given in Table 14. ANN required multiple tests for evaluation using various hidden layers’ configurations with different numbers of neurons along with activation functions and optimisers. Two hidden layers with 64 and 32 neurons achieved the best results by integrating Rectified Linear Unit (ReLU) in hidden layers and Linear in output layers. The Adam optimiser resulted in the best RMSE values of 0.008 alongside maximum R2 values of 0.672.

The optimisation of ANFIS involved choosing correct membership function numbers alongside function types, and training methods should be used for rule extraction. The selected optimal architecture applied five Gaussian membership functions through its training process, which used a Gradient Descents and Least Squares hybrid learning method. Using a fuzzy rule-based system ANFIS generated predictive models that offered robustness and interpretability while achieving the lowest RMSE (0.002) and highest R2 (0.892), thus becoming the most effective model.

The dataset containing 27 samples was properly partitioned into 70% training data and 30% testing data for model generalisation purposes. A split in this ratio works well for small datasets since it lets the model become proficient while setting aside data to test its prediction abilities. A controlled model complexity, together with appropriate input–output relationship quantity, makes small datasets usable until accuracy meets acceptable levels. ANFIS proves its advantage in handling small datasets because it uses rule-based learning to achieve better generalisation than common neural networks. The two methods of predictive modelling produced satisfactory results; the ANN delivered an R2 value of 0.681 coupled with low RMSE readings, while ANFIS achieved an R2 score of 0.841 with comparable low RMSE results. It shows the dataset successfully identified practical patterns. The validation process through cross-validation identified an adequate dataset while preventing overfitting. Real-world operational parameters are fully represented in the dataset by including the essential spindle speed, feed rate, and axial load variables. The wide selection of data values demonstrates proper sufficiency for creating dependable models. The experimental data size usually remains small, but the results that were obtained match the predictions from theoretical models used in these types of laboratory investigations. The dataset fulfils its required properties through models demonstrating robustness and generalisation abilities with many essential variables represented.

Figure 17 depicts the overall results summary of the FSW process and emphasises the key parameters such as spindle feed, feed rate, and axial load. It also compares the reliability predictions using ANFIS and ANN, demonstrating that ANFIS yields lower error and RMSE, making it a more accurate model. The superior performance of ANFIS over ANN in predicting the reliability of friction stir welded AA 1100 aluminium alloy joints can be attributed to several factors. ANFIS combines the learning capabilities of neural networks with the reasoning power of fuzzy logic, allowing it to better handle complex, non-linear relationships and inherent uncertainties in the FSW process.

Its ability to incorporate expert knowledge through fuzzy rules and its adaptability to small datasets and process variations gives it an edge over the purely data-driven approach of ANN. ANFIS also offers better interpretability through its if-then rules, which is crucial for understanding the effects of FSW parameters on joint reliability. The study’s results demonstrate its superior predictive accuracy, showing a significantly lower percentage error.

Model performance visualisation and analysis

The Comparison of ANN and ANFIS performance evaluation through scatter, radar plots and Taylor diagram shows considerable variations in prediction outcomes. The visualisations indicate superior accuracy and reliability levels of ANFIS during training and testing conditions.

The scatter plot shown in Fig. 18 displays actual reliability values with the results predicted by ANN and ANFIS. Multiple ANN predictions in blue points deviate noticeably from the perfect prediction line (y = x), as evidenced by an RMSE value of 0.008. The green points of ANFIS predictions show close proximity to the ideal line while attaining an RMSE of 0.002. An analysis of the scatter plot displays that ANFIS produces more accurate predictions that lead to lower residual errors, so it represents an optimal match for this dataset.

The radar plot shown in Fig. 19 uses two essential metrics, RMSE and R2 score, to rank the models. Statistical metrics indicate ANN reaches R2 = 0.672 and RMSE = 0.008, yet ANFIS surpasses it by delivering R2 = 0.892 and RMSE = 0.002. According to these results, ANFIS demonstrates superior accuracy and stronger actual data correlation, which are visible in the larger radar plot area.

The Taylor diagram shown in Fig. 20 confirms ANFIS superiority by evaluating standard deviation, correlation coefficient, and RMSE values. Actual data forms the blue dot, which depicts the perfect correlation value of \(\rho = 1\). The position of the ANFIS green dot next to the blue dot indicates a strong correlation coefficient (0.892) alongside a minimal RMSE (0.002). The ANN results demonstrate an orange dot with a correlation coefficient of 0.672 and an RMSE value of 0.008 positioned at a distant spot from the benchmark. ANFIS performs more than ANN in capturing data trends according to these metrics. The data visualisations and the numerical studies establish ANFIS as a better model than ANN for predicting reliability values. ANFIS delivers better accuracy and correlation than alternative models, which positions it as the best choice when precision demands arise. The research data demonstrates that ANFIS represents an appropriate method for predictive modelling in this scenario with its ability to deal with intricate patterns in data sets.

Reliability values using MLR

As a traditional statistical approach, MLR was also applied to establish the baseline of reliability prediction. In the MLR, the relationship between weld parameters such as spindle speed, feed rate, and axial load with reliability is modelled using the assumption of linear dependency between variables. The Comparison of MLR predictions with actual reliability is as follows. As can be seen in Table 15, MLR produces reliability estimates that align reasonably with experimental data but do not accurately reflect extreme variations as the ANFIS does. The averaged responses produced by MLR’s predictions lead to limitations in modelling complex non-linear interactions between welding parameters. The ANFIS and ANN achieved better reliability prediction accuracy levels, especially for the extremely low and high values. The performance of MLR demonstrates its inability to manage complex non-linear effects found in welding processes and strengthens the case for advanced methods such as ANFIS and ANN.

MLR shows different results for the reliability prediction of FSW joints compared to both ANN and ANFIS. As outlined in Table 16 an RMSE of 0.058 and an R2 value of 0.412. ANN exhibits better accuracy through its lower RMSE value of 0.008 and higher R2 value of 0.672 but it provides no interpretability to the results. ANFIS demonstrated superior predictive capabilities compared to ANN because it displayed lower percentage error (4.61% and 19.95%) and generated more accurate results through a lower RMSE (0.002 and 0.008).

The Determination Coefficient (DC) analysis validates that predictive models follow the performance classification scheme that was established previously. The best DC value of 0.892 belongs to ANFIS, demonstrating its position as the most trustworthy prediction method. ANN showed moderate performance since its DC reached 0.672, yet MLR achieved the worst result with a DC value of 0.412. ANFIS proves to be superior for precise FSW joint reliability modelling and prediction. The research investigation combined these methodologies to understand predictive power benefits and selected the optimisation method while exploiting their combined strengths. The combination of research methods led to advanced FSW process understanding and delivered dependable results for joint reliability optimisation.

Implications

The present study mainly contributed to technological advancements in using predictive models in FSW, parameter optimisation, and integration of soft computing in manufacturing. It also focuses on improving weld quality, real-time process monitoring and control, and process efficiency. The contributions of the study to theory and practice have been synthesised subsequently.

Theoretical implications

The soft computing techniques, namely ANN and ANFIS, have been compared in the context of predicting the reliability of the FSW joints. As anticipated, ANFIS outperformed ANN due to its hybrid nature encompassing fuzzy logic and neural network traits. The better interpretability and robustness complement the computational effectiveness. The study results encourage machine learning and fuzzy systems to improve accuracy in complex industrial applications in the manufacturing domain. Using Taguchi L27 orthogonal array for designing experiments added structure in analysing the effect of various welding conditions. This technique could be efficient and useful in similar manufacturing processes as it highlights the significance of parameter control for maximising the reliability of joints. It finds direct application in similar processes for other materials and weld conditions. Applying Weibull to predict reliability adds more knowledge to understanding failure time prediction in welding. Comparison of multiple methods viz. MRM and MoM find their use in reliability engineering across different manufacturing fields as time-to-failure is vital to quality assurance studies. Multiple methods could be used to predict reliability, and the best ones can be picked as no single method stands the best for all the processes and experiment conditions. The framework developed also shows the capability of adopting AI techniques in the manufacturing space for predictions. It will enable AI-driven manufacturing to be more intelligent, self-learning, and adaptive.

Practical implications

The key takeaway is the optimal weld parameter identification that maximises the reliability of AA 1100 Aluminium alloy joints. It might interest the automotive, aerospace, and maritime industries that focus on high-reliability welds. Optimisation could help to obtain welds with superior properties and, thereby, durable joints. A combination of ANFIS and real-time monitoring has been proven to improve efficiency and reduce joint defects. The advantage is the adaptability in terms of maintaining optimal parameters of the systems to the varying conditions during the process. The managers could use the framework developed for other materials and conditions, including the processes that involve dissimilar materials. The scalability offered by the study is essential to ensure its reproducibility and suitability to similar industrial processes. The use of feedback systems helps improve the systems’ adaptability to enhance quality and minimise defects. This study demonstrates the superior performance of ANFIS over ANN in predicting FSW joint reliability for AA 1100 aluminium alloy, with ANFIS achieving a significantly lower error rate (4.61% vs 19.95%). Identifying optimal FSW parameters (1200 rpm spindle speed, 18 mm/min feed rate, 7 kN axial load) provides valuable guidance for process optimisation in industrial applications. The success of ANFIS highlights the potential for integrating expert knowledge with data-driven approaches in manufacturing optimisation. Additionally, the model’s ability to capture complex parameter interactions offers deeper insights into the FSW process, which could inform future research and process improvements. The computational efficiency of ANFIS also suggests the potential for real-time monitoring and control applications in FSW processes.

Novel contribution of the work

This work establishes the optimal parameters (1200 rpm, 18 mm/min, 7 kN) for FSW processes that maximise joint reliability (0.87) while introducing Weibull analysis combined with ANN and ANFIS as a new solution for optimising and predicting the reliability of lightweight materials. The following points are the key contributions of this work:

-

Establishing ANFIS as an accurate and efficient tool for FSW reliability prediction

-

Identifying optimal FSW parameters for improved reliability joint and its performance

-

Integrated Weibull reliability analysis with soft computing techniques for precise reliability prediction.

Conclusion and outlook

The main objective of this research was to predict and optimise the reliability of friction stir welded AA 1100 aluminium alloy joints using ANN and ANFIS techniques. The study examined the effects of key FSW parameters such as spindle speed (1100–1300 rpm), feed rate (15–21 mm/min), and axial load (5–9 kN) on joint reliability. ANFIS outperformed ANN in predicting reliability, with an average percentage error of 4.61% compared to ANN’s 19.95% and a RMSE of 0.002 versus 0.008 for ANN. The optimal FSW parameters for maximising joint reliability were a spindle speed of 1200 rpm, feed rate of 18 mm/min, and axial load of 7 kN, resulting in a predicted reliability of 0.87. This combination balances heat generation, material flow, and consolidation to produce high-quality welds. ANFIS’s superior performance can be attributed to its ability to handle non-linear relationships and uncertainties inherent in the FSW process and its capacity to incorporate expert knowledge through fuzzy rules. The interpretability of ANFIS results, provided through its if-then rule base, offers valuable insights for process optimisation. This study demonstrates the potential of ANFIS as a powerful tool for predicting and optimising FSW joint reliability in AA 1100 aluminium alloys, with implications for improving manufacturing efficiency and product quality in industries utilising FSW technology.

This methodology can be extended to other aluminium alloys and dissimilar material combinations for future research to assess its broader applicability. Additional FSW parameters like tool geometry and tilt angle could lead to more comprehensive predictive models. The development and testing of real-time ANFIS-based control systems for FSW processes represent an important next step in maintaining optimal weld quality throughout production. Integrating microstructural analysis and long-term reliability studies (including fatigue and corrosion testing) would provide a complete understanding of the relationships between FSW parameters, microstructure, and joint performance. Finally, exploring hybrid modelling approaches and multi-objective optimisation techniques could enhance this research’s predictive accuracy and practical applicability in industrial settings.

Data availability

All data generated or analysed during this study are included in this published article, as presented in Table 4.

References

Singh, R. P., Dubey, S., Singh, A. & Kumar, S. A review paper on friction stirwelding process. Mater. Today: Proc. 38, 6–11 (2021).

Gebreamlak, G., Palani, S., Sirhabizu, B., Atnaw, S. M. & Gebremichael, E. Dissimilar friction stir welding process-a review. Adv. Mater. Process. Technol. 8(4), 3900–3922 (2022).

Kaygusuz, E., Karaomerlıoglu, F. & Akıncı, S. A review of friction stir welding parameters, process and application fields. Turk. J. Eng. 7(4), 286–295 (2023).

El-Zathry, N. E., Akinlabi, S., Woo, W. L., Patel, V. & Mahamood, R. M. Friction stir-based techniques: An overview. Weld. World 69(2), 327–361 (2024).

Mishra, R. S. & Ma, Z. Y. Friction stir welding and processing. Mater. Sci. Eng. R. Rep. 50(1–2), 1–78 (2005).

Sezhian, M. V., Ramadoss, R., Giridharan, K., Chakravarthi, G. & Stalin, B. Comparative study of friction stir welding process and its variables. Mater. Today: Proc. 33, 4842–4847 (2020).

Gite, R. A., Loharkar, P. K. & Shimpi, R. Friction stir welding parameters and application: A review. Mater. Today: Proc. 19, 361–365 (2019).

Kwon, Y. J., Shigematsu, I. & Saito, N. Mechanical properties of fine-grained aluminium alloy produced by friction stir process. Scr. Mater. 49, 785–789 (2003).

Chauhan, A. & Kumar, S. An overview of optimisation techniques used for friction stir welding process parameters. Res. J. Eng. Technol. 9(1), 21–26 (2018).

Prakash, P., Jha, S. K. & Lal, S. P. A study of process parameters of friction stir welded AA 6061 aluminium alloy. Int. J. Innov. Res. Sci. Eng. Technol. 2(6), 2304–2309 (2013).

Albunduqee, A. S. & Al-Bugharbee, H. R. Optimisation of process parameters of friction stir welding by Taguchi method. Wasit J. Eng. Sci. 7(1), 17–23 (2019).

Rani, P. & Mishra, R. S. Influence of reinforcement with multi-pass FSW on the mechanical and microstructural behavior of dissimilar weld joint of AA5083 and AA6061. SILICON 14(17), 11219–11233 (2022).

Khalafe, W. H., Sheng, E. L., Bin Isa, M. R., Omran, A. B. & Shamsudin, S. B. The effect of friction stir welding parameters on the weldability of aluminium alloys with similar and dissimilar metals. Metals 12(12), 2099 (2022).

Hasnol, M. Z. B. Friction Stir Welding with Different Tool Profiles on Structure and Hardness of Dissimilar Aluminium Alloy AA5083 and AA6061-T6. (Master’s thesis) (Faculty of Mechanical Engineering, Universiti Teknologi Malaysia, (2023))

Osarumwense, O.-I. & Rose, N. C. Parameters estimation methods of the Weibull distribution: A comparative study. Elixir Stat. 69, 23177–23184 (2014).

Ghetiya, N. D., Patel, K. M. & Kavar, A. J. Multi-objective optimisation of FSW process parameters of aluminium alloy using Taguchi-based grey relational analysis. Trans. Indian Inst. Met. 69, 917–923 (2016).

He, X., Gu, F. & Ball, A. A review of numerical analysis of friction stir welding. Prog. Mater. Sci. 65, 1–66 (2014).

Azadegan, A., Porobic, L., Ghazinoory, S., Samouei, P. & Kheirkhah, A. S. Fuzzy logic in manufacturing: A review of literature and a specialised application. Int. J. Prod. Econ. 132, 258–270 (2011).

Chi, S.-C. & Hsu, L.-C. A fuzzy Taguchi experimental method for problems with multi-attribute quality characteristics and its application on plasma arc welding. J. Chin. Inst. Ind. Eng. 18, 97–110 (2001).

Prabhakar, D. A. P. et al. A review of optimisation and measurement techniques of the friction stir welding (FSW) process. J. Manuf. Mater. Process. 7, 181 (2023).

Isa, M. S. M. et al. Recent research progress in friction stir welding of aluminium and copper dissimilar joint: A review. J. Mater. Res. Technol. 15, 2735–2780 (2021).

Li, Y. et al. Double side friction stir Z shape butt lap welding of dissimilar titanium aluminum alloys. Int. J. Mech. Sci. 271, 109135 (2024).

Alok, K., Umesh, K. S. & Avanish, K. D. Pratiksha. 2023. Numerical assessment of hybrid laser-arc welding of NV E690 steel. NanoWorld J. 9, S166–S170 (2023).

Dialami, N., Chiumenti, M., Cervera, M., Segatori, A. & Osikowicz, W. Enhanced friction model for friction stir welding (FSW) analysis: Simulation and experimental validation. Int. J. Mech. Sci. 133, 555–567 (2017).

Toorajipour, R., Sohrabpour, V., Nazarpour, A., Oghazi, P. & Fischl, M. Artificial intelligence in supply chain management: A systematic literature review. J. Bus. Res. 122, 502–517 (2021).

Kumar, S., Triveni, M. K., Katiyar, J. K., Tiwari, T. N. & Roy, B. S. Prediction of heat generation effect on force torque and mechanical properties at varying tool rotational speed in friction stir welding using artificial neural network. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 237, 4495–4514 (2023).

Okuyucu, H., Kurt, A. & Arcaklioglu, E. Artificial neural network application to the friction stir welding of aluminium plates. Mater. Des. 28, 78–84 (2007).

Boulahem, K., Salem, S. B., Shiri, S. & Bessrour, J. Experimental modeling and multi-response optimization in friction stir welding process parameters of AA2024-T3 using response surface methodology and desirability approach. Exp. Tech. 48(5), 833–849 (2024).

Jaypuria, S., Mahapatra, T. R. & Jaypuria, O. Metaheuristic tuned ANFIS model for input-output modeling of friction stir welding. Mater. Today: Proc. 18, 3922–3930 (2019).

Shehabeldeen, T. A., Zhou, J., Shen, X., Yin, Y. & Ji, X. Comparison of RSM with ANFIS in predicting tensile strength of dissimilar friction stir welded AA2024-AA5083 aluminium alloys. Proc. Manuf. 37, 555–562 (2019).

Shehabeldeen, T. A., Abd Elaziz, M., Elsheikh, A. H. & Zhou, J. Modeling of friction stir welding process using adaptive neuro-fuzzy inference system integrated with harris hawks optimiser. J. Market. Res. 8(6), 5882–5892 (2019).

Chaudhary, N. & Singh, S. Experimental investigation and ANFIS-based modelling of effect of process parameters on friction stir spot welding of Al 6061–T6. Adv. Mater. Process. Technol. 10(1), 64–74 (2024).

Lomolino, S., Tovo, R. & Dos Santos, J. On the fatigue behaviour and design curves of friction stir butt-welded Al alloys. Int. J. Fatigue 27, 305–316 (2005).

Elanchezhian, C. et al. Parameter optimisation of friction stir welding of AA8011-6062 using mathematical method. Proc. Eng 97, 775–782 (2014).

Ilangovan, S., Vaira Vignesh, R., Padmanaban, R. & Gokulachandran, J. Comparison of statistical and soft computing models for predicting hardness and wear rate of Cu–Ni–Sn alloy. in Progress in Computing, Analytics and Networking: Proceedings of ICCAN 2017 559–571 (Springer, 2018).

Gokulachandran, J. & Mohandas, K. Comparative study of two soft computing techniques for the prediction of remaining useful life of cutting tools. J. Intell. Manuf. 26, 255–268 (2015).

Rizvi, S. W. A., Singh, V. K. & Khan, R. A. Fuzzy logic based software reliability quantification framework: early stage perspective (FLSRQF). Proc. Comput. Sci. 89, 359–368 (2016).

Pitchipoo, P., Muthiah, A., Jeyakumar, K. & Manikandan, A. Friction stir welding parameter optimisation using novel multi objective dragonfly algorithm. Int. J. Lightweight Mater. Manuf. 4, 460–467 (2021).

Cederqvist, L. & Öberg, T. Reliability study of friction stir welded copper canisters containing Sweden’s nuclear waste. Reliab. Eng. Syst. Saf. 93, 1491–1499 (2008).

Karna, S. K. & Sahai, R. An overview on Taguchi method. Int. J. Eng. Math. Sci. 1(1), 1–7 (2012).

Habashy, D. M. & Lebda, H. I. Comparison between artificial neural network and adaptive neuro-fuzzy inference system for the baryon-to-meson ratios in proton-proton collisions. arXiv preprint http://arxiv.org/abs/2209.12709. (2022).

Sivasundar, V. et al. ANN modeling and optimisation of friction stir welding performance for AA6061 and AA5083 alloy joints. Proc. Inst. Mech. Eng. Part E: J. Process Mech. Eng. https://doi.org/10.1177/09544089241283272 (2024).

Author information

Authors and Affiliations

Contributions

Author 1: Dr.Gokulachandran J led the conceptualization, experimental work, data analysis, original draft preparation, validation, and revisions. Author 2: Dr.Sumesh A supervised the study, provided technical inputs, and assisted in manuscript drafting and review. Author 3: Dr.Narassima M.S contributed to result interpretation, theoretical background, and editing. Author 4: Dr.Thenarasu M focused on model validation, industrial applications, and manuscript corrections. Author 5: Dr. Raghu R handled data visualization and methodology refinement. Author 6: Dr.Dinu Thomas Thekkuden assisted with the literature review, ANN modeling, and proofreading. Author 7: Dr.Erfan Babaee Tirkolaee provided expertise in ANFIS modeling, optimization, and overall scientific review.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Gokulachandran, J., Sumesh, A., Narassima, M.S. et al. Reliability assessment of friction stir welds in AA100 aluminium alloy using ANN and ANFIS predictive models. Sci Rep 15, 33297 (2025). https://doi.org/10.1038/s41598-025-04694-x

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-04694-x