Abstract

The functional monomer 10-methacryloyloxydecyl dihydrogen phosphate (10-MDP) and its calcium salt (Ca-MDP), formed via interfacial nanolayering, are critical for achieving long-term dental bonding durability. Despite extensive clinical use, the crystallinity, three-dimensional (3D) organization, and hierarchical ultrastructure of Ca-MDP remain inadequately characterized at the nanometric scale. This study aims to investigate the crystallinity, structural nature of Ca-MDP salt and their potential role in the durability of 10-MDP-based adhesives. Three characteristic diffraction maxima corresponding to Ca-MDP nanolayers were initially detected using powder X-ray diffraction (XRD) and Transmission Electron Microscopy (TEM). However, further high-resolution analysis via advanced STEM techniques—including High-Angle Annular Dark Field (HAADF), rotationally invariant Center of Mass (riCOM), and integrated Differential Phase Contrast (iDPC)—revealed that the Ca-MDP salt does not exhibit atomic crystallinity but rather forms a layer-ordered amorphous architecture. The Ca²⁺-rich nanolayers demonstrated variable interspacing and lacked definitive lattice fringes typically associated with crystalline phases. Electron tomography further confirmed a nonuniform, anisotropic self-assembly across X, Y, and Z axes, resulting in 3D directional spreading and spatially distinct nanolayered domains. These findings support a novel nanomechanical interlocking hypothesis: during clinical bonding procedures, adhesive resin components are physically entrapped within the Ca-MDP inter-nanolayers—contributing to enhanced durability. This study proposes a new 3D structural model of Ca-MDP self-assembly, offering deeper mechanistic insights into the long-term performance of 10-MDP-containing adhesives.

Similar content being viewed by others

Introduction

Adhesive functional monomers are essential components of dental bonding materials for successful and durable bonding with enamel and dentin. Regardless of the bonding mode/strategy employed, they are able to self-etch (SE) enamel and dentin and chemically bond to the contained calcium (Ca) via stable ionic bonding. The stability of these ionic bonds and their resistance to solubility and hydrolytic degradation are largely dependent on the type, purity, and concentration of the functional monomer employed1.

Several functional monomers, such as 10-methacryloyloxydecyl dihydrogen phosphate (10-MDP), glycerol phosphate dimethacrylate (GPDM), 4-methacryloxyethyl trimellitic anhydride (4-META), and 2-(methacryloyloxyethyl)phenyl hydrogenphosphate (Phenyl-P), have been introduced into the market2,3. While they all share the same working mechanism of having an acidic functional group and the essential need for water to react/ionize, essential differences in hydrophilicity, chemical bonding potential and Ca-salt stability are the determining factors in the success of the resultant adhesive resin mixture and the resultant bonding durability3,4,5.

Today, 10-MDP is the most efficient functional monomer ever employed in dental bonding materials in general. Its unique chemical formula consists of a hydrophilic phosphate group at one molecular side separated by a hydrophobic 10-CH2 carbon-spacer chain from the polymerizable methacrylate group at the other molecular side, which enables the formation of durable chemical ionic bonds with dentin hydroxyapatite (HAp)1,6,7.

Additionally, the majority of market-present universal adhesives (UAs) are mainly 10-MDP formulations1,8. Despite encouraging mid-term clinical bonding results for UAs9,10the inherently thin adhesive layer remains a concern with numerous investigations have sought to mitigate the drawbacks linked to this characteristic11,12. Nevertheless, the sustained clinical success of universal adhesives (UAs) over more than a decade is largely attributed to the inclusion of 10-MDP in their formulation13,14. Its bifunctional structure is able to simultaneously co-polymerize with resin matrices, partially demineralizes tooth HAp in a pH-dependent manner, selectively exposing calcium ions (Ca²⁺) while preserving collagen structure, and forming stable ionic bonds with the phosphate groups of 10-MDP, resulting in a self-assembled, insoluble, interfacial nanolayers known as Ca–MDP nanolayering1,9,15,16. This nanolayering not only reinforces the ‘mineral-protected’ hybrid layer but also contributes significantly to the durability and hydrolytic stability of the adhesive interface over time1,17.

Moreover, the immobilization of 10-MDP on collagen could induce biomimetic mineralization without the use of polymer additives by alternatively attracting calcium and phosphate through electrostatic attraction18,19which can be considered an additional mechanism for the successful durable bonding of 10-MDP formulations.

When 10-MDP-containing formulations are applied to enamel or dentin, either in Etch&Rinse (E&R) or SE bonding modes, the Ca-MDP salt forms via stable ionic bonding and results in the formation of the Ca-MDP nanolayered that stays at the hybrid (and adhesive) layers9,20,21. This Ca-MDP is well known for its essential contribution to the long-term durability of adhesive-tooth interfaces7,19,22.

Briefly, the Ca-MDP single nanolayer is composed of several parallel two-MDP molecules attached/oriented to their methacrylate groups (hydrophobic ends) directed toward each other (back-to-back) and their functional phosphate groups (hydrophilic end) directed away from each other and ionically bonded to the HAp-sourced Ca2+ ion, causing all phosphate groups to be bridged by Ca23 and forming a ~ 3–4 nm-thick highly ordered structure24 that has been proven to be a major player in the durability of adhesive-tissue interfaces in the laboratory11,25 and clinically9,10. Having been employed for more than three decades now across several generations of dental bonding materials1there is a demand to uncover the unknown aspects of the mechanism behind Ca-MDP salt self-assembly and its potential role and contribution to its long-term proven bonding durability.

Ca-MDP nanolayering is believed to be crystalline (or at least to contain a crystalline phase) because of its three characteristic X-ray diffraction (XRD) peaks6,26. However, until recently, the single-layer buildup of the Ca-MDP salt has never been clearly visualized by high-resolution atomic-level electron microscopy due to the high electron beam sensitivity of the Ca-MDP salt, which alters its structure upon high magnification27. Further exploration of its atomic structure requires advanced low-dose electron microscopy techniques, which are crucial for fully understanding its mechanism of action.

For several years, Ca-MDP nanolayering has been detected at adhesive dentin interfaces via conventional TEM. Traditionally, two-dimensional (2D) methods rely on thin tissue sections, such as adhesive-dentin (or enamel) sections28,29. Despite their unprecedented contribution to advancements in adhesive dentistry, these methods have several shortcomings. First, cross-sectional 2D images (either by Scanning Electron Microscopy (SEM) or Scanning Transmission electron microscopy (STEM)) do not fully represent the heterogeneity of bonded interfaces, resulting in masking of the complete image of the morphological structures that cannot be represented as continuous structures in 2D spaces such as hybrid (and adhesive) layers29,30. Second, reconstructing thin serial cross sections can provide three-dimensional (3D) maps31,32but such methods are time-consuming and not possible at the targeted/needed resolution27.

Direct visualization and understanding of the role of 10-MDP in the actual formation of Ca-MDP nanolayers within the adhesive (and the hybrid) layers is limited due to the beam-sensitive nature of the Ca-MDP salt and the high carbon content in dentin organic components27. Even with the current high-tech analytical advances, the beam-sensitive nature and inability to tolerate high electron voltages (as a necessary requirement for super high-resolution visualization) of Ca-MDP salt have hampered investigations via high-kV high-resolution electron microscopes27 and allowed relatively far-atomic scale direct visualization33. However, high-resolution 3D imaging, combined with modified single-particle analysis and low-dose microscopy could potentially provide a complementary approach to overcome these limitations and better characterize the Ca-MDP nanolayering31.

The objective of this study is to: (1) investigate the crystalline nature of the lab-prepared Ca-MDP nanolayers via a series of low-dose high-resolution microscopy techniques, including TEM, STEM analysis via Fast Fourier Transform analysis (FFT) with periodicity measurements, atomic-level STEM characterization, real-time integration center of mass (riCOM) and integrated differential phase contrast (iDPC) analysis, to observe the atomic structure of a single Ca-MDP nanolayer. (2) Explore the 3D hierarchical structure of the Ca-MDP salt nanolayers using 3D Electron Tomography (ET) reconstruction. (3) Analyzing the different directional spreading of the Ca-MDP nanolayers along the vertical Z-axis (in addition to the X-axis and Y-axis) to fully understand its architectural nature. Based on these results, a nanomechanical interlocking mechanism model is proposed, providing unprecedented explanatory insight into the rationale behind the durability of 10-MDP bonded interfaces. The null hypothesis of this study is that Ca-MDP salt is crystalline in nature.

Results

Characterization of the resultant Ca-MDP salt

The Ca-MDP salt was first characterized via XRD and showed the average diffraction pattern obtained, in which three diffraction maxima at 2θ = 2.7°, 5.2°, and 7.1° were clearly observed. The d-spacing calculated from the peak with the strongest signal (2θ = 2.7°) was 3.2 nm (Fig. 1a). TEM imaging revealed the presence of the classic self-assembled Ca-MDP nanolayers with different directions and layouts (Fig. 1b); a highly layer-ordered structure was observed at higher magnification at the nanometric scale in the X and Y directions (Fig. 1c), and the 3D molecular structure of the functional monomer 10-MDP is shown in (Fig. 1d).

XRD pattern and low-resolution TEM characterization of the synthesized Ca-MDP salt. (a) Powder-XRD pattern from 2° to 15° 2θ showing the three characteristic peaks at 2θ = 2.7° (d = 3.27 nm), 5.2° (d = 1.66 nm), and 7.6° (d = 1.1 nm). (b) Representative high-magnification TEM photomicrographs for characterization of Ca-MDP nanolayering formed by drop casting over the Lacey carbon coat of the TEM grid. (c) High magnification of the area highlighted in the yellow square in panel ‘b’ showing the characteristic Ca-MDP nanolayering. (d) Schematic representation of the 10-MDP molecule.

Chemo-analytical ultrastructural atomic-level (S)TEM analysis of Ca-MDP salt

Atomic-level (S)TEM Ca-MDP characterization and periodicity measurements

High-resolution TEM observations at 300 kV (Fig. 2a,b) showed no atomic ordering within the Ca-MDP nanolayers, which thus appeared to be amorphous. High Angle Annular Dark Field (HAADF) images showed overlapping or intersecting domains of layered Ca-MDP structures (Fig. 2c,d), with inconsistent inter-nanolayering distances ranging between 3.12 nm and 4.18 nm (Fig. 2i–ii). In the X-Y plane, the layers appeared to be discontinuous, overlapping or intersecting (Fig. 2d) and (Supplementary Fig. S1).

High-resolution scanning and transmission electron microscopy (S)TEM analysis. Low-magnification (a) and high-magnification (b) TEM images of the Ca-MDP nanolayers observed at low doses clearly show the Ca-MDP nanolayers in their characteristic highly layer-ordered profile. No Ca2+ atomic ordering could be observed. (c) HAADF-STEM image at low magnification where periodicity measurements show regional distancing variations at locations of (i) ~ 4.2 nm and (ii) ~3.8 nm. (d) High-resolution HAADF-STEM image showing the nanolayering stack (white arrows); with the inset of the FFT in (e) shows an average interplanar space of 3.5 nm. (f) High-magnification HAADF-STEM image of a single Ca-MDP nanolayer with no Ca2+ atomic ordering could be observed.

The FFTs confirmed the variability of the intra-Ca-MDP nanolayering distances among different locations by revealing wide diffraction rings and randomly oriented lines with an average distance ranging from 3.5 ± 1.5 nm, from which no proof of crystallinity could be obtained (Fig. 2e). High-resolution images did not show any clear atomic ordering or atomic lattice observation for the single Ca-MDP nanolayering building unit at (sub)atomic resolution (Fig. 2f).

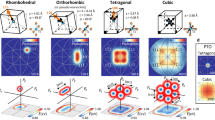

Real-time integration center of mass (riCOM) and integrated differential phase contrast (iDPC) analysis

riCOMs and iDPCs analyze the center of mass movement of an electron beam when passing through a sample. The atoms composing the sample act as beam deflectors, and by tracking these slight deviations, this technique can map atomic positions, facilitate more efficient use of the electrons and allow high-resolution images at low electron doses. The previous observations and outcomes were also confirmed by low-dose riCOM (Fig. 3a/b) and iDPC (Fig. 3c/d) analyses. These analyses were performed at atomic resolution and failed to identify atomic Ca2+ columns.

Three-dimensional assessment of the Ca-MDP salt network

3D electron tomography (ET) of Ca-MDP nanolayers

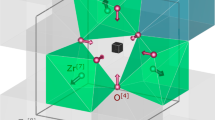

Three-dimensional (3D-ET) confirmed the propagation of the nanolayers in the X, Y, and Z axial directions during the formation phase (Fig. 4). The inter-nanolayering distance observed from the tomography reconstruction was also similar to the periodicity measurements obtained by the FFT analyses (3.5 ± 1.5 nm). The direction of the nanolayers varied randomly and regionally over the 3-axis directions. Additionally, empty spaces were observed between the single Ca nanolayers (see Supplementary Video S2 online).

3D Electron Tomography (3D-ET) of single-particle Ca-MDP nanolayering at ultra-high resolution. (a–f) Tomographical 3D reconstructed figures showing the hierarchical arrangement of the Ca-MDP nanolayers over the X, Y, and Z axes with ‘empty’ spaces between the nanolayers (yellow arrows) that can potentially act as nanomechanical interlocking sites for the other resin monomer components during clinical application.

Directional change observation and nanomechanical interlocking mechanism modeling

A significant observation was the multidirectional regional change in Ca-MDP nanolayering along the X|Y axes (Fig. 5a). These directional changes were distinct, continuous, and intersecting. A representative simulation model is depicted at 90° intersection angles for clearer explanation (Fig. 5b).

(a) HAADF-STEM structural analysis of the Ca-MDP nanolayering showing changes in the directions and intercrossings of the Ca-MDP nanolayers on the X- and Y-axes represented with different arrows’ colors. (b) Nanomechanical interlocking hypothetical model showing the empty spaces in between (red hand pointer) that could act as interlocking sites for the other contained resin monomer components (e.g., Bis-GMA, HEMA, and TEGDMA) during the 10 s reaction time when applied clinically.

The model was further stepwise explained to illustrate the hierarchal self-assembly buildup over the X, Y, and Z axes during Ca-MDP salt formation (Fig. 6) and additionally animated for further explanation (see Supplementary Video S3 online).

Discussion

In this original study, we achieved the highest resolution and magnification to date for Ca-MDP nanolayering, aiming to investigating its (non)crystalline nature, resolving its atomic structure and ultrastructural atomic-scale features that may underlie its durable bonding.

For this work, CaCl₂ was selected as the calcium source specifically due to the need to obtain a sufficient quantity of Ca–MDP salt. This amount of pure salt would be extremely difficult to achieve using HAp discs or natural dentin substrates, which provide limited reactive surface area and calcium availability. Initially, we attempted to image Ca–MDP salt formed at a Ca/MDP molar ratio of 2:1, a concentration regime consistent with previously characterized Ca-MDP salts23,34. However, at this ratio, the resulting structures displayed insufficient electron density and were highly susceptible to beam damage, making atomic-resolution imaging unattainable. To address this, we increased the Ca²⁺ concentration to achieve a Ca/MDP molar ratio of ~ 4.91, which resulted in denser salt aggregation. This adjustment significantly enhanced morphological stability and beam resilience while keeping the same architectural dimensions, enabling successful high-resolution imaging while preserving the structural hierarchy of the organic (CH₂)₁₀ backbone during 3D mapping.

The Ca–MDP salt observations at low to regular magnifications revealed the same characteristic nanolayering pattern that has been previously reported in literature20,29,34. However, when attempting to resolve the atomic-scale structure of these Ca–MDP nanolayers, we encountered a significant technical challenge due to electrostatic charging buildup35 High-voltage electron exposure led to localized charge accumulation on the non-conductive Ca–MDP salt surface, resulting in the disruption and eventual disappearance (“burning”) of the nanolayering architecture—an effect also noted under acidic environmental challenges6.

By employing extremely low-dose imaging conditions, we were able to visualize the Ca-MDP nanolayering at very high resolution, sufficient to detect ordered atomic columns if present. However, we were unable to obtain any atomic diffraction patterns at either low or high magnifications. Consequently, conventional visualization methods previously applied to Ca-MDP nanolayering appear unsuitable for volumetric reconstruction or detailed visualization of nanometric structures at adhesive dentin interfaces. Even by employing state-of-the-art microscopy techniques such as riCOM36 and iDPC37imaging—which are specifically designed to address beam-sensitive materials by utilizing machine learning approaches for dose-efficient phase object reconstructions with super-resolution in (near) real-time using a convolutional neural network37we were unable to resolve individual Ca²⁺ atoms within the Ca-MDP nanolayers.

XRD has traditionally been employed to characterize Ca–MDP structures. In the current study, the minor difference (~ 0.3 nm) between the strongest peak at 2θ = 2.7° (corresponding to a d-spacing of 3.2 nm) and the directly observed inter-nanolayer distance of 3.5 ± 1.5 nm is plausibly attributed to electrostatic charging artifacts that arose during atomic-resolution imaging of the highly beam-sensitive Ca–MDP salt. While the presence of three characteristic XRD peaks has historically supported the belief that Ca–MDP nanolayering is crystalline in nature6,32the advanced experiments in the current study nullify this understanding and suggest a more accurate description of Ca-MDP nanolayering salt as self-assembled layer-ordered amorphous salt, thus leading to rejection of the null hypothesis of this study.

This updated understanding is further supported by the fact that the 2θ angles at which these XRD characteristic peaks are typically observed—ranging between 2° and 14°—are relatively low and insufficient to resolve atomic-level lattice structures to proof crystallinity. High-resolution determination of atomic crystallinity generally requires data collection over a wide angular range, typically up to 80° or more, to reveal short interplanar distances and definitive crystal symmetry38. Hence, the observed low-angle peaks are more indicative of long-range layer ordering rather than true atomic crystallinity. However, these 3 characteristic peaks still remain as a valid method to confirm Ca-MDP salt formation.

Taking the previous data and rationale into account, the three characteristic peaks of the Ca-MDP nanolayering are not valid evidence of its crystalline nature but rather more obviously regarded as indications of the inter-Ca-MDP nanolayering distancing on the X, Y, and Z axes of this salt architecture. More importantly, the XRD peak-distancing variations observed by several research groups6,15,29,33,39 are strongly dependent on the nature of the reactant (CaCl2 vs. HAp vs. human tissue)6,23,33the reaction time (several seconds to several hours)4,6the presence of 10-MDP impurities, the type of XRD visualization (powder vs. thin-film)6,33and the final application of a commercial 10-MDP containing a resin monomer versus a pure 10-MDP monomer32,40.

Although we were not successful in obtaining a clear atomic descriptive model of Ca-MDP nanolayering, we were able to tomographically 3D-reconstruct Ca-MDP single nanolayers in their original self-assembled state. During the microscopy experiment, despite the organized assembly nature of the Ca-MDP at the nanolayer level, the salt was observed to produce an uncontrolled haphazard hierarchical spreading on the X, Y, and Z directions/axes with empty spaces (inter-nanolayering spaces of varying sizes) that contained the two back-to-back 10-MDP molecules.

During the atomic level (S)TEM and 3D-ET microscopy experiments, we observed a directional shift in the assembly pattern at the nanolayer level—specifically, a reorientation in the Ca-MDP nanolayer architecture. This phenomenon was also apparent in conventional TEM visualizations of classic 10-MDP-containing adhesive–dentin interfaces. These observed directional changes, along with the 3D-ET data obtained, allowed us to propose a three-dimensional model in which Ca-MDP nanolayers self-assemble along the Z-axis, in addition to the well-documented assembly along the X and Y axes observed in conventional TEM studies29.

The proposed model of the Ca-MDP salt network (Fig. 5b) illustrates the nanolayering architecture extending across the X, Y, and Z axes, with potential entrapment of resin components between the nanolayers. This model is further visualized in the accompanying animation (Supplementary video 3), which depicts the hierarchical self-assembly process that might occur during the bonding step of restorative treatment.

According to the proposed model, despite the non-uniform and non-directional nature of Ca-MDP salt self-assembly along the Z-axis, the long-term durability of 10-MDP-based adhesive systems can be attributed, at least in part, to the potential mechanical penetration of adhesive resin monomer components into the vacant inter-nanolayer spaces between Ca-MDP nanolayers at the nanometric scale. This infiltration is hypothesized to occur during the ~ 30-second clinical bonding protocol, from a clinical translational standpoint. Consistent with our model, these inter-nanolayer spaces may serve as receptacles for adhesive monomers, which, upon polymerization via a 10-second light-curing phase, are believed to contribute to a nanomechanical interlocking effect. This mechanism may offer an additional reinforcing factor to the well-documented chemical bonding efficacy of 10-MDP-containing adhesives. Furthermore, this hypothesis is supported by the persistent challenge in visualizing Ca-MDP nanolayering in resin–dentin TEM sections, even in ultrathin (< 30 nm) gray-scale sections. The interference of embedded adhesive resin monomers with the electron beam likely obscures the high-resolution detection of the nanolayered architecture27,32. Despite not being directly obtained from a real dentin substrate due to the reasons mentioned above, the Ca-MDP salt nanolayering under investigation is this study is identical (in terms of microscopic dimensions; 3.5 nm) to what has been obtained by Yoshihara et., 2021 when visualized in an extracted tooth that was adhesively restored using Clearfil SE Bond 9 years before extraction32.

This proposed rationale is further supported by previous findings demonstrating that adhesive resin regions containing Ca-MDP nanolayers exhibit higher elastic moduli compared to adjacent regions lacking such nanolayer structures32. Moreover, the three-dimensional ‘low-resolution’ characterization reported in that study may indirectly support the current hypothesis by suggesting the potential presence of resin monomers intercalated between individual Ca-MDP nanolayers. In addition, this rationale may also account for the reported enhancement in bonding durability associated with active adhesive application techniques41 prolonged rubbing times during self-etch (SE) bonding procedures42,43 or extended air-blowing phase44,45. These techniques could potentially facilitate a broader spatial distribution of Ca-MDP nanolayers within both the hybrid and adhesive layers. Such dispersion could, in part, explain the previously observed presence of Ca-MDP nanolayers at sites more distant from the hybrid layer30,46 beyond the immediate reaction zone between dentinal hydroxyapatite and the 10-MDP functional monomer.

Considering all analytical techniques employed, the collected data consistently failed to demonstrate definitive evidence of crystallinity in the Ca-MDP salt, thereby supporting the failure to accept the null hypothesis of the current study. Nevertheless, further interpretation of the findings suggests that the long-term bonding durability associated with 10-MDP-based adhesive systems may be attributed, at least in part, to a nanomechanical interlocking mechanism. This mechanism likely involves the entrapment of adhesive resin components containing 10-MDP within the inter-nanolayering spaces of the Ca-MDP nanolayers during the agitation and gentle air-blowing phases—corresponding to the chemical reaction period between 10-MDP and tissue-derived HAp. Subsequent light curing further stabilizes this interfacial architecture, offering an additional contribution to the durable adhesive performance observed in clinical applications.

Materials and methods

Synthesis of Ca-MDP salt

Two grams of CaCl2 (Purity ≥96%, Sigma Aldrich, USA) were stirred in 6 mL of distilled deionized water. In parallel, 1 mL of 10-MDP (Concentration ~ 100%, Lot P01477, DM Healthcare Products, Inc., San Diego, CA, USA47 was dissolved in 5 mL of absolute ethanol. Next, the 10-MDP solution (0.00367 mol, pH 2.4) was added dropwise to the CaCl2 solution (0.0180 mol, pH 5.9) over 5 min under vigorous stirring. The mixture was left to react for 1 h at room temperature, after which the mixture was centrifuged at 3500 RPM, after which the supernatant was collected and discarded. The resultant Ca-MDP salt was washed three times with absolute ethanol and distilled water separately to remove any unreacted 10-MDP monomer or CaCl2 salt. Half of the obtained salt was then air-dried at room temperature for 24 h. The other half was stored in absolute ethanol solution for further investigations.

Characterization of the resultant Ca-MDP salt

The Ca-MDP salt nanolayering was identified by XRD (D8 Advance, Bruker, Germany) at an acceleration voltage of 40 kV, a current of 40 mA, and a scanning rate of 2 s/step for 2θ/θ scans. Low-resolution TEM visualization was carried out by drop casting 1 µL of the Ca-MDP ethanol solution over a lacey carbon 200 M Cu TEM grid (EMS, PA, USA), after which the mixture was left to dry at room temperature. The TEM images were acquired with a JEOL JEM 1400 (JEOL, Tokyo, Japan) transmission electron microscope operated at 80 kV and equipped with an EMSIS Quemesa 11-megapixel camera (EMSIS GmbH, Münster, DE).

Chemo-analytical ultrastructural atomic-level Ca-MDP salt observation

Atomic-level (S)TEM Ca-MDP characterization and periodicity measurements

To gain a more comprehensive understanding of the Ca-MDP salt structure, we conducted a higher-resolution investigation using high-angle annular dark-field scanning transmission electron microscopy (HAADF-STEM). The contrast of the image using this technique is roughly proportional to Z2 which helps in distinguishing the Ca2+ layers within the structure.

HAADF-STEM and high-resolution (HR) TEM images were acquired at low and high magnifications with an aberration-corrected Thermo Fisher Titan Cubed electron microscope equipped with a Gatan K2 direct detector operated at 300 kV. One microliter of the Ca-MDP ethanol solution was dropcast over a lacey carbon 200 M Cu TEM grid (EMS, PA, USA) and left to dry at room temperature. Ca-MDP nanolayering periodicity measurements and fast Fourier transform (FFT) analysis were carried out using Digital Micrograph software (Gatan, Inc., CA, USA).

Real-time integration center of mass (riCOM) and integrated differential phase contrast (iDPC) analysis

riCOM and iDPC imaging were performed on an aberration-corrected Thermo Fisher Themis Cubed transmission electron microscope operating at 300 kV. iDPC imaging was conducted using a segmented ADF detector and Thermo Fisher Velox software. The experimental data for riCOM were gathered using a custom-made Timepix3 detector37,48 that relies on an Advapix TPX3 camera unit. The data were recorded in event-based format and processed as described by Yu et al.36.

Three-dimensional assessment of the Ca-MDP salt network

3D electron tomography (ET) of Ca-MDP nanolayers

Electron tomography was performed using the abovementioned aberration-corrected Thermo Fisher Titan Cubed electron microscope operated at 300 kV using a Fischione 2020 tomography holder. A high-resolution HAADF-STEM tilt series was acquired over a tilt range between ± 75° with a tilt increment of 2°.

Directional change observation and nanomechanical interlocking mechanism modeling

A detailed manual analysis of the directional changes in the Ca-MDP nanolayering was carried out over the X, Y, and Z axes in the obtained 2D HAADF data and the Z axis in the 3D tomography data. 3D dimensional modeling simulations and animations were constructed and performed using Fusion 360 (Autodesk, CA, USA) to further elucidate the suggested mechanism by which the dental bonding resin components might be nanomechanically interlocked between the Ca-MDP nanolayers.

Data availability

The raw data are not publicly available due to ongoing analyses and complementary studies, but are available from the corresponding author upon reasonable request.

References

Carrilho, E. et al. 10-MDP based dental adhesives: adhesive interface characterization and adhesive stability—a systematic review. Materials 12, 790 (2019).

Tavares, F. V. B. et al. Influence of adhesive systems containing different functional monomers on the longevity of bond strength at different dentin depths. Int. J. Adhes. Adhes. 132, 103723 (2024).

Dressano, D. et al. Chemistry of novel and contemporary resin-based dental adhesives. J. Mech. Behav. Biomed. 110, 103875 (2020).

Fujita, K. et al. Effect of reacted acidic monomer with calcium on bonding performance. J. Dent. Res. 90, 607–612 (2011).

Salz, U., Zimmermann, J., Zeuner, F. & Moszner, N. Hydrolytic stability of self-etching adhesive systems. J. Adhes. Dent. 7, 107–116 (2005).

Zhao, Q. et al. Influence of acidic environment on hydrolytic stability of MDP-Ca salts with nanolayered and amorphous structures. Int. J. Nanomed, 1695–1709 (2022).

Furtado, P. R. P., Savanhago, R. M., Castro, N., Gariani, R. A. & Meier, M. M. Synthesis and characterization of the dental adhesive monomer 10-MDP. Dent. Mater. 40, 2000–2007 (2024).

De Oliveira, R. et al. Does addition of 10-MDP monomer in self-etch adhesive systems improve the clinical performance of noncarious cervical lesion restorations? A systematic review and meta-analysis. Oper. Dent. 46, E224–E239 (2021).

Fehrenbach, J., Isolan, C. P. & Münchow, E. A. Is the presence of 10-MDP associated to higher bonding performance for self-etching adhesive systems? A meta-analysis of in vitro studies. Dent. Mater. 37, 1463–1485 (2021).

de Matos, P. Five-year clinical evaluation of a universal adhesive: A randomized double-blind trial. Dent. Mater. 36, 1474–1485 (2020).

Ahmed, M. H., Yao, C., Van Landuyt, K., Peumans, M. & Van Meerbeek, B. Extra bonding layer compensates universal adhesive’s thin film thickness. J. Adhes. Dent. 22, 483–501 (2020).

Ermis, R. B., Ugurlu, M., Ahmed, M. H. & Van Meerbeek, B. Universal adhesives benefit from an extra hydrophobic adhesive layer when light cured beforehand. J Adhes. Dent 21 (2019).

Ahmed, M. H. et al. Do universal adhesives benefit from an extra bonding layer? J. Adhes. Dent. 21, 117–132 (2019).

Giacomini, M. C. et al. Profile of a 10-MDP-based universal adhesive system associated with chlorhexidine: dentin bond strength and in situ zymography performance. J. MECH. BEHAV. BIOMED. 110, 103925 (2020).

Yaguchi, T. Layering mechanism of MDP-Ca salt produced in demineralization of enamel and dentin apatite. Dent. Mater. 33, 23–32 (2017).

Han, F. et al. Interactions of two phosphate ester monomers with hydroxyapatite and collagen fibers and their contributions to dentine bond performance. J. Dent. 122, 104159 (2022).

Fujita, K., Nikaido, T., Arita, A., Hirayama, S. & Nishiyama, N. Demineralization capacity of commercial 10-methacryloyloxydecyl dihydrogen phosphate-based all-in-one adhesive. Dent. Mater. 34, 1555–1565 (2018).

Nurrohman, H. et al. Immobilization of phosphate monomers on collagen induces biomimetic mineralization. Biomed. Mater. Eng. 25, 89–99 (2015).

Zheng, H. et al. Dual functions of MDP monomer with De-and remineralizing ability. J. Dent. Res. 101, 1172–1180 (2022).

Ahmed, M. et al. Multiparameter evaluation of acrylamide HEMA alternative monomers in 2-step adhesives. Dent. Mater. 37, 30–47 (2021).

Ahmed, M. et al. Acrylamide monomers in universal adhesives. Dent. Mater. 39, 246–259 (2023).

Zhang, Z. et al. The effect of prime-and-rinse approach using MDP micellar solutions on extrafibrillar demineralization and dentin bond performance. Dent. Mater. 37, e300–e313 (2021).

Yokota, Y. & Nishiyama, N. Determination of molecular species of calcium salts of MDP produced through decalcification of enamel and dentin by MDP-based one-step adhesive. Dent. Mater. J. 34, 270–279 (2015).

Tian, F. et al. Effect of nanolayering of calcium salts of phosphoric acid ester monomers on the durability of resin-dentin bonds. Acta Biomater. 38, 190–200 (2016).

Tang, C. et al. Experimental two-step universal adhesives bond durably in a challenging high C-factor cavity model. Dent. Mater. 39, 70–85 (2023).

Yoshihara, K. et al. Nano-controlled molecular interaction at adhesive interfaces for hard tissue reconstruction. Acta Biomater. 6, 3573–3582 (2010).

Ahmed, M. Towards mode durable bonding to dentin Doctoral degree thesis, KU Leuven, (2020).

Ahmed, M., Yao, C., Van Landuyt, K., Peumans, M. & Van Meerbeek, B. Dentin conditioned with a metal salt-based conditioner. Dent. Mater. 38, 554–567 (2022).

Tian, F. et al. Paucity of nanolayering in resin-dentin interfaces of MDP-based adhesives. J. Dent. Res. 95, 380–387 (2016).

Tang, C. et al. Bonding performance of experimental HEMA-free two-step universal adhesives to low C-factor flat dentin. Dent. Mater. 39, 603–615 (2023).

Pichat, J., Iglesias, J. E., Yousry, T., Ourselin, S. & Modat, M. A survey of methods for 3D histology reconstruction. MedIA 46, 73–105 (2018).

Yoshihara, K. et al. Nano-Layering adds strength to the adhesive interface. J. Dent. Res. 100, 515–521 (2021).

Yoshihara, K., Nagaoka, N., Yoshida, Y., Van Meerbeek, B. & Hayakawa, S. Atomic level observation and structural analysis of phosphoric-acid ester interaction at dentin. Acta Biomater. 97, 544–556 (2019).

Ma, Y. et al. 10-MDP in dentin bonding: a novel role in pulp protection via modulation of dental pulp stem cell behavior. Clin. Oral Investig. 29, 326 (2025).

Wang, L. et al. Dynamics of the charging-induced imaging instability in transmission electron microscopy. NANOSCALE ADV. 3, 3035–3040 (2021).

Yu, C. P., Friedrich, T., Jannis, D., Van Aert, S. & Verbeeck, J. Real-Time integration center of mass (riCOM) reconstruction for 4D STEM. Microsc Microanal, 1–12 (2022).

Friedrich, T., Yu, C. P., Verbeeck, J. & Van Aert, S. Phase object reconstruction for 4D-STEM using deep learning. Microsc 29, 395–407 (2023).

Petkov, V. Nanostructure by high-energy X-ray diffraction. Mater. Today. 11, 28–38 (2008).

Zhao, Q., Han, F., Yuan, X. & Chen, C. Effects of solvents and pH values on the chemical affinity of 10-methacryloyloxydecyl dihydrogen phosphate toward hydroxyapatite. ACS Omega. 6, 19183–19193 (2021).

Xu, J. et al. A novel prime-&-rinse mode using MDP and MMPs inhibitors improves the dentin bond durability of self-etch adhesive. J. Mech. Behav. Biomed. Mater. 104, 103698 (2020).

Awad, M. M. et al. Adhesive Sonic agitation improves bonding durability to class-II cavity Preparation. Odontology 111, 409–419 (2023).

Irmak, Ö., Yaman, B. C., Orhan, E. O., Ozer, F. & Blatz, M. B. Effect of rubbing force magnitude on bond strength of universal adhesives applied in self-etch mode. Dent. Mater. J. 37, 139–145 (2018).

Jang, J. H. et al. Effect of various agitation methods on adhesive layer formation of HEMA-free universal dentin adhesive. Dent. Mater. J. 38, 101–106 (2019).

Fu, J. et al. Effect of air-blowing duration on the bond strength of current one-step adhesives to dentin. Dent. Mater. 33, 895–903 (2017).

Saikaew, P., Fu, J., Chowdhury, A. A., Carvalho, R. M. & Sano, H. Effect of air-blowing time and long-term storage on bond strength of universal adhesives to dentin. Clin. Oral Investig. 23, 2629–2635 (2019).

Yao, C. et al. High-performance bioinspired microspheres for boosting dental adhesion. Small, 2310251 (2024).

DM Healthcare Products Inc. 10-MDP Material Safety Data Sheet, < (2015). https://www.dmhpi.com/uploads/5/3/6/9/53696567/h1218_msds.pdf

Poikela, T. et al. Timepix3: a 65K channel hybrid pixel readout chip with simultaneous toa/tot and sparse readout. JINST 9, C05013 (2014).

Acknowledgements

We thank Dr. Peter Baatsen (VIB-KU Leuven Center for Brain & Disease Research, Electron Microscopy Platform & VIB-Bioimaging Core) for her help with the TEM acquisition.

Author information

Authors and Affiliations

Contributions

MHA contributed to conception, design, data acquisition, analysis and interpretation, drafted and critically revised the manuscript; DAE. contributed to conception, design and data interpretation, and critically revised the manuscript; NA. contributed to data acquisition, interpretation, and critically revised the manuscript; MMA. contributed to conception, design and data interpretation, and critically revised the manuscript. All authors gave their final approval and agreed to be accountable for all aspects of the work. All the authors discussed and commented on the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Supplementary Material 2

Supplementary Material 3

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Ahmed, M.H., Esteban, D.A., Attik, N. et al. Nanomechanical interlocking mechanism of 10-MDP nanolayering. Sci Rep 15, 28548 (2025). https://doi.org/10.1038/s41598-025-14181-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-14181-y