Abstract

Timely seedling transplantation, though crucial for horticulture, is increasingly becoming uncertain due to seasonal labour shortages, limited mechanization, and higher import and repair costs of automated vegetable transplanters in India. A simple and cost-effective vegetable transplanting device with automatic plug-tray seedling extraction feature was designed and developed considering very limited studies on simple and indigenous automatic seedling extractor design. The developed extractor uses a mechanical toggle mechanism for robustness and a close loop-controlled embedded system to drive it for optimum performance. The crank rotational speed, seedling root bulb moisture content, and needle penetration depth in root bulb were major affecting factors optimized using the RSM to maximize extraction ratio and minimize failure ratio. The seedling extractor performed optimally at an extraction rate of 38 seedlings per minute, bulb moisture content of 75%, and needle penetration depth of 30 mm. The field testing of the transplanting device with the automatic extractor resulted in seedling extraction ratio of 96.05% and field efficiency of 91.8% at 34.62 and 35.47 plantings.min− 1, respectively, for tomato and cabbage seedlings, saving 92.2% time than the conventional manual method. The developed system holds promising prospects for timely and cost-effective vegetable transplanting in India and developing nations.

Similar content being viewed by others

Introduction

High commercial value and demand round the year in local, national and international market, Indian farmers choosing vegetable cultivation rather than conventional crops. Due to which agricultural development has witnessed a paradigm shift towards horticultural value based industrialization during last decade. Due to lack of appropriate transplanting machinery for mechanizing its production, farmers grow vegetables in small field sizes. Indian Ministry of Agriculture and Farmers Welfare indicate that, during the year 2021-22, the total area under vegetable production in India was about 11.3 million ha with an average yield of 18 tones.ha−11. In India, manual transplanting of vegetable seedling is prevalent, which is a very labour intensive, time consuming, and often results no uniform plant distribution2,3. In addition to that, due huge labour involvement the cost of production goes high, so its large scale production is not economical. Generally, in traditional transplanting about 240–320 man-h.ha−1 are needed3. Hence, to meet the global demand, the mechanization of such transplanting operation will be the only possible solution to increase productivity. Moreover, government policy of the country for enhancing horticultural commodity export, especially vegetables as an exportable commodity, calls for the development of a machine for its large scale mechanized transplanting.

To mechanize transplanting operation, a few attempts have also been reported on development of semi-automatic vegetable transplanter (SVT) for different seedlings3,4,5,6,7,8,9,10,11. The studies on maximum seedlings fed in transplanters with revolving magazine type metering were reported to be 32.7 seedlings.min−1 per row12. But, in SVTs, the seedling feeding rates depend on the skill of the worker which decides transplanter capacity. More often, repetitive action involved in manual seedling feeding often quickly induces physical and mental fatigue in operators, thereby increasing the risk of miss-feeding exponentially13,14,15. Also, manual seedling pick-up and drop intervention experience low transplanting rates and high labour costs3,10.

Based on the constraints reported with semi-automatic vegetable transplanters, researchers have attempted to develop several self-feeding mechanisms in which main focus was on development of automatic seedling pick-and-drop mechanisms. Such devices are known as seedling extractors or pick-up mechanisms, and are synonymous to end-effectors of robots16,17. These transplanters with picking mechanism included mainly pin driver17,18,19,20, extractors and grippers9,17,18,21,22,23 developed a dual pin-type seedling pick-up device for extracting plug-type Chinese cabbage seedlings (Brassicarapa Pekinensis group). Han et al.21 developed a doorframe-typed swing seedling pick-up device for automatic vegetable transplanters (AVT). They used pincette-type mechanism for extraction and dropping of plug vegetable seedlings. Jiang et al.9 and Tian et al.24 developed a 4-needle type end-effectors for transferring the plug-type vegetable seedling in high-density growing trays. Recently, Japan’s Yanmar company and Kubota company have developed a single row fully AVT of PW10 Yanmar, SKP-101 series for open field transplanting. Also, research on seedling transplanting using robots is niggardly unlike in China25,26,27,28. Ferrari Company, Italia developed a multi-row AVT in which seedlings are picked from the seedlings tray and then transplanted with electro-mechanical and pneumatic systems. The seedling picking from the tray reduces the process time of singulation and transplanting29. Apart from that, seedling transfer rates of such transplanters are very low, and initial costs are high. Moreover, the manufacturing companies do not have a local network of after-sales repair and maintenance services. Therefore, due to the non-availability of any proper technology, farmers still prefer to transplant seedlings manually.

Considering the mentioned limitations, during past few years, the process of automatic seedling feeding has been attempted for potted vegetable seedlings to overcome labour shortages and slower transplanting rates30,31,32,33. However, such transplanters, need careful replenishment of seedlings manually with fresh seedlings into the metering device. In addition to that, seedlings need to be either grown in bio-degradable paper pots or filled in the pots before transplanting. Also, paper pot seedlings require careful handling during transportation, and placing them on conveyor belts is manual. On the other hand, plug seedlings grown in multi-cavity trays of HDPE material are being widely used by farmers in developing countries like India due to low cost, ease of handling and transportation. Therefore, looking at the requirements of farmers, with the current pattern of vegetable cultivation and nursery seedling preparation technology, a cost-effective, structurally simple transplanter equipped with simple auto-pick and plant mechanism is the need of hour to match the current mechanization requirements with techno-economic feasibility.

With this background, here we developed a novel as well as cost-effective automatic transplanting device for plug seedlings. In this paper, we tried to design and optimize a seedling pick-up mechanism for vegetable seedlings grown in multi-cavity trays in laboratory; and to evaluate performance of the developed system in field with plug type nursery seedlings. The content of this paper is organized as: In Sect. 2, conceptual design, constructional test set and optimization procedure of seedling pick-up mechanism is described. In Sect. 3, actual working and results with detail discussion on experimental study including infield validation are reported. Lastly, concluding remarks are reported as ‘Conclusions’ in Sect. 4.

Materials and methods

Seedling selection and study location

The study used one-month-old plug-type seedlings of brinjal (Variety-F1- Gaurav Hybrid; Pancha Ganga Seeds), tomato (Variety-F1- Ansal Hybrid; Seminis) and, cabbage (Variety-F1-Saint Hybrid; Seminis) obtained from a commercial nursery (Fig. 1). The commonalities among these three different plug seedlings are; (1) seedlings are prepared in tray cells of same geometric shape and size, (2) uses same growing media prepared from combination of cocopeat, vermiculite and perlite in proportion of 3:1:1, and (3) uses same irrigation schedule to maintain its moisture content in the nersery. Considering these commonalities, these seedlings were used for the experiments. The seedlings were grown in 126 cell plug-trays of 14 × 9 rectangular configurations with coco-peat as growth media with vermiculite and perlite in proportion of 3:1:134,35,36. The individual cell has top diameter 32 mm, bottom diameter 20 mm and depth 30 mm. The seedlings were irrigated twice a day for complete one month and were used throughout the experimentation. The average weight, height, stem diameter, canopy (L × W) and, number of leaves of one-month-old seedlings of brinjal was 10.5 g, 129.4 mm, 2.2 mm, 79.3 × 42.2 mm and, 3.5; tomato was 1.1 g, 162.4 mm, 2.6 mm, 110.1 × 43.6 mm and, 8.5; cabbage was 1.4 g, 114.1 mm, 1.9 mm, 91.9 × 45.3 mm and, 3.8, respectively37. The laboratory and field studies were conducted at Dr. Annasaheb Shinde College of Agricultural Engineering and Technology, Mahatma Phule Krishi Vidyapeeth (MPKV), Rahuri, Maharashtra, India. The study methods were carried out in accordance with the university relevant guidelines and regulations, and the experimental protocols were approved by MPKV, Rahuri.

Development of test bench for transplanting of vegetable seedlings

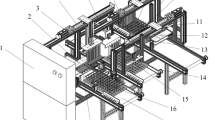

A test bench shown in Fig. 2 was designed for transplanting of vegetable seedlings with an aim that sub-mechanisms of the transplanting device can be tested independently in laboratory and field conditions. The test bench includes four sub-mechanisms viz. automatic seedling extractor prototype, indexing mechanism, embedded system and planting bucket assembly with press wheel. The seedling extractor was designed to pick-up the seedling from plug-tray; indexing mechanism to index the plug-tray seedlings; embedded system for synchronizing the timing of seedling pick-up with respect to indexing mechanism and transplanting bucket; press wheels to firm the soil around the planted seedlings. Constructional details and working of sub-mechanisms of the test set-up is explained under subsequent paragraphs below.

Prototype model of seedling pick-up test bench. (1) DC motor (2) IR proximity sensor (3) Seedling pick-up mechanism (4) Seedling indexing mechanism (5) Micro-switch (6) Stepper motor (lateral shifting) (7) Micro-controller cabinet (8) Stepper motor (longitudinal plug-tray shifting) (9) Geneva wheel mechanism (10) Supporting frame (trolley type).

Automatic seedling pick-up mechanism

A needle-type seedling pick-up mechanism was designed (Fig. 3a, b) and fabricated (Fig. 3c) in computer-aided design (CAD) software PTC Creo 3.0 as shown in, to pick-up the seedlings from the plug-tray and release them to a common point. The pick-up mechanism consists of; (1) pick-up needles, (2) spring (3) push rod, (4) guiding bush, (5) connecting rod, (6) output link, (7) input link, (8) toggle spring, (9) pivot pin, (10) input link stopper, 11) output link stopper, 12) slotted link 13) mounting base, 14) pendulum arm, 15) oscillating arm/link/swinging link, and 16) main frame.

A set of pair of pick-up needles of 3 mm size were used in the mechanism. One end of the needles were hinged on body of pick-up mechanism using two bushes whereas the free ends of needles - tips were kept in contact using a retractable spring as shown in satellite image of Fig. 3 (a). A push rod of the mechanism (forms a part of mechanism) when slides between needles, the needle-tips get separated about 20 mm. The timing of forward and backward movement is adjusted by a multi-link chain mechanism having two sliding pairs and a mechanical toggle mechanism. The working of pusher is described in detail in below heading (working of seedling pick –up mechanism).

CAD model of Seedling pick-up mechanism (a,b) CAD model and (c) fabricated model. (1) pick-up needles, (2) spring (3) push rod, (4) guiding bush, (5) connecting link, (6) output link, (7) input link, (8) toggle spring, (9) pivot pin, (10) input link stopper, 11. output link stopper, 12. slotted link, 13. mounting base, 14. pendulum arm, 15. swinging link, and 16. main frame.

Working of seedling pick-up mechanism

The working (action) stages and positions of push rod are shown in Fig. 4 through position 1–6. The action stages of toggle working are explained as follows.

Position 1: Output link and input link are leaned forward due to toggle-spring. The push rod is toward the needle tips keeping the tips wide open.

Position 2: The input link is experiencing a rearward push by the slotted link, the position of the output link remains the same. The push rod is still toward the needle tips keeping the needle tips wide open.

Position 3: Input link, output link and pivot pin are in-line, forming a straight toggle line resulting in zero force on the output link. Needle tips are opened due to the push rod. Needles start penetrating the root bulb.

Position 4: Slotted link pushes the input link behind pivot pin, forcing the toggle spring to lean the output link rearward quickly. Thus, the connecting link (between output link and push rod) drag the push rod rearward. The push rod’s rearward movement made the needle tips to come closure. At this position, seedling gets gripped by the needles, which are at the peak of the progress stroke.

Position 5: The input link experiences a forward pulling effect due to the slotted link. The output link get away from the tips, thus keeping the needle tips close to each other thus exerting the pressure on seedling to get grasped. This is the regress stroke of the pick-up mechanism.

Position 6: Input link, output link and pivot pin are in-line, forming a straight toggle line resulting in zero force on the output link. With the crank’s slight angular displacement, the input link actuated the toggle spring, thus forcing the output link to slide the push rod forward. Thus, the regress stroke gets ended, and the seedling gets released with the positive thrust of the push rod.

Seedling indexing mechanism

An electro-mechanical indexing mechanism is developed to coordinate the seedlings in pro-tray in X and Y direction for the pick-up mechanism. The indexing mechanism comprises of; (1) Lateral tray shifter, (2) Longitudinal tray shifter, (3) Infra-Red (IR) proximity sensor, (4) Lateral tray micro limit switches, (5) Microcontroller based embedded system, (6) Tray wrapping bars, and (7) Mainframe. The indexing mechanism automatically shifts the entire tray step-by-step in X (row-cell shifting in X-direction) and Y direction (entire row displacement in forward Y-direction) through one cell spacing with the help of two stepper motors. The X directional movement was concerned with lateral tray shifter whereas, Y directional movement is concerned with longitudinal try shifting mechanism.

Lateral tray shifter

The lateral tray shifter has a plug-tray holder, two linear guides, a rectangular frame, a stepper motor (RMCS-2019, NEMA-23 Planetary Geared Stepper Motor), and a rack and pinion gear. Two telescopic flat linear guide rails are provided on the backside of the tray holder. The other side of the rails are nut bolted on fixed frame, thus, keeping the entire tray holder to slide freely along the horizontal rails. The stepper motor, coupled with a pinion gear, is set on the mechanism’s frame. Ultimately, the plug-tray’s side shifting (lateral shifting) is managed by this stepper motor along X-axis.

Longitudinal tray shifting mechanism

The Longitudinal tray shifting mechanism comprises of a drum, drum-shaft, Geneva wheel mechanism (consisting of a 14-slotted wheel and pin-wheel), a stepper motor, and two wrapping bars. A reel-type drum was made from 14 numbers spokes of 4 mm steel rods welded on two discs spaced a distance equal to the width of a standard seedling plug-tray. The drum shaft was horizontally fitted using two pedestal bearings on the sliding frame of the indexing mechanism. The 14-slot Geneva wheel was fitted on one of the drum’s ends to engage with Geneva pin bush-fitted in the stepper motor. The drum was oriented to keep the central axis of the cell being extracted perpendicular to the pick-up needles while penetrating. The stepper motor at the Geneva wheel is fitted on the sliding frame of the indexing mechanism and actuated when the sliding frame touches any of the leaf-switches fitted on either side of the indexing mechanism’s fixed frame.

Two curved guides allow the extracted cell rows of the plug-tray to wrap downward around the cylinder and escape the tray rear word.

Working of seedling indexing mechanism

When extractor reaches at the seedling release position its body move close to an Infra-red (IR) proximity sensor fitted on main frame of the transplanter. The signals from the sensor get communicated to the microcontroller to shift the indexing mechanism laterally by one cell spacing (36 mm). The mechanical movement is done by rack and pinion mechanism and is driven by a stepper motor. The indexing and extraction cycle continues till the seedling in the last cell of the row gets extracted. Then, a micro-switch fitted on the frame gets triggers to shift the entire plug-tray forward with the help of Geneva mechanism which is driven by another stepper motor. Thus, the tray row wraps longitudinally around the drum by 36 mm and new row of seedlings gets oriented for extraction. The micro-limit switch fitted on other extreme ends of indexing mechanism triggers the microcontroller to programmatically reverse the direction after every successive longitudinal index cycle. The lateral and longitudinal shifting of the entire plug-trays is done by these two independent stepper motors. On the other hand, seedling extraction and dropping instances were managed by a push rod of the pick-up mechanism.

Microcontroller based embedded system

Different electronic components used on the transplanter are tabulated in Table 1. The closed-loop control of tray indexing mechanism with synchronized seedling picking and drop is presented by flow chart shown in Fig. 5.

Parameters for optimization of seedling extractor mechanism

The commonly used test indices for testing the efficacy of seedling extractors across several studies17,18,38,39,40 are ‘Success Ratio’, ‘Success Rate’ and ‘Leakage Rate’. However, since the rates compares quantities in different units, the formulae have been modified and reworded as Extraction Ratio (ER) and Failure Ratio (FR) in Eqs. 1 and 2, respectively. Optimizing the operating parameters requires maximizing ER while minimizing FR.

Where N0 -Total number of seedlings in seedling tray, Nf - Number of seedlings not extracted from seedling tray, Ne-Number of seedlings extracted and dropped successfully.

We investigated the effect of three independent parameters viz. moisture content, needle penetration depth, and crank speed on seedling extraction quality for the response variables (dependent parameters) viz. ER and FR. The step-wise regression method fitted the second-order polynomial equation to the experimental data of each response variable. The response surfaces were generated for the fitted model as a function of two variables while keeping third variable at its central value. The machine and operational parameters (moisture content, depth of penetration and crank speed) were optimized for maximum ER and minimum FR. The recorded data of ER and FR were calculated by using Eqs. (1) and (2).

Based on the results of preliminary trials, 75 per cent root bulb moisture content, 25 mm needle penetration depth and 38 rpm crank speed were selected as centre points for optimization of the seedling extraction mechanism.

Statistical design of experiment for optimization of operational parameters

The seedling extractor was tested for increasing rates of seedling extraction, and respective ER and FR were calculated. A Box-Behnken design for three independent variables was used. The independent variables were seedling root bulb moisture content (%; A), needle penetration depth (mm; B) and crank speed (rpm; C), while dependent variables ER and FR were calculated as responses. Generally, root bulb moisture content plays very important role in formation of structurally stable root ball because it is the only part of the seedling which is mostly used in mechanical picking of seedlings41. It is reported that success rate of the pick-up mechanism dropped below 80 per cent when moisture content of the root bulb goes below 48 per cent41. Therefore, for obtaining the structurally stable root bulbs supporting mechanical picking it’s upper and lower moisture levels were required to be determined initially. In preliminary trials, it was observed that average moisture content of root bulbs measured after 24 h of irrigation dropped to 55%, whereas just irrigated (1/2 h) moisture content was 95%. Considering depletions period just after irrigation to 24 h the upper and lower moisture levels were fixed. The moisture contents were measured using the method suggested by Association of Official Agricultural Chemists (AOAC)42. The samples were prepared by trimming the seedlings at its stem and only root bulbs were used. The root bulbs were first weighed using an electronic balance of WENSAR make (model: PGB 1000) of weighing accuracy 0.01 g and then oven dried to constant temperature of 60 ± 2° C43. The independent variables and their variation levels are shown in Table 2 and outline of the experimental design is given in Table 3.

Response surface methodology (RSM) was applied to the experimental data using a statistical software package, Design-Expert version 11.1, to generate response surface plots. The relationship between the responses and three independent variables was evaluated by fitting the second-order polynomial Eq. (3) by step-wise regression method44,45,46.

The response variable and equation of second order polynomial is given below;

Where, Y = Desired value for response, β0, βi, βii, βij = Constants of linear, quadratic and interaction coefficients, Xi, Xj = Level of process variables.

Infield validation and comparison

The tractor drawn automatic vegetable transplanting device was evaluated in the field to understand the performance in actual field conditions. For validating the laboratory results with field results only brinjal crop seedlings were used whereas, for comparing the quality of transplanting in the field three crop seedlings were used viz., tomato, brinjal and cabbage. The field quality comparison parameters for two methods i.e. transplanting with developed transplanter and manual method were intra row distance of seedlings, transplantation depth, missed transplanting, vertical seedlings (seedlings inclined within 30° from vertical), successfully covered seedlings (cover 1), partially covered seedlings (cover 2), excessively covered seedlings (cover 3), survival ratio (seedlings survived after three days of transplanting) and transplanting efficiency (TE).

Before actual trials the field was prepared with one pass of ploughing followed by two passes of rotavator. The soil moisture content and soil bulk density were found to range between 12.5 and 15.8 per cent and 1.54 to 1.65 g.cc−1, respectively.

The tractor speed was calibrated in the field using combination of shifting the lever position and high-low stages of gears to meet the optimized seedlings pick-up rate of 38 seedling.min−1 speed. It was observed that at high lever position and first gear with gradual adjustment of hand throttle gives desired seedling pick-up rate and forward speed was 1.0 km.h−1. The press wheel angle was set at 15° with vertical leaving a space of 50 mm at the bottom to escape the planted seedlings between them. Sufficient soil compaction around planted seedling was confirmed by adding weight of 7 kg on press wheels by trial-and-error method.

The fields of 25 × 50 m size were marked for 600 mm row spacing along the longest size of fields and tractor was driven accordingly along the markings during actual testing. The planting geometry of 450 × 600 mm (plant to plant × row to row spacing) was selected as per the agronomic requirements.

Observations of the manual transplanting of seedlings were recorded at actual farmer’s field with approximately same soil conditions as that of machine transplanting. The mortality of seedlings occurring within three days after transplanting was recorded for mechanical and manual method of transplanting. Transplantation depth and spacing between transplanted seedlings was measured using standard metallic tape of 3 m. The transplanting efficiency was determined by the ratio of seedlings inclined less than 30° from the vertical and proper soil compaction around roots to the total number of seedlings transplanted considering cover 1, cover 2 and cover 3. The angle of root plug axis of seedling with vertical was considered if the stem of seedling was not straight.

Results and discussion

Process of seedling picking

Preliminary prerequisite to complete the seedling transplanting is to pull out the seedling first from seedling tray similar to hand picking and then place it into pit. From the analogy, explained in the Fig. 4 an innovative seedling pick-up mechanism was devised as shown in Fig. 3 and its work processes in Fig. 6 through position a-d. In progress stroke the pick-up needles reaches to seedling root bulb and the push rod still toward the needle tips keeping needle tips wide open (Fig. 6a). With further advancement the needles start penetrating the root bulb however, push rod quickly moves backward allowing needles to come closure due effect of toggle which is explained in Fig. 4. The quick backward movement of push rod and simultaneous closure of needle tips in the seedling root ball tries to grasps the root bulb gradually. When the needles reach at the peak of the progress stroke the seedling gets gripped firmly between the needles (Fig. 6b). When the mechanism moves backward the seedling automatically picked out of tray cell (Fig. 6c). At approximately peak of regress the push rod quickly moves forward simultaneously separating the needle tips apart and pushes the seedling out of the needles (Fig. 6d). This is now again the starting position of pick-up cycle of the mechanism in which impending, piercing, picking, transporting and throwing a seedling phases completed.

Effect of operating parameters on picking quality of seedlings

Extraction ratio of seedling pick-up mechanism

The combination effect of seedling root bulb moisture content, needle penetration depth and crank speed on the extraction ratio of the pick-up mechanism is shown in Fig. 7. The extraction ratio of the seedling pick-up mechanism was in the range of 80.16 to 96.83 per cent. The maximum ER (96.83%) was observed for the treatment combination of run 10 (Table 3), whereas, the minimum ER (80.16%) was observed for the treatment combination of run 6. ANOVA (Table 4) reveals the linear terms A and B and all the quadratic terms A2, B2 and C2 are highly significant (p < 0.01). Furthermore, the linear term C and interaction term B×C were significant (p < 0.05%) for ER, whereas interaction terms A×B and A×C were non-significant for ER. The needle penetration depth was the most influencing parameter followed by seedling root bulb moisture of seedlings.

The lack of fit test was found to be non-significant for ER indicating that the developed model was adequate for predicting the ER of seedling pick-up mechanism for brinjal seedlings. An R2 of 0.8492 obtained for the ER of pick-up mechanism, indicated that the model could explain 84.92 per cent of the response (ER). The model shown in Eq. (4) was selected for representing the variation of the seedling pick-up mechanism and was used for further analysis.

As observed from Fig. 7a, at constant crank speed, the ER increased with moisture content and attained a maximum value of 96.83 per cent at 75 per cent moisture content. Similarly, the ER increased with needle penetration depth. At the needle penetration depth of 25 mm, the ER increased with an increase in crank speed from 33 to 38 rpm and decreased after that (Fig. 7b). Similarly, ER increased with an increase in moisture content from 55 to 75 per cent but reduced with further increase in moisture content (Fig. 7c). As given in Eq. (4), the needle penetration depth had a positive linear effect on the ER, which may be due to the availability of more surface area of the root bulb to the needle contact surface. Similar results were obtained by Choi et al.18, Han et al.19 and Yang et al.47 for plug-type vegetable seedlings. The moisture content and crank speed have slightly negative effect on ER, which may be due to needle surface in contact getting slippery due to increased root bulb moisture. The similar results were obtained by Wang et al.48 for plug-type vegetable seedlings.

The final regression Eq. (4) (excluding the non-significant terms) describes the effects of independent parameters on ER of pick-up mechanism for brinjal seedlings in terms of true values as;

where, Moisture Content (db) is in ‘%’, Needle Penetration Depth is in ‘cm’, and Crank Speed is in ‘rpm’.

The actual vs. predicted values for ER fitted a straight line with an R2 value of 0.9872. Therefore, the Eq. (4) model is suitable for predicting the ER of the seedling extractor mechanism for the selected seedling type.

Failure ratio of seedling pick-up mechanism

The effect of independent parameters (seedling root bulb moisture content, needle penetration depth and crank speed) on the failure ratio of the pick-up mechanism is shown in Fig. 7. The failure ratio of the seedling pick-up mechanism was in the range of 3.96 to 28.28 per cent. The minimum FR (3.96%) was observed for the treatment combination of run 15 (Table 3), whereas, the maximum FR (28.28%) was observed for the treatment combination of run 14. The ANOVA presented in Table 4 reveals that linear terms A, B and C and all the quadratic terms A2, B2 and C2 are highly significant (p < 0.01). The interaction terms A×B and A×C are significant (p < 0.05%) for FR, whereas interaction term B×C are non-significant. The needle penetration depth is the most influencing parameter, followed by root bulb moisture content and crank speed.

The lack of fit test is observed to be non-significant for FR indicating that the developed model was adequate for predicting the FR of seedling pick-up mechanism. With R2 of 0.97, 97.07 per cent variability of the response (FR) could be explained by the model. Therefore, the Eq. (5) model was selected to represent the variation of seedling pick-up mechanism for tomato seedlings and was used for further analysis.

As seen in Fig. 7d, at constant crank speed, the FR decreased with an increase in moisture content to reach a minimum value of 3.96 per cent at 75 per cent moisture content. Similarly, the FR decreased with increase in needle penetration depth. Further increasing the needle penetration from 25 mm and crank speed from 33 to 38 rpm, The FR decreases but increased with increase in parameters (Fig. 7e). Similarly, FR decreased linearly with increase in depth of penetration, and increases with increasing in crank speed from 38 to 43 rpm (Fig. 7f). As given in Eq. (5), the needle penetration depth had a negative linear effect on the FR, whereas, root bulb moisture content and crank speed positively affected the pick-up mechanism. The similar results were obtained by Xin et al.39.

The final regression Eq. (5) (excluding the non-significant terms) describing the effects of independent parameters on FR of the pick-up mechanism in terms of true values as;

where, Moisture Content (db) is in ‘%’, Needle Penetration Depth is in ‘cm’, and Crank Speed is in ‘rpm’.

The actual versus predicted values for FR fitted a straight line with an R2 value of 0.99. Therefore, the Eq. (5) model is suitable for predicting the FR of the seedling extractor mechanism for the selected seedling type.

Optimization and validation of operating parameters for seedling extraction mechanism

After analysing the polynomial equation, a numerical multi-response technique of Design Expert 11.1.2.0 software was used to determine the optimum conditions for the seedling extraction mechanism. The criteria for each independent variable and response and importance of responses were chosen based on desired characteristics of the seedling extraction mechanism and are presented in Table 5. The goals of the process variables i.e., root bulb moisture content, depth of penetration and crank speed were selected within a range.

Optimum conditions for the seedling extraction were determined to obtain maximum ER and minimum FR. The ER and FR were equally important for the successful pick-up of seedlings; therefore, equal importance of 4 was assigned to both. The equal importance of 3 was assigned to all three independent variables. By applying the desirability function method to selected ranges of independent variables, covering our criteria, seedling root bulb moisture content-75 per cent, depth of needle penetration-30 mm and crank speed-38 rpm were obtained as the most desirable solutions for the optimum seedling picking.

The mean values obtained from actual experiments and values predicted by the model are presented in Table 5. With the optimized operating parameters, the experimental values of ER and FR were found to be 96.03 and 5.55 per cent, respectively which were very close to the predicted values 97.55 and 3.65 per cent. The variation of predicted and actual values for the response variables was 1.52 and 1.90 per cent for ER and FR, respectively. These results indicate the model’s suitability for optimizing the seedling extraction parameters for maximum ER and minimum FR possible.

Working process of seedling planting mechanism

A parallelogram type mechanism with a planting bucket was developed to accept the seedlings from pick-up mechanism, transport it to soil and place the seedling into the soil bed (Fig. 8). The lower end of the bucket functions like a bird beak, which when progresses upward remained closed, accepts the seedling thrown by the pick-up mechanism at the top position, digress with seedling till reaches the ground, and opens the symmetrically (beak jaws) to releases the seedling at its extreme bottommost event with zero forward velocity. A retraction spring keeps the jaw intact each other whereas, they get opened when passes through a narrow cavity formed due to sward like stationery cams of the mechanism. The planting bucket’s jaws has two rollers pinned on two sides of the jaws in such a way that when bucket enters the narrow passage the rollers get in direct contact with stationery cams to reduce the frictional effect. The length of the cams was limited in such a way that bucket jaws should closed automatically before receiving the new seedling. Afterwards, the soil alongside of the planted seedlings gets immediately pressed with help of inward tilted trailing type suspended press wheels. The complete working scheme of the planting bucket is presented in Fig. 8 through sequential action a-f whereas Fig. 8g shows line of the transplanted seedlings.

Infield validation

The mean values obtained from actual experiments and values predicted by the model is presented in Table 6. Under the optimized conditions, the predicted values of ER and FR were found to be 97.55 and 3.65 per cent, respectively which were very close to the field values 95.56 and 6.67 per cent. The per cent variation of predicted and actual values for the response variables of seedling pick-up mechanism ranged from 1.99 to 3.41 for ER and 2.7 to 4.3 for FR. These results indicate the suitability of model in optimizing the seedling pick-up mechanism for ER and FR.

Crop based results

Values for various parameters under three different crops indicates satisfactory performance of automatic transplanting in all the parameters except missed transplanting. Intra row distance of seedlings was higher for tomato and brinjal while lower for cabbage crop (Table 7). This variation is negligible as seedling placemet error may exist about less than 5 mm. Also, the machine has mechanically set mechanism (planting jaw) to place the seedlings at equal interval. In such case there is no chance to change the pre-set spacing beyond ± 5 mm unless and until transmission ratios are changed. Also, it is evident from Table 7 that less automatic transplanting method reduces the chance of change in interval from 4.0 to 0.4%.

There are no set criteria for minimum value of missed transplanting. However, missed transplanting is desired to be minimum to avoid replanting the missed places. The automatic transplanting would serve better without compromising time of transplanting. It is worth mentioning here that automatic transplanting indirectly reduces post transplanting shock while providing immediate relief12. Field performance of automatic transplanting of seedlings has been furnished in Table 8. Intra row distance of seedlings (452.0 mm), missed transplanting (9.5%), vertical seedling position (87.4º), cover 1 (96.9%), cover 2 (2.6%), cover 3 (0.5%), transplanting efficiency (93.7%) and survival ratio of seedlings (99.2%) as shown in Table 8. This might be due to machine transplanting has geometrically fixed actions throughout the task. Also, there is little chance of deviation which may create the problem on parameters. Automatic transplanting saves 92.2% time and 14.1% (1281.3 Rs.ha− 1) cost of operation of operation.

Conclusions

A simple, sturdy and innovative automatic extractor was developed to extract the seedlings from a multi-cavity plug-tray and drop them at a standard outlet. The developed close-loop controlled seedling indexing mechanism automates the process of providing the seedlings from the plug-tray for sequential extraction, which is crucial to optimizing the operational parameters of the seedling extractor. The basic unit operations required for extracting seedlings from plug-trays and dropping them was optimized for the operating parameters. Furthermore, the designed seedling extractor can suit several plug-seedling trays configurations with slight modifications in indexing hardware and software and thus can help optimize operational parameters for such configurations. With an extraction ratio of 96.05%, and failure ratio of 3.96% the developed extractor shows promising prospects for integrating with vegetable transplanters for further automating field transplanting operation of plug-type vegetable seedlings.

Data availability

The datasets used and/or analysed during the current study are available from the corresponding author on reasonable request.

Abbreviations

- AVT:

-

Automatic vegetable transplanters

- FR:

-

Failure Ratio

- MPKV:

-

Mahatma Phule Krishi Vidyapeeth

- rpm:

-

Revolution per minute

- RSM:

-

Response surface methodology

- ER:

-

Extraction Ratio

- SVT:

-

Semi-automatic vegetable transplanter

- B0 :

-

Total number of seedlings

- Nf :

-

Number of seedlings not extracted

- Ne :

-

Number of seedlings extracted and dropped

- β0, βi, βii, βij :

-

Constants of linear, quadratic and interaction coefficients

References

Anonymous. Agricultural Statistics at a Glance. Government of India, Ministry of Agriculture & Farmers Welfare, Department of Agriculture & Farmers Welfare, Economics & Statistics Division. 92–93(2023). (2022).

Parish, R. L. Current developments in seeders and planters for vegetable crops. Hort Tech. 15(2), 1–6. https://doi.org/10.21273/HORTTECH.15.2.0346 (2005).

Kumar, G. V. P. & Raheman, H. Vegetable transplanters for use in developing countries a review. Int. J. Veg. Sci. 14(3), 232–255. https://doi.org/10.1080/19315260802164921 (2008).

Satpathy, S. K. & Garg, I. K. Effect of selected parameters on the performance of a semi-automatic vegetable transplanter. Agril Mech. Asia Afr. Latin Am. 39(2), 47–51 (2008).

Manes, G. S. et al. Development and evaluation of tractor operated vegetable transplanter. Agril Mech. Asia Afr. Latin Am. 41 (3), 89–92 (2010).

Narang, M. K., Dhaliwal, I. S. & Manes, G. S. Development and evaluation of a two-row revolving magazine type vegetable transplanter. J. Agril Engg 48(3), 1–7 (2011).

Dihingia, P. C., Kumar, G. V. P., Sharma, P. K. & Neog, P. Hand-fed vegetable transplanter for use with a walk-behind-type hand tractor. Int. J. Veg. Sci. 1–20. https://doi.org/10.1080/19315260.2017.1413477 (2017).

Jiang, Z. et al. Comparing an ant colony algorithm with a genetic algorithm for replugging tour planning of seedling transplanter. Computers Electron. Agric. 113, 225 – 33. https://doi.org/10.1016/j.compag.2015.02.011 (2015).

Jiang, Z., Hu, Y., Jiang, H. & Tong, J. Design and force analysis of end-effector for plug seedling transplanter. PLoS ONE 12(7). https://doi.org/10.1371/journal.pone.0180229 (2017).

Magar, A. P. et al. Feeding performance and challenges in use of semi-automatic vegetable seedling transplanters: a review. Multilogic Sci. 11(38), 1933–1938 (2021).

Miah, M. S. et al. Design and evaluation of a power tiller vegetable seedling transplanter with dibbler and furrow type. Heliyon 9, e17827. https://doi.org/10.1016/j.heliyon.2023.e17827 (2023).

Gaikwad, B. B. Design and development of plug seedling transplanter for vegetable crops. Unpublished PhD Thesis submitted to ICAR-Indian Agricultural Research Institute, New Delhi. (2010).

Splinter, W. E. & Suggs, C. W. Theoretical model for man-machine system in repetitive loading operation. Trans. ASAE 11, 191–194 (1968).

Khadatkar, A., Mathur, S. M. & Gaikwad, B. B. Automation in transplanting: a smart way of vegetable cultivation. Curr. Sci. 115(10), 1884–1892. https://doi.org/10.18520/cs/v115/i10/1884-1892 (2018).

Khadatkar, A., Mathur, S. M., Dubey, K. & Magar, A. P. Automatic ejection of plug-type seedlings using embedded system for use in automatic vegetable transplanter. J. Sci. Industrial Res. 80(12), 1042–1048 (2021).

Ting, K. C., Giacomelli, G. A., Shen, S. J. & Kabala, W. P. Robot work cell for transplanting of seedlings part II - end-effector development. Trans. ASAE 33(3), 1013–1017. https://doi.org/10.13031/2013.31431 (1990).

Khadatkar, A., Pandirwar, A. P. & Paradkar, V. Design, development and application of a compact robotic transplanter using an automatic seedling pick-up mechanism for plug-type seedlings. Sci. Rep. 13(1), 1883. https://doi.org/10.1038/s41598-023-28760-4 (2023).

Choi, W. C., Kim, D. C., Ryu, I. H. & Kim, K. U. Development of seedling pick-up device for vegetable transplanters. Trans. ASAE 45(1), 13–19 (2002).

Tian, S., Qiu, L., Kondo, S. & Yuan, T. Development of automatic transplanter for plug seedling. IFAC Proceedings Volumes 43(26), 79–82. https://doi.org/10.3182/20101206-3-JP-3009.00013 (2010).

Yang, Q. et al. Design of a control system for a mini-automatic transplanting machine of plug seedling. Comput. Electron. Agric. 169, 105226. https://doi.org/10.1016/j.compag.2020.105226 (2020).

Han, L., Mao, H., Hu, J. & Tian, K. Development of a doorframe-typed swinging seedling pick-up device for automatic field transplantation. Span. J. Agricl Res. 13(2), 1–14. https://doi.org/10.5424/sjar/2015132-6992 (2015).

Li, H. et al. Kinematic analysis and test on automatic pick-up mechanism for Chili plug seedling. Trans. CSAE. 31(23), 20–27 (2015).

Yu, Y. et al. Design and experimental research on seedling pick-up mechanism of planetary gear train with combined non-circular gear transmission. Chin. J. Mech. Engg. 32(49), 1–13 (2019).

Tian, Z. et al. Design and experiment of gripper for greenhouse plug seedling transplanting based on EDM. Agronomy 12, 1487. https://doi.org/10.3390/agronomy12071487 (2022).

Hu, J. et al. Dimensional synthesis and kinematics simulation of a high-speed plug seedling transplanting robot. Computers Electron. Agric. 107, 64–72. https://doi.org/10.1016/j.compag.2014.06.004 (2014).

Zhang, Z. et al. Technology progress in mechanical harvest of fresh market apples. ScienceDirect 175(6), 1–13. https://doi.org/10.1016/j.compag.2020.105606 (2020).

Fu, L., Majeed, Y., Zhang, X., Karkee, M. & Faster R e CNN E based apple detection in dense- foliage fruiting-wall trees using RGB and depth features for robotic harvesting. Bio Engg 197, 245–256. https://doi.org/10.1016/j.biosystemseng.2020.07.007 (2020).

Gao, F. et al. Multi-class fruit-on-plant detection for apple in SNAP system using faster R- CNN. Comput. Electron. Agric. 176(6), 1–10. https://doi.org/10.1016/j.compag.2020.105634 (2020).

Ni, Y., Jin, C. & Liu, V. Design and experiment of system for picking up and delivering seedlings in automatic transplanter. Nongye Gongcheng Xuebao/Transactions CSAE. 31(23), 10–19. https://doi.org/10.11975/j.issn.1002-6819.2015.23.002 (2015).

Kumar, G. V. P. & Raheman, H. Development of a walk-behind type hand tractor powered vegetable transplanter for paper pot seedlings. Bio Engg 110(2), 189–197. https://doi.org/10.1016/j.biosystemseng.2011.08.001 (2011).

Magar, A. P. & Nandede, B. M. Design and development of a three row automatic vegetable transplanter for potted seedlings. Final Research Report Submitted to ICAR-Central Institute of Agricultural Engineering, Madhya Pradesh. (2018).

Nandede, B. M. & Raheman, H. A tractor drawn vegetable transplanter for handling paper pot seedlings. Agric. Mecha Asia Afr. Latin Am. 47(4), 87–92 (2016).

Magar, A. P. et al. Optimization, development and evaluation of vegetable seedlings transplanter using inclined magazine-type metering device for cylindrical paper pot seedlings. Agric. Res. https://doi.org/10.1007/s40003-024-00793-9 (2024).

Rao, K. V. R. et al. Training manual on protected cultivation. Technical Report No. CIAE/PFDC/203/426, 46 (2013).

Mohamed, S. & Liu, J. Effect of soil moisture content and end-effector speed on pick-up force and lump damage for seedling transplanting. AgriEngineering 1, 343–356. https://doi.org/10.3390/agriengineering1030026 (2019).

Khadatkar, A., Mathur, S. M., Gaikwad, B. B., Pandirwar, A. & Shrinivas, D. J. Biometric properties of plug vegetable seedlings relevant to the design of vegetable transplanter. J. Agrl Engg. 57(1), 16–24. https://doi.org/10.52151/jae2020571.1700 (2020).

Magar, A. P. et al. Engineering properties of some plug–type vegetable seedlings for development of automatic vegetable transplanter. J. Agrl Engg (India) 1–13. https://doi.org/10.52151/jae2023601.1792 (2023).

Ye, B. et al. Parameter modification guiding optimization design and tests of a rotary transplanting mechanism for rice plug seedlings. Appl. Engg Agric. 31(6), 863–873. https://doi.org/10.13031/aea.31.11198 (2015).

[39] Xin, J. et al. Design and experiment of automatic transplanting device for potted tomato seedlings. Proceedings of the Institution of Mechanical Engineers, Part C: J. Mech. Engg. Sci. 233(3), 1045–1054. https://doi.org/10.1177/0954406218762954 (2018).

Khadatkar, A., Magar, A. P., Sawant, C. P. & Modi, R. U. Development and testing of automatic seedling extractor in robotic transplanter using mechatronics for nursery seedlings. Discover Appl. Sci. 6(51), 1–13. https://doi.org/10.1007/s42452-024-05670-2 (2024).

Jorg, O. J. et al. Design, development and testing of feeding grippers for vegetable plug transplanters. AgriEngineering 3, 669–680. https://doi.org/10.3390/agriengineering3030043 (2021).

AOAC. Standard Official Methods of Analysis of the Association of Analytical Chemists. (14th Ed. Williams, S. W.), Washington DC, 121. (1984).

Ryu, K. H., Kim, G. & Han, J. S. Development of a Robotic Transplanter for Bedding Plants. J. Agric. Engg Res. 78(2), 141–146 (2001).

Taylor, E. H. et al. Spray drying and process optimization of unclarified pomegranate (Punica Granatum) juice. Dry. Tech. 30(May), 787–798. https://doi.org/10.1080/07373937.2012.663434 (2012).

Thirugnanasambandham, K. & Sivakumar, V. Influence of process conditions on the physicochemical properties of pomegranate juice in spray drying process: modelling and optimization. J. Saudi Soc. Agric. Sci. 16(4), 358–366. https://doi.org/10.1016/j.jssas.2015.11.005 (2017).

Muzaffar, K., Bijamwar, V. D. & Kumar, P. Optimization of spray drying conditions for production of quality pomegranate juice powder optimization of spray drying conditions for production of quality pomegranate juice powder. Cogent Food Agric. 76(2), 1–9. https://doi.org/10.1080/23311932.2015.1127583 (2016).

Yang, Y., Ting, K. C. & Giacomelli, G. A. Factors affecting performance of sliding-needles gripper during robotic transplanting of seedlings. Appl. Engg Agric. 7(4), 493–498. https://doi.org/10.13031/2013.26251 (1991).

Wang, M. et al. Design and experiment of crank rocker type clamp seedlings mechanism of vegetable transplanter. Nongye Gongcheng Xuebao/ Trans. CSAE 31(14), 49–57. https://doi.org/10.11975/j.issn.1002-6819.2015.14.007 (2015).

Acknowledgements

Authors are thankful to the Director, ICAR-CIAE Bhopal and Dean, MPKV, Rahuri for their encouragement and constant support during the research. The authors are also thankful to the PI of Centre for Advanced Agricultural Science and Technology for Climate Smart Agriculture and Water Management; and all the staff of the FMPE Division, MPKV Rahuri, for providing the necessary facility to conduct the research.

Author information

Authors and Affiliations

Contributions

APM: Conceptualization, Methodology, Data curation, investigation, writing original draft. SMN: Writing- Review and Editing the draft, supervision. AAW: Logical arrangements in actual experimentation. BBG: Designing Programming and implementation of microcontroller code, Writing- Reviewing and Editing and finalizing the draft. GNS: Statistical analysis and data arrangement. AK: Reviewing, editing, and outlining the original draft. CPS: Reviewing and results computation, and finalization of draft. RUM: Statistical analysis and data arrangement.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Experimental research and field studies on plants must comply with local and national regulations

The plant collection and use were in accordance with all the relevant guidelines. Also, informed consent was taken from all subjects pripor to experiment and/or their legal guardian(s) —for both study participation AND publication of identifying information/images in an online open-access publication (when applicable).

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Magar, A.P., Nalawade, S.M., Walunj, A.A. et al. Development and optimization of an automatic transplanting device for plug tray vegetable seedlings using embedded system. Sci Rep 15, 22483 (2025). https://doi.org/10.1038/s41598-025-86421-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-86421-0