Abstract

Owing to the ultra-wide bandgap energy, high thermal conductivity, and ambipolar capability, GeO2 films are receiving great attention for potential applications in power devices and solar-blind photodetectors. However, the precise control of the crystal structure and optical property is a huge challenge due to close free formation energies of multiple phases, inhibiting the GeO2 based practical device applications. Here, we have fabricated quartz and rutile-GeO2 thin films utilizing the magnetron sputtering based synthetic strategy, which exhibit ultra-wide bandgap energies of 5.51 and 5.88 eV. On the foundation of these ultra-wide bandgap semiconductors, obvious photoresponse characteristics have been achieved at 213 nm and the quartz-GeO2 device exhibits better performances including a short fall time of 148.5 ms, a high photo-dark current ratio of 86.65, large photoresponsivity of 4.56 A/W, and high detectivity of 6.78 × 1013 Jones, which can be attributed to the less oxygen defect exists in the quartz-GeO2 film due to the oxygen-rich growth condition and the better lattice matching with sapphire. Our findings suggest that the GeO2 thin film is a candidate material for optoelectronic device applications and will provide a facile and innovative strategy to develop the solar-blind photodetector.

Similar content being viewed by others

Introduction

Solar blind ultraviolet (UV, 200–280 nm) photodetectors (SBUPs) have the advantages of high sensitivity, good accuracy, high efficiency, strong radiation resistance, and chemical stability, making them widely used in civil and military fields such as corona and arc detection, combustion flame monitoring, and free space communication1,2,3,4. The ultra-wide bandgap semiconductor (UWBS) material plays a vital role in the SBUP application due to the strong optical absorption in the solar blind ultraviolet region and various popular UWBSs including boron nitride, diamond, AlGaN, ZnMgO, Ga2O3, and GeO2 have been growingly explored to develop high-performance SBUPs.

Among these UWBSs, GeO2 emerges to be an ideal candidate for UWBS owing to its suitable ultrawide bandgap, high breakdown electric field, robust chemical stability, and high visible light transparency. Crystal structures of GeO2 can be mainly divided into rutile (tetragonal structure) and quartz (hexagonal structure) phases with similarity in hardness, transparency, and colourlessness. The rutile GeO2 (γ-GeO2) possesses an ultra-wide direct bandgap more than 5.1 eV and exhibits extremely high stability. The quartz GeO2 (a-GeO2) has a wider bandgap energy of approximately ~ 5.9 eV, which implies it is suitable for application in the deeper UV region5,6,7,8,9. Over the last few years, great efforts have been made on the progress in the epitaxial growth of the GeO2 thin film for the development of optoelectronic devices. Deng et al.10 have successfully deposited the (002) and (100) oriented γ-GeO2 thin films with ultra-wide bandgap energies of 5.10 and 5.12 eV on m and c-plane sapphire substrates by employing the pulsed laser deposition method. With the molecular beam epitaxy technology, Chae et al.11 fabricated (010) and (002) oriented γ-GeO2 single crystal films on r-plane sapphire substrates by inserting the buffer layers with different orientations. In our previous work, the strong effect of growth parameters on physical properties of magnetron sputtered GeO2 films were demonstrated and 213-nm SBUPs based on mixed-phase GeO2 films have been achieved for the first time12. These excellent works indicate that both crystal structure and optical bandgap energy of the GeO2 films are highly depending on the epitaxial growth process and parameters, which are also of great significance for UWBSs. For the DC magnetron sputtering growth of the oxide semiconductor film, the Ar/O2 gas flow ratio (GFR) plays an important role due to adjustable physical property of the film and controllable performance of oxide semiconductor based device by changing the GFR13,14. However, up to now, no study on the effect of the Ar/O2 GFR on crystal structure and bandgap energy of the GeO2 thin film and its practical SBUPs has been reported.

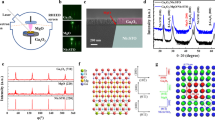

In this work, γ and α-GeO2 films were successfully grown on c-plane Al2O3 substrates by DC reactive magnetron sputtering based epitaxy strategy (Fig. 1), and surface morphologies, crystal structures, element defects, and optical properties of GeO2 films have been systematically investigated. Metal-semiconductor-metal (MSM) SBUPs based on γ and α-GeO2 films were fabricated with the interdigital electrodes. Under 213 nm laser beam irradiation, SBUP based on the α-GeO2 film exhibits the excellent optoelectronic performances including the high photocurrent density of 5.51 nA/mm2, a short fall time (Tf) of 148.5 ms, the photo-dark current ratio (PDCR) of 86.65, the responsiveness (R) of 4.56 A/W and the detectivity (D*) of 6.78 × 1013 Jones. Our findings will promote the development of applications in solar blind ultraviolet range.

Results and discussion

Crystal structure

Figure 2a shows X-ray diffraction (XRD) patterns of A11P2 and A11P4 samples. Two different crystal structures of GeO2 films have been achieved by adjusting the Ar/O2 flow ratio as revealed in the Fig. 2a. The A11P2 sample only has one peak located at 29.5 ° apart from the substrate peak corresponding to (110) plane of the γ-GeO2 film (JCPDS no. 35–0729), indicating the presence of the GeO2 single crystal with the tetragonal phase11,13. In contrast, the XRD pattern of the A11P4 sample exhibits the polycrystalline structure of α-GeO2 film (JCPDS no. 36-1463), seven obvious peaks at 20.6, 27.0, 36.1, 38.2, 39.6, 48.8, and 53.5° corresponding to (100), (101), (110), (102), (11 − 1), (112), and (022) planes of GeO2 films can be observed, respectively13. Full width at half maximum of the (101) peak for A11P4 and the (110) peak for A11P2 as 0.2 and 0.16 ° and the grain sizes of the relevant samples were calculated according to Scherrer’s formula to be 43.2 and 53.4 nm. Actually, the crystal structure of the GeO2 film is very sensitive to the Ar/O2 flow ratio in the magnetron sputtering deposition process. GeO2 thin films prepared in the low O2 flow tends to crystallize in the (100) plane direction the corresponding to the hexagonal phase (see Supplementary Fig. S1). And when the Ar/O2 flow ratio increases to 20:40 sccm/sccm, the crystal structure of GeO2 thin film has undergone a transformation which transitions from the hexagonal phase in polycrystalline structure to tetragonal phase in single crystal. As the Ar/O2 flow ratio continue to increase to 20:80 sccm/sccm, the crystal form has transformed back into the polycrystalline of hexagonal phase. This transformation in the crystal structure can be attributed to the difference in the binding degree of Ge and O atoms during the reactive sputtering process, as well as the carried energy when sputtering onto the substrate13. As the oxygen flow ratio increases, the bombardment of oxygen ions on the target material increases, leading to the increase of energy carried by sputtering onto the substrate15,16,17 and the transformation of the crystal structure.

Surface morphology

To obtain the comprehensive information for surface morphologies of GeO2 thin films, the influence of the Ar/O2 flow ratio on the surface roughness and the grain size of GeO2 films have been investigated. The surface morphology of the A11P2 sample exhibits obvious fluctuations as shown in Fig. 2b and d. The atomic force microscopy (AFM) image of the A11P4 sample shows a relatively dense grain arrangement on the surface (Fig. 2c and e). Moreover, AFM images of GeO2 films with the Ar/O2 flow ratios of 20:10 and 20:20 sccm/sccm were also measured and present in Fig. S2 of the supplementary information. The GeO2 film grown in the hypoxic environment has the higher surface roughness (~ 45 nm) and the larger grain diameter (~ 2 μm), while, in oxygen-enriched environments, the surface roughness and the grain diameter of the grown GeO2 film decreases significantly due to the better combination of Ge and O atoms. The crystallization of the GeO2 film is promoted as the plenty of oxygen provided in the magnetron sputtering deposition process13. For comparison, variations of the surface roughness and the grain diameter for the GeO2 films have been summarized in the Fig. S3 of the supplementary information.

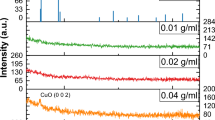

Optical property

The fabricated A11P2 and A11P4 samples exhibit the transmittance higher than 80% in the visible light range and obvious absorption edges around 210 nm as shown in Fig. 2f, implying that these UWBS GeO2 films have potential for solar-blind photodetection. The redshift in the absorption edge of the γ-GeO2 film relative to that of the α-GeO2 film implies the less narrow bandgap. Figure S4 of the supplementary information confirms that the Ar/O2 flow ratio of the magnetron sputtering also has a strong influence on optical properties of GeO2 films. The GeO2 film grown in hypoxic environments has a low transmittance in the full measured spectrum range which is the result of the excessive oxygen vacancies13,18. The defect states in the bandgap of the GeO2 film are induced by these oxygen vacancies, leading to the optical absorption in the near UV or visible region, which is unfavorable to SBUPs. Unlike the GeO2 film deposited in hypoxic environments, when the deposition environment changes to the oxygen-enriched environment, the transmittance of the samples in the visible light range significantly increases and the absorption edge of GeO2 films show blueshifts, which is mainly caused by the increase of oxygen atmosphere reduces oxygen vacancies and improves crystal quality.

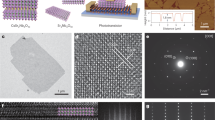

Interface analysis

Figure 3 shows cross-sectional transmission electron microscopy (TEM) images of A11P2 and A11P4 samples. Schematic lines were arranged in different directions on the TEM images to measure interplanar distances. As shown in the Fig. 3(a-c), the A11P2 sample exhibits a three-layer structure. The regular lattice arrangement can be seen from the high magnification TEM image shown in Fig. 3b, indicating that the GeO2 thin film of A11P2 sample is composed of a large range of single rutile phase. While from Fig. 3(d-f), it can be found that the GeO2 film in the A11P4 sample has lattice arrangements in different directions, which confirms the GeO2 film prepared at Ar/O2 flow ratio of 20:80 sccm/sccm have the polycrystalline structure. It’s worth noting that, between the rutile structure GeO2 film and the sapphire substrate, a 54 nm thick transition layer appears and has an obvious amorphous structure (Fig. 3c), but a very thin amorphous transition layer with the thickness of about 7 nm at the interface of the A11P4 sample (Fig. 3d). And the reason for the obvious decrease in the thickness of the transition layer can be attributed to the different oxygen atmospheres during the deposition process, which leads to changes in crystal structure. The crystal growth direction of polycrystalline α-GeO2 at the interface has better lattice matching with the substrate, making it crystallize more easily. Lattice mismatch percentages for both a and b-axis between γ-GeO2 film and c-plane Al2O3 substrate are 7.6% for the A11P2 sample, which are larger than those of 4.8% for the A11P4 sample, leading to the formation of the thicker amorphous layer in the A11P2 sample. Electron diffraction patterns of A11P2 and A11P4 samples, as shown in Fig. 3g and h, exhibit single crystal and polycrystalline patterns, respectively. It is consistent with the observed results of XRD and TEM measurements. The interplanar distances can be found to be 3.10 Å for (110)-oriented lattice plane in the A11P2 sample and interplanar distances of (100) and (101)-oriented lattice planes in the A11P4 sample are 4.22 and 3.23 Å. These interplanar distance values are close to those calculated from XRD measurements, in which the calculated interplanar distance of 3.02 Å corresponds to (110) peak of the A11P2 sample and interplanar distances for (100) and (101) peaks of the A11P4 sample are 4.30 and 3.29 Å. The composition imaging analysis based on Fig. 3i and Fig. S5 of the supplementary information were conducted through the elemental spectra for Ge, Al, O and Pt elements in the A11P2 and A11P4 samples, respectively. Relatively clear and uniform interfaces between the GeO2 film and the sapphire substrate are observed in both A11P2 and A11P4 samples, suggesting the successful fabrication of the high quality GeO2 films.

(a) Cross-sectional TEM image of the A11P2 sample. High magnification TEM images of A11P2 sample for (b) the γ-GeO2 layer and (c) the interface between GeO2 film and substrate. (d) Cross-sectional TEM image of the A11P4 sample. High magnification TEM images of A11P4 sample with (e) the GeO2 layer and (f) the interface between α-GeO2 film and substrate. Electron diffraction patterns of (g) hexagonal and (h) rutile GeO2 layers. (i) Low magnification TEM cross-sectional view of A11P4 test sample and elements mappings of Al, O, In, and Pt atoms in their respective films.

XPS binding energy

To further elucidate the chemical composition and oxygen defects in GeO2 thin films. As shown in Fig. 4a and Fig. S6 of the supplementary information, five core level peaks from O 1s, C 1s, Ge 3s, Ge 3p, and Ge 3d have been obtained, locating at 531.1, 284.0, 183.8, 125.0, and 32.6 eV, respectively10. Auger peaks of the Ge element are in the range from 316.5 to 450.3 eV. Figure 4b and c present X-ray photoelectron spectroscopy (XPS) spectra of Ge 3d peaks for GeO2 thin films prepared for A11P2 and A11P4 samples, which can be resolved into two overlapping components. The O-Ge bonds in GeO2 films are contributed to the formation of peak (GeO2) at higher binding energy positions (33.05 eV). The influence of oxygen defects forms peak (GeO) at lower binding energy positions (31.65 eV). The area ratios of GeO/(GeO + GeO2) of A11P2 sample is about 0.38, while the area ratio of GeO/(GeO + GeO2) of A11P4 sample decreases down to 0.27, indicates the less oxygen defects exist in the A11P4 sample. It is mainly attributed to the better lattice matching between GeO2 thin film and sapphire substrate as confirmed 7-nm amorphous layer in the TEM image, which induces the less number of the oxygen defect in the GeO2 film growth process. Moreover, more oxygen plasmas take part in the magnetron sputtering deposition process for the A11P4 sample, making the increase number of O-Ge bonds to form the more GeO2 molecules and reduce the oxygen vacancy. A11P0 and A11P1 samples prepared in poor oxygen conditions have the area ratios of 0.31 and 0.30 (see Supplementary Fig. S7), which are lower than that of the A11P2 sample. The transition of crystal structure from tetragonal to hexagonal phases results in a more stable tetragonal phase, which is more difficult to adsorb oxygen to fill oxygen vacancies compared to hexagonal phases during high-temperature annealing20,21.The optical bandgap energy of the UWBS thin film plays a crucial role in the photodetector applications. Due to the large bandgap energies of grown GeO2 films, it is difficult to obtain complete absorption edges through transmission absorption spectra for calculating their bandgap energies. Therefore, to ensure the accuracy of bandgap calculation, bandgap energies of A11P2 and A11P4 samples were calculated by analyzing energy loss spectra22,23,24,25,26,27,28, in which bandgap energy values for A11P2 and A11P4 samples have been obtained to be around 5.51 and 5.88 eV. Noting that the γ-GeO2 thin film grown by PLD method exhibits a different bandgap energy value of ~ 5.1 eV, which is caused by the lattice orientation difference in the grown GeO2 films. For comparison, the bandgap energies for A11P0 and A11P1 samples prepared in poor oxygen conditions were also calculated (see Supplementary Fig. S8) and the effect of Ar/O2 flow radio on the bandgap energy of the GeO2 film are summarized in Fig. S9 of the supplementary information.

Device performance

To verify potential applications of GeO2 thin films in the UV region, I-V curves of MSM SBUPs based on A11P2 and A11P4 samples with γ and α-GeO2 crystal structures were measured in dark and at different irradiation optical power densities (IOPDs) of 213 nm laser beam irradiation as depicted in Fig. 5a and b. Compared to the dark current density of 0.07 nA/mm2 for the A11P2 based MSM SBUP, the photocurrent densities have obvious improvement due to optical absorption at solar blind UV range at 40 V, which are 1.84, 3.10, 4.72, and 5.51 nA/mm2 corresponding to the IOPDs of 200, 450, 700, and 950 nW/cm2, respectively. The A11P4 based MSM SBUP has a higher dark current density (0.14 nA/mm2) than that of the A11P2 based MSM SBUP, and the photocurrent densities at 200, 450, 700, and 950 nW/cm2 IOPDs also increase to 9.12, 10.07, 11.02, and 12.22 nA/mm2 at 40 V, respectively. To further investigate the photoelectric properties of the SBUPs, the devices were irradiated with the periodic (~ 10 s) laser beam irradiation at the varying bias voltage. As shown in Fig. 5c and d, I-T curves with 10 V step ranging from 10 to 40 V of SBUPs are displayed at the same IOPD of 950 nW/cm2. The device possesses an instantaneous response to the incident light of a periodic switch and the photocurrent can change remarkably when the applied voltage changes29,30,31.

I-V curves measured at the different irradiation optical power densities of the 213 nm laser beam irradiation for SBUPs based on (a) A11P2 and (b) A11P4 samples. I-T curves measured at with different bias voltages for SBUPs based on (c) A11P2 and (d) A11P4 samples. Tr and Tf of SBUPs based on (e) A11P2 and (f) A11P4 samples.

The response time reflects the response speed of the SBUPs which can be divided into rise time (Tr) and Tf, in which Tr is defined as the time that the photocurrent rises from 10 to 90% and Tf is defined as the time that the photocurrent drops from 90 to 10%. As shown in Fig. 5e and f, Tr and Tf of γ-GeO2 (α-GeO2) MSM SBUPs were calculated to be 155.0 (122.2) and 148.8 (148.5) ms. And as shown in Fig. S10 of the supplementary information, I-T curves were measured at the bias voltage of 40 V and the IOPD of 950 nW/cm2 of SBUPs based on A11P0 and A11P1 samples. Obviously, the SBUP of A11P0 exhibits a higher photocurrent density and a slower photo-response. More matched bandgap energy with the wavelength of the irradiation laser beam make SBUPs based on A11P0 sample has the higher photocurrent density. However, the oxygen poor environments induced the more oxygen defects in the A11P0 sample, which captures the photo-induced carriers and extend the photo-response time.

The photo-dark current ratio (PDCR), an important parameter, can reflect the resolution of photoelectric detectors. The smaller dark current is highly desired for photoelectric detectors, which represents a slighter impact to the photocurrent and makes the higher resolution of the detectors. The PDCR can be calculated as the following Eq. (1)29,30,31,32,33,34,

Where Iph and Id are photocurrent and dark current. Responsivity (R) is the ratio of the photocurrent density generated by the photoelectric detector to the total optical power irradiating onto the effective area of the device surface. And R is used to describe the sensitivity to the optical radiation of the detectors and always calculated as the following Eq. (2)29,30,32,33,34,35,36,37,

In which A is the active area of the device and Pinc is the IOPD. D* represents the ability to detect weak light and is a crucial parameter for evaluating the performance of SUBP, which can be calculated as the following Eq. (3)29,30,31,36,

Where e is the electronic charge, and Jd is the dark current density. Figure 6a-c show the variation of PDCRs, R, and D* of SBUPs based on A11P2 and A11P4 samples at different IOPDs, respectively. With the increase of the IOPD, PDCRs of SBUPs present linear growth and at the IOPD of 950 nW/cm2, PDCRs of SBUPs based on A11P2 and A11P4 samples are 86.65 and 74.69. However, The R of SBUPs shows an opposite trend to PDCRs which declines with the IOPD. At the IOPD of 950 nW/cm2, the R of SBUPs based on A11P2 and A11P4 samples was calculated to be 0.58 and 1.29 A/W, while the maximum R of these SBUPs has been obtained at the IOPD of 200 nW/cm2 as 0.92 and 4.56 A/W corresponding to A11P2 and A11P4 samples. Meanwhile, the D*s of SBUPs based on A11P2 and A11P4 similar variation trends with the Rs, which the maximum value can be obtained as 6.78 × 1013 and 1.89 × 1013 Jones at the IOPD of 200 nW/cm2. A11P4 sample exhibits better PDCR, R, and D* than A11P2 sample which is the result of the scarce of oxygen defects38.

(a) PDCR, (b) R, and (c) D* of SBUPs based on A11P2 and A11P4 samples. Energy band schematic diagrams of MSM SBUPs based on (d) A11P2 and (e) A11P4 samples in dark without bias voltage. Energy band schematic diagrams of MSM SBUPs based on (f) A11P2 and (g) A11P4 samples under 213 nm irradiation with bias voltage.

In order to investigate the mechanism of photoelectric responses for SBUPs based on GeO2 thin films with different crystal structures, the relaxation processes of photo-induced carriers in the working process of the device are further analyzed. The ultraviolet photo electron spectroscopy (UPS) spectrum for the Ag electrode is measured to determine the band offset of the GeO2/Ag heterostructures in the SBUPs. As the cut-off feature is formed by inelastically scattered photo-electrons, the excitation energy has no significant influence on the cut-off position. Therefore, the location of the cut-off is only determined by the work function of the sample39,40,41,42. Therefore, the work function of Ag electrode was calculated as 5.44 eV as shown in Fig. S11 of the supplementary information. Due to the high resistance of the undoped GeO2 film, it is a great difficulty to measure the work function of the GeO2 film by the UPS system. The work function of 4.90 eV is used as reported in the literature for the calculation, and the electron affinity (EA) were calculated as 2.14 and 1.96 eV for A11P2 and A11P4. The barrier height between the conduction band and Ag energy levels (ΔEc) can be calculated based on the work function (Wf) by the equation as the position of conduction band minimum, as the following Eq. (4)43,44,

And the energy level difference between valence band and Ag energy level (ΔEv) can be calculated by the Eq. (5)45,

Where the \(\:{\text{E}}_{\text{g}}^{{\text{GeO}}_{\text{2}}}\) is the bandgap of the GeO2 film which can be calculated by the energy loss peak of O 1s spectrum of the GeO2 film in Fig. 4d and e. The ΔEc is determined to be 3.30 and 3.48 eV and the ΔEv of SBUPs based on γ-GeO2 and α-GeO2 are 2.21 and 2.40 eV.

Energy band diagrams of the GeO2/Ag heterostructures have been shown in Fig. 6d and e. In dark environments, it is difficult for electrons to cross the bandgap and reach the electrode for transmission. However, under 213 nm illumination, electrons gain higher energy to cross the bandgap, thereby increasing the current density of the device as shown in Fig. 6f and g46,47,48,49,50. The SBUP based on the α-GeO2 film has a higher current density and an increase of about 2.22 times compared to the SBUP based on the γ-GeO2 film at the light density of 950 nW/cm2. There is no significant difference on fall times between the detectors prepared based on the two crystal structures, while rise times of detectors based on the α-GeO2 film is almost 0.83 times shorter than that of detectors based on the γ-GeO2 film. It indicates that detector based on the α-GeO2 film have faster response speed and shorter electron relaxation time. By comparing PDCR, R and D* of these devices, it can be clearly seen that the performance of the α-GeO2 based detector is superior to those of the γ-GeO2 based detector. One reason for this can be mainly attributed to the α-GeO2 film has a wider bandgap to be more suitable for absorbing light at a wavelength of 213 nm, which makes it possesses higher photon utilization. Moreover, single crystal γ-GeO2 film exhibits the more oxygen vacancies as confirmed by XPS measurements, which leads to the more capture centers of photon-generated carriers and the single crystal γ-GeO2 film has a smaller \(\Delta {\text{E}}_{{\text{v}}}\), making it easier for deep trap energy levels to capture charge carriers51. Some photon-generated carriers trapped by induced capture centers in the carrier transport process results in a decrease in photoresponse current52,53,54. In order to properly evaluate the level of these undoped GeO2 based devices, SBUPs performances based on other undoped UWBS materials have been summarized in the Table 1. In comparison, the detector prepared based on the α-GeO2 film has more efficient R and a shorter Tr, suggesting, SBUPs based on α-GeO2 thin films have great potential in the field of solar blind light detection.

Conclusions

The γ and α-GeO2 thin films have been successfully grown on c-plane sapphire substrate using DC magnetron sputtering method, which are confirmed with single crystal and polycrystalline structures, respectively, by using both XRD and electron diffraction measurements. Based on the XPS measurements, the γ and α-GeO2 thin films exhibit an ultra-wide bandgap of approximately 5.51 and 5.88 eV, and the more oxygen vacancies have been found in the γ-GeO2 film due to the larger lattice mismatch verified by the amorphous layer over 50 nm thick and the decrease number of O-Ge bonds in the growth process. Moreover, MSM structure SBUPs based on γ and α-GeO2 thin films have been fabricated by depositing the Ag interdigital electrodes. Under 213 nm ultraviolet laser beam irradiation with a IOPD of 950 nW/cm2, photoresponse current of the SBUP based on α-GeO2 films is 2.22 times higher than that of the γ-GeO2 SBUP at 40 V and the Tr reduced by nearly 0.17. PDCRs present linear growth trends and were calculated as 74.69 and 86.65 for γ and α-GeO2 based SBUPs. The maximum R and D* of SBUPs have been obtained at the IOPD of 200 nW/cm2 as 0.92 and 1.89 × 1013 Jones for the γ-GeO2 SBUP and 4.56 A/W and 6.78 × 1013 Jones for the α-GeO2 SBUP. Obviously, the α-GeO2 device exhibits the better performance for 213-nm SBUP applications due to the appropriate bandgap energy and the less oxygen defects participating in the photo-induced carrier relaxation process. We believe that these results will provide assistance for the development of GeO2 thin films in solar blind light detectors and will broaden the application prospects of GeO2 thin films in ultraviolet applications.

Methods

Before placing them in the sputtering chamber, c-plane Al2O3 substrates were cleaned in ultrasonic cleaning machine with isopropanol, anhydrous ethanol, and deionized water for 5 min respectively, and dried in an oven. And then, the basic pressure of the sputtering chamber was set to be 4 × 10− 4 Pa by the turbomolecular pump system before the start of sputtering. After that the Ar/O2 mixture gas used as a working gas was introduced into the chamber in ratios of 20:10, 20:20, 20:40, and 20:80 sccm/sccm, respectively, to adjust the chamber pressure as 3.5 × 10− 1 Pa, which could also remove the residual air in the sputtering chamber. During the sputtering process, a Ge target material with the purity of 99.999% was used as the deposited metal precursor and the power of the plasma source was set to be 50 W with a distance of 7.5 cm between the sample and the target material. In comparison with GeO2 films fabricated in our previous work, the as-grown GeO2 films were prepared at room temperature to avoid crystal structure selection in the growth process12. After the deposition, GeO2 films were transferred to a muffle furnace and annealed at 1100 ℃ for 2 h at a heating rate of 10 ℃/min in atmospheric environment, and cooled at a rate of 5 ℃/min to obtain A11P0, A11P1, A11P2, and A11P4 samples. To realize GeO2 SBUPs, forked silver electrodes were deposited on GeO2 thin films using magnetron sputtering method and annealed in a vacuum environment for 10 min at the temperature of 200 ℃.

Based on the ultra-wide bandgap GeO2 films, MSM structure devices with interdigital electrodes towards SBUP applications have been designed as shown in Fig. 6. MSM photodetector structures are based on the bottom layer of a c-plane Al2O3 substrate layer with an absorption layer of GeO2 thin films which is deposited on it, and two Ag interdigital electrodes with finger width, length, and spacing as 100, 1500, and 120 μm.

TEM characterizations of GeO2 thin films were performed on Talos F200s operating at 200 kV. Test samples were fabricated with a focused ion beam (FIB) technology12. After selecting the appropriate area on the sample, the standard protocol for the Test sample preparation was operated. A Pt protective layer was deposited on the surface of the exposed GeO2 film by using a Ga ion beam at 30 kV. Then, the target area was ablated with FIB (30 kV) and cut into a prismatic shape. The sample was further mounted on a Cu grid and the final TEM sample. Crystal structures of GeO2 films were measured with 0.02° each step using conventional θ-2θ scan XRD (Bruker D8 Advance) with a Cu Kα (λ = 0.15405 nm) source at 40 kV and surface morphologies of GeO2 thin films were measured by AFM (Ntegra Spectra). UV absorption spectra of thin films were measured by using an UV visible absorption spectrometer. Elemental compositions of GeO2 thin films were identified with the energy step size was 0.05 eV by XPS (Thermo ESCALAB 250XI) with a monochromatized Al Kα x-ray source. During the measurement process, the XPS chamber maintained at a vacuum degree of 1 × 10− 7 mbar and a charge neutralization source was used to neutralize the charging effect. UPS measurements were performed without bias voltage with a He-I 21.22 eV UV lamp and the energy step size was set to be 0.05 eV. Photoelectric characteristics of GeO2 SBUP were tested using a photoelectric performance testing platform with Keithley 2450 Source Table as the source.

Data availability

The datasets used and/or analyzed during the current study available from the corresponding author on reasonable request.

References

Zhang, Q. Y. et al. Enhanced gain and detectivity of unipolar barrier solar blind avalanche photodetector via lattice and band engineering. Nat. Commun. 14, 418 (2023).

Zhao, B. et al. Solar-blind avalanche photodetector based on single ZnO-Ga2O3 core-shell microwire. Nano Lett. 15, 3988–3993 (2015).

Wang, D. H. et al. Pt/AlGaN nanoarchitecture: Toward high responsivity, self-powered ultraviolet-sensitive photodetection. Nano Lett. 21, 120–129 (2021).

Li, L. et al. Ultrahigh-performance solar-blind photodetectors based on individual single-crystalline In2Ge2O7 nanobelts. Adv. Mater. 22, 5145–5149 (2010).

Rahaman, I., Duersch, B. G., Ellis, H. D., Scarpulla, M. A. & Fu, K. Epitaxial growth of rutile GeO2 via MOCVD. Appl. Phys. Lett. 125, 102103 (2024).

Nalam, P. G., Das, D., Tan, S. S. & Ramana, C. V. Controlled phase stabilization enabled tunable optical properties of nanocrystalline GeO2 films. ACS Appl. Electron. Mater. 4, 3115–3124 (2022).

Chae, S. et al. Toward the predictive discovery of ambipolarly dopable ultra-wide-band-gap semiconductors: The case of rutile GeO2. Appl. Phys. Lett. 118, 260501 (2021).

Ma, R., Yu, Z. M., Ye, Z. J., Yang, Y. & Sun, J. M. Electroluminescence from Er-doped GeO2 nanofilms fabricated by atomic layer deposition on silicon: effect of annealing temperature on film properties. Appl. Surf. Sci. 639, 158187 (2023).

Baghdedi, D. et al. Comprehensive growth and characterization study of GeOx/Si. J. Mol. Struct. 1274, 134398 (2023).

Deng, G. F. et al. Heteroepitaxy of (100)-oriented rutile GeO2 film on c-plane sapphire by pulsed laser deposition. Mater. Lett. 326, 132945 (2022).

Chae, S. et al. Germanium dioxide: A new rutile substrate for epitaxial film growth. J. Vac Sci. Technol. A. 40, 050401 (2022).

Wei, C. M. et al. The fabrication of ultra-wide bandgap GeO2 thin films by DC Magnetron sputtering: The impacts of growth temperature and post-annealing process. Vacuum 225, 113233 (2024).

Rathore, M. S. et al. Role of oxygen pressure on the structural and photoluminescence properties of pulsed laser deposited GeO2 thin films. Phys. B. 625, 413466 (2021).

Bose, N., Basu, M. & Mukherjee, S. Study of optical properties of GeO2 nanocrystals as synthesized by hydrothermal technique. Mater. Res. Bull. 47, 1368–1373 (2012).

Cormier, P. A. et al. Titanium oxide thin film growth by magnetron sputtering: Total energy flux and its relationship with the phase constitution. Surf. Coat. Tech. 254, 291–297 (2014).

Martin, N., Santo, A. M. E., Sanjinés, R. & Lévy, F. Energy distribution of ions bombarding TiO2 thin films during sputter deposition. Surf. Coat. Tech. 138, 77–83 (2001).

Pokorny, P., Bulir, J., Lancok, J., Musil, J. & Novotny, M. Generation of positive and negative oxygen ions in magnetron discharge during reactive sputtering of alumina. Plasma Process. Polym. 7, 910–914 (2010).

Yan, Z. et al. Impacts of preparation conditions on photoelectric properties of the ZnO:Ge transparent conductive thin films fabricated by pulsed laser deposition. J. Alloy Compd. 812, 152093 (2020).

Zhang, C. et al. High-performance fully transparent Ga2O3 solar-blind UV photodetector with the embedded indium-tin-oxide electrodes. Mater. Today Phys. 33, 101034 (2023).

Nhu, T. Q., Friák, M., Miháliková, I., Kiaba, M. & Hong, N. H. Profiles of oxygen and titanium point defects in ferromagnetic TiO2 films. J. Phys. D Appl. Phys. 57, 265302 (2024).

Nam, K., Oh, J. H., Bae, J. S. & Lee, S. Effects of heat treatment on the microstructure and optical properties of sputtered GeO2 thin films. Adv. Eng. Mater. 25, 2300456 (2023).

Deng, G. F., Saito, K., Tanaka, T., Arita, M. & Guo, Q. X. Pulsed laser deposition growth of ultra-wide bandgap GeO2 film and its optical properties. Appl. Phys. Lett. 199, 182101 (2021).

Chen, Z. W. et al. Band alignment of Ga2O3/Si heterojunction interface measured by X-ray photoelectron spectroscopy. Appl. Phys. Lett. 109, 102106 (2016).

Wang, X. et al. Energy band bowing parameter in MgZnO alloys. Appl. Phys. Lett. 107, 022111 (2015).

Tashiro, M. et al. Experimental determination of solidified lithium disilicate crystal bandgap energy using EELS and XPS. J. Am. Ceram. Soc. 103, 5139–5144 (2020).

Resende, J., Fuard, D., Le Cunff, D., Tortai, J. H. & Pelissier, B. Hybridization of ellipsometry and energy loss spectra from XPS for bandgap and optical constants determination in SiON thin films. Mater. Chem. Phys. 259, 124000 (2021).

Nichols, M. T. et al. Measurement of bandgap energies in low-k organosilicates. J. Appl. Phys. 115, 094105 (2014).

Posadas, A. B., Lin, C. W., Demkov, A. A. & Zollner, S. Bandgap engineering in perovskite oxides: Al-doped SrTiO3. Appl. Phys. Lett. 103, 142906 (2013).

Kim, D. & Leem, J. Y. Crystallization of ZnO thin films via thermal dissipation annealing method for high-performance UV photodetector with ultrahigh response speed. Sci. Rep. 11, 382 (2021).

Goswami, L. et al. Fabrication of GaN nano-towers based self-powered UV photodetector. Sci. Rep. 11, 10859 (2021).

Elsayed, A. M., Rabia, M., Shaban, M., Aly, A. H. & Ahmed, A. M. Preparation of hexagonal nanoporous Al2O3/TiO2/TiN as a novel photodetector with high efficiency. Sci. Rep. 11, 17572 (2021).

Lu, Y. J., Lin, C. N. & Shan, C. X. Optoelectronic diamond: Growth, properties, and photodetection applications. Adv. Opt. Mater. 6, 1800359 (2018).

Pandit, B., Schubert, E. F. & Cho, J. Dual-functional ultraviolet photodetector with graphene electrodes on AlGaN/GaN heterostructure. Sci. Rep. 10, 22059 (2020).

Chen, J. X., Ouyang, W. X., Yang, W., He, J. H. & Fang, X. S. Recent progress of heterojunction ultraviolet photodetectors: Materials, integrations, and applications. Adv. Funct. Mater. 30, 1909909 (2020).

Abrari, M. et al. Investigating various metal contacts for p-type delafossite α-CuGaO2 to fabricate ultraviolet photodetector. Sci. Rep. 13, 8259 (2023).

Hao, J. D. et al. Deep ultraviolet detectors based on wide bandgap semiconductors: A review. J. Nanopart. Res. 25, 81 (2023).

Ahmadi, M., Abrari, M. & Ghanaatshoar, M. An all-sputtered photovoltaic ultraviolet photodetector based on co-doped CuCrO2 and Al-doped ZnO heterojunction. Sci. Rep. 11, 18694 (2021).

He, H. L. et al. Bandgap engineering and oxygen vacancy defect electroactivity inhibition in highly crystalline n-alloyed Ga2O3 films through plasma-enhanced technology. J. Phys. Chem. Lett. 14, 6444–6450 (2023).

Schlaf, R., Murata, H. & Kafafi, Z. H. Work function measurements on indium tin oxide films. J. Electron. Spectrosc. 120, 149–154 (2001).

Beerbom, M. M., Lagel, B., Cascio, A. J., Doran, B. V. & Schlaf, R. Direct comparison of photoemission spectroscopy and in situ Kelvin probe work function measurements on indium tin oxide films. J. Electron. Spectrosc. 152, 12–17 (2006).

Park, Y., Choong, V., Gao, Y., Hsieh, B. R. & Tang, C. W. Work function of indium tin oxide transparent conductor measured by photoelectron spectroscopy. Appl. Phys. Lett. 68, 2699–2701 (1996).

Yi, Y., Lyon, J. E., Beerbom, M. M. & Schlaf, R. Characterization of indium tin oxide surfaces and interfaces using low intensity x-ray photoemission spectroscopy. J. Appl. Phys. 100, 093719 (2006).

Shao, G. S. Work function and electron affinity of semiconductors: doping effect and complication due to fermi level pinning comment. Energy Environ. Mater. 4, 273–276 (2021).

Qiao, P. F. et al. Origin of two-dimensional hole gas formation on Si-treated diamond surfaces: surface energy band diagram perspective. Appl. Surf. Sci. 584, 152560 (2022).

Liu, J. B. et al. Band alignment engineering at ultra-wide bandgap GeO2/SiO2 heterointerfaces. Results Phys. 58, 107538 (2024).

Guo, D. Y. et al. Oxygen vacancy tuned Ohmic-Schottky conversion for enhanced performance in β-Ga2O3 solar-blind ultraviolet photodetectors. Appl. Phys. Lett. 105, 023507 (2014).

Waheed, H. et al. Band alignment engineering of p-Ge/n-Si heterojunction for low cost tandem solar cell applications. Opt. Mater. 157, 116222 (2024).

Javaid, K. et al. Band offset engineering in ZnSnN2-based heterojunction for low-cost solar cells. ACS Photonics. 5, 2094–2099 (2018).

Wang, X. Y. et al. On-demand preparation of α-phase-dominated tungsten films for highly qualified thermal reflectors. Adv. Mater. Interfaces. 6, 1900031 (2019).

Rehman, U. U. et al. Modulation of thermoelectric power generation performance of ZnO nanostructures by controlling the mn atoms concentration. Ceram. Int. 48, 16183–16187 (2022).

Yakimov, E. B. et al. Photosensitivity of Ga2O3 Schottky diodes: effects of deep acceptor traps present before and after neutron irradiation. APL Mater. 8, 111105 (2020).

Chang, S. P., Chang, L. Y. & Li, J. Y. The influence of different partial pressure on the fabrication of InGaO ultraviolet photodetectors. Sensors-basel 16, 2145 (2016).

Deng, L. P. et al. Surface plasma treatment reduces oxygen vacancies defects states to control photogenerated carriers transportation for enhanced self-powered deep UV photoelectric characteristics. Appl. Surf. Sci. 604, 154459 (2022).

Arora, K., Kumar, N., Vashishtha, P., Gupta, G. & Kumar, M. Investigating the role of oxygen and related defects in the self-biased and moderate-biased performance of β-Ga2O3 solar-blind photodetectors. J. Phys. D Appl. Phys. 54, 165102 (2021).

Oshima, T., Okuno, T. & Fujita, S. Ga2O3 thin film growth on c-plane sapphire substrates by molecular beam epitaxy for deep-ultraviolet photodetectors. Jpn J. Appl. Phys. 46, 7217–7220 (2007).

Wu, C. et al. High sensitive and stable self-powered solar-blind photodetector based on solution-processed all inorganic CuMO2/Ga2O3 pn heterojunction. Mat. Today Phys. 17, 100335 (2021).

Hu, H. Z. et al. α/β phase junction Ga2O3 based high-performance self-powered deep ultraviolet photodetectors with Ti3C2/Ag nanowire hybrid conductive electrode. J. Alloy Compd. 945, 169307 (2023).

Li, Y. Q. et al. Ultrawide-bandgap (6.14 eV) (AlGa)2O3/Ga2O3 heterostructure designed by lattice matching strategy for highly sensitive vacuum ultraviolet photodetection. Sci. China Mater. 64, 3027–3036 (2021).

Acknowledgements

The authors express their sincere gratitude to the support from Natural Science Foundation of China (Grant No. 62204133) and Yongjiang talents program with No. 2022 A-218-G, which have significantly enriched the quality and depth of this study.

Author information

Authors and Affiliations

Contributions

C. M. W. carried out the syntheses, characterized devices and materials, wrote the first draft of the article. X. W. supervised the project and helped with writing the manuscript. J. B. L., X. R. L., C. Y., S. P. H., D. D. M., Z. W. C., and H. G. D. co-advised the research and edited the article.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wei, C., Liu, J., Lan, X. et al. Crystal structure modulating performances for 213-nm GeO2 solar-blind photodetectors via DC reactive magnetron sputtering method. Sci Rep 15, 4094 (2025). https://doi.org/10.1038/s41598-025-86834-x

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-86834-x