Abstract

This work aims at analyzing the performance of a double-pipe heat exchanger (DPHE) using low concentrated (0.02–0.06 vol%) water, methanol, castor oil and silicon oil based Cu-MXene hybrid nanofluids. Convective heat transfer experiments were successfully performed in fabricated modular double pipe heat exchanger without using any twisted tapes, surfaces and effectively measured various heat transfer parameters such as Nusselt number (Nu), heat transfer coefficient (h), rate of heat transfer (Q), overall heat transfer coefficient (U), friction factor (f), pressure drop (∆P), and the thermal performance factor (TPF). The results indicated a considerable improvement in Nu, h, and U with some penalty in ∆P. Moreover, the TPF value of methanol and water-based hybrid nanofluids exceeded unity and showed superior heat transfer characteristics, confirming the viability of improving thermal performance in DPHE. Eventually, the LMTD and U of hybrid nanofluids were positively validated using Aspen HYSYS 12.1 version software to verify the experimental results and showed a variation of less than ± 5.35% for U and LMTD. These results successfully demonstrate the possible usage of proposed Cu-MXene hybrid nanofluids in thermal management systems, automotive cooling, and industrial cooling respectively. In addition, these findings also encourage its use in superior performance and cost-effective thermal management technologies.

Similar content being viewed by others

Introduction

Nanofluids are initially developed by Choi and Eastman1 by dispersing nanosized particles in the range of < 100 nm into base fluids. These fluids show promising properties that may be tailored to specific demands. Several research groups have been motivated to investigate the unique properties of nanofluids over the past 3 decades to develop innovative thermal systems for a range of technological requirements. Increased thermal conductivity of nanofluids over traditional heat transfer fluids like water, oils, etc. is one of the unique advantages of mono nanofluids. These nanofluids are synthetically prepared using various types of nanoparticles such as metals, metal oxides (or) carbides of copper (Cu), silver (Ag), gold (Au), copper oxide (CuO), silicon dioxide (SiO2), aluminium oxide (Al2O3), titanium dioxide (TiO2), iron oxide (Fe3O4), single walled carbon nanotubes (SWCNT), multiwall carbon nanotubes (MWCNT), graphite (Gr), diamond, MXene etc2,3,4. Beyond mono nanofluids, researchers developed a completely new type of heat transfer fluid termed “Hybrid nanofluid” in order to further enhance the characteristics of mono nanofluids. Hybrid nanofluids are created by dispersing two or more different nanoparticles in base fluids5,6,7,8. Due to the presence of two types of different nanoparticles, these hybrid nanofluids have found widespread usage in biomedical9, automotive10, nuclear reactor11, heat pipe12, heat exchanger13, electronic industries14 and other sectors such as thermo-hydraulic performance enhancement applications7.

Generally, compact and energy efficient devices are usually chosen for enhancing the heat exchangers heat transfer performance15,16. It is essential to have heat exchangers to transfer heat across fluids of different temperatures. The efficiency with which working fluids convert heat is crucial in heat transfer applications. The efficacy depends on various thermophysical characteristics such as thermal conductivity, density, viscosity, and specific heat17. Various strategies were developed for enhancing heat exchanger performance and categorized into three distinct categories such as passive, active, and hybrid18. These classifications are distinguished in accordance with the utilization of an energy source. An external power source, such as a vibration or magnetic field, is essential for the active method. The passive method is superior and more widely used because it doesn’t require an external power source and also it only uses flow energy to improve heat transfer by employing fins, inserts, geometrical modifications etc19,20,21,22,23. A list of the recommendations given by different authors for improving heat exchanger performance is highlighted in Table 1.

Moreover, some researchers also studied the behavior of heat exchangers using passive methods. Hussein32 synthesized EG based Aluminium nitride (AlN) nanofluids with concentrations ranging from 1 to 4% to investigate convective heat transfer in a double pipe heat exchanger under laminar flow conditions and observed 160% and 35% enhancement in heat transfer efficiency and thermal performance. Anitha et al.33 compared shell and tube heat exchanger performance using Cu and Al2O3 based mono and hybrid nanofluids ranging from 0.01 to 0.2 vol% concentrations and found that the hybrid nanofluids showed the maximum enhancement in heat transfer coefficient (h) ranging from75% − 139%, and also the efficiency of the HE was enhanced by 124% as compared to mono nanofluids. Irshad et al.4 experimentally examined the thermal performance of a tube heat exchanger under a turbulent flow regime using Therminol55 based hybrid nanofluids of MWCNT–CuO with concentrations ranging from 0.005 to 0.08 wt% and reported 128% enhancement in heat transfer coefficient followed by 38.4% enhancement in Nu and 103.88% enhancement in pumping power with a thermal performance factor of 1.31. Huminic and Huminic34 investigated four different water-based 0.1–0.3 vol% hybrid nanofluids synthesized using nanodiamonds (ND) with Nickel (Ni), Graphene oxide-Cobalt oxide (GO–Co3O4), MWCNT–Fe3O4, and ND–Fe3O4 under laminar and turbulent flow regime using figure of merit analysis and stated that hybrid nanofluids of ND–Ni and MWCNT–Fe3O4 are good candidates for heat transfer applications, while ND–Fe3O4 and GO–Co3O4 are not recommended due to reduced heat transfer coefficient and higher increment in pumping power.

However, there are few works conducted on simulation techniques to estimate hybrid nanofluids efficiency including stretched sheets35, rotating spheres36, and spongy voids37, using a magnetic field. Choudhary et al.38 numerically investigated heat transfer characteristics of TiO2-CuO/water hybrid nanofluid for a porous medium with a wedge shape and stated that enhancement in heat transfer was observed due to the transmission of wedge in the fluid’s direction. Likewise, Nasir et al.39 investigated the applicability of back-propagation artificial neural networks in conjunction with the Levenberg-Marquardt algorithm for evaluating heat transmission in hybrid nanofluids of EG-based MgO-GO under steady mixed convection flow over an exponentially stretched sheet. Similarly, Jat et al.40 studied flow features in a porous medium with non-Newtonian fluid under twisting action between twin concentric tubes. Nasir et al.41 estimated the efficiency of solar radiation by 3D radiative flow over a porous surface using artificial neural networks (ANN). In other works, Choudhary et al.42 investigated water-based Cu-Al2O3 hybrid nanofluids performance using numerical evaluation of nonlinear thermal radiation in the presence of microbes. They claim that hybrid nanofluids exhibited an improved Nusselt number compared to mono nanofluids and base fluid and additionally, stated that disk-shaped nanoparticles are more effective than spherical-shaped nanoparticles. Nasir et al.43 investigated EG-based tri-hybrid nanofluids of Cu-Al2O3-TiO2 by computational method to estimate heat sources, chemical reactions, radiation, and viscous dissipation under different slip conditions. Another arithmetical investigation by Jat et al.44 analyzed the repercussions of Dufour and Soret effects under a magnetic field on water-based CuO-Al2O3 hybrid nanofluid across an irregular flexible sheet in magnetohydrodynamics. In other studies, Choudary et al.45 conducted a numerical analysis to estimate the flow of a magnetohydrodynamic nanofluid by incorporating the movement of microorganisms in various arrangements such as flat plate, wedge, horizontal plate and concluded that Nu is more dominant for horizontal plate compared to standstill and wedge.

Moreover, other investigation studies estimate flow behavior and heat transmission of hybrid nanofluids by employing water-based SWCNT with MWCNT on a porous surface with the heat flux model of Cattaneo-Christov46. Nasir et al.47 studied the effect of water-based titanium oxide nanofluid and EG-based TiO2 nanofluid by employing the Darcy-Forchheimer equation in a radially stretched disk. Brownian motion and magneto-hydrodynamic migration of unstable 2D non-linear convective movement of a thin layer of nanofluid across an inclination stretched sheets were examined by Saeed et al.48. Gul et al.49 studied the effect of magnetic field on heat transfer using water-based hybrid nanofluids of Cu-Al2O3 by naturally occurring convection process within a permeable container and claim that the convective heat transmission inside the enclosure is improved as the Darcy and Rayleigh numbers improve. By taking into account of Gaussian Neural Network, Habib et al.50 investigated heat transfer in chemically reactive fluid flow considering Soret-Dufour effects using machine learning-driven analysis. Nasir and Berrouk51 stated that fluid motion improved due to a couple of stress parameters which are computed by Fick’s mass flux and Fourier’s energy. Alnahdia et al.52 investigated drug delivery systems and blood circulation by dispersing tri-hybrid nanoparticles of CuO-TiO2-Al2O3 in blood. Nasir et al.53 examined the consequences of thermal radiation and thermo-migration on the 3-D spinning nanofluid flow with SWCNT using Homotopy analysis (HAM).

In the current work, four various kinds of base fluids such as water, methanol, castor oil, and silicone oil are used to prepare hybrid nanofluids and improve the thermal performance of DPHE. Castor oil has been chosen as an effective base fluid in our study due to its high viscosity, lubrication, and good thermal stability which make it suitable for stabilizing the particles and also used for high-temperature applications. Moreover, silicon oil is considered a very effective coolant for transformer cooling applications. It also has high thermal stability, chemical inertness, hydrophobic nature, and a wide range of viscosities making it an effective base fluid especially in high temperature applications. These fluids are used as received from the supplier at room temperature. Hybrid nanoparticles were distributed at concentrations varying from 0.02 to 0.06 vol% to improve the thermophysical characteristics of base fluids. Studies on the specific characteristics of these hybrid nanofluids have previously been reported54. Most of the applications of these studies can be envisioned in sectors such as manufacturing, food and pharmaceuticals, power plants, generator cooling, etc.

In the current work, DPHE has been chosen as a heat transfer device due to its simple, straight forward design and low fabrication cost as compared to other types of HEX, such as shell and tube or plate type. In addition, a consistent flow pattern can be achieved, effective for low to medium heat transfer rates. Fouling, blockages or clogging is very low, and it can be easily configured for parallel or counter flow arrangemens.

From the overview of the literature, most of the research works were concentrated on enhancing the heat transfer process in heat exchangers by utilizing inserts, twists, fins, and high loading of nanoparticles. Also, it was noticed that hybrid nanofluids with metal and metal oxide nanoparticle combinations with high concentrations were used as coolants in heat exchangers. No work has been reported in enhancing the heat transfer performance in heat exchangers using a minimum concentration of metal and 2D layered structured hybrid material based nanofluids as coolants. In the current work, we proposed Cu-MXene hybrid nanofluids as an alternative to conventional coolants and conducted an experimental investigation of DPHE with very minimal volume concentrations of Cu and MXenes ranging from 0.02 to 0.06%. The objective of the present investigation is to explore the heat transfer metrics such as thermal performance factor, friction factor, Nusselt number, heat transfer coefficient, and pressure drop in double pipe heat exchanger under laminar flow conditions using Cu-MXene based hybrid nanofluid synthesized by dispersing very low concentration of hybrid nanoparticles (0-0.06 vol%) in four distinct base fluids i.e. methanol, water, silicone oil, and castor oil. In addition, this work also emphasized comparing the experimental heat transfer performance with the ASPEN HYSYS simulation software for verifying various heat transfer parameters.

Experimental study

Synthesis of Cu–MXene based hybrid nanofluids and associated thermophysical properties

Cu-MXene hybrid nanofluids are synthesized using two-step method by dispersing already synthesized MXene nanosheets and copper nanoparticles in base fluids as per the procedure reported in our previously published article54. As indicated in Fig. 1, pre-synthesized Cu nanoparticles at constant 0.01 vol% and MXene nanosheets with concentrations varying from 0.01 to 0.05 vol% are dispersed in different base fluids such as methanol, water, silicone oil, and castor oil containing sodium dodecyl sulfate (SDS) surfactant using magnetic stirring for 20 min at 500 rpm followed by ultra-probe sonication for an hour to prevent aggregation.

The essential parameters to be considered for evaluating heat transfer characteristics are density (ρ), Prandtl number (Pr), viscosity (µ), thermal conductivity (k), and specific heat capacity (Cp). These features were carefully investigated and collected from our previously published article41 and indicated in Tables 2, 3, 4 and 5.

Experimental setup

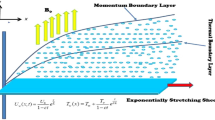

A modular simple double pipe heat exchanger is developed at the laboratory level by considering cost and Cu-MXene hybrid nanofluids for performing convective heat transfer studies. Table 6 represents the details of the exchanger consisting of extremely succinct and straight horizontal cylindrical pipes to enhance convective heat transfer performance without adopting inserts such as baffles or twisted tapes. In order to hold additional fluids, the exterior pipe is designed twice the size of the inner pipe.

The inlet temperatures of the hybrid nanofluids which acts as cold fluid and distilled water as hot stream were kept constant at 30°C and 50°C respectively and the output temperatures were measured using thermocouples. Peristaltic pumps are deployed to control the flow and chiller is used to maintain the cold fluid’s inlet temperature at 30°C as represented in Fig. 2. Since heat migrates from the hot fluid to the cold fluid, insulation was made using polyurethane foam (PU) with a thickness of 0.39” to eliminate the heat loss to the surroundings.

The exchanger, comprising of four essential components like heating, cooling, and chilling, as well as a proportional-integral-derivative (PID) controller with indicator is outlined in Fig. 2. The hot fluid is contained in a 1” thick stainless-steel container to prevent heat loss to the surrounding environment, and it gets heated by an immersion heater. A PID controller is used to regulate the fluid’s temperature.

Firstly, pure base fluids like methanol, water, silicone oil, and castor oil were used in the experiment and circulated in the shell side of the heat exchanger for evaluating the heat exchanger’s performance at 30 °C. On the other hand, at an input temperature of 50 °C, the hot fluid stream was fed into the tube side at a Reynolds number 1220. Later, convective heat transfer studies have been carried out utilizing Cu–MXene hybrid nanofluids at volumetric concentrations from 0.02 to 0.06%, in the same conditions by replacing base fluids. Here, Cu-MXene nanofluids were circulated in the heat exchanger as a cold fluid and measured the temperatures at the inlet and outlet sections of the DPHE to analyze various convective heat transfer characteristics. A detailed discussion on experimental step-up was already reported in our previous work55.

Data reduction

The hydraulic diameter of the inner tube (dhi) is the same as its diameter i.e., \(\:{d}_{hi}={D}_{i}\), but for outer pipe (dho) can be estimated mathematically using Eq. (1)4.

where A is the flow area (m2) and determined as (\(\:\frac{\pi\:}{4}\:\times\:\left({D}_{o}^{2}-\:{D}_{i}^{2}\right))\), \(\:{D}_{i}\) is inner tube diameter, \(\:{D}_{o}\) is outer shell diameter, and P is wetted perimeter.

The Prandtl number (Pr) of the hybrid nanofluids’ are figured out by using Eq. (2) with the help of viscosity, specific heat, and thermal conductivity respectively4.

The heat transfer rates (Q) for hold and cold fluids, reveilles the heat gain of the cold fluid (Qhybnf) and the heat loss of the hot fluid (Qh) should be equal with reference to the energy balance equation i.e. Qhybnf = Qhf, from the current studies, an average of 4.21% deviation is observed, the rate of heat flow in tube side and annulus side are computed utilizing Eq. (3a) and (3b)4.

Equation (3c) provides the average rate of heat transfer in watts

where Q is Heat transfer rate, subscripts i and o stands for inlet and outlet respectively, ṁ mass flow rate of fluid, \(\:{T}_{hybnf}\) temperature of cold fluid, Cp specific heat, and \(\:{T}_{hf}\) temperature of hot fluid respectively.

“Re” is used to indicate type of flow regime based on the fluid’s flow rates, density, diameter, and viscosity. By utilizing Eq. (4a and 4b) “Re” is estimated for hot stream as well as for cold stream16.

where\(\:{{Re}_{hf}\:and\:Re}_{hybnf}\)denotesRe for hot fluid and hybrid nanofluids respectively.

For the counterflow pattern, the logarithmic mean temperature difference (LMTD) is computed from Eq. (5) below15.

where \(\:{T}_{hf,i}\:{and\:T}_{hf,o}\) are temperatures of hot fluid at inlet and outlet, \(\:{T}_{c,i}\:and\:{T}_{c,o}\) are temperature of cold fluid at inlet and outlet respectively.

Equation (6) is used to calculate the average temperatures of hot fluid (\(\:{T}_{hf\:avg})\) and cold fluid (\(\:{T}_{c\:avg})\)

The overall heat transfer coefficient (U) is computed by using Eq. (7)18,

where Qavg average heat transfer rate (W), U is overall heat transfer coefficient (W/m2. K), and A area of heat transfer (m2).

The Sieder and Tate equation has been used to calculate the Nusselt number since the determined Reynolds number (Re) < 2300, which is classified as laminar flow56,57. The following Nusselt number Eq. (8a) and (8b) were applied to the shell side and tube side of DPHE respectively.

\(\:{\:\mu\:}_{w}\)is determined using the wall temperature and Twall could be approximated from Eq. (9)37,38:

The hydraulic diameter (dho), the Nusselt number (Nu), and the thermal conductivity values of hybrid nanofluids (khybnf) have been applied for estimating the annulus heat transfer coefficient (ho), by using Eqs. (10) and (8a) respectively18.

Equation (11) represents friction factor under laminar flow in tube side as well as shell side and computed by using the Darcy friction factor equation. For, flow through annulus i.e., outer pipe (Do), equation is given as57:

where k = \(\:\frac{{D}_{i}}{{D}_{o}}\)

Equation (12) has been utilized to derive the pressure drop (∆P) in a heat exchanger

where \(\:v\) is velocity of the fluid in (m/s)

The following Eq. (13) was used to evaluate the performance evaluation criteria (PEC) (or) thermal performance factor (TPF)defined by Webb et al.58 by considering Nusselt number enhancement ratio to frictional losses13,19,25,58,59,60.

where \(\:{Nu}_{hybnf}\), \(\:{Nu}_{bf}\), \(\:{f}_{hybnf}\), and \(\:{f}_{bf}\) are Nusselt number and frictional losses for hybrid nanofluids and base fluids respectively.

Equation 14 is used to obtain percentage deviation while evaluating accuracy in terms of deviation61.

The following Eq. (15) was applied to figure out the percentage enhancement.

where P stands for attributes such as the LMTD, Nu, h, f, ΔP, and U respectively. While “\(\:e"\) stands for the percentage of enhancement.

Limitations

There are some limitations of the current proposed work and these are listed below.

-

As the hybrid nanofluid were synthesized using low concentrations of nanoparticles, agglomeration and saturation effects at high concentrations need to be explored.

-

Measurement of heat transfer characteristics under turbulent flow conditions were not considered as fabricated equipment is designed for laminar conditions.

-

In addition, long-term operational conditions associated with clogging, fouling, and degradations of hybrid nanofluids were not fully explored.

-

Scaling up to a large scale is also another limitation that need to be considered further.

Results and discussions

The main objective of the proposed work is to enhance the convective heat transfer performance of fabricated modular double-pipe heat exchanger (without any inserts/baffles) using very low concentrated Cu-MXene hybrid nanofluids. In order to accomplish the maximum enhancement, various heat transfer properties such as heat transfer rate, LMTD, heat transfer coefficients, Nusselt number, friction factor, pressure drop, etc. need to be analyzed with respect to the flow rate and concentration of hybrid nanoparticles. A detailed analysis representing the effect of all these heat transfer parameters is discussed in the subsequent sections.

Effect of Reynolds number and concentration of Cu-MXene nanoparticles on heat transfer rate (Q)

The hybrid nanofluids acting as cold fluid and distilled water representing as hot fluid were passed into shell side and tube side at a constant inlet temperature of 303.15 K and 323.15 K respectively using peristaltic pumps. The flow of hot fluid is fixed at 1220 Re for entire experiments and cold stream is varied step by step. Effect of Re and concentration of hybrid nanoparticles on heat transfer rate is shown in Fig. 3. From Fig. 3a–d, it has been observed that the rate of heat transfer rate (Q) enhances with an increase in Re and concentration of hybrid nanoparticles possibly due to increase in thermal conductivity and the flow rate. The heat transfer rates are improved by 25.28%, 24.29%, 172%, and 149.34% for methanol-based, water-based, silicon oil-based, and castor oil-based Cu-MXene nanofluids prepared using concentrations of 0.01% (Cu) and 0.05% (MXene). From Fig. 3, Q is increasing concerning Re and concentration for all hybrid nanofluids. This means that heat transfer is better, which makes them perfect for large-scale industrial uses.

Effect of Reynolds number and concentration of hybrid nanoparticles on log mean temperature difference (LMTD) and validation using ASPEN HYSYS software

Heat exchanger’s thermal performance is used to assess the temperature difference between the hot and cold streams and it can be measured by LMTD using Eq. (5). The influence of concentration of Cu-MXene hybrid nanofluids and Re on LMTD was represented in Fig. 4a–d. From the Fig. 4, the LMTD drops as the concentration of Cu-MXene increases suggesting a wider dispersion of thermal capacity62. A substantial percentage drop in LMTD values can be observed from Table 7 as compared to base fluids by utilizing hybrid nanofluids. Heat exchanger efficiency can be improved, and the size of the exchanger can be reduced.

Furthermore, LMTD is validated by the NRTL thermodynamic fluid package approach in the Aspen HYSYS simulation 12.1 version. Fig. S1 and S2 in the supplemental material displays a depiction of the HYSYS simulator and the validated LMTD values for methanol-based, water-based, silicone oil-based, and castor oil-based hybrid nanofluids were reported in the supplementary information as Fig. S3. The average percentage deviation is predicted from Eq. 14 for Cu-MXene hybrid nanofluids and found approximately − 0.3%, 0.75%, -1.52%, and − 0.29%for methanol-based, water-based, silicone oil-based, and castor oil-based respectively.

Effect of Reynolds number and concentration of hybrid nanoparticles on overall heat transfer coefficient (U)

The overall heat transfer coefficient for all the hybrid nanofluids is calculated using Eq. 7 and shown in Fig. 5. From Fig. 5a–d, it can be seen that the overall heat transfer coefficient increases with an increase in nanoparticle concentration for all the Cu-MXene hybrid nanofluids due to the decrease in the LMTD. The rise in U may also be vindicated by the decline in thermal resistance and enhancement of heat coefficient of hybrid nanofluids as reported by other researchers15. The percentage enhancement of U as compared to base fluids with an increase in the concentration of hybrid nanoparticles is calculated and shown in Table 8. Additionally, Aspen HYSYS 12.1 software was used to validate the results, which were presented as supplementary information in Fig. S4. The percentage deviation for the methanol-based, water-based, silicone oil-based, and castor oil-based hybrid nanofluids was estimated using Eq. (14) and reported as-5.35%, -1.24%, 0.05%, and 1.57% respectively. From Fig. 5, it can also be inferred that these fluids are beneficial for power plants, heating, ventilation, and air conditioning (HVAC) either for heating or cooling purposes due to the enhancement of U over Re.

Effect of Reynolds number and concentration of Cu-MXene nanoparticles on Nusselt number

Nusselt number is estimated using Eq. (8) for all the hybrid nanofluids with respect to the concentration of nanoparticles and shown in Fig. 6. From Fig. 6, it has been noticed that the Nusselt number increases with the increase in the Re and concentration of nanoparticles. This enhancement could be possibly due to the increased turbulence that occurs as the Re increases and better thermophysical properties due to dispersion of Cu-MXene nanoparticles in the base fluids as also reported by other researchers63,64. The maximum enhancement of Nu for methanol-based, water-based, silicone oil-based, and castor oil-based hybrid nanofluids are found to be80.6%, 66%, 42.9%, and 24%, respectively, at 0.06 volume concentration of hybrid nanoparticles. Hence, these hybrid nanofluids can be beneficial for refrigeration, heat recovery systems, and cooling of electronics due to is high values of Nu.

Convective heat transfer experiments were conducted using synthesized Cu-MXene hybrid nanofluids to validate the Nusselt number under laminar flow conditions. The Shah correlation and Hausen correlation65,66 represented in Eqs. (16,17) revealed a satisfactory level of agreement with the experimental Nusselt number as shown in the supplementary information (Fig. S5 and S6). Hybrid nanofluids prepared using 0.02 vol% concentration fits better as compared to other concentrations with R2 as 0.972–0.993 as shown in Fig. S6.

If \(\:{{Re}_{hynf}\times\:Pr}_{hybnf}\times\:\left(\frac{{D}_{o}}{L}\right)\ge\:33.33,\:\:\text{t}\text{h}\text{e}\text{n}\)

If\(\:0.1<{Pr}_{hybnf\:}\times\:\left(\frac{{d}_{e}}{L}\right)\times\:{Re}_{hybnf}<{10}^{4}\), then

where \(\:{Nu}_{hybnf}\) represents hybrid nanofluids Nusselt number, \(\:{Pr}_{hybnf\:}\)shows hybrid nanofluids Prandtl number, \(\:{Re}_{hybnf}\) signifies hybrid nanofluids Reynolds number, \(\:{D}_{o}\)designates outer pipe diameter, and L represents length of heat exchanger.

Effect of Reynolds number and concentration of Cu-MXene nanoparticles on the heat transfer coefficient (h)

Equation (10) is used to compute the hybrid nanofluid heat transfer coefficient (hhybnf) with respect to various concentrations of hybrid nanoparticles. Figure 7 displays the effect of Re and concentration of hybrid nanoparticles on the heat transfer coefficient (h). From the Fig. 7, it has been witnessed that the heat transfer coefficient of all the hybrid nanofluids improved as the Re elevated due to increase in turbulence and heat transfer rate. In comparison to lesser turbulence at lower Re, hybrid nanofluids with higher turbulence at higher Re absorb more heat and exhibit a higher heat transfer rate. As a result, for all hybrid nanofluids, the heat transfer coefficient elevates at high Re and diminishes at low Reynolds numbers. This kind of phenomenon was also reported by other researchers29,63. Moreover, increase in thermal conductivity with increase in concentration of hybrid nanoparticles and Brownian motion of particles by impact and interaction due to change in flow rates of fluids also helps in enhancing the20. The heat transfer coefficients improved by 216%, 146%, 60%, and 82% at volume concentrations of 0.06% for methanol-based, water-based, silicone oil-based, and castor oil-based solutions, respectively. Hence silicone oil-based hybrid nanofluids can be utilized for lubrication, castor oil-based can be used for equipment cooling, and the rest of the fluids can be used for other heat transfer applications.

Effect of Reynolds number and concentration of hybrid nanoparticles on friction factor (f)

Friction factor plays a major role in various commercial and practical applications. The effect of Re and concentration of hybrid nanoparticles on friction factor is shown in Fig. 8. From the Fig. 8, it has been detected that the friction factor declines with increasing Re but amplifies with increasing concentration of hybrid nanoparticles. Friction factor of hybrid nanofluids is higher than that of base fluids due to an improvement in hybrid nanofluids’ Brownian motion and a significant enhancement in thermophysical characteristics5,23. Furthermore, the rises in viscosity and additional shear stress that are applied to the pipe wall generate a stronger friction coefficient. The percentage enhancement of friction factor of the methanol-based, water-based, silicone oil-based, and castor oil-based Cu-MXene hybrid nanofluids are reported as108%, 63%, 52%, and 28%, respectively at 0.06 vol% concentration of hybrid nanoparticles.

Effect of Reynolds number and concentration of hybrid nanoparticles on pressure drop

The practical application of heat exchangers depends on the fluid’s heat-transfer efficiency and pressure drop characteristics. Nanoparticles add little to no alteration in the properties of any base fluid; however, they significantly alter the pressure drop15,66. Figure 9 shows the effect of Re and concentration of hybrid nanoparticles on the pressure drop. From the Fig. 9, it can be seen that the pressure drop of Cu-MXene based hybrid nanofluids is greater than that of the base fluids and increase with increase in Re and concentration of hybrid nanoparticles. Higher viscosity of hybrid nanofluids in comparison to base fluids leads to increased flow resistance, and as nanofluids becomes denser and more viscous, high concentrations of hybrid nanofluids instantly lead to an increase in pressure drop15. Cu-MXene based hybrid nanofluids exhibited pressure drop enhancement of 113%, 65%, 56%, and 31% for methanol-based, water-based, silicone oil-based, and castor oil-based, respectively (Fig. 9a–d). The existence of high concentrations, fluid flow rate63, and thermophysical characteristics26 are responsible for the enhancement in pressure drop. It can be inferred that methanol-based hybrid nanofluids can be applicable for low viscosity cooling equipment’s and water-based hybrid nanofluids can be suitable for heat exchangers. Whereas silicone oil-based and castor oil-based hybrid nanofluids are more suitable for high temperature lubrication.

Effect of Reynolds number and concentration of hybrid nanoparticles thermal performance factor (TPF)

In addition to above mentioned heat transferred parameters and pressure drop, other important findings such as thermal performance factor is very much essential to analyze the performance of any type of heat exchanger67. The TPF is established using integrated impact of flow and thermal characteristics and computed based on the Nusselt numbers and friction factors15,30,63to enhance the convective heat transfer. The TPF value should always be greater than unity for the efficient performance of heat exchanger15,63. The heat exchanger’s thermal performance factor was estimated using Eq. (13) and shown in Fig. 10. From the Fig. 10, it can be seen that the methanol and water-based hybrid nanofluids exhibit TPF higher than 1 for all concentrations and demonstrated noteworthy performance over the whole range of volume concentration and Re. On the other hand, Silicone oil-based hybrid nanofluids at 0.02% concentration exhibited a marginally deviating value from 1 at high Re. At 0.06% concentration, a maximum TPF value of 1.24 has been noticed as Re increases from 100 to 230 as illustrated in Fig. 10c. Castor oil-based hybrid nanofluids shows lower TPF (~ 0.997) at initial concentrations of 0.02 and 0.025 vol% and thereafter displays higher TPF (1.014–1.16)for 0.03–0.06 vol% hybrid nanofluids.

Cost analysis

Cost analysis can be determined by considering weighted average capital, equipment installation, service, and maintenance costs68. According to the Hall method69, cost analysis was carried out by considering the HEX standards, flow characteristics, and framework of the material.

The heat exchanger’s overall cost is determined using the Hall approach using Eq. (18).

where CO, CYO, and CUI are overall cost, yearly operational cost, and up-front investment cost.

The area of the heat exchanger affects the up-front investment cost, which may be estimated with the assistance Eq. (19)69.

where A is heat exchanger’s area (m2).

For stainless steel material, a1, a2, and a3values were taken as 8000, 259.2, and 0.9 respectively70.

The entire yearly operational cost is calculated using Eq. (20) by summing up the cost of pumping power to compensate for pressure losses69.

where Cy refers to annual operation cost and it is estimated by Eq. (21)69,

where H and Cu stands for overall yearly operating hours and utility cost respectively69.

where ṁ, ΔP, ρ, and η represents mass flow rate (kg/s), pressure drop (Pa), density, and pump efficiency (70%), subscripts t and s represent tube side and shell side respectively.

The interest rate (i), the lifespan of the project (n), and overall yearly operating hours (H) and utility cost (Cu)are 25%, 5 years,2190 h/year, and 0.12 respectively. For ordinary industries, the average rate of interest, “i,” is considered as 25%.

To determine the overall cost of the heat exchanger, the following experimental data, which is displayed in Table 9, is considered and incorporated into the aforementioned calculations.

Using the above data shown in Table 6, the overall cost of a double pipe heat exchanger is found to be $ 8730.

Comparison of heat transfer metrics from the current work with previously conducted studies

Table 10 displays a comparison of various convective heat transfer parameters of the current study with those of previous investigations. In comparison to other hybrid nanofluids, the Cu-MXene hybrid nanofluids utilized in the current work possess higher enhancement in heat transfer capacities especially for methanol-based and water-based at very low concentrations ranging from 0.02 to 0.06%. This is probably due to excellent stability and thermal conductivity of hybrid nanofluids.

Uncertainty analysis

Each investigation was carried out multiple times with hybrid nanofluids and their base fluids. In general, the accuracy of the experimental results relies on how precisely every approach and measuring instrument is being carried out. The uncertainty of the parameters can be assessed utilizing the root sum square combination of the effects of each individual input in addition to Moffat’s error propagation73, specifically developed by Kline & McClintock74. Tables 11 and 12 provides the details of the major parameters’ maximum error and uncertainty associated with each experimental run.

Equations (23–27) are used to figure out the uncertainties related to Re, Q, Nu, h, and f75. The previously published investigation shows the uncertainty values of the ρ, µ, and k respectively54.

The uncertainty calculations for water-based Cu-MXene hybrid nanofluids at 0.02 vol% is shown below.

For heat transfer rate, uncertainty is calculated as below.

\(\:\:\:\:\:\:\:\:\:\:\:=\:\:\:\sqrt{{\left(0.01\right)}^{2}+{{\left(0.025\right)}^{2}+\left(0\right)}^{2}}\)= 0.027%

For the Nusselt number, uncertainty is calculated as below.

= \(\:\sqrt{{{\left(0\right)}^{2}+{\left(0.005\right)}^{2}+\left(0.008\right)}^{2}}\) = 0.0094%

For heat transfer coefficient (h), uncertainty is calculated as below.

\(\:\:=\:\:\:\sqrt{{{\left(0.011\right)}^{2}+{\left(0.008\right)}^{2}+\left(0\right)}^{2}}\)= 0.0136%

For the Reynolds number (Re), uncertainty is calculated as below.

= \(\:\sqrt{{{\left(0.00011\right)}^{2}+\left(0.0562\right)}^{2}+{\left(0\right)}^{2}+{\left(0.0077\right)}^{2}}\) = 0.0567%

For friction factor (f), uncertainty is calculated as below.

= \(\:\sqrt{{{\left(0\right)}^{2}+{\left(0\right)}^{2}+{\left(0.0077\right)}^{2}+\left(0.00011\right)}^{2}+\:{\left(0.00166\right)}^{2}}\) = 0.00788%

Economic and environmental benefits of Cu-MXene hybrid nanofluids

Copper is a noble and reasonably priced metal that may be used in many applications as a substitute for the costliest noble metals like gold and silver due to its unique properties. Furthermore, copper nanoparticles are considered capable thermal fluids that may replace traditional fluids in cooling applications76. Similarly, MXenes are also considered a quickly evolving family of materials comprising 2D layers and have remarkable thermal characteristics77 and nontoxic nature78. Hybrid nanofluids containing nanoparticles of Cu and MXene in base fluids improve the thermal conductivity of convectional fluids which further enhances heat transfer efficiency thereby reducing operational cost, size of the heat exchanger equipment, power consumption, and amount of coolant requirement. Table 13, indicates the thermal conductivity values of common coolants utilized in industries.

Limitations and future work

The major limitation of the current study can be the scalability challenges associated with the large-scale processes. In addition, the oxidation behavior of copper is another major concern that will influence the thermophysical properties of hybrid nanofluids. Hence, thorough and detailed strategies need to be framed to prevent possible oxidation for longer usage and storage. Investigation of Cu-MXene hybrid nanofluids for corrosion in DPHE is also another challenging ask and can be considered as a possible future scope. Further enhancement of heat transfer in DPHE can also be conducted by developing hybrid nanofluids using commercial coolants such as radiator coolants, EG, etc. Moreover, a predictive model can be developed using various software’s like Ansys Fluent, COMSOL.

Conclusion

Cu-MXene hybrid nanofluids were successfully synthesized using various base fluids to study the heat transfer performance of a modular double pipe heat exchanger. The convective heat transfer parameters such as Q, LMTD, Nu, h, ∆P, f, and TPF were determined through experimental approaches and validated using Aspen HYSYS simulation software for all concentrations of hybrid nanoparticles.

The heat transfer coefficient (h) was successfully improved for all Cu-MXene based hybrid nanofluids compared to their base fluids by 216%, 146%, 60%, and 82% for methanol-based, water-based, silicone oil-based, and castor oil-based Cu-MXene hybrid nanofluids respectively. Enhancement of pressure drop (ΔP) with 65%, 110%, 31%, and 56% was observed for water-based, methanol-based, castor oil-based, and silicone oil-based Cu-MXene hybrid nanofluids respectively. The thermal performance factor (TPF) values were reported to be greater than one, especially for methanol-based and water-based Cu-MXene hybrid nanofluids with 1.414 and 1.412 respectively, which indicates improved performance of heat transfer in DPHE. Finally, Cu-MXene hybrid nanofluids synthesized using water-based, methanol-based, castor oil-based, and silicon oil-based are highly recommended for cooling or heating applications and high temperature lubrications that are applicable either in electronics or industrial appliances under laminar flow conditions.

Data availability

Data is provided within the manuscript or supplementary information files.

Abbreviations

- DPHE:

-

Double pipe heat exchanger

- ID:

-

Inner diameter (m)

- OD:

-

Outer diameter (m)

- Di :

-

Inner tube diameter (m)

- Dio :

-

Inner tube outer diameter (m)

- Do :

-

Outer shell inner diameter (m)

- Doo :

-

Outer shell outer diameter (m)

- A:

-

Pipe cross-sectional area (m2)

- dh :

-

Hydraulic diameter (m)

- L:

-

Length of heat exchanger (m)

- NRTL:

-

Non-Random Two-Liquid model

- P:

-

Wetted perimeter (m)

- LMTD:

-

Log mean temperature difference

- TPF:

-

Thermal performance factor

- Q:

-

Heat transfer rate (W)

- Cu:

-

Copper

- SDS:

-

Sodium dodecyl sulfate

- RPM:

-

Revolutions per minute (r.min− 1)

- PID:

-

Proportional Integral Derivative

- H:

-

Heat transfer coefficient (W/m2. K)

- ṁ:

-

Mass flow rate (kg/s)

- Cp:

-

Specific heat (J/kg. K)

- Nu:

-

Nusselt number (\(\:\frac{h\:\times\:\:d}{k})\)

- Pr:

-

Prandtl number \(\:\left(\frac{{C}_{p}\times\:\:\mu\:}{k}\right)\)

- Re:

-

Reynolds number \(\:\left(\frac{D\times\:\rho\:\times\:v}{\mu\:}\right)\)

- T:

-

Temperature (°C)

- HEX:

-

Heat exchanger

- t:

-

Time (s)

- v :

-

Fluid velocity (m/s)

- k:

-

Thermal conductivity (W/m. K)

- wt:

-

Weight (g)

- v/c:

-

Volume concentration

- vol%:

-

Volume concentration (%)

- w:

-

DPHE at wall conditions

- \(\:u\) :

-

Uncertainty (%)

- Ф:

-

Volume concentration

- µ:

-

Dynamic viscosity (Pa.s)

- ƒ:

-

Friction factor

- ρ:

-

Density (kg/m3)

- ɛ:

-

Effectiveness

- ΔT:

-

Temperature difference (°C)

- ΔP:

-

Pressure drop (Pa\(\:)\)

- \(\:{h}_{f}\) :

-

Hot fluid

- hybnf :

-

Hybrid nanofluids

- b:

-

Bulk

- f :

-

Fluid

- i:

-

Inner

- o:

-

Outlet

- bf:

-

Base fluids

- c:

-

Cold fluid

- avg:

-

Average

References

Choi, S. U. & Eastman, J. A. Enhancing thermal conductivity of fluids with nanoparticles (No. ANL/MSD/CP-84938; CONF-951135-29). (1995). Argonne National Lab. (ANL), Argonne, IL (United States).

Said, Z. et al. Synthesis, stability, density, viscosity of ethylene glycol-based ternary hybrid nanofluids: Experimental investigations and model -prediction using modern machine learning techniques. Powder Technol. 400, 117190. https://doi.org/10.1016/j.powtec.2022.117190 (2022).

Bakthavatchalam, B. et al. Optimization of thermophysical and rheological properties of Mxene ionanofluids for hybrid solar photovoltaic/thermal systems. Nanomaterials 11(2), 1–28. https://doi.org/10.3390/nano11020320 (2021).

Irshad, K., Islam, N., Zahir, M. H., Pasha, A. A. & Abdelgawad, A. F. Thermal performance investigation of Therminol55/MWCNT + CuO nanofluid flow in a heat exchanger from an exergy and entropy approach. Case Stud. Therm. Eng. 34, 102010. https://doi.org/10.1016/j.csite.2022.102010 (2022).

Turcu, R. et al. New polypyrrole-multiwall carbon nanotubes hybrid materials. J. Optoelectron. Adv. Mater. 8(2), 643–647 (2006).

Nasir, S. & Berrouk, A. S. Comparative study of computational frameworks for magnetite and carbon nanotube-based nanofluids in enclosure. J. Therm. Anal. Calorim. 149(5), 2403–2423. https://doi.org/10.1007/s10973-023-12811-z (2024).

Ranga Babu, J. A., Kumar, K. K. & Srinivasa Rao, S. State-of-art review on hybrid nanofluids. Renew. Sustain. Energy Rev. 77, 551–565. https://doi.org/10.1016/j.rser.2017.04.040 (2017).

Nasir, S. et al. Heat transport study of ternary hybrid nanofluid flow under magnetic dipole together with nonlinear thermal radiation. Appl. Nanosci. 12(9), 2777–2788. https://doi.org/10.1007/s13204-022-02583-7 (2022).

Ijaz, S. & Nadeem, S. Biomedical theoretical investigation of blood mediated nanoparticles (Ag-Al2O3/blood) impact on hemodynamics of overlapped stenotic artery. J. Mol. Liq. 248, 809–821. https://doi.org/10.1016/j.molliq.2017.10.112 (2017).

Ali, M. K. A. et al. Reducing frictional power losses and improving the scuffing resistance in automotive engines using hybrid nanomaterials as nano-lubricant additives. Wear 364, 270–281. https://doi.org/10.1016/j.wear.2016.08.005 (2016).

Uzun, S., Genç, Y. & Acır, A. Investigation of hybrid nanofluids effects on heat transfer characteristics in VVER-1000 nuclear reactor. Prog. Nucl. Energy. 154, 104489. https://doi.org/10.1016/j.pnucene.2022.104489 (2022).

Han, W. S. & Rhi, S. H. Thermal characteristics of grooved heat pipe with hybrid nanofluids. Therm. Sci. 15(1), 195–206. https://doi.org/10.2298/TSCI100209056H (2011).

Allahyar, H. R., Hormozi, F. & ZareNezhad, B. Experimental investigation on the thermal performance of a coiled heat exchanger using a new hybrid nanofluid. Exp. Thermal Fluid Sci. 76, 324–329. https://doi.org/10.1016/j.expthermflusci.2016.03.027 (2016).

Eswaramoorthi, S., Nasir, S., Loganathan, K., Gupta, M. S. & Berrouk, A. Numerical simulation of rotating flow of CNT nanofluids with thermal radiation, ohmic heating, and autocatalytic chemical reactions. Alexandria Eng. J. 113, 535–550. https://doi.org/10.1016/j.aej.2024.10.124 (2025).

Alklaibi, A. M., Mouli, K. V. V. C. & Sundar, L. S. Heat transfer, and friction factor of Fe3O4–SiO2/Water hybrid nanofluids in a plate heat exchanger: Experimental and ANN predictions. Int. J. Therm. Sci. 195, 108608. https://doi.org/10.1016/j.ijthermalsci.2023.108608 (2024).

Fetuga, I. A. et al. Thermohydraulic performance of a semi-alternated twisted tape insert and cylindrical baffles in a tube with ternary nanofluid under sinusoidal wall temperature. Alexandria Eng. J. 73, 607–623. https://doi.org/10.1016/j.aej.2023.05.005 (2023). & Marcos de Oliveira Siqueira

Xuan, Z., Zhai, Y., Li, Y., Li, Z. & Wang, H. Guideline for selecting appropriate mixing ratio of hybrid nanofluids in thermal management systems. Powder Technol. 403, 117425. https://doi.org/10.1016/j.powtec.2022.117425 (2022).

Mashoofi Maleki, N., Pourahmad, S., Haghighi Khoshkhoo, R. & Ameri, M. Performance improvement of a double tube heat exchanger using novel electromagnetic vibration (EMV) method in the presence of Al2O3-water and CuO-water nanofluid; an experimental study. Energy 281, 128193. https://doi.org/10.1016/j.energy.2023.128193 (2023).

Kumar, V. & Sahoo, R. R. 4 E’s (Energy, exergy, economic, Environmental) performance analysis of air heat exchanger equipped with various twisted turbulator inserts utilizing ternary hybrid nanofluids. Alexandria Eng. J. 61(7), 5033–5050. https://doi.org/10.1016/j.aej.2021.09.037 (2022).

Ghani, S., Gamaledin, S. M. A., Rashwan, M. M. & Atieh, M. A. Experimental investigation of double-pipe heat exchangers in air conditioning applications. Energy Build. 158, 801–811. https://doi.org/10.1016/j.enbuild.2017.10.051 (2018).

Abadeh, A., Davoodabadi Farahani, S., Barani, E. & Öztop, H. F. Heat transfer through horizontal microtube of nanofluids under magnetic field for thermal analysis systems. J. Magn. Magn. Mater. https://doi.org/10.1016/j.jmmm.2023.170537 (2023).

Singh, S. K. & Sarkar, J. Improving hydrothermal performance of double-tube heat exchanger with modified twisted tape inserts using hybrid nanofluid. J. Therm. Anal. Calorim. 143(6), 4287–4298. https://doi.org/10.1007/s10973-020-09380-w (2021).

Wang, X. et al. Heat transfer and flow characteristic of a flat confined loop thermosyphon with ternary hybrid nanofluids for electronic devices cooling. Appl. Therm. Eng. 221, 119758. https://doi.org/10.1016/j.applthermaleng.2022.119758 (2023).

Huang, D., Wu, Z. & Sunden, B. Effects of hybrid nanofluid mixture in plate heat exchangers. Exp. Thermal Fluid Sci. 72, 190–196. https://doi.org/10.1016/j.expthermflusci.2015.11.009 (2016).

Abidi, A. & Sajadi, S. M. Numerical assessment of hydraulic behavior and thermal efficiency of multiphase hybrid nanofluid in a shell-and-tube heat exchanger with inclined baffles. Eng. Anal. Boundary Elem. 156, 114–125. https://doi.org/10.1016/j.enganabound.2023.08.002 (2023).

Scott, T. O., Ewim, D. R. E. & Eloka-Eboka, A. C. Experimental study on the influence of volume concentration on natural convection heat transfer with Al2O3-MWCNT/water hybrid nanofluids. Materials Today: Proceedings, 105, 78–84. (2024). https://doi.org/10.1016/j.matpr.2023.07.290

Hamza, N. F. A. & Aljabair, S. Evaluation of thermal performance factor by hybrid nanofluid and twisted tape inserts in heat exchanger. Heliyon 8(12). https://doi.org/10.1016/j.heliyon.2022.e11950 (2022).

Hashemi Karouei, S. H., Ajarostaghi, S. S. M., Gorji-Bandpy, M. & Hosseini Fard, S. R. Laminar heat transfer and fluid flow of two various hybrid nanofluids in a helical double-pipe heat exchanger equipped with an innovative curved conical turbulator. J. Therm. Anal. Calorim. 143(2), 1455–1466. https://doi.org/10.1007/s10973-020-09425-0 (2021).

Bhattad, A. et al. Thermal performance evaluation of Plate-Type heat exchanger with Alumina–Titania hybrid suspensions. Fluids 8(4). https://doi.org/10.3390/fluids8040120 (2023).

Sundar, L. S. & Ramana, E. V. Influence of magnetic field location on the heat transfer and friction factor of CoFe2O4-BaTiO3/EG hybrid nanofluids in laminar flow: an experimental study. J. Magn. Magn. Mater. 579, 170837. https://doi.org/10.1016/j.jmmm.2023.170837 (2023).

Naphon, P. & Wiriyasart, S. Experimental study on laminar pulsating flow and heat transfer of nanofluids in micro-fins tube with magnetic fields. Int. J. Heat Mass Transf. 118, 297–303. https://doi.org/10.1016/j.ijheatmasstransfer.2017.10.131 (2018).

Hussein, A. M. Thermal performance and thermal properties of hybrid nanofluid laminar flow in a double pipe heat exchanger. Exp. Thermal Fluid Sci. 88, 37–45. https://doi.org/10.1016/j.expthermflusci.2017.05.015 (2017).

Anitha, S., Thomas, T., Parthiban, V. & Pichumani, M. What dominates heat transfer performance of hybrid nanofluid in single pass shell and tube heat exchanger? Adv. Powder Technol. 30(12), 3107–3117. https://doi.org/10.1016/j.apt.2019.09.018 (2019).

Huminic, G. & Huminic, A. Heat transfer capability of the hybrid nanofluids for heat transfer applications. J. Mol. Liq. 272, 857–870. https://doi.org/10.1016/j.molliq.2018.10.095 (2018).

Nasir, S., Shah, Z., Islam, S., Bonyah, E. & Gul, T. Darcy Forchheimer nanofluid thin film flow of SWCNTs and heat transfer analysis over an unsteady stretching sheet. AIP Adv. 9(1), 015223. https://doi.org/10.1063/1.5083972 (2019).

Nasir, S., Berrouk, A. S., Gul, T. & Zari, I. Chemically radioactive unsteady nonlinear convective couple stress Casson hybrid nanofluid flow over a gyrating sphere. J. Therm. Anal. Calorim. 148(22), 12583–12595. https://doi.org/10.1007/s10973-023-12608-0 (2023).

Nasir, S., Berrouk, A. S., Gul, T. & Ali, A. Develop the artificial neural network approach to predict thermal transport analysis of nanofluid inside a porous enclosure. Sci. Rep. 13(1), 21039. https://doi.org/10.1038/s41598-023-48412-x (2023).

Choudhary, S., Kumar Jarwal, V., Choudhary, P., Loganathan, K. & Pattanaik, B. Mass-based hybrid nanofluid model for thermal radiation analysis of MHd flow over a wedge embedded in porous medium. J. Eng.2024(1), 9528362. (2024). https://doi.org/10.1155/2024/9528362

Nasir, S., Berrouk, A. & Aamir, A. Exploring nanoparticle dynamics in binary chemical reactions within magnetized porous media: A computational analysis. Sci. Rep. 14(1), 25505. https://doi.org/10.1038/s41598-024-76757-4 (2024).

Jat, K. et al. Computational study on torsional Casson fluid flow through concentric cylinders in a porous medium. Alexandria Eng. J. 108, 400–414. https://doi.org/10.1016/j.aej.2024.07.109 (2024).

Nasir, S., Berrouk, A. S. & Aamir, A. Efficiency analysis of solar radiation on chemical radioactive nanofluid flow over a porous surface with magnetic field. Case Stud. Therm. Eng. 63, 105231. https://doi.org/10.1016/j.csite.2024.105231 (2024).

Choudhary, P., Choudhary, S., Jat, K., Loganathan, K. & Eswaramoorthi, S. Impacts of unsteady MHD hybrid nanofluid over a non-linear stretchable porous sheet with thermal radiation and gyrotatic microorganisms. Int. J. Thermofluids. 23, 100788. https://doi.org/10.1016/j.ijft.2024.100788 (2024).

Nasir, S., Berrouk, A. S. & Gul, T. Analysis of chemical reactive nanofluid flow on stretching surface using numerical soft computing approach for thermal enhancement. Eng. Appl. Comput. Fluid Mech. 18(1), 2340609. https://doi.org/10.1080/19942060.2024.2340609 (2024).

Jat, K., Sharma, K., Soni, P. & Choudhary, P. Numerical analysis of heat and mass transport of hybrid nanofluid over a nonlinear stretchable sheet with magnetic field in presence of Soret and dufour Effect. In Journal of Physics: Conference Series (Vol. 2844, No. 1, p. 012019). IOP Publishing. (2024), December.

Choudhary, P., Choudhary, S., Jat, K., Loganathan, K. & Eswaramoorthi, S. Significances of melting heat transfer and bioconvection phenomena in nanofluid flow over a three different geometries. Int. J. Thermofluids. 24, 100855. https://doi.org/10.1016/j.ijft.2024.100855 (2024).

Habib, S. et al. Enhancing thermal transport in chemically reacting nanoparticles using the energy source and Cattaneo-Christov heat flux model. Energy Convers. Management: X 24, 100807. https://doi.org/10.1016/j.ecmx.2024.100807 (2024).

Nasir, S. et al. Comparative analysis of the hydrothermal features of TiO2 water and ethylene glycol-based nanofluid transportation over a radially stretchable disk. Numer. Heat. Transf. Part. B: Fundamentals. 83(5), 276–291. https://doi.org/10.1080/10407790.2023.2173343 (2023).

Saeed, A., Kumam, P., Nasir, S., Gul, T. & Kumam, W. Non-linear convective flow of the thin film nanofluid over an inclined stretching surface. Sci. Rep. 11(1), 18410. https://doi.org/10.1038/s41598-021-97576-x (2021).

Gul, T. et al. Simulation of the water-based hybrid nanofluids flow through a porous cavity for the applications of the heat transfer. Sci. Rep. 13(1), 7009. https://doi.org/10.1038/s41598-023-33650-w (2023).

Habib, S., Nasir, S., Khan, Z., Berrouk, A. S. & Islam, S. Machine learning-driven analysis of heat transfer in chemically reactive fluid flow considering Soret-Dufour effects. Int. J. Thermofluids 25, 100982. https://doi.org/10.1016/j.ijft.2024.100982 (2025).

Nasir, S. & Berrouk, A. S. Numerical and intelligent neuro-computational modelling with Fourier’s energy and Fick’s mass flux theory of 3D fluid flow through a stretchable surface. Eng. Appl. Comput. Fluid Mech. 17(1), 2270675. https://doi.org/10.1080/19942060.2023.2270675 (2023).

Alnahdi, A. S., Nasir, S. & Gul, T. Couple stress ternary hybrid nanofluid flow in a contraction channel by means of drug delivery function. Math. Comput. Simul. 210, 103–119. https://doi.org/10.1016/j.matcom.2023.02.021 (2023).

Nasir, S. et al. Three-dimensional rotating flow of MHD single wall carbon nanotubes over a stretching sheet in presence of thermal radiation. Appl. Nanosci. 8, 1361–1378. https://doi.org/10.1007/s13204-018-0766-0 (2018).

Kumar, K. R. & Shaik, A. H. Synthesis, thermophysical characterization and thermal performance analysis of novel Cu-MXene hybrid nanofluids for efficient coolant applications. RSC Adv. 13(42), 29536–29560. https://doi.org/10.1039/D3RA05429B (2023).

Kumar, K. R. & Shaik, A. H. Novel 2D layered MXene nanofluids for enhancing the convective heat transfer performance of double-pipe heat exchangers. ACS Omega 9(40), 41758–41775. https://doi.org/10.1021/acsomega.4c06080 (2024).

Sieder, E. N. & Tate, G. E. Heat transfer and pressure drop of liquids in tubes. Industrial Eng. Chem. 28(12), 1429–1435 (1936).

Armstrong, M., Sivasubramanian, M. & Selvapalam, N. Experimental investigation on the heat transfer performance analysis in silver nano-coated double pipe heat exchanger using displacement reaction. Mater. Today: Proc. 45, 2482–2490. https://doi.org/10.1016/j.matpr.2020.11.100 (2021).

Webb, R. L. Performance evaluation criteria for use of enhanced heat transfer surfaces in heat exchanger design. Int. J. Heat Mass Transf. 24(4), 715–726. https://doi.org/10.1016/0017-9310(81)90015-6 (1981).

Khdair, A. I. Numerical solution for optimization of curved turbulator geometry in a double-pipe heat exchanger containing two-phase Cu-GO/Therminol VP-1 hybrid nanofluid to achieve maximum exergy efficiency. Eng. Anal. Boundary Elem. 155, 803–813. https://doi.org/10.1016/j.enganabound.2023.07.004 (2023).

El Maakoul, A. et al. Numerical design and investigation of heat transfer enhancement and performance for an annulus with continuous helical baffles in a double-pipe heat exchanger. Energy. Conv. Manag. 133, 76–86. https://doi.org/10.1016/j.enconman.2016.12.002 (2017).

Singh, S., Verma, P. & Ghosh, S. K. Numerical and experimental analysis of performance in a compact plate heat exchanger using graphene oxide/water nanofluid. Int. J. Numer. Methods Heat. Fluid Flow. 31(11), 3356–3372. https://doi.org/10.1108/HFF-08-2020-0539 (2021).

Ambreen, T., Saleem, A. & Park, C. W. Thermal efficiency of eco-friendly MXene based nanofluid for performance enhancement of a pin-fin heat sink: Experimental and numerical analyses. Int. J. Heat Mass Transf. 186, 122451. https://doi.org/10.1016/j.ijheatmasstransfer.2021.122451 (2022).

Garud, K. S. & Lee, M. Y. Numerical investigations on heat transfer characteristics of single particle and hybrid nanofluids in uniformly heated tube. Symmetry 13(5), 876. https://doi.org/10.3390/sym13050876 (2021).

Das, L. et al. Thermohydraulic performance investigation of a heat exchanger with combined effect of ribbed insert and Therminol55/MXene + Al2O3 nanofluid: A numerical two-phase approach. Heliyon 9(3). https://doi.org/10.1016/j.heliyon.2023.e14283 (2023).

Sajid, M. U. & Ali, H. M. Recent advances in application of nanofluids in heat transfer devices: A critical review. Renew. Sustain. Energy Rev. 103, 556–592. https://doi.org/10.1016/j.rser.2018.12.057 (2019).

Malika, M., Bhad, R. & Sonawane, S. S. ANSYS simulation study of a low volume fraction CuO–ZnO/water hybrid nanofluid in a shell and tube heat exchanger. J. Indian Chem. Soc. 98(11), 100200. https://doi.org/10.1016/j.jics.2021.100200 (2021).

Kumar, V. & Sarkar, J. Particle ratio optimization of Al2O3-MWCNT hybrid nanofluid in minichannel heat sink for best hydrothermal performance. Appl. Therm. Eng. 165, 114546. https://doi.org/10.1016/j.applthermaleng.2019.114546 (2020).

Li, L., Zhao, J. & Shao, J. Coupled performance evaluation method of heat exchanger in a lead-cooled fast reactor based on life-cycle cost and exergy analysis. Ann. Nucl. Energy. 199, 110355. https://doi.org/10.1016/j.anucene.2024.110355 (2024).

Peters, M. S., Timmerhaus, K. D. & West, R. E. Plant Design and Economics for Chemical Engineers vol. 4 (McGraw-Hill, 1968).

Caputo, A. C., Pelagagge, M. P. & Salini, P. Heat exchanger design based on economic optimization. Appl. Therm. Eng. 28, 1151–1159 (2008).

Kumar, A. & Hassan, M. A. Heat transfer in flat tube car radiator with CuO-MgO-TiO2 ternary hybrid nanofluid. Powder Technol. 434, 119275. https://doi.org/10.1016/j.powtec.2023.119275 (2024).

Suresh, S., Venkitaraj, K. P., Selvakumar, P. & Chandrasekar, M. Synthesis of Al2O3–Cu/water hybrid nanofluids using two step method and its thermo physical properties. Colloids Surf., A 388(1–3), 41–48. https://doi.org/10.1016/j.colsurfa.2011.08.005 (2011).

Moffat, R. J. Describing the uncertainties in experimental results. Exp. Thermal Fluid Sci. 1(1), 3–17. https://doi.org/10.1016/0894-1777(88)90043-X (1988).

Kline, S. J. Describing uncertainty in single sample experiments. Mech. Eng. 75, 3–8 (1953).

Sundar, L. S. & Mouli, K. V. C. Effectiveness and number of transfer units of plate heat exchanger with Fe3O4–SiO2/Water hybrid nanofluids: experimental and artificial neural network predictions. Case Stud. Therm. Eng. 53, 103949. https://doi.org/10.1016/j.csite.2023.103949 (2024).

Bal, D. K. et al. Biocompatible polymer-capped oxidation-resistant copper nanoparticles for nanofluid and hydrogel applications. Eur. Phys. J. Plus 137, 1–16. https://doi.org/10.1140/epjp/s13360-021-02280-4 (2022).

Kumar, E. A., Kokulnathan, T., Wang, T. J., Anthuvan, A. J. & Chang, Y. H. Two-dimensional titanium carbide (MXene) nanosheets as an efficient electrocatalyst for 4-nitroquinoline N-oxide detection. J. Mol. Liq. 312, 113354. https://doi.org/10.1016/j.molliq.2020.113354 (2020).

Ma, X., Yang, L., Xu, G. & Song, J. A comprehensive review of MXene-based nanofluids: Preparation, stability, physical properties, and applications. J. Mol. Liq. 365, 120037. https://doi.org/10.1016/j.molliq.2022.120037 (2022).

Acknowledgements

Authors would like to thank Vellore Institute of Technology, Vellore for providing necessary research facilities for conducting this work.

Funding

Open access funding provided by Vellore Institute of Technology.

Author information

Authors and Affiliations

Contributions

K.R.K. conducted the experiments and written the manuscript draft. M.R.C. analyzed the results and corrected the written draft. B.K. conducted Aspen simulation studies. A.H.S. constructed the objectives of the proposed work and executed. Also, involved in writing the manuscript and overall reviewing the proposed work.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Rajesh Kumar, K., Chandan, M.R., Kiran, B. et al. Novel Cu-MXene hybrid nanofluids for the experimental investigation of thermal performance in double pipe heat exchanger. Sci Rep 15, 9937 (2025). https://doi.org/10.1038/s41598-025-94330-5

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-94330-5

Keywords

This article is cited by

-

Thermal and exergy enhancement of a double-pipe heat exchanger using a novel vortex generator and a hybrid nanofluid: a numerical approach

Journal of Thermal Analysis and Calorimetry (2026)

-

Scalable Surfactant-Free Synthesis of Stable Ti₃C2Tx MXene Nanofluids for Enhanced Thermal Transport in Ethylene Glycol

Arabian Journal for Science and Engineering (2025)