Abstract

Sudden brittle fracture of as cast microsize metallic glasy fibers hinders engineering applications of metallic glass wires. Therefor inhancement in ductility of microsize metallic glassy fibers are required.

In the current work, the tensile mechanical behavior of Cu and Ni bilayer electrodeposited Ni54Nb42Al4 metallic glass (MG) fibers with a presizely controle different volume fractions (R) of bilayer coating i.e., R = 0% to R = 95% is investigated by using electrochemical deposition technique. Experimental results reveal that yield stress, tensile stress and fracture stress is decreased with the increasing volume fractions (R) of bilayered Cu and Ni-coating. However the plastic strain is significantly increased with the increasing R values (R = 65% and above). The coating thickness and good interface bonding between two layers (Cu & Ni), as well as with the surface of MG fibers is responsible for larger enhancement in tensile plasticity of bilayered coated Ni-Nb-Al MG fibers. The plastic deformation of Cu/Ni bilayer electrodeposited MG fiber with a coating volume fraction, R = 95% is 5.8%. Electrochemical deposition of Cu/Ni bilayer onto Ni54Nb42Al4 fibers formed a new composit innovative product which can play a significant role in engineering applications.

Similar content being viewed by others

Introduction

In the present study, Ternary Ni54Nb42Al4 (at %) MG fibers were produced through melt-extraction technique, which shows good glass forming ability with high fracture strength, and high elastic deformation1. As cast NiNbAl metallic glassy fibers exhibited highly brittle fracture without plastic deformation, especially under tensile loading at room temperature1,2,3 and reduced the engineering applications of NiNbAl fibers. Monolayer Cu, Ni, Fe and Cu/Ni bilayer coating has been adopted to improve the plasticity of bulk metallic glasses under compressive loading at room temperature to avoid brittle fracture4,5,6. Literature review shows that different techniques have been used by different research groups to improve compressive plasticity in metallic glasses5,6. The most fissile and feasible approach is the electrochemical deposition of metals on the surface of metallic glasses7. Some other research groups are reported that, the electrochemical deposition of metallic surface layer onto the metallic glasses is a successful approach to improve the corresponding plasticity of metallic glasses at room temperature8.

However improvement in plasticity is dependent on the thickness and quality of interface bonding of electrodeposited metal surface layer onto metallic glass fiber and the thickness of electrodeposited metal surface depends on the electrodeposition time duration9. Generally aqueous solutions have been used for electrochemical deposition of different metals onto the surface of metallic glasses10,11. One of the most important features of electrochemical deposition is that, it is easy to control the thickness of electrodeposits and their composition by the variation of electrochemical parameters especially electrochemical deposition time duration12.

As-cast Ni54Nb42Al4 MG fibers undergo linear elastic and heterogeneous deformation with highly catastrophic fracture without tensile plasticity1,13,, however the tensile plasticity of Ni54Nb42Al4 MG fibers can be improved by electrochemical deposition of Cu/Ni-bilayer onto the surface of MG fibers. Dense shear bands have been widely observed on the fracture surface of Cu/Ni-electrodeposited BMGs under compressive loading at room temperature14,15. Shear bands attract lot of research interest toward itself due to direct controlling of deformation behavior and plasticity16. Coating of a ductile metallic layer (Cu) onto the surface of MG fibers can successfully avert brittle fracture of MG fibers in tension17,18, and enhanced the tensile plasticity, but still there is no accessible data demonstrating the achieve of Cu/Ni-bilayer coating on tensile plasticity of micro-size MG fibers. For improvement of the tensile plasticity and solving problems allied to the realistic applications of Ni54Nb42Al4 fibers in MEMS, magnetic devoice, sport equipment and robotic system. It is necessary to investigate the effect of ductile/hard metals electrodeposition on the tensile deformation behavior of Cu/Ni bilayer electrodeposited MG fibers.

The uniaxial tension test was used to determine the mechanical characteristics of Cu/Ni bilayer electrodeposited MG fibers. The present article investigated the enhancement of tensile plasticity in Ni54Nb42Al4 fibers with different volume ratios of bilayered coating, R = 0% to R = 95% at the strain rate of 1 × 10-4s-1. The tensile plasticity is significantly enhanced with the increasing R value is discussed in detail.

Research methodology

The melt-extraction technique was used for the fabrication of Ni54Nb42Al4 (at %) metallic glass fibers1. The master alloy ingots were remelted four times to insure homogeneity, for further detail please sees our previous article1.

Cu/Ni-bilayer with different coating volume fractions (R), was electrodeposited onto the surface of extruded NiNbAl metallic glass fibers.

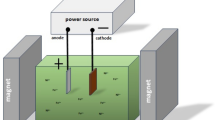

Schematic illustration of Cu-electrochemical deposition onto MG fiber (specimen preparation) is shown in our previous work18. For electrochemical deposition of Cu/Ni bilayer onto Ni54Nb42Al4 MG fibers, 2230G-30–1 Triple channel DC power supply (Keithley, A Tektronix Company) machine was used. The anode for Cu-coating was a soluble copper plate with 2 mm width and 60 mm height and for Ni-coating a nickel plate with 2mm width and 60mm height and the cathode was Ni54Nb42Al4 MG fiber.

Electrochemical deposition was performed in the constant current density of 1 mA/mm2 for metallic glass fibers with different coating volume ratios (R). The equations used for the calculation of current (I), volume ratio (R) and time (t) can be seen in our previous published article18. Before electrochemical deposition each fiber was cleaned with ethanol and rinsed with distil water. Cu/Ni bilayer of different R values was electrodeposited on the surface of Ni54Nb42 Al4MG fibers by electrochemical deposition in a solution bath with 150g/500ml CuSO4.5H2O and 10% H2SO4 for Cu electrochemical deposition, 30 g/500 ml NiCl2.6H2O, 75g/500ml NiSo4.6H2O and then added 18g/500ml H3BO3 for Ni-electrodeposition at room temperature. The current for anode of Ni are carefully controlled to attain constant molar ratio of Ni metal. For Cu-coating, Common acid sulfate solution was used, which exhibited good tensile ductility (11–16%) with relatively low yield strength of 120 MPa to 150 MPa19. For Ni-coating hard watts electrolyte was used, produced hard coating Ni-layer with a tensile strength 1000 MPa, but with limited plasticity20.

In order to investigate the deformation morphology of core MG fibers of bilayer Cu/Ni-coated MG fibers, the outer hard Ni-coating was paper polished and the inner soft Cu-coating was electropolished before SEM observation. The setup of appratus and electrolyte for Cu-coating was same as mentioned in our previous published article18. Same setup was used for electropolishing, however, the Cu-coating sample was set as the anode and the Cu plate was set as cathode. The electrolyte used was the same as the electrolyte for Cu-coating. The power supply was working in the constant Voltage mode, with a voltage of o.5 V to electropolish the Cu-coatings. At this low voltage, the core MG fiber cannot be electropolished.

The surface morphology and the diameters of the metallic glass fibers were determined in scanning electron microscope (SEM) (SU-1510, HITACHI company Japan)1. The amorphous nature of as-cast fibers was examined by the X-ray diffraction (XRD) with Cu-Kα radiation in D/max-2550X-ray Diffract meter (D/max-255, Rigaku Company)1. Mechanical properties of Cu/Ni bilayer coated fibers were determine by Tension tests conducted in a MTF-100 machine with a gauge length of 20 mm and a constant strain rate of 1 × 10–4 s-13.

Results

Melt-extration technique and extrusion process of as cast MG fibers

Ni54Nb42Al4 MG fibers were extracted via melt-extraction technique1. Schematic illustration of the melt-extraction process is shown in Fig. 1a. To remove flaws and diameters variation in MG fibers, an extrusion process, i.e., cold drawing, were used to make the MG fibers smooth on the surface, and homogeneous in diameter, as shown in Fig. 1c and 1d. The as-cast fibers were pulled through a hard alloy mold along the direction indicated by the arrow as shown in Fig. 1b. By using cold-drawing process, the diameter of the MG fiber was reduced, and the uniformity of the diameter of the MG fibers, and the roundness were consequently improved. The flawless extruded NiNbAl MG fibers are mentioned in Fig. 1c, d. The variation in diameter after cold-drawing the MG fibers are kept in the range from 70 – 180 µm. After the extrusion in the hard alloy moulds, the MG fibers are smooth, circular, and flawless, which are shown in Figs. 1e and f. The extruded MG fibers exhibits improved mechanical properties under tensile loading at room temperature as compared to as-cast MG fibers.

XRD and DSC analysis of extruded MG fibers

The volume ratio of Cu/Ni bialyer coating was different i.e., R = 0%, R = 10%, R = 25%, R = 45%, R = 85% and R = 95% to insure the effect of different R values on tensile deformation behavior of Cu/Ni bilayer coated Ni-Nb-Al MG fibers. Figure 2(a) shows XRD and inset Fig. 2(b) shows DSC curve of As-cast Ni54Nb42Al4 MG fibers. The only single broad peak without substantial crystallization peaks exhibits the fully amorphous nature of metallic glass fibers1. Metals electrodeposited metallic glasses can undergo significant plastic deformation, at high quality metals electrochemical deposition21.

To check the quality of electrochemical deposition before tensile test, we examined the surface morphology of mono Cu-coated and bilayered Cu/Ni-coated NiNbAl fibers via SEM as mentioned in Figs. 3a, b and c. We also examined the cross-sectional area study of the mono Cu, Ni and Cu/Ni bialyer electrodeposited Ni54Nb42Al4 MG fibers with different diameter, as shown in Figs. 4a, b and c respectively. These figures shows uniform metal coating and good interface bonding between layers due to the continuous agitation of electrolyte and rotation of MG fiber. The coating thickness of Cu/Ni bilayer was different due to precisely control volume fractions (R) of bilayer coating for each specimen, i.e., R = 10%, R = 25% and R = 45%, 85% and 95%.

Surface morphology of Cu/Ni-coated Ni54Nb42 Al4 glassy fibers

The surface morphology of mono Cu, Ni and Cu/Ni bilayer electrodeposited Ni54Nb42Al4 MG fibers are shown in Fig. 4a, b and c. The mono Cu and Cu/Ni bialyer electrodeposited MG fibers exhibited circular and smooth surfaces without grooves, flaws and scratches. The bilayered Cu/Ni bilayer electrodeposited MG fibers exhibited improve mechanical properties as compared to as cast and mono Cu and Ni-coated MG fibers.

The effect of Cu/Ni bialyer electrochemical deposition on mechanical characteristics of Cu/Ni bilayer electrodeposited Ni54Nb42Al4 MG fibers, were investigated and significant enhancement of tensile plasticity is observed for R = 85% and R = 95%, as shown in Figs. 5a (e) and (f). Tensile stress–strain curves of the as-cast, as well as Cu/Ni bilayer electrodeposited Ni-Nb-Al fibers with different coating volume ratios (R), at the same strain rate 1 × 10–4 s-1, as shown in Fig. 5a. Our experimental results revealed that, the stress–strain curves for as-cast as well as low R value (R = 10% to R = 45%) electrodeposited Ni-Nb MG fibers are fractured catastrophically without significant enhancement in tensile plasticity, as shown in Figs. 5a (b-c), like bulk metallic glasses22 and MG fibers1,23,24,25. Transition from brittle shear fracture to ductile fracture for Cu/Ni bilayer electrodeposited MG fibers can be observed for R = 45% to R = 95%, as shown in Fig. 5a (d-f).

Shows stress–strain curves for tensile deformation behavior of bilayered Cu/Ni-electrodeposited Ni-Nb-Al MG fibers with different R values. (a) shows stress–strain curves of bilayered Cu/Ni-coated Ni-Nb-Al MG fibers with different R values, (b) shows mechanical properties of bilayered Cu/Ni-coated MG fibers, (c) shows tensile stress–strain curves of as-cast, mono Cu, Ni and bilayered Cu/Ni-coated Ni-Nb-Al MG fibers, (d) shows mechanical properties of as-cast & Cu, Ni and Cu/Ni-coated MG fibers.

Mechanical properties of Cu/Ni bilayer electrodeposited Ni54Nb42Al4 fibers

The mechanical properties of Cu/Ni bilayer electrodeposited Ni54Nb42Al4 MG fibers are strongly dependent on volume fractions (R) of Cu/Ni bialyer electrochemical deposition. The as-cast MG fiber is found to yield at 1884 MPa without plastic deformation before final fracture. Whereas Cu/Ni bilayer coated fibers with different R values are yielded at lower stress as compared to as-cast fibers. The mechanical properties, i.e., yield stress; tensile stress and fracture stress is decreased with the increasing R values, while plastic strain is increased with the increasing R value, as shown in Fig. 5b. The Cu/Ni bilayer coated specimen with R = 95% yield at lowest strength 97.18 MPa, followed by a highest plastic strain of 5.8%, as shown in Fig. 5a (f). The comparative study of mono Cu, Ni and Cu/Ni bialyer electrochemical deposition onto the surface of extruded Ni54Nb42Al4 MG fibers with same coating volume fractions (R = 85%) at same strain rate 1 × 10–4 s-1 illistrate that, the Cu/Ni bialyer electrodeposited Ni54Nb42Al4 MG fiber yielded at 210 MPa with the highest plastic strain of 5.8%, as shown in Fig. 5c,d. Most of metallic glasses and metallic glass fibers exhibited zero plasticity under tensile loading at room temperature1,18,26, therefore 5.8% tensile plasticity enhancement of highly brittle nature Ni54Nb42Al4 MG fiber is a good sign for their engineering applications. The mechanical properties of comparative study of mono Cu, N-electrodeposited and Cu/Ni bilayer coated Ni54Nb42Al4 MG fibers are shown in Fig. 5d and Table 2.

In order to further investigate the fracture process in coated samples under tensile loading at room temperature, a comprehensive study of fractographies was performed (Fig. 6). Usually it is believed that, the fracture of MGs and MG fibers are initiated from inside of the sample and spread outside on whole the surface of the sample under tensile loading via tinny voids formation from the centre of the sample, as shown in Fig7a, as mentioned in literature7,18,27.

Five stages tensile déformation behavoir of bilayer Cu/Ni-coated Ni54Nb42Al4 MG fiber with different R values (a) Shows five stages deformation behavio of bilayer Cu/Ni-coated MG wire with R = 75% and (b) shows five stages deformation behavior of Cu/Ni-coated wire with R = 85% and clearly show a significance enhancement in tensile plasticity of thick coated MG wire.

On further loading the size of the voids is increased and crack is initiated on both the sides in opposite direction, as shown in Fig. 7b, literature also confirmed this kind of fracture behavior in metallic glasses under tensile loading7,27.

Tensile fractographies of as-cast and Cu/Ni bialyer electrodeposited Ni54Nb42Al4 MG fiber are shown, in Fig. 8a–h. The void formations as shown in Fig. 7a,b as well as vain patterns seen on the surfaces of as-cast as well as low R values Cu/Ni bilayer coated MG fibers and the localization of deformation are due to shear softening in the shear bands28, as shown in Fig. 8a,c. The viscous vein like patterns are changed into finger patterns, especially for higher R values, R = 85% and R = 95%, as shown in Fig. 8e,g, such type of phenomena can also observed for different as cast MG fibers1,29,30,31. The vein patterns on the fracture surface of as-cast as well as low R values, as shown in Fig8a,c, is changed into viscous fingering for higher R values, as shown in Fig. 8e,g, which is the indication of mode-II fracture32,33,34. These findings indicate that, the tensile plasticity is significantly enhanced for thick (R = 95%) Cu/Ni bialyer coated Ni54Nb42Al4 MG fibers as compared with the mono Cu and Ni-electrodeposited MG fibers.

(a–f) shows fractographies of as-cast and Cu/Ni-coated Ni54Nb42Al4 MG fibers. (a) As-cast Ni-Nb-Al MG fiber shows generation of few vein patterns on fracture surface, (b) As-cast MG fiber shows single shear band on fracture surface (c) and (d) shows bilayered Cu/Ni-coated Ni54Nb42Al4 MG fiber with dense vein patterns on fracture surfaces, (e) & (f) shows dense vein patterns changes into viscous fingering with R = 85% on fracture surface of Cu/Ni-coated MG fibers. (g) shows transition of viscous fingering into dimples, (h) Shows shear bands on side surface of Cu/Ni-electrodeposited Ni54Nb42Al4 fiber.

Multiple secondary shear bands are also clearly seen on the side surface of polished specimen with R = 95%, as shown in Fig. 8h. These secondary shear bands are parallel to the direction of the fracture plane. Bilayer Cu/Ni-coating thickness is directly proportional to the coating time duration, as shown in Fig. 9. We observed during dual bath electrochemical deposition of Cu/Ni bilayer onto the surfaces of MG fibers that, initially the rate of electrodeposition of Ni was higher as compared to Cu-electrodeposition but with the increasing coating time duration, the rate of Ni-coating is decreased, as shown in Fig. 6.

Experimental results revealed that the value of yield strength is decreased with the increasing R values. We noted that the yield strength of coated MG fibers is dependent on volume ratio (R) of metal coating, especially under tensile loading at room temperature. The variations in the yield strength with the increasing R value are, due to larger blocking capacity of a thick Cu/Ni-coated layer on the surface of MG fiber. These results reveal that, enhancement of tensile plasticity in highly brittle nature MG fibers under tensile loading is possible by coating of a thick (R = 85% & R = 95%) Cu/Ni bialyer electrochemical deposition onto the surfaces of Ni54Nb42Al4 MG fibers with precisely controlled volume fractions (R) of bilayer coating as shown in Figs. 5e,f, 6b.

Discussion

The electrochemical deposition of Cu/Ni bilayer onto the surface of BMGs, significantly affect the plastic deformation behavior of BMGs at room temperature5, 6. The uniaxial tension test was performed to determine the plasticity enhancement of Cu/Ni bilayer electrodeposited Ni54Nb42Al4 MG fibers. Cu/Ni bialyer electrochemical deposition has strong consistency towards Ni-Nb-Al MG fibers and can successfully shield the fibers from external forces and acidic environment. Electrochemical deposition of metals on the surface of fibers is an issue of great importance for the constancy and effectiveness of practical application in complex environments35.

We obtained uniform bilayer coating of Cu/Ni onto Ni54Nb42Al4 MG fibers by keeping electrolyte stirred and current density of 1 mA/mm-2. The five stages deformation behavior of uniform bilayer coated Cu/Ni onto NiNbAl fibers is mentioned in Figs. 6a,b. In Fig. 6a, in stage I, the bilayer Cu/Ni-coated fiber (R = 75%) deform linearly. In stage II, the coating deforms plastically while the wire core elastically. In stage III, the core fiber fractures. In stage IV, The Cu/Ni-coating deform plasticaly and in the stage V, the coating necks and then fractures and we observed negliable enhancement in tensile plasicity. Where as in Fig. 6b, In stage I, both coating and MG core deform elastically, in stage II, the coating deforms plastically while the wire core elastically. In stage III, both bilayer coating and MG core deform plasticaly, in stage IV MG core fracture and in stage V coating fractures. We can obsered a significance enhancement in tensile plasticity of thick bilayered coated wires with R = 85% as shown in Fig. 6b. The rapid stress reduction in Stage IV in Fig. 6b was due to the fracture of the MG wire. The improved ductility is possibly achieved by this local fracture, because the deformation near the fractured positions is accommodated only by the ductile electrodeposited material.

Electrochemical deposition technique specially coating of Cu/Ni bilayer onto MG fibers, the residual stress in Nano crystalline deposits can leads to decrease in fracture strength of electrodeposited MG fibers36,37, as shown in Fig. 5b, with the enhancement of coating volume ratio, R. Due to bilayered Cu/Ni-coating onto the surfaces of MG fibers, the tensile stress is decrease with the larger R values, due to larger residual stress, as shown in Fig. 5b,d37.

The mechanical properties of as-cast, as well as, mono Cu, Ni and Cu/Ni-coated Ni54Nb42Al4 MG fibers are summarized in Tables1 and 2. The data illistrate that, the yield stress of as-cast Ni54Nb42Al4MG fiber is 1730 MPa higher than that (730 MPa) of R = 10% Cu/Ni bilayer electrodeposited MG fiber. The fracture strength and tensile strength are decreased, while plastic strain is increased with the increasing volume ratios, R (%) of metals coating. The coating thickness of Cu/Ni bilayer was different, due to precisely control volume ratios i.e., R = 10%, R = 25%, R = 45%, R = 85% and R = 95% respectively. This is evidence in the softening effect of Cu/Ni bilayer electrochemical deposition9. The highest plastic strain is 5.8% for volume ratio, R = 95%.

To control volume ratios, (R) of bilayer coating, the electrochemical deposition time duration was kept constant for each R value, the electrodeposited volume V_t is proportional to the electrodeposition duration t, the electrodeposited volume should be given by V_t = {R_t0*V_0 / t_0*(1-R_t0)}*t. Hence, Eq. 1 can be written as follows:

where t is the time required for a specific volume ratio (R).

R = volume ratio

Vt is the volume of metal coated for a specific time duration, i.e.,(5 min).

Vo is the volume of electrodeposited NiNbAl MG fiber

where, L is the length of coated MG fiber, do is the original diameter of MG fiber and d1 is the diameter of metal coated fiber.

The deformation behavior of MG fibers resistant material with tensile force applied corresponding to the `extensive fiber axis.

where \({\upsigma }_{\text{c}}\) is the average tensile stress of metals coated metallic glass fibers.

Vf is the volume fractions of coated fibers, \({\upsigma }_{\text{f}}\) average tensile stress of coated fibers, \({\text{v}}_{\text{m}}\) is the volume fractions of coated material \({\upsigma }_{\text{m}}\) is the aveage tensile stress of composit material.

Equation 4 shows the stress–strain behavior of fiber unspecified to be tested separately. Metallic glass fiber show high strength and very high strength to density ratio; these properties cause to be them gorgeous in aerospace applications38. The uniaxial stress–strain response of MG fiber can be divided into several stages. In the stage I, the strain is small and fiber deform elastically. Our MG fibers are linear elastically deformed, so we have,

where \({\upsigma }_{\text{c}}\) is the average tensile stress, Ec is the tensile moduli,\({\upvarepsilon }_{\text{c}}\) stress carried by composit material, Vf volume of fiber, Ef elastic moudli of fiber, Vm is the volume of composite MG wires and \({\upvarepsilon }_{\text{m}}\) tensile strain of composit MG fibers..

In some fibers reinforced materials, the matrix deforms permanently at a strain at which the fiber remain elastic. This is stage II deformation, for which,

where \({\upsigma }_{\text{m}}\left({\upvarepsilon }_{\text{c}}\right)\) is assumed to be the stress carried by the matrix as determine from a tensile test of the matrix38. The stage II modulus \({\text{E}}_{\text{f}}\) is define as the instantaneous slope of the composite, stress–strain curve during stage II deformation that is,

In most cases the second term of Eq. 7 is much less than the first so that

Although \(\frac{{d\sigma_{m} }}{{d\varepsilon_{c} }}\) is presumed to be the slope of the stress–strain curve of the electrodeposited fibers tested by itself38.

This is not always the case during stage II is that of a constrained matrix. The sufficiency of the estimate of Eq. (8) depends on the volume of \({\text{V}}_{\text{f}}{\text{E}}_{\text{f}}\) relative to the second term of Eq. 7 provided V is satisfactorily larger. Equation 8 remains a rational estimate for the secondary modulus. Many high strength fibers do not deformed permanently before fracture. So the tensile strain of such fiber is frequently found in stage II. While thick bilayer Cu/Ni-coated MG fibers usually deform plastically before fracture, such fibers shows stage III in their tensile curves, as shown in Fig. 4a and c. The volume fraction ratio express during stage III is,

In the Eq. 9\({\upsigma }_{\text{f}}{\upvarepsilon }_{\text{c}}\) and \({\upsigma }_{\text{m}}{\upvarepsilon }_{\text{c}}\) are the comparative wire and matrix flow stresses at the multiplestrain \({\upvarepsilon }_{\text{c}}\).The three stage deformation behavior of bilayered Cu/Ni-electrodeposited MG fiber is described in.

Figure 5a–d is suitable when only the first two stages of wires deform are observed. In stage I the fiber and Cu/Ni-electrodeposited layer deform elastically. In stage II matrix deform plastically and wire deform elastically, thus the slope of stress–strain curve is reduce, while in stage III both matrix and wire deform plastically. The wire fracture strain \({(\upvarepsilon }_{\text{f}})\) is less than that of matrix. Matrix fracture is not essentially simultaneous with wire fracture, so a secondary tensile strength \(({\text{V}}_{\text{m}} ({\text{T}.\text{S}.)}_{\text{m}})\) is observed. MG fibers tension strength is instantaneous with fiber fracture; this strength is articulated as follow,

In the above Eq. 10, \({(\text{T}.\text{S}.)}_{\text{c}}\) is the wire tension strength and \({\upsigma }_{\text{m}}{(\upvarepsilon }_{\text{f}})\) is the matrix flow stress at the MG fiber fracture strain \({\upvarepsilon }_{\text{f}}\).

Tensile fracture surface morphology of Cu/Ni bilayer electrodeposited Ni54Nb42Al4 fiber revealed that dense veins like patterns originated on the tensile fracture surface of as-cast and low R value Cu/Ni bialyer electrodeposited NiNbAl MG fibers, while secondary shear bands are originated from side surface of tensile fracture sample with R = 95%, as shown in Fig. 8h, while single shear bands can be observed on fracture surface of un-coated fiber, as shown in Fig. 8b. These factors mean that crystalline phase during electrodeposition of bilayered Cu/Ni onto fibers block the shear bands propagation, resulting in a delocalization of neighboring un-deformed regions. Increase plasticity of fibers is expected due to this shear delocalization39. The beginning, dissemination, and more branching of shear bands is the signal of enhancement of plasticity in bilayered coated fibers. Thus plasticity of coated fiber is reliant frankly on the concentration of shear bands formation during deformation40. Thick Cu/Ni-electrodeposition onto the surfaces of Ni54Nb42Al4 fibers inhibited the fast propagation of primary shear band and promoted the secondary shear bands, as represented in Fig. 8h, as a result the plasticity is increased41. Our experimental results revealed that there should be a considerable thick Cu/Ni bilayer (100μm and above) on the surface of as cast fibers, as shown in Fig. 5a (d-f).

The plasticity enhancement using electrochemically deposited Cu/Ni-bilayer described to an excellent bonding between Ni54Nb42Al4 fibers and Cu/Ni-deposited layer. Cu/Ni bilyer coating thickness is gradually increased with the increasing R values as shown in Fig. 9. The soft Cu- electrodeposited layer can stop the fast propagation of single shear band and Ni-electrodeposited layer can defuse uniformity with the amorphous fibers layer and be appreciably extended without rupture10,21. Finally the tensile plasticity enhancement could be connected with the thickness, quality of electrodeposits and good interface bonding between Cu and Ni-coated layers, as well as with the surface of MG fibers.

Conclusions

The tensile plasticity enhancement of Cu/Ni bilayer electrodeposited Ni54Nb42Al4 metallic glaay fibers with different volume fractions (R) of bilayered coating were determined by using tension test. Tension test results reveal that a maximum tensile plasticity of 5.8% have been achieved for R = 95% Cu/Ni bialyer coated Ni54Nb42Al4 MG fibers. Thick Cu/Ni bialyer electrochemical deposition onto the MG fibers hindered the initiation and fast propagation of primary shear bands and enhanced the tensile plasticity of coated Ni-Nb-Al fibers. Basically, the homogeneous Cu/Ni bilayer coating, coating thickness and good interface bonding between layers is responsible for enhancement of tensile plasticity in coated MG fibers. The improvement in the tensile plasticity is due to electrodeposition of a thick Cu/Ni-bilayer is a break through to enhance the reliability and application of highly brittle nature Ni54Nb42Al4 MG fibers as functional, electronic and engineering materials.

The novelty of the current work is the first time enhancement of tensile plasticity in ternary Ni54Nb42Al4 fibers by Cu/Ni bialyer coating under tensile loading at room temperature. The current exploration may open up a new perspective to understand the enhancement of tensile plasticity in MG fibers by Cu/Ni bialyer electrochemical deposition.

Data availability

The data in this work are available from the corresponding author on reasonable request.

References

Hussain, I. et al. Cooling rate-dependent yield behavior of metallic glass wires. Mat. Sci. Eng. A 683, 236–243 (2017).

Argon, A. S. Plastic deformation in metallic glasses. Acta Metall. 27, 47–58 (1979).

Spaepen, F. A microscopic mechanism for steady state inhomogeneous flow in metallic glasses. Acta Metall. 25, 407–415 (1977).

Choi, Y. C. & Hong, S. I. Enhancement of plasticity in Zr-base bulk metallic glass by soft metal plating. Scripta Mater. 61, 481–484 (2009).

Chen, W. et al. Encapsulated Zr-based bulk metallic glass with large plasticity. Mat. Sci. Eng. A 528, 2988–2994 (2011).

Chen, W. et al. Plasticity enhancement of a Zr-based bulk metallic glass by an electroplated Cu/Ni bilayered coating. Mat. Sci. Eng. A 552, 199–203 (2012).

Nieh, T. G. et al. Effect of surface modifications on shear banding and plasticity in metallic glasses: An overview. Prog. Nat. Sci. Mater. Inter. 22, 355–363 (2012).

Sun, B. A. et al. Origin of Shear Stability and Compressive Ductility Enhancement of Metallic Glasses by Metal Coating. Sci. Rep 6, 27852 (2016).

Meng, M. et al. Improved plasticity of bulk metallic glasses by electrodeposition. Mat. Sci. Eng. A 615, 240–246 (2014).

Ren, L. W. et al. Enhancement of plasticity in Zr-based bulk metallic glasses electroplated with copper coatings. Intermetallics 57, 121–126 (2015).

Low, C. T. J., Wills, R. G. A. & Walsh, F. C. Electrodeposition of composite coatings containing nanoparticles in a metal deposit. Surf. Coat. Technol. 201, 371–383 (2006).

Ibañez, A. & Fatás, E. Mechanical and structural properties of electrodeposited copper and their relation with the electrodeposition parameters. Surf. Coat. Technol. 191, 7–16 (2005).

Wang, W. H. Bulk Metallic Glasses with Functional Physical Properties. Adv. Mater. 21, 4524–4544 (2009).

Hatherly, M. & Malin, A. S. Shear bands in deformed metals. Scr. Metall. 18, 449–454 (1984).

Møller, P. C. F. et al. Shear banding and yield stress in soft glassy materials. Phys. Rev. E https://doi.org/10.1103/PhysRevE.77.041507 (2008).

Greer, A. L. et al. Shear bands in metallic glasses. Mat. Sci. Eng. R 74, 71–132 (2013).

Yu, P. et al. Enhance plasticity of bulk metallic glasses by geometric confinement. J. Mater. Res. 22, 2384–2388 (2007).

Hussain, I. Tensile behavior of Cu-coated Pd40Cu30Ni10P20 metallic glassy wire. Sci. Rep. 8, 5659 (2018).

Kanani, N. Electroplating and Electroless plating of copper and its alloys. Steven age. Finishing Publication Ltd, 78–80 (2003).

Dennis, J. K. Nickel and Chromium plating (Cambridge Woodhead Publishing Ltd, 1993).

Lu, X. L. et al. Gradient confinement induced uniform tensile ductility in metallic glass. Sci. Rep. 3, 3319 (2013).

Mukai, T. et al. Dynamic response of a Pd40Ni40P20 bulk metallic glass in tension. Scripta Mater. 46, 43–47 (2002).

Wang, H. et al. Relating residual stress and microstructure to mechanical and giant magneto-impedance properties in cold-drawn Co-based amorphous microwires. Acta Mater. 60, 5425–5436 (2012).

Wu, Y. et al. Nonlinear tensile deformation behavior of small-sized metallic glasses. Scripta Mater. 61, 564–567 (2009).

Yi, J. et al. Micro-and Nanoscale Metallic Glassy Fibers. Adv. Eng. Mat 12, 1117–1122 (2010).

Zberg, B. et al. Tensile properties of glassy MgZnCa wires and reliability analysis using Weibull statistics. Acta Mater. 57, 3223–3231 (2009).

Zhang, Z. F. et al. Difference in compressive and tensile fracture mechanisms of Zr59Cu20Al10Ni8Ti3 bulk metallic glass. Acta Mater. 51, 1167–1179 (2003).

Wang, H. et al. Nanocrystallization enabled tensile ductility of Co-based amorphous microwires. Scripta Mater. 66, 1041–1044 (2012).

Takayama, S. Drawing of Pd77.5Cu6Si16.5 metallic glass wires. Mat. Sci. Eng. 38 41–48 (1979).

Hagiwara, M. et al. Mechanical properties of Fe-Si-B amorphous wires produced by in-rotating-water spinning method. Metall. Trans. A 13, 373–382 (1982).

Sun, H. et al. Tensile Strength Reliability Analysis of Cu48Zr48Al4 Amorphous Microwires. Metals 6, 296 (2016).

Sun, B. A. et al. Origin of Shear Stability and Compressive Ductility Enhancement of Metallic Glasses by Metal Coating. Sci. Rep. 6, 27852 (2016).

Gu, X. J. et al. Compressive plasticity and toughness of a Ti-based bulk metallic glass. Acta Mater. 58, 1708–1720 (2010).

Yi, J., Wang, W. H. & Lewandowski, J. J. Guiding and Deflecting Cracks in Bulk Metallic Glasses to Increase Damage Tolerance. Adv. Eng. Mat. 17, 620–625 (2015).

Yu, P. et al. Enhancement of Strength and Corrosion Resistance of Copper Wires by Metallic Glass Coating. Mater. Trans. 50, 2451–2454 (2009).

Drory, M. D. et al. On the decohesion of residually stressed thin films. Acta Metall. 36, 2019–2028 (1988).

Ziebell, T. D. & Schuh, C. A. Residual stress in electrodeposited nanocrystalline nickel-tungsten coatings. J. Mat. Res 27, 1271–1284 (2012).

Courtney, T. H. Mechanical Behaviors of Materials. Science 2, 252–255 (1990).

Neurohr, K. Electrodeposition of metals. J. Electroch. Soc. 162, 256–264 (2015).

Li, B. et al. Fundamental constraints on the strength of transition-metal borides: The case of CrB4. Phy. Rev. B. https://doi.org/10.1103/PhysRevB.87.174106 (2013).

Qiu, S. B. & Yao, K. F. Novel application of the electrodeposition on bulk metallic glasses. Appl. Surf. Sci. 255, 3454–3458 (2008).

Acknowledgements

This work was financially supported by Karakoram International University Gilgit. Ref: KIU-ORIC-(2022-23).

Author information

Authors and Affiliations

Contributions

Ishtiaq Hussain and Zahid Hussain imitated the project, I. Hussain and Z. Hussain performed the experiments and write manuscript. Iftikhar Ali , Shamsher Ali and Doglus Law contributed to data analyzing and discussion.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Hussain, I., Hussain, Z., Ali, S. et al. Tensile plasticity in Cu and Ni-coated Ni54Nb42Al4 metallic glassy fibers. Sci Rep 15, 26404 (2025). https://doi.org/10.1038/s41598-025-96997-2

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-96997-2