Abstract

Under China’s “double carbon” goals, which are to achieve carbon peak (CO2 emissions peak by 2030) and carbon neutrality (net-zero CO2 emissions by 2060), the manufacturing industry is facing the dilemma of low-carbon transition. Enhancing the industry’s resilience to these challenges is crucial for improving the quality of its development. This article introduces a new concept of “carbon resilience”, based on resilience theory. Carbon resilience refers to the endogenous dynamic capability of the manufacturing industry to respond to the long-term heightened demands and short-term constraints imposed by relevant low-carbon emission reduction policies, exemplified by the “double carbon” goals. Then, using industry data for 25 manufacturing sectors from 2011 to 2020, we explore the impact of overall carbon resilience, as well as carbon resilience of manufacturing industries with different carbon emission intensities, on the quality of industry development. We also explore the mediating role of resource allocation efficiency in these relationships. Finally, we conduct a predictive analysis of the relationship between carbon resilience and the quality of industry development from 2024 to 2030. The results indicate a significant positive correlation between carbon resilience and the quality of industry development. The impact of carbon resilience on development quality is greatest in high-carbon emission industries, followed by medium-carbon emission industries, and weakest in low-carbon emission industries. Additionally, in the manufacturing industry and high-carbon emission industries, resource allocation efficiency plays a sufficiently mediating role between carbon resilience and the quality of industry development. However, in medium- and low-carbon emission industries, resource allocation efficiency does not mediate between the two. Notably, further predictions reveal that carbon resilience will have a negative impact on the quality of industry development between 2024 and 2030. Based on these findings, policymakers should actively shape carbon resilience, optimize the production process through technological innovation, promote the industrial chain’s extension into high-tech industries, and optimize the efficiency of resource allocation, thus comprehensively promoting the quality of industry development.

Similar content being viewed by others

Introduction

In today’s world, the importance of environmental protection is growing across all countries (Kudlak, 2017). In response to this, China announced its “Double Carbon Goals” in September 2020. The goals explicitly state that carbon dioxide emissions will peak before 2030 and aim to achieve carbon neutrality by 2060 (Li et al., 2023), with the objective of promoting a comprehensive green transformation of economic and social development (Chen et al., 2020). By examining the governance of China’s manufacturing development, we aim to provide valuable insights for the governance of manufacturing in other countries. In fact, China’s manufacturing industry is facing serious challenges due to its development model characterized by high investment, high energy consumption, and high emissions (Li et al., 2020). In particular, the traditional rough manufacturing development mode is no longer sustainable for achieving the “double carbon” goals. Consequently, reducing carbon emissions and implementing green transformation have become essential strategies for enhancing the development quality of China’s manufacturing industry (Beraud et al., 2022). However, several factors pose challenges to China’s manufacturing industry, including rising environmental protection costs, fluctuating raw material prices and declining international competitiveness in product pricing. These factors have severely constrained the low carbon transformation of the manufacturing industry and the quality of its development. Therefore, how to improve the quality of industry development in the context of the “double carbon” goals has become an urgent issue for China to explore.

In particular, with the introduction of the “double carbon” goals, China has put forward many new requirements for the low-carbon transformation of the manufacturing industry, which will significantly impact the industry’s original development path. Resilience, as the ability of a system to withstand external shocks, contributes to the system actively respond to crises, overcome difficulties, bounce back and achieve sustainable improvement (Meerow et al., 2016). This concept provides a new perspective and approach for the manufacturing industry to cope with the low carbon transition and enhance development quality. Therefore, this paper proposes the new concept of carbon resilience, drawing on the general system evolution connotation of resilience. Carbon resilience is defined as a set of endogenous stabilizing, adaptive and evolutionary capacities within an industry. The shaping and enhancement of carbon resilience will determine the extent by which industry accepts and adapts to the “double carbon” development logic. Carbon resilience can serve as the underlying governance logic for the manufacturing industry in the “double carbon” era, with governance solutions for the manufacturing industry being proposed based on carbon resilience monitoring (Jin et al., 2021). The scientific interpretation and accurate measurement of carbon resilience in existing studies still require further exploration. It is also unclear whether carbon resilience affects the quality of industry development and whether its impact varies at different levels of carbon emissions.

Additionally, the “double carbon” goals will force the manufacturing industry to continuously enhance quality, increase operational efficiency, reduce production costs, and shorten cycle times through the deep integration of green energy technologies and the new generation of smart technologies. This integration will catalyze the accelerated formation of new business modes, such as green manufacturing, intelligent manufacturing and service-oriented manufacturing, while also instigating a profound shift in resource allocation. Therefore, does carbon resilience contribute to resource allocation efficiency, thereby influencing the quality of industry development? Previous studies have mainly explored the impact of environmental policies or environmental regulations on resource allocation (Najjar and Cherniwchan, 2021; Walker, 2011). Some scholars have also explored the role of resource allocation efficiency on the quality of industry development (Marin and Vona, 2021) or production efficiency (Peters, 2020). However, there is currently no clear answer regarding whether resource allocation efficiency affects the relationship between carbon resilience and the quality of industry development.

To fill this gap, this paper introduces a new concept of carbon resilience, and constructs a carbon resilience monitoring system. On this basis, this study explores the impact of carbon resilience as a whole, as well as carbon resilience of high-, medium- and low-carbon emission industries, on the quality of industry development. The mediating role of resource allocation efficiency is also explored. In addition, the relationship between carbon resilience and the quality of industry development is further predicted. This paper aims to answer the following questions: (1) How to scientifically explain the dynamic composition of carbon resilience in the manufacturing industry? How to accurately measure carbon resilience? (2) Does carbon resilience affect the quality of industry development? Are there differences in the impact of carbon resilience on the quality of industry development in different industries? (3) Does resource allocation efficiency play a mediating role in the above relationship? (4) Taking the current state of manufacturing development as an example, how will carbon resilience affect the quality of industry development as China realizes its 2030 carbon peak target?

This paper provides some theoretical contributions to the existing literature. First, this paper proposes a new concept of carbon resilience, informed by the unique context of the “double carbon” goals and drawing on resilience theory. The characteristic dimensions of carbon resilience are deconstructed, and a monitoring system for carbon resilience in the manufacturing industry is proposed. Unlike existing studies that mainly explore carbon risks (Patrick and Marcin, 2021), we investigate carbon resilience, which is the ability to withstand external shocks. Our work not only broadens the application scope of resilience theory, but also provides new theoretical support for the low-carbon transformation of the manufacturing industry. Second, this paper finds that carbon resilience positively impacts the quality of industry development. However, higher levels of carbon resilience do not necessarily translate to better outcomes. In future development, an excessive emphasis on enhancing carbon resilience may hinder improvements in the quality of industry development. Current research focuses on improving the quality of industry development from the perspectives of environmental regulation (Popp, 2006) and technological innovation (Presley et al., 2000). This paper takes carbon resilience as an entry point to explore its impact on the quality improvement of manufacturing development, providing empirical evidence for using carbon resilience to improve the quality of industry development. It also provides a balanced perspective for understanding the effects of carbon resilience. Third, this paper finds that resource allocation efficiency fully mediates the relationship between carbon resilience and the quality of industry development. Existing studies mainly explore the relationship between resource allocation efficiency and the quality of industry development (Ji et al., 2023). We incorporate “carbon resilience - resource allocation efficiency - industry development quality” into a unified analytical framework. Our research provides a new perspective for understanding the relationship between carbon resilience and the quality of industry development, and expands the internal mechanism between the two. Our work also expands the antecedents of resource allocation efficiency. Finally, by further exploring the differences in the direct and indirect impacts of carbon resilience on the development quality of high, medium and low carbon emission sectors, this study provides an important reference for the precise design of governance strategies to enhance the development quality of different types of sectors.

The remainder of this paper is organized as follows: Section 2 is literature review. Section 3 describes the theoretical construction and hypothesis formulation. Section 4 outlines the research method. Section 5 presents the results. Section 6 presents the conclusions and implications.

Literature review

The purpose of this paper is how to improve the quality of manufacturing development. To this end, this paper first reviews the literature on the quality of industry development. In addition, by combing the resilience-related theories, this paper proposes a new concept of carbon resilience and its characteristic dimensions. Given the limited existing studies on the relationship between carbon resilience and the quality of industry development, this paper also reviews closely related literature.

Quality of industry development

Scholars have explored the factors influencing manufacturing development, primarily focusing on external environmental regulation, technological innovation, and green and low carbon. Specifically, (1) Environmental regulation. Environmental regulation may impose a “push-back” effect, as the external pressure it exerts may force firms to innovate, allocate resources more rationally, and overcome organizational inertia, thereby enhancing productivity. Wang and Shen (2016) pointed out that the stricter the environmental regulations, the stronger the profitability of the cleaning industry, thereby widening the profit gap between clean and polluting industries. Popp (2006) argued that environmental regulation can drive innovation and facilitate the diffusion of existing technologies, thus improving the quality of development. (2) Technological innovation. Scholars have mainly explored the impact of green technologies on the quality of the manufacturing development. Hart (1995) found that green manufacturing technologies have a significant mitigating effect on environmental pollution. These technologies not only help companies reduce environmental costs, but also play an effective role in balancing economic development with environmental protection. In 1996, the Society of Manufacturing Engineers (SME) published the “Green Manufacturing” Blue Book, which combined green manufacturing with sustainable development as an innovative model of mechanical engineering aimed at addressing environmental pollution and resource shortages in the context of rapid industrialization. Presley et al. (2000) believed that the efficiency of process innovation and manufacturing capability can be improved by strengthening theoretical research on intelligent process innovation and effectively applying its findings. Cao et al. (2021) pointed out that China’s green credit policy helps stimulate enterprises’ environmental protection behaviors and helps alleviate the capital chain risks caused by the mismatch of investment and financing terms. Furthermore, it can resolve the contradiction between environmental protection and economic development. (3) Green and low carbon. Green and low carbon has become the future direction of manufacturing. Especially in the context of the “double carbon” goals, the green and low-carbon transformation of the manufacturing industry must balance economic, ecological and social benefits. By optimizing the industry’s structure and continuously innovating in green technologies, we can promote a dual-cycle approach and enhance the industry’s international competitiveness (Cai et al., 2019; Dube et al., 2011; Huang, 2022). Scholars have found that green low-carbon transition can reduce energy consumption intensity and carbon emissions through green innovation (Tariq et al., 2022), thereby improving economic efficiency and the quality of development.

Carbon resilience

Definition of carbon resilience

Early research on resilience can be traced back to two seminal papers by Staw, Dutton (1981) and Meyer (1982). In recent years, with the increase of external threats to the system, the concept of resilience has been given new theoretical life. As a result, how to make systems more resilient has become an important topic in management practice (Longstaff and Yang, 2008). Existing scholars have primarily defined the concept of resilience from a capability perspective. For example, Kahn et al. (2016) considered resilience as the ability to absorb stress, and maintain or improve function in the face of adversity. Weick (1993) believed that resilience emphasizes not only the ability to adapt, but also the ability to respond proactively and creatively to crises in an uncertain environment. Sahebjamnia et al. (2018) argued that resilience enables systems to adapt positively and return to their original state despite experiencing negative events. Ma et al. (2018) identified resilience as the ability of systems to survive, adapt, recover and even prosper in the face of unexpected events. Burnard and Bhamra (2019) saw resilience as the ability to reduce vulnerability in the face of systemic crises.

By analyzing existing definitions of resilience, it is found that resilience consists of two key elements: external shocks and positive adaptation to shocks. The concept of “carbon resilience” proposed in this article can be understood as the endogenous dynamic capability of the manufacturing industry to respond to the long-term higher requirements and short-term constraints brought about by low-carbon development. Carbon resilience is distinct from general resilience. It pays special attention to the shocks arising from the unique context of green and low-carbon attributes. Carbon resilience is more targeted and better aligns with development scenarios. It takes the complex changes in economics, technology, and institutions faced during low-carbon development and green transformation as external stimuli. The shaping and enhancement of carbon resilience will influence the manufacturing industry’s acceptance of and adaptation to the logic of green transformational development. By proposing the concept of carbon resilience, we can help the global manufacturing industry adopt more effective measures when facing shocks related to green and low-carbon development. Liang and Guo (2024), based on the “double carbon” goals, consider the impact of external environmental changes on institutional, technological, and economic aspects as external catalysts for the formation of carbon resilience. Specifically, institutional changes mainly refer to China’s ongoing exploration of a “double carbon” policy system. Under the overarching framework of the national “carbon neutral” strategy, various ministries, industry associations and local governments have successively issued implementation plans, industrial strategies and supporting policies. In addition, technological changes mainly involve China’s efforts to establish a self-reliant and controllable system for green and low-carbon technologies, while accelerating their widespread application. The key technologies include low-carbon energy substitution, emissions reduction in industrial processes, waste recovery and recycling, intelligent grid-connected technologies, and energy storage. However, in the process of innovative technology development and application, green and low-carbon technologies still suffer from problems, such as large initial investment, high cost and slow returns. Finally, economic shocks mainly refer to the ongoing advancement of industrialization and urbanization in China, which is expected to persist in the foreseeable future, resulting in sustained high levels of energy consumption and carbon emissions. In the short term, stricter carbon reduction targets may exacerbate economic shocks, posing challenges to manufacturing costs, financing, and overall economic performance (Liang and Li, 2023).

Taken together, drawing on the general system evolution connotation of resilience, this study proposes a new concept of carbon resilience. This paper views the complex changes in economic, technological and institutional changes centered on the “double carbon” goals as an external catalyst for change. Moreover, this paper also considers the increased demands and short-term constraints on manufacturing arising from the “double carbon” goals. Based on the above research, carbon resilience is defined as the endogenous dynamic capability of the manufacturing industry to show stability, adaptability, and reconfiguration evolution in response to the shocks of low-carbon development and green transition.

Composition of carbon resilience

At different shocks stages, the dynamic properties of resilience will change. Resilience shows predictability before a shock occurs, defensiveness during the shock, and growth after a shock occurs. Somers (2009) incorporated the concept of anticipation into his resilience framework. He believed that resilience involves not only the ability to survive, but also the ability to identify potential risks and take proactive measures to address them. Only by recognizing early signs of a crisis can the system react quickly enough to avoid escalation. Raetze et al. (2022) pointed out that resilience is a composite with multiple attributes, of which (anticipatory, defensive, and growth) all play an important role in the composition of resilience. Only in combination can a system respond effectively to shocks from adverse events. Scholars have mainly evaluated resilience in terms of resilience action processes, structure and capacity (Sharma et al., 2020). In addition, it has been shown that the process of developing resilience involves three stages: passive resistance, active coping and reflective learning. These stages correspond to the three dynamic capabilities of the system: perception, adjustment, and evolution. Therefore, carbon resilience can also be understood as the core dynamic capacity of the manufacturing industry to cope with the higher long-term requirements and short-term constraints imposed by the “double carbon” goals, encompassing stabilizing, adaptive and evolutionary capacities.

-

(1)

Stabilizing capacity

Stabilizing capacity is fundamental to resist external risks and maintain stability. It is reflected in the speed of response to take urgent action during an external crisis (Massari et al., 2023). The introduction of the “double carbon” goals has placed greater demands on the development of high carbon-emitting manufacturing industries, along with short-term constraints (Ivanov and Rozhkov, 2020). In light of the “double carbon” goals and the implementation of policies across various sectors, low carbon technology innovation has become a key way to maintain industry stability and product structure, and steadily promote the transformation and upgrading of high carbon-emitting manufacturing industries.

-

(2)

Adaptive capacity

Adaptive capacity is the ability of a system to accept new information, explore new approaches and cope with change in response to external shocks, resolving internal conflicts and other challenging issues (Woods, 2015). Only by accurately understanding and quickly adapting to changes in the external environment can enterprises maintain resilience and sustainable development in the complex and changeable market environment.

-

(3)

Evolutionary capacity

Evolutionary capacity is a key capability for systems to survive, develop and grow over time in complex and changing environment (Moya and Goenechea, 2022). It is the ability to recover and even surpass previous states through self-learning and other means, facilitating sustainable survival and long-term growth in an ever-changing environment. This capacity is expressed as the learning summary of the response to the impact process and the adaptation of existing strategies (Beermann, 2011). The greater the evolutionary capacity of the system, the greater its ability to autonomously renew, change the structure of the original production experience, and adopt new development models and strategies, thereby enhancing its carbon resilience. The evolutionary capacity of a system can be well represented by examining the manufacturing low carbon development initiatives and low carbon development strategic planning.

Measurement of carbon resilience

Existing scholars have mainly evaluated system resilience in terms of resilience action processes, structure and capacity. For example, Li and Zhu (2021) proposed system resilience indicators including dynamic equilibrium, compatibility, high mobility, flatness, buffering power, and redundancy. Patriarca et al. (2017) evaluated resilience from the perspective of the resilience action process, identifying four dimensions: monitoring, response, prediction and learning. Mcinroy and Longlands (2010) proposed a four-dimensional resilience evaluation system, comprising infrastructure and ecosystems, economy and society, leadership and strategy, and health and well-being. Ahern (2011) proposed indicators of urban resilience, including multifunctionality, redundancy and modularity, eco-social diversity, multi-scale network connectivity, and adaptive planning and design. Schlör et al. (2018) proposed urban resilience indicators that include productivity, infrastructure, quality of life, equity, and environmental sustainability. Burton (2014) proposed indicators of community resilience, including social, institutional, economic, and infrastructure.

The monitoring of resilience values based on resilience characteristics is a new quantitative way of measuring the development of social-ecological systems, with the quantification of these characteristics serving as a key method for portraying resilience values. Meanwhile, resilience value monitoring acts as a “bridge” between resilience science and quantitative governance solutions for manufacturing. Therefore, drawing from the resilience characteristics proposed by scholars and the composition of carbon resilience described above, we believe that carbon resilience comprises three dimensions: stability, adaptability and evolvability.

-

(1)

Stability reflects the inherent conditions and endowments of the manufacturing industry. It is the most essential characteristic of resisting risks and maintaining system integrity. The more stable the system is, the less likely it will be affected by shocks (Liang and Guo, 2024). The strength of stability depends on the system’s inherent endowments, with a well-endowed system being better equipped to withstand the impact of external shocks (Massari et al., 2023). There are four indicators for measuring stability in the manufacturing industry, namely total energy consumption, carbon dioxide emissions, number of industrial waste gas treatment facilities, and operating costs of industrial waste gas treatment facilities (Qian, 2021).

-

(2)

Adaptability reflects the internal adjustment of the manufacturing industry to external environment changes. Adaptability is the system’s acceptance of new information, exploration of new methods, and response to new changes when dealing with external shocks, thus driving the recovery of the system’s functional level and promoting proactive adjustment (Desjardine et al., 2019). There are two indicators for measuring adaptability in the manufacturing industry, namely the rate of change in CO2 emissions and the rate of change in the number of green patent citations (Linnenluecke, 2017).

-

(3)

Evolvability reflects the survival, development and long-term growth of the manufacturing industry in a complex and ever-changing environment. Evolvability refers to the process of optimizing elements and reconfiguring structures through self-learning and self-adaptation after external shocks, which is manifested in the continuous improvement of resilience values (Jin et al., 2021). There are two indicators for measuring evolvability in the manufacturing industry, namely the state of low carbon development institutional development and the state of low carbon development strategic planning.

Carbon resilience and the quality of industry development

There is a dearth of existing research on the relationship between carbon resilience and the quality of industry development. Closely related to this literature, some scholars have explored manufacturing resilience, focusing mainly on both measurement and influencing factors. (1) Regarding the measurement of manufacturing resilience, Li and Liu (2021) and Liu and Zhang (2021) calculated the actual potential growth rate and counterfactual potential growth rate based on the labor productivity of the manufacturing industry by using the HP filtering method, and took the difference between the two as an indicator to measure manufacturing resilience. Martin and Sunley (2014), Fingleton et al. (2012), and Doran and Fingleton (2017) refined the resilience measurements based on the core variable approach, time series models, and causal structure models. (2) Most research on the factors influencing manufacturing resilience and industry resilience have used manufacturing as a sample, analyzing resilience from the perspective of the supply chain associated with manufacturing. Soni et al. (2014) used an explanatory theory model to analyze the factors influencing supply chain resilience and their interrelationships. This analysis was also conducted using an explanatory structural modeling approach, which concluded that supply chain collaboration capability and agility are the key factors affecting supply chain resilience. Junaid et al. (2020) selected supply chain resilience, supply chain agility and supply chain robustness as criteria for supply chain risk management through a case study of the automotive industry. The analysis yielded that supply chain resilience is the most important criterion for managing supply chain risk. Rajesh (2021) and Agarwal and Ussif (2022) found that flexible business strategies, lean production and technological innovation help to improve manufacturing resilience.

Taken together, there is a dearth of existing research on carbon resilience and the quality of industry development. Therefore, this paper proposes the connotation of carbon resilience and its characteristic dimensions drawing on the connotation of general system resilience. It also empirically analyzes the relationship between carbon resilience and the quality of industry development by constructing a carbon resilience monitoring system.

Theoretical framework and hypotheses development

The impact of carbon resilience on the quality of industry development

The signing of agreements like the Paris Agreement (Schleussner et al., 2022) and the introduction of low carbon emission reduction policies, such as the “double carbon” goals, will lead to a more unstable external environment for the manufacturing industry (Jabbour et al., 2021). The low carbon transformation of manufacturing industry is subject to more short-term constraints and long-term requirements (Sun et al., 2022). In the short term, the manufacturing industry faces the impact of rising environmental costs, fluctuating raw material prices, and declining international competitiveness of product prices during low carbon transformation, which in turn affects the quality of industry development (Johansson et al., 2021). In the long term, the “double carbon” goals will inevitably force the manufacturing industry to continually enhance the quality of its development through a low carbon transition.

Carbon resilience can effectively measure the manufacturing industry’s ability to withstand the impacts of low-carbon emission reduction policies and its capacity for low-carbon transformation. However, since carbon resilience is a newly introduced concept in this article, there is a lack of existing research on the relationship between carbon resilience and the quality of industry development. Therefore, this study delves into areas closely related to manufacturing carbon resilience, including resilience theory (Burnard and Bhamra, 2019), green and low-carbon manufacturing, environmental regulation (Wang and Shen, 2016), and theoretical frameworks such as environmental sustainability and labor economics. It delves into the connotation of carbon resilience in manufacturing and its connection to the quality of industry development. Through the literature review, this paper finds that scholars generally agree that resilience can effectively promote the improvement of manufacturing development quality (Sun et al., 2022). In view of this, combined with practical scenarios, this paper analyzes the relationship between carbon resilience and the quality of industry development. Optimal resource allocation and the enhancement of innovation capabilities are considered key factors in improving production efficiency and competitiveness. Similarly, enterprises need to adopt green production methods, optimize resource utilization, and reduce environmental pollution to achieve sustainable development. Carbon resilience, based on the above theoretical foundations, promotes the improvement of manufacturing development quality. This requires that the manufacturing industry, while responding to low-carbon policies, not only optimize resource allocation and enhance innovation efficiency, but also pay attention to environmental protection and sustainable development.

Firstly, manufacturing industries with carbon resilience can promptly perceive and gain insights into potential external threats and opportunities. They are adept at swiftly adjusting their strategies to optimize resource allocation, seizing future development opportunities to enhance innovation efficiency rapidly (Colberg, 2022). Additionally, they are proficient in promoting the integration of internal and external resources to enhance resource allocation efficiency, thereby mitigating the adverse impacts of unforeseen negative events (Larsson et al., 2016). Secondly, manufacturing industries with carbon resilience inherently possess diversified industrial structures and rich resource reserves, which can further invigorate the industries’ vitality (Salmanzadeh-Meydani et al., 2023). Lastly, manufacturing industries with carbon resilience also exhibit a higher demand for education, R&D, and innovative elements. The availability of high-level knowledge talent and advanced production technologies serves as a catalyst for driving the green development of these industries (Multan and Sobotka, 2022).

In conclusion, with the help of carbon resilience, the process of low carbon transformation in manufacturing industry is improving. The quality of industry development will continue to improve with the advancement of low carbon transformation. Based on the above analysis, the first hypothesis is formulated:

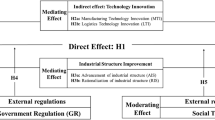

H1: carbon resilience has a positive impact on the quality of industry development.

Differences in the impact of carbon resilience on the quality of manufacturing industry development with different carbon intensity

Considering the huge differences in carbon emissions across various manufacturing sub-sectors, there will inevitably be notable differences in the governance strategies adopted by manufacturing industries with different carbon emission intensities. Additionally, differences in carbon emission intensities within the manufacturing sector may exert an influence on the correlation between carbon resilience and the quality of industry development. Consequently, this paper categorizes the manufacturing industry into high-carbon emission industries, medium-carbon emission industries, and low-carbon emission industries, based on the carbon emission intensity calculations for Chinese manufacturing sub-sectors conducted by Fu et al. (2021). Industries with a carbon intensity ranging from 0.91 to 4.47 tons are categorized as high carbon-emitting, those with a carbon intensity ranging from 0.21 to 0.61 tons as medium carbon-emitting, and those with a carbon intensity of less than 0.2 tons as low carbon-emitting. Utilizing the carbon emission inventory and energy inventory sourced from the China Emission Accounts and Datasets (CEADs), alongside revised Chinese carbon emission factors, Fu et al. (2021) calculated the carbon emissions of manufacturing sub-sectors. The findings revealed that the average emission intensity of high-carbon emission industries is 1.99 tons per 10,000 yuan, which is 5.9 times that of medium-carbon emission industries (0.34 tons per 10,000 yuan), and 19.9 times that of low-carbon emission industries (0.10 tons per 10,000 yuan). In summary, this paper examines the Chinese manufacturing industry from the perspectives of high-carbon emission industries, medium-carbon emission industries, and low-carbon emission industries.

High-carbon emission sectors are subject to more stringent access thresholds and U.S. Energy Information Administration policies compared to medium and low carbon emission sectors (Liao et al., 2022). For example, high-carbon emission industries represented by ferrous metal smelting and rolling processing industries are the top priority for carbon peak efforts (Mujjuni et al., 2021). China has clearly defined carbon peak tasks for these key industries, and formulated relevant policy documents to form industry carbon emission standards (Wang, Li, 2022). These industries face a more volatile external environment and require the capability of carbon resilience to withstand external shocks (Ates and Bititci, 2011). Manufacturing industries with carbon resilience can gain timely insights into the external situation, guide enterprises to integrate internal and external resources, and strengthen independent R&D. It also improves energy utilization efficiency and reduces carbon emission intensity, thus enhancing the quality of industry development (Su et al., 2014). Furthermore, compared to high-carbon emission industries, medium-carbon emission industries have experienced a reduction in carbon emission intensity. Their resource allocation has become more rational and better aligned with the demands of green and low-carbon development. Low-carbon emission industries are characterized by “low consumption and low emissions”. Compared to high-carbon and medium-carbon emission industries, the external environment for low-carbon emission industries is relatively stable, and the impact of carbon resilience on the quality of their development is relatively limited (Aldieri et al., 2021).

In conclusion, from the perspective of sub-sectors, carbon resilience may have a greater impact on the development quality of high-carbon emission industries, followed by medium-carbon emission industries, and the weakest low-carbon emission industries. Based on the above analysis, the following hypothesis is formulated:

H2: the impact of carbon resilience on development quality differs across manufacturing industries with varying carbon emission intensities.

Mediating effect of resource allocation efficiency on carbon resilience and the quality of industry development

The improvement of resource allocation efficiency depends on the free flow of production factors. Carbon resilience, as a kind of ability of manufacturing industry to withstand external shocks, is conducive to optimizing resource allocation and promoting the rational flow of production factors. Thus, carbon resilience can improve resource allocation efficiency.

Specifically, resource redundancy is a fundamental factor in shaping carbon resilience (Soikkeli et al., 2023), similar to the way humans store energy in their bodies. Sufficient energy reserves allow the body to take measures to cope with shocks. Similarly, resources can help the manufacturing industry cope with unexpected situations and control events from shifting towards adverse trends, ensuring reduced volatility and stabilizing operations in the face of shocks (Stevenson et al., 2016). This helps to reduce the manufacturing industry’s dependence on capital and labor production factors, and optimize the operation modes of various production factors, thus enhancing resource allocation efficiency. In addition, the adaptation function is a key factor in the formation of carbon resilience (Ten Broeke et al., 2017). It enables the manufacturing industry to quickly adjust resources within the system, manage the flow of elements, and facilitate information transfer. This adaptability allows the industry to respond rapidly and proactively, ensuring the continuity of normal system operations. The manufacturing industry can also develop new operational models for production factors during adaptation adjustments (Nelson et al., 2007), and quickly allocate labor, capital, and other production factors, thus effectively improving resource allocation efficiency. Finally, strategy is the core factor in the formation of carbon resilience, playing a holistic and long-term role in planning and organization. In the low-carbon development of the manufacturing industry, the formulation of strategies will take into account various aspects, such as institutional construction and strategic planning. The synergistic effect of the three elements of resource redundancy, adaptive function and strategy can promote the free flow of elements within the system, improve the synergistic effect between various production factors, and enhance resource allocation efficiency (Cai et al., 2019).

The improvement of resource allocation efficiency contributes to the quality of industry development (Ji et al., 2023). Specifically, resource allocation efficiency helps to realize efficiency transformation. Efficiency transformation is one of the important changes for high-quality development. Meanwhile, improving resource allocation efficiency is an important way to realize efficiency transformation. It has been shown that optimizing resource allocation can significantly improve productivity in China (Shao et al., 2013; Gai et al., 2015). Additionally, the impact of resource allocation efficiency on the quality of industry development is reflected in the variability of all production factors (Aamir et al., 2022). The manufacturing industry can choose clean energy to replace its original production factors, and change the production input combination, thereby affecting the cost function. In the long term, changes in the cost function may impact the quality of industry development either negatively or positively, depending on the efficiency of the emission reduction input factors replacing the original production factors (Peng et al., 2023). Finally, the gradual optimization of resource allocation efficiency influenced by carbon resilience can also raise industry entry barriers. Under the influence of carbon resilience, the manufacturing industry invests certain human and material resources in pollution control and emission reduction to meet regulatory goals. After complying with the regulations, costs for new entrants will increase. These additional costs mainly stem from purchasing, installing, and maintaining pollution control equipment, which may deter new entrants from entering the market.

Furthermore, the paper further takes into account the differences in the inherent conditions of various types of manufacturing industries. According to H2, the carbon resilience of high-carbon emission industries is likely to have the greatest impact on the quality of development, followed by the medium-carbon emission industries, and the weakest impact in the low-carbon emission industries. In the process where carbon resilience affects the quality of industry development through resource allocation efficiency, there will also be differences. The high pollution and energy consumption associated with high-carbon emission industries will lead to its resource allocation being inherently high-carbon. Thus, in the process of pursuing the optimization of resource reallocation, the carbon resilience of high-carbon emission industries has the greatest effect in significantly improving the quality of industry development through improving resource allocation efficiency. Moreover, in contrast to high-carbon emission industries, medium- and low-carbon emission industries, due to their resource endowments, have more low-carbon resource allocation characteristics, and their energy consumption and pollution levels are inherently lower. These industries require less adjustment. As a result, the impact of carbon resilience in medium- and low-carbon emission industries on improving development quality through resource allocation efficiency will correspondingly attenuate. Based on this comprehensive analysis, the following hypothesis is proposed:

H3: carbon resilience influences the quality of industry development through resource allocation efficiency. However, the role of resource allocation efficiency differs under varying carbon emission intensities Fig. 1.

Research method

Model setting

Firstly, after analyzing the meaning of carbon resilience and the quality of industry development, we find that the development logic of the quality of industry development is path dependent and lagging. Static panel model fails to reflect the dynamic process of change in the quality of industry development under the “double carbon” policy. Liang and Guo (2024) employs the Generalized Method of Moments (GMM) for analysis. Adopting a dynamic panel model can better address endogeneity issues and observe the dynamic effects on the quality of industry development. The following measurement model is constructed:

In Eq. (1), i denotes industry and t denotes time. \({\rm{QDI}}\) indicates the quality of industry development. \({\rm{CR}}\) denotes the carbon resilience. The parameter \({{\rm{\alpha }}}_{1}\) depicts the impact of carbon resilience on the quality of industry development. \({{\rm{QID}}}_{{\rm{i}},{\rm{t}}-{\rm{n}}}\) denotes the quality of industry development lagging n periods. Z is a set of control variables, including Industry Structure (IS), Social Contribution (SC) and Degree of Government Intervention (DGI). \({{\rm{\varepsilon }}}_{{\rm{it}}}\) is the random disturbance term.

Incorporating IS, SC, and DGI as control variables aims to more accurately explore the impact of carbon resilience on the quality of industry development. IS significantly influences carbon emissions due to differences in production and technology. Serving as a control variable helps isolate the interference of industry characteristics on carbon emissions (Gan, 2020). SC reflects the comprehensive performance of enterprises, especially the importance of sustainable development. As a control variable, it helps distinguish enterprises that actively adopt measures to reduce emissions and enhance resilience (Han and Ren, 2020). DGI reflects the impact of policies on carbon emissions and enterprises performance. Serving as a control variable helps exclude the potential interference of government policies on the relationship between carbon resilience and the quality of industry development (Han and Ren, 2020). Collectively, these three variables enhance the robustness and reliability of the findings.

To examine whether carbon resilience can contribute to the quality of industry development by improving resource allocation efficiency, with reference to Baron and Kenny (1986), this paper uses a three-step method to build a mediating effect model, as follows:

Where Resmis represents the mediating variable, while the meanings of other variables are consistent with those in Eq. (1). Equation (2) describes the impact of carbon resilience on resource allocation efficiency, and Eq. (3) indicates the mediating role of resource allocation efficiency on carbon resilience and the quality of industry development.

Variable selection and description

Explained variables

This section presents the Quality of Industry Development (QID). Based on the 14th Five-Year Plan and the outline of visionary goals, the quality of industry development evaluation index system is determined, as shown in Table 1.

-

(1)

Output efficiency

For the evaluation of industry output efficiency, existing scholars have adopted a variety of ways to measure it. Such as, Kuan et al. (1988) used industrial total factor productivity to analyze industry output efficiency. Zhuang (2022) and Chen et al. (2018) took into account environmental ecological issues when measuring total factor productivity, added environmental factors and used green total factor productivity (GTFP) for output efficiency analysis. Therefore, drawing on the development quality evaluation index system constructed by Liu (2018) and Rasheed and Ion (2022), this paper chooses to measure the output efficiency dimension of industry development quality from four aspects: GTFP, asset-liability ratio, return on total assets, and cost-profit ratio.

-

(2)

Technological innovation

Regarding the measurement of technological innovation, existing scholars mainly use indicators such as patents, R&D intensity, and innovation output as measurement standards (Archibugi and Planta, 1996; Chi et al., 2021; Freeman and Soete, 2009; Liu et al., 2022; Nam et al., 2014). Therefore, combined with the current situation of innovation development of China’s manufacturing industry, this paper mainly measures the technological innovation dimension of industry development quality from four aspects: R&D personnel equivalent, R&D expenditure, the number of R&D projects (topics), and the number of effective invention patents.

-

(3)

Product upgrading

In existing studies, some scholars believe that the improvement of industry development quality is influenced by products, and conduct research on the improvement of product supply quality and enterprise brand building (Bevilacqua et al., 2017). Product upgrading is a concrete manifestation of the quality improvement in industry development. New product development and the industry’s emphasis on it are essential elements of quality improvement in industry development (Lalic et al., 2017). Thus, this paper measures the product upgrading dimension of industry development quality in terms of the number of new product development projects and new product development expenditures.

-

(4)

Industry size

Industry size is the most direct indicator of industry development quality. By measuring industry size, we can gain insights into changes in industry development and the economic level of the industry (Bosman et al., 2020). Therefore, this paper mainly measures the industry size dimension of industry development quality from two aspects: the economic level of the industry and the scale of industrial assets.

Core explanatory variable

In this section, the core explanatory variable Carbon Resilience (CR) is presented. Based on the previous analysis, this paper constructs and finalizes the carbon resilience evaluation index system in accordance with the principles of objectivity, feasibility, and data availability, as illustrated in Table 2.

After constructing an indicator system for measuring carbon resilience, the next step is to calculate a comprehensive evaluation index of carbon resilience using the TOPSIS entropy weight method. This approach offers the advantage of standardizing the index and determining weights objectively based on variation, thus minimizing the influence of human factors. The specific calculation process is presented as follows:

The first step is to standardize the selected indicators. The standardization methods for positive and negative indicators are expressed in Eq. (4) as follows:

Where, \(i\) represents the year. \(j\) represents each underlying measure. \({a}_{{ij}}\) and \({e}_{{ij}}\) represent the original and standardized changed indicator values, respectively. max(\({a}_{{ij}})\) and min(\({a}_{{ij}})\) represent the maximum and minimum values, respectively.

The second step involves calculating the information content of the indicator. \({{\rm{C}}}_{{\rm{j}}}\) denotes the amount of information of the \({\rm{jth}}\) indicator. \({{\rm{C}}}_{{\rm{j}}}={{\rm{\delta }}}_{{\rm{j}}}\mathop{\sum }\nolimits_{{\rm{t}}=1}^{{\rm{m}}}\left(1-{{\rm{r}}}_{{\rm{tj}}}\right)\), where \({{\rm{\delta }}}_{{\rm{j}}}\) represents the standard deviation of index \({\rm{j}}\) and \({{\rm{r}}}_{{\rm{tj}}}\) represents the correlation coefficient between index \({\rm{j}}\) and index \({\rm{t}}\).

The third step focuses on calculating the weight of the \({jth}\) indicator, as follows:

The fourth step is to construct a weighting matrix of indicators, as follows:

The fifth step is to select the optimal and inferior solutions, as follows:

The sixth step calculates the distance of the measurement object from the optimal and inferior solutions, as follows:

Finally, we calculate the comprehensive index of carbon resilience (CR), as follows:

However, this paper acknowledges that carbon resilience varies across different industries. Therefore, to ensure the pertinence and accuracy of the evaluation, separate calculations are conducted for each industry. In addition, since carbon resilience encompasses three dimensions of stability, adaptability, and evolvability, each of which further includes multiple secondary indicators, a step-by-step and dimension-by-dimension strategy is adopted in calculating carbon resilience.

The specific calculation process is as follows: Firstly, a single dimension within a single industry is calculated, and the weights and scores of the stability, adaptability, and evolvability of the industry are determined in sequence. Subsequently, a comprehensive calculation is conducted on the data of these three dimensions to obtain the final carbon resilience value. This process ensures the accuracy and rigor of data calculation.

Mediating variable

The resource allocation efficiency discussed in this text is measured using industry productivity dispersion, drawing on the studies of Li and Sheng (2018). The alleviation of resource misallocation is specifically characterized by a sustained decline in the productivity dispersion of firms within an industry.

To measure industry productivity dispersion, the paper first calculates firm total factor productivity (TFP) using the OP method, denoted as lnTFPipft. It then takes the standard deviation of the logarithmic values of firm productivity within the same four-digit industry code, represented as TFPdisipt = sd(lnTFPipft).

In robustness tests, productivity dispersion is measured using the Gini coefficient, Theil index, coefficient of variation, and interquartile range. The industry’s productivity is calculated using the OP method. Due to the lack of actual industrial added value data, this paper compares the current value of industrial total output with its actual value to obtain a price deflator index. The actual industrial added value is then calculated by dividing the firm’s nominal industrial added value by the price deflator index. The actual capital stock is represented by the average annual balance of the net value of fixed assets, labor is measured as the average annual number of employees in the firm, and the current investment is defined as the increase in capital stock minus the depreciation of fixed assets.

This approach reflects a rigorous methodology that assesses productivity and resource allocation efficiency within an industry by approximating the actual economic input and output of the enterprise. This paper utilizes multiple metrics to ensure that its measures are robust and can withstand scrutiny, which strengthens the credibility of its findings.

Control variables

Three control variables are selected for this paper. Firstly, the industry structure (IS) is measured using the Theil index, drawing on Gan and Yu (2020). The specific formula is \(TL=\left(\frac{{Y}_{it}}{{Y}_{t}}\right)\mathrm{ln}\left(\frac{{Y}_{it}/{L}_{it}}{{Y}_{t}/{L}_{t}}\right)\), where Yit represents the output value of i industry in t year, Lit represents the employment of i industry in t year, Yt represents the total output value of the 25 manufacturing i industries in t year, and Lt represents the total employment of the 25 manufacturing i industries in t year. The social contribution (SC) is represented by the ratio of the average number of employees in an industry to the total number of employees (Han and Ren, 2020). The specific formula is \(S{C}_{it}=\frac{AN{E}_{it}}{TN{E}_{it}}\), where SCit denotes the social contribution index, ANEit denotes the average number of employees in i industry in t year, and TNEit denotes the total number of employees in i industry in t year. The degree of government intervention (DCI) is measured by the proportion of total assets of state-owned holding enterprises to total assets (Han and Ren, 2020). The specific formula is \(DC{I}_{it}=\frac{SH{E}_{it}}{T{A}_{it}}\), where DCIit denotes the degree of government intervention index, SHEit denotes the total assets of state-owned holding enterprises, and TAit denotes the total assets.

Data collection

The data selected in this paper span from 2011 to 2020, due to significant gaps identified in the data for certain key industries for the years 2021 and beyond during the data screening process. Specifically, data for industries such as agricultural and sideline food processing, tobacco manufacturing, other manufacturing, special equipment manufacturing, metal products, machinery and equipment repair, and waste resource comprehensive utilization were incomplete or not published after 2021. The missing data from these industries is crucial for a comprehensive analysis of the development status of the manufacturing sector. In summary, to ensure the accuracy and comprehensiveness of the findings, we have decided to use data from the period 2011 to 2020. The original data are sourced from various reliable and valid resources in academic research, including the “China Statistical Yearbook”, “China Science and Technology Statistical Yearbook”, “China Environment Statistical Yearbook”, “China Energy Statistical Yearbook”, “China Industrial Statistical Yearbook”, “China Economic Information Network (CEINET)”, and the CSMAR. Internet data are employed to effectively compensate for the deficiencies of traditional statistical data, such as time lags and lower accuracy.

To further ensure accuracy and comparability, this paper adjusts the manufacturing sector based on the “Classification of National Economic Industries of the People’s Republic of China” (2011 and 2017 versions). Fu et al. (2021) analyzed the carbon emission intensity of China’s manufacturing industry in 2017 and concluded that there are significant differences in carbon emission intensity among various manufacturing industries. Based on carbon emission intensity, we further classify the 25 sub-industries into three categories: high-carbon emission industries, medium-carbon emission industries, and low-carbon emission industries. The primary reason for classifying manufacturing industries is that high-carbon emission industries typically exhibit high energy consumption and large emissions, exerting significant pressure on the environment and resources. Medium-carbon emission industries fall into an intermediate category, with carbon emission intensities lying between those of high-carbon and low-carbon industries. Low-carbon emission industries, typically have low energy consumption and minimal emissions, resulting in a relatively smaller environmental impact. This classification not only helps to clearly define industry boundaries, but also provides strong support for policy formulation, enterprise strategic adjustment and resource allocation optimization, thereby promoting the overall transformation of the manufacturing industry towards low-carbon, green and sustainable development. The refined sub-sectors of manufacturing after adjustment are presented in Table 3, and all industries referred to in this paper are based on this table.

Results

Measurement results of the carbon resilience and industry development quality

The measured results of carbon resilience and quality of industry development from 2011–2020 are shown in the Table 4 and Table 5, respectively.

As can be seen from Tables 4 and 5, carbon resilience and industry development quality have fluctuated upward. The reasons for these fluctuations are related to the changing market environment in China. To achieve low-carbon development, China has adjusted the manufacturing industry’s development model. The introduction of relevant environmental regulatory policies has caused turbulence in the external environment for manufacturing operations, resulting in the above fluctuations (Chen et al., 2020).

As can be seen from Table 4, the carbon resilience of various manufacturing industries experienced minimal fluctuations between 2011 and 2014. This is because during this period, the Chinese government and the industry itself did not pay much attention to low carbon emission reduction. After 2015, the carbon resilience values of various industries began to fluctuate significantly. This paper suggests that this volatility is related to external market shocks. For example, in 2015, China set a target for carbon emissions reduction to be achieved by 2030. In 2016, 178 countries around the world signed the Paris Agreement (Schleussner et al., 2022). The occurrence of these events highlighted the importance of low-carbon development. The increasing resource and environmental constraints on manufacturing development led to more significant fluctuations in carbon resilience values (Li et al., 2020). After 2017, the manufacturing industry gradually adapted to changes in the external environment, and the carbon resilience growth situation once again returned to a relatively stable state.

As can be seen from Table 5, the quality of industry development in all sectors follow a relatively stable upward trend from 2011–2020. However, there was a fluctuating situation around 2016. After that, the quality of industry development accelerated. This paper argues that fluctuations in the quality of industry development occur later than fluctuations in carbon resilience due to policy lags. But this volatility is also related to changes in the external market environment due to low-carbon emission reduction policies. With the introduction of the “double carbon” goals in 2019, the external environment for the manufacturing industry became more unstable. The green and low-carbon transformation of the manufacturing industry will be subject to more long-term requirements and short-term constraints (Johansson et al., 2021). As can be seen from the carbon emission path of developed countries, it takes a long process to achieve carbon peak and carbon neutrality. These countries reached a natural peak by the 1970s and 1980s, experienced a long plateau in carbon emissions, and then gradually entered a phase of decline. Compared to developed countries, China has reached a lower peak level of carbon emissions, and the transition time from peak to neutrality is shorter, lacking an intermediate period. With the increasing impact of the “double carbon” goals, the importance of building carbon resilience in the manufacturing sector will also be emphasized, while the quality of industry development will deteriorate due to changes in the external environment (Su et al., 2014). Therefore, continuous dynamic measurement of carbon resilience and development quality in the manufacturing sector should be carried out over a longer period of time to achieve long-term dynamic monitoring.

Descriptive statistics for each variable

To differentiate and discuss the types of manufacturing industries according to their carbon emissions, the descriptive statistics of the variables are classified. These statistics are shown in Table 6.

Benchmark regression

Table 7 presents the baseline regression results. In column (1) of Table 7, the regression coefficient of carbon resilience on the quality of industry development is significantly positive at the 1% level. The results indicate that carbon resilience significantly improves the quality of industry development. In other words, enhancing carbon resilience is a necessary way to improve the quality of industry development, validating H1. The possible explanation is that external environmental stimuli are a prerequisite for resilience to work. Carbon resilience, as a dynamic capability to withstand external shocks, can help the manufacturing industry analyze external shocks and take effective countermeasures in a timely manner, thus realizing the quality improvement of industry development (Sun et al., 2022).

By comparing the regression results in columns (2)–(4), it can be found that the impact of carbon resilience on the quality of industry development varies across industries with different carbon intensities. Carbon resilience has the greatest impact on the quality of industry development in the high-carbon emission industries, followed by the medium-carbon emission sectors, and the lowest in the low-carbon emission industries. Therefore, H2 is validated. The signing of agreements like the Paris Agreement and the introduction of environmental regulation, such as the “double carbon” goals, will lead to increased instability in the external environment for the manufacturing industry (Jabbour et al., 2021). Compared with medium- and low-carbon emission industries, high-carbon emission industries are significantly affected by their pronounced high-energy and high-emission development patterns. High-carbon emission industries with carbon resilience can adjust quickly, promote the integration of internal and external resources, and improve resource allocation efficiency, thus promoting the quality of industry development. Consequently, carbon resilience has the greatest impact on the quality of development in high-carbon emission industries (Ates and Bititci, 2011).

Robustness Tests

To verify the reliability of the results, the following methods were used for robustness testing. The results are shown in Table 8.

-

(1)

Gradually increasing control variables

To address the potential bias of omitted variables and ensure that the baseline regression results are not driven by the selection of control variables, we followed the practices of Oster (2019) and adopted the method of gradually adding control variables. Specifically, we first constructed a parsimonious model containing only core explanatory variables and then sequentially incorporated additional control variables. As shown in Table 8, in all specifications, the coefficients of the key variables remain statistically significant and stable. The results are consistent with the baseline regression results, indicating that the conclusions are robust.

-

(2)

Replacement models

To further validate robustness, we re-estimated the key relationships using three alternative models: Ordinary Least Squares (OLS) with clustered standard errors (Bertrand et al., 2004); Fixed Effects (FE) models to account for unobserved heterogeneity (Wooldridge, 2010); and Difference Generalized Method of Moments (Diff-GMM) to mitigate endogeneity concerns in dynamic panel settings (Arellano and Bond, 1991). As demonstrated in Table 9, the results are still consistent with Table 7, further indicating the robustness of our conclusions.

Mechanism analysis

Table 10 presents the empirical results regarding the mediating role of resource allocation efficiency. In column (1) of Table 10, we report the overall effect of carbon resilience on the quality of industry development. The estimated coefficient of carbon resilience is positive and statistically significant at the 1% level, indicating that carbon resilience can effectively contribute to the quality of industry development. In column (2) of Table 10, we investigate the impact of carbon resilience on resource allocation efficiency. The estimated coefficient of carbon resilience is positive and statistically significant at the 5% level, suggesting that carbon resilience can significantly contribute to resource allocation efficiency. In column (3) of Table 10, we investigate the impact of carbon resilience on the quality of industry development by promoting resource allocation efficiency. The estimated coefficient of carbon resilience is insignificant, while the estimated coefficient of resource allocation efficiency is positive and statistically significant at the 1% level. The results suggest that resource allocation efficiency plays a sufficiently mediating role between carbon resilience and the quality of industry development. That is, carbon resilience promotes the quality of industry development by promoting resource allocation efficiency.

In terms of sub-sectors, in the high-carbon emission industries, the coefficient for carbon resilience on the quality of industry development is 0.018, and it does not pass the significance level test. The coefficient for resource allocation efficiency on the quality of industry development is 0.330, and it passes the significance test at the 5% level. This suggests that carbon resilience does not have a statistically significant impact on the quality of industry development in the high-carbon emission industries, while resource allocation efficiency significantly affects it. Therefore, it can be concluded that resource allocation efficiency fully explains the impact of carbon resilience on the quality of industry development in the high-carbon emission industries. In the medium-carbon emission industries, as shown in columns (7) - (9) of Table 10, the impact of carbon resilience on resource allocation efficiency does not pass the significance level test. This indicates that in the medium-carbon emission industries, resource allocation efficiency does not play a mediating role. In the low-carbon emission industries, as shown in columns (10) - (12) of Table 10, the impact of carbon resilience on resource allocation efficiency also does not pass the significance level test. This means that in the low-carbon emission industries, resource allocation efficiency likewise does not play a mediating role. The above results suggest that resource allocation efficiency primarily plays a complete mediating role in the high-carbon emission industries. In other words, only in the high-carbon emission industries can carbon resilience fully affect the quality of industry development through resource allocation efficiency.

Based on the analysis of the aforementioned results, the primary reason can be attributed to the differences in inherent conditions among various types of manufacturing industries (Peng et al., 2023). The carbon resilience of high-carbon emission industries may exert the greatest impact on their development quality, followed by medium-carbon emission industries, with low-carbon emission industries experiencing the weakest impact. Due to the characteristics of high-carbon emission industries with high pollution and energy consumption, under the influence of low-carbon emission reduction policies such as the “double carbon” goals, their adjustment potential is the greatest, and the transformation of resource allocation is also the most significant (Mujjuni et al., 2021). Thus, the impact of carbon resilience on resource allocation efficiency is greatest in these industries. Furthermore, resource allocation efficiency primarily serves as a complete mediator in high-carbon emission industries. In contrast to high-carbon emission industries, medium- and low-carbon emission industries inherently possess relatively lower levels of energy consumption and pollution due to their resource endowments, and their resource allocations tend to be more low-carbon. Consequently, they do not require extensive adjustments, meaning that carbon resilience does not significantly enhance development quality through resource allocation efficiency. As a result, resource allocation efficiency does not play a mediating role in medium- and low-carbon emission industries. Thus, Hypothesis 3 is validated.

Further analysis

With the introduction of the “double carbon” policy, there is an increasing urgency for green development in manufacturing industry (Li et al., 2020). The “double carbon” goals will significantly reshape the energy structure and production technologies of manufacturing over the next 40 years, accelerating its transition towards sustainability. Despite the various measures already taken by the manufacturing industry to promote green transformation, it is evident that the “double carbon” goals will have long-term implications on its future development (Beraud et al., 2022). Thus, predicting future trends in this sector based on current circumstances can help manufacturing swiftly adapt to changes in underlying operational logic caused by “double carbon” goals. Through strategic planning and proactive management of potential future challenges, we can achieve sustainable improvement in both quality and longevity of manufacturing development (Jin et al., 2021). The Grey model GM(1, 1) was used to predict carbon resilience, yielding predicted values of carbon resilience and the quality of industry development from 2024 to 2030.

Predicted results analysis

Figure 2 indicates that the average carbon resilience and the average quality of industry development will exhibit an upward trend over the next seven years. With the proposal of “double carbon” goals, reducing carbon emissions has become essential for achieving high-quality sustainable development in the manufacturing industry (Chen et al., 2020). However, due to the high emission, pollution and energy consumption associated with traditional manufacturing, along with the industry’s own lack of motivation for green development and government environmental regulation, this may lead to a more volatile environment for the manufacturing industry’s future development (Li et al., 2020). As a result, it is important for the manufacturing sector to have the capacity to withstand shocks. In conjunction with the realistic situation and market environment of future manufacturing development, and considering the formation process of resilience, it is imperative to acknowledge that the manufacturing industry cannot be disregarded in the pursuit of the “double carbon” goals. The manufacturing industry will continue to face ongoing challenges and must develop carbon resilience to promptly assess external environmental conditions and implement effective countermeasures. Simultaneously, carbon resilience helps to seize potential development opportunities and use these opportunities to further enhance carbon resilience (Jin et al., 2021). Consequently, these findings align with the prediction results presented in Fig. 2, affirming the continuous upward trajectory of the carbon resilience value over the next seven years (2024 to 2030).

Manufacturing industries with carbon resilience are able to perceive potential external threats and opportunities in a timely manner, quickly adjust resource allocation, and grasp future development prospects to mitigate the adverse impacts of unexpected negative events (Wang, Li, 2022). To summarize, with the help of carbon resilience, the process of green and low-carbon transformation of the manufacturing industry has been continuously improved. As this transformation progresses, the quality of industry development will continue to improve.

However, Fig. 2 shows that carbon resilience is growing faster than the quality of industry development. Whether the mismatch in growth rates displayed in the forecast results will have an impact on the relationship between carbon resilience and industry development quality remains to be explored.

Prediction results of the relationship between carbon resilience and the quality of industry development

Table 11 presents the regression results of the relationship between carbon resilience and the quality of industry development over the next seven years. The results show that carbon resilience has a negative impact on the quality of industry development.

Compared with the regression results of the data from 2011 to 2020, this discrepancy primarily stems from the continuous turbulence in the external environment brought about by the “double carbon” goals. To ensure smooth operations, the industry has chosen to adopt various measures to prioritize resilience enhancement over efficiency (Soikkeli et al., 2023). However, this has led to resource redundancy and a complicated system structure, resulting in increased investment and decreased efficiency (Stevenson et al., 2016). A fundamental prerequisite for improving the quality of industry development is efficient growth, which is precisely the reason why carbon resilience has a negative impact on its overall quality. Therefore, in the future development, the “priority” of resilience and efficiency improvement may become a dilemma faced by the development of manufacturing industry.

Discussion

Carbon resilience, as a key capability for the manufacturing industry to navigate the low-carbon transition in response to the “double carbon” goals, holds great significance in promoting high-quality development of the industry. Therefore, this paper firstly proposes a new concept of carbon resilience, that is, the endogenous dynamic capacity of the manufacturing industry to cope with the long-term requirements and short-term constraints brought about by the low-carbon transition. It includes three dimensions: stability, adaptation and evolution. Our results deepen the theoretical framework of resilience and provide new ideas for the manufacturing industry to address the challenges and opportunities of decarbonization.

Secondly, the evaluation index system of carbon resilience and the quality of industry development are constructed, respectively. By measuring and analyzing the evaluation index system, we find that carbon resilience of the manufacturing industry and the quality of industry development are both an upward trend. However, there are significant differences in their development trends over time.

Thirdly, we find that carbon resilience has a significant positive impact on the quality of industry development. The results are consistent with previous scholars’ views that resilience can improve the quality of industry development (Sun et al., 2022). However, this impact varies among the three types of industries with differing carbon intensities. The carbon resilience of high-carbon emission industries has the greatest impact on the quality of industry development, followed by medium-carbon emission industries, while low-carbon emission industries exhibit the weakest influence. The results provide guidance for the government to accurately formulate industry development policies to promote industrial upgrading.

Fourth, the empirical results of the mediating effect model show that resource allocation efficiency serves as a significant mediator between carbon resilience and the quality of industry development. In other words, carbon resilience promotes the quality of industry development by improving resource allocation efficiency. Our results are partly consistent with previous scholars’ views that resource allocation efficiency can improve the quality of industry development (Ji et al., 2023). However, for industries with three different carbon intensities, the role of resource allocation efficiency in the relationship between carbon resilience and the quality of industry development varies. In high-carbon emission manufacturing, carbon resilience promotes the improvement of industry development quality through resource allocation efficiency. Conversely, in medium- and low-carbon emission manufacturing, carbon resilience does not promote the improvement of industry development quality through resource allocation efficiency. Our research provides implications for different types of industries to use carbon resilience to improve the quality of industry development.

Finally, we further predict and analyze the carbon resilience and the quality of industry development from 2024 to 2030. The results show that over the next seven years, carbon resilience is expected to have a negative effect on the quality of industry development. This result is consistent with the previous scholars’ view that overemphasizing resilience may bring about potential negative impacts (Liang and Guo, 2024).

Conclusion and implications

Conclusion