Abstract

Efforts to improve proton exchange membrane fuel cell (PEMFC) durability are crucial for a hydrogen-based society, but their widespread adoption, especially in heavy-duty vehicles, is limited by membrane degradation from radical attacks. Herein, we report polar-solvent- and water-soluble fullerene derivatives C60(C6H3(OH)2-3,4)5(OH)n and C60(C6H4COOH)5(OH)n (n = 0–13) as radical scavengers which are homogeneously dispersed into the Nafion membranes. The hydroxy and carboxylic acid functional groups in the fullerene derivatives not only improved water solubility but also facilitated proton conductivity and chelating scaffold for Ce ions as co-scavengers. The fabricated Nafion membrane with functionalized fullerene derivatives and the chelation of Ce significantly enhanced durability, delaying membrane degradation for 1050 h compared to pristine Nafion membrane, which degraded with 100 h. It also reduced the F⁻ ion release rate to 10% of that of the reference Nafion membrane. These findings highlight the potential of functionalized fullerenes and their derivatives as effective PEMFC additives, enhancing both performance and durability for wider hydrogen energy system adoption.

Similar content being viewed by others

Introduction

Proton exchange membrane fuel cells (PEMFCs) are efficient and eco-friendly power generators with diverse applications, from portable electronics to automotive and stationary power1,2,3,4. However, such applications require long-term durability, which can be achieved by developing proton exchange membranes (PEMs) capable of enduring extended cycles5,6,7. The degradation of PEMs such as Nafion is driven by the crossover of oxygen from the cathode to the anode, followed by the generation of H2O2 and subsequent production of hydroxyl (•OH) and peroxyl (•OOH) radicals through a Fenton reaction with a trace amount of Fe2+ in the membrane8,9,10,11,12,13,14. This process has detrimental effects on PEMFC performance, including membrane thinning and pinhole formation15,16,17,18. One of the most effective methods for inhibiting radical-induced PEM degradation is the use of ceria (CeO2) as an antioxidant19,20, which produces Ce3+ and Ce4+ ions that reduce •OH and •OOH radicals to water20,21,22. However, the high water solubility of Ce ions leads to ion relocation and concentration reduction owing to migration from the membrane during long-term operation23,24,25,26,27,28. Consequently, parts of the membrane that no longer contain Ce ions will be attacked by radicals and degrade. Therefore, a better approach for inhibiting radical-induced PEM degradation is highly desirable29,30,31,32.

Fullerene and its derivatives have exceptional radical-scavenging ability owing to their unique chemical structure and high electron affinity, allowing them to mitigate oxidative damage to the surrounding components33,34. Furthermore, their multiple protic functional groups interact with water molecules, leading to enhanced proton conductivity. Tasaki et al. pioneered the development of fullerene/PEM composites35,36. However, despite their high proton conductivity, their mechanical stability is reduced by the poor compatibility between fullerene and the host matrix. Another major issue is the low dispersibility of fullerenes in most solvents and matrices. Although dispersibility can be improved by surface modification, π-conjugation is sacrificed in most water-dispersible fullerene derivatives, such as fullerenol C60(OH)n, because of the random attachment of hydroxyl (–OH) groups37,38,39.

Herein, we developed highly water-soluble and stable fullerene derivatives that can act as both radical scavengers and Ce anchors within a Nafion matrix. Phenolic (C6H4OH) or benzoic acid groups (C6H4COOH) and the hydroxy groups were introduced at the top and bottom of fullerene, respectively (Fig. 1). The insights gained from this study will contribute to a deeper understanding of radical-scavenging materials and their role in mitigating oxidative degradation in PEMFCs.

Results and discussion

Synthesis and properties of water-soluble fullerene derivatives

We synthesized water/alcohol-soluble polyfunctionalized fullerene derivatives for the purpose of homogenously dispersion of them into the water/alcohol-soluble Nafion membrane through two or three quantitative and cost-effective steps, as described in the Electronic Supplementary Information (ESI, Section 1). Initially, the regioselective and high-yielding penta-addition of an organocopper reagent in an o-dichlorobenzene/tetrahydrofuran mixed solvent produced C60(C6H3-(OMe)2-3,5)5H (PhOMe-10)40. Subsequent treatment of PhOMe-10 with BBr3 resulted in the removal of ten methyl groups to produce ten hydroxy groups41, yielding C60(C6H3-(OH)2-3,5)5H (PhOH-10) quantitatively. The attachment of the five aryl groups, giving color change from blackish to red, reduced the size of the π-electron conjugation from 60π to 50π electrons systems. PhOH-10 showed high solubility in polar solvents such as methanol and ethanol, except water, highlighting its compatibility with Nafion matrices. Introduction of the hydroxy groups using sodium hydroxide onto the opposite side of the aryl groups in PhOH-10 produced C60(C6H3-(OH)2-3,5)5(OX)nH (X = H, Na, tetrabutylammonium, n = 3–13; PhOH-10-OH salt), which exhibited exceptional water solubility (ESI, Table 1). The hydroxylation to the bottom part of the fullerene molecule showed color change to pale yellow, indicating further reduced the size of the π-conjugated system. This was also confirmed by the blue-shifted and enhanced photoluminescence (ESI, Fig. 3a). The Fourier-transform infrared (FT-IR) spectrum of PhOH-10-OH exhibited peaks at 2900–3600, 1680, 1460, and 1600 cm–1 (ESI, Fig. 3b), indicating the presence of RO–H, C = O, and C = C bonds.

A penta(carboxylic acid) fullerene derivative C60(C6H4COOH)5H (PhCOOH-5) was prepared according to the previous report40,42. Introduction of the hydroxy groups at the bottom of the fullerene molecule was conducted to produce highly water-soluble C60(C6H4COOX)5(OX)nH (X = H, Na, tetrabutylammonium, n = 3–13; PhCOOH-5-OH salt). The blue-shifted and enhanced photoluminescence and the FT-IR spectra similarly confirmed bottom hydroxylation (ESI, Fig. 3b). Excellent dispersion of PhCOOH-5-OH in the presence of Ce ions in water was confirmed by dynamic light scattering size distribution analysis (ESI, Fig. 3c). The analysis of a 0.5 wt% aqueous solution of PhCOOH-5-OH salt with varying amounts of Ce(NO3)3 ∙ (H2O)6 (0–1 equiv) (ESI, Fig. 4) exhibited that the particle diameter decreased to 1.2 nm of mono-dispersion with 0.1 equiv of Ce ion, which afforded negative charge on the functional groups of fullerene derivatives through replacement of proton and Na ion by Ce ion, enhancing dispersion through electrostatic repulsion (ESI, Fig. 5). At 0.2 equiv or more, Ce ion induced cross-linking, forming larger aggregates (30–120 nm). Note that complete desalination of Na ion to proton in PhOH-10-OH and PhCOOH-5-OH salts is achieved after Nafion membrane fabrication with repeated acid (0.1 M H2SO4)/pure water washing.

Stability and Electrochemical Properties of Hybrid PEMs

Hybrid PEMs were prepared by mixing different concentrations of PhOH-10 with a Nafion solution. The PhOH-10/Nafion hybrid PEMs were highly transparent at PhOH-10 concentrations ranging from 0.1 to 2.5 wt% (ESI, Fig. 6a). However, at concentrations above 2.5 wt%, the color shifted from light yellow to dark orange, suggesting the possible agglomeration and reduced dispersion of PhOH-10 in the Nafion matrix. The proton conductivities and water uptake of the hybrid PEMs were comparable to those of Nafion 212 and recast Nafion across the PhOH-10 concentration range (ESI, Fig. 6b). Nevertheless, beyond the optimal loading of 2.5 wt%, the proton conductivity decreased, likely due to PhOH-10 aggregation obstructing the proton-conducting channels.

Membrane durability was assessed through Fenton tests, which measured the efficacy of PhOH-10 as a radical scavenger in the hybrid PEMs (ESI, Fig. 6c). The concentration of F− ions detected in solution during tests decreased shows that its efficacy increased with increasing PhOH-10 concentration up to 0.5 wt% before diminishing, possibly due to PhOH-10 agglomeration reducing the available active π-conjugation sites for radical reactions.

An essential requirement for radical scavengers in PEMs is their retention within the Nafion matrix without leaching. The stability of PhOH-10 was evaluated by conducting water elution tests on an acid-treated hybrid PEM at 130 °C over four days, with daily sampling to measure the concentration of the remaining PhOH-10. Photoluminescence spectroscopy analysis revealed that the PhOH-10 concentration was stable at 0.53, 0.50, 0.52, 0.47, and 0.49 wt% after 0, 1, 2, 3, and 4 days, respectively, indicating less than 6% leaching (ESI, Fig. 6d). This confirms the stability of PhOH-10 aggregates, which remained effectively trapped in hydrated Nafion ion clusters due to the aggregates size (ESI, Fig. 4) and was therefore not susceptible to leaching13,30,43.

Enhanced dispersion in the Nafion matrix was achieved by using the highly water-soluble fullerenes PhOH-10-OH and PhCOOH-5-OH. Highly transparent hybrid PEMs were obtained at the optimal fullerene concentration of 0.5 wt% (ESI, Fig. 7a). PhOH-10-OH/Nafion and PhCOOH-5-OH/Nafion exhibited a uniform pale yellow color, indicating the excellent dispersion of the fullerenes in the Nafion matrix, even after harsh acid post-treatment. The mechanical properties, including tensile strength and Young’s modulus, were significantly improved (Table 1), confirming effective fullerene incorporation into the Nafion matrix through interaction with the sulfonic acid groups of Nafion44,45. The lower proton conductivity of the recast Nafion compared to that of Nafion 212 could be attributed to the lower water uptake (24.9%), which was slightly lower than the 28.0% of Nafion 212. The water uptake of Nafion is well known to be affected by the heat treatment. The recast Nafion underwent heat treatment at 140 °C for 4 h followed by at 170 °C for 2 h, temperatures around and above the glass transition point. This heat treatment likely increased physical cross-linking due to crystallization, thereby reducing water content slightly and subsequently lowering proton conductivity. Since Nafion 212 is a commercial product, we do not know the membrane fabrication conditions. However, 170 °C is a relatively high temperature for heat treatment, so we believe that significant changes in physical properties can occur. Fullerene derivatives can effectively bridge neighboring Nafion chains, increasing the attractive forces between them. This enhances the resistance of Nafion to deformation and consequently, its mechanical stability. PhOH-10/Nafion exhibited the best mechanical properties, partly because of the use of a high-boiling-point dispersing fluid (N,N-dimethylformamide (DMF))46.

The water uptake of PhOH-10-OH/Nafion and PhCOOH-5-OH/Nafion exceeded that of both commercial and recast Nafion because of the hydrophilicity of the –OH groups. At high water content, the sulfonic acid groups in the membrane fully dissociate owing to the hydration of protons and SO3− ions. Protons require four water molecules to form their initial hydration shell, whereas SO3− ions need two to three. The membrane absorbs more water, more free water and ion pathways are created. This enables protons to move freely via the Grotthuss mechanism, in which protons hop between water molecules, or the vehicle mechanism, in which protons are carried by water molecules47,48. This reduces resistance and significantly enhances proton conductivity. Additionally, –OH groups serve as proton-hopping sites, further improving proton conductivity35. Conversely, both the water content and proton conductivity of PhOH-10/Nafion remained similar to those of pure Nafion, owing to the absence of directly bonded –OH groups.

The incorporation of Ce ions into Nafion membranes is known to reduce proton conductivity. However, in the present study, the proton conductivity of PhCOOH-5-OH/Ce/Nafion was found to be higher than that of PhCOOH-5-OH/Nafion. This enhancement can be attributed to the addition of 0.5 wt% fullerene derivatives relative to the weight of the Nafion membrane, along with the controlled incorporation of Ce ions at a molar ratio of 0.5 equiv. with respect to the fullerene derivatives corresponding to one Ce ion per two molecules of fullerene derivatives. Given the minimal amount of cerium ions introduced, no significant decrease in proton conductivity was observed.

The oxidative stability of Nafion and hybrid PEMs was investigated through Fenton tests (ESI, Fig. 7b). Fluoride ion (F⁻), generated by radical attacks on the PEM, was measured using ion chromatography. Among the tested samples, PhOH-10/Nafion demonstrated superior performance, exhibiting the slowest initial membrane degradation and the lowest F⁻ concentration in solution. PhOH-10-OH/Nafion and PhCOOH-5-OH/Nafion also exhibited reduced F⁻ concentrations compared to pure Nafion, highlighting the promising radical scavenging properties of the fullerene derivatives.

To enhance radical-scavenging ability, Ce ion was chelated to the phenolic hydroxyl or carboxyl groups of fullerene derivatives (Fig. 2a). We fabricated the hybrid PEMs using 0.5 wt% fullerene derivatives and 0.06 wt% Ce ion relative to Nafion. After repeated thorough acid/water washing of the membrane, approximately 0.002 wt% of Ce remained, as detected by inductively coupled plasma (ICP) analysis. This residual Ce was firmly chelated to the fullerene surface, demonstrating resistance to dissolution in water. To investigate complexation between fullerene derivatives and Ce ion, C60(C6H3-(OH)2-3,5)5Me(OH)n (MePhOMe-10-OH), a derivative easily identified by mass spectrometry (MS), was synthesized (ESI, Fig. 10, 11) and analyzed using X-ray diffraction (XRD). The XRD analysis revealed two broad peaks, with the second peak shifting and broadening upon Ce ion incorporation. The interplanar spacing (d) increased from 13.46 Å to 14.01 Å, suggesting that Ce ion was incorporated between the fullerene cages (ESI, Fig. 11a). X-ray photoelectron spectroscopy (XPS) analysis revealed the coexistence of Ce3+ and Ce4+ species, indicating the presence of a mixed oxidation state of Ce ions (ESI, Fig. 11b).

The chelation of Ce ions significantly improved the durability of the hybrid PEMs compared to their fullerene-only counterparts, with the enhancement being particularly pronounced in the PhOH-10/Ce/Nafion system. This increased resistance to chemical degradation is attributed to the synergistic mitigation of free radicals through the π-conjugation in PhOH-10 and the facile redox cycling of Ce ions. Specifically, Ce3+ ions reduce •OH radicals into OH– through generating Ce4+ (Fig. 1). Furthermore, the formation of a fullerene derivative/Ce complex prevent migration of the Ce ion within the Nafion matrix and minimizes its dissolution to exhaust water. This stabilization is supported by the consistently low F⁻ concentrations observed in the hybrid PEMs compared to those of fullerene-only systems (Fig. 2b). The reason for the higher chemical stability of recast Nafion than Nafion 212 between 3 and 9 h may be attributed to the difference in water uptake. The lower water uptake of the membrane may have inhibited the diffusion of OH radicals generated by the Fenton’s reagent into the membrane (further discussion is provided in ESI, Section 549,50,51). The weight change of the Nafion membranes before and after the Fenton test was within the margin of error for all samples, indicating no significant variation. This suggests that the results presented in Fig. 2 correspond to an early stage of membrane degradation52,53,54.

PEMFC performance and durability

Accelerated durability tests were conducted using membrane electrode assemblies (MEAs) containing the hybrid PEMs. Supplementary Fig. 12a shows the changes in the initial polarization curve and area-specific resistances of the MEAs using H2/air reactant gases. Voltage decay for the hybrid films of Nafion/highly water-soluble fullerene derivatives such as PhOH-10-OH, PhCOOH-5, PhOH-10-OH/Ce, and PhCOOH-5/Ce was minimal compared with the Nafion/Ce membrane, likely because of wettability of these fullerene derivatives. Lower water-soluble fullerenes, PhOH-10 and PhOH-10/Ce might induce ionic cluster shrinkage55,56, limiting proton conductivity and water permeability, and showed higher area-specific resistance. The cyclic voltammogram showed an increase in the Pt–H adsorption area, indicating that the fullerene derivatives did not poison the Pt catalyst (ESI, Fig. 12b). Supplementary Fig. 12c confirms that the fullerene derivatives also did not affect the electrochemically active surface area calculated from the cyclic voltammogram.

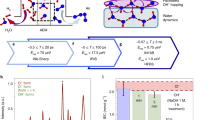

The results of the durability tests for the fullerene derivative/Nafion hybrid PEMs, recast Nafion, and Nafion 212 at 30% relative humidity (RH) and 90 °C are shown in Fig. 3a. None of the tested PEMs exhibited pronounced open-circuit voltage (OCV) decay. Particularly, the water retention capacity of PhOH-10-OH/Nafion, PhOH-10-OH/Ce/Nafion, PhCOOH-5-OH/Nafion, and PhCOOH-5-OH/Ce/Nafion, arising from the hygroscopic nature of the –OH groups, kept the MEAs adequately wet even under low RH, enabling effective PEMFC performance and hence, low OCV decay.

Overall, the recast Nafion exhibited the lowest durability (ca. 100 h), followed by PhOH-10-OH/Nafion (160 h), PhCOOH-5-OH/Nafion (200 h), and PhOH-10/Nafion (300 h), emphasizing the radical-scavenging effects of the fullerene derivatives. Toward the end of the test, there were sudden OCV drops, suggesting that the dry–wet cycle may trigger membrane damage, such as pinhole formation56,57. However, the presence of Ce chelated on the fullerene derivatives, even at very low concentrations, resulted in a significantly lower OCV decay. The OCV durability time extended to 400 h, 600 h, and 1050 h with PhOH-10/Ce/Nafion, PhOH-10-OH/Ce/Nafion, and PhCOOH-5-OH/Ce/Nafion, respectively. The synergistic radical-scavenging activity of Ce ions and the fullerene derivatives converted •OH and •OOH radicals into water, effectively sustaining the hybrid PEMs for extended periods. This also demonstrates that Ce was effectively enclosed within the coordination complex alongside the fullerene derivatives and no Ce migration from the membrane was observed in this study.

During the open-circuit operation, the release of F− confirmed the ability of PhOH-10, PhOH-10-OH, and PhCOOH-5-OH, as well as their Ce-chelated forms, to scavenge radicals (Fig. 3b). Nafion 212 and recast Nafion exhibited early chemical degradation, as evidenced by the presence of F− in condensed water during the OCV analysis, with the F− concentration rapidly increasing in less than 100 h. In contrast, PhOH-10/Nafion, PhOH-10-OH/Nafion, and PhCOOH-5-OH/Nafion released F− at a slower rate. The most effective radical scavenging was observed for PhCOOH-5-OH/Ce/Nafion, followed by PhOH-10-OH/Ce/Nafion and PhOH-10/Ce/Nafion. Notably, PhCOOH-5-OH/Ce/Nafion exhibited a reduction in the F⁻ ion release rate, decreasing to 10% of the rate observed with pristine Nafion membrane. Thus, Ce ions attached to fullerene derivatives remain stable under harsh conditions, enhancing the performance of the PEM and delaying OCV decay by reducing the number of radicals in the system.

The proposed mechanism likely involves reaction of the fullerene π-conjugated systems and •OH radicals giving hydroxylated fullerenes with covalent C60–OH bonds58, which are protonated in the PEM to generate H2O and fullerene carbocation species C60+59. The resulting carbocation intermediate having high electron affinity can subsequently be reduced back to the fullerene π-conjugated system by leakage currents or crossover hydrogen60,61. In the Ce ion co-existence system, the redox cycling of Ce³⁺/Ce⁴⁺ not only contributes to radical scavenging but also facilitates the reduction of hydroxylated fullerene, thereby enhancing the efficiency of the fullerene-based radical scavenging mechanism. In situ X-ray absorption near edge structure (XANES) measurements of PhCOOH-5-OH/Ce/Nafion showed self-reducing behavior of Ce4+ chelated on the fullerene derivatives, which spontaneously reverted to Ce3+ at room temperature (ESI, Fig. 13). This characteristic is particularly advantageous in enhancing the efficiency of radical scavenging systems utilizing fullerene and Ce ions.

Time-of-flight secondary ion mass spectrometry (ToF-SIMS) chemical mapping and line analysis of PhOH-10/Ce/Nafion showed that both PhOH-10 and Ce ions were homogeneously dispersed in the Nafion matrix before the OCV analysis, as shown in Fig. 4. After durability testing, the Ce ion concentration and dispersion remained constant, suggesting that PhOH-10 or its decomposition products retained the Ce ions. Mass spectral analysis in the positive mode identified fullerene fragment ions (C56+, C58+, C60+, C62+, C64+, etc.) (ESI, Fig. 14). However, after the durability testing, the fragments were fewer and primarily observed near the anode. This indicates that structural changes such as hydroxylation occurred in PhOH-10 during durability testing, resulting in fewer fullerene fragment ions by the ionization. The persistence of these fragments near the anode was likely due to hydrogen reduction, which allowed PhOH-10 to remain intact.

In summary, the fullerene derivatives PhOH-10, PhOH-10-OH, and PhCOOH-5-OH represent a significant advantage in the development of highly water-soluble compounds that can serve as radical scavengers and anchoring agents in PEMFC systems. These derivatives exhibited excellent dispersion in the Nafion matrix, which is crucial for optimal PEM performance. Comprehensive analysis confirmed high durability of PhOH-10-OH/Nafion and PhCOOH-5-OH/Nafion hybrid membranes, along with their favorable mechanical and conductive properties. OPV durability tests revealed that PhOH-10 enhanced the MEA durability by 1.5–2 times compared to Nafion membranes without containing fullerene derivatives. Furthermore, the chelation of Ce in PhOH-10/Ce/Nafion, PhOH-10-OH/Ce/Nafion, and PhCOOH-5-OH/Ce/Nafion significantly extended PEM longevity upto approximately 10 times compared to the pristine Nafion membrane. When discussing durability from the chemical aspect, importantly, PhCOOH-5-OH/Ce/Nafion reduced the F⁻ ion release rate to 10% of that of the Nafion membrane. These findings highlight the potential of tailored fullerene derivatives and their derivatives in improving PEMFC performance and durability, representing a significant advancement in the design of advanced radical scavengers for PEMFC applications.

Methods

The synthesis and characterization of C60(C6H3-3,5-(OH)2)5H (PhOH-10), C60(C6H3-3,5-(OX)2)5(OX)nH (X = H, Na, TBA, n = 3 to 13; PhOH-10-OH salt), C60(C6H4CO2H)5H (PhCOOH-5), and C60(C6H4CO2X)5(OX)nH (X = H, Na, TBA, n = 3–13; PhCOOH-5-OH salt) (Fig. 1) are described in detail in ESI Section 1.

Composite membrane fabrication

A 20 wt% Nafion® solution (Fujifilm, Japan) was heated to 50 °C under vacuum to evaporate the solvent. The dried Nafion resin was then dissolved either in DMF for PhOH-10 or in H2O/1-propanol (1:1 wt ratio) for PhOH-10-OH salt and PhCOOH-5-OH salt until a transparent and homogeneous solution was formed with a final Nafion solution concentration of 30 wt%. After dissolution, a specific amount of PhOH-10, PhOH-10-OH, or PhCOOH-5-OH salt was added to the solution to obtain a mass fraction of 0.5 wt%. For the preparation of Cerium containing film, an aqueous solution containing 0.5 equiv. of cerium (III) nitrate hexahydrate (Ce(NO3)3 ∙ (H2O)6, 99%, trace metals basis, Sigma-Aldrich) for fullerene derivative and the same molar of citric acid was introduced. The resulting precursor was mixed for 1 h at room temperature, followed by 30 min of mixing and degassing using a planetary centrifugal mixer (AR-100, THINKY USA, Inc.). Subsequently, the hybrid precursor was cast onto a LumirrorTM T60 film (thickness: 250 µm; Toray, Japan) and allowed to dry at 50 °C for 16 h. The temperature was then increased to 140 °C for 4 h, followed by heating under vacuum at 170 °C for 2 h to remove any residual solvent and increase Nafion crystallinity. The composite membrane was washed with 0.1 M H2SO4, followed by deionized water at 80 °C for 1 h each to restore the Nafion to its acid form ref. 62. The thickness of the films was measured at nine distinct points using a thickness gauge (PG-02A, Teclock, Japan). A recast Nafion was prepared in an identical manner but without any filler to serve as a benchmark for comparison with fullerene/Nafion hybrid PEMs. Characterizations of the prepared PEM are described ESI Section 1.

Fabrication of membrane electrode assembly (MEA) and evaluation of PEMFC performance and stability

The commercial Pt/carbon black catalysts TEC10EA50E and TEC10E50E (Tanaka Kikinzoku Kogyo K. K., Japan) with Pt loadings of 0.21 and 0.2 mg cm–2 (approximately 50 wt%), respectively, were used as the anode and cathode, respectively, in the MEA. The MEA, with an active area of 25 cm2, was created by sandwiching the PEM between the two electrodes, followed by hot-pressing under a pressure of 10 kg cm–2 at 130 °C for 5 min. The MEA was combined with PEN sub-gaskets (thickness: 20 µm), gas diffusion layers (Toray Industries, Co., Ltd., Japan), and Teflon gas-sealing gaskets, and fixed in a single cell fixture. The performance of the PEMFC was assessed using a test station (CHINO Corporation, Japan) in accordance with the New Energy and Industrial Technology Development Organization (Japan) protocol. The MEA was conditioned at 80 °C and a constant current density of 1 A cm–2 for 15 h. The RH values of the anode and cathode were set to 90% and 60%, respectively. The H2 and air flow rates at the anode and cathode, respectively, were fixed at 0.298 L min−1 and either 1 L min−1 for Nafion and the PhOH-10-OH/Nafion and PhCOOH-5-OH/Nafion hybrid PEMs or 0.7 L min−1 for the PhOH-10/Nafion hybrid PEM, respectively.

During the open-circuit phase, the H2 and air flow rates at their respective electrodes were set to 0.829 L min−1, with the back pressure maintained at normal levels. The cell temperature remained constant at 90 °C, and the RH of the gas was set to 30%. An open-circuit test was conducted for up to 1200 h to assess the durability of the MEA. Water effluent was collected and F– levels were analyzed by IC. Diagnostic tests were performed before and after the durability test to assess changes in performance. The polarization curve was plotted, covering the range from open circuit to high current density, and the area-specific resistance was measured.

Data availability

All chemical structure, electrochemical, and spectroscopic source data generated in this study are provided in ESI. Additional datasets related to this study are available from the corresponding author upon request.

References

Keith, D. W. & Farrell, A. E. Rethinking hydrogen cars. Science 301, 315–316 (2003).

Steele, B. C. H. & Heinzel, A. Materials for fuel-cell technologies. Nature 414, 345–352 (2001).

Jinnouchi, R. et al. The role of oxygen-permeable ionomer for polymer electrolyte fuel cells. Nat. Commun. 12, 4956 (2021).

Huda, M., Kawahara, T., Park, J.-H., Kawasumi, M. & Matsuo, Y. Single-walled carbon nanotubes supported Pt electrocatalyst as cathode catalyst of a single fuel cell with high durability against start-up/shut-down potential cycling. ACS Appl. Energy Mater. 6, 12226–12236 (2023).

Shin, D. W., Guiver, M. D. & Lee, Y. M. Hydrocarbon-based polymer electrolyte membranes: importance of morphology on ion transport and membrane stability. Chem. Rev. 117, 4759–4805 (2017).

Wang, Y. et al. Fundamentals, materials, and machine learning of polymer electrolyte membrane fuel cell technology. Energy Ai. 1, 100014 (2020).

Agarwal, T. et al. Biosourced antioxidants for chemical durability enhancement of perfluorosulfonic acid membrane. Adv. Funct. Mater. 34, 2308856 (2024).

Sugawara, S. et al. Performance decay of proton-exchange membrane fuel cells under open circuit conditions induced by membrane decomposition. J. Power Sources 187, 324–331 (2009).

Borup, R. et al. Scientific aspects of polymer electrolyte fuel cell durability and degradation. Chem. Rev. 107, 3904–3951 (2007).

Gubler, L., Dockheer, S. M. & Koppenol, W. H. Radical (HO•, H• and HOO•) formation and ionomer degradation in polymer electrolyte fuel cells. J. Electrochem. Soc. 158, B755–B769 (2011).

Han, M., Shul, Y.-G., Lee, H., Shin, D. & Bae, B. Accelerated testing of polymer electrolyte membranes under open-circuit voltage conditions for durable proton exchange membrane fuel cells. Int. J. Hydrog. Energy 42, 30787–30791 (2017).

Kundu, S., Simon, C. L. & Fowler, M. W. Comparison of two accelerated NafionTM degradation experiments. Polym. Degrad. Stab. 93, 214–224 (2008).

Ghassemzadeh, L., Peckham, T. J., Weissbach, T., Luo, X. & Holdcroft, S. Selective formation of hydrogen and hydroxyl radicals by electron beam irradiation and their reactivity with perfluorosulfonated acid ionomer. J. Am. Chem. Soc. 135, 15923–15932 (2013).

Okonkwo, P. C., Belgacem, I. B., Emori, W. & Uzoma, P. C. Nafion degradation mechanisms in proton exchange membrane fuel cell (PEMFC) system: A review. Int. J. Hydrog. Energy 46, 27956–27973 (2022).

Mauritz, K. A. & Moore, R. B. State of understanding of Nafion. Chem. Rev. 104, 4535–4586 (2004).

Katzenberg, A. et al. Highly permeable perfluorinated sulfonic acid ionomers for improved electrochemical devices: insights into structure-property relationships. J. Am. Chem. Soc. 142, 3742–3752 (2007).

Ren, P. et al. Degradation mechanism of proton exchange membrane fuel cell under typical automotive operation conditions. Prog. Energy Combust. Sci. 80, 100859 (2020).

Venkatesan, S. V., Lim, C., Holdcroft, S. & Kjeang, E. Progression in the morphology of fuel cell membranes upon conjoint chemical and mechanical degradation. J. Electrochem. Soc. 163, F637–F643 (2016).

Sharma, P. P. & Kim, D. H. A facile and sustainable enhancement of anti-oxidation stability of Nafion membrane. Membranes 12, 521 (2022).

Zhiyan, R. et al. Ceria nanorods as highly stable free radical scavenger for highly durable proton exchange membranes. Rsc. Adv. 11, 32012–32021 (2021).

Gubler, L. & Koppenol, W. H. Kinetic simulation of the chemical stabilization mechanism in fuel cell membranes using cerium and manganese redox couples. J. Electrochem. Soc. 159, B211–B218 (2012).

Yurova, P. A., Malakhova, V. R., Gerasimova, E. V., Stenina, I. A. & Yaroslavtsev, A. B. Nafion/surface modified ceria hybrid membranes for fuel cell application. Polymers 13, 2513 (2021).

Park, J. & Kim, D. Effect of cerium/18-crown-6-ether coordination complex OH• quencher on the properties of sulfonated poly(ether ether ketone) fuel cell electrolyte membranes. J. Membr. Sci. 469, 238–244 (2014).

Baker, A. M. et al. Cerium migration during PEM fuel cell accelerated stress testing. J. Electrochem. Soc. 163, F1023–F1031 (2016).

Vinothkannan, M., Hariprasad, R., Ramakrishnan, R., Kim, A. R. & Yoo, D. J. Potential bifunctional filler (CeO2-ACNTs) for Nafion matrix toward extended electrochemical power density and durability in proton-exchange membrane fuel cells operating at reduced relative humidity. ACS Sustain. Chem. Eng. 7, 12847–12857 (2019).

Kusoglu, A. & Weber, A. Z. New insights into perfluorinated sulfonic-acid ionomers. Chem. Rev. 117, 987–1104 (2017).

Qiu, D., Peng, L., Lai, X., Ni, M. & Lehnert, W. Mechanical failure and mitigation strategies for the membrane in a proton exchange membrane fuel cell. Renew. Sustain. Energy Rev. 113, 109289 (2019).

Kwon, T. et al. Antioxidant technology for durability enhancement in polymer electrolyte membranes for fuel cell applications. Mater. Today 58, 135–163 (2022).

Rui, Z. et al. Design of proton exchange membranes with high durability for fuel cells: From the perspective of machine learning. J. Membr. Sci. 683, 121831 (2023).

Rui, Z. & Liu, J. Understanding of free radical scavengers used in highly durable proton exchange membranes. Prog. Nat. Sci.: Mater. Int. 30, 732–742 (2020).

Tam, J., Liu, J. & Yao, Z. Effect of microstructure on the antioxidant properties of fullerene polymer solutions. RSC Adv. 3, 4622–4627 (2013).

Rambabu, G., Nagaraju, N. & Bhat, S. D. Functionalized fullerene embedded in Nafion matrix: a modified composite membrane electrolyte for direct methanol fuel cells. Chem. Eng. J. 306, 43–52 (2016).

Mori, T. et al. Preclinical studies on safety of fullerene upon acute oral administration and evaluation for no mutagenesis. Toxicology 225, 48–54 (2006).

Kokubo, K., Yamakura, S., Nakamura, Y., Ueno, H. & Oshima, T. Radical-scavenging ability of hydrophilic carbon nanoparticles: from fullerene to its soot. Fuller. Nanotub. Car. N. 22, 250–261 (2014).

Tasaki, K. et al. Fabrication and characterization of fullerene-Nafion composite membranes. Polymer 48, 4438–4448 (2007).

Tasaki, K. et al. Fullerene composite proton conducting membranes for polymer electrolyte fuel cells operating under low humidity conditions. J. Membr. Sci. 281, 570–580 (2006).

Chiang, L. Y. et al. Multi-hydroxy additions onto C60 fullerene molecules, J. Chem. Soc., Chem. Commun. 1791−1793 (1992).

Li, J. et al. C60 fullerol formation catalysed by quaternary ammonium hydroxides. J. Chem. Soc., Chem. Commun. 1784−1785 (1993).

Kokubo, K., Shirakawa, S., Kobayashi, N., Aoshima, H. & Oshima, T. Facile and scalable synthesis of a highly hydroxylated. Nano Res. 4, 204–215 (2011).

Matsuo, Y., Muramatsu, A., Tahara, K., Koide, M. & Nakamura, E. Synthesis of 6,9,12,15,18-pentamethyl-1,6,9,12,15,18-hexahydro(C60-Ih)[5,6]fullerene. Org. Synth. 83, 80–87 (2006).

Matsuo, Y., Muramatsu, A., Kamikawa, Y., Kato, T. & Nakamura, E. Synthesis and structural, electrochemical, and stacking properties of conical molecules possessing buckyferrocene on the apex. J. Am. Chem. Soc. 128, 9586–9587 (2006).

Zhong, Y.-W., Matsuo, Y. & Nakamura, E. Convergent synthesis of a polyfunctionalized fullerene by regioselective five-fold addition of a functionalized organocopper reagent to C60. Org. Lett. 8, 1463–1466 (2006).

Eskandari, H., Paul, D. K., Young, A. P. & Karan, K. Humidity-dependent hydration and proton conductivity of PFSA ionomer thin film at fuel-cell-relevant temperature: effect of ionomer equivalent weight and side-chain characteristics. ACS Appl. Mater. Interfaces 14, 50762–50772 (2022).

Zawodzinski, T. A. Jr et al. Water uptake by transport through Nafion® 117 membranes. J. Electrochem. Soc. 140, 1041–1047 (1993).

Sethurman, V. A., Weidner, J. W., Haug, A. T. & Protsailo, L. V. Durability of perfluorosulfonic acid and hydrocarbon membranes: effect of humidity and temperature. J. Electrochem. Soc. 155, B119–B124 (2008).

Iriarte, D. et al. Effect of acid treatment on the physico-chemical properties of Nafion 117 membrane. Int. J. Hydrog. Energy 47, 21253–21260 (2022).

Coms, F. D., Liu, H. & Owejan, J. E. Mitigation of perfluorosulfonic acid membrane chemical degradation using cerium and manganese ions. ECS Trans. 16, 1735–1747 (2008).

Park, J., Park, Y. & Kim, D. Chemical stability enhancement of crown ether grafted sulfonated poly(arylene ether ketone) fuel cell membrane by cerium ion fixation. J. Polym. Sci. A: Polym. Chem. 57, 101–109 (2019).

Delaney, W. E. & Liu, W. Use of FTIR to analyze ex-situ and in-situ degradation of perfluorinated fuel cell ionomers. ECS Trans. 11, 1093 (2007).

Hammer, R., Schönhoff, M. & Hansen, M. R. Comprehensive picture of water dynamics in Nafion membranes at different levels of hydration. J. Phys. Chem. B 123, 8313–8324 (2019).

Kumar, A. et al. Influence of different parameters on total fluoride concentration evaluation in ex-situ chemical degradation of Nafion based membrane. Korean J. Chem. Eng. 38, 2057–2063 (2021).

Seo, D. C., Jeon, I., Jeong, E. S. & Jho, J. Y. Mechanical properties and chemical durability of Nafion/sulfonated graphene oxide/cerium oxide composite membranes for Fuel-Cell applications. Polymers 12, 1375 (2020).

Teixeira, F. C., Teixeira, A. P. S. & Rangel, C. M. Chemical stability of new nafion membranes doped with bisphosphonic acids under Fenton oxidative conditions. Int J. Hydrog. Energy 48, 37489–37499 (2023).

Phachaipum, S., Prapainainar, C. & Prapainainar, P. Proton-exchange polymer composite membrane of Nafion and microcrystalline cellulose for performance improvement of direct glycerol fuel cell. Int J. Hydrog. Energy 52, 1111–1120 (2024).

Choi, Y., Youn, D. H., Lee, S. O., Kim, Y. & Lee, J. S. Sulfonated resorcinol-formaldehyde polymer gels synthesized in Nafion ion clusters as nanoscale reactors for a filler of hybrid proton exchange membranes. Int. J. Hydrog. Energy 37, 9766–9774 (2012).

Endoh, E. et al. Membrane degradation mitigation of PEFC during cold-start application of the radical quencher Ce3+. ECS Electrochem. Lett. 2, F73–F75 (2013).

Trogadas, P., Parrondo, J. & Ramani, V. Degradation mitigation in polymer electrolyte membranes using cerium oxide as a regenerative free-radical scavenger. Electrochem. Solid-State Lett. 11, B113–B116 (2008).

Hashiguchi, M. et al. FeCl3-mediated synthesis of fullerenyl esters as low-LUMO acceptors for organic photovoltaic devices. Org. Lett. 14, 3276–3279 (2012).

Lin, H.-S. & Matsuo, Y. Functionalization of [60]fullerene through fullerene cation intermediates. Chem. Commun. 54, 11244–11259 (2018).

Matsuo, Y. & Nakamura, E. Syntheses, structure, and derivatization of potassium complexes of penta(organo)[60]fullerene-monoanion, -dianion, and -trianion into hepta- and octa(organo)fullerenes. J. Am. Chem. Soc. 127, 8457–8466 (2005).

Abe, Y., Tanaka, H., Guo, Y., Matsuo, Y. & Nakamura, E. Mobility of long-lived fullerene radical in solid state and nonlinear temperature dependence. J. Am. Chem. Soc. 136, 3366–3369 (2014).

Kim, Y. S. et al. Origin of toughness in dispersion-cast Nafion membranes. Macromolecules 48, 2161–2172 (2015).

Acknowledgements

This study was supported by the New Energy and Industrial Technology Development Organization (NEDO) of Japan (JPNP20003). The authors express their gratitude to NEDO FC-Platform for their technical support. Authors deeply thank to Dr. Kaoru Sasakawa (FC-Cubic) for ToF-SIMS measurements.

Author information

Authors and Affiliations

Contributions

R.B. was mainly responsible for PEM fabrication and membrane analysis. H.O., K.M., and Y.O. synthesized and analyzed the fullerene derivatives. T.A., T.O., C.L. evaluated the PEMFC stability. M.H. and T.W. designed and analyzed XAFS measurements. S.S. and T.Y. contributed to the quantum calculations. R.B., K.M., M.K., and Y.M. were the primary authors of this paper and were chiefly responsible for the experimental design and data analysis.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Communications Materials thanks Soonyong So and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. Primary Handling Editors: Jet-Sing Lee. [A peer review file is available].

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Balgis, R., Ohashi, H., Miwa, K. et al. Water-soluble fullerene derivatives as radical scavengers for highly durable proton exchange membrane fuel cells. Commun Mater 6, 136 (2025). https://doi.org/10.1038/s43246-025-00845-9

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s43246-025-00845-9