Abstract

The ultimate realization of top-down atomic manipulation is to push or pull molecules in a way that changes their function, such as catalysis. The forces in a stretched polymer distort molecular conformation in ways that couple to reactivity, but the use of this type of polymer mechanochemistry to bias the outcome of a reaction has been limited to stoichiometric reactions. Here we demonstrate that the selectivity of a catalytic site can be manipulated by straining a polymer support to which the catalyst is covalently bound. The enantiomeric ratio of the products of the hydrogenation of a series of 2-acetamidoacrylates by a bisphosphine rhodium catalyst increases with macroscopic strain, reaching up to twice its initial value when the support is compressed by 73% in a single dimension. Reactivity reverts upon relaxing support. Control experiments, structure–activity studies using strained macrocycles, and computations support mechanochemical coupling as the dominant cause of the improved selectivity and suggest that larger effects are possible with advances controlling the molecular topology of the supporting network.

Similar content being viewed by others

Main

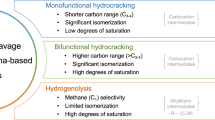

Extrinsic mechanical forces can have large effects on the outcomes of chemical reactions1,2,3,4, including access to stoichiometric reactions that are thermally inaccessible in the absence of force5. Examples include reactions that are formal violations of orbital symmetry (such as Woodward–Hoffmann) rules6 and the generation and chemical capture of tension-trapped transition states7. Despite these advances in stoichiometric reactivity, the use of coupled extrinsic mechanical force to similarly bias the outcomes of catalytic reactions remains relatively unexplored; the few related examples comprise either on/off switching or studies of the effect of intrinsic tension in strained macrocycles8,9,10. If sufficient externally applied mechanical forces could be transduced to catalytic sites, the resulting mechanochemical effects might be amplified through catalysis in ways that provide access to synthetically useful manifestations of polymer mechanochemistry. In this article, we report the macroscopic, mechanical regulation of single-site catalytic selectivity, in which the extrinsic and symmetric (achiral) mechanical stretching of a rubbery polymer support is delivered to a ligand-coordinated, single-site transition metal catalyst covalently coupled to that support (Fig. 1). Macroscopic-to-molecular force transduction improves the enantioselectivity of the catalytic reaction in a way that complements historical approaches such as changing the composition of the catalyst (for example, the choice of metal, ligand or counter-ion in transition-metal-catalysed reactions)11,12, the temperature13,14, the pressure15,16 or the solvent17,18. The enhancement increases with increasing strain, and the enantioselectivity returns to its original value once the strain is relaxed; we use the term ‘multistate mechanocatalysis’ (MMC) to reflect these attributes. Reactivity patterns across multiple substrates and force-coupling mechanisms support mechanochemical coupling as the unifying factor underlying the observed reactivity. Small-molecule systems and computations are used to quantify the effect and elucidate mechanistic details.

a, Changing ligand (X-shaped unit), metal (m), solvent, temperature or pressure (white box). Colour differences in the catalyst complex represent different ligand or metal environments. b, Coupling the catalyst complex (same X-shaped unit and m) to variable tension in a supporting polymer matrix (grey lines represent first network; orange lines represent second network polymer). R and S indicate the enantiomeric forms of the product.

Our approach was inspired by recent observations on catalysts using strained macrocyclic ligands9,10,19,20,21, which suggested that the approach of extrinsically modulated MMC might be viable. A related conception of mechanocatalysis was described by Klibanov et al., who concluded that mechanically induced changes in enzymatic activity were responsible for observed rate accelerations and decelerations when fibres, onto which enzymes are cross-linked, were placed under tension22,23,24,25,26. Relative to this work and the few examples in which mechanical force has been used to convert a latent catalyst into an active one8,27,28,29,30,31,32, MMC is distinguished by the potential it affords to toggle reversibly between multiple ‘on’ states with different and tunable reaction outcomes.

Results and discussion

Characterizing the parent homogeneous reaction

We identified the rhodium(I)-catalysed enantioselective hydrogenation of methyl 2-acetamidoacrylate (1) to yield methyl acetylalaninate (2; Fig. 2) as an attractive system to illustrate MMC for two reasons. First, the high turnovers, fast rates and broad solvent compatibility of the reaction facilitate its extension into non-traditional reaction media. Second, the predominant stereoisomer product, and the selectivity for that stereoisomer’s formation, are influenced heavily by the rhodium-bound ligand12,33. Although high selectivity for the hydrogenation of 1 is realized with a number of chiral phosphine ligands34,35,36,37, we sought a ligand scaffold with modest initial selectivity to make potential MMC effects more easily detectable. To this end, a mixture of [Rh(COD)2][BF4] (1.25 mM, 1 mol%), (R)-MeOBiphep, and 1 (0.125 M) in methanol under H2 (1 atm) at 25 °C for 24 h converts 1 to 2 in >99% yield with an enantiomeric ratio (e.r.) of 63:37 for the R and S enantiomers (Fig. 2). Throughout the paper, we use e.r. rather than enantiomeric excess (e.e.) because its direct correlation with the relative energies of the R and S pathways facilitates a comparison of force effects in bulk supports to those in small-molecule systems.

Top: the overall reaction (reaction (1)) of 1 produces a mixture of mirror image enantiomers of product 2. Bottom: the free energy diagrams for the hydrogenation of 1 with (R)-Rh(MeOBiphep)+ at the MN15/def2TZV level of the density functional theory in vacuum of the two diastereomeric paths with the structures associated with the pro-S pathway depicted. The Cartesian coordinates of the minimum-energy conformers of each stationary state are available from figshare60.

Our combined experimental and computational analyses of reaction (1) catalysed by (MeOBiphep)Rh+ support a mechanism involving reversible complexation of substrate to the solvated (P–P)Rh+ complex followed by reversible oxidative addition of H2 to the diastereomeric (P–P)Rh(1)+ complexes (CS) and irreversible migratory insertion of the rhodium dihydride complexes Int1 to form rhodium alkyl hydride complexes Int2 (Fig. 2). This mechanism is consistent with extensive previous studies of the enantioselective hydrogenation of α-acylaminoacrylates catalysed by rhodium bis(diarylphosphine) complexes34,35,36,37. The enantioselectivity of the hydrogenation of 1 catalysed by (MeOBiphep)Rh+ depends negligibly on p(H2), increasing from 63:37 e.r. to 64:36 e.r. as p(H2) increased from 0.7 to 4.3 bar, which indicates that pre-equilibrium conditions for the formation of the diastereomeric rhodium–enamide complexes CS are largely realized35. The observed enantioselectivity of hydrogenation therefore reflects the relative kinetics of the conversion of the diastereotopic complexes CS to Int2, which involves contributions of two elementary steps: the reversible conversion of CS to Int1, and the irreversible conversion of Int1 to Int2 (Fig. 2).

Some attributes of the (MeOBiphep)Rh+-catalysed reaction are worth noting. First, the enantioselectivity of the reaction is independent of conversion up to complete consumption of starting material (Supplementary Tables 3 and 4). Second, the catalyst gradually loses activity over time, especially when reactions are run to completion and then restarted with the same catalyst (Supplementary Fig. 2 and Supplementary Table 7). Deactivation, particularly upon recycling, is common in catalysts of this type38,39,40,41,42, and has been attributed to the high oxygen sensitivity of the (P–P)Rh+ complex38,39,40,41,42. Third and importantly, catalyst deactivation changes only the rate of the reaction; it does not change the enantioselectivity (Supplementary Fig. 2 and Supplementary Table 7). As demonstrated below, we find that these three intrinsic attributes of the homogeneous catalytic reaction also hold for the polymer-supported systems under investigation here. The core hypothesis of this work is that macroscopic strain in polymer networks can be used as a tool to further tune the enantioselectivity of the reaction, and the independence of the e.r. with respect to conversion and deactivation allows the e.r. to be compared directly from one strain state of a system to another even as the overall rates of reaction change due to, for example, the presence of the network support; the presence or absence of clamps and plates that restrict reactant transport between the support and surrounding solvent, but that are necessary to apply strain; and the deactivation that inevitably occurs as a single support is transitioned across multiple strain states.

Polymer-supported complexes

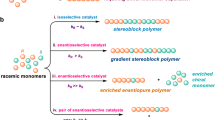

To test whether force-coupled changes in enantioselectivity could be realized in the bulk, we sought supports that can be stretched to high strains without breaking, and in which the ligands are in locations that are prone to high tension. Our strategy uses double-network (DN) gels43,44 (Fig. 3a) that comprise a first network that is prestretched and brittle due to swelling and an interpenetrating second, soft and elastic network that is then formed within this prestretched network. When the DN gel is stretched, the force is concentrated in the prestretched first network45,46. We therefore embedded the MMC into the crosslinker of the first network. As the first network is increasingly strained, some strands within it break, but the interpenetrating second network holds the DN together by absorbing stress that is transferred due to strand scission in the first network45,46. As a result, DNs are typically tougher than either the first or second single network alone, and we hypothesized that they would allow greater tension to be applied to the bound catalysts. The first network was made by free radical addition polymerization of ethyl acrylate (47.5 wt%), 2′-butoxy-[1,1′-biphenyl]-2-yl acrylate (Hsc, 2.5 wt%; Fig. 3a,c) and the mechanically active phosphine crosslinker (R)-6,6′-bis(diphenylphosphaneyl)-[1,1′-biphenyl]-2,2′-diyl diacrylate (Pxl, 0.025 equiv.; Fig. 3a) in toluene. The second network was introduced by swelling the first network in methyl acrylate with 1,4-butanediol diacrylate crosslinker (0.025 mol%) and polymerizing those components within the first network. Following polymerization, the resulting metal-free DN (N1) was extracted three times with toluene to remove residual monomer or free oligomer.

a, Pxl is used as a crosslinker in N1. b, Psc is used as a co-monomer in N1con. The cartoon shows how internal forces (denoted by f) along stretched strands within N1 are coupled to the diaryl dihedral angle of the ligand in Pxl but not Psc. c, Chemical structures of Pxl, Psc, Hxl and Hsc. d, UV–vis absorption spectra of Rh(I)-free N1 gel (grey curve), N1·Rh gel (blue curve) and [(MeOBiphep)Rh(COD)]+BF4‒ (orange curve). e, Cyclic tensile experiment of Rh(I)-loaded N1·Rh gel. Source data are available from figshare60.

Subsequently, we soaked N1 (50 mg) in a solution of [Rh(COD)2][BF4] (2.7 mM) in methanol (1 ml) to prepare the polymer-supported N1·Rh for hydrogenation of methyl 2-acetamidoacrylate (1). These putative MMC supports were subsequently characterized by ultraviolet–visible (UV–vis) spectroscopy, inductively coupled plasma mass spectrometry (ICP-MS) and tensile testing. As shown in Fig. 3d, compared with metal-free N1 (grey curve), the rhodium-loaded DN gel N1·Rh displays a distinct absorption band at 450 nm (blue curve), which is similar to [(MeOBiphep)Rh(COD)]+BF4‒ in solution (orange curve), indicating that intact (Pxl)Rh MMCs are formed within the DN. ICP-MS analysis reveals that the support captured approximately 0.032 μmol of rhodium per mg of support, with the unbound rhodium removed by washing prior to use (Supplementary Table 14). Further ICP-MS analysis following the hydrogenation of 1 reveals negligible leaching of rhodium (<1%) under the conditions of the reaction (Supplementary Table 14). The N1·Rh DNs can be stretched under cyclic loading up to 200% strain, and there is no obvious hysteresis on the timescale of minutes below strains of approximately 70% (Fig. 3e). The hysteresis at higher strain is attributed to covalent bond scission in the primary network43,47, which in turn suggests that maximum-activity sustained MMC in N1·Rh requires extensional strains less than but close to 70%. At higher tensile strains, fracture of the support limits the ability to conduct the desired experiments.

MMC

The enantioselectivity of reaction (1) in the bulk was investigated in N1·Rh (containing mechanically active Pxl) stretched manually to different strains in a homemade clamp and immersed in solution (Supplementary Fig. 4). The strain (ɛ) of the stretched networks was calculated as ɛ = (Lf − Li)/Li, where Li is the initial distance between the clamps and Lf is the final distance. The total volume of reaction was increased to 5 ml to completely submerge the gel. Otherwise, the reaction conditions were operationally similar to those used in the small-molecule system with (R)-MeOBiphep as a ligand, but with a lower catalyst loading (1.6 μmol in the support) and substrate concentration (7 mM). The e.r. of product 2 was determined at each applied strain and is shown in Table 1, entries 1–4, and Fig. 4a. The e.r. produced by a single MMC support increases with ɛ, to values of 2.13, 3.00 and 3.76 at ɛ = 0%, 30% and 50%, respectively, and it returns to its initial value (2.14) when the support is returned to its initial state. Similar strain-dependent and reversible modulation of enantioselectivity is also observed under uniaxial compression of N1·Rh between parallel plates (Table 1, entries 9–11, and Fig. 4b), with a maximum e.r. of 4.56 (corresponding to a change in e.e. of 36–64%) observed when the gel is compressed to approximately 73% strain, or 27% of its initial thickness (Table 1, entry 12). For both extension and compression, the activity of N1·Rh decreases as the same support is used over multiple iterations of the reaction at different strains. As noted above for the homogeneous reaction, however, the enantioselectivity of the heterogeneous reaction is independent of both conversion and catalyst activity (Supplementary Fig. 7 and Supplementary Tables 11 and 12), allowing MMC effects to be quantified.

a,b, Bottom: change in enantioselectivity of hydrogenation as a function of stretching strain (a) and compressing strain (b) of N1·Rh and N1con·Rh. Top: schematic of network catalyst activity before and after stretching (a) and compressing (b). The ‘Relax’ designation indicates that the enantioselectivity returns to its initial value when the strain is removed. Data are shown as mean ± s.d., with n = 3 biologically independent replicates per condition. Each replicate corresponds to a separately prepared batch of polymer support. Uncertainty in strain is ±2%. Source data are available from figshare60.

It is worth noting that the polymeric supports differ from other heterogeneous catalysts where reactions take place only on the surface of the support. The networks used here are gels; they swell under the reaction conditions, and the catalysis occurs throughout the network, and primarily within the interior (where most of the catalytic sites reside). For example, a similar enantioselectivity is observed for reactions in which the substrate is directly introduced into the network interior prior to hydrogenation as compared to reactions in which the substrate is initially present only in the surrounding solvent (Supplementary Information, pages 19–20).

To confirm that the enhanced enantioselectivity of reaction (1) in N1·Rh under applied strain is due to coupled force, we synthesized the control network N1con·Rh, in which a bisphosphine ligand (Psc) is covalently linked to the polymer through a single site (Fig. 3b). The dihedral angle of the ligand in the resulting catalyst is therefore mechanically decoupled from tension in the polymer support. Under the same reaction conditions and a comparable range of applied strain, we found a negligible change in e.r. with strain when N1con·Rh was subjected to either uniaxial stretching (e.r. = 2.03 at ɛ = 0% versus e.r. = 1.94 at ɛ = 50%; Fig. 4a and Table 1, entries 5–8) or uniaxial compression (e.r. = 1.86 at ɛ = 0% versus e.r. = 1.94 at ɛ = 50%; Fig. 4b and Table 1, entries 13–15), supporting a mechanical origin for the improved selectivity observed in N1·Rh48.

To gain quantitative insights into the effect of force on reaction outcome, we used a series of strained macrocycles that has been utilized previously9,10,19,20. Macrocyclic molecular force probe (MFP) ligands E(m,n) and Z(m,n) comprise stiff stilbene (1,1′-biindane) tethered to the MeOBiphep moiety. These strained macrocycles subject the oxygen atoms of the bisphosphine moiety to a compressive (Z) or stretching (E) force whose magnitude is controlled by the tether length that has been calculated previously to vary from approximately –65 pN for Z(2,2) to 228 pN for E(2,3) (Table 2 and Fig. 5a). The tension is coupled to the dihedral angle of the chiral MeOBiphep ligand, and this coupling has been demonstrated to influence the rate or selectivity of other reaction classes9,10,19,20. Previous work has also shown that the effect of force applied intramolecularly and quantified in this way is indistinguishable from that applied in a strained polymer49. The MFP ligands therefore provide a convenient method to apply force to metal complexes and to quantify the effect of that force on product selectivity using conventional reaction conditions and spectroscopic methods, and these experimental methods are supported and extended by calculations of the force dependence.

a, Schematic representation of the compression (left) and extension (right) of a bisphosphine ligand in Z(m,n) and E(m,n) macrocycles. b, Measured e.r. of hydrogenation as a function of the calculated force across the phenoxyl atoms for substrates 1 and 3–5. Error bars represent 1 s.d.; data are shown as mean ± s.d., with n = 3 biologically independent replicates per condition. Each replicate corresponds to a separately prepared batch of polymer support. 2-Naphth, 2-naphthalene. c, Calculated e.r. of reaction (1) at nine values of tensile force applied across the MeOC⋯COMe coordinate of the biphenyl ligand of the catalyst/substrate complex at the MN15/def2TZVP level of density functional theory in vacuum; the values were derived by numerical kinetic modelling assuming irreversible traversal of TS2 (Fig. 2). We confirmed that the constituent elementary steps of the reaction mechanism do not change at forces of 0.5 nN and 2.0 nN (Supplementary Fig. 3). Lines connecting the circles are for guiding only. Source data are available from figshare60.

The hydrogenation of 1 catalysed by rhodium MFP complexes was studied under the same conditions applied to the force-free MeOBiphep system (Fig. 2). As shown in Fig. 5b and Table 2, the enantioselectivity of reaction (1) improves as more extension force is applied to the Biphep dihedral. The largely unaltered Z(2,3) ligand (−6 pN) yields an R:S ratio of 64:36 (Table 2, entry 2), which is similar to that obtained using MeOBiphep (e.r. 63:37). In comparison, a compressive force of −65 pN applied via the Z(2,2) ligand lowers the selectively to R:S = 51:49 (Table 2, entry 1), whereas forces of tension increase it to 77:23 (Table 2, entry 3) and 92:8 (Table 2, entry 4) at 130 pN (E(3,3)) and 228 pN (E(2,3)), respectively. As shown in Supplementary Tables 3 and 5, the enantioselectivity does not change with conversion, and is similarly independent of ligand concentration. The difference in apparent activation energies of the competing reaction paths to products (R)-2 and (S)-2 is given by RT‧ln(e.r.). A plot of ln(e.r.) versus force (Fig. 5b) established a linear relationship between the difference in the activation energies of the competing pathways and force. A linear relationship between activation barrier and force has been observed previously when the same MFP ligands modulate the oxidative addition or reductive elimination at Pd(0) and Pt(II) centres19,20, respectively, and the semilog correlation observed in Fig. 5b is consistent with this trend. We similarly explored whether the force effects observed for reaction (1) translate to additional 2-acetamidoacrylates (3–5). The e.r. for the hydrogenation of all three substrates increases with force in the same manner as 1, although the force dependence varies (Fig. 5b). We chose the least sensitive substrate 3 for evaluation in MMC; the e.r. of the hydrogenation of 3 catalysed by N1·Rh increases upon compression (Supplementary Fig. 6), as was observed for the hydrogenation of 1.

Mechanistic considerations

The relationship between enantioselectivity and mechanical stress/strain in polymer networks is complex because uniform macroscopic strain leads to non-uniform forces on individual catalytic species. To better understand the force-dependent activity of catalytic sites, we turned to the results of our MFP study in combination with a computational analysis of the reaction pathway. Calculated changes in the force-coupled enantioselectivity of reaction (1) at the MN15/def2TZVP level of density functional theory agree with the experimental dependence shown in Fig. 5, and allow further extrapolation to high forces (Fig. 5c). Although the computational force dependence includes contributions from both elementary steps that convert rhodium–enamide complex CS to alkyl hydride complex Int2 (Fig. 2), the predominant contribution comes from the differential effect of increasing force on the diastereomeric transition states for β-migratory insertion (TS2, Fig. 2).

The observed and calculated force dependencies provide insights into the force-coupled effects in the elastomeric supports. The experiments using macrocyclic bisphosphine ligands show that force differences of approximately 300 pN improve the e.r. of reaction (1) by an order of magnitude (Fig. 5b), and computations predict the same scaling to persist up to 1 nN (Fig. 5c). For calibration, the change in ln(e.r.) observed for the hydrogenation of 1 in N1·Rh stretched to 50% strain is 0.57 (Fig. 4a), and the change in ln(e.r.) with added force obtained from the molecular force probe ligands is 7.2 × 10−3 pN−1 (slope of best linear fit to the data in Fig. 5b). The ratio of these two values suggests that the average embedded Pxl at 50% strain is reacting under force on the order of 80 pN.

The results of Fig. 5b,c suggest that the enantioselectivity enhancement achieved in this work is limited by the distribution of macroscopic load across the network rather than an intrinsic limit of MMC. Here, the application of mechanical force is easily accessible; MMC is achieved using a material and device that are immediately accessible in almost any chemistry laboratory. The simplicity of the implementation, however, comes with a trade-off. A small fraction of Pxl-containing strands within the network certainly experiences forces much greater than 80 pN. In fact, hysteresis in the stress–strain curves (Fig. 3e) is attributed to strand scission, which indicates that some strands within the network are experiencing force well in excess of 1 nN. At those forces, the computations predict >99% e.e. is being achieved. In other words, the calculations suggest the tantalizing likelihood that a small number of high-force sites make a disproportionate contribution to the observed force-dependent enantioselectivity, with the selectivity at individual sites potentially exceeding 99% e.e. The net effect from these much more selective catalytic sites is probably cancelled by counterparts that experience lower forces or are entirely uncoupled from macroscopic tension due to network defects50. Thus, improved network designs that either focus stress on the MMC component or distribute force more evenly will increase MMC effects. Additional gains can be realized through device engineering. For example, forces of over the 1 nN threshold predicted to generate 300-fold improvements are easily delivered to single macromolecules using atomic force microscopy techniques51. The demonstration of MMC motivates the development of other device architectures that can deliver similar forces to larger arrays of single molecules or ensembles of a few strands, in ways that complement the use of molecular switches and machines52,53 in organic synthesis.

Conclusions

The ability to transduce macroscopic mechanical forces applied across length scales of centimetre to subnanometre molecular complexes and the reactions that they catalyse in a tunable and reversible manner, as demonstrated here, suggests opportunities for practical and conceptual advances in catalysis that are distinct from those available through traditional approaches. Extrinsic mechanical forces are among the most easily delivered forms of energy input, in that they do not require specialized equipment or power sources—the macroscopic forces applied in this study, for example, are easily generated by a human hand. The consequences of the applied mechanical energy are dictated by the details of the molecular coupling. Here, force is applied macroscopically in a symmetric, achiral manner, and its effect on the asymmetric, chiral reaction outcome is due to the chiral transduction path dictated by the coupled ligand structure. Both the reaction and the methods used here were chosen to test the concept and probe the fundamental underpinnings of macroscopic MMC using single-site transition metal catalysis rather than to achieve high rates of conversion, but the effects observed in the supported catalysts here bode well for future extensions that provide even greater practical advantages. The experiments using molecular force probe ligands and computation demonstrate that even larger enhancements are possible as polymer network systems and devices are optimized to improve reactant transport and to sustain and efficiently transduce even greater loads. Because the force effects are reversible, we further envision opportunities to manipulate ligand geometry on the timescale of catalytic turnover and to realize gains in catalyst kinetics in addition to selectivity as reported here. Such a vision motivates both advances in polymer physics and materials design, and a further understanding of mechanically coupled ligand effects in catalysis, including the identification of complexes and reactions that are particularly susceptible to extrinsic force effects.

Methods

Rhodium-catalysed hydrogenation using molecular force probe ligands

A solution of [Rh(COD)2][BF4] (0.508 mg, 1.25 µmol, 2.5 mM) and P–P (P–P = MeOBiphep, Z(2,2), Z(2,3), E(2,3), E(3,3); 2.5 µmol, 5.0 mM) in methanol (0.5 ml) in a 5-ml vial was stirred at 25 °C for 15 min. The resulting solution was added to a solution of 2-amidoacrylate (1, 17.9 mg, 125 µmol, 250 mM) in methanol (0.5 ml). The vial was capped with a septum and connected to a hydrogen-filled balloon via a needle and the solution was stirred (300 rpm) at 25 °C for 24 h. The resulting solution was passed through a plug of silica gel and analysed by gas chromatography (GC) with a Supelco β-Dex 225 column (30 m × 0.25 mm × 0.25 μm), using an initial oven temperature of 70 °C for 3.0 min, followed by a temperature increase to 140 °C at a rate of 5.0 °C min−1, and then to 215 °C at a rate of 15.0 °C min−1. The relative concentrations of 1, (R)-2 and (S)-2 were determined by integrating the GC peaks (Supplementary Fig. 1a and Supplementary Table 2). GC peak assignments were confirmed using authentic samples of 1, (R)-2 and (S)-2.

The effect of restoring force on the enantioselective hydrogenation of 2-acetamidoacrylates 3 (ref. 54), 4 (ref. 55) and 5 (ref. 56) was determined by using procedures analogous to that used for the hydrogation of 1 (Supplementary Table 2). For the hydrogenation of 3, the filtered reaction mixture was analysed by GC with a Supelco β-Dex 225 column (30 m × 0.25 mm × 0.25 μm). The relative concentrations of R and S methyl 2-acetamidobutanoate were determined by integrating the peaks at retention times of tR = 14.5 min and tR = 15.1 min, respectively (Supplementary Fig. 1b). For the hydrogenations of 4 and 5, the filtered reaction mixture was analysed by high-performance liquid chromatography with a Chiralcel OD-H column (90:10 hexane:isopropanol, 0.5 ml min−1, 25 °C, 220 nm). The relative concentrations of R and S methyl 2-acetamido-3-(naphthalen-2-yl)propanoate were determined by integrating the peaks at tR = 18.9 min and tR = 25.6 min, respectively (Supplementary Fig. 1c). The relative concentrations of d- and l-phenyl acetylalaninate were determined by integrating the peaks at tR = 21.5 min and tR = 31.5 min, respectively (Supplementary Fig. 1d).

Synthesis of first networks

S1

A 50% (w/w) solution of ethyl acrylate/Hsc (97.5/2.5 molar ratio) as monomer, Pxl (2.5 mol% of monomer) as crosslinker and 2-hydroxy-2-methylpropiophenone (HMP) (1 mol% of monomer) as initiator in toluene was sonicated for 10 min and then slowly poured into a glass mould consisting of two flat soda-lime glass plates (thickness, 3 mm) separated by silicone rubber (thickness, 0.8 mm) as a spacer. The solutions were irradiated with UV light (365 nm, 4 mW cm−2) from both sides of the glass mould for 24 h. The samples were then removed from the mould and immersed in toluene for at least 1 week to wash out unreacted components; dialysis baths were changed every day. The resulting swollen first network S1 was subsequently used for DN synthesis. The reactant feed concentrations are summarized in Supplementary Table 8.

S1con

A 50% (w/w) solution of ethyl acetate/Psc (97.5/2.5 molar ratio) as co-monomers, Hxl (2.5 mol% of monomers) as crosslinker and HMP (1 mol% of monomers) as initiator in toluene was sonicated for 10 min and then slowly poured into a glass mould consisting of two flat soda-lime glass plates (thickness, 3 mm) separated by silicone rubber (thickness, 0.8 mm) as a spacer. The solutions were irradiated with UV light (365 nm, 4 mW cm−2) from both sides of the glass mould for 24 h. The samples were then removed from the mould and immersed in toluene for at least 1 week to wash out unreacted components; dialysis baths were changed daily. The resulting swollen first network S1con was subsequently used for DN synthesis. The reactant concentrations are summarized in Supplementary Table 8.

Synthesis of DNs

The feed composition of the second networks used in the syntheses of DNs N1 and N1con are identical. The dialysed first networks were swollen in a solution of methyl acrylate (100 g) as second monomer, 1,4-butanediol diacrylate (57.5 mg, 0.025 mol% of monomer) as crosslinker and HMP (9.5 mg, 0.005 mol% of monomer) as UV initiator for 3 days. The swollen gels were then sandwiched between two flat soda-lime glass plates and irradiated with UV light (365 nm, 4 mW cm−2) for 24 h to synthesize the stretchable second poly methyl acrylate network in the presence of the brittle first networks. The DN gels were then removed from the mould and immersed in toluene for at least 1 week with dialysis baths changed daily, dried under vacuum at 25 °C for 3 days, and stored at room temperature until later use. The compositions of the second network of DN gels are summarized in Supplementary Table 9. Assuming that all phosphine ligand is incorporated into the network, the concentration of bisphosphine ligand in the resulting DNs can be calculated using equation (1),

where Cp–p denotes the concentration of ligand in the resulting cured DN, mcured denotes the mass of cured single-network gel, mtotal denotes the total mass of the feed monomers used in the synthesis of the single network, ML-feed denotes the molar amount of bisphosphine (Pxl or Psc) used in the synthesis of the single network, and mDN denotes the mass of the cured DN. This returns a maximum theoretical bisphospine content (Supplementary Table 9) of 4.6 × 10−2 µmol mg−1 for N1 and 4.8 × 10−2 µmol mg−1 for N1con, or 2.3 µmol for N1 and 2.4 µmol for N1con bisphosphine per 50 mg of network. The actual loading of rhodium achieved in N1, as determined by ICP-MS, is 3.2 × 10−2 μmol mg−1, or roughly 70% of the theoretical maximum.

Loading rhodium into DNs

Excised samples of DNs N1 (~50 mg, ~1.8 µmol bisphosphine) and N1con (~50 mg, ~1.8 µmol bisphosphine) were immersed in solutions of [Rh(COD)2][BF4] (1.5 equiv. relative to bisphosphine) in methanol (1 ml) for ≥3 days at 25 °C. The resulting Rh(I)-loaded DNs N1·Rh and N1con·Rh were then immersed in methanol (2 ml) for ≥3 days to remove unbound rhodium, with the baths changed every 12 h. The resulting Rh(I)-loaded DN catalyst gels were then used for subsequent hydrogenation and characterization.

Cyclic testing of N1·Rh

Uniaxial tensile cyclic testing of N1·Rh was performed at the nominal strain rate of 1% s−1. The samples were stretched to a target strain (50%, 60%, 70% and 100%) and then immediately unloaded at the same rate. The nominal strain (ɛ) is given by equation (3). The nominal stress was calculated as the measured load divided by the original cross-sectional area vertical to the load.

Rhodium-catalysed hydrogenation on solid supports

Uniaxial stretching

Catalytic hydrogenation of 1 using rhodium-loaded DNs as a function of uniaxial strain were performed utilizing a bespoke stretching device of approximate dimensions 5.5 × 2.1 × 2.1 cm comprising a pair of 3-mm-thick clamps positioned 6 mm apart with one clamp anchored to the base of the device and the second anchored to a movable platform (Supplementary Fig. 4). The platform is connected to a thumb screw such that turning the thumb screw increases the separation of the clamps, giving up to 16-mm separation (167% strain) at full travel. A sample of N1·Rh (~3 mm × ~12 mm × ~1.1 mm; 50 mg, 1.6 µmol Rh) was securely clamped onto the stretching device. The secured gel and device were then placed in a 40-ml vial containing a solution of methyl 2-acetamidoacrylate (1, 5 mg, 7 mM) in methanol (5 ml), which was sufficient volume to completely submerge the gel (Supplementary Fig. 4). The vial was capped with a septum, attached to a hydrogen-filled balloon via a needle, and the liquid phase was stirred at 25 °C for 2 days and then analysed by GC (Table 1, entry 1). Without removing the gel from the mould, N1·Rh was rinsed three times with methanol, strained to 30% and immersed in a fresh solution of 1 (5 mg, 7 mM) in methanol (5 ml) in a 40-ml vial; the percentage strain was determined by measuring the distance between the clamps before and after the gel was stretched using a caliper. The vial was again capped with a septum and attached to a hydrogen-filled balloon via a needle. The liquid phase was stirred at 25 °C for 4 days and then analysed by GC (Table 1, entry 2). The procedure was then repeated sequentially at 50% strain (8 days) and 0% strain (8 days) (Table 1, entries 3–4).

Uniaxial compression

Catalytic hydrogenation of 1 using rhodium-loaded DNs as a function of uniaxial compression was performed utilizing a compressing device comprising two 21-mm-diameter stainless steel plates attached to one another via four machine screws which control the separation of the plates (Supplementary Fig. 4). Rh(I)-loaded DN N1·Rh of dimensions ~6 mm × ~6 mm × ~1.1 mm (~50 mg, 1.6 µmol Rh) was secured between the plates of the compressing device and the secured gel and device was then immersed in a solution of methyl 2-amidoacrylate (1, 5 mg, 17.5 mM) in methanol (2 ml) in a 40-ml vial. The vial was capped with a septum and attached to a hydrogen-filled balloon via a needle. The liquid phase was stirred at 25 °C for 2 days and then analysed by GC (Table 1, entry 9). The sample of N1·Rh was rinsed three times with methanol, compressed 30% by measuring the distance between the plates before and after compression using a caliper, and immersed in a fresh solution of 1 in methanol in a 40-ml vial under hydrogen (balloon). The solution phase was stirred for 4 days and analysed by GC (Table 1, entry 10). The procedure was then repeated at 50% compression (8 days) and 73% compression (16 days) (Table 1, entries 11–12). The enantioselective hydrogenations of 3 as a function of uniaxial compression using N1·Rh was performed by following a similar procedure (Supplementary Table S10).

Computational analysis

All calculations were performed with Gaussian 16.C in vacuum using the Berny algorithm to locate stationary points with tight convergence criteria and ultrafine integration grids. Conformational ensembles of all kinetically significant stationary states were built systematically as previously described except with the MN15/def2TSV model chemistry. We chose MN15 because it was previously recommended for calculation of reaction barriers in organometallic complexes of transition metals57. We confirmed the wavefunction stability of the converged geometries of all transition states with the stable test. Geometries under extrinsic force were optimized using the iop(1/165) overlay procedure with very soft spring constant (10−6 hartree bohr−1). We optimized all stationary states (both diastereomers of CS through Int4) at 0, 0.5 and 2 nN and product-determining states (both diastereomers of CS, TS1, Int1, TS2) additionally at 0.1, 0.25, 0.75, 1, 1.5 and 2.5 nN at MN15/def2TSV. The latter states were then reoptimized at MN15/def2TZVP.

Thermodynamic corrections were calculated in the ideal-gas/rigid-rotor/pseudoharmonic oscillator approximation after replacing all frequencies <500 cm−1 with 500 cm−1 to avoid artefactually large contributions of such modes to entropy, as previously recommended58. Using analytical frequency calculations on converged geometries coupled to an external spring to estimate thermodynamic corrections is theoretically valid because the molecule plus its coupled spring comprise a stationary state59. Free energies at def2TZVP were calculated by adding electronic energies at def2TZVP to thermodynamic corrections derived for converged geometries at def2TZV because analytical frequency calculations at def2TZVP were unaffordably costly.

Kinetic modelling was performed by numerical integration of the corresponding differential rate laws using the ode85 function of Matlab, assuming that the two diastereomeric CS complexes are always in thermodynamic equilibrium and each TS2 is traversed irreversibly, that is, in the simulations the ratio of the concentrations of Int2, [RS-Int2]/[SS-Int2], always equalled the ratio of the concentrations of the products, [R-product]/[S-product].

Data availability

All data supporting the conclusions of this study, including source data for the figures and tables herein, are available either within the article and its Supplementary Information or from figshare via https://doi.org/10.6084/m9.figshare.28299872 (ref. 60).

References

Li, J., Nagamani, C. & Moore, J. S. Polymer mechanochemistry: from destructive to productive. Acc. Chem. Res. 48, 2181–2190 (2015).

O’Neill, R. T. & Boulatov, R. The many flavours of mechanochemistry and its plausible conceptual underpinnings. Nat. Rev. Chem. 5, 148–167 (2021).

Hu, H., Ma, Z. & Jia, X. Reaction cascades in polymer mechanochemistry. Mater. Chem. Front. 4, 3115–3129 (2020).

Lloyd, E. M., Vakil, J. R., Yao, Y., Sottos, N. R. & Craig, S. L. Covalent mechanochemistry and contemporary polymer network chemistry: a marriage in the making. J. Am. Chem. Soc. 145, 751–768 (2023).

Wang, L. et al. Mechanochemistry of cubane. J. Am. Chem. Soc. 144, 22865–22869 (2022).

Brown, C. L. et al. Substituent effects in mechanochemical allowed and forbidden cyclobutene ring-opening reactions. J. Am. Chem. Soc. 143, 3846–3855 (2021).

Lenhardt, J. M. et al. Trapping a diradical transition state by mechanochemical polymer extension. Science 329, 1057–1060 (2010).

Piermattei, A., Karthikeyan, S. & Sijbesma, R. P. Activating catalysts with mechanical force. Nat. Chem. 1, 133–137 (2009).

Yu, Y., Zheng, X., Duan, C., Craig, S. L. & Widenhoefer, R. A. Force-modulated selectivity of the rhodium-catalyzed hydroformylation of 1-alkenes. ACS Catal. 12, 13941–13950 (2022).

Kean, Z. S. et al. Photomechanical actuation of ligand geometry in enantioselective catalysis. Angew. Chem. Int. Ed. 53, 14508–14511 (2014).

Rechavi, D. & Lemaire, M. Enantioselective catalysis using heterogeneous bis(oxazoline) ligands: which factors influence the enantioselectivity? Chem. Rev. 102, 3467–3494 (2002).

Tang, W. & Zhang, X. New chiral phosphorus ligands for enantioselective hydrogenation. Chem. Rev. 103, 3029–3070 (2003).

Lautens, M. & Rovis, T. A new route to the enantioselective synthesis of cycloheptenols. Temperature effects in the asymmetric reductive ring opening of [3.2.1] oxabicycloalkenes. J. Am. Chem. Soc. 119, 11090–11091 (1997).

Mohr, J. T., Hong, A. Y. & Stoltz, B. M. Enantioselective protonation. Nat. Chem. 1, 359–369 (2009).

Sun, Y., Landau, R. N., Wang, J., LeBlond, C. & Blackmond, D. G. A re-examination of pressure effects on enantioselectivity in asymmetric catalytic hydrogenation. J. Am. Chem. Soc. 118, 1348–1353 (1996).

Watkins, A. L. & Landis, C. R. Origin of pressure effects on regioselectivity and enantioselectivity in the rhodium-catalyzed hydroformylation of styrene with (S,S,S)-BisDiazaphos. J. Am. Chem. Soc. 132, 10306–10317 (2010).

Keck, G. E. & Krishnamurthy, D. Pronounced solvent and concentration effects in an enantioselective Mukaiyama aldol condensation using binol-titanium(IV) catalysts. J. Am. Chem. Soc. 117, 2363–2364 (1995).

Cainelli, G., Galletti, P. & Giacomini, D. Solvent effects on stereoselectivity: more than just an environment. Chem. Soc. Rev. 38, 990–1001 (2009).

Wang, L. et al. Mechanochemical regulation of oxidative addition to a palladium(0) bisphosphine complex. J. Am. Chem. Soc. 142, 17714–17720 (2020).

Yu, Y. et al. Force-modulated reductive elimination from platinum(II) diaryl complexes. Chem. Sci. 12, 11130–11137 (2021).

Duan, C., Zheng, X., Craig, S. L. & Widenhoefer, R. A. Force-modulated C–C reductive elimination from nickel bis(polyfluorophenyl) complexes. Organometallics 42, 1918–1926 (2023).

Berezin, I. V., Klibanov, A. M., Gol’dmakher, V. S. & Martinek, K. Mechanochemistry of catalytic systems. Control of the enzymic activity of trypsin immobilized in polyacrylamide gel by mechanical action. Dokl. Akad. Nauk SSSR 218, 367–370 (1974).

Klibanov, A. M., Samokhin, G. P., Martinek, K. & Berezin, I. V. Mechanochemistry of catalytic systems. Control of enzymic properties of α-chymotrypsin chemically added to a kapron thread by mechanical action. Dokl. Akad. Nauk SSSR 218, 715–718 (1974).

Berezin, I. V., Klibanov, A. M. & Martinek, K. The mechanochemistry of immobilized enzymes. How to steer a chemical process at the molecular level by a mechanical device. Biochim. Biophys. Acta 364, 193–199 (1974).

Berezin, I. V., Klibanov, A. M., Samokhin, G. P. & Martinek, K. Mechanochemistry of immobilized enzymes: a new approach to studies in fundamental enzymology. I. Regulation by mechanical means of the catalytic properties of enzymes attached to polymer fibers. Methods Enzymol. 44, 558–571 (1976).

Klibanov, A. M., Samokhin, G. P., Martinek, K. & Berezin, I. V. Enzymatic mechanochemistry: a new approach to studying the mechanism of enzyme action. Biochim. Biophys. Acta Enzymol. 438, 1–12 (1976).

Jakobs, R. T. M. & Sijbesma, R. P. Mechanical activation of a latent olefin metathesis catalyst and persistence of its active species in ROMP. Organometallics 31, 2476–2481 (2012).

Groote, R., Jakobs, R. T. M. & Sijbesma, R. P. Performance of mechanochemically activated catalysts is enhanced by suppression of the thermal effects of ultrasound. ACS Macro Lett. 1, 1012–1015 (2012).

Groote, R., van Haandel, L. & Sijbesma, R. P. The effect of molecular weight and catalyst concentration on catalytic activity in mechanochemically activated transesterification using silver(I)–N-heterocyclic carbene latent catalysts. J. Polym. Sci. A 50, 4929–4935 (2012).

Michael, P. & Binder, W. H. A mechanochemically triggered ‘click’ catalyst. Angew. Chem. Int. Ed. 54, 13918–13922 (2015).

Wei, K. et al. Mechanical activation of platinum–acetylide complex for olefin hydrosilylation. ACS Macro Lett. 6, 1146–1150 (2017).

Michael, P., Biewend, M. & Binder, W. H. Mechanochemical activation of fluorogenic CuAAC ‘click’ reactions for stress-sensing applications. Macromol. Rapid Commun. 39, 1800376 (2018).

Xie, J.-H., Zhu, S.-F. & Zhou, Q.-L. Transition metal-catalyzed enantioselective hydrogenation of enamines and imines. Chem. Rev. 111, 1713–1760 (2011).

Halpern, J. Mechanism and stereoselectivity of asymmetric hydrogenation. Science 217, 401–407 (1982).

Landis, C. R. & Halpern, J. Asymmetric hydrogenation of methyl (Z)-α-acetamidocinnamate catalyzed by [1,2-bis(phenyl-o-anisoyl)phosphino]ethane]rhodium(I): kinetics, mechanism and origin of enantioselection. J. Am. Chem. Soc. 109, 1746–1754 (1987).

Landis, C. R., Hilfenhaus, P. & Feldgus, S. Structures and reaction pathways in rhodium(I)-catalyzed hydrogenation of enamides: a model DFT study. J. Am. Chem. Soc. 121, 8741–8754 (1999).

Gridnev, I. D., Imamoto, T., Hoge, G., Kouchi, M. & Takahashi, H. Asymmetric hydrogenation catalyzed by a rhodium complex of (R)-(tert-butylmethylphosphino)(di-tert-butylphosphino)methane: scope of enantioselectivity and mechanistic study. J. Am. Chem. Soc. 130, 2560–2572 (2008).

Alberico, E., Möller, S., Horstmann, M., Drexler, H.-J. & Heller, D. Activation, deactivation and reversibility phenomena in homogeneous catalysis: a showcase based on the chemistry of rhodium/phosphine catalysts. Catalysts 9, 582 (2019).

Meißner, A., Alberico, E., Drexler, H.-J., Baumann, W. & Heller, D. Rhodium diphosphine complexes: a case study for catalyst activation and deactivation. Catal. Sci. Technol. 4, 3409–3425 (2014).

Selke, R., Häupke, K. & Krause, H. W. Asymmetric hydrogenation by heterogenized cationic rhodium phosphinite complexes. J. Mol. Catal. 56, 315–328 (1989).

van den Broeke, J., de Wolf, E., Deelman, B.-J. & van Koten, G. Enhanced hydrogenation activity and recycling of cationic rhodium diphosphine complexes through the use of highly fluorous and weakly-coordinating tetraphenylborate anions. Adv. Synth. Catal. 345, 625–634 (2003).

Kleman, P., Barbaro, P. & Pizzano, A. Chiral Rh phosphine–phosphite catalysts immobilized on ionic resins for the enantioselective hydrogenation of olefins in water. Green Chem. 17, 3826–3836 (2015).

Ducrot, E., Chen, Y., Bulters, M., Sijbesma, R. P. & Creton, C. Toughening elastomers with sacrificial bonds and watching them break. Science 344, 186–189 (2014).

Millereau, P. et al. Mechanics of elastomeric molecular composites. Proc. Natl Acad. Sci. USA 115, 9110–9115 (2018).

Matsuda, T., Kawakami, R., Namba, R., Nakajima, T. & Gong, J. P. Mechanoresponsive self-growing hydrogels inspired by muscle training. Science 363, 504–508 (2019).

Wang, Z. et al. Toughening hydrogels through force-triggered chemical reactions that lengthen polymer strands. Science 374, 193–196 (2021).

Webber, R. E., Creton, C., Brown, H. R. & Gong, J. P. Large strain hysteresis and Mullins effect of tough double-network hydrogels. Macromolecules 40, 2919–2927 (2007).

Kelber, J. B. et al. Reversible soft mechanochemical control of biaryl conformations through crosslinking in a 3D macromolecular network. Angew. Chem. Int. Ed. 59, 23283–23290 (2020).

Akbulatov, S., Tian, Y. & Boulatov, R. Force–reactivity property of a single monomer is sufficient to predict the micromechanical behavior of its polymer. J. Am. Chem. Soc. 134, 7620–7623 (2012).

Zhong, M., Wang, R., Kawamoto, K., Olsen, B. D. & Johnson, J. A. Quantifying the impact of molecular defects on polymer network elasticity. Science 353, 1264–1268 (2016).

Wang, Z., Kouznetsova, T. B. & Craig, S. L. Pulling outward but reacting inward: mechanically induced symmetry-allowed reactions of cis- and trans-diester-substituted dichlorocyclopropanes. Synlett 33, 885–889 (2022).

Pizzolato, S. F., Štacko, P., Kistemaker, J. C. M., van Leeuwen, T. & Feringa, B. L. Phosphoramidite-based photoresponsive ligands displaying multifold transfer of chirality in dynamic enantioselective metal catalysis. Nat. Catal. 3, 488–496 (2020).

Biagini, C. et al. Dissipative catalysis with a molecular machine. Angew. Chem. Int. Ed. 58, 9876–9880 (2019).

Chen, H.-X. et al. Synthesis of α,α-difluorinated phosphonate pSer/pThr mimetics via rhodium-catalyzed asymmetric hydrogenation of β-difluorophosphonomethyl α-(acylamino)acrylates. Org. Lett. 20, 3278–3281 (2018).

Jiang, H. et al. Topology-based functionalization of robust chiral Zr-based metal–organic frameworks for catalytic enantioselective hydrogenation. J. Am. Chem. Soc. 142, 9642–9652 (2020).

Obara, N., Watanabe, T., Asakawa, T., Kan, T. & Tanaka, T. Efficient synthesis of 3-amino-1,5-benzodiazepine-2-one derivatives. Synlett 28, 1183–1186 (2017).

Yu, H. S., He, X., Li, S. L. & Truhlar, D. G. MN15: a Kohn–Sham global-hybrid exchange–correlation density functional with broad accuracy for multi-reference and single-reference systems and noncovalent interactions. Chem. Sci. 7, 5032–5051 (2016).

Cramer, C. J. Essentials of Computational Chemistry (Wiley, 2004).

Kucharski, T. J. & Boulatov, R. The physical chemistry of mechanoresponsive polymers. J. Mater. Chem. 21, 8237–8255 (2011).

Zheng, X. et al. Source data for ‘Strain-dependent enantioselectivity in mechanochemically coupled catalytic hydrogenation’. figshare https://doi.org/10.6084/m9.figshare.28299872 (2025).

Acknowledgements

This material is based upon work supported by the US Department of Energy, Office of Science, Office of Basic Energy Sciences Program under award number DE-SC0018188 (R.A.W. and S.L.C.). We thank T. Oas for help designing the tension clamp and encouraging conversations, and H. Hsu-Kim for assistance with the ICP-MS analyses.

Author information

Authors and Affiliations

Contributions

S.L.C. and R.A.W. conceived of the concept. X.Z. established the system. X.Z., C.-Y.C., C.D., Y.Y., J.M., S.L.C. and R.A.W. designed the experiments. R.T.O. and R.B. designed, executed and analysed the computations. X.Z., C.-Y.C. and C.D. performed the catalysis experiments and analysed the data. Y.Y. and J.M. contributed to the synthesis of the force probe ligands. N.A.R. performed and analysed the ICP-MS experiments. X.Z., C.-Y.C., S.L.C. and R.A.W. wrote the paper.

Corresponding authors

Ethics declarations

Competing interests

S.L.C., R.A.W., C.D. and X.Z. are coinventors on a patent application DU8316US. The other authors declare no competing interests.

Peer review

Peer review information

Nature Synthesis thanks Rint Sijbesma and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–16, Discussion and Tables 1–15.

Supplementary Data 1

Source data for Supplementary Figs. 2 and 7 and Tables 1, 3–6, 10, 13 and 15.

Source data

Source Data Fig. 2

Statistical source data for Fig. 2.

Source Data Fig. 3

Statistical source data for Fig. 3.

Source Data Fig. 4

Statistical source data for Fig. 4.

Source Data Fig. 5

Statistical source data for Fig. 5b.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zheng, X., Chiou, CY., O’Neill, R.T. et al. Strain-dependent enantioselectivity in mechanochemically coupled catalytic hydrogenation. Nat. Synth 4, 1319–1328 (2025). https://doi.org/10.1038/s44160-025-00839-y

Received:

Accepted:

Published:

Issue date:

DOI: https://doi.org/10.1038/s44160-025-00839-y