Abstract

Ligands play a crucial role in enabling challenging chemical transformations with transition metal-mediated homogeneous catalysts. Despite their undisputed role in homogeneous catalysis, discovery and development of ligands have proven to be a challenging and resource-intensive undertaking. Here, in response, we present a self-driving catalysis laboratory, Fast-Cat, for autonomous and resource-efficient parameter space navigation and Pareto-front mapping of high-temperature, high-pressure, gas–liquid reactions. Fast-Cat enables autonomous ligand benchmarking and multi-objective catalyst performance evaluation with minimal human intervention. Specifically, we utilize Fast-Cat to perform rapid Pareto-front identification of the hydroformylation reaction between syngas (CO and H2) and olefin (1-octene) in the presence of rhodium and various classes of phosphorus-based ligands. By reactor benchmarking, we demonstrate Fast-Cat’s knowledge scalability, essential to fine/specialty chemical industries. We report the details of the modular flow chemistry platform of Fast-Cat and its autonomous experiment-selection strategy for the rapid generation of optimized experimental conditions and in-house data required for supplying machine-learning approaches to reaction and ligand investigations.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to the full article PDF.

USD 39.95

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The authors declare that all data supporting the findings of this study are available within the main text and Supplementary Information.

Code availability

The source code for the Pareto-front mapping and digital twin models have been deposited in the repository ‘Fast-Cat’ (https://github.com/AbolhasaniLab).

References

Franke, R., Selent, D. & Börner, A. Applied hydroformylation. Chem. Rev. 112, 5675–5732 (2012).

Whiteker, G. T. & Cobley, C. J. in Organometallics as Catalysts in the Fine Chemical Industry 35–46 (Springer, 2012).

Botteghi, C., Paganelli, S., Schionato, A. & Marchetti, M. The asymmetric hydroformylation in the synthesis of pharmaceuticals. Chirality 3, 355–369 (1991).

Stanley, G. G. in Kirk‐Othmer Encyclopedia of Chemical Technology 1–19 (Wiley, 2017).

Vilches-Herrera, M., Domke, L. & Börner, A. Isomerization–hydroformylation tandem reactions. ACS Catal. 4, 1706–1724 (2014).

Klein, H., Jackstell, R., Wiese, K. D., Borgmann, C. & Beller, M. Highly selective catalyst systems for the hydroformylation of internal olefins to linear aldehydes. Angew. Chem. Int. Ed. 40, 3408–3411 (2001).

Seayad, A. et al. Internal olefins to linear amines. Science 297, 1676 (2002).

Yan, Y., Zhang, X. & Zhang, X. A tetraphosphorus ligand for highly regioselective isomerization–hydroformylation of internal olefins. J. Am. Chem. Soc. 128, 16058–16061 (2006).

Breit, B. & Seiche, W. Hydrogen bonding as a construction element for bidentate donor ligands in homogeneous catalysis: regioselective hydroformylation of terminal alkenes. J. Am. Chem. Soc. 125, 6608–6609 (2003).

van der Veen, L. A., Kamer, P. C. & van Leeuwen, P. W. Hydroformylation of internal olefins to linear aldehydes with novel rhodium catalysts. Angew. Chem. Int. Ed. 38, 336–338 (1999).

Jiao, Y., Torne, M. S., Gracia, J., Niemantsverdriet, J. H. & van Leeuwen, P. W. Ligand effects in rhodium-catalyzed hydroformylation with bisphosphines: steric or electronic? Catal. Sci. Technol. 7, 1404–1414 (2017).

Van Leeuwen, P. W. & Claver, C. Rhodium Catalyzed Hydroformylation Vol. 22 (Springer, 2002).

Zhu, C. et al. Flow chemistry-enabled studies of rhodium-catalyzed hydroformylation reactions. ChemComm 54, 8567–8570 (2018).

Raghuvanshi, K. et al. Highly efficient 1-octene hydroformylation at low syngas pressure: from single-droplet screening to continuous flow synthesis. ACS Catal. 10, 7535–7542 (2020).

Van Rooy, A., de Bruijn, J. N., Roobeek, K. F., Kamer, P. C. & Van Leeuwen, P. W. Rhodium-catalysed hydroformylation of branched 1-alkenes; bulky phosphite vs. triphenylphosphine as modifying ligand. J. Organomet. Chem. 507, 69–73 (1996).

van Rooy, A., Orij, E. N., Kamer, P. C. & van Leeuwen, P. W. Hydroformylation with a rhodium/bulky phosphite modified catalyst. A comparison of the catalyst behavior for oct-1-ene, cyclohexene, and styrene. Organometallics 14, 34–43 (1995).

Diebolt, O., Tricas, H., Freixa, Z. & van Leeuwen, P. W. Strong π-acceptor ligands in rhodium-catalyzed hydroformylation of ethene and 1-octene: operando catalysis. ACS Catal. 3, 128–137 (2013).

Vogl, C., Paetzold, E., Fischer, C. & Kragl, U. Highly selective hydroformylation of internal and terminal olefins to terminal aldehydes using a rhodium-BIPHEPHOS-catalyst system. J. Mol. Catal. A 232, 41–44 (2005).

Kamer, P. C. J., van Leeuwen, P. W. N. M. & Reek, J. N. H. Wide bite angle diphosphines: Xantphos ligands in transition metal complexes and catalysis. Acc. Chem. Res. 34, 895–904 (2001).

Ichihara, T., Nakano, K., Katayama, M. & Nozaki, K. Tandem hydroformylation–hydrogenation of 1-decene catalyzed by Rh-bidentate bis(trialkylphosphine)s. Asian J. Chem. 3, 1722–1728 (2008).

Fuchs, E., Keller, M. & Breit, B. Phosphabarrelenes as ligands in rhodium‐catalyzed hydroformylation of internal alkenes essentially free of alkene isomerization. Chem. Eur. J. 12, 6930–6939 (2006).

Kuil, M., Soltner, T., van Leeuwen, P. W. & Reek, J. N. High-precision catalysts: regioselective hydroformylation of internal alkenes by encapsulated rhodium complexes. J. Am. Chem. Soc. 128, 11344–11345 (2006).

Besset, T., Norman, D. W. & Reek, J. N. Supramolecular encapsulated rhodium catalysts for branched selective hydroformylation of alkenes at high temperature. Adv. Synth. Catal. 355, 348–352 (2013).

Gao, H. et al. Using machine learning to predict suitable conditions for organic reactions. ACS Cent. Sci. 4, 1465–1476 (2018).

Zhou, Z., Li, X. & Zare, R. N. Optimizing chemical reactions with deep reinforcement learning. ACS Cent. Sci. 3, 1337–1344 (2017).

Epps, R. W. et al. Artificial chemist: an autonomous quantum dot synthesis bot. Adv. Mater. 32, 2001626 (2020).

Schweidtmann, A. M. et al. Machine learning meets continuous flow chemistry: automated optimization towards the Pareto front of multiple objectives. J. Chem. Eng. 352, 277–282 (2018).

Abolhasani, M. & Kumacheva, E. The rise of self-driving labs in chemical and materials sciences. Nat. Synth. 2, 483–492 (2023).

Bennett, J. A. & Abolhasani, M. Autonomous chemical science and engineering enabled by self-driving laboratories. Curr. Opin. Chem. Eng. 36, 100831 (2022).

Epps, R. W., Volk, A. A., Ibrahim, M. Y. & Abolhasani, M. Universal self-driving laboratory for accelerated discovery of materials and molecules. Chem 7, 2541–2545 (2021).

Volk, A. A. & Abolhasani, M. Autonomous flow reactors for discovery and invention. Trends Chem. 3, 519–522 (2021).

Granda, J. M., Donina, L., Dragone, V., Long, D.-L. & Cronin, L. Controlling an organic synthesis robot with machine learning to search for new reactivity. Nature 559, 377–381 (2018).

Sans, V., Porwol, L., Dragone, V. & Cronin, L. A self optimizing synthetic organic reactor system using real-time in-line NMR spectroscopy. Chem. Sci. 6, 1258–1264 (2015).

Steiner, S. et al. Organic synthesis in a modular robotic system driven by a chemical programming language. Science 363, eaav2211 (2019).

Bradford, E., Schweidtmann, A. M. & Lapkin, A. Efficient multiobjective optimization employing Gaussian processes, spectral sampling and a genetic algorithm. J. Glob. Optim. 71, 407–438 (2018).

Clayton, A. D. et al. Automated self-optimisation of multi-step reaction and separation processes using machine learning. J. Chem. Eng. 384, 123340 (2020).

Christensen, M. et al. Data-science driven autonomous process optimization. Commun. Chem. 4, 112 (2021).

MacLeod, B. P. et al. Self-driving laboratory for accelerated discovery of thin-film materials. Sci. Adv. 6, eaaz8867 (2020).

Roch, L. M. et al. ChemOS: orchestrating autonomous experimentation. Sci. Robot. 3, eaat5559 (2018).

Gómez-Bombarelli, R. et al. Design of efficient molecular organic light-emitting diodes by a high-throughput virtual screening and experimental approach. Nat. Mater. 15, 1120–1127 (2016).

Coley, C. W. et al. A robotic platform for flow synthesis of organic compounds informed by AI planning. Science 365, eaax1566 (2019).

Taylor, C. J. et al. Accelerated chemical reaction optimization using multi-task learning. ACS Cent. Sci. 9, 957–968 (2023).

Shields, B. J. et al. Bayesian reaction optimization as a tool for chemical synthesis. Nature 590, 89–96 (2021).

Ahneman, D. T., Estrada, J. G., Lin, S., Dreher, S. D. & Doyle, A. G. Predicting reaction performance in C–N cross-coupling using machine learning. Science 360, 186–190 (2018).

Tabor, D. P. et al. Accelerating the discovery of materials for clean energy in the era of smart automation. Nat. Rev. Mater. 3, 5–20 (2018).

Volk, A. A. et al. AlphaFlow: autonomous discovery and optimization of multi-step chemistry using a self-driven fluidic lab guided by reinforcement learning. Nat. Commun. 14, 1403 (2023).

Deneault, J. R. et al. Toward autonomous additive manufacturing: Bayesian optimization on a 3D printer. MRS Bull. 46, 566–575 (2021).

Gutmann, B., Cantillo, D. & Kappe, C. O. Continuous‐flow technology—a tool for the safe manufacturing of active pharmaceutical ingredients. Angew. Chem. Int. Ed. 54, 6688–6728 (2015).

Hartman, R. L., McMullen, J. P. & Jensen, K. F. Deciding whether to go with the flow: evaluating the merits of flow reactors for synthesis. Angew. Chem. Int. Ed. 50, 7502–7519 (2011).

Movsisyan, M. et al. Taming hazardous chemistry by continuous flow technology. Chem. Soc. Rev. 45, 4892–4928 (2016).

Volk, A. A., Campbell, Z. S., Ibrahim, M. Y., Bennett, J. A. & Abolhasani, M. Flow chemistry: a sustainable voyage through the chemical universe en route to smart manufacturing. Annu. Rev. Chem. Biomol. Eng. 13, 45–72 (2022).

Nambiar, A. M. K. et al. Bayesian optimization of computer-proposed multistep synthetic routes on an automated robotic flow platform. ACS Cent. Sci. 8, 825–836 (2022).

Nieves-Remacha, M. J. & Jensen, K. F. Mass transfer characteristics of ozonolysis in microreactors and advanced-flow reactors. J. Flow Chem. 5, 160–165 (2015).

Brzozowski, M., O’Brien, M., Ley, S. V. & Polyzos, A. Flow chemistry: intelligent processing of gas–liquid transformations using a tube-in-tube reactor. Acc. Chem. Res. 48, 349–362 (2015).

Hessel, V., Kralisch, D., Kockmann, N., Noël, T. & Wang, Q. Novel process windows for enabling, accelerating, and uplifting flow chemistry. ChemSusChem 6, 746–789 (2013).

Plutschack, M. B., Pieber, B. U., Gilmore, K. & Seeberger, P. H. The hitchhiker’s guide to flow chemistry||. Chem. Rev. 117, 11796–11893 (2017).

Ibrahim, M. Y. S., Bennett, J. A., Mason, D., Rodgers, J. & Abolhasani, M. Flexible homogeneous hydroformylation: on-demand tuning of aldehyde branching with a cyclic fluorophosphite ligand. J. Catal. 409, 105–117 (2022).

Joshi, J. B., Pandit, A. B. & Sharma, M. M. Mechanically agitated gas–liquid reactors. Chem. Eng. Sci. 37, 813–844 (1982).

Gentric, C., Mignon, D., Bousquet, J. & Tanguy, P. A. Comparison of mixing in two industrial gas–liquid reactors using CFD simulations. Chem. Eng. Sci. 60, 2253–2272 (2005).

Günther, A., Jhunjhunwala, M., Thalmann, M., Schmidt, M. A. & Jensen, K. F. Micromixing of miscible liquids in segmented gas−liquid flow. Langmuir 21, 1547–1555 (2005).

Günther, A., Khan, S. A., Thalmann, M., Trachsel, F. & Jensen, K. F. Transport and reaction in microscale segmented gas–liquid flow. Lab Chip 4, 278–286 (2004).

Daulton, S., Balandat, M. & Bakshy, E. Differentiable expected hypervolume improvement for parallel multi-objective Bayesian optimization. Adv. Neural Inf. Process. Syst. 33, 9851–9864 (2020).

Jacobs, I., de Bruin, B. & Reek, J. N. Comparison of the full catalytic cycle of hydroformylation mediated by mono‐and bis‐ligated triphenylphosphine–rhodium complexes by using DFT calculations. ChemCatChem 7, 1708–1718 (2015).

Dieleman, C. B., Kamer, P. C., Reek, J. N. & van Leeuwen, P. W. Xantphite: a new family of ligands for catalysis. Applications in the hydroformylation of alkenes. Helv. Chim. Acta 84, 3269–3280 (2001).

Zuidema, E. et al. The rate‐determining step in the rhodium–Xantphos‐catalysed hydroformylation of 1‐octene. Chem. Eur. J. 14, 1843–1853 (2008).

Shahhosseini, M., Hu, G. & Pham, H. Optimizing ensemble weights and hyperparameters of machine learning models for regression problems. Mach. Learn. Appl. 7, 100251 (2022).

Lundberg, S. M. & Lee, S.-I. A unified approach to interpreting model predictions. Adv. Neural Inf. Process. Syst. 30, 106786–6795 (2017).

Bateni, F. Smart Dope: a self‐driving fluidic lab for accelerated development of doped perovskite quantum dots. Adv. Energy Mater. 14, 2302303 (2024).

Sadeghi, S. et al. Autonomous nanomanufacturing of lead-free metal halide perovskite nanocrystals using a self-driving fluidic lab. Nanoscale 16, 580–591 (2024).

Koscher, B. A. et al. Autonomous multi-property-driven molecular discovery: from predictions to measurements and back. Science 382, 6677 (2023).

Acknowledgements

J.A.B., N.O., M.K., S.S. and M.A. gratefully acknowledge the financial support from Eastman Chemical Company.

Author information

Authors and Affiliations

Contributions

M.A. and J.A.B. conceived the project. J.A.B., N.O., S.S. and M.A. designed the algorithms. J.A.B. programmed the Pareto-mapping algorithm and built the flow platform with M.K. N.O. programmed the digital twin models and performed Shapley analysis under advisement of J.R. and M.A. M.K. conducted the reactor benchmarking experiments. J.A.B. conducted the investigations and data anlayses under advisement of J.R. and M.A. M.A. acquired funding and directed the project. J.A.B., N.O. and M.A. drafted the paper. All authors provided feedback on the paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Chemical Engineering thanks Xiaonan Wang and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data

Extended Data Fig. 1 Different experimental strategies for fundamental and applied studies of homogeneous catalysis.

(a) Manual vs. (b) automated, vs. (c) autonomous experimental catalysis. Autonomous experimentation utilizes intelligent experiment-selection to fast-track unveiling the full performance map (red pins) of each catalyst/ligand system with minimum human intervention and experimental cost. The red flask represents a reactor for homogeneous catalysis.

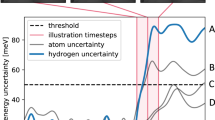

Extended Data Fig. 2 Fast-Cat’s hardware validation and benchmarking to quantify the inherent experimental noise.

a) Reaction stabilization time for a given experimental condition in multiples of the reactor residence time. b) Reaction stability across multiple automatic refills of the syringe pumps from the reagent reservoirs (mean of 3 replicates +/− standard deviation). c) Consecutive in-line GC sampling of a single hydroformylation reaction condition. d) Fast-Cat’s experimental noise via random sampling; starting in-flow hydroformylation reaction with condition 1 followed by 5 randomly selected reaction conditions before returning to condition 1 (labelled as condition 7) (mean of 3 samples at each reaction condition +/− standard deviation). Detailed reaction conditions available in the Supplementary Information section Benchmarking and Validation Conditions.

Extended Data Fig. 3 The hydroformylation reaction space exploration of 1-octene with ligand L1 using the digital twin built by the in-house experimental data of Fast-Cat.

a) Surface plots of predicted aldehyde yield with L1 as a function of (i) pressure and temperature, (ii) pressure and olefin to Rh fraction, and (iii) temperature and olefin to Rh fraction. b) Surface plots of predicted aldehyde regioselectivity with L1 as a function of (i) temperature and H2 flowrate, (ii) temperature and ligand to Rh fraction, and (iii) ligand to Rh fraction and H2 flowrate. For all surface plots shown in panels A) and B), the process parameters other than the two variable parameters used for each surface plot were maintained at a constant value (Xi = 0.25, 0.5 and 0.75) for each surface.

Supplementary information

Supplementary Information

Supplementary Figs. 1–23, Discussion and Tables 1–12.

Source data

Source Data Fig. 3

Statistical source data.

Source Data Fig. 4

Statistical source data.

Source Data Fig. 5

Statistical source data.

Source Data Extended Data Fig./Table 2

Statistical source data.

Source Data Extended Data Fig./Table 3

Statistical source data.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bennett, J.A., Orouji, N., Khan, M. et al. Autonomous reaction Pareto-front mapping with a self-driving catalysis laboratory. Nat Chem Eng 1, 240–250 (2024). https://doi.org/10.1038/s44286-024-00033-5

Received:

Accepted:

Published:

Version of record:

Issue date:

DOI: https://doi.org/10.1038/s44286-024-00033-5

This article is cited by

-

Accelerating primer design for amplicon sequencing using large language model-powered agents

Nature Biomedical Engineering (2025)

-

Autonomous multi-robot synthesis and optimization of metal halide perovskite nanocrystals

Nature Communications (2025)

-

Steering towards safe self-driving laboratories

Nature Reviews Chemistry (2025)

-

Autonomous catalysis research with human–AI–robot collaboration

Nature Catalysis (2025)

-

Ligand-induced self-assembly of twisted two-dimensional halide perovskites

Nature Synthesis (2025)