Abstract

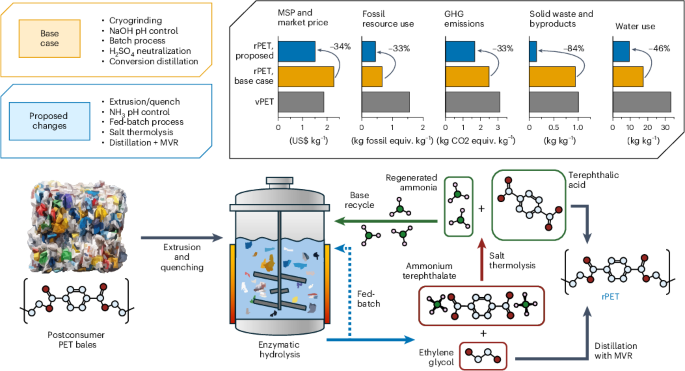

Enzymatic depolymerization of poly(ethylene terephthalate) (PET) has received considerable attention for closed-loop polyester recycling. However, current approaches for enzymatic PET recycling face challenges to achieve commercial viability with lower environmental impacts compared with virgin polyester manufacturing. Here we present multiple process innovations for enzymatic PET recycling that enable economic and environmental feasibility. We show that substrate amorphization through extrusion and quenching is energy-efficient and enables near-quantitative enzymatic conversion in 50 h. Using ammonium hydroxide for pH control and thermolysis of the isolated diammonium terephthalate salt reduces the acid and base consumption by >99%, lowering annual operating expenses by 74%. Fed-batch processing increased ethylene glycol concentration, leading to a 65% reduction in energy consumption for ethylene glycol recovery. These improvements were modeled in an optimal process, with recycled PET estimated to be US$1.51 kg−1 relative to US domestic virgin PET at US$1.87 kg−1 and eliminating key life cycle obstacles to scale this technology.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The authors declare that the data supporting the findings of this study are available within the Article and its Supplementary Information. Source data are provided with this paper.

References

Garcia, J. M. & Robertson, M. L. The future of plastics recycling. Science 358, 870–872 (2017).

Martín, A. J., Mondelli, C., Jaydev, S. D. & Pérez-Ramírez, J. Catalytic processing of plastic waste on the rise. Chem 7, 1487–1533 (2021).

Ellis, L. D. et al. Chemical and biological catalysis for plastics recycling and upcycling. Nat. Catal. 4, 539–556 (2021).

Jehanno, C. et al. Critical advances and future opportunities in upcycling commodity polymers. Nature 603, 803–814 (2022).

Vidal, F. et al. Designing a circular carbon and plastics economy for a sustainable future. Nature 626, 45–57 (2024).

Uekert, T. et al. Technical, economic, and environmental comparison of closed-loop recycling technologies for common plastics. ACS Sustain. Chem. Engin. 11, 965–978 (2023).

Postconsumer PET Recycling Activity in 2018 (National Association for PET Container Resources, 2019).

Mohan, A. M. Untangling the thermoform recycling conundrum. Packaging World https://www.packworld.com/sustainable-packaging/recycling/article/22921860/thermoform-recycling-challenges-and-opportunities (2024).

Allen, R. D. & James, M. I. in Circular Economy of Polymers: Topics in Recycling Technologies (eds Collias, D. I. et al.) Vol. 1391, Ch. 4, 61–80 (American Chemical Society, 2021).

Klotz, M., Haupt, M. & Hellweg, S. Potentials and limits of mechanical plastic recycling. J. Ind. Ecol. 27, 1043–1059 (2023).

The 50 States of Recycling (Eunomia Research & Consulting, 2023).

Werner, M. N. A. et al. Closing the Plastics Circularity Gap (Google & AFARA, 2022).

Peng, Z. S. T. J., Wallach, J., Youngman, A. Advanced Recycling: Opportunities for Growth (McKinsey & Co., 2022).

The New Plastics Economy: Rethinking the Future of Plastics (The Ellen MacArthur Foundation, 2016).

Herriot, A. Plastic Recycling Reimagined: A High-Level Overview of Non-mechanical Recycling (WRAP, 2023).

Tournier, V. et al. An engineered PET depolymerase to break down and recycle plastic bottles. Nature 580, 216–219 (2020).

Wei, R. et al. Possibilities and limitations of biotechnological plastic degradation and recycling. Nat. Catal. 3, 867–871 (2020).

Carniel, A., Waldow, Vd. A. & Castro, A. M. d. A comprehensive and critical review on key elements to implement enzymatic PET depolymerization for recycling purposes. Biotechnol. Adv. 52, 107811 (2021).

Bell, E. L. et al. Directed evolution of an efficient and thermostable PET depolymerase. Nat. Catal. 5, 673–681 (2022).

Arnal, G. et al. Assessment of four engineered PET degrading enzymes considering large-scale industrial applications. ACS Catal. 13, 13156–13166 (2023).

Tournier, V. et al. Enzymes’ power for plastics degradation. Chem. Rev. 123, 5612–5701 (2023).

Oda, K. & Wlodawer, A. Development of enzyme-based approaches for recycling PET on an industrial scale. Biochemistry 63, 369–401 (2024).

Chen, S. et al. Biochemical characterization of the cutinases from Thermobifida fusca. J. Mol. Cat. B 63, 121–127 (2010).

Sulaiman, S. et al. Isolation of a novel cutinase homolog with polyethylene terephthalate-degrading activity from leaf–branch compost by using a metagenomic approach. Appl. Env. Microbiol. 78, 1556–1562 (2012).

Yoshida, S. et al. A bacterium that degrades and assimilates poly(ethylene terephthalate). Science 351, 1196–1199 (2016).

Danso, D. et al. New insights into the function and global distribution of polyethylene terephthalate (PET)-degrading bacteria and enzymes in marine and terrestrial metagenomes. Appl. Env. Microbiol. 84, e02773–02717 (2018).

Sonnendecker, C. et al. Low carbon footprint recycling of post-consumer PET plastic with a metagenomic polyester hydrolase. ChemSusChem 15, e202101062 (2021).

Erickson, E. et al. Sourcing thermotolerant poly(ethylene terephthalate) hydrolase scaffolds from natural diversity. Nat. Commun. 13, 7850 (2022).

Seo, H. et al. Landscape profiling of PET depolymerases using a natural sequence cluster framework. Science 387, eadp5637 (2025).

Then, J. et al. Ca2+ and Mg2+ binding site engineering increases the degradation of polyethylene terephthalate films by polyester hydrolases from Thermobifida fusca. Biotechnol. J. 10, 592–598 (2015).

Shirke, A. N. et al. Stabilizing leaf and branch compost cutinase (LCC) with glycosylation: mechanism and effect on PET hydrolysis. Biochemistry 57, 1190–1200 (2018).

Son, H. F. et al. Rational protein engineering of thermo-stable PETase from Ideonella sakaiensis for highly efficient PET degradation. ACS Catal. 9, 3519–3526 (2019).

Hong, H. et al. Discovery and rational engineering of PET hydrolase with both mesophilic and thermophilic PET hydrolase properties. Nat. Commun. 14, 4556 (2023).

Lu, H. et al. Machine learning-aided engineering of hydrolases for PET depolymerization. Nature 604, 662–667 (2022).

Cribari, M. A. et al. Ultrahigh-throughput directed evolution of polymer-degrading enzymes using yeast display. J. Am. Chem. Soc. 145, 27380–27389 (2023).

Singh, A. et al. Techno-economic, life-cycle, and socioeconomic impact analysis of enzymatic recycling of poly(ethylene terephthalate). Joule 5, 2479–2503 (2021).

Uekert, T. et al. Life cycle assessment of enzymatic poly(ethylene terephthalate) recycling. Green Chem. 24, 6531–6543 (2022).

Wei, R. et al. Biocatalytic degradation efficiency of postconsumer polyethylene terephthalate packaging determined by their polymer microstructures. Adv. Sci. 6, 1900491 (2019).

Brizendine, R. K. et al. Particle size reduction of poly(ethylene terephthalate) increases the rate of enzymatic depolymerization but does not increase the overall conversion extent. ACS Sustain. Chem. Eng. 10, 9131–9140 (2022).

Chang, A. C. et al. Understanding consequences and tradeoffs of melt processing as a pretreatment for enzymatic depolymerization of poly(ethylene terephthalate). Macromol. Rapid Commun. 43, e2100929 (2022).

Thomsen, T. B., Hunt, C. J. & Meyer, A. S. Influence of substrate crystallinity and glass transition temperature on enzymatic degradation of polyethylene terephthalate (PET). N. Biotechnol. 69, 28–35 (2022).

Colachis, M. et al. An efficient and scalable melt fiber spinning system to improve enzyme-based PET recycling. Chem. Eng. J. Adv. 19, 100624 (2024).

Patel, A. et al. Melt processing pretreatment effects on enzymatic depolymerization of poly(ethylene terephthalate). ACS Sustain. Chem. Eng. 10, 13619–13628 (2022).

Sherwood, T. K. Mass Transfer between Phases (Pennsylvania State Univ., 1959).

Rudzki, H. S. Purification of terephthalic acid. US patent 2,829,160 (1974).

Panasyuk, G. P., Azarova, L. A., Budova, G. P. & Izotov, A. D. Synthesis and characterization of ammonium terephthalates. Inorg. Mater. 38, 385–389 (2002).

Murdoch, W. S. Production of terephthalic acid and ethylene glycol from polyethylene terephthalate by ammoniolysis. US patent 6,723,873 B1 (2004).

Kubic Jr, W. L. & Tan, E. C. Reactive extraction process for separating 2,3-butanediol from fermentation broth. Ind. Eng. Chem. Res. 62, 5241–5251 (2023).

Recycling Markets https://www.recyclingmarkets.net/ (2024).

Average Freight Revenue per Ton-Mile (Bureau of Transportation Statistics, 2024); https://www.bts.gov/content/average-freight-revenue-ton-mile

USA Trade Import and Export Data (US Census Bureau, 2024); https://usatrade.census.gov/

Uekert, T., Walzberg, J., Wikoff, H. M., Doyle, M. M. & Carpenter, A. C. Strategies for considering environmental justice in the early-stage development of circular economy technologies. ACS Sustain. Chem. Eng. 12, 8307–8312 (2024).

EPA toxic release inventory (TRI) | Basic search. US Environmental Protection Agency https://guideme.epa.gov/ords/guideme_ext/f?p=guideme:chemical-list-basic-search (2024).

Toto, D. & February, E. D. PET Bale Prices Continue to Climb (Recycling Today, 2024).

Chemical Recycling: Making Fiber-to-Fiber Recycling a Reality for Polyester Textiles (GreenBlue, 2017).

Duijn, H. V. et al. Sorting for Circularity, Europe: an Evaluation and Commercial Assessment of Textile Waste across Europe (Textile Exchange, 2022).

Scaling Textile Recycling in Europe—Turning Waste into Value (McKinsey & Company, 2022).

Alt, H. M. B. et al. Analysis of ethylene glycol and 1,4-butanediol by HPLC-RID. protocols.io https://doi.org/10.17504/protocols.io.6qpvr8wrplmk/v1 (2024).

Humbird, D. et al. Process Design and Economics for Biochemical Conversion of Lignocellulosic Biomass to Ethanol: Dilute-Acid Pretreatment and Enzymatic Hydrolysis of Corn Stover. Report No. NREL/TP-5100-47764 (National Renewable Energy Laboratory, 2011).

Franklin Associates. Life Cycle Impacts for Postconsumer Recycled Resins: PET, HDPE, and PP (The Association of Plastic Recyclers, 2018).

U.S. Life Cycle Inventory Database. National Renewable Energy Laboratory https://www.lcacommons.gov/lca-collaboration/National_Renewable_Energy_Laboratory/USLCI_Database_Public/datasets (2021).

Steubing, B., de Koning, D., Haas, A. & Mutel, C. L. The Activity Browser—an open source LCA software building on top of the brightway framework. Softw. Impacts 3, 100012 (2020).

Mutel, C. Brightway: an open source framework for Life Cycle Assessment. J. Open Source Softw. 2, 236 (2017).

Huijbregts, M. A. J. et al. ReCiPe2016: a harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 22, 138–147 (2017).

Advancing Sustainable Materials Management: 2018 Tables and Figures (US Environmental Protection Agency, 2020).

Nicholson, S. R. et al. The critical role of process analysis in chemical recycling and upcycling of waste plastics. Annu. Rev. Chem. Biomol. Eng. 13, 301–324 (2022).

NAPCOR’s 2022 PET Recycling Report Demonstrates Bottle-to-Bottle Circularity Continues on the Rise (National Association for PET Container Resources, 2023).

Ho, J. et al. Regional Energy Deployment System (ReEDS) Model Documentation (Version 2020) (2021).

Bolinger, M., Wiser, R. & O’Shaughnessy, E. Levelized cost-based learning analysis of utility-scale wind and solar in the United States. iScience 25, 104378 (2022).

Cost and Performance Characteristics of New Generating Technologies, Annual Energy Outlook 2022 (US Energy Information Administration, 2022).

Milbrandt, A., Bush, B. & Melaina, M. Biogas and Hydrogen Systems Market Assessment (National Renewable Energy Laboratory, 2016).

Study on the Use of Biofuels (Renewable Natural Gas) in the Greater Washington, D.C. Metropolitan Area (ICF Resources, 2020).

Acknowledgements

Funding for N.P.M., S.H.D., J.S.D., T.U., B.N.-B., E.L.B., C.A.S., J.E.M. and G.T.B. was provided by the US Department of Energy (DOE), Office of Energy Efficiency and Renewable Energy (EERE), Advanced Materials and Manufacturing Technologies Office (AMMTO) and Bioenergy Technologies Office (BETO). This work was performed as part of the Bio-Optimized Technologies to keep Thermoplastics out of Landfills and the Environment (BOTTLE) Consortium and was supported by AMMTO and BETO under contract no. DE-AC36-08GO28308 with the National Renewable Energy Laboratory (NREL), operated by Alliance for Sustainable Energy, LLC. Funding to N.P.M., J.S.D., A.C.C., M.J.S. and G.T.B. was also provided by the US DOE EERE offices, AMMTO and BETO, under contract no. DE-FOA-0002029, and to N.P.M., J.S.D., B.N.-B. and G.T.B. by the Department of Energy (DOE) Technology Commercialization Funding (TCF), administered by the DOE Office of Technology Transitions. A.R.P. was supported by Research England through the Expanding Excellence in England (E3) scheme, and by BBSRC grants BB/X011410/1 and BB/Y007972/1. The views expressed in the Article do not necessarily represent the views of the DOE or the US Government. The US Government retains and the publisher, by accepting the Article for publication, acknowledges that the US Government retains a nonexclusive, paid-up, irrevocable, worldwide license to publish or reproduce the published form of this work, or allow others to do so, for US Government purposes.

Author information

Authors and Affiliations

Contributions

Conceptualization: N.P.M., S.H.D., J.S.D., A.R.P., J.E.M., M.J.S. and G.T.B. Investigation: N.P.M., S.H.D., J.S.D., T.U., A.C.C., S.M., B.N.-B., E.L.B. and C.A.S. Visualization: N.P.M., S.H.D. and J.S.D. Resources: M.A., H.M.A. and K.J.R. Funding acquisition: J.E.M., A.R.P., M.J.S. and G.T.B. Writing—original draft: N.P.M., S.H.D., J.S.D. and G.T.B. Writing—review and editing: all authors have reviewed and approved of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

N.P.M., S.H.D., J.S.D., A.R.P. and G.T.B. have filed pending US provisional application numbers 63/642,940 and 63/668,257, covering ethylene glycol and terephthalate salt recovery from polyethylene terephthalate enzymatic hydrolysis. G.T.B. is a member of the advisory board of Samsara Eco. The other authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data

Extended Data Fig. 1 Process flow diagram of the enzymatic PET recycling process, adapted from Singh et al.36.

Individual sub-processes are shown as labeled: feedstock pre-treatment of PET subdivided into flake preparation and micronization, enzymatic hydrolysis to EG and TPA; monomer and co-product recovery as subdivided into product clarification, TPA crystallization, and EG distillation; and repolymerization to rPET from EG and TPA. A summary of economic results is provided in Supplementary Table 9.

Extended Data Fig. 2 Univariate sensitivity analysis for the proposed enzymatic hydrolysis process.

a. Percent change in the process MSP for rPET across various process parameters. The 5-year average US market price of $1.87/kg for vPET production36,51 is shown for reference as a dashed gray line. b. Percent change in the GHG emissions for rPET across various process parameters. The emissions for vPET production are shown for reference as a dashed gray line. Figure data are provided in Supplementary Tables 23–24.

Extended Data Fig. 4 Sankey diagram for percent utility consumption in the proposed process.

Steam generated in the recrystallization and compression processes is reused in the evaporation and distillation operations. The final utility percentages include the energy flow in steam generation.

Supplementary information

Supplementary Information

Supplementary Figs. 1–24, Tables 1–27 and discussion.

Supplementary Data 1

Conversion profiles for the bioreactor runs, data used for concentration determinations, and complete reactive extraction dataset.

Source data

Source Data Fig. 1

Numerical values for the graphs in Fig. 1.

Source Data Fig. 2

Numerical values for the graphs in Fig. 2.

Source Data Fig. 3

Numerical values for the graphs in Fig. 3.

Source Data Fig. 4

Numerical values for the graphs in Fig. 4.

Source Data Extended Data Fig. 1

Summary of discounted cash flow analysis for the base-case process shown in Extended Data Fig. 1.

Source Data Extended Data Fig. 2

Numerical values for the graphs in Extended Data Fig. 2.

Source Data Extended Data Fig. 3

Numerical values for the graphs in Extended Data Fig. 2.

Source Data Extended Data Fig. 4

Numerical values used to generate the Sankey diagram in Extended Data Fig. 4.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Murphy, N.P., Dempsey, S.H., DesVeaux, J.S. et al. Process innovations to enable viable enzymatic poly(ethylene terephthalate) recycling. Nat Chem Eng 2, 309–320 (2025). https://doi.org/10.1038/s44286-025-00212-y

Received:

Accepted:

Published:

Issue date:

DOI: https://doi.org/10.1038/s44286-025-00212-y

This article is cited by

-

Recent advances in enzyme engineering for improved deconstruction of poly(ethylene terephthalate) (PET) plastics

Communications Materials (2025)