Abstract

Additive manufacturing (AM) has advanced rapidly, enabling the fabrication of complex, multi-material structures for engineering and biomedical applications. Among soft materials, hydrogels are promising for tissue engineering due to their high water content, biocompatibility, and tunable rheology. However, extrusion-based hydrogel printing still faces challenges including low stiffness, poor structural fidelity, and unstable flow, especially in non-planar, freeform fabrication. Here, we review the recent developments in toolpath optimization for non-planar hydrogel printing. Key progress in extrusion control, slicing algorithms, and multi-axis systems is outlined. We also highlight support-free strategies such as embedded printing, adaptive flow regulation, Eulerian path planning, and neural slicing and their applications in tissue engineering. We conclude that reliable non-planar AM of hydrogels requires coupling material behavior with real-time process control and advanced path planning. Future work should focus on adaptive algorithms for dynamic flow, collision avoidance, and in situ correction to enable precise, functional, biomimetic structures.

Similar content being viewed by others

Introduction

Additive manufacturing (AM) has undergone rapid development in recent years, enabling the high-precision fabrication of components from a wide range of materials, including polymers1, metals2, ceramics3, and hydrogels4. These technological advancements have significantly expanded the applicability of AM by allowing for the integration of material properties tailored to specific functional requirements, such as reduced weight, enhanced biocompatibility5,6,7,8, and improved structural integrity. Alongside material innovations, process-level improvements, particularly in toolpath optimization, have further enhanced the quality, precision, and performance of AM-produced structures9.

Originally developed for rigid materials, toolpath optimization techniques are increasingly being adapted to bioprinting, where the focus shifts to the extrusion of soft, often bioactive, materials. This transition has enabled the fabrication of complex structures that replicate the mechanical and biological characteristics of native tissues10,11. These capabilities are particularly critical in biomedical applications, where printed constructs must not only possess functional integrity but also interact compatibly with biological systems (i.e., living cells).

Despite these advancements, bioprinting with hydrogels, i.e., one of the most commonly used bioinks, remains challenging. A key limitation lies in maintaining a stable and controllable material flow during extrusion while preserving the structural fidelity of the printed form12. This becomes even more complex in multi-directional AM, where changes in extrusion orientation can disrupt flow consistency, leading to defects or mechanical weakness. Consequently, achieving reliable hydrogel-based fabrication requires strategies that support both geometrical complexity and structural precision.

Central to overcoming these challenges is the optimization of extrusion parameters and toolpath design. In particular, maintaining a steady and adaptable hydrogel flow across varying print directions is essential for producing high-quality, multi-directional structures. Addressing this need, the present review investigates the following research question:

How can a steady and adaptable flow of hydrogel be achieved for material extrusion in multi-directional AM through toolpath optimization?

To answer this question, the review article is structured as follows. Section “Hydrogels and their characteristics” highlights the hydrogels commonly used in AM, with a focus on the rheological and mechanical properties of hydrogels relevant to extrusion-based printing. Section “AM techniques for creating hydrogel-based constructs” compares different AM techniques to assess their suitability for multi-directional fabrication and identify overlapping performance criteria. Section “AM techniques for creating hydrogel-based constructs” reviews recent advancements in toolpath optimization, including T-code generation and slicing algorithms, with an emphasis on strategies designed for soft materials. Finally, the insights from material selection, AM methodologies, and process control are combined to propose a framework for improving the stability and adaptability of hydrogel extrusion in multi-directional AM systems.

Hydrogels and their characteristics

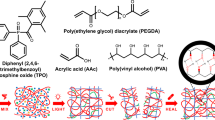

Hydrogels are water-rich, three-dimensional polymer networks formed via chemical or physical cross-linking, typically composed of natural or synthetic polymers. Their ability to absorb and retain substantial amounts of water, generally more than 10% by weight, makes them particularly attractive for biomedical applications such as tissue engineering and biofabrication13.

Mechanically, hydrogels exhibit low stiffness (typically below 100 kPa), high flexibility, and a non-linear stress–strain response, resembling the behavior of soft biological tissues14. Their structural integrity is largely governed by hydrogen bonding and cross-link density. Although they demonstrate large deformations before failure, their low toughness and yield stress limit their standalone mechanical load-bearing capabilities.

Rheologically, hydrogels exhibit viscoelastic and shear-thinning behavior, where viscosity decreases under increasing shear rate, ideal for extrusion-based AM. This property allows smooth flow during deposition and rapid stabilization post-extrusion, which is essential for preserving shape fidelity. Their flow behavior can be described by the Herschel-Bulkley model15,16:

where, τ is the shear stress, τ0 is the yield stress, k is the consistency index, n is the flow index, and \(\dot{\gamma }\) is the shear rate.

Hydrogels are often modified or blended to meet functional requirements. Multi-material approaches, such as combining gelatin with silk fibroin or alginate, enable improved printability, mechanical performance, and biological compatibility5,6. Additives such as calcium phosphate11 or carbon fibers17 are incorporated to enhance stiffness or tensile strength, respectively, supporting applications in both soft and hard tissue engineering.

For reproducible performance in AM, hydrogels must be characterized using standardized benchmarks. Mechanical testing, often via tensile or compressive loading, yields values for elastic modulus, ultimate tensile strength, and toughness, while rheological testing is used to measure parameters such as dynamic viscosity and shear moduli. Due to their fragility, specialized low-force setups are typically employed for accurate evaluation18.

AM techniques for creating hydrogel-based constructs

This section outlines the primary material extrusion (MEX) methods in AM, compares different extrusion mechanisms, and discusses critical process parameters influencing print quality. The aim is to evaluate techniques for their suitability in producing structurally and biologically functional hydrogel-based constructs.

Extrusion mechanisms

In pneumatic extrusion, material is extruded by applying air pressure, typically in the range of 0.1–1 kPa12, through a syringe or reservoir, as illustrated in Fig. 1A. This method is adaptable and cost-effective, offering relatively stable flow and sufficient precision for most (bio)printing applications.

A Extrusion mechanisms: pneumatic-driven (left), piston-driven (center), and screw-driven (right). Figure adapted from12. On the progress of hydrogel-based 3D printing: Correlating rheological properties with printing behaviour. Int. J. Pharm., 615, 121506. https://doi.org/10.1016/j.ijpharm.2022.121506. © 2022 Elsevier. Adapted with permission. B Common material extrusion (MEX) methods: shear thinning, coaxial printing, coagulation bath, and embedded printing. Adapted from57 Copyright 2018, IOP Publishing. C Close-up of coaxial printing with dual-material deposition (outer red shell and white core)58. D Schematic coagulation bath or embedded printing of hydrogels in non-planar configurations depending on the medium. Reproduced from25 [Adv. Mater. 35, 2206958], © 2023 Wiley-VCH GmbH, with permission. E Embedded 3D printing using the core-shell 3D printing combining multiple extrusion methods for enhanced mechanical properties59.

Piston-driven extrusion applies direct mechanical force to extrude material at a controlled rate12. Uniform pressure is applied across the piston surface to produce a continuous material flow. The digitally controlled actuation allows fine adjustments of extrusion rate, offering higher control over pressure compared to pneumatic systems.

Screw-driven extrusion utilizes a rotating screw to convey and compress material toward the nozzle. This mechanism allows for precise control of flow by extruding small volumes per rotation. However, it generally results in a non-continuous, droplet-like deposition pattern12, making it more suitable for applications requiring small, discrete quantities or highly viscous materials.

Material extrusion methods

Shear-thinning

Shear-thinning or direct ink writing (DIW) is an extrusion-based AM technique that deposits viscoelastic inks layer-by-layer through a nozzle (Fig. 1B). Its success relies heavily on the rheological behavior of the ink, particularly shear-thinning, a property where viscosity decreases with increasing shear rate. During extrusion, this behavior allows the material to flow more easily, behaves as a fluid for smooth deposition19,20. Once the material exits the nozzle and shear stress is removed, the viscosity recovers, enabling the printed structure to retain its shape.

Due to the typically slow gelation or solidification of many shear-thinning inks, additional support materials or substrates are often required to prevent deformation or collapse during printing. The precise tuning of shear-thinning behavior is therefore critical to achieving structural fidelity in DIW processes.

Coaxial printing

Coaxial, or core-shell, printing employs a dual-channel nozzle that simultaneously extrudes two materials concentrically (Fig. 1C). This method enables physical separation between a structural outer shell and an often functional or bioactive core. The shell often provides mechanical support, while the core may serve biological purposes, such as cell encapsulation or controlled drug release6.

The balance between flow rates of inner and outer streams is critical for maintaining concentricity and structural fidelity. The total flow rate is given by:

These equations describe the relationship between velocity (v), cross-sectional area (A), and flow rate (Q) for both inner (i) and outer (o) fluids15.

Coagulation bath

In this method, material is extruded directly into a liquid bath containing crosslinking agents21. The bath serves both as a physical support and as a chemical environment for immediate gelation. The interaction between the extrudate and the bath depends on their relative densities and viscosity.

The buoyant force experienced by the material must be lower than the yield stress acting over the contact area to avoid deformation:

where, Δρ is the density difference between bath and extrudate, V is volume, g is gravitational acceleration, σy is the yield stress, and Ah is the contact area22.

While this method enables printing of overhanging or complex structures, clogging is a common issue due to immediate crosslinking upon contact with the bath.

Embedded 3D printing

Embedded 3D printing involves depositing soft materials within a support bath, typically a yield-stress fluid, that provides mechanical stability during extrusion23. Unlike coagulation baths, embedded media are generally viscoelastic and shear-responsive, allowing localized flow around the moving nozzle while preserving the shape of the deposited structure (Fig. 1D, E).

To prevent material from sinking or deforming, the following condition must be met:

Where τy is the yield stress of the bath, ρ is the material density, and h is the depth of the extrudate24.

Higher printing speeds can cause local fluidization around the nozzle, potentially leading to misalignment or structural failure22. Careful tuning of the viscosity ratio between support and extrudate is essential to minimize disturbance during and after printing25.

Freeform reversible embedding of suspended hydrogels (FRESH) exemplifies this approach, where sacrificial support baths can be removed after curing without damaging the printed structure26,27.

Parameterization of 3D printing

The quality of extrusion-based AM is directly influenced by a set of interdependent material, mechanical, and process parameters. Table 1 summarizes the primary factors affecting printability and structural integrity.

The ratio of the path volume to the extruded volume, Vpath/Vout, is often used to control feature thickness. Higher Vout results in thicker extrudates, while high path velocities with low material outflow can cause discontinuities or underfilling (Table 1).

Difficulties experienced in AM of hydrogels

Multi-directional and non-planar AM processes, particularly when using hydrogels, are susceptible to a range of printing errors due to the complex interplay of material properties, extrusion dynamics, and toolpath strategies. This section outlines the most common issues encountered in AM and discusses mitigation strategies to improve structural fidelity and functional outcomes.

Sagging

Sagging refers to the downward deflection of extruded material due to gravitational forces acting on unsupported sections (see Fig. 2A). This is particularly problematic when the distance between support points increases, leading to mid-span deformation. Strategies to mitigate sagging include minimizing unsupported distances and increasing the viscous stiffness of the hydrogel. A stiffer material resists deflection better, preserving structural integrity during and after deposition.

A Sagging resulting from gravitational forces over time, particularly with increased span length. Reproduced from12 [Int. J. Pharm. 615, 121506], © 2022 Elsevier, with permission. B Material accumulation in corners due to over-extrusion. Reproduced from61, with permission. Copyright 2021, Elsevier. C Over- and under-extrusion: left side shows blobs caused by over-extrusion, right side shows disconnected lines due to under-extrusion. Adapated with permission22. Copyright 2019, Royal Society of Chemistry. D Optimized toolpaths with adjusted corner acceleration reduce material overshoot, although precise corner definition remains challenging. reproduced from29 [Addit. Manuf. 29, 100753], © 2022 Elsevier, with permission. E Variable distances between hydrogel collapsing due to filament fusion62.

Small-angle curves

Sharp turns in the toolpath (i.e., those below 120°) are especially challenging to execute with high accuracy. Huang et al.28, found that connecting materials such as carbon wires often fail to produce fully closed corners, leading to weak spots, misalignments, or inconsistent thickness. To address this, toolpaths should be designed to avoid acute angles wherever possible. The problem of small-angle curves as described for carbon-fibers is also applicable to AM using hydrogels. Additionally, secondary issues such as corner rounding, swelling, and ringing (i.e., mechanical vibrations induced by sudden changes in tool movement) can be reduced by lowering print acceleration or increasing system rigidity29.

Over-extrusion

Over-extrusion occurs when the material flow rate exceeds the required deposition rate, leading to excess material accumulation and a loss of dimensional precision (see Fig. 2C-top)22. This issue is often observed in corners or direction changes, where the inner arc receives more material than the outer arc. Inconsistent extrusion can compromise resolution and disrupt scaffold porosity. Proper calibration of extrusion rate and tool acceleration, along with adaptive toolpath planning, can help prevent localized overfilling (Fig. 2B, D).

Under-extrusion

Under-extrusion, or underfill, results from insufficient material flow relative to the movement of the printhead. This leads to discontinuous lines, weak strut connections, and incomplete node formation (see Fig. 2C-bottom)22. In severe cases, mechanical failure can occur due to reduced cross-sectional area. Solutions include optimizing feedrate, increasing applied pressure, or adjusting nozzle geometry to ensure a consistent and adequate material supply.

Filament fusion

When adjacent filaments are printed too closely, surface tension and interfacial adhesion can cause them to merge over time (see Fig. 2E)°. This phenomenon, known as filament fusion, reduces resolution and pore uniformity, particularly in grid-like or porous scaffolds12. Materials with low yield stress or insufficient crosslinking are more prone to fusion, resulting in time-dependent shape loss and occlusion of porous architectures.

Clogging

Clogging is commonly caused by excessive material viscosity or premature gelation inside the nozzle. It may also result from low shear rates, which fail to reduce viscosity sufficiently during extrusion12. High concentrations of crosslinking agents worsen this issue by accelerating gelation. Avoiding rapid curing and maintaining optimal material rheology are key to preventing clog formation and preserving continuous flow.

Anisotropic material

Due to the layer-by-layer nature of AM, printed objects often exhibit anisotropic mechanical behavior. Properties along the direction of extrusion are generally stronger and more predictable, while interlayer bonding is weaker, resulting in poor mechanical performance in the perpendicular direction. This anisotropy poses a significant limitation in load-bearing applications. Non-planar toolpath strategies and anisotropy-aware print planning, such as aligning layers with expected stress directions, are essential to mitigate interlayer weakness and improve isotropic performance30.

Multiple degrees of freedom AM

This section highlights advanced AM strategies that utilize increased degrees of freedom (DOF) in the nozzle, print bed, or both. Multi-axis and freeform printing methods expand geometric capabilities beyond conventional planar techniques, offering advantages in surface quality, structural performance, and support-free fabrication.

Multi-axis AM

Conventional layer-by-layer AM techniques are often limited when producing overhangs, inclined features, or complex geometries. Multi-axis additive manufacturing (MAAM) addresses these challenges by introducing additional rotational degrees of freedom in either the nozzle or the build plate, enabling deposition along non-planar paths and varied orientations. As illustrated in Fig. 3A, various configurations exist for orienting both the nozzle and the build plate. Figure 3B highlights the limitations associated with increasing the range of motion between the nozzle and the printed object.

A Various printhead orientations relative to the printed surface. Orientations (3) and (4) align with the surface normal, whereas (1) and (2) align with the z-axis. B Optimal and suboptimal nozzle positions in multi-axis printing: (1-3) show ideal conditions, (4-6) depict failure-prone configurations. Inspired by the figure presented in63. Modified and redrawn by the authors. C Potential collision scenarios between extruded material and nozzle, influenced by nozzle shape, nozzle-object height, and deposition angle64. D Stress-optimized slicing of the Bunny CAD model, where slicing orientation aligns with internal stress directions to improve mechanical performance and surface finish65.

By orienting the printhead or substrate relative to the geometry of the part, MAAM reduces the reliance on support structures and improves surface smoothness. However, this flexibility introduces new constraints related to kinematic control and collision avoidance. During printing, interference between the nozzle and the partially completed structure can result in deposition errors or mechanical failure. These interactions depend on nozzle shape, orientation, clearance, and material swelling or deformation (see Fig. 3C).

To manage these complexities, simulation platforms such as RoboDK31 and MATLAB®’s RobotStudio environment32 are used to plan toolpaths, calculate inverse kinematics, and identify potential collisions. Incorporating the computer aided design (CAD) model into such simulations enables predictive analysis of motion planning and robotic arm positioning.

MAAM can be implemented by adding rotational joints to either the extruder or the print bed. While these additional DOFs provide greater accessibility to undercuts and angular features, they also introduce increased mechanical error and require more complex calibration.

Recent studies focus on applying MAAM to materials with high viscosity and low thixotropy, which are less susceptible to deformation from self-weight or gravitational forces. For instance, Wang et al.1, demonstrated that 3D printed structures deviate from their intended CAD geometry when inadequate compensation is made for deflection and motion errors, particularly in the case of complex objects such as the Bunny model.

Freeform printing

Freeform AM extends the capabilities of MAAM by enabling support-free deposition in 3D through optimized toolpath planning and dynamic orientation. In this approach, both the nozzle and the printed object are continuously reoriented to enable material extrusion along complex trajectories. This allows for fewer printed lines and better alignment with mechanical stress directions, resulting in stronger and more efficient structures.

A key requirement for freeform printing is the use of rapidly solidifying materials. Without the support of underlying layers, slow-curing materials are prone to sagging and collapse. Hydrogels, while attractive for biomedical applications, pose challenges due to their slow gelation and sensitivity to mechanical disturbance during printing.

One significant advantage of freeform printing is the reduced material usage, as support structures are minimized or eliminated. However, this method introduces additional complexity in toolpath planning. Standard 2D slicing algorithms are insufficient for non-planar printing. Instead, advanced slicers such as Neural Slicer1, Slic3r, and Cura12 are required to generate continuous, surface-conforming paths (see Fig. 3D).

Printing freeform structures with hydrogels further increases the risk of collision or deformation, as newly deposited layers may still be in a gelation phase and susceptible to swelling or drift. This necessitates real-time adaptation of the toolpath to prevent material-nozzle interference. Methods such as impedance-responsive path planning are under development to address this issue and will be discussed in the following section.

Process and motion control improvements

To optimize adjustable flow during material extrusion, particularly for soft and non-planar AM, enhancements to current motion control algorithms are essential. Local defects such as over- and under-extrusion, especially prevalent at sharp corners or abrupt trajectory changes, can compromise the structural integrity and fidelity of printed constructs. These issues are often linked to mechanical jerk and abrupt acceleration changes along the toolpath, which conventional G-code-based systems are ill-equipped to handle.

G-code, the widely used standard for AM, operates on a sequential, spatially defined command structure. Each line represents a discrete instruction, executed one after another, typically without regard to the temporal relationship between motions. While effective for basic 2D or 2.5D printing, this approach introduces limitations in continuous flow applications. Specifically, it can result in undesirable stop-start behavior, inconsistent extrusion, and increased wear on hardware, all of which become particularly problematic in non-planar or high-curvature regions.

To overcome these limitations, time-aware control strategies have been introduced. One such strategy is the T-code algorithm, proposed by Propst et al.33, which redefines toolpath planning through time-based motion control. Instead of executing spatial commands one at a time, T-code defines motion along the entire path using synchronized velocity and acceleration profiles. This reduces transient accelerations and decelerations, resulting in smoother printhead trajectories and more consistent material deposition. The benefits are particularly apparent when navigating complex geometries, where conventional G-code may cause flow irregularities, leading to artifacts such as blobs, gaps, or filament thinning.

In practice, T-code is implemented as a supplementary layer. G-code is imported into a Python environment, where the average velocity and acceleration of each toolpath segment are calculated. Time values are assigned accordingly, allowing the printhead to move fluidly between points without intermediate stops. Synchronization “pings” between the printer and the T-code script ensure that temporal and spatial instructions remain aligned, mitigating deviations during printing33.

Although T-code has so far been demonstrated primarily in 2.5D geometries with non-thixotropic materials and single-nozzle setups, it shows promise for extension into multi-material and full 3D non-planar extrusion. For example, printing color gradients using multiple nozzles has revealed that T-code improves material blending and exposes flow behavior more precisely under continuous motion33. Challenges remain, for instance, minimizing color or material bleeding when switching between materials33, but these are active areas for future investigation.

Impedance-responsive toolpath planning

For future applications such as in vivo or on-body printing, the print surface is often non-rigid, irregular, or deformable, conditions that standard AM systems are not equipped to handle. Kucukdeger et al.34, investigated such scenarios by printing directly on biological substrates such as skin, fruit, or meat. In these cases, impedance-responsive control can be used to dynamically adjust the toolpath based on real-time feedback.

Traditional printheads operate blindly with respect to the distance between the nozzle and the substrate, following a precomputed G-code path. An impedance-responsive system introduces feedback capabilities, allowing the printhead to detect proximity to the surface and respond accordingly. When a deviation or potential collision is detected, the toolpath is dynamically updated to maintain a safe and effective extrusion distance34.

This approach is particularly advantageous when printing onto soft or swelling materials, or in scenarios where surface geometry may change during the process. Real-time adjustment of the nozzle height improves deposition consistency and minimizes contact errors.

Chaudhry et al.10 applied this principle in a 4-DOF AM robot capable of producing dermal layers with high precision. The system was able to dynamically update the G-code based on positional feedback, maintaining optimal standoff distances and improving structural fidelity throughout the build.

Toolpath optimization

The manufacturing process in AM is governed by a pre-defined toolpath that dictates how material is deposited across each layer. An effective toolpath must ensure complete and continuous coverage of each layer, while also minimizing geometric and mechanical inconsistencies.

Toolpath planning

Recent developments in non-planar slicing algorithms can be broadly categorized into four key areas of improvement: (i) enhancing surface quality through adaptive curved layers, (ii) aligning material deposition with principal stress directions to improve mechanical performance, (iii) reducing or eliminating the need for support structures, and (iv) minimizing build time35.

Reducing print time requires minimization of both extrusion and non-extrusion movements. Travel time, defined as the movement of the nozzle without material deposition, can be optimized by designing continuous toolpaths and reducing singularities in the mesh. A singularity occurs when the toolpath reaches a node from which further movement is not possible without intersecting already-deposited material36. In complex geometries, toolpaths from different orientations may intersect, increasing the number of singularities and local stress concentrations.

Non-planar slicing approaches typically follow one of two strategies, both of which depend heavily on nozzle orientation. The first orients the nozzle locally normal to the surface of the printed object, often requiring multiple rotational DOFs and robotic actuation to follow curved surfaces. The second strategy orients the nozzle along the negative z-axis (i.e.,\(\left[\begin{array}{ccc}0&0&-1\end{array}\right]\)) using layer stacking and overhang management to approximate curvature, often resulting in the staircase effect (Fig. 3A.1).

The staircase effect, a stepped approximation of curved surfaces, can significantly degrade surface smoothness, especially in applications requiring biocompatibility or tight dimensional tolerances37. This phenomenon is closely tied to tessellation error, defined as the mismatch between the printed mesh and the original CAD geometry due to coarse triangular approximations. To reduce this error, more nodes or finer mesh resolutions are introduced at the cost of increased computation and slicing time9.

Toolpath strategy depends on the intended function of the printed object. For example, in neural slicing, where deposition follows principal stress lines, the printhead must be oriented normal to the object’s surface1. In solid AM structures, hybrid strategies may combine non-planar outer layers for high surface fidelity with planar infill for simplicity and efficiency38. However, in hydrogel-based printing, such separation is less feasible due to the thin-walled and flexible nature of the material.

Where mechanical performance is critical, it is preferred that load-bearing paths align with principal stress tensors, resulting in anisotropic material behavior that matches the functional demands of the final structure.

Toolpath optimization methods

Toolpath optimization aims to enhance specific properties of the printed object, such as strength, resolution, build speed, or material efficiency. While many optimization algorithms have been developed for high-stiffness materials such as polymers, ceramics, and metals, these methods are increasingly being adapted for softer materials with low yield stress, such as hydrogels.

It is important to note that for hydrogel-based AM, internal infill strategies commonly used for stiffer materials are often not applicable, due to the need for open pore structures, lower viscosity, and the biological or mechanical sensitivity of the printed object.

Skeletonization and graph theory-based optimization

In large-scale or geometrically complex models, a common strategy is to reduce the object to a skeletonized graph composed of nodes and struts, extracted from the STL mesh. These nodes represent key structural points, and the toolpath is planned by connecting them in an efficient traversal pattern.

Graph theory is widely used to generate optimized paths through this skeletal structure. In the simplest case, each strut is visited exactly once, creating an Eulerian path that minimizes redundant motion. Huang et al.28, however, proposed allowing selected struts to be revisited to reduce sharp turns and mechanical vibrations, particularly in dense mesh areas.

For non-planar AM, grid-based volumetric structures such as tetrahedral meshes are often employed to define node connectivity. Alternative topologies include hexahedral, gyroid, or diamond structures, each selected based on application requirements, material behavior, and printability. The chosen grid affects not only toolpath complexity but also mechanical properties and support requirements.

Eulerian methods

In grid-based structures such as tetrahedral meshes, Eulerian optimization methods allow for the creation of continuous, support-free paths. The initial node is selected to maximize the probability of completing a layer with minimal singularities.

By applying graph theory and Laplacian matrix analysis, an optimized toolpath can be generated that minimizes disconnected segments and stress concentrations (see Fig. 4A)39. The Laplacian matrix quantifies the connectivity between nodes, where di represents the number of edges connected to node i, and − 1 indicates a connection between nodes i and j:

A Schematic of Eulerian path toolpath optimization in a 7-step process. Reproduced from66, © 2022 Elsevier, with permission. B Minimal surface techniques following the Enneper-Weisenstrass algorithm41. C Schematic of conventional slicing of a layer (left) and slicing following the stress distribution optimization method (right). D Adaptive slicing with non-planar layers as the result of varying nozzle orientation67.

Minimizing singularities is essential to reduce the likelihood of collisions and ensure structural continuity. Singularities not only disrupt mechanical performance but also leave gaps that increase localized stress.

The automated Eulerian route optimization (AERO) algorithm applies graph theory to generate efficient toolpaths for stochastic lattice structures containing hundreds of struts25. Implemented in MATLAB® and Python, AERO uses the Laplacian matrix to build a complete substructure before extending or repeating sections of the lattice. The algorithm prioritizes continuity and redundancy minimization across the entire print path.

Neural and S3 slicing

Liu et al.1, introduced the Neural Slicer algorithm to enable multi-axis 3D printing of objects with over 50 non-planar layers, printed without support structures. This algorithm generates toolpaths that follow the geometry of the surface, with the printhead rotating in multiple axes to align deposition with principal stress directions, particularly along the dominant stress axis σ130.

In combination with the S3 slicing method developed by Zhang et al.9, the toolpath is optimized for structural fidelity, surface quality, and mechanical stiffness. The S3 algorithm evaluates trade-offs among these criteria to select an ideal slicing strategy, particularly effective in large or topologically complex models, such as the Bunny benchmark.

Stress distribution reinforcement

To enhance the mechanical performance of printed components, toolpaths can be aligned with principal stress directions (Fig. 5A). Kipping et al.17, employed finite element method (FEM) simulations to evaluate stress distributions within a material and to determine optimal placement strategies for carbon fiber reinforced polymers (CFRPs). Two primary alignment strategies were proposed: fixed-angle algorithms and geodesic algorithms.

A Side and top view of a bioprinted vascular scaffold with branches. Figure adapted from68. Writing in the granular gel medium. Sci. Adv., 1(8), e1500655. https://doi.org/10.1126/sciadv.1500655. ©2015 The Authors. Published by AAAS. Licensed under CC BY-NC. Used with permission. B A 3D printed scaffold mimicking non-planar geometries used for skin regeneration with an adapted geometry to the surface topography of a wound10. C Handheld bioprinting device enabling in situ scaffold deposition during surgery. Reproduced from47. Adapted from Biofabrication, 2023; DOI: 10.1088/1758-5090/acc42c. D Soft robots movement caused by deformation of the hydrogel structure. Figure adapted from50. Stimuli-responsive polymer-based bioinspired soft robots. Micro Nano Syst. Lett., 11, 6. https://doi.org/10.1186/s40486-023-00167-w. ©2023 The Authors. Published by SpringerOpen under the terms of the Creative Commons Attribution 4.0 International License (CC BY 4.0).

In fixed-angle algorithms the CFRP layers maintained constant, parallel alignment throughout the structure17. These methods are more suitable for flat or moderately curved surfaces. In contrast, geodesic algorithms generated contour-parallel paths that conformed to the surface geometry while aligning with the principal stress vectors. Although geodesic methods offer improved adaptation to stress trajectories, they are less effective for highly convex or complex geometries due to risk of self-intersecting isocontours.

These strategies can be translated to hydrogel-based non-planar AM, where thin-lined scaffolds replicate structural patterns informed by stress directions (see Fig. 4C). Aligning hydrogel filament paths with principal stress directions can improve mechanical reinforcement while preserving flexibility, an essential feature in soft or biocompatible scaffolds.

Heatmap-based toolpath optimization

An alternative strategy for path generation employs analogies from thermal simulations. Shan et al.40 proposed a method in which heat distribution across a CAD model was used to generate curved, support-free layers. In this approach, isotherms (i.e., surfaces of constant temperature) served as substitutes for traditional slicing layers. The thermal gradient, defined between fixed temperature values at the model’s top and bottom boundaries, guides the layer generation process.

This approach ensures that printing paths conform smoothly to the geometry of the object without introducing intersecting or overlapping trajectories. Because thermal gradients are inherently continuous and differentiable, the resulting toolpaths reduce collision risks and eliminate abrupt directional changes. Boundary surfaces are treated as thermally insulated, meaning that the printing direction (aligned with the thermal gradient) is always orthogonal to the local surface normal. This results in a naturally conformal, non-planar deposition process that requires no additional support structures.

Furthermore, the top and bottom surfaces of the model remain smooth and continuous, avoiding stair-stepping effects, as they follow constant-temperature contours. Overall, this method offers a robust, geometry-adaptive framework for toolpath optimization in the fabrication of complex, curved structures.

Minimal surface of a 3D shape

The minimal surface of a 3D shape can be determined using Enneper-Weierstrass parametrization, which defines a triply periodic minimal surface (TPMS) structure for porous scaffolds41. These surfaces exhibit minimal area for a given boundary condition, allowing for the generation of highly porous yet structurally efficient geometries (see Fig. 4B).

Once the surface is generated, it can be reduced to a strut-and-node representation, which may then be evaluated using graph-based methods such as the Laplacian matrix (Eq. (5)). However, this minimal surface does not inherently consider internal stress distributions. To optimize both form and function, it is advisable to combine the parametrization with finite element simulations (e.g., COMSOL Multiphysics or finite element method) to account for mechanical loading scenarios.

For hydrogels, minimal surface structures offer the benefit of reduced material usage and increased porosity, improving diffusion, mechanical compliance, and biocompatibility, key parameters for scaffold design.

NURBS-based toolpath generation

The non-uniform rational b-spline (NURBS) algorithm enables the generation of smooth, stackable, curved surfaces through parametric equations. NURBS surfaces are defined by their degree in the u and v directions and are widely used in CAD software for modeling complex geometries:

This formulation can accurately model conics such as ellipses, hyperbolas, and circular arcs, making NURBS particularly suitable for bioinspired and soft structures10,42. NURBS-based toolpath generation is primarily concerned with surface conformity rather than mechanical optimization.

To improve overall structural performance, NURBS can be coupled with stress-informed path planning. Aligning print layers with principal stress trajectories, especially in multi-material or anisotropic structures, can reduce the need for support and enhance functional performance. However, this is an area of ongoing research, particularly for bioprinting applications where material additions (e.g., fillers or reinforcements) can compromise properties such as biocompatibility or mimetic behavior.

Non-planar deposition with adjustable speed

Atarihuana et al.38 introduced a method to enhance non-planar printing by dynamically adjusting deposition speed and extrusion rate. Their approach addresses common issues such as stair-stepping and inconsistent surface quality by optimizing both trajectory inclination and material flow.

The algorithm builds directly on the tessellated STL mesh, maintaining continuity between triangle surfaces while preserving a constant layer height. To calculate extrusion for each segment, the Euclidean distance between consecutive toolpath points is multiplied by a filament flow factor. This adaptive method allows the extrusion value E to be recalculated for each line, ensuring consistent material deposition:

where, ft is the dimensionless extrusion factor, wt is the line width (typically the nozzle diameter), lt is the layer height, and (xi, yi, zi) represent the local coordinates of two consecutive toolpath points.

By integrating this method into non-planar AM workflows, the toolpath can be adapted in real-time to varying inclinations and curvatures, leading to smoother surfaces, reduced structural discontinuities, and improved print fidelity, particularly for applications involving soft materials or complex geometries.

Adaptive slicing

Adaptive slicing is a hybrid approach that combines traditional 2.5D printing with non-planar features by varying the layer height across the build (see Fig. 4D). This technique is often used to improve surface quality and reduce overall build time while maintaining geometric accuracy37.

The primary advantage of adaptive slicing lies in its efficiency. Thicker layers are used in less geometrically complex regions, reducing the number of layers required and thereby decreasing print time and travel distance of the nozzle. This accumulation of varied layer heights also helps approximate curvature more effectively than uniform slicing.

However, the method introduces mechanical trade-offs. Layers with increased height, formed by higher extrusion rates, tend to have lower inter-line adhesion due to larger voids between extruded tracks. These regions are also more susceptible to warping. In contrast, thinner layers offer better resolution and bonding but are structurally weaker, more prone to delamination, and have reduced load-bearing capacity due to higher slenderness.

Overall, while adaptive slicing improves surface finish and printing efficiency, its mechanical limitations must be considered, particularly in applications involving load-bearing or biocompatible components10.

Having compared the current optimization strategies used in non-planar AM, it is evident that future toolpath planning algorithms should prioritize two primary objectives: enabling support-free building and enhancing mechanical performance. These factors are especially critical for hydrogel-based structures, where shape fidelity and structural resilience are inherently limited by material properties.

Current advancements of non-planar AM in biomedical applications

This section highlights recent advancements of non-planar AM in biomedical applications, and discusses the need for further expansion of non-planar AM capabilities to meet clinical and functional requirements.

Skin tissue scaffolds

Skin scaffolds require flexibility, conformity to non-planar surfaces, and shape retention post-deposition. Chaudhry et al.10 demonstrated non-planar AM strategies for generating in situ scaffolds tailored to the topography of skin wounds. Figure 5C illustrates scaffold geometries that closely mimic dermal surface contours, minimizing the staircase effect associated with planar layer-by-layer deposition.

This method enables the fabrication of multilayered structures representing the epidermis, dermis, and hypodermis, with the top layer typically under 0.5 mm thick. Tan et al.43 further demonstrated that 2D grids of alginate microgels can be adapted to 3D surfaces, enabling the creation of soft, flexible scaffolds of the skin using the FRESH method.

Multifunctional organ scaffolds

Printing scaffolds for multifunctional soft tissues, such as cardiac, hepatic, or neural tissues, requires precise control over geometry, porosity, and biocompatibility achieved by either embedded 3D printing or FRESH. These tissues are delicate and demand continuous nutrient and oxygen delivery, necessitating vascular networks within the scaffold. The addition of nutrients to the support bath can benefit the compatibility of an organ scaffold.

Hydrogels infused with stem cells have been used to fabricate miniature constructs of the liver, brain, and heart, which remain viable for several days44,45. The presence of vasculature and controlled porosity is critical for ensuring long-term cell survival and tissue functionality.

Vascular scaffolds

Vascular structures, such as capillaries and blood vessels, are often fabricated using coaxial extrusion techniques (see Fig. 5B). A sacrificial core forms the lumen, which is removed post-printing following the FRESH technique, leaving a hollow hydrogel tube. The outer shell supports embedded cells to evaluate biocompatibility and function over time.

Since vascular structures are inherently non-planar and spatially complex, freeform AM technologies are essential for their fabrication. The design of these scaffolds includes control over pore size and porosity to regulate mass transport processes such as osmosis and diffusion, particularly in in vivo applications.

Scaffold-free printing

Scaffold-free AM approaches have emerged as an alternative for producing hollow, vascularized constructs. Xu et al.46 developed an inkjet-based method to print tubular 3D cellular structures in a CaCl2 coagulation bath as support. By decreasing the printhead speed, they achieved rugged overhangs of up to 63° and 5 mm in height.

Christensen et al.21 further confirmed the feasibility of scaffold-free freeform AM for forming tubular geometries with similar diameters in both horizontal and vertical planes. These methods are advantageous for minimizing material waste and eliminating the need for post-processing steps to remove sacrificial supports.

Handheld bioprinting

Handheld bioprinting offers a portable, surgeon-operated solution for in situ scaffold fabrication. Zhao et al.47 developed a compact bioprinter for direct manual deposition of hydrogel-based scaffolds, suitable for applications such as bone, skin, muscle, and dental pulp reconstruction (see Fig. 5C).

This approach allows for rapid, sterile, and biocompatible interventions directly in the surgical field. However, print quality and accuracy are dependent on the skill of the clinician. While ideal for coarse or flexible scaffolds, further development is needed to enable precision fabrication for more delicate or mechanically demanding tissues.

Discussion and future works

The integration of non-planar toolpath planning with soft hydrogel extrusion remains a relatively underexplored area in AM. While hydrogels are well-suited for biomedical applications due to their biocompatibility, water content, and tunable rheological properties, their low yield strength and mechanical stiffness pose significant challenges for freeform, self-supporting 3D printing. Most successful implementations to date, such as tubular or vascular scaffolds, still rely on external support structures or embedding media to preserve shape fidelity.

One of the most effective strategies for support-free hydrogel printing has been embedded 3D printing, where a viscoelastic support bath stabilizes extruded filaments during deposition25. However, this introduces new complexities, particularly concerning the interaction between the nozzle and the surrounding medium. Localized shear thinning and material mixing can alter flow dynamics, highlighting the need for further research into these interactions to improve predictability and consistency of print outcomes23.

Non-planar printing provides a promising alternative to embedded support strategies by enabling self-supporting geometries through advanced toolpath planning. Algorithms such as Eulerian path planning or scaffold-based node connection can enhance shape fidelity without requiring sacrificial materials. However, this transition introduces a new set of challenges, especially in controlling extrusion consistency across complex trajectories and orientations. Sharp turns and curvature-induced variations often lead to under- or over-extrusion, making adaptive flow control critical to maintaining dimensional accuracy.

To address these issues, time-aware control systems such as the T-code algorithm have been proposed to ensure smoother tool motion and reduce mechanical jerk. By replacing traditional stepwise G-code execution with time-based motion control, T-code minimizes disturbances in material flow, resulting in more uniform filament deposition and better resolution, particularly at high-curvature regions33. Combined with computational feedforward models and impedance-responsive sensors, these systems allow real-time correction of toolpath deviations and nozzle positioning34.

Such process control strategies also extend to broader optimization goals. By integrating stress-aware slicing (e.g., neural or heat-map-based algorithms) and geometric adaptation techniques such as NURBS, AM systems can generate toolpaths that conform to both the structural and mechanical requirements of the printed object. These strategies are especially useful in soft robotics and tissue engineering, where the alignment of material deposition with internal stress trajectories improves both shape retention and load distribution48,49.

In particular, non-planar AM opens promising directions for soft robotics. The combination of hydrogels and complex, curvature-informed geometries allows for the fabrication of actuators capable of crawling, morphing (Fig. 5D), or responding to stimuli such as heat, light, or magnetic fields50,51,52. Non-planar toolpath planning further enhances these devices by aligning printed features with functional deformation paths, improving actuation fidelity and overall mechanical performance.

The challenge of integrating hard and soft materials in multi-material AM also stands to benefit from non-planar strategies. Interfaces between materials with drastically different mechanical properties are typically weak points. However, non-planar interlocking geometries and topologically optimized surfaces can improve adhesion and stress distribution across these boundaries, enabling robust transitions between rigid and compliant regions53,54.

Future research should focus on unifying material properties, tool motion, and extrusion parameters into an adaptive toolpath planning framework. Such a framework should dynamically adjust layer height, deposition rate, and print speed based on local curvature and mechanical stress fields. This would enable the construction of more biomimetic and anatomically complex structures with minimal post-processing or support requirements.

From a scalability perspective, most non-planar AM demonstrations remain confined to extrusion-based platforms. However, the underlying principles, such as curvature-aware slicing and stress-aligned deposition, can be extended to other AM modalities such as digital light processing (DLP), polyjet printing, or two-photon polymerization (2PP). For instance, while 2PP offers unmatched resolution, its throughput limitations make it impractical for organ-sized constructs. Introducing non-planar slicing strategies into higher-throughput systems could help bridge this gap, offering a balance between precision and scalability55,56.

Furthermore, expanding non-planar capabilities across platforms could improve surface conformity, reduce support material usage, and enhance tissue integration for regenerative medicine. These improvements will be key to producing large-scale, clinically relevant scaffolds that replicate the mechanical and morphological characteristics of native tissues.

Finally, incorporating collision-aware planning-treating the nozzle as a dynamic obstacle, can increase the reliability of freeform and embedded printing processes. This is particularly relevant in complex environments where printed structures coexist with support media or where in situ bioprinting must accommodate anatomical variability.

Conclusion

This review highlights the current progress of AM with a focus on toolpath optimization for non-planar, hydrogel-based fabrication. While AM has progressed significantly in terms of hardware capabilities and multi-material integration, its application to soft, biocompatible materials, particularly hydrogels, remains limited by challenges in structural stability, flow control, and shape fidelity. The extrusion of hydrogels, characterized by low stiffness and yield strength, requires careful consideration of both material properties and mechanical process parameters to enable the successful formation of complex 3D structures.

Non-planar printing strategies offer a promising direction to address these challenges by enabling the fabrication of freeform geometries with reduced reliance on support structures. However, realizing this potential depends on advances in slicing algorithms, flow rate control, and motion planning. Algorithms such as Eulerian optimization, neural slicing, and heatmap-based path planning show considerable promise for enabling self-supporting geometries and mimicking biologically relevant shapes. Moreover, developments in real-time control of extrusion parameters, such as adaptive velocity and pressure modulation, are essential for maintaining consistency in complex, multi-directional toolpaths.

Biomedical applications, including skin, vascular, and multifunctional soft tissue scaffolds, demonstrate the translational potential of non-planar AM. Yet, realizing clinically relevant outcomes requires further research into integrated material-process-toolpath systems that can ensure precision, repeatability, and biocompatibility.

The future works should aim to couple material rheology, flow dynamics, and toolpath geometry in a unified framework for non-planar printing. Enhancing real-time adaptability, collision avoidance, and in situ feedback mechanisms will be crucial for advancing hydrogel-based AM towards clinical translation and broader applications.

Data availability

No datasets were generated or analysed during the current study.

References

Liu, T., Zhang, T., Chen, Y., Huang, Y. & Wang, C. C. L. Neural slicer for multi-axis 3d printing. ACM Trans. Graph. 43, 1–15 (2024).

Altiparmak, S. C., Yardley, V. A., Shi, Z. & Lin, J. Extrusion-based additive manufacturing technologies: State of the art and future perspectives. J. Manuf. Process. 83, 607–636 (2022).

Román-Manso, B. et al. Embedded 3d printing of architected ceramics via microwave-activated polymerization. Adv. Mater. 35, 2209270 (2023).

Wulle, F. et al. Multi-axis 3D printing of gelatin methacryloyl hydrogels on a non-planar surface obtained from magnetic resonance imaging. Addit. Manuf. 50, 102566 (2022).

Cheng, G. et al. Advanced silk fibroin biomaterials for cartilage regeneration. ACS Biomater. Sci. Eng. 4, 2704–2715 (2018).

Kim, G., Ahn, S., Kim, Y., Cho, Y. & Chun, W. Coaxial structured collagen-alginate scaffolds: Fabrication, physical properties, and biomedical application for skin tissue regeneration. J. Mater. Chem. 21, 6165 – 6172 (2011).

Mirzaali, M., Shahriari, N., Zhou, J. & Zadpoor, A. Chapter sixteen - quality of am implants in biomedical application. In Kadkhodapour, J., Schmauder, S. & Sajadi, F. (eds.) Quality Analysis of Additively Manufactured Metals,689–743, https://doi.org/10.1016/B978-0-323-88664-2.00015-4 (Elsevier, 2023).

Mirzaali, M. J., Moosabeiki, V., Rajaai, S. M., Zhou, J. & Zadpoor, A. A. Additive manufacturing of biomaterials-design principles and their implementation. Materials 15, 5457 (2022).

Zhang, T. et al. S3-slicer: A general slicing framework for multi-axis 3d printing. ACM Trans. Graph. 41, 1–15 (2022).

Chaudhry, M. S. & Czekanski, A. Surface slicing and toolpath planning for in-situ bioprinting of skin implants. Biofabrication 16, 025030 (2024).

Eichholz, K. F. et al. Integrating melt electrowriting and fused deposition modeling to fabricate hybrid scaffolds supportive of accelerated bone regeneration. Adv. Healthc. Mater. 13, 2302057 (2024).

Bom, S., Ribeiro, R., Ribeiro, H. M., Santos, C. & Marto, J. On the progress of hydrogel-based 3d printing: Correlating rheological properties with printing behaviour. Int. J. Pharmaceutics 615, 121506 (2022).

Kaliaraj, G. S., Shanmugam, D. K., Dasan, A. & Mosas, K. K. A. Hydrogels−a promising materials for 3D printing technology. Gels. 9, 260 (2023).

Gandin, A. et al. Simple yet effective methods to probe hydrogel stiffness for mechanobiology. Sci. Rep. 11, 22668 (2021).

Yu, I. & Chen, R. An experimental and numerical study on coaxial extrusion of a non-newtonian hydrogel material. J. Manuf. Sci. Eng., Trans. ASME 143, 081008 (2021).

Schwab, A. et al. Printability and shape fidelity of bioinks in 3d bioprinting. Chem. Rev. 120, 11028–11055 (2020).

Kipping, J., Kállai, Z. & Schüppstuhl, T. A set of novel procedures for carbon fiber reinforcement on complex curved surfaces using multi axis additive manufacturing. Appl. Sci. (Switz.) 12, 5819 (2022).

Ahearne, M. Mechanical testing of hydrogels. The Mechanics of Hydrogels: Mechanical Properties, Testing, and Applications (eds Li, H. & Silberschmidt, V) 73–90 https://doi.org/10.1016/B978-0-08-102862-9.00003-8 (2022).

Davoodi, E. et al. Extrusion and microfluidic-based bioprinting to fabricate biomimetic tissues and organs. Adv. Mater. Technol. 5, 1901044 (2020).

Baniasadi, H. et al. Innovations in hydrogel-based manufacturing: A comprehensive review of direct ink writing technique for biomedical applications. Adv. Colloid Interface Sci. 324, 103095 (2024).

Christensen, K. et al. Freeform inkjet printing of cellular structures with bifurcations. Biotechnol. Bioeng. 112, 1047–1055 (2015).

Wu, Y. et al. Dissecting the interplay mechanism among process parameters toward the biofabrication of high-quality shapes in embedded bioprinting. Adv. Funct. Mater. 34, 2313088 (2024).

Deng, X. et al. All-aqueous embedded 3d printing for freeform fabrication of biomimetic 3d constructs. Adv. Mater. 36, 2406825 (2024).

O’Bryan, C. S. et al. Three-dimensional printing with sacrificial materials for soft matter manufacturing. MRS Bull. 42, 571–577 (2017).

Weeks, R. D. et al. Embedded 3d printing of multimaterial polymer lattices via graph-based print path planning. Adv. Mater. 35, 2206958 (2023).

Hinton, T. J. et al. Three-dimensional printing of complex biological structures by freeform reversible embedding of suspended hydrogels. Sci. Adv. 1, e1500758 (2015).

Patrício, S. G. et al. Freeform 3d printing using a continuous viscoelastic supporting matrix. Biofabrication 12, 035017 (2020).

Huang, Y. et al. Learning based toolpath planner on diverse graphs for 3d printing. ACM Trans. Graph. (TOG) 43, 16 (2024).

Comminal, R., Serdeczny, M. P., Pedersen, D. B. & Spangenberg, J. Motion planning and numerical simulation of material deposition at corners in extrusion additive manufacturing. Addit. Manuf. 29, 100753 (2019).

Fang, G. et al. Exceptional mechanical performance by spatial printing with continuous fiber: Curved slicing, toolpath generation and physical verification. Addit. Manuf. 82, 104048 (2024).

Pierre, J. et al. Non-planar material-extrusion additive manufacturing of multifunctional sandwich structures using carbon-reinforced polyetheretherketone (peek). Addit. Manuf. 84, 104124 (2024).

Zhou, L., An, J., Zhao, R. & Mu, H. Trajectory planning and simulation of industrial robot based on matlab and robotstudio. 2021 IEEE 4th International Conference on Electronics Technology, ICET 2021 910–914 (2021).

Propst, S. & Mueller, J. Time code for multifunctional 3d printhead controls. Nat. Commun. 16, 1035 (2025).

Kucukdeger, E. et al. Automated characterization of macroscale tissue 3d spatial material properties via robotically-directed impedimetric sensing. IEEE Trans. Autom. Sci. Eng. 21, 3408–3420 (2024).

Nayyeri, P., Zareinia, K. & Bougherara, H. Planar and nonplanar slicing algorithms for fused deposition modeling technology: a critical review. Int. J. Adv. Manuf. Technol. 119, 2785–2810 (2022).

Zhang, T. et al. Toolpath generation for high density spatial fiber printing guided by principal stresses. Compos. Part B: Eng. 295, 112154 (2025).

Lettori, J., Raffaeli, R., Borsato, M., Pellicciari, M. & Peruzzini, M. Non-uniform planar slicing for robot-based additive manufacturing. Computer-Aided Des. Appl. 21, 104–118 (2024).

Atarihuana, S., Fernández, F., Erazo, J., Narváez, M. & Hidalgo, V. Optimal strategies for filament orientation in non-planar 3d printing. Processes 12, 2811 (2024).

Zhang, T., Chen, X., Fang, G., Tian, Y. & Wang, C. C. L. Singularity-aware motion planning for multi-axis additive manufacturing. IEEE Robot. Autom. Lett. 6, 6172–6179 (2021).

Shan, Y., Shui, Y., Hua, J. & Mao, H. Additive manufacturing of non-planar layers using isothermal surface slicing. J. Manuf. Process. 86, 326–335 (2023).

Guo, Y., Liu, K. & Yu, Z. Tetrahedron-based porous scaffold design for 3d printing. Designs 3, 16 (2019).

Sharma, S., Singla, E. & Kant, R. Robotic path planning for direct slicing method to minimize support structure in fused filament fabrication process. ACM International Conference Proceeding Series 2023, https://doi.org/10.1145/3610419.3610428 (2001).

Tan, W. S. et al. Development of a new additive manufacturing platform for direct freeform 3d printing of intrinsically curved flexible membranes. Addit. Manuf. 36, 101563 (2020).

Zamanian, B. et al. Interface-directed self-assembly of cell-laden microgels. Small 6, 937–944 (2010).

Skylar-Scott, M. A. et al. Biomanufacturing of organ-specific tissues with high cellular density and embedded vascular channels. Sci. Adv. 5, eaaw2459 (2019).

Lee, H., Jang, T. S., Han, G., Kim, H. W. & Jung, H. D. Freeform 3d printing of vascularized tissues: Challenges and strategies. J. Tissue Eng. 12, 20417314211057236 (2021).

Pagan, E. et al. A handheld bioprinter for multi-material printing of complex constructs. Biofabrication 15, 035012 (2023).

Wang, R. et al. Direct 4d printing of ceramics driven by hydrogel dehydration. Nat. Commun. 15, 1–11 (2024).

Khani, N., Nadernezhad, A., Bartolo, P. & Koc, B. Hierarchical and spatial modeling and bio-additive manufacturing of multi-material constructs. CIRP Ann. 66, 229–232 (2017).

Panda, S., Hajra, S., Rajaitha, P. M. & Kim, H. J. Stimuli-responsive polymer-based bioinspired soft robots. Micro Nano Syst. Lett. 11, 2 (2023).

Moosabeiki, V. et al. Multi-material 3d printing of functionally graded soft-hard interfaces for enhancing mandibular kinematics of temporomandibular joint replacement prostheses. Commun. Mater. 5, 1–11 (2024).

de Jong, P. H., Schwab, A. L., Mirzaali, M. J. & Zadpoor, A. A. A multibody kinematic system approach for the design of shape-morphing mechanism-based metamaterials. Commun. Mater. 4, 1–13 (2023).

Kunkels, L. B. et al. High-performance 3d printed mechanically interlocked soft-hard interfaces of hydrogels and polylactide. Adv. Mater. Technol. 10, 2401081 (2025).

Djumas, L., Molotnikov, A., Simon, G. P. & Estrin, Y. Enhanced mechanical performance of bio-inspired hybrid structures utilising topological interlocking geometry. Sci. Rep. 6, 1–10 (2016).

Li, J. et al. Multi-scale additive manufacturing of 3d porous networks integrated with hydrogel for sustained in vitro tissue growth. Acta Biomaterialia 196, 198–212 (2025).

Yarali, E. et al. 4d printing for biomedical applications. Adv. Mater. 36, 2402301 (2024).

Fazal, F. et al. Co-axial wet-spinning in 3d bioprinting: state of the art and future perspective of microfluidic integration. Biofabrication 11, 012001 (2018).

Shan, J., Kong, Z. & Wang, X. Formation of stable vascular networks by 3d coaxial printing and schiff-based reaction. Gels 10, 366 (2024).

Karyappa, R., Goh, W. H. & Hashimoto, M. Embedded core-shell 3d printing (ecs3dp) with low-viscosity polysiloxanes. ACS Appl. Mater. Interfaces 14, 41520–41530 (2022).

Stankey, P. P. et al. Embedding biomimetic vascular networks via coaxial sacrificial writing into functional tissue. Adv. Mater. 36, 2401528 (2024).

Shin, S. & Hyun, J. Rheological properties of cellulose nanofiber hydrogel for high-fidelity 3d printing. Carbohydr. Polym. 263, 117976 (2021).

Peng, B. Y. et al. A three-dimensional bioprinted copolymer scaffold with biocompatibility and structural integrity for potential tissue regeneration applications. Polymers 14, 3415 (2022).

Chen, Y., Zhang, T., Huang, Y., Liu, T. & Wang, C. C. L. Co-Optimization of Tool Orientations, Kinematic Redundancy, and Waypoint Timing for Robot-Assisted Manufacturing. IEEE Transactions on Automation Science and Engineering 22, 12102–12117 https://doi.org/10.1016/j.addma.2021.102566 (2025).

Maissen, S., Zürcher, S. & Wüthrich, M. Adaptation of conventional toolpath-generation software for use in curved-layer fused deposition modeling. J. Manuf. Mater. Process. 2024, Vol. 8, Page 270 8, 270 (2024).

Fang, G. et al. Reinforced fdm: multi-axis filament alignment with controlled anisotropic strength. ACM Trans. Graph. 39, 1–15 (2020).

Nguyen, L., Buhl, J. & Bambach, M. Continuous eulerian tool path strategies for wire-arc additive manufacturing of rib-web structures with machine-learning-based adaptive void filling. Addit. Manuf. 35, 101265 (2020).

Guidetti, X. et al. Stress flow guided non-planar print trajectory optimization for additive manufacturing of anisotropic polymers. Addit. Manuf. 72, 103628 (2023).

Bhattacharjee, T. et al. Writing in the granular gel medium. Sci. Adv. 1, e1500655 (2015).

Acknowledgements

The authors declare that no external support or assistance was received in the preparation of this work.

Author information

Authors and Affiliations

Contributions

P.V. conducted the literature review, prepared the first draft of the manuscript, and created the figures. M.J.M. provided conceptual oversight, supervised the work, and revised the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

van der Valk, P.C.W.M., Mirzaali, M.J. Non-planar additive manufacturing with hydrogels: a review of flow control and toolpath strategies. npj Soft Matter 1, 5 (2025). https://doi.org/10.1038/s44431-025-00006-5

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s44431-025-00006-5