Abstract

Dou-Gong is one of the key factors in achieving seismic resistance and energy dissipation for timber architectural heritages. This study carried out experimental and numerical research to investigate the lateral hysteretic behavior of three typical Ming–Qing Dou-Gong: DouGong-PingShenKe (DGPS), DouGong-ZhuTouKe (DGZT) and DouGong-JiaoKe (DGJ). Quasi-static cyclic tests were conducted to obtain the failure modes, hysteresis curves, and seismic performance parameters. The results indicated that all specimens exhibited significant sliding and pinching effects, with DGZT and DGJ demonstrating better energy dissipation capacity. Based on the experimental data, refined finite element models were developed and validated, from which the force flow paths were extracted to establish a simplified model. The experiment results can provide a crucial basis for understanding the seismic mechanism of Ming-Qing Dou-Gong, and the simplification method can offer an efficient and reliable tool for the seismic performance evaluation of timber architectural heritages.

Similar content being viewed by others

Introduction

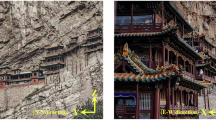

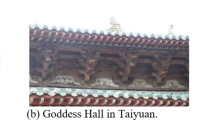

Wood, as a green material, is used to construct buildings especially in ancient times1,2. But the long-term property and flammability of wood pose a threat to timber architecture3,4,5. Dou-Gong is an important structural component, which is widely used in traditional timber architectural heritages, especially in east Asia6. It is not only a structural system, but also a symbol of status. As shown in Fig. 1, in common architecture (1a), Dou-Gong only contains few layers and the size is small, while in significant architecture such as gate towers (1b), Dou-Gong is not only bigger and complex, but is also usually painted with beautiful colors to show the noble status of the building and its owner. The common civilians are not allowed to use Dou-Gong in their house or only can use small and simple Dou-Gong. The officers can live in houses with bigger and more complex Dou-Gong, and the emperor will live in a palace with the highest level of Dou-Gong.

Dou-Gong possess significant cultural value7,8,9. It can be divided into two main types: Dou-Gong in Tang-Song-Yuan dynasties (Song-style) and Dou-Gong in Ming-Qing dynasties (Qing-style). The form and configuration of Song-style Dou-Gong comply with the regulation of “Building Standards of Song Dynasty(营造法式)”, while the Qing-style Dou-Gong is fabricated according to “Rules and Regulations for Construction Engineering of Qing Dynasty(清工部工程做法则例)”. The two types of Dou-Gong are different in size, structure, configuration, et al. Song-style Dou-Gong has more complex structure while the Qing-style Dou-Gong is designed more concisely. Thus, the structural effect of Song-style Dou-Gong is considered to be more pronounced compared to that of Qing-style Dou-Gong10,11. However, during the long-term use, the mechanical properties of Dou-Gong will decrease, causing the instability of the structure.

Many scholars have carried out experimental and numerical studies on the mechanical properties of Dou-Gong12,13,14. Zhang et al. conducted four tests to investigate the failure mode, force-displacement curve, and energy use of Song-style Dou-Gong15. Xue et al. investigated the eccentric compression performance of Qing-style Dou-Gong which set on the columns, they selected three different eccentricity and obtained failure mode, vertical strength, compressive stiffness and deformability of Dou-Gong16. Zhang et al. carried out horizontal quasi-static experiments and finite element simulations on the mechanical characteristics of Xia-Ang in the Song-style Dou-Gong set on columns17. They found that the horizontal stiffness increased 29.41% when the Dou-Gong with Xia-Ang was pushed by the beam. Meanwhile, numerous scholars were dedicated to establish theoretical model to understand the mechanical behavior of Dou-Gong18,19,20. Meng et al. fabricated a 1:2 scale model of a Dou-Gong layer and established a theoretical model for the estimation of the restoring force21. He et al. proposed a rotation and interlayer sliding model based on deformation modes and validated the theoretical results through experiments22. Wang et al. conducted quasi-static tests and developed a theoretical model about the deformation behaviors and hysteresis characteristics of the Puzuo layer(Song-style Dou-Gong)23. Additionally, due to the complexity of Dou-Gong, calculating the refined model needs considerable time and computational resources. Therefore, research on simplified model of Dou-Gong presents an effective methodology. Chen et al. used beam-short column system to simulate the Dou-Gong based on the results of 1:3 scale experiments, and investigated the lateral structural performance of Yingxian Wood Pagoda24. Chen et al. studied the simplified model of Song-style Dou-Gong based on the finite element analysis10. Yang et al. simplified Dou-Gong based on shear plastic hinges, and divided Dou-Gong into multiple connected beams and studied the seismic performance of the Hanging Temple25. However, the aforementioned research mainly focused on Song-style Dou-Gong and their vertical performance.

As shown in Fig. 2, compared with the complex Song-style Dou-Gong, which is characterized by multiple layers, pronounced cantilever components, the Ming-Qing Dou-Gong exhibits distinct geometric and mechanical features. Firstly, its components are smaller in section size and arranged more compactly, following the regulations of “Rules and Regulations for Construction Engineering of Qing Dynasty”. Secondly, the structural form is simplified, often with fewer layers and less pronounced cantilever. The force transfer path in Ming-Qing Dou-Gong tends to be more direct. These inherent differences suggest that the hysteretic behavior, characterized by sliding, pinching, and energy dissipation, could differ significantly from that of Song-style Dou-Gong, generating the inapplicability of the common simplified method. Additionally, Qing-style Dou-Gong are considered as a decorative structure instead of load bearing structure. However, numerous researches have revealed that Qing-style Dou-Gong can still play the role of energy consumption in earthquakes. Therefore, understanding the lateral hysteretic behavior and simplified strategy of Qing-style Dou-Gong is necessary.

In summary, existing research mainly focused on Dou-Gong in Tang-Song-Yuan dynasties. Research on Dou-Gong in Ming-Qing dynasties is lacking. Therefore, this study focused on the typical mid-to-high-level Dou-Gong used in official Ming-Qing dynasty architecture, such as city gates and large halls. The investigative includes three steps: (1) Experiments: quasi-static cyclic tests are first conducted on three typical Ming-Qing Dou-Gong specimens to obtain their fundamental lateral hysteretic behavior, failure modes, and key seismic performance parameters. (2) Numerical analysis: based on the experimental data, validated three-dimensional finite element models are developed to gain deeper insight into the internal force transfer mechanisms and stress distribution. (3) Simplified modeling: by extracting the primary force flow paths from the numerical results, a simplified model is proposed and its accuracy is verified by comparing its predictions with both the experimental results and the refined FE simulations. The results of this research could help understand the structural function of Qing-style Dou-Gong in official buildings and provide a simplified model that can save computational resources.

Methods

Typical Dou-Gong in Ming-Qing dynasties

Dou-Gong is an indispensable component in large-scale traditional Chinese timber buildings. Through the interlocking stacking of multiple layers of Dou and Gong, Dou-Gong is able to effectively dissipate energy through slip, friction, and deformation between components under earthquake, reducing the damage of earthquakes to buildings26,27. Typical Dou-Gong in Ming-Qing dynasties can be divided into three types based on their location: DouGong-PingShenKe (DGPS), DouGong-ZhuTouKe (DGZT) and DouGong-JiaoKe (DGJ). As shown in Fig. 3, DGPS are set between columns and do not connect with columns. DGZT are set on the columns and DGJ are set on the corner.

Three typical Ming-Qing buildings were investigated through filed survey, including Desheng Men(Beijing province), Zhengyang Men(Beijing province) and Bianjing Lou(Shanxi province). The structure of Dou-Gong was obtained which is shown in Fig. 4.

According to the investigation of Dou-Gong structure, the Dou-Gong in Desheng Men was selected as the typical example. The exploded diagram of DGPS, DGZT and DGJ is shown in Fig. 5.

Preparation of typical Dou-Gong specimens

The species of wood have great influence on the mechanical properties of Dou-Gong. First, the wood species were tested. As shown in Fig. 6, the boundary between earlywood and latewood is clear, with earlywood being red-brown and latewood being brown. The transverse section of the tracheids in earlywood are square or polygonal, while that of tracheids in latewood is flat and rectangular. The earlywood tracheids show obvious helical thickening. The wood rays are divided into two types: single row and spindle shaped. Based on the microstructure of the wood species, the sample was identified as Pinaceae.

The same wood species were used to prepare Dou-Gong specimens, the density of which is 471.6 kg/m3, and the moisture content of which is coordinated to 12%. The specimens were constructed at a 1:3 scale based on surveyed dimensions of historical Dou-Gong. The prepared specimens are shown in Fig. 7. Additionally, the mechanical properties of timber were tested in accordance with GB/T 1927–2021. Each parameter was tested five times. The specific test results were shown in Table 1.

Loading scheme

Figure 8 shows the experimental device. The experimental device uses a horizontal actuator (Fig. 8B) to apply horizontal low-cycle repeated loads. The horizontal actuator had a maximum payload capacity of 500 kN and a maximum stroke of 200 mm, which was sufficient to drive the specimens to failure under the designed loading scheme. To ensure the accuracy of the horizontal load, a counterpoise is used as the balance system (Fig. 8A). The fixture was symmetrically arranged on both sides of Zheng-Xin-Fang, fastened by bolts, and connected to the long rod with a triangular one-way hinge, finally connected to the hydraulic actuator. An aluminum frame (Fig. 8D) is installed above the Tiao-Yan-Lin to limit the displacement of the specimens. To simulate the vertical roof load and horizontal load in actual conditions, dumbbell pieces (5 kg each) are hung on the Yan-Lin and Tiao-Yan-Lin (Fig. 8C). The specific weight of dumbbell pieces was calculated according to GB 50009-2012, which is shown in Fig. S1 and Table S1. The loading system was checked and remained stable throughout the quasi-static test process. To more accurately simulate the boundary conditions of Dou-Gong in the timber frames, Fang was used as constraints at the bottom of the experimental device (Fig. 8E). The back of Dou-Gong was constrained with a combination of bolts and steel plates to limit its displacement Fig. 8F).

The horizontal loading process (displacement-controlled) is shown in Fig. 9. The loading amplitudes were set to ±2 mm, ±4 mm, ±6 mm, ±8 mm, ±10 mm, ±12 mm, ±16 mm, ±20 mm, ±24 mm and ±32 mm, with the horizontal actuator at a speed of 2 mm/min. From 1 mm to 24 mm, each amplitude had 3 loops and 2 loops from 24 mm to 32 mm. Before the formal test, a pre-loading cycles was conducted to eliminate initial gaps between the components. After the system reached a stable condition, the displacement zero point was redefined and the formal cyclic loading protocol was conducted.

Method for simplified model

The refined finite-element models of DGPS, DGZT and DGJ, which is of the same size with the tested specimens, were established through ANSYS workbench 2023R1. Solid187 elements were employed to simulate the mechanical behavior of the timber and aluminum alloy frame. “Hard-contact” model was used to simulate the contacts between the components, and the friction coefficient of timber is set as 0.3. The mechanical parameters are determined based on the experimental results and our previous research10,20,28, which is shown in Table 2.

Through a pre-calculation, when the minimum size of the element is 30 mm, the calculation would be the most efficient. Given that this research primarily aims to clarify the force transfer mechanism of Dou-Gong and to develop a simplified model, the finite-element analysis focuses mainly on the elastic stress phase. However, owing to the small dimensions of the hidden dowel and it is mainly under compression perpendicular to grain. Therefore, a bilinear constitutive model is employed. In this model, the elastic modulus in the plastic phase is defined as that of the elastic phase multiplied by a reduction factor (Fig. 10). The nonlinear static analysis was performed using the Sparse Direct Solver. Convergence was based on force criteria with a tolerance of 0.5%.

The refined FE model was subjected to the same constraints, vertical loads and horizontal displacement loads as in the test as shown in Fig. 11.

According to our previous research10, the horizontal load transferring path of Dou-Gong is studied. Based on the numerical results of stress flow, the force flow paths were extracted, and the simplified models Dou-Gon specimens were established, as shown in Fig. 12.

Method for calculating the member dimension

Based on the corresponding relationship between the simplified members and the Dou-Gong specimens, the components in the simplified model can be divided into two types: (1) Components that exist in typical Dou-Gong specimens. (2) Components that do not exist in original specimens.

For the first type of components, which mainly includes Fang, Gong, Qiao and Lin, et al. The cross-sectional dimensions of these components can be directly determined by the original components. The second type of components mainly includes inclined brace I, inclined brace II and central virtual column, which is shown in Fig. 13. The inclined brace I mainly bear the load transferred from Qiao. Thus, contact section height can be taken as l1, and the angle between the contact surface and the inclined brace is γ, Hence, the cross-sectional height can be calculated as l1sinγ, and the cross-sectional width can be taken as the width of Shi-Ba-Dou. The main function of inclined brace II is to transfer the load between Fang. The cross-sectional dimensions of inclined brace II can be calculated using the same method with inclined brace I. The cross-sectional height is l2sinθ, and the cross-sectional width is equal to Fang-Tou-Liang or Heng-Wan. For the central virtual column, the cross-sectional dimensions mainly depend on the dimensions of the middle part that provides lateral stiffness resistance. The section with the smallest cross-sectional dimensions of each component on the path can be selected as the cross-sectional dimension of the middle virtual column.

According to the wood embedment theory29, the deformation of wood under compressive stress applied perpendicular to grain consists of two parts. The first is the direct deformation resulting from embedment pressure, while the second is the indirect deformation caused by tension among wood fibers. The profile of the indirectly loaded region can be represented by an exponential curve, as shown in Eq. (1).

where \(\delta\) represents the embedment depth of the rigid body, \(\alpha =\frac{3}{2Z}\) and \(Z\) is defined as the thickness of compressed wood. According to the previous research28, the length of the simplified equivalent deformation area can be calculated by Eq. (2).

Owing to the small geometrical size of the hidden dowel, the indirectly loaded area will decrease if the length of the deformable region is shorter than \(l\). The corresponding deformation pattern of the hidden dowel is illustrated in Fig. 14.

\({\delta }_{y}\) is the yield displacement and can be expressed as Eq. (3):

Where \({C}_{x}=\frac{2}{\alpha h}\left(1-{e}^{-\frac{3\alpha a}{2}}\right)+1\), \({C}_{y}=1+\frac{1}{\alpha {na}}\left(1-{e}^{-\frac{3\alpha {na}}{2}}\right)+1\), \({C}_{{mx}}=\frac{8}{\alpha h}+1\) and \({C}_{{my}}=\frac{4}{\alpha {na}}+1\). \({f}_{m}\) is the compressive strength perpendicular to grain, \(n\) is related to the orientation of the wood grain.

The resultant force Fi (i = 1, 2, 3) caused by deformation is shown in Eq. (4):

where \({V}_{i}\), \({V}_{e,i}\), \({V}_{p,i}\) are the total deformation volume, elastic deformation volume and plastic deformation volume, and \(r\) is the ratio of the slopes of the plastic and elastic deformation area on a stress-train diagram30.

The relevant parameters can be obtained by Eqs. (5)–(8):

As shown in Fig. 15, the stress analysis of Gong is given by Eq. (9):

The stress analysis for the hidden dowel can be expressed as Eqs. (10)–(12):

The critical angle θ at the ultimate load and its corresponding secant slope k are obtained by solving the relationship between the horizontal load \(P\) and \(\tan \theta\), as expressed in Eqs. (5)–(8). Consequently, the lateral stiffness of the typical unit is given by D = k/H.

In the simplified model, the typical unit is represented by three beam elements connected by hinges at the bottom. These members possess identical cross-sections, expressed as \({\kappa }_{1}b\times {\kappa }_{1}b\), where κ₁ is determined based on the principle of equivalent lateral stiffness. The equilibrium equation for this simplified system is presented in Eq. (13):

The displacement at the intersection of the members is Eq. (14):

The horizontal can be expressed as Eq. (15):

According to the equivalent lateral stiffness of the origin model and the simplified model, Eq. (15) can be expressed as Eq. (16):

Where \(I=\frac{{{\kappa }_{1}}^{4}}{12}{b}^{4}\), which is the cross-section moment of inertia. The section size reduction factor can be written as Eq. (17):

Results

Failure modes

The loading process of DGPS is shown in Fig. 16. During 2 mm–8 mm, internal gaps between the components of Dou-gong were gradually compressed. At a range of 10 mm–16 mm, there were almost no gaps inside the components, and it was in the static friction stage. Dou-Gong showed obvious shaking, and some components (such as Dou) were damaged. In the 20mm-32mm stage, as the displacement increased, the deformation and compression effect of the timber became more pronounced, with a large amount of timber splitting. At 32 mm, some components were damaged and fell off, and structural failure was observed. The Failure mode of DGPS is shown in Fig. 17. The primary damage manifested as: (1) Splitting and crushing of the wood fibers at the contact interfaces between the Zheng-Xin-Fang, Shi-Ba-Dou and San-Cai-Sheng. DGPS lacks the direct vertical support of a column. Lateral forces are transferred primarily through compressive bearing between stacked components. Under large displacement cycles, high localized compressive stresses perpendicular to the grain at these interfaces exceed the wood’s embedment strength, leading to fiber crushing, particularly at the ends where high compressive stress concentrated (Fig. 17a, b). (2) Slip and separation at the mating surfaces between Ang and Shi-Ba-Dou (Fig. 17d, e). This phenomenon is fundamental to the “semi-rigid” and layered nature of Dougong. Components are primarily stacked and interlocked, not monolithically connected. Under reversed loading, the lack of moment-resisting connections allows for relative slip at mating surfaces once friction is overcome. This slip is a major source of energy dissipation in the early stages. However, the cumulative slip results in permanent offsets, contributing to the overall lateral drift of the assembly. (3) Failure of the mortise-tenon joints, especially the hidden tenons, which exhibited shear cracks and partial withdrawal from its corresponding mortise under the cyclic loading (Fig. 17f). As the Dou-gong deforms laterally, adjacent components experience relative rotation and displacement, translating into tensile and shear forces on the tenons, leading to progressive shear cracking in the tenon.

For DGZT and DGJ, the experimental phenomena were basically similar. Firstly, in the early stage, the input energy was mainly dissipated by the gaps between the components. As the displacement further increased, the gaps decreased, and the timber began to deform and crack. In final stage, the deformation and cracking of the timber further accumulated and some timber components being damaged and detached, resulting in the failure of the structure. The specific experimental process and typical failure modes are shown in Figs. S3–S6.

Hysteresis curves

Based on the sensor data, the hysteresis curves and skeleton curves were drawn, which are shown in Fig. 18. Before the 8 mm cycle, the hysteresis curve of DGPS presented an inverted S-shaped, indicating that the specimen was affected by sliding, and its ductility and seismic energy dissipation capacity tended to weaken. Moreover, due to the asymmetry of the Dou-Gong structure, the hysteresis curve also showed asymmetry. During 8 mm to 12 mm, the hysteresis curve still presented an inverted S-shaped, and the pinching effect was severe. During 12 mm to 20 mm cycles, when the horizontal force pulled outward, the hysteresis curve characteristics presented a Z shape, the slip amount increased, and the energy dissipation capacity significantly weakened. During 20 mm to 32 mm cycles, the shape of the hysteresis curve also exhibited fluctuating characteristics, reflecting the transient shift caused by the damage of internal components of the structure, indicating that the Dou-Gong structure began to fail.

For DGZT, up to the 12 mm cycle, the hysteresis curve consistently remained between a bow shape and an inverted S-shape, reflecting limited ductility and relatively weak energy dissipation capacity, accompanied by an obvious asymmetric response. During the 12 mm to 20 mm cycles, the hysteresis curve characteristics showed that as the displacement increased, the load first increased and then decreased, reflecting that the internal components of DGZT may have been damaged when the displacement was large. At that period, the seismic performance was significantly weakened. During the 20 mm to 32 mm cycles, the slip amount of the hysteresis curve further increased, and the seismic performance weakened.

Before the 8 mm cycle, the hysteresis curve of DGJ was similar to a spindle shape, indicating that when the displacement was relatively small, the DGJ exhibited more ductile behavior and better energy dissipation characteristics. During the 8 mm to 12 mm cycles, the hysteresis curve exhibited a Z-shaped characteristic, with an increasing in slip and a weakening of seismic performance. During the 12 mm to 20 mm cycles, the hysteresis curve characteristics still presented a Z-shape. During the 20 mm to 32 mm cycles, the Z-shaped hysteresis curve became more pronounced, the slip amount increased, and the energy dissipation capacity weakened significantly.

In general, due to the different location, the hysteresis curves of three Dou-Gong showed distinct different. DGPS exhibited the most pronounced pinching effect, with significant contraction observed in the middle segment of the curve. This indicated substantial stiffness degradation and a notable slip recovery during reverse loading. In comparison, the pinching behavior of DGZT and DGJ was relatively mild. Their curves appeared fuller, especially under small displacements, suggesting tighter contact among internal components and less sliding. In terms of hysteretic curve symmetry, DGPS displayed obvious asymmetric characteristics, with marked differences in positive and negative load-bearing capacities. This asymmetry was attributed to its arrangement between columns and the corresponding asymmetric load transfer path. DGZT also showed a certain degree of asymmetry, though to a lesser extent. In contrast, DGJ maintained good symmetry under small displacements, reflecting a more uniform structural configuration and better coordinated force distribution.

The skeleton curves of DGZT and DGJ were S-shaped and anti Z-shaped, respectively, showing nonlinear characteristics and having elastic and yield stages. However, the skeleton curve of DGPS was comparatively different. This might be because the structure of DGPS was simpler, and the sliding effect between components was relatively weaker. Meanwhile, it showed a brief initial increase in secant stiffness due to rapid gap closure, although its overall stiffness remained the lowest among the three types throughout the test.

The ductility coefficients of three types of Dou-Gong are shown in Table 3. It can be found that the ductility coefficients of three specimens are different. DGZT demonstrated the most balanced and ductility performance, with coefficients of 5.79 and 6.56 in the positive and negative directions, respectively, indicating stable hysteretic energy dissipation. In contrast, DGPS exhibited strong directional asymmetry, with a ductility coefficient of only 1.64 in the positive direction compared to 8.40 in the negative direction. DGJ showed the most limited ductility overall, with values of 1.29 and 2.70 in the positive and negative directions, suggesting a more brittle failure mode and restricted plastic deformation capacity. Additionally, all the Dou-Gong showed asymmetric in the positive and negative direction. The ductility coefficients of negative direction are larger than positive direction.

Comparison of seismic properties

In order to further understand the seismic performance of three types of Dou-Gong. The overall envelope area and secant stiffness are selected to evaluate the hysteretic performance. The secant stiffness is calculated by Eq. (18):

where F+ and F− are the positive and negative peak loads during each loading cycle, U+ and U− are the corresponding displacements, kT is the secant stiffness. The stiffness calculation method is shown in Fig. 19.

The secant stiffness reflects the real stiffness with different loading conditions during the hysteretic test31. As shown in Fig. 20, the general trend of secant stiffness decreases with the increase of load amplitude. The secant stiffness of DGPS and DGZT experienced an upward trend in the beginning of the loading process, which may be generated by the gap between the components. The residual stiffness of DGPS, DGZT and DGJ is 56.81%, 19.63% and 15.57% of the initial stiffness, respectively.

The envelope area of hysteretic curves can reflect the energy dissipation capacity. The experimental results are shown in Fig. 21. It can be seen that the energy dissipation capacity of all Dou-Gong specimens under positive loading is better than that under negative loading, especially DGPS. Considering the negative direction enters the slip stage earlier, the structure shows an instable trend in this direction. The envelope area of DGZT and DGJ is 152.3% and 122.2% larger than that of DGPS, indicating that DGZT and DGJ have better energy dissipation capacity. The observed differences in energy dissipation capacity may be partly attributed to their distinct positions and the associated boundary conditions. The locations of DGZT and DGJ likely facilitate different force-transfer mechanisms compared to DGPS, contributing to their larger envelope areas. Other factors, including specific component geometries and the evolution of internal damage, also influence the hysteretic behavior.

Validation of the simplified model

According to the aforementioned method, the simplified model was established. ANSYS was used for analysis, and the results were compared with those of the refined model to verify the reliability of the simplified model. In order to meet the modeling requirements of large-scale buildings, beam elements were used for simulation. The material parameters and boundary conditions were consistent with those of the refined model. The vertical load was applied to the purlin by line load, and the horizontal force was applied at both ends of the beam, without considering complex contact conditions. Compared to regular FE model, the simplified model can greatly save computational resources. The comparison of refined model and simplified model is show in Table 4 in which can be observed that the element and node number of the simplified model is only 1.02%–6.99% of that of refined model. In addition, it takes 10–20 h to complete the calculations for the refined FE model, while the simplified model only requires 1–2 min, indicating an increase in computational efficiency.

The finite element analysis results of three Dou-Gong at the maximum loading displacement are shown in Fig. 22. Where O represents the outward pulling of the horizontal force direction, I represents the inward pulling of the horizontal force direction, Max is the maximum combined stress, Min is the minimum combined stress. The results show that the stress distribution of the simplified model is consistent with the stress flow of the refined model.

The comparison of skeleton curves and secant stiffness is shown in Fig. 23. For DGPS and DGJ, the skeleton curves of both experimental and simplified model are consistent. However, due to the existence of knot, oblique grain and other defects, the variability of wood mechanical properties is large, and the errors in the processing of Dou-Gong specimens are difficult to avoid, while the friction slip behavior in Dou-Gong components depends on the complex contact interaction between many single components, so it is difficult for the simplified beam-element model to fully replicate the accurate cyclic slip viscosity behavior and local damage evolution. Therefore, the simplified results showed a little different at the displacement of 20 mm to 32 mm. The trend of secant stiffness change is the same, but the specific value of simplified results is different. While for DGZT, the secant stiffness of simplified model was first at a low level at the beginning, and then increased. But the overall trend of simplified model is consistent with experimental result, indicating that the accuracy of the simplified model is within an acceptable range. Meanwhile, the computational cost of simplified model is greatly reduced. Making the simplified method acceptable for seismic assessment of traditional large-scale architecture.

Discussion

In this study, the lateral hysteretic behavior of three typical Dou-Gong in Ming-Qing dynasties was investigated through experiments and numerical simulations. A theoretical simplified method was proposed and the simplified model was validated by tests and FEM (finite element method) model. The main conclusions are as follows:

-

(1)

The experimental results demonstrate that the lateral behavior of Dou-Gong is characterized by significant sliding, pinching, and progressive stiffness degradation, which are inherent mechanisms for energy dissipation in traditional timber structures. The secant stiffness of all specimens generally decreased with increasing displacement amplitude. DGPS retained the highest residual stiffness (56.81% of initial), whereas DGZT and DGJ experienced more significant stiffness degradation, retaining only 19.63% and 15.57%, respectively, indicating the different function of the three types of Dou-Gong.

-

(2)

A simplified beam-element model was developed based on force flow analysis derived from refined finite element simulations. This model improves computational efficiency by simulating the solid model with beam elements. The element and node number of the simplified model is only 1.02%–6.99% of that of solid model.

-

(3)

The simplified model was validated through finite element analysis, showing good agreement with experimental results in terms of skeleton curves and stress distribution. Although some discrepancies were observed in secant stiffness at large displacements, the overall behavior was consistent, confirming the reliability of simplification method.

Data availability

All data generated during this study are included in this published article.

References

Cui, Z., Chun, Q. & Sun, J. Fire dynamic characteristics of historical timber lounge bridges considering enclosure shapes. Case Stud. Therm. Eng. 74, 106951 (2025).

Song, H., Chun, Q., Han, Y., Gao, X. & Cui, Z. Research on flexural behavior of square and circular cross-section timber beams strengthened with externally bonded and near-surface-mounted hybrid FRP plates. Constr. Build. Mater. 451, 138742 (2024).

Cui, Z. & Chun, Q. Experimental and numerical study on fire development process and fire risk assessment of historic timber lounge bridges. Herit. Sci. 12, 404 (2024).

Cui, Z., Chun, Q., Wang, Z., Lin, B. & Sun, J. Research on mechanical properties and fire resistance of flame-retardant laminated veneer lumber fabricated with fast-growing poplar. Eur. J. Wood Wood Prod. 83, 7 (2025).

Yang, N. & Bai, X. Forecasting structural strains from long-term monitoring data of a traditional Tibetan building. Struct. Control Health Monit. 26, e2300 (2019).

Song, X. et al. Mechanical behavior of a Chinese traditional timber pagoda during construction. Eng. Struct. 196, 109302 (2019).

Zhang, C., Chun, Q., Lin, Y., Han, Y. & Jia, X. Quantitative assessment method of structural safety for complex timber structures with decay diseases. J. Build. Eng. 44, 103355 (2021).

Wu, C. W., Xue, J. Y. & Song, D. J. Experimental and numerical study on the mechanical performance of Dou-Gong bracket at the corner under vertical load. Int. J. Archit. Herit. 18, 526–550 (2024).

Ting, Z., Song, X. F., Zhang, L. & Sun, R. W. Experimental and numerical study on Dou-Gong joint of ancient wooden structure in Qing Dynasty. Int. J. Archit. Herit. 18, 84–101 (2024).

Chen, Q. et al. Simplified calculation model for typical Dou-gong under horizontal load. J. Wood Sci. 70, 54 (2024).

Hua, Y., Chun, Q. & Jia, X. Simplified calculation model for typical Dou-Gong exposed to vertical loads. Buildings 12, 689 (2022).

Li, X. et al. Fire-resistant performance and residual bearing capacity of Dou-Gong brackets in Chinese ancient wooden architecture treated with transparent fireproof coatings. Constr. Build. Mater. 489, 142201 (2025).

Song, D., Xue, J. & Wu, C. Experimental and theoretical study on seismic behavior of Dou-Gong brackets on column under the load in overhanging and width directions. Eng. Struct. 299, 117138 (2024).

Wang, X. et al. Experimental and numerical study on the static and hysteretic behavior of a novel wood isolation device. J. Build. Eng. 49, 104061 (2022).

Zhang, C., Meng, X., Wang, X. & Li, W. Comparative study of the mechanical characteristics of the Song Dynasty Dou-Gong from multiple angles. Int. J. Archit. Herit. 19, 2761–2778 (2025).

Xue, J., Liang, X., Wu, C., Song, D. & Qi, L. Experimental and numerical study on eccentric compression performance of Dou-Gong brackets at column tops. Structures 35, 608–621 (2022).

Zhang, L., Dong, W. & Zhou, T. Study on the mechanical characteristics of Xia-Ang in the Song-style Dou-Gong set on columns. Structures 41, 475–487 (2022).

Wu, Z. J., Wang, X. W., Bu, X. & Dong, J. S. Design and shear bearing capacity calculation of all-welded irregular joints in steel traditional Chinese buildings. Buildings 15, 184 (2025).

Zhang, X. C., Wu, C. W., Xue, J. Y. & Ma, H. Fast nonlinear analysis of traditional Chinese timber-frame building with Dou-Gon. Int. J. Archit. Herit. 14, 1252–1268 (2020).

Zhang, C. W., Chun, Q., Lin, Y. J., Wang, H. Y. & Li, P. Experimental and nonlinear finite-element analysis study on lateral push resistance of San-Dou components perpendicular and parallel to grain in traditional timber buildings. J. Wood Sci. 68, 41 (2022).

Meng, X. J., Li, T. Y. & Yang, Q. S. Lateral structural performance of column frame layer and Dou-Gong layer in a timber structure. KSCE J. Civ. Eng. 23, 666–677 (2019).

He, J., Yang, W., Xie, L. & Wu, J. Theoretical model of restoring bending moment of Zhutou Puzuo based on deformation patterns with emphasize on rotation and interlayer sliding. J. Wood Sci. 71, 33 (2025).

Wang, J., Wang, X., Zhang, X., Sun, Y. & Yang, N. Experimental and theoretical analysis of the lateral performance of the Puzuo layer in traditional timber structure. Int. J. Archit. Herit. 19, 2530–2549 (2025).

Chen, Z., Zhu, E. & Pan, J. Lateral structural performance of Yingxian Wood Pagoda based on refined FE models. J. Build. Struct. 34, 150–158 (2013).

Yang, Z. et al. Seismic vulnerability assessment of historical timber temples: a case study of the Hanging Temple in China. Npj Herit. Sci. 13, 4 (2025).

Qi, L. J. et al. Seismic performance evaluation and engineering application of modern Chinese traditional-style buildings: the state-of-art review. Structures 56, 105022 (2023).

Cao, J. X., Li, X. Y., Liu, Y. Y., Qian, H. & Yu, D. Seismic performance investigation of the Dou-gong joints of traditional Chinese timber structures. Eur. J. Wood Wood Prod. 81, 173–186 (2023).

Lin, Y. et al. Research on the simplified model for early Chinese Dou-Gong under horizontal load. Structures 74, 108570 (2025).

Ogawa, K., Sasaki, Y. & Yamasaki, M. Theoretical modeling and experimental study of Japanese “Watari-ago” joints. J. Wood Sci. 61, 481–491 (2015).

Cheng, X., Shen, B., Liu, W. & Lu, W. Experimental study on mechanical properties of Song-style Dougong joints with Ang. J. Build. Struct. 40, 133–142 (2019).

Eom, T. S., Kim, J. Y. & Park, H. G. Building analysis for inelastic earthquake design of regular moment frames and dual systems addressing moment redistribution. Eng. Struct. 34, 147–154 (2012).

Acknowledgements

This study is supported by National Key Research and Development Program of China [2023YFF0906100] and Key Research and Development Project of Jiangsu Province [BE2022833].

Author information

Authors and Affiliations

Contributions

C. Z.: writing—original draft, visualization, methodology, conceptualization. C. Q.: writing—review & editing, supervision, resources, funding acquisition. Y. Y.: writing—review & editing, methodology, conceptualization. C. Q.: writing—original draft, methodology, investigation. H. Q.: writing—review & editing, investigation. S. X.: writing—review & editing. All authors contributed to the study conception and design.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Cui, Z., Chun, Q., Yuan, Y. et al. Experimental and numerical research on the lateral hysteretic behavior and simplified model of typical Dou-Gong in Ming-Qing dynasties. npj Herit. Sci. 14, 57 (2026). https://doi.org/10.1038/s40494-026-02340-x

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s40494-026-02340-x