Abstract

Amphiphilic lipid formulations, such as self-emulsifying drug delivery systems, offer advantages for enhancing drug release control and expanding their applicability across various administration routes. By integrating microfabrication techniques with these lipid-based systems, additional functionalities such as controlled drug release can be introduced. This can broaden lipid’s potential for advanced biomedical and pharmaceutical applications. However, lipids face major fabrication challenges due to their thermolability, solvent incompatibility, and poor mechanical properties. Here, we present a novel microfabrication route for self-emulsifying lipid drug delivery systems based on thermal imprinting of a stiffness-tunable mold, which stays inflexible during the thermal imprinting step and softens upon swelling for the demolding step. The stiffness tuning process is reversible to some extent through a simple drying process, allowing reuse of the mold. The presented method resolves the issues of mechanical stress and lipid dissolution during the demolding process, enabling the scalable and cost-efficient fabrication of lipid microstructures down to 20 µm resolution and a 5:1 aspect ratio. As a proof-of-concept, we fabricated honeycomb-shaped self-emulsifying drug delivery lipid microstructures on a mucoadhesive film. Lipid microstructure increases the mechanical robustness and accelerates lipid dissolution for sublingual administration of poorly water-soluble drugs. In vivo testing in mouse models confirmed efficient mucosal penetration and submucosal drug accumulation, showing potential as sublingual drug delivery devices.

Similar content being viewed by others

Introduction

Lipids are widely used in the field of drug delivery applications due to their high biocompatibility, biodegradability, capability to encapsulate poorly water-soluble and hydrolysis-sensitive drugs, as well as their self-assembly nature due to hydrophobicity and amphiphilicity1,2. Lipids are fabricated into various drug delivery devices, including lipid nanoparticles2, lipid implants3, and self-emulsifying drug delivery systems4. The controlled shaping of lipids at the micrometer scale can bring advantages to existing drug delivery systems, in particular, to aim for controlled drug release functions from a millimeter-scale implant and minimal invasiveness from lipid nanoparticles. Additionally, the increased interaction of the devices with the surrounding environment can be achieved by harnessing the high surface area to volume ratio and application-specific design that can be achieved with microstructures. Lipid structures with dimensions in the millimeter scale have been fabricated by inkjet printing5,6, material extrusion methods7,8,9, or conventional molding10,11 for drug implants and self-emulsifying drug delivery systems (SEDDS) tablets, while the structuring of lipids at the micron scale has not yet been reported. The main hurdles for the microfabrication of lipids include their poor mechanical properties, low melting temperature, and the incompatibility of lipids with organic solvents, making the use of standard microfabrication processes impossible.

Microstructuring using molds offers high-resolution patterning down to the micro and nanoscale with complex geometries, as exemplified by thermal imprinting (nanoimprinting), mainly used for patterning UV-curable or thermoplastic materials12. Traditionally, thermal imprinting leverages the difference in thermal expansion between the mold and the material to reduce mechanical stress during the demolding process13,14. However, this approach typically requires elevated temperatures over 100 °C, which are incompatible with thermolabile materials such as lipids and many drugs. An alternative strategy involves the use of soft molds with low Young’s modulus, for example, polydimethylsiloxane (PDMS)15,16. While PDMS provides improved mechanical compliance compared to rigid molds, its mechanical properties are still too stiff for extremely fragile structures like lipid microstructures. Furthermore, PDMS’s low Young’s modulus may cause mold deformation during the imprinting process, losing the accuracy of the design replication17,18. An additional solution as a remedy to the mechanical demolding stress is the use of water/solvent-soluble molds, which eliminate mechanical stress during the demolding process and enable complex 3D designs, but the sacrificial stamps can’t be reused19,20.

We have previously demonstrated the fabrication of water-soluble micromolds using two-photon photolithography (TPP), achieving lipid microstructures with a resolution of 2 µm21. While this approach showed significant potential for advancing lipid microstructuring by removing demolding stress, high temperature, and organic solvent exposure, its application was limited to water-immiscible hydrophobic lipids due to the prolonged exposure to water during the selective mold dissolution process. This limits the use of amphiphilic lipids and surfactants, such as SEDDS lipids or lipid nanoparticles, thereby restricting the fabrication of functional lipid microstructures due to the risk of immersion during the mold dissolution process. This compromises the desired drug release profiles and limits the application variability. Moreover, the mold fabrication process is time-consuming and involves manual handling due to the use of TPP and multiple fabrication technologies, making it unsuitable for the scalable production required in commercialization in drug delivery applications.

SEDDS has been developed to improve the oral administration of poorly water-soluble drugs. It is based on forming lipid micelles in which the drugs are dissolved when immersed in water, thus allowing their transport to the gastrointestinal tract4. The surfactant component of SEDDS also improves their mucus penetration22,23,24. Providing SEDDS formulations with specific shapes at the micrometer scale brings additional advantages, particularly in enabling precise control over drug release by tuning the surface-to-volume (S/V) ratio of the structure. Moreover, microstructured SEDDS can significantly improve the structural mechanical properties of the lipid matrix, which is typically fragile in bulk form. These enhancements expand the potential application of SEDDS beyond gastrointestinal delivery to alternative administration routes such as rectal or oromucosal pathways. Although water-soluble molds enabled the fabrication of hydrophobic water-immiscible lipid microstructures by removing mechanical stress in a demolding step, exposure to water or polar solvents during demolding can cause dissolution and displacement of the SEDDS structures composed of amphiphilic lipids and surfactants. Therefore, the development of a suitable mold and demolding method for the SEDDS fabrication process is needed.

In this work, we present a scalable microfabrication route for SEDDS lipid formulations using thermal imprinting of stiffness-tunable molds. The stiffness-tunable mold is composed of polyvinyl alcohol (PVA) is stiff for the thermal imprinting step and softens upon swelling for the demolding process. The presented process not only reduces the stress during the demolding process but also prevents the dissolution of lipid microstructure. SEDDS microstructures are embedded into a mucoadhesive film and applied for sublingual delivery of poorly water-soluble drugs. Enhanced mechanical properties and drug release profile of SEDDS microstructures have been characterized in vitro. The drug delivery performance of this system has been studied both in vitro and in vivo, showing its potential as a promising drug delivery device.

Results

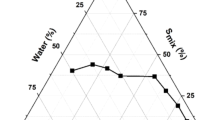

SEDDS lipid formulations play a key role in the dissolution time, size of micelles, and drug loading capacity. In particular, the smaller the micelle, the more efficient the mucus layer penetration and cellular uptake25. Table 1 shows direct light scattering (DLS) measurements of the micelle size for different types of lipids tested with varying mixing ratios dissolved in artificial saliva at 37 °C. All tested lipids are approved for oral administration and commercially available from Gattefossé. Initially, we screened different lipid–surfactant combinations from the Gattefossé excipient list, restricting our selection to materials with melting points above 37 °C to ensure a solid state at room temperature and under physiological conditions. The screening results indicated that the PEG-32 stearate/Suppocire AP combination resulted in the smallest micelle size.

Small micelles with high dissolution rates and high drug solubility are preferred for sublingual drug delivery applications. We screened the dissolution rate and drug solubility with different surfactant ratios. The dissolution rate of the composite is proportional to the surfactant ratio (Fig. S1), and drug solubility is inversely proportional to the surfactant ratio (Fig. S2). The composite of 1:1 PEG-32 stearate and Suppocire AP has a dissolution rate that can fully dissolve in 5 min without critically decreasing drug solubility. The zeta potential of the micelles from the selected lipid composite is –2.43 mV, allowing the micelles to diffuse freely through the mucus layer without ionic interaction. The micelles maintained their average size (13 nm) and zeta potential (−2.45 mV) without significant alteration after 24 h at 37 °C in artificial saliva.

Gelatin-chitosan (GC) film is selected as a substrate for the SEDDS lipid microstructure for its application in drug delivery. The GC film was made with 50 wt% gelatin and 50 wt% chitosan, which are both biodegradable and edible polymers26. Electrostatic interactions between the protonated chitosan and negatively charged mucin layer result in muco-adhesion27. The interpenetration of the polymer chains into the mucin layer induced by the polymer hydration further enhances the muco-adhesion. A GC film with a thickness of 15 µm is prepared by pouring polymer precursor into a mold, followed by drying.

Silicon and PDMS (0.8 MPa Young’s modulus) molds are initially tested for the fabrication of SEDDS lipid microstructure, but they both damaged the fragile lipid microstructure during the demolding process due to mechanical stress (Fig. S3). A conventional PVA mold was immersed in water at 24 °C to achieve selective dissolution and avoid mechanical stress on the lipid structures during demolding. However, the SEDDS formulations fully dissolved before the PVA mold could be completely removed.

The successful fabrication of SEDDS lipid microstructures relies on achieving high pattern fidelity while avoiding damage to the structure during the demolding process, a significant challenge due to the mechanical fragility and solvent sensitivity of lipid materials. A key requirement is a mold material that provides sufficient mechanical strength during thermal imprinting and can be removed without applying damaging stress to the lipid structures. In this work, we introduce a swelling-controlled, stiffness-tunable PVA mold that enables both rigid pattern transfer and gentle, low-stress demolding by tuning its mechanical properties through swelling-induced softening. The mold possesses a high Young’s modulus in the dry state for the thermal imprinting to ensure structural fidelity, and softens into a low Young’s modulus by swelling for the demolding.

PVA, which can swell when immersed in water or other polar solvents, has been chosen for the mold materials. By controlling the degree of swelling, Young’s modulus of swollen PVA mold decreases, but remains intact in shape; thus, it can be demolded from lipid microstructure without applying critical mechanical stress. We chose partially hydrolyzed (∼80%) PVA with low molecular weight (Mw: 85,000–12,400 Da), as it can be swelled and dissolved in a 4 °C 1:1 ethanol/water swelling solvent. The 4 °C temperature was selected to minimize the dissolution of the lipid composite during contact with the swelling solvent (Fig. S4). PVA molds (Young’s modulus: 1.9 GPa) were prepared by casting a PVA solution into a silicon master mold.

The fabrication of the SEDDS lipid microstructure involves four main steps: thermal imprinting using a PVA mold, softening by immersion in a swelling-controlled environment, demolding, and drying (Fig. 1a). For thermal imprinting, PVA molds were imprinted into the lipid film at 0.1 MPa and 45 °C, just above the lipid’s melting point (43 °C). Swelling PVA molds at 4 °C 1:1 ethanol/water condition softened PVA, allowing it to be detached from the substrate without disturbing the lipid microstructure. Although the PVA mold adheres strongly to the lipid after imprinting, detachment is easily achieved because only the mold undergoes swelling. This approach also significantly reduces the lipids’ exposure time to the solvent compared to complete mold dissolution, thereby minimizing lipid loss during demolding.

a Fabrication of SEDDS lipid microstructure: A lipid composite layer placed on top of a gelatin-chitosan film is thermally imprinted using a stiffness-tunable PVA mold. Thermal imprinting of hard PVA mold under 0.1 MPa at 45 °C. Softening of PVA mold by immersion of the PVA mold through immersion in a 50 vol% ethanol/water solvent at 4 °C followed by demolding. The final step involves drying at 24 °C under a vacuum. b Young’s modulus of the swelled PVA mold after immersed in 50 vol% ethanol/water solvent at 4 °C (n = 3.) b Young’s modulus of the dry PVA mold after reuse cycle (immersed in 50 vol% ethanol/water for 6 min and dried) (n = 3, *p < 0.05). d Optical image of the lipid microstructure with 40 µm wall width. e SEM images of honeycomb SEDDS lipid microstructure with wall widths of 20 µm, 40 µm, 80 µm, and 160 µm. f Optical profilometer image of the lipid microstructure with 40 µm wall width. g Optical profilometer scan profile of honeycomb SEDDS lipid microstructure with different wall widths (20, 40, 80, 160 µm) along the white arrow in (d) (n = 3). h Effect of wall width dimension on the fabricated wall width and thickness (n = 3)

To ensure demolding of the PVA mold without compromising the integrity of the lipid microstructure, the degree of swelling of the PVA mold should be controlled. Excessive swelling can lead to deformation or displacement of the lipid microstructure due to expansion of the mold, while insufficient swelling results in a rigid mold that generates mechanical stress during the removal, damaging the structure. To optimize this balance, we systematically evaluated the swelling behavior of PVA films under various solvent conditions, targeting a low swelling to minimize both overexpansion and mechanical stress at 4 °C (Table S1). Through a series of tests using different polar solvents and water/solvent mixtures, we identified a 1:1 (v/v) water/ethanol mixture as the optimal solvent with a controlled swelling ratio of 27%.

Optimizing the immersion time of the PVA mold is important to ensure sufficient softening by swelling without causing lipid dissolution, thereby maintaining the fidelity of lipid microstructure fabrication. Figure 1b presents the evaluation of Young’s modulus of the swelled PVA mold as a function of immersion time in a 1:1 water/ethanol solvent at 4 °C. Starting from the initial Young’s modulus of 1.9 GPa decrease in Young’s modulus continued till 6 min, reached a plateau at 7 min (134 kPa), after the PVA mold became a sticky gel phase, which could not be manipulated with tweezers. Based on these results, an immersion at 1:1 water/ethanol solvent at 4 °C for 6 min was selected to soften the PVA mold adequately for demolding. Additionally, the stiffness-changing process is reversible: the softened PVA mold can be restored to its original stiffness. The practical reusability limit of the PVA mold was determined based on its mechanical properties, as shown in Fig. 1c. This figure presents Young’s modulus of the PVA mold after repeated use (swelling and drying) cycles. While the modulus remains relatively stable through the first three cycles, a significant drop in stiffness is observed after the third reuse. This drop is critical, as the mold must maintain a minimum rigidity of approximately 1 GPa to withstand the thermal imprinting pressure and ensure feature fidelity during molding. Measurements of Young’s modulus after the sixth and seventh cycles revealed values below 1 GPa, indicating that the mold is no longer sufficiently stiff for thermal imprinting. Furthermore, after the third cycle, the mold begins to exhibit visible deformation and distortion following the drying process, compromising replication quality. This mechanical degradation defines a practical reusability threshold of three cycles, beyond which the mechanical integrity and fabrication accuracy can no longer be guaranteed.

The honeycomb shape was selected not only to increase the S/V ratio for fast dissolution time but also to enhance the structural mechanical strength of the thin lipid layer. Four different honeycomb structures with identical hexagon side lengths of 100 µm, each having different wall widths (20, 40, 80, and 160 µm) and a thickness (z-height) of 90 µm, have been designed, fabricated, and characterized. Figure 1d and Fig. S5 show optical images of a representative honeycomb microstructure with 40 µm wall width on a GC film. Figure 1e shows SEM images of honeycomb structures with 20, 80, and 160 µm wall widths. All structures were successfully fabricated at high yield without visible defects. Structures with a wall width below 20 µm could not be fabricated because the PVA mold was damaged during its detachment from the Si mold due to its high aspect ratio.

We measured the dimensions of the lipid microstructure with an optical profiler and compared it with the designed parameters to evaluate the fidelity of the fabrication process. Figure 1f shows the optical profile scan of the 40 µm width device (different widths are shown in Fig. S6). Figure 1g shows the optical profilometer scan profiles of the 20, 40, 80, and 160 µm width lipid microstructure optical profiler scan of the fabricated microstructure, where the plotted lines represent thickness variations measured along the x-direction, which is indicated by the white arrow in Fig. 1f. The profile indicates that the lipid structures are fabricated as designed, with a sharp edge at their sidewalls. The thickness of lipid residues in areas without lipid structures is less than 1 µm. For all four lipid microstructures with different hexagon widths, the fabricated line width decreased by 3 µm from the designed dimension (Fig. 1h). This may be attributed to the shrinkage of the PVA mold or an average of 90% of the Si mold during the drying process (Fig. S7). Figure 1h also shows a reduction in the structure thickness at a smaller hexagon wall width (a 20 µm width structure has 92% of the thickness of a 160 µm width structure). The reduction in structure thickness in narrow wall widths corresponds to the reduction in etching depth of the Si mold in narrower line widths (Fig. S8), which is then replicated in the PVA mold and the final lipid microstructure. This is caused by the aspect ratio-dependent etching (ARDE)28, which is a known limitation of the so-called Bosch process used for the silicon mold fabrication.

The calculated volume, surface area, and S/V ratio of honeycomb SEDDS lipid structures with different wall widths (20, 40, 80, 160 µm) and a lipid film without microstructuring with a thickness of 90 µm in a 2.5 × 2.5 mm rectangle are summarized in Table 2. With a decrease in wall width, the surface and S/V ratio of the lipid structure increase, while its volume decreases. There is more than a 2 times S/V ratio difference between the unstructured lipid film and the honeycomb SEDDS lipid microstructure with 160 µm wall width. According to Noyes-Whitney equation (Eq. 1) where m is the mass and t is time, A is the surface area, D is the diffusion coefficient, h is the diffusion layer thickness, Cs is the solubility of the solute, and C is the concentration of the bulk solution, the dissolution rate of the structure is proportional to the surface area of the solute under diffusion-controlled condition.

The equation justifies the use of microstructure to enhance the dissolution rate of the SEDDS lipid formulation.

The honeycomb SEDDS lipid microstructure was immersed in 50 µL of artificial saliva at 37 °C, and its dissolution was observed over time, as shown in Fig. 2a. The dissolution time was determined visually and corresponds to the moment when the structure loses its original shape. The dissolution rate is calculated by dividing the total microstructure volume by the time required for complete dissolution. The dissolution rate is faster with increasing SA/V ratio, reaching a maximum of 1.6 nL/sec for the structure with the thinnest wall width (20 µm) and a minimum value of 0.15 nL/sec in the unstructured lipid film (Fig. 2b). This validates that microstructured SEDDS lipids can significantly enhance their dissolution rate as expected from the Noyes-Whitney equation (Eq. 1). Equation (1) reflects a linear relationship between dissolution rate and surface area at a fixed time. The non-linear relationship observed in Fig. 2b likely results from the increasing SA/V of microstructures as they dissolve over time, which enhances dissolution kinetics and accelerates material release.

a Dissolution of a honeycomb SEDDS lipid structure with a wall width of 40 µm in artificial saliva at 37 °C over time. b Dissolution rate of SEDDS lipid microstructures with different wall widths and lipid film of the same thickness. (*p < 0.05 tested with the film) (n = 3). c The Strain–Stress curve of a GC film and a SEDDS lipid-coated GC film under elongation slope change at 19% strain is due to the delamination of the lipid film. d Critical strain of film compared to honeycomb structure with wall widths of 40 µm and 20 µm on GC film. (*p < 0.05 tested with the film) (n = 5). e Corresponding optical image of each structure under its critical strain

Figure 2c shows the stress-strain curves of a bare GC film and a GC film coated with a 90 µm SEDDS lipid film under stretching. The GC film has a yield strength of 0.53 MPa with a Young’s modulus of 21.2 MPa, exhibiting plastic behavior until failure at a strain of 54%. The lipid-coated GC film has a yield strength of 0.5 MPa with Young’s modulus of 37.3 MPa. The lipid-coated GC film undergoes plastic behavior with the evolution of cracks on the lipid film until a 19% strain, at which point delamination of the lipid film occurs, continuing until failure at a strain of 53%. This is measured under stretching, while the device undergoes bending during actual sublingual administration, which exerts a strain of less than 10%29, preventing any delamination issues. Young’s modulus of the lipid film, calculated from Eq. 2, is 41.1 MPa:

where E is Young’s modulus of the lipid-coated GC film, Eg is Young’s modulus of the GC, film, and hg is the thickness of the GC film, El is Young’s modulus of the lipid layer, and hl is the thickness of the lipid film.

The SEDDS lipid film exhibits a higher Young’s modulus than the GC composites and relies solely on intermolecular forces (hydrogen bonds, van der Waals forces, dipole interactions) to form a solid structure. The lipid layer is more vulnerable to fracture under mechanical stress compared to the GC film. The honeycomb microstructure is known to enhance the mechanical stability of the structure against stress30. We evaluated the enhanced mechanical stability of the honeycomb SEDDS lipid microstructure on the GC film by its critical strain, which is determined as the strain at which the lipid structure shows the first crack during elongation. Honeycomb SEDDS lipid microstructures with a wall width of 40 and 20 µm on GC films have critical strains of 5.4% and 8.1%, respectively, while the lipid film has a critical strain of only 1.6% (Fig. 2d). Figure 2e shows the corresponding optical image of the films at critical strain. The higher critical strain observed for the 20 µm width microstructure is attributed to the increased hexagon unit density, which distributes force more equally30. These results confirm that the honeycomb design improves the mechanical properties of the fragile SEDDS lipid for our purpose to exploit it as a sublingual drug delivery patch. Implementing patterns with a high S/V ratio with high mechanical stability, such as serpentine or fractal instead of a honeycomb, may also improve the mechanical properties.

To demonstrate the potential of the fabricated SEDDS lipid microstructure as a drug delivery device, we applied it for sublingual drug administration. The fast-dissolving and flexible characteristics of the developed microstructure make it particularly well-suited for this route of delivery. Moreover, by leveraging the solubilization capacity of SEDDS, this platform broadens the range of drugs that can be administered sublingually to include poorly water-soluble compounds, which are traditionally challenging to deliver via this route. Therefore, we embedded honeycomb SEDDS lipid microstructure into mucoadhesive GC film and named it lipid microstructure on a sublingual mucoadhesive patch and abbreviated as “LSMP”.

To show the drug delivery feasibility of the SEDDS lipid microstructure, three different lipophilic drugs (Fenofibrate, Tolfenamic acid, Danazol,) and a lipophilic dye (Dil) with very poor water solubility (<0.5 µg/ml) have been selected as model drugs in this study. These drugs are widely used as representative models for evaluating SEDDS performance in enhancing solubility and oral bioavailability of poorly water-soluble drugs31,32,33, while Dil serves as a hydrophobic fluorescent tracer for visualization of release and distribution. All drugs were dissolved in the molten lipid at a concentration of 20 mg/ml to form lipid-drug composites. Figure 3a displays the FTIR spectra of lipid and lipid-drug composites after lipid microfabrication. There was no alteration in the peaks from the lipid (C = O stretching of ester group at 1750 cm−1) in all 3 lipid-drug composites. The peak of fenofibrate (C = O stretching of Ketone group at 1655 cm−1, and C-Cl stretch peak at 761 cm−1) and tolfenamic acid (C = O stretching of carboxyl group at 1683 cm−1 and N–H band at 1582 cm−1, and C-Cl stretch peak at 764 cm−1) are observed in the FTIR spectra of both the pure drug powder and each lipid composite indicating that no chemical alteration occurred during the dissolution of the drugs into the lipid and the fabrication process. There was no additional peak in the danazol-lipid composite compared to the lipid alone because the intrinsic peak of danazol overlaps with the peak of the lipid, and the intensity of the separate peak is too small to detect.

a FTIR spectra of the lipid, lipid drug composites (same as lipid microstructures), and the pure drugs Danazol, Tolfenamic acid, and Fenofibrate confirm that the drugs remain chemically unaltered after the microfabrication process. b X-ray diffraction patterns of lipid, lipid-danazol, lipid-fenofibrate, and lipid-tolfenamic acid composites after the microfabrication process. In vitro drug release study: Temporal evolution of UV–Vis spectrometry of the supernatant of artificial saliva, when honeycomb SEDDS lipid microstructure (160 µm wall width) contains (c) Fenofibrate, (d) Tolfenamic acid, (e) Danazol, (f) Dil, and (g) lipid microstructure with an 80 µm wall width containing fenofibrate. (n = 3) (The time gap between two consecutive black or blue lines is 20 s. The blue line indicates saturation, the red line indicates the state after 3 h, and the dotted line indicates the spectrum of the solid drug immersed in artificial saliva after 3 h) Evolution of the UV–Vis spectrum of Dil in agarose from honeycomb lipid structure with 160 µm wall (h) with and (i) without GC film. (n = 3) (The time gap between two consecutive black or blue lines is 1 min in Fig. 4h, i)

Figure 3b shows the X-ray diffraction (XRD) analysis of the lipid and lipid-drug composites after the lipid microfabrication process. The lipid exhibits diffraction peaks at 2θ = 18.9° and 23.2°, indicating a semi-crystalline state. There were no additional diffraction peaks in any of the three lipid-drug composites, while solid drug powder showed inherently intense peaks indicating their crystallinity (Fig. S9). This indicates that the lipophilic drugs are fully solubilized in the lipid and do not exist in an undissolved, crystallized state.

To study the in vitro drug release from the lipid microstructure, four lipid microstructures with an identical geometry (160 µm thick width) containing different lipophilic compounds (Fenofibrate, Tolfenamic acid, Danazol, Dil) were immersed in artificial saliva at 37 °C, and the evolution of the UV–Vis spectrum of the supernatant was measured every 20 s until the absorbance reached saturation (blue line), and 3 h after immersion (red line) (Fig. 3c–f). All lipid microstructures showed a gradual increase in their absorbance over time while maintaining their intrinsic UV–Vis peaks. All structures with different drugs saturated above 90% of the absorbance after 3 h, within 260 s while the same dose of drugs in solid powder form immersed in artificial saliva (dotted line) didn’t dissolve much after 3 h. There was no significant difference in saturation time between different molecules: Tolfenamic acid, Danazol, Dil (220s), and Fenofibrate (260s), although their molecular weight is different (Fenofibrate: 360.8, Tolfenamic acid: 261.7, Danazol: 337.5, Dil: 933.89). These results suggest that the dissolution of SEDDS forming lipid micelles is the main mechanism of drug release from the lipid microstructures, and drug release is independent of the type of drug, as long as the drug is dissolved in the lipid composite. This observation is consistent with previous studies on SEDDS, which have shown that drug release kinetics are often governed more by the self-assembly and solubilization behavior of the lipid micelles than by the physicochemical properties of the encapsulated drug itself34.

Drug release kinetics from lipid microstructures were further investigated to understand how they can be controlled by lipid structure design. The in vitro release profile of the lipid microstructures with 80 µm thick wall containing Fenofibrate saturated after 140 s, which is 21% faster than the structures with 160 µm thick wall. Its absorbance after 3 h is also 20% lower because of a correspondingly smaller volume (Fig. 3g). These results are consistent with the differences in volume and dissolution rates of the lipid microstructure prepared in Table 2 and Fig. 2b.

To investigate more realistically the effect of the GC film on the penetration of the released drug into mucosal tissue, lipid structures with and without the GC film were placed on the top surface of an agarose gel and immersed in artificial saliva at 37 °C (Fig. 3h, i). The UV–Vis spectrum of the agarose phantom was measured every minute until saturation and after 3 h. The Dil absorbance of the agarose gel increased over time in both conditions, indicating the penetration of released Dil from the lipid into the agarose. The absorbance of the agarose gel with GC film saturated after 12 min, which is 95% of the maximum absorbance measured after 3 h, while the absorbance of the agarose gel without GC film continued to increase after 12 min and only reached 72% of the maximum value. After 3 h, the absorbance of the agarose gel with GC film is 20% higher than the one without the agarose gel. The GC film enhanced the penetration of the released Dil into the agarose gel by reducing losses to the surrounding medium and acting as a diffusion barrier for dissolved drugs, resulting in the unidirectional release of the drugs into the underlying agarose.

The cytotoxicity of the degradation products of the LSMP was assessed on epithelial cells in vitro. Neither the dissolved lipid SEDDS micelles in artificial saliva nor the degradation product of the GC film in artificial saliva significantly decreased the viability of the epithelial cells after 4 h and 24 h of incubation (Fig. 4a). This result indicated that the lipid microstructures are fully composed of biocompatible materials.

a Cytotoxicity of the LSMP degradation products on HeLa cells. The percentage of cell viability was normalized to untreated cells. Data are presented as mean ± SD. (n = 3) (ns: p > 0.05). b Transepithelial and paracellular transport of Dil (red channel) released from LSMP. Cell nuclei were identified by DAPI (blue channel). c Sublingual mucosal penetration of Dil administered as a liquid formulation (top panel) or from LSMP (bottom panel). d Plasmatic bioavailability of Dil after intravenous (IV) or sublingual (SL) administration. (n = 4) (****p < 0.0001). e Released Dil (red channel) accumulation in the sublingual tissue. Cell nuclei were identified by DAPI (blue channel)

To assess the feasibility of LSMP in delivering a lipophilic API to the sublingual mucosa, Dil-loaded LSMPs were prepared and administered to the sublingual cavity of mice. The tongues of the mice were collected 12 min after administration and the sublingual region was analyzed after nuclear staining (DAPI). The LSMPs dissolved and disappeared in the sublingual cavity after 10 to 15 min. Sections of the sublingual mucosa collected 12 min after LSMP administration showed a paracellular distribution of Dil throughout the sublingual mucosa (Fig. 4b), proving that the lipophilic Dil successfully penetrated through the mucus and the epithelial membrane. Dil was also largely distributed in the submucosa, below the basal lamina. This distribution was not observed when Dil was administered in liquid form in micelle dispersed in PBS, prepared by dissolving the same amount of lipid SEDDS as in the LSMP. In that case, Dil remained on the outer surface of the sublingual mucosa (Fig. 4c). These results further strengthen our hypothesis regarding the effect of the GC film in improving drug absorption by acting as a backing layer, which has been demonstrated previously in vitro in Fig. 3h, i.

To evaluate the blood bioavailability of Dil after sublingual administration, the amount of dye in the plasma was quantified 10 and 30 min after administration and compared to the blood bioavailability after intravenous (IV) administration (Fig. 4d). The plasmatic levels of Dil dropped to around 10% of the initial injected dose 30 min after IV administration, whereas no Dil was measured at this time point after SL administration. This may be due to the high affinity of Dil for lipid-rich cell membranes, which is the primary function of Dil as a cell membrane staining dye35. As seen in Fig. 4e, the penetrated Dil accumulated around the sublingual blood vessels, in the connective tissue, and the muscle compartment, preventing systemic absorption of Dil. Additionally, IV administration results show that Dil has a very short in vivo half-life of 20 min, which may be attributed to its tendency to remain associated with lipid-rich environments such as blood cells or vessels, which results in low plasmatic concentration.

Discussion

Microstructuring SEDDS lipid composites is more challenging than microstructuring water-immiscible hydrophobic lipids. Since SEDDS lipid composites are engineered to be dispersed in aqueous environments, exposure to water or polar solvents during demolding can lead to their dissolution and disintegration. In this study, we developed a potentially scalable and cost-effective micromanufacturing method for SEDDS lipid microstructures using stiffness-tunable PVA molds. The PVA molds are mechanically robust during thermal imprinting and soften through swelling in a water/ethanol mixture at low temperatures. This enables stress-reduced demolding without applying mechanical force, while minimizing the dissolution of the lipid during the demolding process.

State-of-the-art lipid microfabrication using TPP-fabricated water-soluble molds enables high-resolution patterning down to 2 micrometers and supports complex 3D designs21. However, while suitable for prototyping, this approach involves multiple fabrication steps, manual handling, and high costs, making it impractical for large-scale applications. In contrast, thermal imprinting with a stiffness-tunable mold offers a scalable alternative, thanks to its improved process flow and rapid cycle times, and it has the potential for high-throughput production. Also, TPP-fabricated water-soluble molds’ dissolution processes typically require prolonged water immersion, which makes them incompatible with amphiphilic lipid systems like SEDDS, since contact with water leads to self-emulsification or degradation upon water contact, which leads to low drug encapsulation efficiency and dissolution of the microstructure. Furthermore, unlike conventional water-soluble molds that are single-use due to their sacrificial nature, the reversible stiffness-tunable PVA mold can be reused multiple times by simply drying it after the non-destructive demolding process. Additionally, the silicon master mold used to cast the PVA molds is permanently reusable, further reducing material waste and overall fabrication costs, making the process more sustainable and economically efficient for scaled-up production for commercialization of the technology.

The limitation of the stiffness-tunable mold is its design restriction to 2.5D, with a current resolution limit of 20 µm and an achievable aspect ratio of 5:1. This constraint arises from the mechanical challenges of demolding PVA from the silicon master mold, particularly at higher aspect ratios, which can lead to mold deformation or structural collapse. However, this limitation can be mitigated by reducing the aspect ratio of the structures or by applying a superhydrophobic coating to the silicon mold to facilitate the cleaner release of the PVA mold. Despite this constraint, 2.5D structuring can be sufficient for a wide range of biomedical applications, particularly in drug delivery systems where in-plane geometry plays a dominant role in controlling drug release kinetics, S/V ratio, and tissue interaction. For example, in sublingual or mucosal drug delivery patches, flat or film-like geometries are often preferred for optimal adhesion, dissolution, and diffusion36,37. Therefore, while structuring into complex 3D shapes remains to be explored, the accessible resolution and design flexibility of this approach are well-suited to the requirements of drug delivery applications. Stiffness-tunable molds can be used for other unconventional materials for microfabrication with mechanically fragile and solvent-sensitive characteristics, such as biodegradable polymer, sucrose, or food-grade lipids.

In this study, the honeycomb microstructure was fabricated due to its high S/V ratio, which supports efficient drug release, and its inherent mechanical strength, which helps preserve structural fidelity during demolding and sublingual administration. Stress dissipating property of the honeycomb structure is well-established in structural engineering and biological systems30. This helps preserve microstructure fidelity and reduces the risk of collapse or deformation, especially in mechanically fragile materials such as lipids. In addition, the regular packing and high areal efficiency of honeycomb arrays allow for dense and consistent drug loading across the surface. Other geometries, such as radial, serpentine, or fractal patterns, can be explored in future studies to tailor drug release profiles or match specific tissue interfaces

The sublingual route is an interesting delivery route for both systemic and local administration of drugs. Most sublingual drug delivery formulations focus on delivering Class 1 drugs in the biopharmaceutical classification system of active pharmaceutical ingredients, which have high water solubility and high mucus permeability38,39,40,41,42. Other formulations also deliver water-soluble complex primary proteins like vaccines or insulin36,43,44,45,46. Yet, an efficient sublingual administration of lipophilic drugs is challenging to obtain due to their poor solubility in saliva, as well as limited penetration into mucosal tissues. Mucosal penetration could be increased either by the use of permeation enhancers47 or the use of mucoadhesive devices48,49. To overcome the poor water solubility, SEDDS has been used to form drug micelles in an aqueous environment for drug administration4. There are several previous studies that utilized lipid-based SEDDS formulations for sublingual administration of poorly water-soluble drugs. Recently, Friedl et al. developed SEDDS-loaded mucoadhesive patches using electrospun polymer fibers incorporating SEDDS formulations50. Although electrospun microfibers can increase the surface area by forming microstructures, their random deposition results in varying S/V ratios, leading to inconsistent drug release profiles between batches, unlike the precisely micropatterned lipid-based systems in our case. Furthermore, the incorporation of SEDDS into the polymer extends the drug release time to over 1 h, increasing the likelihood of saliva swallowing and patch loss during administration. Lastly, in vivo administration of electrospun fibers showed that the drug distribution was mostly localized near the epithelial membrane, but did not reach the basal lamina blood vessels located below for systemic administration. Our patches allow for deeper penetration of the drugs down to the blood vessels, due to the separated mucoadhesive film, which acts as a backing layer.

For in vivo demonstration of the SEDDS lipid microstructure embedded in a mucoadhesive film as a sublingual drug delivery device, mice were used as an animal model. However, mice have a keratinized epithelium in the sublingual region, unlike humans, which makes drug permeation more difficult. This can be considered a limitation of using mice as an animal model, but conversely, it can be interpreted as overcoming a more challenging permeation condition compared to humans, which facilitates easier translation to human applications. Furthermore, the keratinized layer of the mouse sublingual mucosa is the thinnest among all buccal mucosa51, minimizing the impact of the keratinized layer. In vivo administration of SEDDS lipid microstructures resulted in efficient mucosal penetration of the model drug (Dil) and a broad distribution within the sublingual tissue and mucosa. It could then be interesting to consider SEDDS lipid microstructures for the delivery of drugs with local action directly in the sublingual tissue for medical applications, such as the treatment of buccal infections, tumors of the buccal cavity, or mucosal wound healing50,52,53. An increased retention of drugs in the mucosa is also interesting to avoid systemic delivery and consequently reduce drug side effects on off-target organs in the case of chemotherapy for buccal cancers. However, although systemic administration of the model drug was not shown due to the high affinity of Dil with the cell membrane and its short in vivo half-life, the possibility of systemic administration remains to be investigated in future studies using other poorly water-soluble drugs to demonstrate the proof of concept of SEDDS lipid microstructures for systemic administration. Repeated dosing or the integration of additional permeation enhancers may help to achieve high plasmatic levels54.

Methods

GC film fabrication

A chitosan solution was prepared by dissolving 2 w/v% of chitosan (Low molecular weight, Sigma-Aldrich, St. Louis, MO, USA) into DI water with 1 v/v% acetic acid (Sigma-Aldrich, St. Louis, MO, USA) under 1200 rpm stirring for 1 h. After glycerol was added to the chitosan solution with 10 wt% compared to dry chitosan, a Gelatin solution was prepared by dissolving gelatin (From porcine skin, Sigma-Aldrich, St. Louis, MO, USA) in DI water with a 6 w/v% concentration under 1200 rpm stirring at 70°C for 1 h. Glycerol was subsequently added to the gelatin solution with 10 wt% of dry gelatin. Then, the chitosan and gelatin solutions were mixed with a 1:1 polymer weight ratio, and the pH was adjusted between 5.2 and 6 using a KOH solution to obtain a polyelectrolyte and stirred at room temperature for 6 h. The final solution was poured into a polystyrene petri dish and dried for 24 h under a vacuum at 24 °C. The GC film was detached from the petri dish using tweezers. The formation of the electrostatic bond between gelatin and chitosan has been confirmed by TGA and FT IR (Fig. S10).

Fabrication of PVA mold

A positive Si mold was prepared by photolithography using AZ 1512 photoresist and deep reactive ion etching. First AZ 1512 was patterned on a Si substrate. After anisotropic Si etching was done with Si-Bosch process with a holder temperature of 30 °C with 75:1 photoresist mask selectivity and SF6 duration of 8 s. The Si mold surface was treated with Trichloro(1H,1H,2H,2H-perfluorooctyl) silane (Sigma-Aldrich, St. Louis, MO, USA) to make its surface hydrophobic. The detailed process flow is described in the supporting information (Fig. S11). A PVA solution was prepared by dissolving PVA (Mw 85000-12400, Sigma-Aldrich, St. Louis, MO, USA) in deionized water with a 7 w/v% concentration. The PVA solution was poured onto the Si mold. Vacuum was applied for 1 h, and then it was dried at 50 °C for 24 h.

Lipid-drug composite preparation, thermal imprinting, and demolding

PEG-32 stearate (Gelucire 4816, Gattefosse SAS, Lyon, France) and Suppocire AP (Gattefosse SAS, Lyon, France) granules were melted at 50 °C and mixed in a 1:1 volume ratio using a vortex mixer. The drugs used in this study (Danazol, Fenofibrate, Tolfenamic acid, and Dil) were dissolved in the molten lipids at 50 °C with a concentration of 20 mg/ml. Subsequently, 10 µL of the lipid-drug composite was drop-cast onto a GC film, and a PVA mold was placed above it. Thermal imprinting was performed using NanoImprint EHN-3250 under 0.1 MPa at 45 °C for 15 min, with a cooling time of 20 min to 20°C. After imprinting, the whole structures were immersed in 50% Ethanol/Water at 4 °C for 6 mins and demolded manually by tweezers. Finally, the device was dried under a vacuum at 24 °C for 24 h.

Young’s modulus measurement of PVA molds

PVA mold with the dimension of 5 mm × 5 mm with a thickness of 100 µm has been used for all the tests. For the evaluation of the effect of immersion time, the PVA mold is immersed in 50 vol% ethanol solvent at 4 °C at different times. After, the mold is taken out and the solvent remaining in the exterior is removed by dust-free tissue. Both ends of the sample were mounted on a Strain-Stress Measurement Machine (Linkam MFS, Linkam Scientific, Salfords, UK) at 24 °C. Elongation strain was applied to the sample while measuring the stress exerted on the film. Young’s modulus was obtained by the slope of the measured strain stress graph. For the evaluation of the effect of reuse, the PVA mold is immersed in 50 vol% ethanol solvent at 4 °C for 6 min followed by drying under vacuum at 24 °C for 3 h. After each reuse cycle, Young’s modulus of the sample was measured.

DLS measurement

Different lipid formulations listed in Table 1 were dissolved in artificial saliva (Artificial Saliva for Pharmaceutical Research Amylase and Lysozyme customized, Biochemazone, Alberta, Canada) at 37 °C, maintaining a 1:100 volume ratio of lipid formulation to artificial saliva. The resulting solutions were analyzed using the Zetasizer Nano ZS (Malvern Panalytical GmbH, Herrenberg, Germany). Each sample underwent five independent 2 min runs. Dynamic light scattering (DLS) measurements were performed at a fixed scattering angle of 90°, which is a standard setup for general nanoparticle size analysis. The intensity autocorrelation function obtained from the measurements was processed using the Malvern software’s cumulants analysis method to determine the intensity-weighted log-normal size distribution. The average hydrodynamic diameter was extracted based on a single-mode fit.

Evaluation of lipid microstructure dissolution rate

Honeycomb lipid microstructures with different wall width and a lipid film without microstructures were immersed in 50 µL artificial saliva (Artificial Saliva for Pharmaceutical Research Amylase and Lysozyme customized, Biochemazone, Alberta, Canada) at 37 °C, and the evolution of the lipid microstructure was observed over time with a camera. The final dissolution time was determined visually with a span error of 10 s.

Optical profilometer measurement

Lipid microstructures, silicon molds, and PVA molds have been scanned by optical profiler (Bruker Contour X, Bruker, MA, USA) using a vertical scanning interferometry mode with a scan speed of 1x and a scan length of 700 µm. Multiple scans were performed at the same location on microstructures fabricated in different batches. The average thickness was calculated by averaging these repeated scan profiles.

Mechanical measurement

A GC film, with a thickness of 15 µm, was prepared in a rectangular shape measuring 5 mm by 40 mm. The lipid was then coated on the GC film, either with a thickness of 90 µm or in the form of honeycomb lipid microstructures with 2.5 × 2.5 mm dimension with 90 µm thickness, with varying wall widths (20, 40 µm), fabricated at the center of the GC film. Both ends of the sample were mounted on a Strain-Stress Measurement Machine (Linkam MFS, Linkam Scientific, Salfords, UK) at 37 °C. Elongation strain was applied to the sample while measuring the stress exerted on the film. The film was observed over time using the mounted microscope to detect the strain at which the first crack appeared in the lipid, representing the critical strain of the lipid structure.

XRD measurement

XRD samples are prepared using the same methodology as for preparing lipid microstructures with dimensions of 10 × 10 × 0.1 mm. The samples were stored at 24 °C for 1 week, after which XRD measurements were conducted using Bruker D8 Discover (Bruker, MA, USA) in Bragg Brentano mode. It was equipped with a Johansson Kalpha1 monochromator and a LynxEye 1D detector. The total scan time was approximately 45 min. The samples were loaded into low-background silicon crystal sample holders, and a knife was placed above the sample to minimize background from air scattering.

FTIR measurement

FTIR samples were prepared following the same methodology used for fabricating SEDDS lipid microstructures, with dimensions of 2.5 × 2.5 × 0.1 mm. The lipid films were placed directly on the FTIR spectrometer (Spectrum 3, PerkinElmer, MA, USA). Spectra were recorded in the range of 4000–650 cm−1 with a resolution of 4 cm⁻¹. Each measurement consisted of 5 scans.

In vitro drug release measurement

For all in vitro drug release experiments, 2.5 × 2.5 mm lipid structure with 90 µm thickness, which contains different drugs (Danazol, Fenofibrate, Tolfenamic acid, and Dil) with 20 mg/ml concentration, was used. SEDDS lipid microstructure was immersed in 100 µL artificial saliva at 37 °C, and the evolution of UV–Vis spectrometry of its supernatant (2 µL) was measured every 20 sec until the absorbance reached saturation and after 3 h using a UV–vis spectrophotometer (NanoDrop™ 2000c Spectrophotometers, Thermo Fisher Scientific, Waltham, MA, USA). For solid drugs, drugs were dissolved in ethanol with 0.1 wt%, then dispensed on a glass substrate and dried for 24 h. Glass substrates were immersed in 100 µL artificial saliva and the evolution of UV–Vis of its supernatant was measured after 3 h.

In vitro drug penetration into Agarose gel

Agarose gel was prepared by dissolving 2 wt% agarose (Sigma-Aldrich, St. Louis, MO, USA) in water and heating it in the microwave at 700 W for 10 s, then cooling it down to 40 °C. A volume of 750 µL of the prepared agarose solution was poured into a UV cuvette (Semi micro cuvette, BrandTech Scientific, Inc., Essex, UK) and allowed to solidify. Honeycomb SEDDS lipid structures with a wall width of 160 µm, both with and without the GC film containing Dil, were placed on the top surface of the agarose gel and immersed in 50 µL of artificial saliva at 37 °C. UV–Vis spectroscopy of the agarose gel was conducted 1 mm below the top surface every 2 min until the absorbance saturated and after 3 h.

Cytotoxicity

HeLa cells (human epithelial cell line from adenocarcinoma, ATCC® CCL-2) were cultured in DMEM containing 10% (v/v) heat-inactivated FBS. Cells were maintained at 37 °C and 5% CO2. Two days before the cytotoxicity tests, cells were seeded in a 96-well plate at a density of 20000 cells/well. The cells were grown without antibiotics and were detached by the action of trypsin. In parallel, the GC films or the LSMP were incubated overnight at 37 °C in culture medium containing salivary enzymes (lysozyme, α-amylase, and hyaluronidase) at 100 μg/mL in 0.15 M NaCl, 20 mM HEPES, pH 6.5. The culture medium was then removed from the wells and replaced with the medium containing membrane degradation products. Cells were then incubated at 37 °C for 4 and 24 h. Negative controls were performed with 0.1% (v/v) SDS, and positive controls were performed with cells alone. The PrestoBlue™ Assay (Thermo Scientific™, Waltham, MA, USA) was used to evaluate the cytotoxicity of the LSMP degradation products. Briefly, 10 µL of PrestoBlue™ Cell Viability Reagent was added to the wells, and the plates were incubated for 20 min at 37 °C. Fluorescence was detected at 560 nm and 590 nm (Spark® Multimode Microplate, Tecan, Grödig, Austria). Data were determined as the mean of three replicates.

Animals

In vivo studies were conducted on 6-to-8-week-old male C57bl/6J mice (Charles River Laboratories, France) at the animal facility PBES of Lyon, France. All animals were maintained in pathogen-free conditions. All of the experiments were performed following animal welfare regulations for their use for scientific purposes governed by European Directive 2010/63/EU. Protocols were validated by the local Animal Ethics Evaluation Committee (CECCAPP: C2EA-15) and authorized by the French Ministry of Education and Research.

Sublingual administration of formulations

LSMPs were cut to fit the size of the mouse tongue (2 mm × 5.5 mm) and sterilized by UV light. Dil-loaded LSMPs or liquid formulations were administered sublingually (ventral part of the tongue) to anesthetized mice (isoflurane 4%). After administration, a gentle pressure was exerted for a few seconds on the dorsal part of the tongue to ensure contact of the LSMP or the liquid solution with the sublingual mucosa. After the sublingual administration of formulations, the animals were kept anesthetized (isoflurane 4%) for an additional minute. After this minute, they were left free to swallow or groom until cervical dislocation and sample collection (blood and tongues).

Mucosal penetration

For the visualization of the Dil penetration in the sublingual mucosa, formulations were administered to groups of 3 mice: control group (PBS, no Dil), 50 ng of liquid Dil-lipid nanoemulsion in 10 µl of PBS, and 50 ng in LSMP. Tongues were collected around 12 min after sublingual administration. The tissues were snap frozen in Optimal Cutting Temperature compound (OCT, Tissue-Tek, Sakura Finetek Europe, The Netherlands), and stored at -80 ˚C until cryosection. Sagittal sections, 40 μm thick, were performed using a cryostat microtome (Leica Biosystems, Germany), incubated with the nuclear stain DAPI (Thermo Scientific, Pierce Biotechnology, Rockford, IL, USA) and mounted with PBS (Euromedex, France). Images of tongue sections were immediately captured using a confocal microscope (LSM 710, Zeiss, Germany) equipped with a 40x objective. Of note, no mounting media containing glycerol was used to avoid the extraction of membrane-bound Dil.

Plasmatic bioavailability

Blood samples were collected at different time points (5 min and 30 min) after IV administration of 1 µg of Dil, or 30 min after SL administration of 3x more Dil (3 µg). Blood was obtained from exsanguination following decapitation on anaesthetized mice. Blood samples were collected in tubes containing 3% of citrate, centrifuged (4 min, 10.000 g, 4 °C) and kept in the dark at 4 °C for further analysis the same day. Plasma levels of Dil were quantified with a spectrofluorometer (i-control Infinite® M1000 Pro, Tecan, Switzerland) at 550 nm (ex)/654 nm (em).

Statistical analysis

Data collected by at least three independent experiments were presented as the mean ± standard deviation. The significant difference between sample groups in Fig. 2 was determined by one-way ANOVA with Tukey’s post-hoc analysis with the lipid film. For all analyses, statistical significance was expressed as a p-value, with a p-value smaller than 0.05. (*p < 0.05) was considered statistically significant. The significant difference between the sample groups means with the control mean in Fig. 4 was determined by one-way ANOVA Dunnett’s multiple comparison test (not significant (ns): p > 0.05; ****p < 0.0001). For all analyses, statistical significance was expressed as a p-value, a p-value larger than 0.05 was considered to be significant, and a p-value smaller than 0.0001 was considered statistically significant. All data were analyzed using Microsoft Excel (Microsoft, Redmond, WA, USA).

Data availability

All data that support the key findings in this study are available within the main text and the Supplementary Information file. All raw data generated during the current study are available from the corresponding authors upon request.

References

Hou, X., Zaks, T., Langer, R. & Dong, Y. Lipid nanoparticles for mRNA delivery. Nat. Rev. Mater. 6, 1078–1094 (2021).

Xu, L. et al. Lipid nanoparticles for drug delivery. Adv. Biomed. Res. 2, 2100109 (2022).

Kreye, F., Siepmann, F. & Siepmann, J. Lipid implants as drug delivery systems. Expert Opin. drug Deliv. 5, 291–307 (2008).

Gursoy, R. N. & Benita, S. Self-emulsifying drug delivery systems (SEDDS) for improved oral delivery of lipophilic drugs. Biomed. Pharmacother. 58, 173–182 (2004).

Içten, E. et al. Dropwise additive manufacturing of pharmaceutical products for amorphous and self emulsifying drug delivery systems. Int. J. Pharm. 524, 424–432 (2017).

Kyobula, M. et al. 3D inkjet printing of tablets exploiting bespoke complex geometries for controlled and tuneable drug release. J. Control. Release 261, 207–215 (2017).

Johannesson, J., Khan, J., Hubert, M., Teleki, A. & Bergström, C. A. 3D-printing of solid lipid tablets from emulsion gels. Int. J. Pharm. 597, 120304 (2021).

Vithani, K. et al. A proof of concept for 3D printing of solid lipid-based formulations of poorly water-soluble drugs to control formulation dispersion kinetics. Pharm. Res. 36, 1–13 (2019).

Abdelhamid, M. et al. Personalization of lipid-based oral dosage forms via filament-based 3D-printing. Appl. Mater. Today 40, 102399 (2024).

Kreye, F. et al. Controlled release implants based on cast lipid blends. Eur. J. Pharm. Sci. 43, 78–83 (2011).

Tollemeto, M. et al. Production and ex vivo characterization of melting lipid needle patches applied for transdermal delivery of lipophilic drugs. ACS Mater. Lett. 6, 5199–5207 (2024).

Guo, L. J. Nanoimprint lithography: methods and material requirements. Adv. Mater. 19, 495–513 (2007).

Kim, J. K. et al. Effect of surface tension and coefficient of thermal expansion in 30 nm scale nanoimprinting with two flexible polymer molds. Nanotechnology 23, 235303 (2012).

Kwon, B. & Kim, J. H. Importance of molds for nanoimprint lithography: hard, soft, and hybrid molds. J. Nanosci. 2016, 6571297 (2016).

Moran, I. W., Briseno, A. L., Loser, S. & Carter, K. R. Device fabrication by easy soft imprint nano-lithography. Chem. Mater. 20, 4595–4601 (2008).

Fan, Z. et al. Three-dimensional nanopillar-array photovoltaics on low-cost and flexible substrates. Nat. Mater. 8, 648–653 (2009).

Bhingardive, V., Menahem, L. & Schvartzman, M. Soft thermal nanoimprint lithography using a nanocomposite mold. Nano Res. 11, 2705–2714 (2018).

Delamarche, E., Schmid, H., Michel, B. & Biebuyck, H. Stability of molded polydimethylsiloxane microstructures. Adv. Mater. 9, 741–746 (1997).

Kleger, N. et al. Light-based printing of leachable salt molds for facile shaping of complex structures. Adv. Mater. 34, 2203878 (2022).

Wick-Joliat, R., Tschamper, M., Kontic, R. & Penner, D. Water-soluble sacrificial 3D printed molds for fast prototyping in ceramic injection molding. Addit. Manuf. 48, 102408 (2021).

Park, J., Brugger, J. & Bertsch, A. Additive manufacturing of water-soluble 3D micro molds for complex-shaped lipid microparticles. Nat. Commun. 16, 1734 (2025).

Kanuganti, S., Jukanti, R., Veerareddy, P. R. & Bandari, S. Paliperidone-loaded self-emulsifying drug delivery systems (SEDDS) for improved oral delivery. J. Dispers. Sci. Technol. 33, 506–515 (2012).

Araya, H., Tomita, M. & Hayashi, M. The novel formulation design of self-emulsifying drug delivery systems (SEDDS) type O/W microemulsion III: the permeation mechanism of a poorly water soluble drug entrapped O/W microemulsion in rat isolated intestinal membrane by the Ussing chamber method. Drug Metab. Pharmacokinetics 21, 45–53 (2006).

Sermkaew, N., Wiwattanawongsa, K., Ketjinda, W. & Wiwattanapatapee, R. Development, characterization and permeability assessment based on Caco-2 monolayers of self-microemulsifying floating tablets of tetrahydrocurcumin. Aaps Pharmscitech 14, 321–331 (2013).

Friedl, H. et al. Development and evaluation of a novel mucus diffusion test system approved by self-nanoemulsifying drug delivery systems. J. Pharm. Sci. 102, 4406–4413 (2013).

Jridi, M. et al. Physical, structural, antioxidant and antimicrobial properties of gelatin–chitosan composite edible films. Int. J. Biol. Macromol. 67, 373–379 (2014).

Abruzzo, A. et al. Mucoadhesive chitosan/gelatin films for buccal delivery of propranolol hydrochloride. Carbohydr. Polym. 87, 581–588 (2012).

Gottscho, R. A., Jurgensen, C. W. & Vitkavage, D. Microscopic uniformity in plasma etching. J. Vac. Sci. Technol. B: Microelectron. Nanometer Struct. Process. Meas. Phenom. 10, 2133–2147 (1992).

Stolar, S. & Gick, B. An index for quantifying tongue curvature. Canadian Acoustics 41 (2013).

Zhang, Q. et al. Bioinspired engineering of honeycomb structure–Using nature to inspire human innovation. Prog. Mater. Sci. 74, 332–400 (2015).

Kanaujia, P., Ng, W. K. & Tan, R. B. Solid self-emulsifying drug delivery system (S-SEDDS) for improved dissolution rate of fenofibrate. J. Microencapsul. 31, 293–298 (2014).

Cuine, J. F. et al. Evaluation of the impact of surfactant digestion on the bioavailability of danazol after oral administration of lipidic self-emulsifying formulations to dogs. J. Pharm. Sci. 97, 995–1012 (2008).

Sahbaz, Y. et al. Ionic liquid forms of weakly acidic drugs in oral lipid formulations: preparation, characterization, in vitro digestion, and in vivo absorption studies. Mol. Pharmaceutics 14, 3669–3683 (2017).

Pouton, C. W. Formulation of poorly water-soluble drugs for oral administration: physicochemical and physiological issues and the lipid formulation classification system. Eur. J. Pharm. Sci. 29, 278–287 (2006).

Honig, M. G. & Hume, R. I. Dil and diO: versatile fluorescent dyes for neuronal labelling and pathway tracing. Trends Neurosci. 12, 333–341 (1989).

Paris, A.-L. et al. Sublingual protein delivery by a mucoadhesive patch made of natural polymers. Acta Biomater. 128, 222–235 (2021).

Pichayakorn, W., Monton, C., Sampaopan, Y., Panrat, K. & Suksaeree, J. Fabrication and characterization of buccal film loaded self-emulsifying drug delivery system containing Lysiphyllum strychnifolium stem extracts. AAPS PharmSciTech 23, 194 (2022).

Bolourchian, N., Hadidi, N., Foroutan, S. & Shafaghi, B. Development and optimization of a sublingual tablet formulation for physostigmine salicylate. Acta Pharmaceutica 59, 301–312 (2009).

Al-Ghananeem, A. M., Malkawi, A. H. & Crooks, P. A. Scopolamine sublingual spray: an alternative route of delivery for the treatment of motion sickness. Drug Dev. Ind. Pharm. 33, 577–582 (2007).

Bolourtchian, N., Hadidi, N., Foroutan, S. M. & Shafaghi, B. Formulation and Optimization of Captopril Sublingual Tablet Using D-Optimal DesignSublingual Tablet Using D-Optimal Design. Iran. J. Pharm. Res. 7, 259–267 (2008).

Haegeli, L. et al. Sublingual administration of furosemide: new application of an old drug. Br. J. Clin. Pharmacol. 64, 804–809 (2007).

Aburahma, M. H., El-Laithy, H. M. & Hamza, Y. E.-S. Preparation and in vitro/in vivo characterization of porous sublingual tablets containing ternary kneaded solid system of vinpocetine with β-cyclodextrin and hydroxy acid. Sci. Pharmaceutica 78, 363–380 (2010).

Patil, N. H. & Devarajan, P. V. Insulin-loaded alginic acid nanoparticles for sublingual delivery. Drug Deliv. 23, 429–436 (2016).

Wu, J. et al. Systemic delivery of proteins using novel peptides via the sublingual route. J. Control. Release 368, 290–302 (2024).

Caffarel-Salvador, E. et al. A microneedle platform for buccal macromolecule delivery. Sci. Adv. 7, eabe2620 (2021).

Kim, Y. et al. Sublingual dissolving microneedle (SLDMN)-based vaccine for inducing mucosal immunity against SARS-CoV-2. Adv. Healthc. Mater. 12, 2300889 (2023).

Şenel, S. & Hıncal, A. A. Drug permeation enhancement via buccal route: possibilities and limitations. J. Control. Release 72, 133–144 (2001).

Rawas-Qalaji, M., Thu, H. E. & Hussain, Z. Oromucosal delivery of macromolecules: challenges and recent developments to improve bioavailability. J. Control. Release 352, 726–746 (2022).

Sattar, M., Sayed, O. M. & Lane, M. E. Oral transmucosal drug delivery–current status and future prospects. Int. J. Pharm. 471, 498–506 (2014).

Friedl, J. D. et al. SEDDS-loaded mucoadhesive fiber patches for advanced oromucosal delivery of poorly soluble drugs. J. Control. Release 348, 692–705 (2022).

Paris, A., Colomb, E., Verrier, B., Anjuère, F. & Monge, C. Sublingual vaccination and delivery systems. J. Control. Release 332, 553–562 (2021).

Ryu, J. H. et al. Chitosan oral patches inspired by mussel adhesion. J. Control. Release 317, 57–66 (2020).

Jin, B. Z., Dong, X. Q., Xu, X. & Zhang, F. H. Development and in vitro evaluation of mucoadhesive patches of methotrexate for targeted delivery in oral cancer. Oncol. Lett. 15, 2541–2549 (2018).

Sacerdote, P., Coluzzi, F. & Fanelli, A. Sublingual sufentanil, a new opportunity for the improvement of postoperative pain management in Italy. Eur. Rev. Med. Pharmacol. Sci. 20, 1411–1422 (2016).

Acknowledgements

The authors acknowledge funding from the European Research Council (ERC) under the European Union’s Horizon 2020 research and innovation program (Project “MEMS 4.0”, ERC-2016-ADG, grant agreement No. 742685). The authors thank Dr. Yves Leterrier and Nareg Kara-Yacoubian from EPFL STI IMX LPAC for their help in mechanical strain measurement, Pascal Alexander Schouwink from EPFL XRD SAP for the XRD measurements, and Nicolas Zaugg for the optical profilometer measurement. We acknowledge the contribution of SFR Biosciences (UMS3444/CNRS, US8/Inserm, ENS de Lyon, UCBL) facility PLATIM and the contributions of the CELPHEDIA Infrastructure (http: //www.celphedia.eu/), especially the AniRA center in Lyon.

Author information

Authors and Affiliations

Contributions

J.P., A.B., and J.B. conceived the idea. J.P. and N.Z. fabricated the lipid microstructure. J.P. and N.Z. performed characterization of the fabricated mold and lipid structure. J.P. performed dissolution and mechanical property analysis of lipid structure. J.P. performed an in vitro drug release analysis of the patch. H.H. performed an in vitro cytotoxicity assay of the patch. R.R., E.C., and C.M. performed in vivo validation of the patch. J.P. and C.M. wrote the first manuscript. A.B., C.M., and J.B. revised the manuscript. C.M. and J.B. coordinated and supervised the research. All authors contributed to discussions regarding the research.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Park, J., Rovera, R., Bertsch, A. et al. Fabrication of self-emulsifying lipid microstructure by stiffness-tunable mold for drug delivery applications. Microsyst Nanoeng 11, 229 (2025). https://doi.org/10.1038/s41378-025-01052-9

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41378-025-01052-9