Abstract

Hierarchical self-assembly in soft materials generates complex nanostructures with critical applications ranging from biomedicine to energy storage systems. Advanced transmission electron microscopy (TEM) methodologies—including cryogenic-TEM, electron tomography, and liquid-phase TEM—have significantly advanced our ability to visualize these assemblies with unprecedented spatiotemporal resolution. This perspective examines how machine learning integration overcomes inherent limitations in TEM analysis of beam-sensitive soft materials, enabling automated feature extraction, 3D reconstruction, and dynamic process analysis. We propose future directions for creating integrated analytical platforms that predict material properties from imaging data, accelerating the development of next-generation functional materials for extreme environments and emerging global challenges.

Similar content being viewed by others

Introduction

The unprecedented global impact of coronavirus disease 2019 has underscored the critical importance of understanding self-assembly processes at the molecular and nanoscale levels. The rapid transmission of severe acute respiratory syndrome coronavirus 2 (SARS-CoV-2) is driven by sophisticated self-assembly mechanisms of viral proteins, resulting in highly ordered nanostructures with precise molecular mechanical properties (Fig. 1a, b)1. The presence of spike proteins and capsids exemplifies its ability to recognize host cells and facilitate subsequent infection1. Understanding these self-assembly processes not only elucidates viral pathogenesis but also serves for the design of functional materials, such as mRNA vaccines utilizing lipid nanoparticles, which encapsulate and deliver genetic material through precise molecular organization2. This insight provides a novel approach to the development of therapeutic agents for infectious diseases, thereby advancing clinical medicine and public health intervention. Notably, cryogenic transmission electron microscopy (cryo-TEM), which was awarded the 2017 Nobel Prize in Chemistry for enabling the direct visualization of native structures under physiological conditions, has achieved atomic-resolution imaging of membrane proteins, ribosomes, and virus capsids3. Recently, regulatory agencies including the U.S. Food and Drug Administration, the Pharmaceuticals and Medical Devices Agency in Japan, and the National Medical Products Administration in China have recognized TEM as a standardized analytical guidelines for the development and industrialization of drug and gene delivery nanocarriers4.

a Hierarchical, complex assembly of proteins into SARS-CoV-21. Ultrastructure of the ribonucleoprotein (RNP), RNP hexagon with representative tomogram slices (left) and a whole virion visualized through a cryogenic transmission electron micrograph (right). b Spikes of SARS-CoV-2 showing the refined orientation of the prefusion and postfusion conformations as a representative molecular machinery system. Reproduced with permission from ref.1. Copyright 2020 Cell Press. c AI-predicted protein structure: Intertwined homotrimer (PDB 6SK0) predicted by AlphaFold (left). Protein-protein interactions of PDB 7T82 predicted by AlphaFold 3 and evaluation of the experimental accuracy (right). The structures are colored by pLDDT (predicted local distance difference test) and by chain. DockQ interface scores and predicted aligned error (PAE) matrix are shown to indicate prediction accuracy and confidence9,10. Reproduced with permission from refs. 9,10. Copyright 2021, 2024 Springer Nature.

Soft matter–encompassing biomaterials like cell membranes and proteins, as well as synthetic materials like polymers, liquid crystals, membranes, gels, and colloids–can form complex structures through self-assembly in response to external stimuli due to their high sensitivity5,6. TEM has become an indispensable tool for interpreting structure-function relationships, allowing for the direct observation of microphase separation, atomic and molecular arrangements in crystal structures, and investigating chemical compositions5. However, when examining hydrated specimens, the high vacuum conditions necessary for minimizing electron scattering can compromise the integrity of native hydrated structures, leading to distorted images and limiting three-dimensional (3D) imaging capabilities6. To address these challenges, researchers have implemented cryo-TEM, electron tomography (ET), and in-situ liquid-phase TEM (LP-TEM), complemented by advancements in high-resolution optics for TEM at low accelerating voltages5. Despite these advancements, fundamental limitations persist due to the inherently low electron density contrast of soft matter compared to hard matter and its susceptibility to degradation from electron beam exposure.

Artificial intelligence (AI), first conceptualized by Alan Turing in the 1950s, has evolved through key developments including perceptrons, backpropagation algorithms, and deep learning (DL) frameworks7. Recent advances in large language models such as ChatGPT, Claude, and DeepSeek, alongside AI applications, are reorganizing various scientific fields including autonomous driving, materials discovery, and medical diagnostics7. The introduction of DL frameworks (e.g., TensorFlow and PyTorch) and large-scale computing resources has enabled AI-driven automation across structural biology, pharmaceutical research, and nanofabrication8. TEM generates vast amounts of high-dimensional image data requiring accurate and efficient analysis. Traditional manual approaches to analyzing the vast amounts of high-dimensional TEM image data are time-consuming nature and prone to bias, driving the need for AI-integrated TEM analysis. The next-generation TEM in soft matter research may identify self-assembly pathways through real-time 3D analysis with high spatiotemporal, correlate structural properties with material characteristics, and predict self-assembly dynamics under varying conditions. The AI-integration is further advancing automation and enabling real-time data analysis5.

The advent of DL in structural biology has been transformative. Notably, advanced biomolecular prediction models such as AlphaFold 3 now quantitatively reproduce experimentally validated structural features with remarkable precision (Fig. 1c)9,10. This includes achieving interface-level fidelity in predicting protein-protein, protein-ligand, and antibody-antigen complexes, reflected in high structural prediction accuracy metrics like sub-2 Å root mean square deviation and high DockQ scores, both of which strongly correlate with functional specificity and interaction strength. Such successes underscore the power of DL in deciphering complex, sequence-defined biomaterials. However, the predictive power of these sophisticated models currently faces limitations when extended to systems where molecular identity is less defined, and the constituent building blocks are more heterogeneous. This is often the case for synthetic polymers and their supramolecular assemblies. In these artificial systems, factors such as conformational heterogeneity, polydispersity, and the intricate interplay of multivalent non-covalent interactions make the ab initio prediction of secondary structures and their resultant hierarchical assemblies particularly challenging. Consequently, while acknowledging the strides made in biomolecular prediction, this perspective mainly focuses on the role and potential of AI-integrated TEM in the analysis of artificial synthetic soft matter. For complex soft materials where predictive modeling is still in its nascent stages, these AI-integrated TEM techniques discussed in this perspective are indispensable for resolving the native architectures and assembly pathways.

In this perspective, we explore the recent developments and research directions in electron microscopy analysis for identifying hierarchical, complex self-assembly structures in soft materials, with a particular emphasis on artificial synthetic systems. We summarize the limitations of manual analysis methods and examine how machine learning (ML) solutions are addressing these challenges. Additionally, we discuss the transformative potential of integrating AI with electron microscopy for soft matter self-assembly research, with implications for biomaterials, nanomedicine, and functional materials. Ultimately, this integration will enable comprehensive analytical platforms–from molecular design and experimentation to post-processing and analysis–that can predict materials from imaging data, propose modification strategies for existing materials, and accelerate the development of next-generation materials for emerging applications.

Recent progress and achievement

Direct visualization of molecular self-assembly: Leveraging TEM and AI integration

Complex nanosystems derived from molecular hierarchical self-assembly of soft matter are being actively investigated as advanced functional materials, including biomimetic drug delivery systems and next-generation energy materials2,3,5. Elucidating the structure-function relationships and enhancing the properties of these materials necessitates TEM analysis capable of simultaneously achieving atomic-scale spatial resolution and millisecond temporal resolution. TEM has evolved into a versatile analytical platform that extends far beyond simple imaging to provide comprehensive characterization of materials across multiple dimensions5,6. Self-assembled soft materials serve as building blocks for hierarchical superstructures in solution, including nanotubes, nanosheets, and networks, which continuously rearrange according to thermodynamic equilibrium and non-equilibrium states. These supramolecular structures find applications in diverse fields including nanolithography, electronics, and drug delivery, necessitating imaging techniques capable of analyzing their formation and ordered structures in solution.

TEM has provided unprecedented spatial resolution for materials characterization from atomic to molecular scales by utilizing electron beams as a light source based on Rayleigh scattering principles. In imaging mode, bright-field (BF) and dark-field (DF) modalities reveal critical morphological features, interfaces, porosity distributions, and structural defects. These fundamental observations enable researchers to visualize how molecular building blocks arrange themselves into functional hierarchical structures. Concurrently, selected area electron diffraction (SAED), convergent beam electron diffraction, and Kikuchi pattern analysis provide crystallographic information including phase identification, orientation mapping, chemical ordering, and strain distribution within self-assembled domains. For compositional analysis, energy-dispersive X-ray spectroscopy (EDS) and electron energy loss spectroscopy reveal chemical bonding states, elemental distributions, and optical properties. As shown in Fig. 2a, these complementary TEM approaches enable precise characterization of complex soft material assemblies11,12,13. Through conventional imaging, we can observe how block copolymer self-assembly creates soft patches that serve as building blocks capable of forming highly hierarchical and precisely assembled superstructures, with assembly behavior dictated by the surface properties of these patches11. Additionally, SAED patterns reveal the crystalline structures of conjugated polymers, which can exhibit different electromagnetic properties depending on molecular orientation12. In multicompartmentalized nanostructures, EDS mapping enables elemental labeling of individual compartments, providing valuable insights into the spatial distribution of chemical components within complex assemblies13.

a Direct visualization and interpretation of organic polymer molecular self-assembly into well-defined nanostructures leveraging imaging11, diffraction12, and spectroscopy13 in TEM. Reproduced with permission from refs. 11,12,13. Copyright 2023 Springer Nature, 2010 American Chemical Society, and 2021 AAAS. b, c Representative neural network applications in TEM-based morphological, crystallographic, and electronic analysis of self-assembled nanostructures17,18,19,20. b U-Net17 architectures are applied across all analysis domains. The data flow for U-Net based segmentation of nanoprisms and nanotubes, showing features obtained at different convolution layers leading to the prediction after training and comparison of thresholds for assessment of connected particle boundaries. c Fully convolutional network (FCN)18 and convolutional neural network (CNN)19 are primarily utilized for imaging and diffraction data, while unsupervised deep networks (UDN)20 is adapted for spectroscopy analysis. FCN capable of microtubule annotation in a tomogram. Each neural network trained independently to recognize microtubule18 (left). CNN predictions on sum of the convolutional layer filters for crystal class, especially hexagonal structure not rhombohedral structure19 (middle). Unsupervised two-step network of EDS images of quantum dots, followed by a sinogram generation network and FBP and for chemical composition identification and 3D organization20 (right). Reproduced with permission from refs. 17,18,19,20. Copyright 2020 American Chemical Society and 2017, 2018, and 2021 Springer Nature.

However, conventional TEM faces significant challenges when analyzing soft materials. Owing to their composition of low atomic number elements, they exhibit weak electron scattering cross-sections14. This leads to the low phase contrast and makes structural visualization particularly challenging. Furthermore, when analyzing solution-state particles, the vacuum environment required for TEM operation typically necessitates drying samples on grids prior to imaging, which can lead to structural deformation. Additionally, potential structural damage from high-energy electron beam interactions, including atomic displacement and radiation effects, remains a fundamental concern. In response to these limitations, cryo-TEM has emerged as a powerful technique for analyzing biological particles such as viral proteins and is now widely applied in various fields, from biological research to the study of soft materials and nanomaterials. While cryo-TEM enables non-destructive structural analysis by vitrifying liquid-phase specimens, its static imaging nature inherently limits its ability to capture dynamic structural transformations. This will be discussed in more detail in Fig. 3a.

a Cryo-electron tomography21,22,23,24,25 reveals the hydrated native morphology and 3D construction of liquid-phase self-assembled nanoparticles with hierarchical complex assembly (left). Liquid-phase TEM26,27,28,29 demonstrations for observing dynamic assembly processes and motion in real-time (right). Reproduced with permission from refs. 21,22,23,24,25,26,27,28,29. Copyright 2014 American Chemical Society, 2018, 2019, 2021, 2023, 2024 Springer Nature, and 2015, 2017 Wiley-VCH. b Challenges in analyzing hierarchical complex assemblies with TEM (top), are complemented by representative ML applications that address these limitations30,31 (bottom). U-Net based 3D semantic segmentation of targeted ribosome as a representative aggregates, with statistical analysis of distance-to-membrane30 (bottom left). Temporal diffusion analysis of particles exhibiting different behaviors as a function of time31 (bottom right). These demonstrates how ML enables statistical analysis of previously inaccessible dynamic phenomena in assembly and motion captured by advanced TEM. The motion-based point cloud prediction network (MoNet) contributed to determine the fractional Brownian motion (FBM), Brownian motion, continuous-time random walk (CTRW) classifications. Reproduced with permission from refs. 30,31. Copyright 2021 Springer Nature and 2021 National Academy of Sciences.

These persistent challenges have motivated the development of neural network-based AI-integrated TEM analysis (Fig. 2b, c)15,16,17,18,19,20. These emerging computational approaches address the fundamental issues of low contrast in organic polymers and enhance our ability to extract meaningful structural information without excessive beam damage. The integration of AI with TEM represents a significant advancement in our capability to analyze the complex hierarchical structures formed through soft material self-assembly, enabling unbiased pattern detection and high-throughput quantification of structural parameters across diverse length scales correlating with multidimensional data.

Recent advances in computer vision algorithms and statistical analysis methods have significantly enhanced our ability to extract quantitative information from TEM data. However, analyzing TEM data remains challenging as, unlike conventional RGB-scale images, TEM images formed by electron signals are grayscale maps often lack edge sharpness due to scattering artifacts, challenging precise boundary localization due to specimen thickness, and material sensitivity to electron beams. This makes the extraction of morphological, crystallographic, and electronic component information time-consuming and requires specialized knowledge, especially with the emergence of in-situ TEM experiments producing large volumes of images.

With the introduction of DL models, segmentation and classification methodologies have been successfully applied to high-throughput TEM image analysis. Neural networks commonly utilized for automated analysis include U-Net16, fully convolutional networks (FCN), and convolutional neural networks (CNN), each addressing specific aspects of TEM data interpretation (Fig. 2b, c)15,16,17,18,19,20. Initially applied to cell detection and morphometry, U-Net enables mapping of nanoparticle interaction landscapes and self-assembly kinetic laws through nanoparticle segmentation in LP-TEM videos (Fig. 2b)17. This model effectively identifies boundaries of Au nanoparticles with spatial heterogeneity and low signal-to-noise ratio (SNR). Beyond identifying boundaries, U-Net based segmentation applied to TEM images, including challenging LP-TEM data (Fig. 2b)17, yields quantitative spatial and statistical information. For instance, derived parameters like radial distribution functions (g(r)) from tracked Au triangular nanoprisms allow for direct validation of AI model predictions by confirming alignment with experimental observations and simulation results, such as identifying anisotropic spatial motifs consistent with predicted packing behaviors. This validation confirms the capability of ML to extract physically relevant structural information from complex TEM datasets, setting the stage for analyzing more dynamic processes like anisotropic diffusion, etching, and assembly.

FCN provides complementary capabilities by replacing fully-connected layers with convolutional layers to classify each pixel, generating effective binary maps and facilitating visualization of morphologies by enabling annotation of multiple features within tomograms (Fig. 2c, left)18. Meanwhile, CNN composed of convolutional, pooling, and fully-connected layers, produces feature maps and dimensionality reduction, generating one-dimensional vectors for classification tasks (Fig. 2c, middle)19. This classification method enabled crystal representation through diffraction image calculation, even quantitatively matching predicted structural classes with their symmetry-driven physical properties, such as phase transition pathways and defect tolerance.

Finally, despite challenges in high-resolution 3D reconstruction due to high background noise in EDS spectra, combinations of unsupervised deep networks (UDN) facilitate chemical property analysis of nanomaterials by enabling high-quality 3D reconstruction through sonogram generation networks with limited labeled spectra (Fig. 2c, right)20. The effectiveness of these UDN-based 3D reconstructions was validated against experimental data, such as high-angle annular dark-field scanning TEM (HAADF-STEM) images and Fourier shell correlation analysis, for both core-shell and mono-elemental nanocrystals. Notably, the ML-based reconstructions demonstrated improved shape fidelity and reduced artifacts compared to conventional algorithms, highlighting their potential for more robust characterization. These advanced computational methods collectively address the inherent limitations of conventional TEM analysis for soft materials, providing more robust and comprehensive characterization of self-assembled structures across multiple dimensions.

Neural network-augmented microscopy with enhancement of spatiotemporal resolution

While conventional TEM and AI-integrated analysis provide valuable insights into soft material structures, capturing the full complexity of hierarchical assemblies requires more advanced approaches. Building upon these foundations, Fig. 3 explores the enhanced capabilities of cryo-ET and LP-TEM for 3D and dynamic visualization of self-assembly processes21,22,23,24,25,26,27,28,29. These methods not only address the limitations of traditional TEM in preserving native structures but also generate rich, multidimensional datasets that pose new analytical challenges5,8,15. Here, we demonstrate how ML algorithms facilitate automated segmentation, feature extraction, and quantitative characterization of hierarchical assemblies across multiple length scales and time domains.

Cryo-TEM enables visualization of the native morphology of hydrated self-assemblies, providing insights into complex soft material structures21,22. As shown in Fig. 3a, this methodology allows direct observation of the chain folding orientation of conjugated polymers assembled in nanofibers formed through solution-state crystallization-driven assembly21. Additionally, SAED analysis enables crystallographic characterization of crystalline polymer-core structures in core-corona block assemblies22.

When combined with ET for 3D analysis, these approaches reveal intricate internal architectures of complex assemblies21,22,23,24,25. ET enables volumetric reconstruction through iterative back-projection of tilt-series projections acquired at angular increments, typically spanning ±60–70° tilt ranges at 1–2° intervals. Through computerized reconstruction algorithms (e.g., filtered back projection, weighted back projection, and simultaneous iterative reconstructive technique), ET visualizes not only external morphologies but also internal architectures such as onion-like vesicles with water channels between multiple compartments for multi-drug loading capabilities23, cubosomes composed of inverse cubic mesophase with double-channel structures24, and RNA origami tertiary structures revealing various conformational states of 6-helix bundle with a clasp helix, demonstrating a folding landscape driven by helix-helix compaction interactions25. ET faces several technical challenges, including the missing wedge phenomenon resulting from mechanical limitations in tilt angles, which compromises reconstruction accuracy5. The inherent trade-off between spatial resolution and electron dose creates additional difficulties, as extended exposure times for improved SNR risk specimen damage in beam-sensitive soft materials. The integration of direct electron detectors and automated data collection systems has enabled high-throughput TEM tomography, generating terabyte-scale 4D datasets with enhanced SNRs8, which necessitate DL frameworks for processing tasks from automated tilt-series alignment to feature segmentation.

Both cryo-TEM and ET provide information only about fixed states, limiting their ability to capture dynamic material behavior in solution. This limitation has elevated the importance of in-situ LP-TEM (Fig. 3a, right)26,27,28,29, which enables direct visualization of dynamic self-assembly processes in native liquid environments. Unlike cryogenic methods, LP-TEM reveals real-time molecular behavior, including single polymer chain motion26, complex mechanisms such as liquid-liquid phase separation during vesicle membrane formation27, and the dynamic assembly and motion of polymer chains and micelles, including the responsive behavior of block copolymers with lower critical solution temperature characteristics28. Furthermore, LP-TEM can even capture the self-assembly by chemical reaction-triggered molecular transformation. The reduction of disulfide bonds in cyclic peptides converts into acyclic peptides to form spherical aggregates, which in turn evolved into fibers29.

LP-TEM employs specialized liquid cells to maintain samples within the vacuum environment of the electron microscope. Silicon nitride cells facilitate chemical reactions and temperature control, while graphene-based cells offer superior resolution for atomic-scale imaging6. This methodology enables solution injection, in-situ mixing, and precise control over environmental conditions, making it ideal for studying hierarchical self-assembly under physiologically relevant conditions. Despite these advantages, LP-TEM faces challenges with polymer samples, including sample preparation complexity, electron beam-induced damage, and low SNRs. These limitations emphasize the need for advanced computational approaches to enhance image quality and extract meaningful information from noisy data, reinforcing the importance of AI integration for advancing TEM characterization techniques for soft materials.

Imaging hierarchical complex self-assembled soft materials with spatiotemporal resolution still presents significant challenges (Fig. 3b, top), including unexpected specimen damage from electron beam interactions, undesired chemical reactions induced by the electron beam, difficulty distinguishing fine structural details due to low SNRs, tracking complex dynamics with spatiotemporal heterogeneity across different scales, and computational challenges in analyzing the huge volumes of multidimensional data5,6,17.

To address these challenges, we present two representative ML-assisted approaches. The first focuses on 3D segmentation in cryo-ET for macromolecular identification (Fig. 3b, bottom left)30. Cryo-ET generates sufficient resolution and 3D perspectives to identify macromolecular assemblies, enabling analysis of mutual interactions between assemblies. Unlike fluorescence microscopy, which facilitates structural assessment through specific fluorescent markers labeling target sites, cryo-ET necessitates utilizing the structures based on their inherent characteristics without markers. The missing wedge problem in Fourier space generates artifacts and results in anisotropic resolution, which, combined with low SNR, complicates identification within tomograms. DeepFinder, a 3D CNN-based algorithm following U-Net architecture, establishes a multi-class network for macromolecule identification and coordinate determination in cryo-tomograms, facilitating statistical analyzes including distance-to-membrane measurements. While ML has contributed to addressing 3D interpretation difficulties in cryo-ET, providing multidimensional imaging modalities for materials with rich reconfigurability and spatiotemporal heterogeneity remains a significant challenge5,8.

The second approach employs statistical analysis-based ML for predicting particle motion and behavior in LP-TEM analysis (Fig. 3b, bottom right)31. A CNN-based model called motion-based point cloud prediction network (MoNet) has been developed to analyze nanoparticle trajectories in LP-TEM, predict diffusion class probabilities, and determine dominant motion types (Fractional Brownian motion, Brownian motion, continuous-time random walk). This enables precise analysis of particle motion characteristics in 3D space. Additionally, high-speed, high-fidelity segmentation using U-Net has been employed to extract self-assembly dynamics of individual nanoparticles, such as etching kinetics and diffusion coefficients. CNN models have successfully predicted the motion of Au nanoparticles exhibiting anomalous diffusion behavior modulated by electron beam dose rates. However, applications for soft matter remain underdeveloped due to electron beam sensitivity and difficulties in distinguishing structural details, with few reports on LP-TEM image analysis workflows for low-contrast materials such as polymers.

Conclusion and prospect

This perspective has explored the remarkable advancements in TEM for investigating hierarchical self-assembly in nanostructured soft materials. TEM has evolved from a simple imaging tool to a sophisticated analytical platform capable of providing multidimensional insights into complex soft matter structures across spatial, temporal, and compositional dimensions. The integration of conventional TEM with advanced methodologies such as cryo-TEM, ET, and LP-TEM has expanded our ability to directly visualize dynamic molecular interactions and phase transitions at the nanoscale, establishing crucial correlations between structural features and material properties.

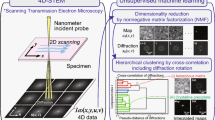

The emergence of AI integration with TEM represents a pivotal development in addressing the inherent limitations of traditional analytical approaches. Neural network-based methods have demonstrated promising capabilities in enhancing low-contrast imaging, enabling automated feature extraction, facilitating 3D reconstruction, and analyzing dynamic processes in beam-sensitive soft materials. These AI-augmented microscopy techniques have significantly improved spatiotemporal resolution while alleviating electron beam damage, allowing for more comprehensive characterization of self-assembled structures than previously attainable. Despite these advances, several challenges remain in fully realizing the potential of AI-integrated TEM analysis. A pivotal challenge involves establishing the computational infrastructure necessary to process increasingly large and complex datasets. Modern TEM modalities, particularly 4D-STEM and in-situ LP-TEM with advanced detectors, generate voluminous data (often hundreds of gigabytes to terabytes per hour), demanding high-throughput storage solutions (e.g., solid-state drives arrays configured in redundant array of independent disk configurations) and robust data management frameworks. To fully exploit these capabilities, efficient data processing and ML model execution heavily rely on graphics processing unit (GPU)-accelerated pipelines, typically implemented using frameworks such as PyTorch or TensorFlow30,32. For example, ML inference for tasks like image segmentation can achieve near real-time speeds (seconds per large frame) on NVIDIA GTX Titan Volta GPUs32, while training has also been successfully performed using Tesla K80 or Quadro RTX 5000 GPUs depending on model complexity and dataset size30. Additionally, scalable computing infrastructures, such as edge computers connected to high-performance computing clusters, have been proposed to support real-time feedback, automated control, and atomic-level simulations in ML-integrated workflows33. Thus, a scalable integration of software frameworks, hardware accelerators, and data I/O architectures is essential for advanced AI-augmented electron microscopy.

The preparation of appropriate training datasets with corresponding masks for custom prediction tasks is complicated by the minimal intensity differences between organic samples and backgrounds in soft materials. Unbalanced datasets present substantial challenges in training high-accuracy predictive models, requiring careful consideration of sampling strategies and class weighting during model development5. Furthermore, robust evaluation metrics are essential to assess whether trained models successfully perform their intended prediction tasks in complex hierarchical systems. Looking forward, the convergence of TEM and AI offers transformative opportunities for advancing soft matter self-assembly research, improving our ability to design responsive, adaptive, and multifunctional materials. The development of comprehensive automated systems—from molecular design through experimentation to post-processing and analysis—coupled with integrated ML-driven modules, opens new avenues for predicting material properties and refining existing materials through targeted physicochemical data collection.

The next generation of ML-integrated TEM platforms will likely feature enhanced capabilities for real-time analysis, reduced electron beam damage, improved contrast for organic polymer materials, and more sophisticated multidimensional data interpretation. These developments will be crucial for elucidating the complex assembly pathways and structure-property relationships that govern functional behavior in soft materials, ultimately accelerating the discovery and development of next-generation functional materials for addressing emerging global challenges.

Challenges and opportunities

Cryo-TEM, while originating as a methodology for analyzing biological specimens, has undergone a remarkable evolution to become a critical analytical tool for characterizing functional materials across diverse fields (Fig. 4a)34. Notably, it now plays an indispensable role in analyzing fuel cells, lithium-ion batteries, and various energy storage materials (Fig. 4b)35. The exponential growth in energy materials studies utilizing cryo-TEM demonstrates its effectiveness for non-destructive, solution-state structural analysis without traditional sample preparation artifacts.

a Expansion of cryo-TEM from biology into energy, environmental sustainability-related research fields34. Reproduced with permission from ref. 34. Copyright 2020 American Chemical Society. b Timeline showing the increasing adoption of cryo-TEM in battery research for visualizing interfacial phenomena and structural changes35. Number of publications data obtained from the ISI Web of Science, as of Jan. 2025. Reproduced with permission from ref.35. Copyright 2017 AAAS. c Proposed integrated platform architecture combining ML-enhanced TEM analysis with other AI-based analytical methods. This integration enables predictive materials design and modification strategies based solely on imaging data, offering a comprehensive solution for accelerated materials development.

As nanotechnology advances and material diversity expands, we find ourselves at a critical juncture where the Fourth Industrial Revolution, space exploration initiatives, and climate change adaptation are driving unprecedented materials innovation. This technological convergence necessitates comprehensive investigation of self-assembled soft materials under extreme conditions and a fundamental reframing of associated theoretical frameworks (Fig. 4c). Understanding how hierarchical soft materials behave under extreme temperatures, pressures, radiation environments, or microgravity conditions will be essential for developing next-generation functional materials that can meet emerging global challenges. The exploration of these frontier conditions will inevitably generate massive datasets that far exceed traditional analytical capacities. ML-enhanced TEM will therefore emerge as an essential innovative technology for processing and interpreting this vast volume of complex, multidimensional big data. The integration of ML algorithms with advanced TEM represents not merely an incremental improvement in characterization capabilities, but a paradigm shifts in how we approach materials analysis and discovery.

The ultimate goal lies in creating comprehensive AI-integrated solutions that cross-validate TEM imaging data with complementary characterization techniques such as X-ray scattering, spectroscopy, and mechanical testing. Such a unified materials informatics platform could significantly transform the field by not only characterizing existing materials but also suggesting design modifications and predicting properties based solely on imaging data. This capability would dramatically accelerate materials development cycles, enabling researchers to rapidly identify promising candidates for specific applications without extensive trial-and-error experimentation. In summary, we anticipate that overcoming the limitations of conventional TEM through AI-assisted automation, multi-modal imaging, and computational integration will fundamentally redefine the paradigm of soft matter self-assembly research. Through the synergistic application of ML, high-throughput microscopy, and in-situ imaging, researchers will unlock novel functionalities in materials design, drug discovery, and energy storage technologies. This convergence of advanced TEM with AI will enable exceptional precision in understanding and designing hierarchical nanostructures, ultimately accelerating solutions to society’s most pressing challenges through tailored materials development.

References

Yao, H. et al. Molecular architecture of the SARS-CoV-2 virus. Cell 183, 730–738 (2020).

Li, W. Learning from nature: chemical self-assembly for materials science. Matter 3, 968–969 (2020).

Klug, A. From macromolecules to biological assemblies (nobel lecture). Angew. Chem. Int. Ed. Engl. 22, 565–582 (1983).

Draft Guidance for Industry. Liposome Drug Products: Chemistry, Manufacturing, and Controls; Human Pharmacokinetics and Bioavailability; and Labeling Documentation U.S. Food and Drug Administration. http://www.fda.gov/downloads/drugs/guidancecomplianceregulatoryinformation/guidances/ucm070570.pdf Accessed Apr. 2018.(2018).

Lyu, Z., Yao, L., Chen, W., Kalutantirige, F. C. & Chen, Q. Electron microscopy studies of soft nanomaterials. Chem. Rev. 123, 4051–4145 (2023).

Proetto, M. T. et al. Dynamics of soft nanomaterials captured by transmission electron microscopy in liquid water. J. Am. Chem. Soc. 136, 1162–1165 (2014).

Mei, Q., Xie, Y., Yuan, W. & Jackson, M. O. A Turing test of whether AI chatbots are behaviorally similar to humans. Proc. Natl Acad. Sci. USA 121, e2313925121 (2024).

Spurgeon, S. R. et al. Towards data-driven next-generation transmission electron microscopy. Nat. Mater. 20, 274–279 (2021).

Jumper, J. et al. Highly accurate protein structure prediction with AlphaFold. Nature 596, 583–589 (2021).

Abramson, J. et al. Accurate structure prediction of biomolecular interactions with AlphaFold 3. Nature 630, 493–500 (2024).

Gröschel, A. H. et al. Guided hierarchical co-assembly of soft patchy nanoparticles. Nature 503, 247–251 (2013).

Kayunkid, N., Uttiya, S. & Brinkmann, M. Structural model of regioregular poly(3-hexylthiophene) obtained by electron diffraction analysis. Macromolecules 43, 4961–4967 (2010).

Qiu, X. et al. Superstructured mesocrystals through multiple inherent molecular interactions for highly reversible sodium ion batteries. Sci. Adv. 7, eabh3482 (2021).

Wu, H., Friedrich, H., Patterson, J. P., Sommerdijk, N. A. J. M. & de Jonge, N. Liquid-phase electron microscopy for soft matter science and biology. Adv. Mater. 32, 2001582 (2020).

Cheng, Z., Wang, C., Wu, X. & Chu, J. Review in situ transmission electron microscope with machine learning. J. Semicond. 43, 081001 (2022).

Falk, T. et al. U-Net: deep learning for cell counting, detection, and morphometry. Nat. Methods 16, 67–70 (2019).

Yao, L., Ou, Z., Luo, B., Xu, C. & Chen, Q. Machine learning to reveal nanoparticle dynamics from liquid-phase TEM videos. ACS Cent. Sci. 6, 1421–1430 (2020).

Chen, M. et al. Convolutional neural networks for automated annotation of cellular cryo-electron tomograms. Nat. Methods 14, 983–985 (2017).

Ziletti, A., Kumar, D., Scheffler, M. & Ghiringhelli, L. M. Insightful classification of crystal structures using deep learning. Nat. Commun. 9, 2775 (2018).

Han, Y. et al. Deep learning STEM-EDX tomography of nanocrystals. Nat. Mach. Intell. 3, 267–274 (2021).

Wirix, M. J. M., Bomans, P. H. H., Friedrich, H., Sommerdijk, N. A. J. M. & de With, G. Three-dimensional structure of P3HT assemblies in organic solvents revealed by cryo-TEM. Nano Lett. 14, 2033–2038 (2014).

Tian, J. et al. High-resolution cryo-electron microscopy structure of block copolymer nanofibres with a crystalline core. Nat. Mater. 22, 786–792 (2023).

Park, M.-K. et al. Stepwise drug-release behavior of onion-like vesicles generated from emulsification-induced assembly of semicrystalline polymer amphiphiles. Adv. Funct. Mater. 25, 4570–4579 (2015).

La, Y. et al. Templated synthesis of cubic crystalline single networks having large open-space lattices by polymer cubosomes. Nat. Commun. 9, 5327 (2018).

Liu, J. et al. Non-averaged single-molecule tertiary structures reveal RNA self-folding through individual-particle cryo-electron tomography. Nat. Commun. 15, 9084 (2024).

Nagamanasa, K. H., Wang, H. & Granick, S. Liquid-cell electron microscopy of adsorbed polymers. Adv. Mater. 29, 1–6 (2017).

Ianiro, A. et al. Liquid–liquid phase separation during amphiphilic self-assembly. Nat. Chem. 11, 320–328 (2019).

Korpanty, J., Parent, L. R., Hampu, N., Weigand, S. & Gianneschi, N. C. Thermoresponsive polymer assemblies via variable temperature liquid-phase transmission electron microscopy and small angle X-ray scattering. Nat. Commun. 12, 6568 (2021).

Touve, M. A., Carlini, A. S. & Gianneschi, N. C. Self-assembling peptides imaged by correlated liquid cell transmission electron microscopy and MALDI-imaging mass spectrometry. Nat. Commun. 10, 4837 (2019).

Moebel, E. et al. Deep learning improves macromolecule identification in 3D cellular cryo-electron tomograms. Nat. Methods 18, 1386–1394 (2021).

Jamali, V. et al. Anomalous nanoparticle surface diffusion in LCTEM is revealed by deep learning-assisted analysis. Proc. Natl Acad. Sci. USA 118, e2017616118 (2021).

Lobato, I., Friedrich, T. & Van Aert, S. Deep convolutional neural networks to restore single-shot electron microscopy images. npj Comput. Mater. 10, 10 (2024).

Kalinin, S. V. et al. Machine learning in scanning transmission electron microscopy. Nat. Rev. Methods Primers 2, 11 (2022).

Li, Y., Huang, W., Li, Y., Chiu, W. & Cui, Y. Opportunities for cryogenic electron microscopy in materials science and nanoscience. ACS Nano 14, 9263–9276 (2020).

Li, Y. et al. Atomic structure of sensitive battery materials and interfaces revealed by cryo–electron microscopy. Science 358, 506–510 (2017).

Acknowledgements

This research was supported by the Basic Science Research Program (2022R1A2C2012889, RS-2023-00281553) through the National Research Foundation of Korea (NRF), funded by the Ministry of Science and ICT (MSIT). This work was also supported by the InnoCORE program of the MSIT (GIST InnoCORE KH0830).

Author information

Authors and Affiliations

Contributions

J.Y. and J.H.H. prepared the figures. J.Y. and E.L. wrote and edited the manuscript. All authors discussed the contents together and commented on the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Yoon, J., Hwang, J.H. & Lee, E. Dive into soft matter imaging: artificial intelligence-integrated electron microscopy. NPG Asia Mater 18, 1 (2026). https://doi.org/10.1038/s41427-025-00629-0

Received:

Revised:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41427-025-00629-0