Abstract

Structural designs inspired by physical and biological systems have been previously utilized to develop mechanical metamaterials with enhanced properties based on clever geometric arrangement of constituent building blocks. Here, we use the DNA origami method to realize a nanoscale metastructure exhibiting mechanical frustration, a counterpart of the well-known phenomenon of magnetic frustration. By selectively actuating reconfigurable struts, it adopts either frustrated or non-frustrated states, each characterized by distinct free energy profiles. While the non-frustrated state distributes the strain homogeneously, the frustrated mode concentrates it at a specific location. Molecular dynamics simulations reconcile the contrasting behaviors and provide insights into underlying mechanics. We explore the design space further by tailoring responses through structural modifications. Our work combines programmable DNA self-assembly with mechanical design principles to overcome engineering limitations encountered at the macroscale to design dynamic, deformable nanostructures with potential applications in elastic energy storage, nanomechanical computation, and allosteric mechanisms in DNA-based nanomachinery.

Similar content being viewed by others

Introduction

Mechanical metamaterials are designed by arranging mechanically coupled, cellular building blocks to achieve nonlinear stress responses1, shape morphing2, or auxetic deformation3,4. The geometric configuration of the building blocks is key in metastructure design since it gives rise to the observed behaviors. Architected metamaterials cater to a wide variety of applications in aerodynamics5,6, biomedicine7, photonics8, and acoustics9. Among various design strategies, mechanical frustration is a unique approach in the development of mechanical metamaterials, whose behavior is analogous to magnetic frustration. In magnetic frustration, electronic spins cannot interact cooperatively due to geometric constraints imposed by their arrangement in a lattice, resulting in magnetic states with high ground-state degeneracy10. A paradigmatic form of magnetic frustration is exhibited by the Ising model of spins with antiferromagnetic coupling arranged on a triangular or Kagome lattice11. By drawing an analogy between mechanical deformation and electronic spin, similar models can be leveraged to design frustrated metamaterials12,13,14,15. When deformations in neighboring cells of the metamaterial can interact cooperatively, adaptable structures are realized; in contrast, conflicting interactions lead to an inadaptable state where strains are localized. Due to the vast combinatorial number of possible arrangements of the mechanical building blocks, this approach allows for an extremely large design space for structures exhibiting mechanical frustration behaviors. Previous studies following this method used 3D-printed lattices deforming under external forces16, but these are only viable at the meso- to macroscale (i.e., micrometer-sized or larger structures where classical elasticity theories hold). Frustrated metamaterials have never been realized at the nanoscale, because of difficulties in precise assembly and structural accuracy. A design approach that enables mechanical frustration at the nanometer level can open avenues to develop architected nanomaterials with tunable responses, large-scale deformation, and ‘action-at-a-distance’ capabilities.

DNA origami is a bottom-up approach for constructing arbitrary nanostructures based on sequence complementarity17,18. Given the excellent programmability and structural predictability, DNA self-assembly has demonstrated both static and dynamic19 materials including 2D networks20,21, 3D polyhedra22, nanoframe lattices23, reconfigurable switches24, kinematic mechanisms25,26, and nanomachines powered by electric fields and chemical potentials27,28,29,30,31. Most deformable DNA constructs fall under the umbrella of adaptability, where their components interact in synchrony to exhibit overall deformations or even negative Poisson’s ratios32,33. Their mechanical properties can be tailored by engineering structural components34, defects35, and chemical adducts36,37. Recent reports used computational mechanics to understand relevant properties and thermodynamic models to elucidate free energy landscapes38,39,40.

Here, we integrate DNA origami with computational design principles to develop nanoscale metastructures. The current work builds upon earlier mechanically frustrated structures designed using the Ising model41, utilizing DNA as a platform to study frustration at a smaller scale. We construct a Kagome-like lattice using DNA wireframes and calculate the free energies via molecular dynamics (MD) simulations to demonstrate adaptable and inadaptable structures. DNA is used as rigid edges in the wireframe as well as deformable struts. This allows us to dynamically transform between adaptable and inadaptable states, unlike macroscale metamaterials, which are normally set by design. Coarse-grained MD models elucidate contrasting behaviors with distinct strain/stress distributions and show how to design metastructures with multistability. We realize the structural design in experiment by using external stimuli (two-step DNA reactions and UV light irradiation) and demonstrate the frustration with buckling edges that can be recovered reversibly. Following the principles of the adaptable and inadaptable states, we expand the design concept by tuning the free energy landscapes through structural modifications, for example, changes in loading conditions and introduction of defects in selective edges. The resulting structures show rerouted strain distributions and distinct responses that can be tailored, thus demonstrating the versatility of our approach.

Results

Designing geometric frustration

Drawing inspiration from the Kagome lattice in spin-frustrated systems, we designed a six-cell hexagonal lattice as a model system (Fig. 1a, b) for engineering mechanically frustrated DNA metastructures. Our DNA lattice is composed of honeycomb-patterned, two-helix bundle (2HB) edges with a designed length of ~28 nm each (see Supplementary Figs. 2 and 3 for design details). To demonstrate both frustrated and non-frustrated states in a single lattice, we embedded additional adjustable struts42 shown as colored edges in Fig. 1c, which served as actuators in experiment. This structure switches between adaptable and inadaptable modes in response to external loadings applied to the green and blue edges, respectively (Fig. 1d, e; the red is the common edge for actuation). In theory, mapping the deformation of the constituent cells predicts that the adaptable mode will deform freely, distributing the strain throughout the structure, whereas the inadaptable state will be frustrated and localize the strain with buckling edges (Supplementary Fig. 1). While this is an effective process for designing macroscale metamaterials, nanoscale constructs such as our DNA lattices require additional consideration. This is due to the interplay between thermal fluctuations and the intrinsic mechanical properties of DNA, leading to more complex behaviors. MD simulation is an excellent approach to elucidate this interplay. Coarse-grained models have proven to be successful in explaining structural behaviors of DNA nanostructures34,43. We performed coarse-grained MD simulations using the oxDNA platform44,45. Figure 1f, g shows the equilibrium conformations of the DNA metastructure in the adaptable and inadaptable states.

a Interactions of electronic spins (red arrows) lead to a stable (ferromagnetic) state in a square arrangement, while a triangular design cannot minimize the energy (anti-ferromagnetic). The spins in the Kagome lattice exhibit complex magnetic frustration behaviors. b Electronic spin can be replaced by mechanical strain in two distinct deformation modes. Interactions between neighboring building blocks lead to adaptability (cooperative deformation) or inadaptability (frustration due to conflicting deformation). Both modes differ geometrically only in the orientation of a unit cell. c Schematic of theoretical DNA origami design combining both modes into a single lattice, with edges made of 84-nt-long 2HB DNA. The edges highlighted in red, blue, and green can serve as actuators (DNA jacks). d, e Activating the red edge in conjunction with green steers the structure into the adaptable state (d), while blue and red together lead to the inadaptable state (e). f, g MD simulated conformations of adaptable and inadaptable DNA. The structures are colored based on internal forces, with blue indicating compression and red indicating extension. h Free energy profiles of adaptable and inadaptable modes using umbrella sampling. The x-axis is the distance of the edges indicated by green and blue arrows in (f and g).

Buckling occurred consistently in a particular edge across multiple rounds of MD simulations. To delve deeper into the underlying mechanism dictating the observed conformations, we calculated the free energy profiles using umbrella sampling46. Fig. 1h presents the free energy landscapes of the two modes as a function of distance shown as green and blue arrows in Fig. 1f, g. The adaptable mode exhibits a steep-welled, single minimum in its free energy, while the inadaptable state shows two distinct minima: a gradual dip with a flat bottom from 17 to 20 nm and a minimum at ~28 nm. The single minimum in the adaptable mode indicates that the most stable state occurs when the edge is fully extended, suggesting that strain is not concentrated at a particular point. Since all the edges in the state move coherently, the deformation of the cells and nodes is not impeded by any conflicts. Consequently, the corresponding free energy profile is similar to that of a single 2HB DNA edge (Supplementary Fig. 11a), implying that the deformation of the rest of the structure does not play a major role in affecting the free energy of the edge. In contrast, the dual minima of the inadaptable free energy landscape indicate two stable states where the edge is either buckled or fully extended. The short spike in free energy between the two minima shows that while the buckled and extended states are stable, intermediates that are partially bent are not. This hints that the edge experiences a snap buckling, i.e., the edge exists in either extended or buckled states, switching between them with sufficient energy overcoming the small activation barrier. The minimum at ~28 nm implies that the buckling in the inadaptable state is transferred into other edges within the structure.

Unlike in macroscopic structures, random thermal fluctuations of a DNA metastructure increase the propensity of multistability, where the likelihood of other edges being stuck in buckled states also increases. Therefore, nanoscale frustrated metastructures exhibit a larger number of stable states in comparison to their macroscale counterparts. In addition, these states are not fixed as the inadaptable structure may transition from one stable mode to another by interchanging buckling. Figure 1f, g also indicates that while the adaptable state is symmetric, the inadaptable mode has a broken symmetry, suggesting that the distinct responses observed are caused by differences in symmetry as well. The inadaptable free-energy peak separating the two minima is relatively small (< 5 kBT in magnitude), enabling transitions between the states and thus unlocking mechanical bistability at room temperature. The shape of the energy wells in Fig. 1h is a direct consequence of the design choice of using 2HB edges, which are comparatively flexible. Choosing 4HB or 6HB edges will change the shape of the profile due to the higher energy cost associated with bending the stiffer edges, i.e., the wells of energy minima will become relatively deeper and narrower (Supplementary Fig. 11b)47. The profiles can be tailored further, by changing the lengths of the single-stranded DNA sections at the vertices connecting the edges; in the current design, 60° and 120° junctions have 5 and 3 nucleotides (nts), respectively.

Experimental demonstration

We demonstrated the lattice design experimentally using deformable DNA origami wireframes. First, we constructed DNA structures corresponding to both modes separately. Starting from the synthesized initial undefined state (where the three adjustable edges are missing), we added two sets of staple strands to assemble either the adaptable or inadaptable modes (Fig. 2a). Figure 2b shows the theoretical designs, atomic force microscopy (AFM) scans, and contrast images of the adaptable state. As expected, the assembled DNA has mostly straight edges, with all interior triangles retaining shape. In contrast, the inadaptable DNA displays evident buckling in some edges (highlighted by blue and white arrows in the schematics and AFM images in Fig. 2c), while the remaining edges are largely straight as designed. Both structures follow our designs accurately.

a Construction of adaptable and inadaptable structures from an initial undefined state by adding respective staples. b, c Schematics, AFM scans, and contrast images of adaptable and inadaptable DNA nanostructures. The blue and white arrows highlight the buckled edge in the schematics and AFM images, respectively (c). d Illustration of DNA jack edges analogous to a mechanical car jack and their function for external loading. By modulating the length of DNA jack edges, the nanostructure can be deformed into either adaptable or inadaptable states. e Scheme for two-step DNA reactions for reconfiguration. This is achieved by first adding corresponding jack releaser strands to change from the initial extended mode to the undefined states and then introducing a set of jack staples to reconfigure into either inadaptable or adaptable modes. This chemical loading is reversible such that the origami can transition between initial, adaptable, and inadaptable states with appropriate inputs. f Initial state with all three jack edges extended. g, h, Images of adaptable and inadaptable structures reconfigured after chemical loading. i Schematic of a jack edge with UV-responsive staples. The purple dot indicates the UV photocleavable moiety. UV irradiation cleaves the staples, leading to the release of the jack. j, k Schematics, AFM scans, and contrast images of adaptable and inadaptable structures transitioning to undefined states after UV exposure. l Edge length and angle distributions measured from AFM images of the initial state with all three jacks extended. m Experimental yields of DNA structures measured from AFM (brown) and agarose gel electrophoresis (grey). The numbers in the panel denote the number of structures analyzed for AFM yields (source data for (l and m) are provided in the Source Data file). The scale bar in all AFM images is 50 nm.

Next, we studied deformation behaviors of our DNA metastructure upon external loading. Since it is difficult to apply forces precisely at specific vertices due to the small size of the structure, we used chemical loading to induce deformation. We achieved this by using adjustable DNA ‘jack’ mechanisms as illustrated in Fig. 2d. Like a car jack, the DNA jack can be adjusted in length via two-step DNA reactions—toehold-mediated strand displacement of one set of staples and re-annealing with a new set of staples of interest42. This actuation will deform the entire structure into different modes reversibly. Figure 2d (bottom) shows the DNA jack in action, as a part of the building block, increasing the number of possible deformation modes in comparison to the regular building block in Fig. 1b, c. In the deformation experiments, we began from the initial state with all jacks extended and deformed into either of the states by first adding the respective ‘releasers’ and then the staples for short jacks (Fig. 2e). The initial state with all jacks extended (Fig. 2f) transforms into either the adaptable (Fig. 2g) or inadaptable (Fig. 2h) modes when subject to different loadings. The structures assumed in both states are consistent with those observed in the direct assemblies in Fig. 2b, c. The AFM scans of the intermediate steps during chemical loading are shown in Supplementary Figs. 18 and 20. The lengths of the jack edges before and after reconfiguration change from 28 nm to <6 nm. The end-to-end distance of the buckled edges in the inadaptable state is about 18 nm, as predicted by free energy calculations in Fig. 1h. In rare cases, buckling occurs in multiple edges (Fig. 2h, first row). A considerable advantage of this chemical loading method is that it allows for reversible structural transformations between initial, adaptable, and inadaptable states (Supplementary Figs. 22 and 23).

From an energetic perspective, the adaptable and inadaptable structures are two distinct modes of distributing strain energy that is introduced into the system via strand displacement. Therefore, releasing the elastic energy will spontaneously transform the deformed structures into relaxed states. To test this hypothesis, we used jack staples with photoresponsive moieties which would be cleaved by UV light irradiation, leading to the breakage of the jacks, as depicted in Fig. 2i36. Indeed, both adaptable and inadaptable structures transitioned into their undefined states after 30 min exposure to UV light (Fig. 2j, k). Such a process is faster compared to a strand displacement experiment (taking ~12 h). We also measured the edge lengths and internal angles of the equilateral triangles and rhombic shapes within the hexagonal lattice from the AFM images of the initial state with all the jacks extended (Fig. 2e (i), f and S3 inset). As shown in Fig. 2l, the average edge length measured is approximately 28 nm and the angles are around 60° and 120°, matching our theoretical design. The yields of synthesized structures were estimated using AFM images and agarose gel electrophoresis, which range from 75% to 90% (Fig. 2m). The yields from the gel data are slightly higher than those from AFM scans because the structures with minor defects can travel at the same speed as correct structures in agarose.

Computational mechanics

We used coarse-grained MD models to study structural and mechanical behaviors during deformation. Compared to traditional elasticity theory predictions, MD simulations are advantageous as they account for both thermodynamic and mechanical properties. Instead of using chemical loading, simulations allow for application of external forces directly to the DNA structure, enabling us thus to study how deformation and strain evolve over time. First, we removed the jack edges, leaving short residues (10 base-pairs) on each side to aid force application (highlighted by arrows in Fig. 3a(i) and b(i)), and pulled them closer from 28 to 6 nm using harmonic traps in oxDNA. Figure 3 shows a series of snapshots representing effective (normalized) strain distributions in the adaptable and inadaptable modes. The strain map of the adaptable mode has a nearly uniform distribution throughout the domain. There are small segments of high strain (in red), which is a result of thermal fluctuations. No edges remain stuck in a state of excessive strain. Contrastingly, several edges of the inadaptable mode show significantly greater strain (and flexure) compared to their adaptable counterparts at the same timestep. While the strain fluctuates in most edges, it starts to develop in a particular edge and becomes more prominent with time (Fig. 3b (vii)–(xi)). Finally, the strain is concentrated into the edge and the structure becomes stuck in a buckled state (as also seen in Supplementary Movies 1 and 2 showing the evolution of the adaptable and inadaptable states, respectively). Upon removal of the loading, both structures spontaneously return to their initial configurations (shown in (xii)), consistent with experimental observations in Fig. 2j, k. The average forces required to pull the structures is approximately 15 pN per jack, while the maximum force that could be theoretically exerted is ~57 pN (estimated from the binding free energies of jack staple sequences), suggesting that the chemical loading provided experimentally was sufficient32.

a Snapshots of oxDNA configurations under mechanical loading from (i) initial to (xi) adaptable states. Each snapshot represents the conformation in the intervals of 5 × 106 steps. The edges being pulled are highlighted using black arrows in (i). The structure returns to the initial state after removal of external forces (xii). b Snapshots of DNA conformations during deformation from (i) initial to (xi) inadaptable states. The inadaptable mode bounces back to the initial state (xii), with the buckled edge completely recovered. All the edges in the structures are colored based on normalized strain calculated using the local tangent vector \(\overrightarrow{{t}_{{{{\rm{n}}}}}}\) at each location. We use the tangent vector 10-nt upstream (n-10) and downstream (n + 10) to obtain the strain at nt no. n as \({strain}=1-{\left(\overrightarrow{{t}_{n-10}}.\overrightarrow{{t}_{n+10}}\right)}^{2}\) which ranges from 0 to 1. The buckled edge shows the highest local strain in (b) and small kinks also have relatively high strain in (a).

Notably, most edges that show high strain in Fig. 3b are the diagonal struts of a rhombic group of edges similar in geometry to those shown in Fig. 2c and h. This is in fact an indicator of edges that are more likely to buckle. To understand this, we analyzed two (red and blue) rhombi each in the adaptable and inadaptable modes shown in the insets to Fig. 4a, b and plotted the normalized bend deflection of the diagonal struts against the average angle enclosed during the simulation in Fig. 3. Since there is no buckling in the adaptable mode, both the angle and bend deflection are nearly invariant throughout the deformation. Though the adaptable distributions deviate slightly (Fig. 4a (iii)), they return to an equilibrium angle of ~60° with minimal deflection. On the other hand, the distributions of the red and blue rhombi diverge in the inadaptable mode because the red diagonal edge is trapped into the buckled state during deformation while the blue edge remains extended (Fig. 4b (vi)–(x)).

a, b Bend deflection of central struts of colored rhombi (shown in red and blue in insets) vs average angle enclosed (red and blue dots in insets) for the adaptable (a) and inadaptable (b) states. Each colored dot represents the normalized deflection at a particular time instant in the given time interval. The normalized bend deflection is defined as the maximum distance from the line joining the opposite ends of an edge (length ‘a’ shown in (d) inset) divided by the edge thickness (d = 4 nm). The snapshots in Fig. 3i–x are representative conformations for the intervals (i)–(x). While the adaptable state remains constant all throughout, the distributions of the inadaptable state diverge with time due to buckling of the red strut. c, d Evolution of bend deflection of all edges with time for the adaptable (c) and inadaptable (d) modes. At each time instant, each circle represents the bend deflection of an edge normalized by thickness d. Two edges with relatively high bend deflection are numbered for reference. e, f, Internal forces for each edge extracted from MD simulations at equilibrium for adaptable (e) and inadaptable (f) states. The force distribution in (e) is more widespread, while most edges in (f) follow a narrow distribution with excessive compression concentrated in a single edge (edge 27). These patterns indicate the mechanism of strain distributions within the structure. The edges in (e and f) are also colored on the basis of relative position, highlighted by the inset in (f). The edges experiencing significant flexure (37) and buckling (27) are highlighted. The complete numbering of all edges is given in Supplementary Fig. 3.

Figure 4c, d shows the normalized bend deflection of each edge over time during deformation. With 36 edges in each structure, we plotted the average normalized bend deflection for each edge. Thus, each point represents the bend deflection of a particular edge at a particular instant of time. All edges of the adaptable mode shown in Fig. 4c stay within the confined region shaded grey, implying that none of the edges bend excessively. While few edges experience a flexure at some instants (marked edge 37), they bounce back and never permanently settle into a buckled state. However, the inadaptable mode has many more edges in the extrema of the grey region, with one of the edges experiencing severe buckling (marked edge 27 in Fig. 4d) during the latter half of the simulation. This supports the visual observations in Fig. 3b, with the buckled edge 27 having the highest strain. While this analysis focuses on planar effects of frustration, the structure in free solution likely experiences out-of-plane deformations with the edges buckling along the weakest direction (i.e., with the lowest bending modulus as shown in Supplementary Figs. 12 and 13). Anisotropy in stiffness can be mitigated by choosing thicker, more symmetrical edges like 4HB and 6HB designs. However, these options come with inherent trade-offs like challenges in self-assembly due to the requirement for multiple scaffolds as well as higher activation energies to switch between stable minima.

Examining the structures further, the final states of the simulation shown in Fig. 3 were used as input after ligating their jack edge residues. We simulated equilibrium conformations for a long period of time (i.e., 144 × 106 steps). The average internal force at the central section of each edge was extracted for both modes (Fig. 4e, f). The edges were grouped based on their relative location within the structure to understand if that has any role in determining their stress states. They were grouped into outer hexagon (pink), inner hexagon (light blue), outer spokes (green), and inner spokes (red), as illustrated in the inset of Fig. 4f. When comparing the adaptable and inadaptable modes, the exterior hexagons are primarily under extension in both cases; however, the distribution of the inner hexagons differs markedly. In Fig. 4f, one edge (no. 27) is a clear outlier, experiencing greater compression relative to others and therefore buckling as seen in Fig. 3b. Figure 4f also indicates that the interior spokes are the edges most likely to buckle in the inadaptable state, with most being in compression. Additionally, the distribution of internal forces in Fig. 4e is wider, suggesting an equal spread of forces throughout the structure. Conversely, most edges of the inadaptable state in Fig. 4f lie in a narrow distribution with the buckled edge being a lone outlier, suggesting localization of stresses. External loading and internal force simulations together elucidate stark differences in response of the two modes.

Expanding design space

The adaptable and inadaptable states described thus far are two examples from a vast space of possible combinatorial designs. The capabilities of this approach can be expanded further by exploiting the modularity of DNA origami. Previous studies reported that minor changes in structural and/or experimental conditions can potentially have major implications on the response of DNA assemblies27,35,48. By engineering small changes in components, free energy of a structure may be modified with a greater range and a finer control, beyond what is designed in Fig. 1. We thus explored a combination of three strategies—(i) changing the location of mechanical inputs (i.e., different edges used as jacks), (ii) decreasing the number of inputs, and (iii) reducing mechanical stiffness by introducing defects—to tune free energy profiles for structural designs and tailored responses. By rerouting strain to different parts and switching between inadaptability and adaptability (i.e., between bistable and monostable free-energy profiles) through small modifications, we show that DNA has great potential to design mechanical frustration as well as construct nanoscale metastructures with diverse responses without major changes to the initial geometry.

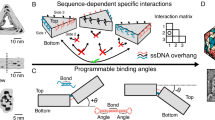

The ideal locations for different inputs or introducing defects are determined by examining the interactions between neighboring blocks, similar to the design of the adaptable and inadaptable states as described in Supplementary Fig. 1. First, we changed the jack locations to reroute the strain such that the final conformation still exhibits inadaptability but with buckling in a different edge. While keeping the common jack (shown in red color in Fig. 5a schematic), we used another edge colored blue for actuation. The new input results in strain rerouting from the inner hexagon to an outer edge (highlighted brown in the schematic and colored red in the MD structure), displaying the ‘rerouted inadaptable state’ in the MD-simulated structure. Accordingly, the free energy profile of the brown edge shows two minima (bistability); however, the profile is slightly flatter compared to Fig. 1h, which is likely due to the edge being located close to the outer perimeter and therefore easier to bend. This design was confirmed experimentally by AFM imaging where buckled edges indicated by white arrows are at the brown edge location. Given that geometric frustration arises due to conflicting inputs, removing one input should revert the structure back to adaptability. In Fig. 5b, the missing jack (no staples for constituting the edge) is represented by the black dotted line and leads to a single minimum in free energy. MD simulation shows an adaptable-like conformation with all the edges nearly straight, as seen in the AFM images. The same approach can be extended to our original inadaptable mode to engineer adaptability by removing one of the jacks (dotted line in Fig. 5c). Both the free energy profile and the MD conformation are now similar to those of the adaptable mode with AFM structures devoid of any buckling. It is interesting to note that removing an input in the adaptable mode does not significantly change the free-energy landscape nor conformation (Fig. 5d). We estimated the yields of these structures based on AFM images and agarose gel electrophoresis (Supplementary Figs. 26–34). Figure 5e shows that the experimental yield ranges from 75 to 90%, comparable to those in Fig. 2m.

a Schematic, strain-colored MD-conformation (similar to Fig. 3), free energy profile, and AFM images of a DNA metastructure with two jack inputs. The common jack and the new input are colored red and blue, respectively. The free energy profile of the brown-colored edge shows double minima, indicating strain localization, consistent with the MD-structure and AFM images (white arrows indicate buckled edges). This mode is referred to as a ‘strain-rerouted inadaptable’ state. b The strain-rerouted inadaptable mode transforms into ‘adaptable-like behavior’ when the new input is omitted (indicated by black dotted line). All the edges in the MD-conformation and AFM images are nearly straight. c Modifying the inadaptable mode by omitting the inadaptable jack edge (dotted line). Similar to (b), the free energy has a single minimum at ~28 nm. d The original adaptable state is modified by omitting the adaptable jack (dotted line). The conformation and free energy landscape are similar to Fig. 1f and h. e Structural yields from AFM (brown, labeled with the number of structures analyzed) and gel electrophoresis (grey). Source data for (e) is provided in the Source Data file. f Schematics comparing regular 2HB edges with those having four 5-nt nicks (thinner edge). g Adaptable mode with a defective edge (thin, brown) showing behavior nearly identical to Fig. 2. h Inadaptable state with defects in the original buckled edge (thin, brown). The free energy profile shifts markedly to a single minimum in the buckled region. i Inadaptable structure with defects shifted to an alternate edge (thin, black, inner strut). The MD-conformation shows buckling in both the original buckled (brown) and defective edges, also confirmed by the AFM images. j Introducing defects into the outer spoke edge studied in this figure (c) shifts the free-energy minimum, transitioning from an extended edge to a severely buckled state. In all panels, red, blue, and green struts denote the common, inadaptable, and adaptable jack edges. Dotted lines represent missing inputs with jack staples omitted. The definition and scale for the strain distributions in MD-conformations are the same as those in Fig. 3. All free energy profiles are plotted against brown edges. The scale bar in all AFM images: 50 nm.

Next, we tuned the free energy by introducing four 5-nt nick defects as illustrated in Fig. 5f. The defective edges are denoted with thinly warped edge profiles. The nicks weaken the stiffness of the edge and consequently lower the free energy profile as shown in Supplementary Fig. 11c. The adaptable design has a sharp free-energy profile, therefore, a slight decrease in the profile should not affect the conformation and behavior drastically. We confirm this by inserting nicks into the thin brown inner spoke in Fig. 5g. The free energy still exhibits a single minimum despite the defects and the structure shows adaptability. When the stiffness was reduced for the same edge in the inadaptable mode, however, the energy minimum shifted to ~18 nm in favor of buckling as seen in Fig. 5h. The MD and AFM structures exhibit similar buckling as the original inadaptable mode. The free energy can be further altered with strain rerouted by inserting nicks in a different edge (black thin inner spoke in Fig. 5i). Interestingly, the brown edge displays a bistability with a small activation energy (~ 2 kBT) to switch between minima. The decrease in the energy is due to the neighboring edge becoming weaker and prone to buckle (Supplementary Fig. 11d), therefore making it easier to transfer buckling. This highlights the effect of thermal fluctuations on DNA nanostructures, elucidating the interplay between thermodynamics and mechanics. The AFM scans show distinct buckling in both the brown and defective edges.

The defect insertion strategy can be combined with a single input for further design. The free energy profile of the adaptable-like structure in Fig. 5c has a considerable portion of the curve (from 16 to 26 nm) under 5 kBT. Inserting nicks in this structure weakens the construct into an inadaptable state with a single minimum as shown in Fig. 5j. The MD conformation and AFM images reflect this effect with the severely buckled edges indicated by white arrows. The designs explored here demonstrate that reducing the number of inputs can be as a means to mitigate the conflict and shift structures towards adaptability, while defects can effectively reroute the strain for steering structures into monostable states. This mechanistic insight helps reform free energy landscape and tailor structural responses as desired.

Discussion

Our work showcases the powerful synergy between DNA self-assembly techniques and mechanical design principles, paving the way to the development of a previously unexplored class of nanoscale frustrated metamaterials. By leveraging proper geometric and mechanical design, we were able to tune the free-energy profiles of nanostructures and precisely tailor their response to external stimuli. The inherent modularity of DNA origami makes the metastructures more versatile by engineering both adaptability and inadaptability into a single lattice, which is difficult to achieve with pure top-down approaches. While the DNA metastructures explored in this work are a small subset, they offer a glimpse into the vast design space that can be tapped, by introducing simple modifications into the structural parameters and consequently their free energies. As evident, MD simulations and free-energy profiles are pivotal for efficient exploration of this vast design space, which is tenuous and physically unrealistic to be explored by experiments alone.

The ability to route strain from external loading can be leveraged to develop methods of storing mechanical energy inside nanostructures. In nature, motor proteins like kinesin use controlled storage and release of strain energy to achieve directional motion with high processivity and directionality49,50. The extension and contraction of bundles of actomyosin filaments inside a cell are crucial for enabling cell motility51. The design approaches described here may be extended to develop synthetic motors capable of localized storage and release of strain on-demand. An example of this capability is seen through the release of strain to photo-stimuli in Fig. 2. This capability could also be used to perform nanoscale mechanical computations through shape memory. For example, different sequences of input stimuli would lead to unique strain states, potentially enabling a retrieval of the sequence of inputs based on the final strain state alone.

Frustration plays a crucial role in several biomolecular functions like protein folding, aggregation52, allostery, catalysis, and DNA-protein binding53. Allostery is often triggered by the transfer of strain from one part of a protein to another upon ligand binding at a given site, or other external stimuli. Although chemically different, the mechanics underlying this phenomenon are similar to those engineered in this work, namely, the strategic redistribution of strain through chemo-mechanical coupling. Replicating allosteric phenomena in synthetic systems has been challenging so far, but DNA nanotechnology offers an ideal platform for their construction and study. Although the present study focused on 2D deformations, it can serve as a steppingstone toward extending these principles to the design of 3D metastructures. Expanding the lengthscale of these structures would require greater structural fidelity and assembly of individual blocks into a larger lattice23,54,55,56,57.

While the current design exploited dual energy minima, further modifications could help engineer more complex energy landscapes with multiple minima. The concept of mechanical frustration can thus be employed to provide a diverse set of design tools for programming both free energy and mechanical properties. As shown here, the tools provided by structural DNA nanotechnology are well suited to implement mechanical frustration at the nanoscale and could potentially be used to understand natural systems as well as enhance the capabilities of architected nanomaterials.

Methods

DNA origami design

The wireframe DNA origami was designed using Cadnano58 and Scadnano59. The structure consisted of 38 2HB edges on a hexagonal lattice, each edge being 84 nts long (~ 28 nm in length and ~4 nm in diameter). The Scadnano design of the structure is shown in Supplementary Fig. 2. The single-stranded nucleotide (ssnt) joints within the structure were designed following recommendations by a previous work on wireframe DNA origami60. Joints with an expected angle of 120° have 3 ssnts, while 5 ssnts were used for a desired angle of 60° (Supplementary Fig. 3 inset). The edges are assigned numbers from 0 to 38 (Supplementary Fig. 3). The edges no. 4, 25, and 17 are the reconfigurable jack edges for adaptable and inadaptable modes as described in Fig. 1. The edge no. 15 was also explored for structural deformation as shown in Fig. 5a. The staples for jack edges have additional toeholds (8 nts) and a slightly different arrangement for maximum contraction in length. By design, all staples were 42-nt long except the jack staples with an additional 8-nt toehold. The jack staple arrangements and the two-step DNA reactions for chemical loading are illustrated in Supplementary Fig. 4. The extended jack edges (Supplementary Fig. 4a) were shortened by first adding releasers to remove all the jack staples (Supplementary Fig. 4b) and then adding a new set of jack staples which bound to each contiguous scaffold segment, pulling the ends together from ~28 nm in the initial state to approximately 5 nm in the final state (Supplementary Fig. 4c). NUPACK61 analysis estimates the free energy ΔG to be ~171 kcal/mol per jack (gained from the addition of short jacks). The maximum force that can be applied theoretically during chemical loading is therefore ~57 pN per jack (ΔG/Δx), where Δx (the change in length after contraction) is estimated to be about 20 nm. This is well beyond the actual forces required (obtained from MD simulations) that are in the range of approximately 15 pN per jack (Supplementary Fig. 5). Thus, the design ensures that adequate force (energy) is provided to the system for chemical loading. For UV-triggered reconfiguration experiments, the jack staples were functionalized with photocleavable moieties as illustrated in Fig. 2i. The nomenclature for the staple sequences is based on their position following the convention of first going left to right and then top to bottom; a complete list of sequences is included in Supplementary Tables 2–8 and the Source Data file. The unused free scaffold segment was concentrated into two loops on one side of the structure, which served as markers to identify structural orientation during AFM scans.

DNA origami assembly

All DNA oligomers were purchased from Integrated DNA Technologies. The M13mp18 scaffold used was procured from Bayou Biolabs. All the other chemicals used were purchased from Sigma Aldrich. DNA origami nanostructures were constructed by mixing 5 nM M13 scaffold strands with 4 × DNA staple oligonucleotides for regular edges and 8 × DNA staples for jack edges in 1 × TAE buffer (solution of 40 mM trisaminomethane 1 mM ethylenediaminetetraacetic acid disodium salt, and 20 mM acetic acid) with 6 mM magnesium acetate (referred to as TAEM6). This mixture was annealed from 95 to 65 °C at 1 °C per 2 min, 65 to 60 °C at 1 °C per 25 min, 60 to 50 °C at 1 °C per 60 min, and 50 to 35 °C at 1 °C per 40 min after which it was cooled down to 4 °C. The duration of the complete thermal cycle was about 1 day. The adaptable and inadaptable structures shown in Fig. 2b, c were constructed by adding respective staples for two short jack edges and third extended jack (Fig. 2a (ii) and (iii)), along with staples for other edges. The initial extended state (Fig. 2e (i) and f) was prepared by adding the extended jack staples with toeholds for three jacks along with staples for other edges. These mixtures were subjected to the same thermal cycle mentioned above. The DNA nanostructures for UV-triggered reconfiguration experiments were synthesized similar to their regular counterparts, with UV cleavable jack staples. Synthesis of DNA nanostructures in Fig. 5 was the same as that in Fig. 2b, c with appropriate jack and defective staples replaced.

Reconfiguration through external stimuli

The initial state prepared was the starting point for reconfiguration to both adaptable and inadaptable states. This was achieved by two-step reactions: toehold-mediated strand displacement with releasers and re-annealing with a new set of staples. After the synthesis of the initial state, the excess staples were removed using 100 kDa Pall Nanosep centrifugal filters, by centrifuging a mixture (55 μL) of DNA origami solution with 400 μL of TAEM6 buffer at 5000 rpm for 3 min. This process was repeated twice more after which the origami was redispersed in new TAEM6 buffer. The releasers of the respective jack edges depending on the desired final state (adaptable or inadaptable) were added in 4 × concentration to the purified mixture and incubated for ~14 h (55 °C for 3 h and then cooled down to 35 °C over 11 h). The resulting origami solution (containing adaptable or inadaptable undefined states) was again purified to remove excess staples. Then, selected short jack staples were added to the undefined states and incubated for 16 h (55 °C for 4 h and cooled slowly to 35 °C over 12 h) to deform the structure into the final configuration. The resulting DNA was again purified by centrifugation to remove excess staples and prepare the sample for AFM imaging.

Reversibility between adaptable and inadaptable states was tested by starting from either adaptable or inadaptable states, adding releaser strands, and incubating for ~14 h (55 °C for 3 h and then cooled down to 35 °C over 11 h). The initial undefined state was then obtained (with all three jack edge staples missing). After purification to remove excess staples, respective short jack staples were added to the initial undefined state to reach either adaptable or inadaptable state based on the reconfiguration direction. UV-triggered reconfiguration was performed by exposing DNA assemblies with photocleavable jack staples to UVa light (~ 365 nm; using a Spectroline E-series UV lamp) for 30 min.

AFM imaging

AFM imaging was performed in air using the Peak-Force Tapping mode using a Bruker Dimension Icon with SCANASYST-AIR probes. The DNA origami samples were diluted to 0.5–1 nM during deposition. The samples were prepared for AFM by adding 2 μL of DNA solution and 8 μL of TAEM6 buffer, which was incubated for 5 min. To improve adhesion of DNA to mica, 20 μL buffer with 2.5 mM NiCl2 was added and allowed to incubate for additional 2 min. The sample was then blown dry with compressed air and washed with 80 μL deionized water. Each mica sample was scanned at multiple locations using typical scan sizes of 5 × 5 μm, 2 × 2 μm, 500 × 500 nm, and 100 × 100 nm. The AFM images were analyzed using Bruker Nanoscope software, Gwyddion, and ImageJ. Gwyddion was used to generate the contrast images presented in Fig. 2 by using Gaussian edge detection that helped highlight the bent edges distinctly and thus visualize the structures better.

The edge lengths and angles of the extended state (Fig. 2e) were estimated using ImageJ (measuring >20 edges and 10 angles per structure) after setting the appropriate scale for each image. The yield was estimated from zoom-out scans (2 µm × 2 µm) by comparing structures with expected conformations and those with misforms. Structures that were folded over (non-planar deposition) were excluded from the estimation.

MD simulations via oxDNA

We studied our DNA metastructure with coarse-grained MD simulations using the oxDNA44,45,62 platform (on a NVIDIA GTX 2060/4070 GPU). All simulations performed used average sequence parameters at a temperature of 300 K with a diffusion coefficient of 2.5 and a salt concentration of 0.5 M48. The time increment dt was 0.005 (approximately 15 fs). The equilibrium structure of the initial state was obtained by first relaxing the Cadnano structure with greater backbone force for 105 steps after which MD simulations were performed. Parts of the reconfigurable edges of the equilibrium conformation in the initial state were deleted using oxView to prepare the input files for mechanical deformation. A few base-paired nucleotides (5 or 10 bps) were left uncut to prevent the 2HB helices from fraying when applying external loading using harmonic traps available in oxDNA. The jack edge residues were subject to spring forces, moving at a constant velocity and covering about 20 nm over 50 × 106 steps. The nucleotides were grouped based on their edges using the DBSCAN algorithm. The edge numbers are consistent with those shown in Supplementary Fig. 3.

The harmonic traps exerted nearly constant and equal force on both jack residues. The traps started from the initial positions of the jack ends towards each other. The force exerted by the trap can be calculated by

where k is the stiffness set to 0.1 in the simulation (i.e., ~5.7 pN/nm). \(\overrightarrow{{r}_{{trap}}}\) and \(\overrightarrow{{r}_{{jack}-{nts}}}\) are the instantaneous position vectors of the trap and jack edge nts, respectively. The evolution of mechanical loading with time in both modes is shown in Supplementary Fig. 5. The slight increase in forces in the end is when both jack ends come in contact and are pulled past each other. Both final states after loading return to their initial conformations upon removal of external forces, implying that these structures can potentially be used to store mechanical energy. The trajectory as well as the average jack distance for the adaptable and inadaptable modes on removing external forces is shown in Supplementary Figs. 6 and 7. The separation between the jack residues is gradual for the adaptable mode. The inadaptable mode experiences a relatively rapid recovery followed by fluctuations. Therefore, both structures can potentially release stored energy in different ways.

Computational analysis

The bending of each edge was quantified to understand mechanics and discern irreversible buckling from thermal fluctuations. For each edge, an averaged configuration was obtained by taking the average of center of masses of the 4 nts at each section of the 84-nt-long 2HB edge (i.e., 84 sections per edge) as illustrated in Supplementary Fig. 8. The bend deflection was defined as the maximum distance of the averaged curve for each edge from the straight line (displacement) joining the edges (a in Fig. 4d inset). The deflection was then normalized by dividing with d = 4 nm (diameter of the 2HB edge) to prevent thermal fluctuations from being classified as bending. The normalized bend deflection (a/d) values ranged from −3 to 3. The bend deflection vs time plot in Fig. 4c, d was obtained by averaging bend deflection values over windows of 500 × 103 steps for each of the 36 edges in each mode. Note that the number of edges is not 38 but 36, since two reconfigurable jacks are partially cut off for each mode.

A quantitative estimate for the bending/strain was developed by defining the local strain as a function of the dot product of the tangent vectors at different sections. The strain was obtained by using the formula

where \(\overrightarrow{{t}_{n-10}}\) and \(\overrightarrow{{t}_{n+10}}\) are tangent vectors, 10 nts upstream and downstream of the section where strain is being calculated. This was computed at multiple sections in each edge at a particular time instant. This method is illustrated in Supplementary Fig. 8. Given the formula used, the first and last 10 sections of the edge are excluded from calculations. Therefore, each edge has 64 data points of strain. The plots are colored using a log normalized ‘rainbow’ colormap using Python and oxView.

Free energy calculations

Traditional MD simulations often fail to explore the whole conformation space (i.e., a wide range of non-equilibrium edge lengths or unfavorable states) due to the high possibility of being confined to equilibrium states. This shortfall can be overcome by applying a bias potential, forcing the structure to explore different conformations by using umbrella sampling. This is achieved by using an order parameter, a structural property that is varied over multiple windows in a series of simulations. For Fig. 1h, the critical difference is in the mechanical state of edge no. 27 (the edge that buckles in the inadaptable state). We set the end-to-end distance of this edge in both states as the order parameter. In Fig. 5, the brown-colored edges were investigated. We used the ligated structures from the loading simulations as the input for the umbrella sampling simulations. A harmonic biasing force was used

where V is the bias potential exerted by a spring of stiffness k = 11.4 pN/nm. \(L\) and \({L}_{o}^{i}\) are the end-to-end distance and the set value for window i to bias over 80 simulation windows, varying the length of the edge \({L}_{0}^{i}\) (see additional description in SI section 4). The range of order parameter was chosen such that we scanned beyond the edge lengths observed during bending and full extension. The first few million steps were discarded from all the windows to allow the structure to reach equilibrium. We then used the weighted histogram analysis method to extract the final free energy profile after unbiasing the simulation63.

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on request. Source data are provided with this paper.

References

Zhang, H., Guo, X., Wu, J., Fang, D. & Zhang, Y. Soft mechanical metamaterials with unusual swelling behavior and tunable stress-strain curves. Sci. Adv. 4, eaar8535 (2018).

Hwang, D., Barron, E. J., Haque, A. B. M. T. & Bartlett, M. D. Shape morphing mechanical metamaterials through reversible plasticity. Sci. Robot. 7, eabg2171 (2022).

Lakes, R. Foam structures with a negative Poisson’s ratio. Science 235, 1038–1040 (1987).

Du, Y., Li, R., Madhvacharyula, A. S., Swett, A. A. & Choi, J. H. DNA nanostar structures with tunable auxetic properties. Mol. Syst. Des. Eng. 9, 765–774 (2024).

Mintchev, S., Shintake, J. & Floreano, D. Bioinspired dual-stiffness origami. Sci. Robot. 3, eaau0275 (2018).

Faber, J. A., Arrieta, A. F. & Studart, A. R. Bioinspired spring origami. Science 359, 1386–1391 (2018).

Kapnisi, M. et al. Auxetic cardiac patches with tunable mechanical and conductive properties toward treating myocardial infarction. Adv. Funct. Mater. 28, 1800618 (2018).

Smith, D. R., Pendry, J. B. & Wiltshire, M. C. Metamaterials and negative refractive index. Science 305, 788–792 (2004).

Cummer, S. A., Christensen, J. & Alù, A. Controlling sound with acoustic metamaterials. Nat. Rev. Mater. 1, 1–13 (2016).

Kasuya, T. A Theory of metallic ferro-and antiferromagnetism on Zener’s model. Prog. Theor. Phys. 16, 45–57 (1956).

Kanô, K. & Naya, S. Antiferromagnetism. The Kagomé ising net. Prog. Theor. Phys. 10, 158–172 (1953).

Zhou, Y., Zhang, Y., Wen, Z. & Chen, C. Q. Polar domain walls induced by sequential symmetry breaking in frustrated mechanical metamaterials. Commun. Phys. 7, 329 (2024).

Meeussen, A. S., Oğuz, E. C., Shokef, Y. & Hecke, M. V. Topological defects produce exotic mechanics in complex metamaterials. Nat. Phys. 16, 307–311 (2020).

Kang, S. H. et al. Complex ordered patterns in mechanical instability induced geometrically frustrated triangular cellular structures. Phys. Rev. Lett. 112, 098701 (2014).

Wu, L. & Pasini, D. Zero modes activation to reconcile floppiness, rigidity, and multistability into an all-in-one class of reprogrammable metamaterials. Nat. Commun. 15, 3087 (2024).

Udani, J. P. & Arrieta, A. F. Taming geometric frustration by leveraging structural elasticity. Mater. Des. 221, 110809 (2022).

Rothemund, P. W. K. Folding DNA to create nanoscale shapes and patterns. Nature 440, 297–302 (2006).

Zhang, F. et al. Complex wireframe DNA origami nanostructures with multi-arm junction vertices. Nat. Nanotechnol. 10, 779–784 (2015).

Kim, M. et al. Harnessing a paper-folding mechanism for reconfigurable DNA origami. Nature 619, 78–86 (2023).

Wintersinger, C. M. et al. Multi-micron crisscross structures grown from DNA-origami slats. Nat. Nanotechnol. 18, 281–289 (2023).

Liu, L., Li, Z., Li, Y. & Mao, C. Rational design and self-assembly of two-dimensional, dodecagonal DNA quasicrystals. J. Am. Chem. Soc. 141, 4248–4251 (2019).

Iinuma, R. et al. Polyhedra self-assembled from DNA tripods and characterized with 3d DNA-paint. Science 344, 65–69 (2014).

Li, Y. et al. Ultrastrong colloidal crystal metamaterials engineered with DNA. Science 9, eadj8103 (2023).

Song, J. et al. Reconfiguration of DNA molecular arrays driven by information relay. Science 357, eaan3377 (2017).

Marras, A. E., Zhou, L., Su, H.-J. & Castro, C. E. Programmable motion of DNA origami mechanisms. Proc. Natl. Acad. Sci USA. 112, 713–718 (2015).

Zhou, L., Marras, A. E., Su, H.-J. & Castro, C. E. DNA origami compliant nanostructures with tunable mechanical properties. ACS Nano 8, 27–34 (2014).

Shi, X. et al. A DNA turbine powered by a transmembrane potential across a nanopore. Nat. Nanotechnol. 19, 338–344 (2024).

Kopperger, E. et al. A self-assembled nanoscale robotic arm controlled by electric fields. Science 359, 296–301 (2018).

Büchl, A. et al. Energy landscapes of rotary DNA origami devices determined by fluorescence particle tracking. Biophys. J. 121, 4849–4859 (2022).

Gerling, T., Wagenbauer, K. F., Neuner, A. M. & Dietz, H. Dynamic DNA devices and assemblies formed by shape-complementary, non–base pairing 3d components. Science 347, 1446–1452 (2015).

Bazrafshan, A. et al. Tunable DNA origami motors translocate ballistically over Μm distances at Nm/S speeds. Angew. Chem. Int. Ed. 132, 9601–9608 (2020).

Li, R., Chen, H. & Choi, J. H. Auxetic two-dimensional nanostructures from DNA. Angew. Chem. Int. Ed. 60, 7165–7173 (2021).

Li, R., Madhvacharyula, A. S., Du, Y., Adepu, H. K. & Choi, J. H. Mechanics of dynamic and deformable DNA nanostructures. Chem. Sci. 14, 8018–8046 (2023).

Chhabra, H. et al. Computing the elastic mechanical properties of rodlike DNA nanostructures. J. Chem. Theory Comput. 16, 7748–7763 (2020).

Lee, C., Kim, K. S., Kim, Y.-J., Lee, J. Y. & Kim, D.-N. Tailoring the mechanical stiffness of DNA nanostructures using engineered defects. ACS Nano 13, 8329–8336 (2019).

Li, R., Chen, H., Lee, H. & Choi, J. H. Conformational control of DNA origami by DNA oligomers, intercalators and UV Light. Methods Protoc. 4, 38 (2021).

Lee, J. Y., Kim, Y. & Kim, D.-N. Predicting the effect of binding molecules on the shape and mechanical properties of structured DNA assemblies. Nat. Commun. 15, 6446 (2024).

DeLuca, M. et al. Thermally reversible pattern formation in arrays of molecular rotors. Nanoscale 15, 8356–8365 (2023).

Wang, Y. et al. Steric Communication between dynamic components on DNA nanodevices. ACS Nano 17, 8271–8280 (2023).

Li, R., Chen, H., Lee, H. & Choi, J. H. Elucidating the mechanical energy for cyclization of a DNA origami tile. Appl. Sci. 11, 2357 (2021).

Meeussen, A. S., Oğuz, E. C., Hecke, M. V. & Shokef, Y. Response evolution of mechanical metamaterials under architectural transformations. N. J. Phys. 22, 023030 (2020).

Li, R., Chen, H. & Choi, J. H. Topological assembly of a deployable Hoberman flight ring from DNA. Small 17, 2007069 (2021).

Yoo, J. & Aksimentiev, A. In situ structure and dynamics of DNA origami determined through molecular dynamics simulations. Proc. Natl. Acad. Sci USA 110, 20099–20104 (2013).

Poppleton, E., Romero, R., Mallya, A., Rovigatti, L. & Šulc, P. Oxdna.Org: a public webserver for coarse-grained simulations of DNA and RNA nanostructures. Nucleic Acids Res. 49, W491–W498 (2021).

Rovigatti, L., Šulc, P., Reguly, I. Z. & Romano, F. A comparison between parallelization approaches in molecular dynamics simulations on GPUs. J. Comput. Chem. 36, 1–8 (2015).

Torrie, G. M. & Valleau, J. P. Nonphysical sampling distributions in Monte Carlo free-energy estimation: umbrella sampling. J. Comput. Phys. 23, 187–199 (1977).

Wong, C. K., Tang, C., Schreck, J. S. & Doye, J. P. K. Characterizing the free-energy landscapes of DNA origamis. Nanoscale 14, 2638–2648 (2022).

Sample, M., Liu, H., Diep, T., Matthies, M. & Šulc, P. Hairygami: analysis of DNA nanostructures’ conformational change driven by functionalizable overhangs. ACS Nano 18, 30004–30016 (2024).

Carter, N. J. & Cross, R. A. Mechanics of the kinesin step. Nature 435, 308–312 (2005).

Rosenfeld, S. S., Fordyce, P. M., Jefferson, G. M., King, P. H. & Block, S. M. Stepping and stretching: how kinesin uses internal strain to walk processively. J. Biol. Chem. 278, 18550–18556 (2003).

Bao, G. Mechanics of biomolecules. J. Mech. Phys. Solids 50, 2237–2274 (2002).

Lenz, M. & Witten, T. A. Geometrical frustration yields fibre formation in self-assembly. Nat. Phys. 13, 1100–1104 (2017).

Ferreiro, D. U., Komives, E. A. & Wolynes, P. G. Frustration in biomolecules. Q. Rev. Biophys. 47, 285–363 (2014).

Yao, G. et al. Meta-DNA structures. Nat. Chem. 12, 1067–1075 (2020).

Zhou, W. et al. Space-tiled colloidal crystals from DNA-forced shape-complementary polyhedra pairing. Science 383, 312–319 (2024).

Kulikowski, J. et al. DNA-silica nanolattices as mechanical metamaterials. Matter 7, 2144–2160 (2024).

Posnjak, G. et al. Diamond-lattice photonic crystals assembled from DNA origami. Science 384, 781–785 (2024).

Douglas, S. M. et al. Rapid Prototyping of 3d DNA-origami shapes with caDNAno. Nucleic Acids Res. 37, 5001–5006 (2009).

Doty, D., Lee, B. L. & Stérin, T. scadnano: A browser-based, scriptable tool for designing DNA nanostructures. In DNA 2020: Proceedings of the 26th International Meeting on DNA Computing and Molecular Programming, Vol. 174. (eds. Geary, C. & Patitz, M. J.) 9:1–9:17 (Schloss Dagstuhl--Leibniz-Zentrum für Informatik, 2020). https://drops.dagstuhl.de/opus/volltexte/2020/12962

Wang, W. et al. Complex wireframe DNA nanostructures from simple building blocks. Nat. Commun. 10, 1067 (2019).

Fornace, M. E. et al. Nupack: analysis and design of nucleic acid structures, devices, and systems. Preprint at ChemRxiv. https://doi.org/10.26434/chemrxiv-2022-xv98l (2022).

Poppleton, E. et al. Coarse-grained simulations of nucleic acids made simple. J. Open Source Softw. 8, 4693 (2023).

Grossfield, A. Wham: the weighted histogram analysis method. version 2.0.11, http://membrane.urmc.rochester.edu/wordpress/?page_id=126.

Acknowledgements

The authors thank Prof. P. Sulc, Dr. M. Matthies, and M. Sample at Arizona State University for help with free energy calculations, Prof. A. Arrieta at Purdue University for insightful discussion, and T. Avery for aid with experimental analysis. This work was financially supported by the U.S. Department of Energy, Office of Science, Basic Energy Sciences under award no. DE-SC0020673. J.H.C. also acknowledges the Friedrich Wilhelm Bessel Research award from the Alexander von Humboldt Foundation.

Author information

Authors and Affiliations

Contributions

A.S.M., F.C.S. and J.H.C. conceived the idea; A.S.M., R.L. and J.H.C. designed the research; A.S.M., A.A.S., Y.D., S.S. performed the experiments; A.S.M. conducted the numerical computation; A.S.M., F.C.S., and J.H.C. analyzed the data. All authors participated in writing the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks the anonymous reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Madhvacharyula, A.S., Li, R., Swett, A.A. et al. Realizing mechanical frustration at the nanoscale using DNA origami. Nat Commun 16, 5164 (2025). https://doi.org/10.1038/s41467-025-60492-z

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-025-60492-z

This article is cited by

-

Support field neural representation learner framework for learning stability landscapes in molecular geometry

npj Biomedical Innovations (2025)