Abstract

Producing high-concentration liquid metal (LM) inks is highly desirable for next-generation flexible electronics, and yet remains a dulling challenging due to the large surface tension and high density of LM droplets. Herein, a general finite-gel strategy is proposed to enable the fabrication of high-concentration liquid metal (LM) inks. In the LM-based inks, the LM droplets are confined in the relaxed finite-gel networks, which provide strong repulsive effects to avoid the reunition of the adjacent LM droplets. The unique structure imparts the LM-based inks with a good colloidal stability even at a very high LM concentration of 30,000.0 g/L. The LM-based inks also present tunable rheological behavior and are suitable for various processing technologies. Moreover, the proposed finite-gel strategy is scalable, and could be expanded to various cryogel systems (e.g., curdlan, gelatin, and gellan gum). This work takes a crucial step forward to producing highly concentrated LM-based inks for flexible electronics.

Similar content being viewed by others

Introduction

Conductive inks are essential to the next-generation flexible electronics in view of their good processability, and hold great potential in soft robots, wearable healthcare monitoring devices, and human–machine interfaces1,2,3,4. During the past decade, various solid conductive fillers (silver nanowires5, carbon nanotubes6, graphene7, and MXene8) have been incorporated with surfactants or polymer matrices into suitable solvents to fabricate conductive inks. Despite significant progress, achieving highly stretchable and durable flexible electronics with these solid filler-based inks remains a considerable challenge due to their inherent rigidity and poor interfacial contact9,10. In contrast to rigid solid fillers, liquid metal (LM) has been explored as a favorable alternative for the fabrication of stretchable electronics in view of its low modulus, good deformability, and satisfactory stretchability11,12,13. However, the resulting LM droplets in inks are often unstable and tend to rapidly reunite due to the large surface tension and high density (e.g., 548.8 mN/m and 6.4 g/cm3 for galinstan alloy)14,15.

Recently, many efforts have been made to address the poor stability of LM-based inks by assembling surfactants onto the surface of LM droplets, such as tannic acid (TA)16, polydopamine17, sodium alginate (SA)18, and cellulose nanofiber (CNF)19. These LM-based inks are actually solution systems, and the LM concentrations in solvents are kept relatively low (less than 20 g/L) to ensure colloidal stability, with values such as 7.9 g/L for SA18, 10.0 g/L for CNF19, and 5.0 g/L for glucomannan20. These solution systems always exhibit poor thixotropy owing to their low viscosity and insufficient viscoelasticity, which present challenges for direct application in patterning technology21. One main strategy to address this problem is to increase the LM concentration by centrifugation, but the resulting LM-based inks lack homogeneity, and the uniformity, as well as high precision in patterning technology, cannot be guaranteed16,19. Adding more surfactants or introducing additional polymers could also improve the thixotropy22,23, nevertheless, these strategies are always accompanied by a decrease in the conductivity and stretchability of flexible electronics. It is urgent to yield highly concentrated LM-based inks with a very small quantity of surfactant, yet a considerable challenge.

In conventional strategies, the stable dispersion of LM droplets mainly relies on the formation of surface-modified layer, which can provide electrostatic repulsion to prevent LM droplets from reuniting with each other at low LM concentrations, as schematically shown in Fig. 1a. At high LM concentrations, the collision probability of adjacent LM droplets significantly increases, which makes the droplets easily bond with each other and form large aggregates due to the bridging effect of surfactants, resulting in the destruction of colloidal stability. There seems to be an irreconcilable contradiction between high concentration and good stability in the LM-based inks. It was recently reported that Carbopol hydrogel can facilitate the fabrication of highly concentrated LM-based ink with a LM concentration of 29,761.9 g/L due to the formation of an internal phase emulsion gel, and the ink can be used for direct-ink-writing 3D printing21. However, the formation of high internal phase emulsion ink requires several stringent conditions, such as a neutral environment, a narrow LM content distribution (74.0–82.5 vol%), and a limited water content. This not only results in poor generality in other gel systems but also restricts the applicability in various processing technologies (e.g., screen printing, spray-coating, and dip-coating) due to a lack of rheological tunability.

Schematic microstructures of the LM-based inks prepared by the a conventional strategy and b finite-gel strategy. c Comparison of the LM concentrations of the agar@LM inks with the previously reported LM-based inks. d Comprehensive assessment between the agar@LM inks and the previously reported LM-based inks based on five key metrics (stability, LM concentration, processing versatility, environmental friendliness, and generality). Source data are provided as a Source Data file.

Herein, we report a general finite-gel strategy to realize the design of highly concentrated LM-based inks with tunable rheological behavior for multiple processing technologies by constructing the relaxed finite-gel networks with good interfacial interactions. In such LM-based inks, the LM droplets are restricted to distribute within the relaxed finite-gel networks, which could provide strong repulsive effects to prevent LM droplets from reuniting with each other even at high LM concentrations (Fig. 1b). Moreover, the strong interfacial interaction between the agar and LM droplets guarantees the stability and durability of the agar@LM inks. Our finite-gel strategy endows the agar@LM inks with competitive advantages over conventional systems: (1) an ultra-high LM concentration of 30,000.0 g/L at an only 3.0 wt% agar content in water (Fig. 1c)16,17,18,19,20,21,22,23,24,25,26,27,28,29,30,31,32,33, (2) tunable rheological behavior with a wide viscosity range of 53.9–20,913.0 Pa s at 0.1 s−1, showing high applicability for multiple processing technologies (e.g., direct writing, screen printing, spray-coating, and dip-coating), (3) good generality for various cryogel systems, such as curdlan, gelatin, and gellan gum. A more comprehensive performance assessment of the LM-based inks is provided based on five key metrics (stability, LM concentration, processing versatility, environmental friendliness, and generality) in a radar chart (Fig. 1d). The chart shows that the finite-gel LM-based inks are better than the conventional LM-based inks, including the TA@LM inks16, and SA@LM inks18, CNF@LM inks19, lignin@LM inks34.

Results

Synthesis and characterization of the agar@LM inks

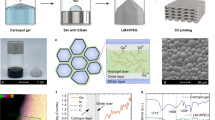

Figure 2a schematically shows the preparation process of the agar@LM inks, which includes mixing LM with agar, gelling of the agar@LM mixture, and homogenization of the agar@LM gel (Supplementary Fig. 1). Agar was selected as a model polymer to promote the dispersion of LM due to its good water solubility and strong gelation ability (Fig. 2a). Specifically, bulk LM was first added to aqueous agar solution to obtain a homogeneous agar@LM mixture through sonication, which was further gelled into a non-flowing hydrogel (Fig. 2b). The hydrogel was sheared into high-viscosity agar@LM inks by homogenization, which could form diverse patterns on different substrate surfaces (Fig. 2c and Supplementary Figs. 2–5). The agar@LM inks with 150.0 g/L LM in 1.5 wt% agar exhibit good colloidal stability, without any obvious settling even after static storage for 48 h (Fig. 2d). However, after static storage for only 1 h, clear stratifications are observed for the conventional LM-based inks with the same LM concentration and surfactant content, including the polyvinylpyrrolidone (PVP)@LM ink, lignin@LM ink, CNF@LM ink, TA@LM ink, and SA@LM ink (Fig. 2e and Supplementary Fig. 6a–d).

a Schematic diagrams of the preparation of the agar@LM inks. b Digital photographs of the agar@LM gel. Scale bar, 1 cm. c Digital photographs of the agar@LM inks. Scale bar, 4 mm. Digital photographs of d the agar@LM inks and e the PVP@LM inks with the LM concentration of 150.0 g/L, surfactant content of 1.5 wt%, and water content of 85.8 wt% before and after static storage for different times. f TSI curves of the agar@LM inks and the conventional LM-based inks. g The illustration of the principle for multiple light scattering analysis. h BS% of the agar@LM inks and the PVP@LM inks as a function of the height. i The LM concentrations in the agar@LM inks with different agar contents. j Comparison of the LM concentrations between the agar@LM inks and the previously reported LM-based inks. Source data are provided as a Source Data file.

Multiple light scattering analysis is further used to quantitatively evaluate the stability of the LM-based inks. The turbiscan stability index (TSI) curve of the agar@LM ink (150 g/L LM) exhibits a weak increase over time, with a value of only 0.2 after static storage for 48 h (Fig. 2f), indicating good stability. In sharp contrast, after 1 h of storage, the TSI values of conventional LM-based inks with the same LM content increase rapidly over time, and reach 12.7, 2.9, 2.4, 1.1, and 1.1 for the lignin@LM ink, CNF@LM ink, PVP@LM ink, TA@LM ink, and SA@LM ink, respectively. Even at a much higher PVP content (20.0 wt%), the TSI value of the PVP@LM ink is still as high as 2.0, which indicates poor stability (Supplementary Fig. 7). There is also no significant variation in the intensity of the backscattered light (BS) from top to bottom over 48 h for the agar@LM ink. However, the BS intensity substantially differs from top to bottom for the lignin@LM ink, CNF@LM ink, PVP@LM ink, TA@LM ink, and SA@LM ink at the initial states, and the distinctions are more pronounced after only 1 h due to the sedimentation of LM droplets (Fig. 2g, h and Supplementary Fig. 6e–i). These results demonstrate the better colloidal stability of the agar@LM inks at high LM concentrations. The agar@LM inks also exhibit good chemical stability, without chemical oxidation for more than 72 h in air (Supplementary Fig. 8). The stable storage time of the agar@LM inks could be further extended to as high as 216 h in a nitrogen atmosphere (Supplementary Fig. 9). The above results provide solid evidence of the better colloidal and chemical stability of the agar@LM inks.

It is highly desirable to realize the fabrication of high-concentration LM-based inks with low levels of surfactants. Thus, the effects of agar content on the LM concentration of the agar@LM inks are investigated, and the results are shown in Fig. 2i. The LM concentration rapidly increases with increasing agar content. Specifically, only 0.3 wt% agar enables good dispersion of 50.0 g/L LM droplets in the agar@LM inks. This high LM concentration at a low agar content (0.3 wt%@50.0 g/L) is far better than those of the conventional surface-modified LM-based inks, such as 0.3 wt%@7.9 g/L for SA@LM ink18 0.5 wt%@10.0 g/L for CNF@LM ink19, and 5.9 wt%@10.5 g/L for amino cellulose (AC)@LM ink29. When the agar content is increased to 1.5 wt%, the LM concentration further increases to 900.0 g/L for the agar@LM inks, and an ultra-high LM concentration of 30,000.0 g/L is achieved for the agar@LM ink at only 3.0 wt% agar content (Supplementary Fig. 10), demonstrating their better performance compared to the conventional LM-based inks (Fig. 1c, Supplementary Table 2).

Moreover, the agar@LM inks exhibit resistance to strongly acidic and high-salt environments, without any settlement even after being subjected to acidic (pH = 4) and high-salt (1 M NaCl) conditions (Supplementary Figs. 11, 12). However, the stability of the previously reported LM-based inks (e.g., Carbopol@LM inks) is disrupted when they are subjected to the same conditions, which restricts their application scenarios. The variation in LM concentration as a function of surfactant/LM content (namely the weight ratio of surfactant to LM) is further used to evaluate the agar@LM inks. As shown in Fig. 2j, the agar@LM inks exhibit the maximum LM concentration of 30,000 g/L at only 0.1 wt% surfactant/LM content, which is better than that reported in previous studies, indicating the high efficiency of agar in contributing to the stable dispersion of LM droplets16,17,18,19,20,21,22,23,24,25,26,27,28,29,30,31,32,33.

Stabilization mechanisms of the agar@LM inks

To figure out the stabilization mechanisms of the agar@LM inks, a simulation experiment is performed by dropping a 5.0 μL LM microdroplet into a pure finite-gel agar ink (0.3 wt%) and a PVP dispersion. Figure 3a reveals that the LM microdroplet remains suspended at the top of the pure agar ink for 20 min, remaining at a position almost identical to that at time zero. In contrast, the LM microdroplet rapidly sinks to the bottom of the PVP dispersion within 4 s (Supplementary Movie 1). The modulus curves in Fig. 3b indicate the formation of the finite-gel networks in the agar inks, whereas the PVP dispersions exhibit liquid characteristics (Supplementary Fig. 13). These results demonstrate that the finite-gel networks in the agar@LM inks play a critical role in stabilizing LM droplets.

a A simulation experiment to illustrate the good stabilizing effect of the finite-gel networks. Scale bar, 3 mm. b The modulus of the pure agar inks and the PVP dispersions as a function of shear strain. c The modulus of the agar@LM inks as a function of temperature. d Schematic illustration of the finite-gel networks disruption and LM settlement with the temperature increases. The blue line represents agar. The gray ball represents LM droplets. e The TEM and (f, g) the EDS of the agar@LM inks. h T2 distribution of water in the agar@LM inks and the PVP@LM inks. The blue line represents agar, the gray line represents PVP. i XDLVO theory diagram of the agar@LM inks. The blue line represents agar. The gray ball represents LM droplets. Source data are provided as a Source Data file.

The evolution of the finite-gel networks is investigated by using a rheometer to explore the stability mechanism of the agar@LM inks. The modulus curve in Fig. 3c shows that the agar@LM inks exhibit a typical sol-gel transition with increasing temperature, and the transition temperature (Tsol-gel) is ~68 °C at 250 rad/s (Supplementary Figs. 14, 15). When the temperature is below Tsol-gel, the agar@LM inks are in a gelatinous state with the formation of the finite-gel networks, which results in good stability (left inset of Fig. 3c). However, once the temperature exceeds Tsol-gel, the finite-gel networks in the agar@LM inks gradually become disrupted, and thus the LM droplets begin to settle (right inset of Fig. 3c, d and Supplementary Figs. 16, 17, Movie 2). The agar content is also a crucial parameter in the formation of the finite-gel networks. The digital photographs in Supplementary Fig. 18 reveal that the agar@LM inks start to present good stability when the agar content is ≥0.3 wt%. This finding indicates that the critical content (0.3 wt%) for agar to form the finite-gel networks is low, which is the main mechanism responsible for the high concentrations of the LM-based inks. From the transmission electron microscopy (TEM) images, the LM droplets are observed to be distributed in the form of spherical particles in the agar@LM inks, with a thin layer surrounding the LM droplets in the magnified TEM images (Fig. 3e, f and Supplementary Fig. 19a). The corresponding energy dispersive spectrometry (EDS) images reveal that the C element related to the agar is present throughout the whole region, whereas the Ga element related to the LM is only spread on the LM droplet (Fig. 3f, g and Supplementary Fig. 19b, c). These phenomena indicate that agar is not only coated onto the surface of the LM droplet but also distributed around the LM droplet to form the finite-gel networks.

The binding state of water is critical to the stability of the gel networks35. Low-field nuclear magnetic resonance (LF-NMR) is employed to monitor the behavior of water in the agar@LM inks (Fig. 3h). The spin–spin relaxation times (T2) of water in the 0.1–250 and 250–5000 ms regions correspond to the trapped water and free water, respectively. The T2 values of the water in the agar@LM inks are all distributed in 0.1–250 ms, while those of the water in the PVP@LM inks are mainly located in 250–5000 ms. In other words, the proportion of trapped water is 100% for the agar@LM inks, which is much greater than that in the PVP@LM inks (less than 5%) (Supplementary Fig. 20). These findings indicate that all the water in the agar@LM inks participates in the formation of the finite-gel networks. It is beneficial for increasing the viscosity, thus significantly improving the kinetic stability of the LM droplets based on Stokes’ law (Supplementary Figs. 21, 22)36. Besides, the trapped water introduces an additional hydration layer (schematic diagram in Fig. 3i), which generates a Lewis acid-base repulsion (WAB) to the LM droplets according to the extended Derjaguin-Landau-Verwey-Overbeek (XDLVO) theory (Fig. 3i, details of the calculations are provided in the Supplementary Information)37,38. WAB is large enough to overwhelm the van der Waals attraction (WLW), preventing the LM droplets from reuniting with each other. Notably, the agar@LM inks still exhibit high stability even after the elimination of electrostatic repulsion (WEL) (Supplementary Fig. 12e). The above results suggest that the trapped water in the finite-gel networks critically contribute to the good stability of the agar@LM inks.

In addition to the finite-gel networks, the interfacial interaction between agar and LM droplets is another decisive factor in the stability of the agar@LM inks. Fourier transform infrared spectra show that the O-H stretching vibration peak (3310 cm−1) of the agar@LM composites exhibits a typical red-shift compared with that (3339 cm−1) of agar (Fig. 4a)34. X-ray photoelectron spectroscopy reveals that the gallium oxide (Ga2O3) peak area of the agar@LM composites is greater than that of the pure LM (Fig. 4b, c). The results collectively indicate the formation of a coordination interaction between the trivalent gallium of Ga2O3 (Ga3+) and hydroxyl groups (-OH) of agar16. The molecular dynamics (MD) simulation is employed to quantify the coordination interaction between the LM and agar at the molecular level. In Fig. 4d and Supplementary Fig. 23, the binding energy value between the LM and agar is −2.9 eV at the initial state, and still maintains at a high level even when the agar@LM droplet deforms or ruptures. This suggests a strong coordination interaction between the LM and agar. In addition, DFT calculation suggests that there is a significant electron shift between the O atom on agar and Ga3+ in Ga2O3. Specifically, as shown in Fig. 4e, the white area represents an increase in charge density, whereas the black area displays a decrease in charge density, so it is clear that the electron shifts from the O atom on the agar to the Ga3+ in Ga2O3 (Supplementary Fig. 24). This apparent electron shift originates from the coordination between the lone electron pairs in the O atoms of -OH and the empty orbital of Ga3+ in Ga2O339,40. Figure 4f further shows that agar (−18.9 mV) and LM (+25.9 mV) have opposite charges. This would promote the adsorption of agar on the surface of LM in the inks, and thus promote the formation of the coordination interaction between the agar and LM41.

a Fourier transform infrared spectroscopy of the LM, the agar, and the agar@LM composites. b X-ray photoelectron spectroscopy of the agar@LM composites. c Ga 2p spectrum of the composites from the LM-based inks and the agar@LM inks. d Tensile stress-strain curves from molecular dynamics simulations of the agar@LM droplets. The inset shows the strain distribution of the agar@LM droplet at different strains (0%, 10%, 30%, and 50%), and the binding energy between the LM and agar. e DFT calculation between the agar and LM with Ga2O3. f Zeta potential of the agar, LM, and agar@LM inks. Error bars represent standard deviation, n = 3. g Schematic diagrams of the stabilization mechanisms of the agar@LM inks. Source data are provided as a Source Data file.

Based on the above analysis, the good stability of the agar@LM inks can be attributed to the cooperative effect of the finite-gel networks and good interfacial interaction between the agar and LM. As shown in Fig. 4g, the finite-gel networks restrict the space for the distribution of LM droplets, which could provide a strong repulsive effect to prevent LM droplets from reuniting with each other even at high LM concentrations. The good interfacial interaction contributes to anchoring the LM droplets onto the skeleton of the finite-gel networks, ensuring the stability and durability of the agar@LM inks. The cooperation effect of the finite-gel networks and strong interfacial interaction between the agar and LM resolve the contradiction between the large concentration and high stability of the LM-based inks.

Tunable rheological behaviors of the agar@LM inks

To broaden their applicability for various processing technologies, it is highly desirable for the LM-based inks to present tunable rheological behaviors, however, achieving such properties is still a challenge for conventional LM-based inks (Supplementary Fig. 25). Notably, the agar@LM inks exhibit ideal tunable rheological behavior, with an wide initial viscosity range of 53.9–20,913.0 Pa s (0.1 s⁻¹) and a storage modulus range of 164.7–93,190.0 Pa (0.1% strain) (Fig. 5a, b, and Supplementary Figs. 26, 27). The tunable rheological behavior of the agar@LM inks is due to the greater robustness of the finite-gel networks at higher agar or LM contents. Moreover, the agar@LM inks display typical shear-thinning behavior, high viscoelasticity, and ideal thixotropy (Fig. 5a–c), which collectively ensure their continuous printability and subsequent rapid solidification.

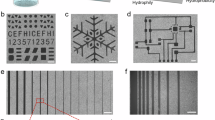

The rheological properties of the agar@LM inks with different agar contents include (a) viscosity, (b) modulus, and (c) thixotropic. d Schematic diagrams of the dip-coating process. e The SEM images for the dip-coated threads. Scale bar, 500 μm. Scale bar of the inset enlarged image, 100 μm. f Digital photographs of the embroidered pattern of “SCU”. Scale bar, 2 cm. g Schematic diagrams of the direct writing process. h Digital photographs of the direct written secret codes at different light power densities. i Schematic diagrams of the screen printing process. j Digital photographs of the screen printing circuit. Scale bar, 2 cm. The SEM images for the touch electronic device. Scale bar, 500 μm. k Digital photographs of the functioning touch electronic device. Source data are provided as a Source Data file.

In view of their tunable rheological behavior, the agar@LM inks show good applicability for various processing technologies. Specifically, for the low-concentration agar@LM ink (0.3 wt%@50.0 g/L), the initial viscosity and viscoelasticity are at a low level, and the agar@LM ink is in a typical liquid-like state, which makes it suitable for dip/drop/spray-coating technologies (Supplementary Fig. 2). For example, highly conductive LM-coated threads could be easily fabricated by dipping pure thread into the agar@LM ink (Fig. 5d). The LM-coated threads exhibit a very low electrical resistance of 4.3 Ω and good fatigue resistance, which is attributed to the formation of dense LM networks (Fig. 5e and Supplementary Fig. 28). The LM-coated threads are further embroidered on the fabric to obtain the SCU conductive paths. The brightness of the LED bulbs does not dim when the fabric is rolled, highlighting the potential of the LM-coated threads for use in durable wearable electronics (Fig. 5f).

For the middle-concentration agar@LM ink (0.5 wt%@150 g/L), the initial viscosity and viscoelasticity are at a moderate level, and the agar@LM ink presents a semisolid state, which is suitable for direct writing technologies (Supplementary Fig. 3). For example, the agar@LM ink can be combined with thermochromic materials for direct writing security codes (Fig. 5g and Supplementary Fig. 29). As shown in Fig. 5h, the written code is initially displayed as “0528”, which is a false code. When the code is exposed to 100 mW cm−2 light, the true code is revealed to be “1531”. A higher light power density of 200 mW cm−2 would generate another false code for dual anti-counterfeiting protection. These light-responsive color changes of the written code originate from the good photo-thermal ability of the agar@LM composites (Supplementary Fig. 30), which could induce thermochromic materials to fade or develop colors in the presence of the specific light wavelengths, resulting in the code to be anti-counterfeiting properties.

For the high-concentration agar@LM ink (1.5 wt%@900.0 g/L), the initial viscosity and viscoelasticity are at a high level, and the agar@LM ink is in a solid-like state, which is suitable for screen printing and blade-coating technologies (Supplementary Fig. 4). As shown in Fig. 5i, the flexible circuits could be fabricated by screen printing the agar@LM ink onto a polyurethane substrate, followed by the assembly of commercially available LED chips and pressure sensors on the circuits. The agar@LM inks achieve high-precision patterning with a circuit line width of 0.6 mm (Fig. 5j). To establish electrical conductivity, the printed circuits are sintered by the mechanical-compaction technique (Supplementary Fig. 31). The agar@LM circuits exhibit fatigue resistance under cyclic stretching (Supplementary Fig. 32) and anti-leakage performance, indicating their good durability (Supplementary Fig. 33). As proof, the agar@LM circuit is applied in flexible wearable electronic devices worn on the hands (Fig. 5k). The pressure sensor and LED on each finger are connected in a series circuit, while the LEDs on different fingers are connected in a parallel circuit. Initially, the LEDs do not light up because of the high resistance of the pressure sensor. When five fingers simultaneously press the desktop, all LEDs light up because of the reduced resistance of the pressure sensors. The LEDs can also be individually lit up when the corresponding finger (little finger, middle finger) presses the desktop. Such circuits are expected to be applied in wearable healthcare monitoring devices. It is also demonstrated that the agar@LM patterns exhibit great uniformity, strong adhesion, and high precision (Supplementary Figs. 34–36, Table 3), and more discussions could be seen in the Supplementary Information.

The agar@LM inks can also be blade-coated into uniform films for application in solar thermoelectric generator (STEG) devices (Supplementary Fig. 30). The STEG devices rapidly yield a high open-circuit voltage of 180.7 mV and a good short-circuit current of 19.7 mA, and the performance remains repeatable under continuous irradiation for 3000.0 s. Additionally, the agar@LM inks address the sedimentation of LM droplets in the conventional LM/polymer composites. In Supplementary Fig. 37, a homogeneous LM/nitrile rubber (NR) composite is prepared by adding the agar@LM inks into the NR emulsion. The LM droplets are homogeneously distributed in the agar@LM@NR film, whereas the LM droplets clearly settle at the bottom of the PVP@LM@NR film. The results highlight the generality and versatility of the agar@LM inks, which hold great promise in the flexible electronics field.

Generality of the finite-gel strategy

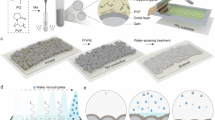

Notably, the finite-gel strategy could be generalized to various cryogel systems with physically crosslinked networks, including locust bean gum, curdlan, linseed gum, carrageenan, gelatin, gellan gum, konjac, bean jelly, and ice jelly systems (Fig. 6a). The general principle of the finite-gel strategy is that the weak physical crosslinking networks in the cryogel can be disrupted under a force field (vortex and shear) and reorganized via hydrogen bonding after the force field is withdrawn, resulting in high-viscosity LM-based inks. These inks demonstrate good stability (Fig. 6b) and satisfactory rheology (high viscosity and viscoelasticity) (Fig. 6c), which are difficult to achieve at the same time in previous work. Specifically, the TSI values for these LM-based inks with an LM concentration of 50.0 g/L are all less than 1, indicating great stability (Fig. 6d and Supplementary Figs. 38, 39). The LM-based inks also have good thixotropy for direct application in patterning technology (Supplementary Figs. 40–42). Notably, recyclability is also a topic that should be addressed owing to the increasing accumulation of electronic waste (e-waste)42,43. The above-mentioned cryogels are all prepared from natural materials, implying good degradability for LM recycling. As shown in Fig. 6e, the LM can be recovered when the agar@LM inks are exposed to a hydrochloric acid solution, and the mass recovery is as high as 93.3%. This recyclability demonstrates that the LM-based inks with finite-gel networks have great potential for environmental protection and sustainability.

a Schematic illustration of the general finite-gel strategy. The LM-based inks with the finite-gel networks exhibit b good stability, and c high viscosity and viscoelasticity. The blue line represents the cryogel molecules. The gray ball represents the LM droplet. d TSI values of the different LM-based inks with finite-gel networks. e Recycling properties of the agar@LM inks under hydrochloric acid conditions. Source data are provided as a Source Data file.

Discussion

We report a general finite-gel strategy to fabricate the agar@LM ink with a high LM concentration of 30,000.0 g/L at only 3.0 wt% agar. It is demonstrated that the formation of the finite-gel networks and good interfacial interaction are critical for realizing the high-concentration LM-based inks, which provide strong repulsive effects to prevent LM droplets from reuniting with each other even at high LM concentrations. The LM-based inks also present tunable rheological behavior and are suitable for various processing technologies, including dip-coating, spray-coating, filtration, drop-casting, direct writing, blade-coating, screen printing, and 3D printing. The finite-gel strategy could be extended to various cryogel systems, such as curdlan, gelatin, and gellan gum. This work enables a wide range of options to produce highly concentrated LM-based inks for various processing technologies and applications in flexible electronics.

Methods

Materials

Galinstan alloy, which is composed of 68.5 wt% gallium, 21.5 wt% indium, and 10 wt% tin, is purchased from Northeast Nonferrous Metals Co., Ltd. Agar is purchased from Biofroxx, Germany. Polyvinyl pyrrolidone (PVP, 99.7+%), sodium alginate (SA, 99.7+%), gelatin (99.5+%), hydrochloric acid (HCl, 30%, 99.5+%) is purchased from Chengdu Kelong Chemical Reagent Factory. Lignin (97.5+%) is obtained from the Jinan Kost Experimental Equipment Co. Carbopol U20 is purchased from Lubrizol Corporation, USA. Triethanolamine (99+%) is provided by BASF SE. Tannic acid (95+%), locust bean gum, carrageenan (99.5+%), and xanthanate gum (99.9+%) are obtained from Shanghai Aladdin Biochemical Technology Co. Gellan gum (99+%) is obtained from Shanghai Macklin Biochemical Technology Co., Ltd. Curdlan (80+%), linseed gum and carrageenan are obtained from Zhejiang YINO Biotechnology Co. Ice jelly, bean jelly, and konjac are purchased from Sichuan Ayilang Food Co., Shanghai Guangxi Food Technology Co., and Hefei Yipinyuan Trading Co., respectively. Cellulose nanofiber aqueous dispersion (6 wt%) is from Songhu Shengjian Technology (Dongguan) Co., Ltd. The waterborne polyurethane (WPU) emulsion (50 wt%, F0401) is supplied by Shenzhen Jitian Chemical Co. Nitrile rubber is from Dongguan Shunjie New Material Technology Co. Deionized (DI) water is made with an ultrapure water machine.

Fabrication of LM-based inks

The agar@LM inks are fabricated in three steps: (1) a specified content of LM (0.5 g, 1.5 g, 3.0 g, 6.0 g, 9.0 g, 200.0 g, 300.0 g) is dispersed in 5.0 mL DI water by sonication at 400 W for 2 min, and agar (0.05 wt%, 0.1 wt% 0.3 wt%, 0.5 wt%, 0.7 wt%, 1.5 wt%, 2.0 wt%, 3.0 wt% in 10 mL water) is dissolved in boiling water of 5.0 mL for 10 min. (2) The LM dispersion and agar dispersion are mixed and sonicated at 400 W for 2 min in a water bath, then the mixtures are cooled in an ice water bath for 30 min for gelation. (3) The agar@LM gels are sheared into the agar@LM inks at 11,000 rpm for 5 min, followed by vacuuming to fabricate the agar@LM inks. The other LM-based inks (locust bean gum@xanthanate gum@LM, curdlan@LM, linseed gum@LM, carrageenan@LM, gelatin@LM, gellan gum@LM, konjac@xanthanate gum@LM, bean jelly@LM, ice jelly@LM) are fabricated via the above process by replacing the agar with the corresponding cryogels. For comparison, the lignin@LM inks (the solvent is ethanol), CNF@LM inks, TA@LM inks, and the SA@LM inks are also prepared via the above process by replacing the agar with the corresponding surfactants. The Carbopol@LM inks are prepared via preparation of Carbopol gel and mixing the Carbopol gel with LM at a speed of 25,000 rpm for 5 min. The Carbopol gel is formed by dispersing 0.24 g Carbopol in 36 g DI water, and then adjusting the pH to 7.0 with 0.28 g triethanolamine.

Fabrication of the printed circuits

First, a PU film is fabricated by blade-coating the WPU. Next, the printed circuits are patterned by screen printing, in which a rubber block is used to blade-coat the agar@ inks through the open area of the screen onto the PU film. The high conductivity is achieved by scratching the circuits. The flexible wearable device is prepared by fixing LEDs and pressure sensors onto the circuit through double-sided tapes, and the circuit is connected to the power supply with copper tapes. Finally, the circuit is encapsulated by a thin PU film to protect the circuit.

Characterization

Field emission scanning electron microscopy (SEM, Inspect-F, FEI, Finland) with X-ray energy dispersive spectrometry (EDS, AztecLive Ultim Max100, Oxford, UK) is used to characterize microstructure and elemental mapping at an acceleration voltage of 5 kV. TEM images are taken using a Talos F200S TEM instrument with EDS from SUPER X. TEM measurements are performed using a carbon-free micro-grid as a substrate, thus the detected carbon is completely derived from the agar. Low-field nuclear magnetic system (LFNMS, VTMR20-010V-I, Suzhou Niumag Analytical Instruments Co.) is applied to clarify the behavior of water. Fourier Transform infrared spectroscopy (FTIR spectra) is recorded by Nicolet 6700 (Thermal Scientific, USA). The chemical composition of specimens is characterized using X-ray photoelectron spectroscopy (XPS, XSAM800, Shimadzu-Kratos Ltd., Japan). Zeta potential is performed by nanoparticle size and zeta potential meter (zetasizer, Malvern Panalytical, UK). The pH values are detected by the SMART SENSOR, PH818. The real-time resistance of the specimens during the bending-release cycle is investigated using an electrochemical analyzer (CHI800D). The compression test is carried out by Shenzhen Sansi Testing Instrument Co., an electronic general testing machine (CTM2000). An Air Mass 1.5 Global (AM 1.5G) is used to simulate solar light. The open-circuit voltage and short-circuit current are measured by a digital multimeter (Fluke 17B+). The surface temperature of the agar@LM film is detected by an infrared camera (FLUKR TIX580, USA). The optical micrograph is recorded by a polarizing microscope (LV100NPOL, Nikon, Japan). Water contact angle (WCA) is measured using a contact Angle goniometer (DA30, Kruss, Germany) at room temperature. X-ray diffraction patterns are collected using the Ultima IV (Rigaku Corporation, Japan) diffractometer. The reflectance of the agar@LM film is measured by an FTIR spectrometer (Nicolet 6700) with an integrating sphere (PIKE). The transmittance and reflectance data are collected on a Lambda750s UV–vis–NIR spectrometer with an integrating sphere. The electrical conductivity of the specimens is measured with a four-point probe (RTS-8, Guangzhou Four-Point Probe Technology Co., Ltd., China). The adhesion performances of the agar@LM coatings on the cellulose films are characterized by the cross-cut tape test.

Stability analysis

The colloidal stability of the inks is evaluated by two approaches. Firstly, digital photographs are used to observe the colloidal stability of the inks at different times. The ink is stored in bottles with a diameter of 22 mm and a height of 50 mm. Secondly, the colloidal stability of the inks is quantified by multiple light-scattering instruments (Turbiscan Lab, Formulaction, France). TSI is less than 1 means that the inks exhibit good stability, while a TSI greater than 1 indicates that the inks are unstable.

Rheological measurements

Rheological measurements are conducted using a MCR 302 rotational rheometer (Anton Paar, Graz, Austria), which equips a parallel plate with a diameter of 25 mm. The plate-plate gap is set to 1 mm. The rheological parameters include (1) a frequency sweep at 1% strain to determine the viscosity of the inks, (2) a strain sweep at 30 rad/s from 0.01% to 100% to obtain the modulus (storage modulus-G’ and loss modulus-G”), (3) a frequency sweep at 0.1 1/s for 30 s, 200 1/s for 30 s, and 0.1 1/s for to obtain the thixotropy of inks, (4) a temperature sweep from 50 °C to 90 °C is at an angular frequency of 250 rad/s, which is determined by frequency sweeps at 1% strain from 10 to 600 rad/s.

Theoretical formulas for XDLVO

We use the extended Derjaguin–Landau–Verwey–Overbeek (XDLVO) theory to investigate the mechanism of good stability for agar@LM inks. According to XDLVO theory, the interaction between two particles is the sum of the attractive van der Waals (WLW), the repulsive electrostatic double-layer or Coulomb interactions (WEL), and the Lewis acid–base interaction energy (WAB). The specific calculation formula is shown in the Supplementary Information.

The molecular dynamics (MD) simulation

Initial atomic models of the amorphous LM core (~4 nm), Ga₂O₃ crystalline middle layer (~1 nm), and outer agar molecular chain layer (~2 nm) are constructed using Atomsk. These components are assembled into a unified system via Packmol. The composite model is then parameterized in Material Studio (MS): CVFF force fields are assigned to agarose molecules, while Lennard–Jones (LJ) potentials govern Ga₂O₃ and the LM core. The fully configured system is exported as a LAMMPS-compatible data file. Subsequent tensile simulations employ an NVE ensemble for structural relaxation, followed by NVT-ensemble strain application. Stress–strain profiles and structural snapshots are recorded, with agar chains rendered as lines, metal atoms as spheres, and all atoms color-coded by element/stress. Finally, binding energies at varying strains are computed using MS’s Forcite module by subtracting the sum of individual subsystem energies from the total system energy.

The density functional theory (DFT) calculations

The Vienna Ab Initio Package is used to perform all the density functional theory (DFT) calculations within the generalized gradient approximation by the PBE formulation. We have chosen the projected augmented wave potentials to describe the ionic cores and take valence electrons into account using a plane wave basis set with a kinetic energy cutoff of 400 eV. Partial occupancies of the Kohn−Sham orbitals are allowed using the Gaussian smearing method and a width of 0.05 eV. The electronic energy is considered self-consistent when the energy change is smaller than 10−5 eV. A geometry optimization is considered convergent when the force change is smaller than 0.02 eV/Å. Grimme’s DFT-D3 methodology is used to describe the dispersion interactions. During structural optimizations, the Γ point in the Brillouin zone is used for k-point sampling, and all atoms are allowed to relax. Finally, the adsorption energies (Eads) are calculated as Eads= Ead/sub-Ead-Esub, where Ead/sub, Ead, and Esub are the total energies of the optimized adsorbate/substrate system, the adsorbate in the structure, and the clean substrate, respectively.

Statistics and reproducibility

All experiments were repeated independently with similar results at least three times.

Data availability

All data supporting the findings of this study are available within this article and Supplementary Information or from the corresponding authors upon request. The data generated in this study are provided in the Supplementary Information/Source Data file. Source data are provided in this paper. Coordinate files are provided. Source data are provided with this paper.

References

Jiang, Y. et al. A universal interface for plug-and-play assembly of stretchable devices. Nature 614, 456–462 (2023).

Lin, R. et al. Soft electronics based on particle engulfment printing. Nat. Electron. 8, 127–134 (2025).

Xie, X. et al. Liquid-in-liquid printing of 3D and mechanically tunable conductive hydrogels. Nat. Commun. 14, 4289 (2023).

Yang, Y. et al. Free-standing printed electronics with direct ink writing. Nat. Electron. 7, 630–631 (2024).

He, T. et al. Epidermal electronic-tattoo for plant immune response monitoring. Nat. Commun. 16, 3244 (2025).

Liang, X. et al. Stable and biocompatible carbon nanotube ink mediated by silk protein for printed electronics. Adv. Mater. 32, 2000165 (2020).

Zhang, L. et al. Electrochemically exfoliated graphene additive-free inks for 3D printing customizable monolithic integrated micro-supercapacitors on a large scale. Adv. Mater. 36, 2313930 (2024).

Ko, T. Y. et al. Functionalized MXene ink enables environmentally stable printed electronics. Nat. Commun. 15, 3459 (2024).

Handschuh-Wang, S. et al. The liquid metal age: a transition from Hg to Ga. Adv. Mater. 36, 2408466 (2024).

Zheng, S. et al. Pressure-stamped stretchable electronics using a nanofibre membrane containing semi-embedded liquid metal particles. Nat. Electron. 7, 576–585 (2024).

Jiang, H. et al. Malleable, printable, bondable, and highly conductive MXene/liquid metal plasticine with improved wettability. Nat. Commun. 15, 6138 (2024).

Li, N. et al. Transformable 3D curved high-density liquid metal coils—an integrated unit for general soft actuation, sensing and communication. Nat. Commun. 15, 7679 (2024).

Wang, Q. et al. Stretchable and permeable liquid metal micromeshes featuring strain-insensitive resistance through in situ structural transformations. Adv. Mater. 37, 2417799 (2025).

Oh, J. et al. A liquid metal based multimodal sensor and haptic feedback device for thermal and tactile sensation generation in virtual reality. Adv. Funct. Mater. 31, 2007772 (2021).

Kim, J. H. et al. Imbibition-induced selective wetting of liquid metal. Nat. Commun. 13, 4763 (2022).

Xu, Y. et al. Convergent synthesis of diversified reversible network leads to liquid metal-containing conductive hydrogel adhesives. Nat. Commun. 12, 2407 (2021).

Gan, T., Shang, W., Handschuh-Wang, S. & Zhou, X. Light-induced shape morphing of liquid metal nanodroplets enabled by polydopamine coating. Small 15, 1804838 (2019).

Li, X. et al. Liquid metal droplets wrapped with polysaccharide microgel as biocompatible aqueous ink for flexible conductive devices. Adv. Funct. Mater. 28, 1804197 (2018).

Li, X. et al. Evaporation-induced sintering of liquid metal droplets with biological nanofibrils for flexible conductivity and responsive actuation. Nat. Commun. 10, 3514 (2019).

Hu, Y. et al. Self-standing, photothermal-actuating, and motion-monitoring Janus films one-pot synthesized by green carboxymethyl glucomannan/liquid metal nanoinks. ACS Appl. Mater. Interfaces 14, 23717–23725 (2022).

Lin, Z. et al. High internal phase emulsions gel ink for direct-ink-writing 3D printing of liquid metal. Nat. Commun. 15, 4806 (2024).

Qi, X. et al. Versatile liquid metal/alginate composite fibers with enhanced flame retardancy and triboelectric performance for smart wearable textiles. Adv. Sci. 10, 2303406 (2023).

Xu, J. et al. Printable and recyclable conductive ink based on a liquid metal with excellent surface wettability for flexible electronics. ACS Appl. Mater. Interfaces 13, 7443–7452 (2021).

Ye, Y. & Jiang, F. Highly stretchable, durable, and transient conductive hydrogel for multi-functional sensor and signal transmission applications. Nano Energy 99, 107374 (2022).

Wang, L. et al. High colloidal stable carbon dots armored liquid metal nano-droplets for versatile 3D/4D printing through digital light processing (DLP). Energy Environ. Mater. 7, e12609 (2024).

Chung, K. Y. et al. Naturally crosslinked biocompatible carbonaceous liquid metal aqueous ink printing wearable electronics for multi-sensing and energy harvesting. Nano-Micro Lett. 16, 149 (2024).

Zhang, M. et al. Versatile fabrication of liquid metal nano-ink based flexible electronic devices. Appl. Mater. Today 22, 100903 (2021).

Lou, Y., Liu, H. & Zhang, J. Liquid metals in plastics for super-toughness and high-performance force sensors. Chem. Eng. J. 399, 125732 (2020).

Chu, F. U. et al. Multiple hydrogen bonds network enabled sustainable and reproducible cellulose/liquid metal composite elastomer for clean energy collection and conversion. Compos. Sci. Technol. 242, 110201 (2023).

Wei, Q. et al. Surface engineering of liquid metal nanodroplets by attachable diblock copolymers. ACS Nano 14, 9884–9893 (2020).

Farrell, Z., Reger, N., Anderson, I., Gawalt, E. & Tabor, C. Route to universally tailorable room-temperature liquid metal colloids via phosphonic acid functionalization. J. Phys. Chem. C. 122, 26393–26400 (2018).

Lee, G. H. et al. Rapid meniscus-guided printing of stable semi-solid-state liquid metal microgranular-particle for soft electronics. Nat. Commun. 13, 2643 (2022).

Veerapandian, S. et al. Hydrogen-doped viscoplastic liquid metal microparticles for stretchable printed metal lines. Nat. Mater. 20, 533–540 (2021).

Zheng, Y. et al. Lignin-based encapsulation of liquid metal particles for flexible and high-efficiently recyclable electronics. Adv. Funct. Mater. 34, 2310653 (2023).

Zhao, W., Wu, B., Lei, Z. & Wu, P. Hydrogels with differentiated hydrogen-bonding networks for bioinspired stress response. Angew. Chem. Int. Ed. 63, e202400531 (2024).

Xue, X. et al. Segregated and non-settling liquid metal elastomer via jamming of elastomeric particles. Adv. Funct. Mater. 33, 2210553 (2023).

Bepete, G. et al. Surfactant-free single-layer graphene in water. Nat. Chem. 9, 347–352 (2017).

Gonella, G. et al. Water at charged interfaces. Nat. Rev. Chem. 5, 466–485 (2021).

Liu, M. et al. Scalable assembly of micron boron nitride into high-temperature-resistant insulating papers with superior thermal conductivity. Mater. Horiz. 12, 4349–4362 (2025).

Wang, S. et al. Strong, tough, ionic conductive, and freezing-tolerant all-natural hydrogel enabled by cellulose-bentonite coordination interactions. Nat. Commun. 13, 3408 (2022).

Yi, S. et al. CNT-assisted design of stable liquid metal droplets for flexible multifunctional composites. Compos. Part B Eng. 239, 109961 (2022).

Mi, X. et al. Ink formulation of functional nanowires with hyperbranched stabilizers for versatile printing of flexible electronics. Nat. Commun. 16, 2590 (2025).

Yang, Q. et al. Ecoresorbable and bioresorbable microelectromechanical systems. Nat. Electron 5, 526–538 (2022).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (grant no. 52103043 to L.J., 51973142, U24A2074 to D.Y., and U21A2090 to Z.L.), and Key Laboratory of Engineering Dielectrics and Its Application (Harbin University of Science and Technology), Ministry of Education (grant no. KFM202306 to L.J.). We would like to thank the Analytical & Testing Center of Sichuan University for the XPS work.

Author information

Authors and Affiliations

Contributions

R.M. and L.J. conceptualized the project, carried out experiments and co-wrote the manuscript. Z.G., J.L. and M.L. carried out the theory simulation and analyzed the results. Z.W. and G.S. contributed to the sample preparation and manuscript editing during revision. L.J., D.Y. and Z.L. supervised the work and revised the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks the anonymous reviewers for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Ma, R., Jia, L., Guo, Z. et al. A general finite-gel strategy for highly concentrated liquid metal inks. Nat Commun 16, 9085 (2025). https://doi.org/10.1038/s41467-025-63433-y

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-025-63433-y