Abstract

The escalating issue of plastic “white pollution” urgently calls for efficient and sustainable recycling strategies. Herein, we propose an approach for the depolymerization of polyamides via alcoholysis, utilizing methyl tosylate as an activator to cleave robust amide C-N bonds under mild reaction conditions. This strategy facilitates the efficient conversion of diverse polyamides into high-value monomers, such as ε-caprolactam, amino acid esters, or diamines/diesters, with nearly quantitative yields and excellent selectivities. Experimental and theoretical mechanistic investigations reveal that p-toluene sulfonic acid plays a crucial role in the efficient alcoholysis of polyamides, mediating the formation of a tetrahedral intermediate through the nucleophilic attack of alcohol on the amide group. This protocol not only demonstrates exceptional applicability to complex waste plastic mixtures containing polyamides but also highlights its potential for scalable implementation, offering a practical and sustainable recycling approach for more effective management of white pollution.

Similar content being viewed by others

Introduction

The increasing global consumption of plastics has led to severe environmental issues, mainly due to improper disposal and insufficient recycling of end-of-life plastics. Alarmingly, nearly 91% of plastic waste is either incinerated for energy recovery or landfilled1, resulting in elevated greenhouse gas emissions and the leakage of microplastics into the environment2,3,4. This poses significant environmental and health risks, as plastic waste continues to accumulate in ecosystems. To promote an environmentally friendly economy, significant emphasis has been placed on plastic recycling, primarily through mechanical and chemical approaches5,6,7. While physical recycling is widely used, it typically results in lower-quality recycled plastics, limiting its long-term sustainability8. In contrast, chemical technologies have emerged as the most promising approach, as they break down polymers into monomers, which can be repolymerized into virgin plastics, thus facilitating a closed-loop system. This makes chemical recycling particularly critical for achieving a circular plastic economy.

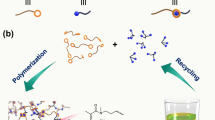

Polyamide (PA), commonly known as nylon, is one of the five major engineering polymers, with a global market exceeding 8.5 million tons per year2. Among them, PA6 and PA66, which account for over 90% of the market, have been the primary focus of recycling efforts9,10. However, PAs are notoriously resistant to degrade under mild conditions due to their excellent chemical stability (Fig. 1a), arising from the resonance stabilization of amide bonds (resonance energy: 15–20 kcal/mol) and strong hydrogen bonding between amide groups (ΔHdiss = 8–12 kcal/mol)11,12. This makes depolymerization of PA thermodynamically challenging. Thus, harsh conditions, including prohibitively high temperature (>200 °C) and/or pressure (>70 bar), are generally required, whenever in hydrolysis13,14,15,16,17,18,19,20,21, ammonolysis22,23,24,25, alcoholysis26,27,28,29,30,31,32, or hydrogenolysis33,34,35,36, even with strong acid/base additives.

Notably, increasing attention has been directed towards the depolymerization of PA6 to recover its cyclic monomer, ε-caprolactam (ε-CPL), which can be repolymerized into virgin PA6 via ring-opening polymerization37,38. A well-established strategy to achieve this goal is degradation in supercritical or subcritical (sc.) solvents (Fig. 1b). Goto and co-workers have systematically studied the depolymerization of PA6 in sc. water. PA6 was decomposed into ε-aminocaproic acid through hydrolysis followed by cyclodehydration to ε-CPL in up to 85% yield. However, ε-CPL can further degrade into side products under such severe conditions (300–400 °C, up to 35 MPa)18,39. Kamimura group pioneered the use of sc. alcohols for this purpose, demonstrating superior performance compared to water. In the presence of sc. secondary or tertiary alcohols, PA6 is readily converted into ε-CPL, with yields of up to 93% achieved in sc. isopropanol. However, primary alcohols are not suitable for this process28,29,30,31. Other approaches, including microwave-assisted degradation in ionic liquids40,41, lanthanide/yttrium-organic catalysis42,43, and pyrolysis under alkaline conditions44,45, have also been explored (Fig. 1c). However, these methods still necessitate exceptionally high temperatures (>220 °C) to melt PA6 and overcome the thermodynamic barrier. Furthermore, these known approaches are specifically tailored to the degradation of PA6 and can hardly be extended to other PAs, including PA66.

Inspired by the aforementioned works, we envisioned that PAs could be subjected to alcoholysis to produce corresponding diesters/diamines, or amino acid esters which serve as critical precursors to generate lactams. However, this process is generally hindered by the thermodynamic equilibrium of amide C-N bonds, owing to their poor reactivity and the inferior nucleophilicity of alcohols compared to amines46. Therefore, the addition of amide-activating and/or amine capture reagents is necessary to enable this challenging process47,48. Considering that Brønsted acids can act as both amide activators and amine scavengers, we hypothesized that they could facilitate PA alcoholysis. Herein, we demonstrate that methyl tosylate (TsOMe), which generates p-toluenesulfonic acid (TsOH) in situ, enables the efficient alcoholysis of PAs under mild conditions (Fig. 1c). This protocol is effective for both commercially available and post-consumer PAs, enabling the production of corresponding precursors. Particularly for PA6, an additional cascade cyclization step efficiently converts it to ε-CPL, a valuable monomer, in excellent yields. This approach not only provides a closed-loop recycling system but also reduces the environmental impact of PA plastic wastes.

Results

Methanolysis of PA6 facilitated by TsOMe

Initially, the commercially available PA6 powder was found to be insoluble in water but was well dissolved in various alcohols, among which the simplest alcohol, MeOH, was selected as the solvent due to its good solubility at elevated temperature (250 mg/mL at 130 °C; Supplementary Fig. 1). Therefore, we selected methanolysis of PA6 as the model reaction for additive screening (Fig. 2a). The reaction was conducted on a 1 mmol scale with 1 equivalent additive in 3 mL MeOH at 140 °C for 16 h in a 15 mL sealed tube. To our delight, various sulfonic acids or sulfonate ester efficiently promoted the degradation of PA6, whereas other Brønsted or Lewis acids were less effective. Screening different sulfonic acids revealed a correlation between methanolysis selectivity and the acidity of the sulfonic acids. As the acidity of sulfonic acids decreases [pKa: CF3SO3H (−14.0), H2SO4 (−3.0), CH3SO3H (−2.6), and TsOH (−0.4)]49, the selectivity for methanolysis increases, although with a slight decline in conversion. We speculated that acids could catalyze the dehydration of MeOH to produce dimethyl ether (Me2O) under heating50, with the resulting water potentially leading to the hydrolysis of amides or esters to acids (Supplementary Fig. 6), thereby reducing methanolysis efficiency. Control experiments revealed that the methanolysis selectivity decreased along with the increase of water content (Supplementary Figs. 7, 8). Interestingly, the TsOMe exhibited superior selectivity for methanolysis than TsOH·H2O (Fig. 2a). Control experiments demonstrated that TsOMe would be quickly converted to TsOH in methanol under heating (140 °C)51, thus facilitating the methanolysis (Supplementary Fig. 5). Finally, considering both conversion and alcoholysis selectivity, TsOMe was selected as the optimal degradation accelerator.

a Additive screening for PA6 methanolysis. Reaction conditions: the mixture of PA6 (commercial powder, 30 mesh, 1 mmol relative to the molecular weight of the monomer), additive (1.0 equiv.), and MeOH (3 mL) was heated at 140 °C for 16 h. b 1H NMR (400 MHz, DMSO-d6) spectrum of the reaction mixture using TsOMe. c The reaction profile of PA6 conversion and the degree of methanolysis versus time with 1.05 equiv. TsOMe at 140 °C. Each data point represents the average of the triplicate experiments. d PA6 degradation profile under excess TsOH. e Fitting curve of pseudo first-order kinetics over PA6 units. f Initial rate kinetic study of TsOH using ε-CPL as a model substrate.

In the presence of 1 equiv. TsOMe, PA6 was readily degraded with 93% conversion. The 1H NMR (Fig. 2b) signals of the reaction mixture at 3.58 and 2.74 ppm were recognized as the protons of the methoxy groups (-COOCH3) and methylene groups adjacent to protonated amino groups (-CH2NH3+), respectively. Two minor peaks around 3.00 and 2.04 ppm were assigned to -CH2- groups adjacent to the amide bonds of oligomers. In addition to methanolysis products (-COOCH3), partial hydrolysis byproduct (-COOH) was also detected (Fig. 2b). The methylene groups adjacent to the ester (2.28 ppm) and carboxyl group (2.21 ppm) were distinguishable by the slight difference in chemical shifts in 1H NMR spectra (Fig. 2b, Supplementary Fig. 36 and Supplementary Fig. 84). Then the equivalency of TsOMe, reaction temperature and MeOH volume (Supplementary Figs. 2-4) were further optimized. The optimal results were obtained with 1.05 equivalents of TsOMe. Insufficient conversion was observed with sub-stoichiometric amount of TsOMe, whereas excessive amounts resulted in reduced selectivity due to the competitive hydrolysis. No significant enhancement in conversion was observed at elevated temperatures (>140 °C). Additionally, varying the volume of MeOH had no notable impact on the methanolysis. Thus, 3 mL of MeOH was selected for further studies to balance solubility and handling considerations.

With the optimized conditions in hand, we monitored the degradation process via 1H NMR spectroscopy (Supplementary Fig. 9). It was evident that the proton signals from methylenes adjacent to amide groups (-CH2CONHCH2-, 3.00 and 2.04 ppm) of PA6 gradually weakened, while those near to the ester groups (-CH2COOCH3, 2.28 ppm) and protonated amino groups (-CH2NH3+, 2.74 ppm) intensified. A reaction profile plotting conversion and methanolysis degree versus time indicated rapid degradation in early stages, reaching approximately 80% within 8 h almost without hydrolysis byproducts (Fig. 2c). The conversion then increased to 97% with 94% alcoholysis selectivity (containing both the methyl ester monomer and oligomers) after 16 h. Notably, upon further extending the reaction time to 24 h, although the overall alcoholysis selectivity decreased to only 88%, the oligomers were further degraded to monomers. As a result, pure methyl ester monomer 1a could be readily isolated as a white solid from the reaction mixture by adding diethyl ether (Et2O) in 95% yield.

Moreover, further kinetic studies with PA6 were performed in the presence of TsOH to determine the reaction order. Noteworthy, the PA6 displayed poor solubility in MeOH at room temperature, rendering it unsuitable for kinetic studies via NMR analysis. As a result, the reaction rate accelerated in the early stage of the transformation, which was reasonable, since the effective concentration of dissolved PA6 in MeOH was gradually increased under reaction conditions. After 75 min, the reaction underwent smoothly, which corresponded to a first-order kinetics (Fig. 3e). Moreover, due to the poor solubility of PA6, the cyclic lactam ε-CPL was also employed as a model substrate instead to investigate the influence of TsOH. The initial reaction rate of 1a increased linearly with the concentration of TsOH (0.025-0.1 M), indicating a first-order dependence (Fig. 3f, Supplementary Fig. 13). The applicability of our method to the C-N bond cleavage of small amide molecules, a challenging issue in organic synthesis, further highlights the versatility of this protocol (Supplementary Fig. 12).

Reaction conditions: the mixture of PA (1 mmol relative to the molecular weight of the monomer), TsOMe (1.5 equiv.) and alcohol (3.0 mL) was heated at 140 °C for 24 h. Conversions and selectivities were determined by 1H NMR in DMSO-d6 with 1,3,5-trimethoxybenzene as an internal standard. All yields are isolated yields. [a] With 1.05 equiv. TsOMe after 24 h; [b] Dried reaction residue was redissolved in methanol and stirred at 50 °C for 30 min before adding Et2O to precipitate the product; [c] Heating for 48 h; [d] Dried reaction residue was redissolved in methanol and stirred at 80 °C for 3 h before adding Et2O to precipitate the product. [e] With 1.2 equiv. TsOMe after 16 h; [f] With 2.1 equiv. TsOMe after 16 h.

Substrate scope and recovery of produced monomers

To explore the feasibility of this protocol, we investigated the scope of PAs and alcohols (Fig. 3). To our delight, all aliphatic primary alcohols were highly compatible, affording the corresponding esters (1a-h) in excellent conversions (96–99%), alcoholysis selectivities (95–99%), and high isolated yields (75–96%). Aromatic alcohols, such as phenylethanol and 3-phenylpropanol, were also suitable, albeit with slightly lower selectivities (1j and 1k). It is worth noting that aliphatic alcohols with longer chains achieved complete degradation by slightly increasing TsOMe dosage and extending reaction time, without compromising selectivities (1b–1e). Conversely, secondary and benzyl alcohols resulted in a significant increase in hydrolysis byproducts (1l-n and 1i), leading to inferior selectivities (40–72%). Nevertheless, by evaporating water from the reaction mixture and stirring the residue in the corresponding alcohol, the hydrolysis products were fully converted back to desired alcoholysis products. Owing to their weak nucleophilicity and high tendency for dehydration, the alcoholysis of PA6 failed in all tertiary alcohols (t-butanol and t-AmOH). Only hydrolysis products were detected despite the PA6 was quantitatively consumed (99% conversion). These findings demonstrate that aliphatic primary alcohols exhibit superior alcoholysis performance, whereas higher-order or benzyl alcohols are prone to dehydration (forming more stable carbocations) under acidic conditions, leading to excessive hydrolysis product formation52,53.

With satisfactory results obtained from PA6, we further investigated its feasibility towards other PAs. Both PA66 and PA610 were efficiently depolymerized into desired diamine tosylates (6a) and diesters (4, 5) in the presence of 2.1 equiv. TsOMe. The two products were readily separated and purified through solvent extraction and recrystallization. Long-chain aliphatic PAs such as PA11 and PA12, typically exhibit greater resistance to hydrolysis due to the hydrophobicity of long alkyl backbones14. However, they performed well with our protocol, probably due to better compatibility in alcohols, achieving comparable conversions and selectivities to PA6, although a slightly higher amount of TsOMe (1.2 equiv.) was required.

In order to achieve a closed-loop recycling, we subsequently conducted a series of post-treatment and/or tandem reactions with PA degradation products, aiming to recover corresponding monomer precursors. Compared to the acidic hydrolysis salts of PAs, which require a complex and costly post-treatment process to obtain amino acids, such as ion-exchange15, our protocol allows the facile recovery of amino acid esters. All three tosylates of amino acid methyl ester (1a-3a) were neutralized to the corresponding amino acid esters in Na2CO3 aqueous solution. The treatment of 2a and 3a resulted in excellent yields (>90%), while 1a would undergo partial polymerization or cyclization during this process due to the great reactivity of product 1. The obtained 2 and 3 can serve as monomers for the synthesis of PA11 and PA1254,55, whereas ε-CPL is more commonly used as PA6 industrial precursor rather than 156. Beyond their roles in polymer synthesis, these amino acid esters have broad applications in biochemistry and pharmacology, such as functioning as linkers for diverse pharmacophores or molecular probes57,58,59, being utilized as building blocks for synthetic polypeptide backbones60, etc. Similarly, the tosylate of diamine 6a could be processed through neutralization and extraction to obtain 1,6-hexylenediamine in 96% yield, which can be used as a monomer for PA66 and PA610 synthesis alongside the diesters produced in the methanolysis step61.

In order to recover PA6 synthetic monomer (ε-CPL), we attempted to induce the intramolecular cyclization of 1a under basic conditions. To the best of our knowledge, few reports have described the intramolecular cyclization of amino acid esters, except for amino acids in the presence of catalysts62,63,64. As is well known, bifunctional compounds like 1a tend to undergo intermolecular polymerization at high concentrations, while intramolecular cyclization is favored at lower concentrations65. Thus, we selected apolar solvents like toluene and xylene to minimize the solubility of 1a. Additionally, we selected weak inorganic bases like K2CO3 and Na2CO3 to restore the nucleophilicity of the amine without disrupting the ester group. Excitingly, ε-CPL was generated in 64% NMR yield at 150 °C within 16 h in xylene, in the presence of 2.0 equiv. K2CO3 (Supplementary Table 6, entry 13). During the reaction, amino acid ester 1 and ε-CPL were identified as the two main components in the liquid phase (Supplementary Fig. 14). It suggests that 1a was initially neutralized under the basic condition to generate 1, which subsequently underwent intramolecular cyclization to form ε-CPL. Furthermore, we found that the addition of 4 Å molecular sieve significantly improved the yield of ε-CPL (Supplementary Table 6, entry 2, 12 and 13). After a series of condition optimization, we ultimately realized the conversion from 1a to ε-CPL in 97% NMR yield. After the reaction, the product was obtained easily in 96% isolated yield and 98% purity (Supplementary Fig. 15) simply through filtration followed by evaporating the solvent.

Interestingly, directly removing the solvent from the methanolysis system without isolating 1a, followed by cyclization under optimized conditions, afforded ε-CPL in 82% NMR yield, demonstrating the potential of this protocol for direct one-pot monomer recovery. 1H NMR and HRMS analyses reveal the formation of small amounts of oligomers as byproducts, likely attributed to residual TsOH and water in the depolymerization system. (Supplementary Fig. 17, 18). To further evaluate the advantage of our approaches, we synthesized the PA6 hydrolysis product 8 following modified literature methods (Supplementary Fig. 19) and subjected it to cyclization under the optimal condition66. The NMR yield of ε-CPL was significantly lower (31%), indicating the superior reactivity of the alcoholysis product 1a compared to acid 8. This reactivity difference aligns with findings from previous study67.

The recycled ε-CPL was repolymerized via anionic polymerization following a literature procedure68, yielding a white fine powder in 96% yield. This solid was characterized by NMR, FT-IR, and GPC to confirm its identity and purity (Supplementary Fig. 20). GPC analysis verified the successful polymerization of ε-CPL (Mn = 41.1 kg/mol, PDI = 1.46). The FT-IR and NMR spectra of the regenerated PA6 were essentially identical to those of the virgin PA6, highlighting the potential of our protocol for closed-loop recycling of PA6. Additionally, the recyclability of TsOMe was investigated. TsOMe was converted into TsOK after the second step of cyclization, and TsOK was easily isolated in 91% yield by extracting the reaction precipitate (Supplementary Fig. 16). Furthermore, according to a literature procedure69, TsOMe was feasibly regenerated from recovered TsOK via treatment with CH₂N₂ in MeOH/H₂O/DMF, highlighting the potential recyclability of TsOMe.

Feasibility for recycling post-consumer and mixed polyamides

After establishing this methodology for the chemical recycling of PAs, diverse post-consumer PA commodities and reinforced material were selected for degradation to verify its feasibility (Table 1). Under otherwise identical reaction conditions, all four types of plastics (including fibers and engineering components), either untreated or simply cut into pieces, achieved excellent conversions (up to 99%) and yields (up to 94%). Gratifyingly, as demonstrated in entry 3, our protocol was also compatible with reinforced nylon plastics. The contained PA66 was nearly quantitatively degraded, and additives in the polyamides were successfully recovered. In a similar experiment using glass fiber-reinforced commercial nylon pellets, we got comparable results (Fig. 4a). Besides obtaining 4 and 6a in 89% and 95% yields, respectively, the glass fibers were fully recovered. SEM analysis of the recovered glass fibers showed an intact morphology and neat surface, making them suitable for reuse (Supplementary Fig. 21). FTIR analysis showed no organic signals in the glass fiber sample (Supplementary Fig. 22), and TGA indicated no mass loss at high temperatures (Supplementary Fig. 23), confirming no polymer residues on the surface. Having successfully demonstrated the feasibility of degrading post-consumer PAs under mild conditions, we subsequently focused on the scalability of our protocol. Degradation of PA6 (from nylon cable ties) in 2.00 g scale was carried out, followed by cascade cyclization to produce ε-CPL (Fig. 4b). As expected, degradation proceeded efficiently and 1a was isolated in 96% yield in the first step. After extending the reaction time in the second step, ε-CPL was obtained in 94% isolated yield and 97% purity, comparable to our results on a small-batch scale.

a The degradation of reinforced PA66 to recover monomers and additives. b Gram-scale recycling from PA6 to ε-CPL. c One-pot degradation of mixed PA6 and PA66 followed by an efficient separation of the products. Conditions: (i) Extracted with diethyl ether (Et2O). (ii) Extracted with dichloromethane (DCM). All yields are isolated yields.

In real-world plastic recycling, post-consumer plastic waste often consists of multiple types of polymers, posing significant challenges for both degradation efficiency and product separation. To assess the applicability of our method in such complex scenarios, we performed methanolysis of PA6 in a 1:1 molar ratio blend with common polymers, including PE, PP, PS, and PET (Table 2). Notably, PE, PP, and PS remained unreacted, existing as either dispersed particles or melted aggregates, and were completely recovered by filtration after the degradation (Supplementary Fig. 24). The presence of PE, PP, and PS did not affect PA6 degradation, with 1a isolated after filtration in excellent yields (93–94%). Although the presence of PET led to a slight decrease in PA6 conversion due to the competition of PET methanolysis catalyzed by TsOH70, increasing the TsOMe dosage to 1.2 equiv. could resolve the issue. Conveniently, the partial alcoholysis products of PET were ether-soluble, enabling the recovery of pure 1a in 92% yield through recrystallization in MeOH/Et₂O (Supplementary Fig. 25). Moreover, our protocol demonstrates compatibility with real PET/PA6 textile blends, a common type of mixed plastic waste. Product 1a was isolated in >90% yield (calculated based on PA6) from the co-degradation system, irrespective of whether the textiles were physically mixed or industrially blended (Supplementary Fig. 26).

In addition, PA6 and PA66 are usually present simultaneously in waste PA streams and are challenging to separate due to their similar structures and properties, particularly in mechanical recycling processes. We envisioned that selective dissolution of the products from PA degradation mixtures could enable the recovery of each component (Supplementary Table 7). For instance, dimethyl adipate (4) exhibits distinct solubility compared to 1a and 6a, which are salts and nearly insoluble in apolar solvents such as Et₂O and petroleum ether. Interestingly, 1a is soluble in dichloromethane (DCM) due to its weakly polar ester group, whereas 6a is not. Furthermore, PA6 and PA66 contain an equivalent number of amide bonds when compared by equal mass, motivating us to explore a one-pot methanolysis for mixed PA6 and PA66, followed by efficient product separation.

To illustrate this, we conducted experiments using a 1:1 weight ratio blend of commercial PA6 and PA66 polymers as a case study (Fig. 4c). After methanolysis under similar conditions, the system was evaporated under vacuum to remove MeOH, and product 4 was selectively extracted from the residue with Et2O, achieving an 87% yield. The solids in the residue, comprising 1a and 6a, were then separated by the treatment with DCM. 1a was dissolved selectively and recovered from the filtrate in 91% yield after removing the solvent. The remaining solid was purified by recrystallization in MeOH/ Et2O, yielding product 6a in 95% yield. 1H NMR spectroscopy confirmed the high purity of separated products (Supplementary Fig. 27–29). This efficient one-pot depolymerization and product separation of mixed plastics underscores the practicality and versatility of our method.

DFT calculations

To elucidate the degradation mechanism and subsequent cyclization process, we conducted Density Functional Theory (DFT) calculations to generate a Gibbs free energy profile. For PA6 methanolysis calculations, we selected Dimer-1 as the model substrate, which represents a realistic intermediate formed during the degradation process (Fig. 5b). Experimental observations revealed that TsOMe rapidly undergoes solvolysis in MeOH to generate TsOH (Supplementary Fig. 5), which subsequently interacts with Dimer-1 and MeOH to form Int-1. The activation of the amide bond in this step is slightly endergonic (ΔG = 5.8 kcal·mol-1), thereby enhancing its electrophilicity. The subsequent nucleophilic attack by methanol on the activated amide bond proceeds through TS-1, forming a tetrahedral intermediate Int-2. This endergonic step (ΔG = 13.5 kcal·mol-1) exhibits an activation barrier of ΔG‡ = 20.8 kcal·mol-1. The reaction pathway continues as TsOH forms hydrogen bonds with the substrate, yielding a more thermodynamically favorable Int-3 (ΔG = -2.1 kcal·mol-1). This intermediate then traverses TS-2 (ΔG‡ = 7.9 kcal·mol-1), where TsOH facilitates the gradual cleavage of the C–N bond concurrent with carbonyl group restoration, ultimately decomposing into two molecules of 1a (ΔG = -31.8 kcal·mol-1). The formation of stable ammonium salts through neutralization of the dissociated primary amine by TsOH further drives this transformation. The mechanistic pathway demonstrates that each amide bond cleavage requires one TsOH molecule, corroborating the first-order TsOH dependence observed in kinetic studies. TsOH plays a dual catalytic role through synergistic proton transfers within substrate complexes, simultaneously activating amide bonds and neutralizing reactive amino groups, thereby enabling efficient degradation under mild conditions. To further validate this proposed methanolysis pathway, the Trimer-1, a longer model substrate, was also subjected to DFT calculations. The results demonstrate a similar energy profile to that of Dimer-1 (Supplementary Fig. 33).

The cascade cyclization mechanism of 1a was investigated in detail (Fig. 5c). Initially, K₂CO₃ neutralizes 1a to generate Int-4, during which KHCO₃ facilitates the approach of chain ends (ΔG = -17.8 kcal·mol⁻¹, Fig. 5c). The subsequent endergonic transformation proceeds through TS-3, where the amino group executes an intramolecular nucleophilic attack on the ester moiety to form the tetrahedral intermediate Int-5 (ΔG = 3.9 kcal·mol⁻¹), overcoming an activation barrier of ΔG‡ = 27.8 kcal·mol⁻¹. Int-5 then undergoes a rearrangement of hydrogen-bonding interaction sites to yield Int-6 (ΔG = 7.5 kcal·mol⁻¹). The final step involves the progression through TS-4 (ΔG‡ = 7.2 kcal·mol⁻¹), characterized by gradual C-O bond dissociation concurrent with carbonyl group restoration, ultimately affording ε-CPL (ΔG = -32.2 kcal·mol⁻¹).

Discussion

In summary, we present an approach for the efficient depolymerization of polyamides (particularly PA6 and PA66) with up to 99% conversion and 99% selectivity under mild conditions, via an alcoholysis process facilitated by methyl tosylate (TsOMe). This protocol converts PAs into their industrial precursors, such as ε-CPL, amino acid esters and diamines/diesters in nearly quantitative yields after subsequent treatments. To the best of our knowledge, this strategy represents one of the mildest conditions known for the transformation of PA6 to ε-CPL (≤150 °C). Experimental and theoretical (DFT) studies reveal the key role of TsOH in alcoholysis pathways involving a tetrahedral intermediate. Our protocol demonstrates versatility across various alcohols and polyamides, successfully addressing the challenges associated with mixed waste plastics through effective recovery and separation of monomers, even in gram-scale. This approach underscores the significance of innovative recycling techniques in mitigating the environmental impact of white pollution, laying the groundwork for future developments in sustainable polymer recycling strategies and promoting a more eco-friendly plastic economy.

Methods

Characterization

1H and 13C spectra were recorded on Bruker 400 DRX spectrometers at 298 K. The chemical shifts (δ) for 1H NMR are given in parts per million (ppm) referenced to the residual proton signal of the deuterated solvent (CHCl3 at δ 7.26 ppm or DMSO at 2.50 ppm); coupling constants are expressed in hertz (Hz). 13C NMR spectra were referenced to the carbon signal of CDCl3 (77.2 ppm) or DMSO-d6 (39.5 ppm). The following abbreviations are used to describe NMR signals: s = singlet, d = doublet, t = triplet, m = multiplet, and q = quartet. High-resolution mass spectra (HR-MS) were acquired using a Q-Exactive Focus Hybrid Quadrupole-Orbitrap Mass Spectrometer (Thermo Fisher) equipped with a Dionex Ultimate 3000 HPLC system (Thermo Fisher). SEM characterization was on an HR-SEM Zeiss Ultra Plus instrument (Carl Zeiss). Fourier transform infrared (FT-IR) spectra were recorded on a Nicolet iS20 FT-IR spectrometer (Thermo Scientific) over the range of 4000–400 cm−1. Gel permeation chromatography (GPC) spectra were recorded on a PL-GPC50 system (Agilent) equipped with a PL HFIPgel column (7.5 × 300 mm, 9 μm). Samples (0.1 mg/mL in HFIP containing 20 mM sodium trifluoroacetate) were injected at a volume of 100 μL and the mobile phase (HFIP containing 20 mM sodium trifluoroacetate) was delivered at a flow rate of 1.0 mL/min at 40 °C. Thermal gravimetric analysis (TGA) measurements were performed on a TG 209 F3 thermogravimetric analyzer (Netzsch) at a heating rate of 10 °C min−1 from 50 to 1000 °C in air atmosphere.

General procedure for methanolysis of PA6 enabled by methyl tosylate

To a 15 mL pressure vessel equipped with a stir bar, PA6 (1 mmol relative to the monomer molecular weight, 1.0 equiv.), methyl tosylate (1.05 mmol, 1.05 equiv.), and methanol (3.0 mL) were added sequentially. The vessel was then tightly sealed and heated in a pre-heated oil bath at 140 °C for 24 h. After cooling to room temperature, the solution was evaporated to dryness using a rotary evaporator. The resulting residue was redissolved in a small amount of methanol and stirred at 50 °C for 30 min. Subsequently, diethyl ether (Et₂O) was added to the oily residue to precipitate 6-methoxy-6-oxohexan-1-aminium tosylate (1a) as a white solid.

General procedure for cascade cyclization reaction to produce ε-CPL

To a pressure vessel (15 mL) equipped with a stir bar, 1a (317 mg, 1.0 equiv.), K2CO3 (415 mg, 3 equiv.), 4 Å molecular sieve (200 mg) and xylene (2 mL) were added in sequence in a glove box atmosphere. The vessel was then tightly sealed and heated in a pre-heated oil bath at 150 °C for 16 h. After cooling to room temperature, the solution was filtered and the filtrate was evaporated to dryness under reduced pressure to obtain ε-CPL.

Data availability

All data are available in the main text or the Supplementary Information. The experimental procedures and characterization of all new compounds are provided in the Supplementary Information. Data supporting the findings of this manuscript are also available from the corresponding author upon request. Source data are provided with this paper.

References

Geyer, R., Jambeck, J. R. & Law, K. L. Production, use, and fate of all plastics ever made. Sci. Adv. 3, e1700782 (2017).

Nicholson, S. R., Rorrer, N. A., Carpenter, A. C. & Beckham, G. T. Manufacturing energy and greenhouse gas emissions associated with plastics consumption. Joule 5, 673–686 (2021).

Stegmann, P., Daioglou, V., Londo, M., van Vuuren, D. P. & Junginger, M. Plastic futures and their CO₂ emissions. Nature 612, 272–276 (2022).

Isobe, A., Iwasaki, S., Uchida, K. & Tokai, T. Abundance of non-conservative microplastics in the upper ocean from 1957 to 2066. Nat. Commun. 10, 417 (2019).

Clark, R. A. & Shaver, M. P. Depolymerization within a circular plastics system. Chem. Rev. 124, 2617–2650 (2024).

Garcia, J. M. & Robertson, M. L. The future of plastics recycling. Science 358, 870–872 (2017).

Chin, M. T. & Diao, T. Industrial and laboratory technologies for the chemical recycling of plastic waste. ACS Catal. 14, 12437–12453 (2024).

Ben Amor, I., Klinkova, O., Baklouti, M., Elleuch, R. & Tawfiq, I. Mechanical recycling and its effects on the physical and mechanical properties of polyamides. Polymers 15, 4561 (2023).

Zheng, L., Wang, M., Li, Y., Xiong, Y. & Wu, C. Recycling and degradation of polyamides. Molecules 29, 1742 (2024).

Minor, A.-J., Goldhahn, R., Rihko-Struckmann, L. & Sundmacher, K. Chemical recycling processes of Nylon 6 to Caprolactam: Review and techno-economic assessment. Chem. Eng. J. 474, 145333 (2023).

Li, G., Ma, S. & Szostak, M. Amide bond activation: the power of resonance. Trends Chem. 2, 914–928 (2020).

Schroeder, L. R. & Cooper, S. L. Hydrogen bonding in polyamides. J. Appl. Phys. 47, 4310–4317 (1976).

Klun, U. & Kržan, A. Rapid microwave induced depolymerization of Polyamide-6. Polymer 41, 4361–4365 (2000).

Češarek, U., Pahovnik, D. & Žagar, E. Chemical recycling of aliphatic polyamides by microwave-assisted hydrolysis for efficient monomer recovery. ACS Sustain. Chem. Eng. 8, 16274–16282 (2020).

Yuan, X. et al. Degradation of Nylon 6 to produce a “pseudo” amino acid ionic liquid. Polym. Degrad. Stab. 109, 171–174 (2014).

Meng, L., Zhang, Y., Huang, Y., Shibata, M. & Yosomiya, R. Studies on the decomposition behavior of Nylon-66 in supercritical water. Polym. Degrad. Stab. 83, 389–393 (2004).

Wang, W., Meng, L. & Huang, Y. Hydrolytic degradation of monomer casting nylon in subcritical water. Polym. Degrad. Stab. 110, 312–317 (2014).

Iwaya, T., Sasaki, M. & Goto, M. Kinetic analysis for hydrothermal depolymerization of Nylon 6. Polym. Degrad. Stab. 91, 1989–1995 (2006).

Mukherjee, A. K. & Goel, D. K. Depolymerization of poly-ϵ-caprolactam catalyzed by sodium hydroxide. J. Appl. Polym. Sci. 22, 361–368 (1978).

Bonfield, J. H., Hecker, R. C., Snider, O. E. & Apostle, B. G. Regeneration of e-Caprolactam from Polyamides. US Patent US3182055A (1965).

Fuchs, H., Neubauer, G., Ritz, J. & Priester, C.-U. Recovery of Caprolactam from Polycaprolactam. US Patent US5359062A (1994).

Duch, M. W. & Allgeier, A. M. Deactivation of nitrile hydrogenation catalysts: new mechanistic insight from a nylon recycle process. Appl. Catal. A: Gen. 318, 190–198 (2007).

Coeck, R., De Bruyne, A., Borremans, T., Stuyck, W. & De Vos, D. E. Ammonolytic hydrogenation of secondary amides: an efficient method for the recycling of long-chain polyamides. ACS Sustain. Chem. Eng. 10, 3048–3056 (2022).

Stuyck, W. et al. A sustainable way of recycling polyamides: dissolution and ammonolysis of polyamides to diamines and diamides using ammonia and biosourced glycerol. Green Chem. 24, 6923–6930 (2022).

McKinney, R. J. Ammonolysis of Nylon. US Patent US5302756A (1994).

Kim, K. J., Dhevi, D. M., Lee, J. S., Cho, Y. D. & Choe, E. K. Mechanism of glycolysis of Nylon 6,6 and its model compound by ethylene glycol. Polym. Degrad. Stab. 91, 1545–1555 (2006).

Datta, J., Błażek, K., Włoch, M. & Bukowski, R. A new approach to chemical recycling of polyamide 6.6 and synthesis of polyurethanes with recovered intermediates. J. Polym. Environ. 26, 4415–4429 (2018).

Kamimura, A., Oishi, Y., Kaiso, K., Sugimoto, T. & Kashiwagi, K. Supercritical secondary alcohols as useful media to convert polyamide into monomeric lactams. ChemSusChem 1, 82–84 (2008).

Kamimura, A. et al. Direct conversion of polyamides to ω-Hydroxyalkanoic acid derivatives by using supercritical MeOH. Green Chem. 13, 2055–2061 (2011).

Kaweetirawatt, T. et al. Nylon 6 Depolymerization in supercritical alcohols studied by the QM/MC/FEP method. RSC Adv. 2, 8402–8409 (2012).

Kamimura, A. et al. Efficient conversion of polyamides to ω-hydroxyalkanoic acids: a new method for chemical recycling of waste plastics. ChemSusChem 7, 2473–2477 (2014).

Kamimura, A., Sugimoto, T. & Kaiso, K. Method of Depolymerizing Polyamides and Method of Manufacturing Polyamide Monomers. EUR Patent EP1801101A1 (2007).

Kumar, A. et al. Hydrogenative depolymerization of nylons. J. Am. Chem. Soc. 142, 14267–14275 (2020).

Tang, M. et al. Upcycling of polyamide wastes to tertiary amines using mo single atoms and Rh nanoparticles. Angew. Chem. Int. Ed. 64, e202416436 (2025).

Niu, Z. & Hu, Q. Ruthenium monatomic alloy catalyst and plastic hydrogenolysis method. CN Patent CN119869514A (2025).

Lin, B., Qiu, Z. & Chen, Z. Catalyst, Preparation method and application thereof, and catalytic hydrogenolysis method. CN Patent CN117000287A (2023).

Varghese, M. & Grinstaff, M. W. Beyond Nylon 6: Polyamides via Ring Opening Polymerization of Designer Lactam Monomers for Biomedical Applications. Chem. Soc. Rev. 51, 8258–8275 (2022).

Zhu, N. et al. Synthesis and characterization of star-branched Polyamide 6 via anionic ring-opening polymerization with N, N′, N″-trimesoyltricaprolactam as a multifunctional activator. Chin. Chem. Lett. 26, 1389–1392 (2015).

Goto, M., Sasaki, M. & Hirose, T. Reactions of polymers in supercritical fluids for chemical recycling of waste plastics. J. Mater. Sci. 41, 1509–1515 (2006).

Kamimura, A., Shiramatsu, Y. & Kawamoto, T. Depolymerization of Polyamide 6 in hydrophilic ionic liquids. Green Energy Environ. 4, 166–170 (2019).

Kamimura, A. & Yamamoto, S. An efficient method to depolymerize polyamide plastics: a new use of ionic liquids. Org. Lett. 9, 2533–2535 (2007).

Wursthorn, L. et al. Selective lanthanide-organic catalyzed depolymerization of nylon-6 to ϵ-caprolactam. Angew. Chem. Int. Ed. 62, e202212543 (2023).

Ye, L. et al. Catalyst metal-ligand design for rapid, selective, and solventless depolymerization of Nylon-6 plastics. Chem 10, 172–189 (2024).

Chen, X.-H., Wu, G., Chen, S.-C. & Wang, Y.-Z. Facile, high-efficiency, and low-cost depolymerization of PA6 to ϵ-Caprolactam enables closed-loop chemical recycling. Polymer 283, 126201 (2023).

Chen, H. et al. Closed-Loop Recycling of Nylon-6 to Caprolactam Catalyzed by a Green and Effective Phosphazene Base. J. Polym. Sci. 62, 5609–5617 (2024).

Deguchi, T., Xin, H.-L., Morimoto, H. & Ohshima, T. Direct catalytic alcoholysis of unactivated 8-aminoquinoline amides. ACS Catal. 7, 3157–3161 (2017).

Kita, Y., Nishii, Y., Higuchi, T. & Mashima, K. Zinc-catalyzed amide cleavage and esterification of β-Hydroxyethylamides. Angew. Chem. Int. Ed. 51, 5723–5726 (2012).

Chen, X. et al. Fe-catalyzed esterification of amides via C-N Bond Activation. RSC Adv. 8, 4571–4576 (2018).

Hans Reich’s Collection. Bordwell pKa Table. https://organicchemistrydata.org/hansreich/resources/pka/ (accessed 2024-10-09).

Gates, B. C. & Johanson, L. N. The dehydration of methanol and ethanol catalyzed by polystyrene sulfonate resins. J. Catal. 14, 69–76 (1969).

Teasdale, A. et al. A detailed study of sulfonate ester formation and solvolysis reaction rates and application toward establishing sulfonate ester control in pharmaceutical manufacturing processes. Org. Process Res. Dev. 14, 999–1007 (2010).

Milakovic, L. et al. Towards understanding and predicting the hydronium ion catalyzed dehydration of cyclic-primary, secondary and tertiary alcohols. J. Catal. 390, 237–243 (2020).

Bockisch, C., Lorance, E. D., Hartnett, H. E., Shock, E. L. & Gould, I. R. Kinetics and mechanisms of dehydration of secondary alcohols under hydrothermal conditions. ACS Earth Space Chem. 2, 821–832 (2018).

Spiccia, N. D., Border, E. C., Illesinghe, J., Jackson, W. R. & Robinson, A. J. Preparation of a Nylon-11 Precursor from Renewable Canola Oil. Synthesis 45, 1683–1688 (2013).

Ladkau, N. et al. Efficient production of the Nylon 12 Monomer ω-Aminododecanoic acid methyl ester from renewable Dodecanoic acid methyl ester with engineered Escherichia Coli. Metab. Eng. 36, 1–9 (2016).

Marchildon, K. Polyamides-still strong after seventy years. Macromol. React. Eng. 5, 22–54 (2011).

Karaj, E. et al. First-in-class dual mechanism ferroptosis-HDAC inhibitor hybrids. J. Med. Chem. 65, 14764–14791 (2022).

Wang, Z. et al. β-Lactone probes identify a papain-like peptide ligase in Arabidopsis Thaliana. Nat. Chem. Biol. 4, 557–563 (2008).

Singh, A., Patel, V. K. & Rajak, H. Appraisal of Pyrrole as connecting unit in hydroxamic acid based histone deacetylase inhibitors: synthesis, anticancer evaluation and molecular docking studies. J. Mol. Struct. 1240, 130590 (2021).

Moon, K.-S., Lee, E., Lim, Y.-B. & Lee, M. Bioactive molecular sheets from self-assembly of polymerizable peptides. Chem. Commun. 4001–4003 (2008).

Yu, Z. et al. Synthesis of renewable nylon monomers with poplar wood. Chem Catal. 2, 595–609 (2022).

Steliou, K., Szczygielska-Nowosielska, A., Favre, A., Poupart, M. A. & Hanessian, S. Reagents for organic synthesis: use of organostannyl oxides as catalytic neutral esterification agents in the preparation of macrolides. J. Am. Chem. Soc. 102, 7578–7579 (1980).

Ishihara, K., Ohara, S. & Yamamoto, H. 3,4,5-Trifluorobenzeneboronic acid as an extremely active amidation catalyst. J. Org. Chem. 61, 4196–4197 (1996).

Qin, Z. et al. Carboxylic acid reductases enable intramolecular lactamization reactions. Green Synth. Catal. 3, 294–297 (2022).

Mosca, S., Yu, Y., Gavette, J. V., Zhang, K.-D. & Rebek, J. Jr. A deep cavitand templates lactam formation in water. J. Am. Chem. Soc. 137, 14582–14585 (2015).

Žagar, E. et al. Quantitative determination of PA6 and/or PA66 content in polyamide-containing wastes. ACS Sustain. Chem. Eng. 8, 11818–11826 (2020).

Carothers, W. H. & Berchet, G. J. Studies on polymerization and ring formation. VIII. Amides from ε-Aminocaproic acid. J. Am. Chem. Soc. 52, 5289–5291 (1930).

Carraher, C. E. Jr. Synthesis of Caprolactam and Nylon 6. J. Chem. Educ. 55, 51–52 (1978).

Wernik, M., Poechlauer, P., Schmoelzer, C., Dallinger, D. & Kappe, C. O. Design and optimization of a continuous stirred tank reactor cascade for membrane-based diazomethane production: synthesis of α-chloroketones. Org. Process Res. Dev. 23, 1359–1368 (2019).

Yang, W. et al. Easily recoverable and reusable p-toluenesulfonic acid for faster hydrolysis of waste polyethylene terephthalate. Green Chem. 24, 1362–1372 (2022).

Acknowledgements

Financial support from the National Natural Science Foundation of China (22271060, T. T.), School of Chemistry and Chemical Engineering at Ningxia University, and the Department of Chemistry at Fudan University is gratefully acknowledged.

Author information

Authors and Affiliations

Contributions

J.Y. performed the experiments, analyzed the data, and wrote the original draft. Y.W. and Y.F. performed some experiments. B.X. performed the theoretical calculations, analyzed the data, and revised the manuscript. T.T. designed the project, supervised J.Y. in conducting this research, and revised the manuscript. All authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Qingheng Lai, Carlos Marquez and Gang Wu for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Yang, J., Wang, Y., Fan, Y. et al. Sustainable recycling of polyamides via C–N bond cleavage facilitated by methyl tosylate under mild conditions. Nat Commun 16, 8884 (2025). https://doi.org/10.1038/s41467-025-64197-1

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-025-64197-1