Abstract

This study focuses on optimizing the design of high-entropy alloy coatings to enhance corrosion resistance in lead-bismuth eutectic environments. Using machine learning methods, including artificial neural networks (ANN), random forest (RF), eXtreme gradient boosting (XGBoost), and support vector machine (SVM), the research predicts the corrosion and mechanical properties of AlCrFeMoTi high-entropy alloy coatings. ANN showed the best comprehensive predictive ability. The study validates the use of machine learning (ML) for optimizing high-entropy alloy (HEA) coating design, offering a novel approach to improving material performance in high-temperature liquid metal environments. This work provides a theoretical foundation for developing corrosion-resistant coatings for advanced nuclear reactors.

Similar content being viewed by others

Introduction

Lead-based reactors are considered as strong candidates for the fourth generation of nuclear reactors because of their excellent temperature characteristics, neutron absorption characteristics and high power density1,2,3. However, structural materials in the lead-bismuth eutectic (LBE) environment are subject to material compatibility challenges such as corrosion and embrittlement1,2,3. To ensure the long-term operational safety and structural integrity of power plant equipment, it is essential to implement effective material enhancement measures. These include developing novel corrosion-resistant structural materials4,5,6,7,8 and advanced protective coatings9,10, which are crucial for improving both corrosion resistance and mechanical strength. Materials for extreme conditions, such as high temperatures and corrosive environments, are vital for advanced energy systems. Surface engineering techniques like thermal spraying have shown strong potential in enhancing oxidation and erosion-corrosion resistance11,12 Meanwhile, combining machine learning with advanced manufacturing offers new possibilities for efficient and sustainable coating design13.

Research has shown that various coating materials can significantly improve the corrosion resistance of structural materials during LBE corrosion testing14,15,16,17, but these coatings still exhibit many shortcomings, hindering their widespread application. High-entropy alloy coatings have excellent corrosion resistance because the introduction of specific metallic elements contributes to the formation of passivation film on the coating surface18,19,20. Moreover, the fabrication techniques employed for high-entropy alloy coatings generally exhibit rapid cooling characteristics21,22 This rapid cooling process promotes extensive nucleation during the alloy solidification, resulting in a refined microstructure. This refinement not only contributes to the reduction of impurity concentrations and compositional segregation at grain boundaries but also effectively decreases the likelihood of galvanic cell effects, further enhancing the corrosion resistance of high-entropy alloy coatings23,24. As a result, many researchers are investigating novel coating materials, particularly high-entropy alloy coatings to further improve the corrosion resistance in LBE environments.

In recent years, in order to adapt to the LBE environment, the research of high entropy alloy coating is gradually increasing25,26,27,28,29,30. Yang et al.15,16 successfully deposited amorphous AlCrFeMoTi high-entropy alloy (HEA) coatings with nearly equimolar ratios on powder metallurgy substrates by magnetron sputtering. After 1000 h corrosion in liquid static LBE at 650 °C, the oxidation corrosion rate of this coating is an order of magnitude lower than that of ferritic/martensitic (F/M) steel, showing excellent resistance to LBE corrosion and excellent resistance to Au-ion irradiation, which brings great potential for LFR applications. Yang et al.17 investigated the effects of Si addition on the microstructure, mechanical properties and LBE corrosion behavior of AlCrFeMoTiSix HEA coatings. It was found that the addition of Si significantly enhanced the LBE corrosion resistance of the coatings, which might be attributed to the formation of more continuous protective Cr2O3 and Al2O3 layers. Deng et al.19 designed and prepared TiNbZrMoV HEA coating by magnetron sputtering technology, and the corrosion behavior of the coatings was investigated at 650 °C in a saturated oxygen LBE environment. The results showed that the coating maintained good integrity and significantly reduced the LBE corrosion of the F/M steel. Zhang et al.18 designed and optimized FeCrAlWx HEA coating, and the experiments found that the FeCrAlW0.75 HEA coatings exhibited the best resistance to LBE corrosion after experiencing LBE corrosion for different durations. The addition of W in the coating improves the bonding strength, reduces the adsorption energy of Pb and Bi on the surface, effectively limits the mutual diffusion of the coating elements with Pb and Bi, and inhibits the dissolution corrosion. Yin et al.31 synthesized (CrAlTiNbV) Nx on F/M steel by non-equilibrium magnetron sputtering. After corrosion at 550 °C and saturated oxygen LBE for 1200 h, it showed excellent corrosion resistance. It was found that high-density grain boundaries with fine grains were more easily formed when high bias pressure was applied, which increased the diffusion paths of Pb and Bi and achieved excellent LBE corrosion resistance.

Researchers developing novel materials typically employ experimental testing along with continuous optimization of material compositions and processes15,17,19,31,32,33,34. However, this approach becomes computationally expensive when dealing with extensive combinatorial spaces and complex nonlinear problems in establishing material process-property relationships. With development of data-driven algorithms, it offers a novel modeling approach to analyze the relationships among composition, structure and performance of materials. Machine learning (ML) -based methods in materials research show considerable application value, particularly for the development of corrosion-resistant materials. ML optimization techniques based on small sample data have demonstrated significant advantages in improving material performance. Xu et al.35 integrated the Efficient Global Optimization (EGO) method with Bayesian optimization theory to construct a ML framework featuring feedback adjustment capabilities, thereby achieving rapid optimization of material performance. This adaptive design method has also achieved important results in other materials fields. Li et al.36 utilized data from 75 different 7-series Al alloys to develop a novel Al alloy with an ultimate tensile strength of 952 MPa through adaptive design ML, significantly enhancing material performance. Additionally, Zhang et al.37 created a bi-objective adaptive design ML model using data from 69 Cu alloys, optimizing a high-performance Cu alloy with an ultimate tensile strength of 858 MPa and a LACS conductivity of 47.6%, thereby demonstrating the effectiveness of ML in multi-objective performance optimization.

In this work, four ML algorithms (ANN, RF, XGBoost and SVM) are used to predict the corrosion and mechanical properties of the high-entropy alloy coating by magnetron sputtering under LBE environment. The model demonstrating the best overall predictive performance was selected as the surrogate model to optimize the magnetron sputtering process parameters. The optimized magnetron sputtering process parameters obtained through this approach achieved synergistic enhancement of both corrosion resistance and mechanical strength, providing critical technical support for ensuring long-term structural integrity of fourth-generation advanced nuclear reactor materials. In contrast to most existing ML-based materials studies that primarily target conventional mechanical or thermal properties, the present work focuses on a more complex corrosion-mechanical performance optimization problem relevant to lead-bismuth eutectic systems. The integration of a neural network predictor with a multi-objective optimization framework enables a data-driven design route that accounts for the coupled influence of composition, process parameters, and environmental conditions, offering a scalable strategy for coating design under extreme service environments.

Results

The optimal surrogate modeling framework was determined through comparative analysis of prediction performance across different machine learning models. To mitigate the influence of random errors during model training, each algorithm underwent 20 repeated training iterations. Subsequently, process parameter optimization was conducted using the surrogate model coupled with MOPSO. Experimental validation confirmed significant improvements in both corrosion resistance and fundamental mechanical properties of the fabricated coating.

Performance of different machine learning models

As shown in Fig. 1, the results of repeated experiments of four ML algorithms (ANN, RF, XGBoost and SVM) are analyzed in the form of boxplots. The training and testing samples are randomly divided for each repeated experiment, and the model parameters are randomly initialized to mitigate the effects of variability inherent in a single experiment. Table 1 details the average and standard deviation of prediction errors of each model for corrosion layer thickness, coating hardness and elastic modulus.

a Corrosion rate, b Hardness, and c Elastic modulus. Blue indicates the training set and red indicates the test set. The box spans the interquartile range (25–75%), with whiskers representing the minimum and maximum values. The horizontal line within each box shows the median, and the dot indicates the mean.

Combined with Fig. 1 and Table 1, it is evident that among the four ML models adopted in this work, ANN model shows the best comprehensive prediction ability. The ANN model exhibited the highest prediction accuracy for corrosion layer thickness. Its performance in predicting hardness and elastic modulus was marginally lower than that of XGBoost and SVM, respectively, with deviations remaining below 5%. In contrast, the other models failed to exhibit satisfactory performance in predicting coating properties. RF model shows significant variability across the three performance metrics and also exhibited lower average accuracy. The XGBoost model shows the best performance in hardness prediction, but it is not effective in predictions related to oxide layer thickness and elastic modulus. Similarly, the SVM model has a good performance on the prediction of elastic modulus, but the prediction of the other two properties is not ideal. Overall, ANN model achieves a good balance in the prediction of the three material properties. Although the current study demonstrates that the ANN model yields robust predictions under limited data conditions, we acknowledge that the dataset comprising 44 samples may not fully capture the complexity of the design space. To partially mitigate this issue, 20 repeated training iterations with random initialization and cross-validation were employed to ensure the robustness of model performance. Nevertheless, further expansion of the dataset, either through additional experimental trials or mining of published results, is necessary to enhance the generalizability of the proposed models. Future research will focus on collecting more diverse HEA coating data to facilitate model retraining, validation, and potential incorporation of uncertainty quantification or sensitivity analysis with respect to dataset size.

In order to facilitate a more intuitive comparison of the predictive performance among the models, it presents a visual comparison using the prediction results of the models that are situated at the median performance level from the repeated trials. Figure 2 shows the prediction results of ANN, RF, XGBoost and SVM models in oxide layer thickness, material hardness and elastic modulus, respectively. From the figure, RF model gives the same prediction results for multiple samples, which is mainly attributed to insufficient sample size leading to inadequate differentiation among the various decision trees in RF algorithm. Consequently, the model produces the same predictive judgment for certain cases across oxide layer thickness, material hardness, and elastic modulus. In contrast, the prediction results from the ANN, XGBoost, and SVM models exhibit a more uniform distribution, with no significant bias towards overly high or low predictions. The R² values of the fitted prediction lines further indicate a strong consistency between the predictions of ANN model and the experimental results.

a Corrosion rate, b hardness, c elastic modulus. The blue circles represent the results of the ANN model, the purple inverted triangles represent the RF model results, the red diamonds correspond to the XGBoost model, and the orange triangles denote the SVM model results. The dashed lines in the corresponding colors indicate the regression fitting lines.

In addition to model performance comparison, the relative importance of input features in these machine learning models was analyzed using SHAP (SHapley Additive exPlanations) values. As shown in Fig. 3, both process parameters and elemental compositions play critical roles in determining the predicted coating properties, though their relative contributions vary across different algorithms. In the ANN model (Fig. 3a), the deposition temperature (Tde) and oxygen concentration (wO₂) exhibit the strongest positive SHAP values for corrosion layer thickness, followed by Al and Mo contents, reflecting their combined effect on forming dense and stable protective layers. For hardness, the substrate bias voltage (Usu) and Cr content dominate, while the elastic modulus is primarily influenced by Al and Ti due to their contribution to stiff intermetallic phases. Compared with ANN, the RF (Fig. 3b) and XGBoost (Fig. 3c) models show a more balanced importance distribution, suggesting their greater capacity to capture multivariate nonlinear interactions, whereas the SVM model (Fig. 3d) displays weaker differentiation among features, indicating limited interpretability. Despite these model-specific variations, all four methods consistently identify Tde, wO₂, and key alloying elements (Al, Mo, and Cr) as the most influential parameters, highlighting the robustness and physical consistency of these predictors in governing both corrosion resistance and mechanical performance.

Optimization of magnetron sputtering process parameters

According to the test results, ANN model is selected as a proxy prediction model for the corrosion and mechanical properties of the high-entropy alloy coating under LBE environment, so as to be used in the following optimization design based on MOPSO magnetron sputtering process. During the design process, factors such as the operational conditions of the lead-bismuth reactor and the performance characteristics of the experimental device are taken into account. The coating composition is determined as AlCrFeMoTi in a ratio of 1:1:1:1:1, with the LBE environment set at a temperature of 450 °C and CO = 10−7 ~ 10−8wt.%. Therefore, the variables that need to be optimized in the ANN model are only the relevant process parameters of magnetron sputtering, which are sputtering temperature (Tde), sputtering power (Psp) and substrate bias voltage (Usu). With reference to the collected data distribution range and previous magnetron sputtering process experience, the optimized search ranges are determined, as detailed in Table 2. Among the Pareto-optimal candidates, the final optimal solution was selected by prioritizing minimal predicted corrosion layer thickness, while ensuring that the predicted hardness and elastic modulus were both within the top 20% of all non-dominated solutions. This selection reflects a balance between corrosion resistance and mechanical performance, in line with the design objectives. In addition, process feasibility was considered by rounding the selected parameters to values that can be easily implemented and controlled in practical sputtering operations.

Based on the single objective particle swarm model, the MOPSO model is further used to optimize the magnetron sputtering process. The maximum and minimum values are shown in Table 2. In the process of multi-objective optimization, a Pareto front method is used to balance the coordination problem between maximizing and minimizing optimization objectives. A total of 100 optimization iterations are performed with 100 particles designed in a single iteration. The final optimized process parameters and the coating properties predicted under the corresponding parameters are shown in Table 2. Considering the practical constraints and operability of the experimental equipment, the optimal parameters derived from the MOPSO algorithm were slightly adjusted to values that are more convenient for experimental control. These adjustments, involving minimal rounding, ensure compatibility with the device settings while maintaining close alignment with the predicted optimal performance. The applied values are presented in Table 2 as ‘Actual process parameters applied’.

Compared with traditional experimental optimization, the ML-based framework significantly improves design efficiency. In our experimental setup, preparing a single HEA coating with a new composition typically requires 3–5 h, including target calibration, deposition, and post-process analysis. Considering the high-dimensional design space, achieving even coarse optimization using trial-and-error methods could require 20–30 such iterations, amounting to over 80–150 h of laboratory time. In contrast, the trained ANN model completes prediction and optimization iterations within seconds on a standard workstation. This reduction from several days of experimental work to a few minutes of computation highlights the practical advantages of ML-driven coating design, especially when coupled with multi-objective optimization strategies like MOPSO.

Verification of coating performance

The elemental composition of the coating is measured by five separate EDS area scan analyses (about 5 μm × 5 μm). The proportion of elements Al, Cr, Fe, Mo, Ti and N is determined, as shown in Fig. 4. The atomic ratios for coating are Fe = 19.58 at.%, Al = 21.02 at.%, Mo = 18.76 at.%, Ti = 18.81 at.%, Cr = 21.39 at.%, N = 1.50 at.%. The coating result shows that the coating composition is approximated to an equimolar ratio.

The surface morphology of the coating is observed by scanning electron microscopy (SEM), and the results are shown in Fig. 5. The coating exhibits a dense, smooth, and uniform surface structure, with no cracks or pores found, indicating that the coatings have a high deposition quality, and fine scratches are observed, which may have been introduced during the polishing process of the substrate (Fig. 5a). The cross-sectional SEM images of the AlCrFeMoTi-1 coatings in the as-deposited state are shown in Fig. 5b, the coating structure is dense and uniform, with a thickness of 1 μm. No cracks were observed between the substrate and the substrate. These results show that the coating has high deposition quality and good interfacial bonding strength, which is conducive to improving the corrosion resistance of LBE.

As shown in Fig. 6, to experimentally validate the corrosion resistance of the ML-optimized coating under realistic service conditions, long-term immersion tests were conducted in both saturated-oxygen and oxygen-controlled lead-bismuth eutectic (LBE) environments at 450 °C for 500 h, 1000 h, and 2000 h. The AlCrFeMoTi-1 coating, synthesized using the ML-predicted parameters, was compared with AlCrFeMoTi-2, a compositionally adjusted variant used to assess the influence of elemental ratios. The optimized AlCrFeMoTi-1 coating remained dense and crack-free in the oxygen-controlled LBE throughout the entire testing period and exhibited only minor degradation after 2000 h in the more aggressive saturated-oxygen condition. In contrast, AlCrFeMoTi-2 showed surface integrity up to 1000 h but developed larger cracks and partial delamination after 2000 h in the saturated-oxygen LBE.

Nanoindentation and scratch tests are performed using a nanoindentation instrument to evaluate the hardness and adhesion strength of the coating. The load-displacement (P-h) curves of the coatings and substrates are shown in Fig. 7. Ten indentation tests are performed on each sample, with a maximum indentation depth of 180 nm and no more than 1/5 of the coating thickness in order to eliminate the interference of the substrate. The indentation location is concentrated in the center of the sample to eliminate the influence of edge effects. Figure 7a demonstrates the typical load-displacement (P-h) curve between the coatings and the substrates. The indentation tests for all samples are loaded and unloaded at a rate of 20 mN/min. Oliver and Pharr methods are used to analyze the values of folded elastic modulus (E) and nano-hardness (H)38. The indentation curve of the coating is shown in Fig. 7. The hardness of the coating reaches 9.5 GPa, which is 2.2 times the hardness of the substrate (3.93 GPa), and its elastic modulus is 184.0 GPa. The hardness values of the two coatings are shown in Fig. 7b. The AlCrFeMoTi-2 coating has hardness values of 8.3 GPa, with elastic moduli of 173.9 GPa.

a Indentation displacement load curve. b Statistical results of hardness and modulus of the two coatings. In (a), the black symbols represent the results obtained from machine learning optimization, while the red symbols represent the results of the reference coating. In (b), the red bars represent the machine learning optimized results, and the yellow bars represent the results of the reference coating.

In addition, as shown in Fig. 7, the hardness and modulus of the high entropy alloy coating are higher than those of the substrate, which is due to the significant solid solution strengthening effect produced by adding a large number of atoms of different sizes39,40. Due to the relatively high content of Ti element with the largest atomic radius, the modulus and hardness of the coating are significantly improved. This is because an increase in Ti content in the coating will lead to an increase in the number of heterogeneous nuclei in the grain boundaries, resulting in grain compression and ultimately leading to grain refinement41. Meanwhile, as a metal element in the hard phase, the increase of Mo content also helps to enhance the elastic modulus and hardness. An increase in the elastic modulus usually implies a decrease in the atomic distances42,43. The elemental composition in the coating is similar, resulting in a reduction in its free volume and atomic arrangement, making it more compact and leading to a higher elastic modulus. In regions with smaller free volumes, the initiation of shear bands becomes more difficult, resulting in higher stress levels required to form continuous shear bands in amorphous AlCrFeMoTi coatings42,44. In addition, the absence of structural defects such as dislocations that can proliferate and migrate in amorphous coatings and the higher kinetics in HEA coatings impede the diffusion of atoms to accommodate the applied strain, which leads to a delay in the nucleation of shear bands45, resulting in higher nano-hardness.

Many researchers have reported that the ratios of H/E and H3/E2 are closely related to wear resistance, and can be used to evaluate the elastic failure strain and plastic deformation resistance of coating materials respectively46,47. Leyland et al.48 pointed out that a higher H/E ratio usually indicates better wear resistance, and a higher H3/E2 ratio means better plastic deformation resistance. According to calculations, H/E = 0.051, H3/E2 = 0.025, This indicates that coatings prepared based on equimolar element ratios can significantly improve the elastic-plastic properties of coatings, and AlCrFeMoTi coatings exhibit better mechanical properties49.

To provide further context, we compared these values with those reported in related studies. In the work by Yang et al.50, the AlCrFeMoTi HEA coating exhibited H/E and H³/E² values of 0.047 and 0.018, respectively, both lower than those observed in our study. This indicates improved elastic strain resistance and plastic deformation tolerance in our ML-optimized coatings. Moreover, Deng et al.51 reported a TiNbZrMoV HEA coating with H/E and H³/E² values of 0.09 and 0.11, respectively, reflecting excellent mechanical robustness. However, their work did not evaluate the coating’s corrosion resistance in LBE environments. In contrast, our study demonstrates a balanced optimization between mechanical performance and corrosion resistance, which is essential for coating applications in high-temperature lead-bismuth systems. The H/E and H³/E² values in our work thus reflect not only favorable mechanical characteristics but also compatibility with long-term LBE exposure.

The bonding strength between the coating and the substrate is a key parameter for its engineering service, and the interfacial adhesion strength of the coating is investigated using scratch tests, as shown in Fig. 8. High bond strength is beneficial for ensuring the structural integrity of the coating under LBE corrosion conditions. The test is a relative characterization of the adhesion strength because the results are highly dependent on the test parameters. The scratch load is increased from 0 to 30 N and the loading rate is 10 N/min. In general, the scratch tests can provide four critical loads: CL1 (which forms the first crack), CL2 (the substrate at the boundary of the scratch trace is exposed first), CL3 (the substrate at the center of the scratch trace is exposed first), and CL4 (the substrate is completely exposed) to determine adhesion. In this work, CL2 was used to characterize the bonding strength of the coating. Based on the friction curve, acoustic signal curve, and optical morphology image shown in Fig. 8, the CL2 of the coating is determined to be 11.11 N. Because of the thinness of the prepared coatings, which were only about 1 μm, the coating eventually flaked off. The coating have relatively flat scratches although some minor fragments and cracks are observed along the edges of the scratches, the CL2 is high enough, indicates good adhesion of the coating to the substrate52,53. The AlCrFeMoTi-1 coating showed minor fragmentation and cracking along the scratch edge, but the scratch profile remained relatively flat, and the highest CL2 value indicated great adhesion to the substrate

In summary, this coating has a dense structure and uniform thickness, as well as high hardness, modulus, and adhesive strength, which also verifies the accuracy of the ML model prediction under the targeted lead-bismuth eutectic (LBE) corrosion environment.

Discussion

In this work, the preparation and optimization process of high entropy alloy coating is discussed. The AlCrFeMoTi high entropy alloy coating is successfully prepared by magnetron sputtering method, and the composition and preparation process of the coatings are optimized by ML model. Based on the coating corrosion data of the researchers, the corrosion behavior of the high-entropy alloy coating is predicted and analyzed by using ML algorithms. The artificial neural network (ANN) model demonstrates the best overall performance among the four ML models (ANN, RF, XGBoost, SVM). It not only achieves the highest accuracy in predicting the corrosion layer thickness, but also approaches optimal levels in predicting hardness and elastic modulus, exhibiting a good balance. By employing the multi-objective particle swarm optimization (MOPSO) algorithm in conjunction with the ANN model, the process parameters for the magnetron sputtering of high-entropy alloy coatings (AlCrFeMoTi) are successfully optimized. A set of Pareto-optimal solutions is ultimately obtained to ensure the coatings possess both excellent corrosion resistance and mechanical performance.

Experimental validation of the optimized process parameters indicated that the predicted coating performance by the ML model is highly consistent with the actual experimental data, demonstrating the effectiveness of the proposed data-driven approach in predicting high-entropy alloy coating performance and optimizing processes specifically for application in LBE environments.

Future research could further explore the prediction of high-entropy alloy coating performance with various combinations of elements and under complex environments. Additionally, attempts could be made to integrate physical information constraints into the data-driven model to further improve prediction accuracy and reliability.

Methods

High entropy alloy coating data

In this work, from the published literature15,17,19,31,54,55,56,57,58, a total of 44 sets of samples from 29 kinds of high entropy alloy coating data based on F/M steel have been collected. The data include coating element composition, substrate temperature during magnetron sputtering (Tde), sputtering power (Psp) and bias pressure (Usu). For the corrosion properties of the material under LBE, the corrosion layer thickness (tc) of the coating under liquid lead-bismuth at different temperatures (T) and oxygen concentration (wO2) are also taken into account. Besides, hardness (HB) and elastic modulus (E) at room temperature are selected as the basic mechanical properties. In order to reduce the effect of processing on the final properties, the training data in the literature are derived from the prepared coatings with good surface morphology.

According to the above data, there are a total of 19 input features including 13 elemental composition, 3 preparation process factors (substrate bias voltage, sputtering temperature and sputtering power), and 3 corrosion environmental factors (corrosion time (t), oxygen concentration and corrosion temperature). 3 properties of corrosion layer thickness, material hardness and elastic modulus are taken as output features. Figures 9–11 present the distribution of features include elemental composition, preparation process, corrosion environment, mechanical properties and corrosion layer thickness, respectively.

As illustrated in Fig. 9, Zr, Si, Ni, N and other elements are less abundant in most coating components. Based on the solubility of elements, high temperature stability of oxides and nitride and their LBE corrosion resistance, Al, Cr, Fe, Mo and Ti are selected as the main elements of the high entropy alloy coating. Although the amount of F/M steel composition optimization data is relatively small compared with the above, the figure indicates that the distribution of relevant element components and preparation process parameters is relatively balanced within the concerned interval, and it can still provide relatively sufficient training data for the subsequent process optimization.

All input and output features were standardized using the z-score normalization method to ensure that variables with different magnitudes and units were comparable during model training as shown in Eq. (1).

Where σ and μ represent the mean and standard deviation of the corresponding variable, respectively. This standardization effectively prevents features with larger numerical ranges from dominating the learning process and facilitates stable model convergence.

To maintain data consistency across different literature sources, only high-entropy alloy coatings prepared by magnetron sputtering under clearly reported testing conditions were included. Corrosion-related parameters were extracted from studies employing liquid lead–bismuth eutectic (LBE) corrosion tests with controlled oxygen concentrations and comparable exposure durations. Entries with incomplete, inconsistent, or incompatible experimental data were excluded to ensure physical comparability and statistical uniformity among all samples used for model development.

Pearson correlation coefficient analysis is performed for all input and output features, and the correlation coefficient matrix results are shown in Fig. 12. As can be seen, there is no obvious linear correlation between the features of most elements and the preparation process. The high linear correlation between a few element features is mainly due to the lack of sampling points due to the small number of samples. However, the relevant elements are not among the coating elemental compositions of interest in this work, and the preliminary training test shows that they do not affect the prediction effect on the corrosion and mechanical properties of the coating. In addition, it can be seen from Fig. 12 that the linear correlation among the features of elemental composition, preparation process and corrosion environment is low. This highly nonlinear relationship also contributes to the difficulty of predicting the corrosion performance of coatings under different elemental compositions and preparation process conditions by empirical methods. Therefore, it is necessary to use ML method for performance prediction.

It should be noted that the observed low Pearson correlation coefficients do not indicate a complete lack of relationship between variables, but rather suggest the absence of strong linear trends. In materials systems, particularly for multi-element coatings, the interactions between elemental composition, processing parameters, and final properties are often governed by nonlinear physical mechanisms such as atomic-scale diffusion, microstructural evolution, and phase stability. These complex dependencies cannot be captured through simple correlation analysis, but can be effectively learned by machine learning models. Therefore, the use of ML is not only justified, but also particularly advantageous in this context.

Test procedure

In this work, a VTC-5RF five-target RF magnetron sputtering instrument was used to prepare the high-entropy alloy coating, as shown in Fig. 13. The instrument is capable of sputtering with five target heads at the same time, allowing the installation of five targets of different materials, and setting parameters such as sputtering time and power for each target head individually to grow films of different compositions. Depending on the power source used (DC or RF), metallic or non-metallic materials can be deposited.

In the process of sample preparation, ferritic/martensitic (F/M) plates were first cut into small flat samples with dimensions of 5 mm × 10 mm × 1 mm, with the elemental composition shown in Table 3. Each sample was drilled with a 2 mm diameter hole. The surface of the samples underwent polishing treatment at room temperature using silicon carbide sandpaper of varying grits (up to 3000#), followed by polishing with a diamond abrasive of at least 1.5 μm to achieve a mirror finish. Subsequently, high-entropy alloy (HEA) coatings were deposited on one side of the samples using magnetron sputtering technology. Prior to sputtering, Al, Cr, Mo, Ti and Fe single-element targets with 99.999% purity were used for sputtering treatment in Ar or Ar+N2 atmosphere to achieve mirror treatment of the substrate. The F/M alloy substrates were then cleaned with acetone and ethanol, followed by a 10-minute substrate cleaning treatment at 500 V Ar+ ions to remove the oxide layer on the surface of the target. The samples were placed on a water-cooled copper sample rack that rotated at 30 rpm to ensure uniform coating thickness, with all metal targets kept at a distance of 10 cm from the rack.

Based on the solubility of elements, high temperature stability of oxides and nitride and LBE corrosion resistance, Al, Cr, Fe, Mo and Ti were selected as the main elements of the high entropy alloy coating. According to the ratio of Al, Cr, Fe, Mo and Ti molar ratio 1:1:1:1:1, the high entropy alloy magnetron sputtering process with the best corrosion and mechanical properties under the element ratio was calculated with the best model, and the coating fabrication was carried out under this process to obtain AlCrFeMoTi-1 coating.

The properties of coatings were characterized by TEM and SEM. The mechanical properties and bonding strength of the original coatings were tested by Anton Paar UNHT, and the scratch morphology was photographed by optical microscope.

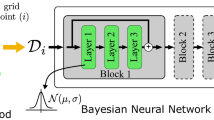

Machine learning model

Four ML algorithms (ANN, RF, XGBoost and SVM) are selected and trained to achieve accurate prediction of corrosion layer thickness, hardness, elastic modulus and other mechanical properties of high entropy alloy coating in liquid lead-bismuth environment under different element composition preparation process conditions. Then the optimization design of high entropy alloy magnetron sputtering process with specific elements is realized by combining with multi-objective particle swarm optimization algorithm.

Artificial neural networks (ANN) are inspired by biological neural networks and consist of interconnected layers of nodes or neurons. They are particularly adept at capturing complex, nonlinear relationships within data, making them a popular choice for multiple types of tasks. Their ability to learn from large datasets and adjust weights through backpropagation enables them to achieve high performance in various applications. Random forest (RF) is an ensemble learning method that constructs multiple decision trees during training. By aggregating the results of numerous trees, RF enhances predictive accuracy and robustness while also mitigating the risk of overfitting that can occur with individual decision trees. Its ability to handle high-dimensional data and missing values further strengthens its applicability in diverse scenarios. Extreme Gradient Boosting (XGBoost) is an optimized scalable implementation of the gradient boosting framework. It has gained popularity due to its efficiency and performance, particularly in scenarios with large datasets and numerous features. XGBoost employs a combination of model regularization and parallel processing, making it highly effective for tasks requiring high precision. Support vector machines (SVM) are supervised learning models that analyze data for classification and regression analysis. It works by finding the hyperplane that best separates different classes in the feature space, maximizing the margin between classes. Its effectiveness in high-dimensional spaces and its ability to incorporate kernel functions allow SVM to model complex relationships in data, making it suitable for a range of applications.

Due to the highly nonlinear correlation between element composition, preparation process, corrosion environment and coating properties, in order to achieve efficient optimization design of magnetron sputtering preparation process of high-entropy alloy coatings, ML algorithm was proposed to predict coating corrosion properties and mechanical properties based on alloy composition, preparation process and corrosion environment. Because the proposed model needs to take into account both the corrosion and mechanical properties of the coating, the difference between the two makes it difficult to introduce appropriate physical information constraints, so only the data-driven method is used to predict the coating properties. The ML models used in this work are ANN, RF, XGBoost and SVM. The four ML models shown in Table 4 are finally determined by the same grid search and 10-fold cross-validation methods. The ANN model is implemented by Pytorch framework59, while the other three models are implemented by Sklearn framework (https://scikit-learn.org/). The relevant model parameter names in Table 4 take the names of these two algorithm frameworks as examples.

To further quantify feature influence and improve model interpretability, a SHAP-based feature attribution analysis was implemented. The SHAP method computes additive contribution values for each input variable by evaluating the difference in model output when a feature is included versus omitted, averaged over all possible feature combinations. Mathematically, the SHAP value φi represents the marginal contribution of feature xi to the model output f(x) across the training distribution. In this study, SHAP values were calculated from the trained machine learning model, and the mean absolute SHAP values were used to rank feature importance for each predicted property. This approach provides an interpretable measure of how composition, process, and environmental factors collectively affect the corrosion and mechanical performance of the high-entropy alloy coatings.

Optimization algorithm

Particle swarm optimization (PSO) is a computational method widely used for solving optimization problems. Single-objective PSO focuses on finding the optimal solution by iteratively improving a set of potential solutions, known as particles, based on their own experience and that of their neighbors. Each particle adjusts its position in the search space by balancing exploration and exploitation, ultimately converging towards a solution that minimizes or maximizes a defined objective function.

In contrast, multi-objective particle swarm optimization (MOPSO) extends the principles of PSO to handle problems involving multiple conflicting objectives. MOPSO aims to find a set of Pareto-optimal solutions, where no single objective can be improved without sacrificing another. By maintaining a diverse population of solutions and applying mechanisms to guide their movement towards the Pareto front, MOPSO enables a more comprehensive exploration of the trade-offs between different objectives.

It is necessary to pay attention to the corrosion rate and mechanical properties of high-entropy alloy coatings when optimizing the process parameters of magnetron sputtering, so that the coatings have both good corrosion resistance and mechanical properties. However, relevant studies60,61,62 have shown that there is an extensive corrosion-strength balance between the corrosion and mechanical properties of materials. This relationship results in two conflicting optimization objectives which are corrosion performance and mechanical performance, rendering the optimization task a multi-objective problem. On the basis of single objective PSO, MOPSO algorithm and Pareto frontier method are used to optimize the sputtering process parameters with respect to the indicators of corrosion rate and mechanical performance. The specific optimization model and optimization process are carried out in refs. 63,64,65, and the corresponding optimization functions are shown in Eqs. (2) and (3).

Performance evaluation

The concerned prediction objects are the corrosion layer thickness and its mechanical properties (hardness and elastic modulus) of the high-entropy alloy coating in liquid lead-bismuth environment. In order to quantitatively evaluate the prediction effect of the ML model, the root-mean-square error RMSE is adopted as the performance metric, which is specifically defined as follows:

Where \({y}_{pre}\) is the thickness of the coating oxide layer, hardness or elastic modulus predicted by the model; \({{\rm{y}}}_{exp}\) is the thickness of the coating oxide layer, hardness or elastic modulus obtained from the experiment. Smaller RMSE values indicate superior model performance.

Data availability

The relevant data previously unpublished and discussed herein are available from the corresponding authors.

References

Alemberti, A., Smirnov, V., Smith, C. F. & Takahashi, M. Overview of lead-cooled fast reactor activities. Prog. Nucl. Energy 77, 300–307 (2014).

Gong, X., Short, M. P., Auger, T., Charalampopoulou, E. & Lambrinou, K. Environmental degradation of structural materials in liquid lead- and lead-bismuth eutectic-cooled reactors. Prog. Mater. Sci. 126, 100920–100936 (2022).

Zhang, J. A review of steel corrosion by liquid lead and lead–bismuth. Corros. Sci. 51, 1207–1227 (2009).

Concetta F. Handbook on Lead-bismuth Eutectic Alloy and Lead Properties, Materials Compatibility, Thermal-hydraulics and Technologies (NEA). 114–119 (OECD Publishing, 2015).

Del Giacco, M., Weisenburger, A. & Mueller, G. Fretting corrosion in liquid lead of structural steels for lead-cooled nuclear systems: Preliminary study of the influence of temperature and time. J. Nucl. Mater. 423, 79–86 (2012).

Del Giacco, M., Weisenburger, A. & Mueller, G. Fretting corrosion of steels for lead alloys cooled ADS. J. Nucl. Mater. 450, 225–236 (2014).

Del Giacco, M., Weisenburger, A. & Müller, G. Fretting of fuel cladding materials for Pb cooled fast reactors - Approach to long term prediction using fretting maps. Nucl. Eng. Des. 280, 697–703 (2014).

Zhang, J. & Li, N. Review of the studies on fundamental issues in LBE corrosion. J. Nucl. Mater. 373, 351–377 (2008).

Heinzel, A., Kondo, M. & Takahashi, M. Corrosion of steels with surface treatment and Al-alloying by GESA exposed in lead-bismuth. J. Nucl. Mater. 350, 264–270 (2006).

Weisenburger, A. et al. Long term corrosion on T91 and AISI1 316L steel in flowing lead alloy and corrosion protection barrier development: Experiments and models. J. Nucl. Mater. 415, 260–269 (2011).

Kumar, K., Kumar, S. & Gill, H. S. High-Temperature Oxidation Performance of HVOF and Plasma Sprayed Ni-20Cr, Ni-20Cr+TiC and Ni-20Cr+TiN coatings on T22 boiler steels. Surface Rev. Lett. 23, 122–132 (2025).

Kumar K., Kumar S. & Gill H. S. High-Temperature Erosion-Corrosion Performance of Plasma and High-Velocity Oxy-Fuel Sprayed TiC and TiN Enriched Ni-20Cr Coatings in an Actual Boiler Environment. J. Mater. Eng. Performance 34, 17900–17914 (2025).

Kumar, S. & Kumar, R. A Comprehensive Study on Additive Manufacturing Techniques, Machine Learning Integration, and Internet of Things-Driven Sustainability Opportunities. J. Mater. Eng. Perform. 34, 825–832 (2025).

Short, M. P. & Ballinger, R. G. A functionally graded composite for service in high-temperature lead- and lead-bismuth-cooled nuclear reactors - I: Design. Nucl. Technol. 177, 366–381 (2012).

Yang, J. et al. A novel AlCrFeMoTi high-entropy alloy coating with a high corrosion-resistance in lead-bismuth eutectic alloy. Corros. Sci. 4, 123–165 (2021).

Yang, J. et al. Effect of Au-ion irradiation on the surface morphology, microstructure and mechanical properties of amorphous AlCrFeMoTi HEA coating. Surf. Coat. Technol. 418, 127252–127263 (2021).

Yang, J. et al. Influence of Si addition on the microstructure, mechanical and lead-bismuth eutectic corrosion properties of an amorphous AlCrFeMoTiSix high-entropy alloy coating. Intermetallics 148, 107649 (2022).

Zhang, P. et al. A novel FeCrAlWx high entropy alloy coating for enhancing lead-bismuth eutectic corrosion resistance. J. Nucl. Mater. 589, 154844 (2024).

Deng, J. et al. Corrosion behavior of refractory TiNbZrMoV high-entropy alloy coating in static lead‑bismuth eutectic alloy: A novel design strategy of LBE corrosion-resistant coating? Surf. Coat. Technol. 448, 128884 (2022).

Qiu, X. W. & Liu, C. G. Microstructure and properties of Al2CrFeCoCuTiNix high-entropy alloys prepared by laser cladding. J. Alloy. Compd. 553, 216–220 (2013).

Liang, Q. et al. Enhancing the crystallization and optimizing the orientation of perovskite films via controlling nucleation dynamics. J. Mater. Chem. A 4, 223–232 (2015).

Han, U., Lattemann, M., Bohlmark, J., Ehiasarian, A. P. & Gudmundsson, J. T. Ionized physical vapor deposition (IPVD): A review of technology and applications. Thin Solid Films 513, 1–24 (2006).

Cai, Y., Chen, Y., Luo, Z., Gao, F. & Li, L. Manufacturing of FeCoCrNiCu x medium-entropy alloy coating using laser cladding technology. Mater. Des. 133, 91–108 (2017).

Jingbin, J. & Peijian, C. Microstructural characterization and corrosion behaviour of AlCoCrFeNiTix high-entropy alloy coatings fabricated by laser cladding. Surf. Coat. Technol. 361, 63–74 (2019).

Wang, W. et al. Enhancing corrosion resistance of T91 F/M steel in liquid lead-bismuth (LBE) by slurry FeAl coating. J. Nucl. Mater. 603, 155458 (2025).

Feng, S., Sun, X., Chen, G. & Chen, X. The lead-bismuth eutectic corrosion rate prediction and composition optimization of ferritic/martensitic steels by physics-guided neural network. Eng. Appl. Artif. Intell. 141, 109807 (2025).

Feng, S. et al. New insight of the enhanced oxidation resistance of T91 steel in 450 °C liquid lead-bismuth eutectic by adding Al and Si element. J. Mater. Sci. Technol. 204, 29–46 (2025).

Zhu, G. et al. Effect of Ti addition on corrosion behaviors of Fe-Ni-Cr-Al high entropy alloys exposed to static lead-bismuth eutectic at 550 °C. Corros. Sci. 236, 112286 (2024).

Zhou, T., Sun, X., Yu, Z. & Chen, X. A generalization ability-enhanced image recognition based multiaxial fatigue life prediction method for complex loading conditions. Eng. Fract. Mech. 295, 109802 (2024).

Zhou, M. et al. Insights into corrosion mechanism of FeCrAlY coating in oxygen-poor static and flowing LBE. Corros. Sci. 241, 112546 (2024).

Yin, X. et al. A high-entropy alloy nitride protective coating for fuel cladding in high temperature lead-bismuth eutectic alloy. J. Nucl. Mater. 568, 153888 (2022).

Cheng, W. et al. Computation of Binding Energy of MCS and GO-Grafted MCS with Waterborne Epoxy Resin Using Density Functional Theory Method: Investigating the Corrosion Resistance of the Composite Coatings. ACS Omega 44, 40374–40386 (2022).

Niederhoffer, T., Vanhoestenberghe, A. & Lancashire, H. T. Methods of poly(3,4)-ethylenedioxithiophene (PEDOT) electrodeposition on metal electrodes for neural stimulation and recording. J. Neural Eng. 20, 23156 (2023).

He, S. et al. Interpretable machine learning workflow for evaluation of the transformation temperatures of TiZrHfNiCoCu high entropy shape memory alloys. Mater. Des. 225, 111513 (2023).

Xu, P. et al. Machine Learning-Assisted Design of Yttria-Stabilized Zirconia Thermal Barrier Coatings with High Bonding Strength. ACS Omega 7, 21052–21061 (2022).

Li, J. et al. Accelerated discovery of high-strength aluminum alloys by machine learning. Commun. Mater. 1, 73 (2020).

Zhang, H., Fu, H., Zhu, S., Yong, W. & Xie, J. Machine learning assisted composition effective design for precipitation strengthened copper alloys. Acta Mater. 215, 117118 (2021).

Wu, Y. Q. & Yan, M. F. Plasticity characterization of the modified layer produced by plasma nitrocarburizing of nanocrystallized 18Ni maraging steel. Vacuum 86, 119–123 (2011).

Li, W., Liu, P. & Liaw, P. K. Microstructures and properties of high-entropy alloy films and coatings: a review. Mater. Res. Lett. 6, 199–229 (2018).

Zhang, W. et al. Preparation, structure, and properties of an AlCrMoNbZr high-entropy alloy coating for accident-tolerant fuel cladding. Surf. Coat. Technol. 347, 13–19 (2018).

Ma, Q. S. et al. Effect of Ti content on the microstructure and mechanical properties of TiAlSiN nanocomposite coatings. Int. J. Refract. Met. Hard Mater. 59, 114–120 (2016).

Dingding, L., Qingbo, L., Lizhong, J., Dong, M. & Yang, C. High-stable photonics-based frequency-quadrupled LFM signal generation for radar applications. In ProcSPIE (SPIE, 2021).

Xiaodi, L., Fucheng, L. & Yong, Y. “Softness” as the Structural Origin of Plasticity in Disordered Solids: A Quantitative Insight from Machine Learning. Sci. China Mater. 12, 123–136 (2018).

Stolpe, M., Kruzic, J. J. & Busch, R. Evolution of shear bands, free volume and hardness during cold rolling of a Zr-based bulk metallic glass. Acta Mater. 64, 231–240 (2014).

Zhou, Q. et al. Identifying the origin of strain rate sensitivity in a high entropy bulk metallic glass. Scr. Mater. 164, 121–125 (2019).

Ou, Y. X. et al. Wear and corrosion resistance of CrN/TiN superlattice coatings deposited by a combined deep oscillation magnetron sputtering and pulsed dc magnetron sputtering. Appl. Surf. Sci. 351, 332–343 (2015).

Zhao, H., Ni, Z. & Ye, F. Effect of carbon content on structure and properties of WCN coatings prepared by RF magnetron sputtering. Surf. Coat. Technol. 287, 129–137 (2016).

Leyland, A. & Matthews, A. On the significance of the H/E ratio in wear control: a nanocomposite coating approach to optimised tribological behaviour. Wear 246, 1–11 (2000).

Zhang, F., Yang, Z., Jiao, J., Liu, W. & Wu, W. The effects of high-speed rail development on regional equity in China. Transp. Res. Part A Policy Pract. 141, 180–202 (2020).

Yang, J. et al. A novel AlCrFeMoTi high-entropy alloy coating with a high corrosion-resistance in lead-bismuth eutectic alloy. Corros. Sci. 187, 109524 (2021).

Deng, J. G. et al. Corrosion behavior of refractory TiNbZrMoV high-entropy alloy coating in static lead-bismuth eutectic alloy: A novel design strategy of LBE corrosion-resistant coating? Surface Coatings Technol. 448, 128884 (2022).

Chen, Q. et al. Microstructure and high-temperature steam oxidation properties of thick Cr coatings prepared by magnetron sputtering for accident tolerant fuel claddings: The role of bias in the deposition process. Corrosion Sci. 165, 108378 (2020).

Chen, L.-T. et al. Microstructure, mechanical and anti-corrosion property evaluation of iron-based thin film metallic glasses. Surf. Coat. Technol. 260, 46–55 (2014).

Ma, M. et al. The role of Si on microstructure and high-temperature oxidation of CoCr 2 FeNb 0.5 Ni high-entropy alloys coating. Corros. Sci. 4, 123–136 (2021).

He, H. et al. Effects of deposition temperature on the microstructure, mechanical properties, high temperature corrosion and oxidation properties of AlCrNbTiZr high entropy alloy coatings. Int. J. Refract. Met. Hard Mater. 112, 106156 (2023).

Lyu, L. et al. Improved lead-bismuth eutectic corrosion resistance and mechanical properties of reactive gas pulse sputtered AlCrFeMoTi/(AlCrFeMoTi)N composite multilayered high-entropy alloy coatings. J. Nucl. Mater. 13, 123–136 (2022).

Yang, J., Zhao, K., Liang, J., Zhang, W. & Yang, J. Corrosion behavior of AlCrFeTiNb and AlCrFeTiNb/(AlCrFeTiNb)N coatings in flowing lead–bismuth eutectic alloy with saturated oxygen concentration at 550 °C. Nucl. Mater. Energy 36, 101499 (2023).

Zhao, S., Liu, C., Yang, J., Zhang, W. & Chang, H. Mechanical and High-temperature Corrosion Properties of AlTiCrNiTa High Entropy Alloy Coating Prepared by Magnetron Sputtering for Accident-tolerant Fuel Cladding. Surf. Coat. Technol. 417, 127228 (2021).

Paszke, A. et al. PyTorch: An Imperative Style, High-Performance Deep Learning Library. In Advances in Neural Information Processing Systems 32, Volume 11 of 20: 32nd Conference on Neural Information Processing Systems (NeurIPS, 2019).

Narita, S., Ueta, S. & Shimizu, T. Influence of Nitrogen and Carbon Contents on Quenched and Tempered Hardness and Corrosion Resistance of High Nitrogen Martensitic Stainless Steels. DENKI-SEIKO 79, 187–196 (2008).

Yuan, M. et al. Simultaneous enhancement of hardness and wear and corrosion resistance of high-entropy transition-metal nitride. J. Am. Ceramic Soc. 106, 1356–1368 (2023).

Zhang, L., Peng, H., Qin, Q., Fan, Q. & Bao, S. Effects of annealing on hardness and corrosion resistance of 60NiTi film deposited by magnetron sputtering. J. Alloys Compounds 746, 45–53 (2018).

Rao, Z. et al. Machine learning-enabled high-entropy alloy discovery. Science 378, 78–84 (2022).

Xu, X. et al. Design of super-hard high-entropy ceramics coatings via machine learning. Ceram. Int. 5, 123–136 (2022).

Zhao, D. Q., Pan, S. P., Zhang, Y., Liaw, P. K. & Qiao, J. W. Structure prediction in high-entropy alloys with machine learning. Appl. Phys. Lett. 118, 231904 (2021).

Acknowledgements

The authors gratefully acknowledge the financial support from the Natural Science Foundation of China (No. 52505156) and and thePostdoctoral Fellowship Program of CPSF (No. GZC20250397).

Author information

Authors and Affiliations

Contributions

Shaowu Feng: Methodology, Investigation, Formal analysis, Validation, Writing – original draft. Xingyue Sun: Conceptualization, Methodology, Supervision, Writing – review & editing. Weiwen Cao: Conceptualization, Methodology, Supervision, Writing – review & editing. Gang Chen: Methodology, Supervision, Writing – review & editing, Funding acquisition.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Feng, S., Sun, X., Cao, W. et al. Optimization of high-entropy alloy coating design using machine learning methods. npj Mater Degrad 9, 164 (2025). https://doi.org/10.1038/s41529-025-00709-0

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41529-025-00709-0