Abstract

A single pot, wet chemical route has been applied for the synthesis of polymer supported copper azide, CuN3, nanoparticles (CANP). The hybrid system was used as ‘catalyst-cum-reagent’ for the azide-alkyne cyclo-addition reaction to construct triazole molecules using substituted benzyl bromide and terminal alkyne. The electron donating group containing terminal alkyne produced 5-alkynyl 1,4-disubstituded triazole product whereas for alkyne molecule with terminal electron withdrawing group facilitate the formation of 1,4-disubstituted triazole molecule.

Similar content being viewed by others

Introduction

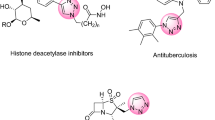

The copper catalyzed 1,3-dipolar cycloaddition of azides and terminal alkynes is considered to be the most protuberant reaction of the Click chemistry concept1 to construct 1,2,3-triazole moieties, widely applicable in pharmaceutical, combinatorial, and material chemistry2,3,4,5. Catalytic conversion of the same reaction using copper as catalyst leads to 1,4 substituted triazole as sole product6,7,8. Reaction between sodium, lithium, or magnesium acetylides with organic azides9 in presence of ruthenium catalyst10 have also been reported where 1,5-disubstituted 1,2,3-triazoles are the major products. Coinage metals, such as, silver11,12 and gold13 have also appeared as catalyst for the construction of 1,4 substituted triazole molecules. The azide-alkyne cycloaddition reaction between carbon nanotube functionalized azide containing polymer and alkyne molecule has been reported using copper acetate as an efficient catalyst14. A Cu(I)-N‐heterocyclic carbene framework has been applied for the azide-alkyne cycloaddition reaction and it was established that six‐membered NHC ligands showed superior performance for the preparation of 1,4‐disubstituted triazoles as compared with the five‐membered one15. A Cu(I)‐catalyzed three component (terminal alkynes, azides, and propargylic carbonate) reaction exhibited the formation of 1,3,5‐trisubstituted triazoles (5‐allenyl‐1,2,3‐triazoles) with a high yield16. An efficient one pot synthesis protocol has been reported for the copper-mediated azide-alkyne cycloaddition using alkenyl-triflate as a precursor17.

Though significant progresses have been made in azide-alkyne cyclo addition reactions but most of them are restricted to the construction of either 1,4 or 1,5-disubstituted-1,2,3-triazole moieties. Few information are also available for the specific synthesis of 1,4,5-trisubstituted 1,2,3-triazole moieties and with much scope to be explored yet. The assembling of 1,4,5-trisubstituted triazoles has been reported using Cu(CH3CN)4 PF6 as catalyst, substituted ethylene diamine as ligand in presence of molecular oxygen as oxidant and 4-methoxymorpholine N-oxide as co-oxidant18. Temperature controlled synthesis of bis-(1,2,3-triazole) and 5-alkynyl-1,2,3-triazole has also been reported from various alkyne and azide molecules19.

Last few years, we also have engaged in the search of effective catalysts for different organic transformations reactions20,21,22,23,24,25,26. In association with our ongoing research on the development of effective catalysts for the azide-alkyne cycloaddition reaction, a single pot approach was reported where in-situ catalyst generation and azide-alkyne cyclo product formation was discussed27. Cu(I)-polyaminobenzoic acid catalyzed azide-alkyne cycloaddition reaction28 and solvent-less microwave irradiation technique using polymer supported copper(I) composite for triazole formation reaction29 have been reported earlier. Role of photonic quantum dot (Cu2S) as catalyst30 and photonic effect of carbon nitride on the catalytically active Cu center31 for 1,2,3-triazole formation have also been reported recently by our group.

In this current communication, we have describe a step-wise route for the synthesis of copper azide nanoparticles (CANP) and applied this material as ‘catalyst cum reagent’ where Cu(I) was performed as a catalytic role and azide counterpart acted as nucleophilic role for azide-alkyne cyclo-addition reaction to construct triazole molecules.

Experimental

Synthesis of copper azide nanoparticles (CANP)

In a typical experiment, 0.093 g of aniline (10−2 mol/dm3) was diluted in 10 mL methanol in a conical flask. To this solution, 10 mL of aqueous CuSO4, 5H2O solution (10−2 mol/dm3) was added slowly under continuous stirring conditions. During the addition, the solution turned to green, while at the end, a green coloured precipitation was formed at the bottom of the conical flask. To the above precipitation, 5 mL aqueous solution of sodium azide (0.065 g) was added drop-wise and allowed to stir for another 2 h. A change in colour from light green to dark green was noticed. Little amount of the precipitated material was collected from the bottom of the conical flask and pipetted onto lacey, carbon-coated, nickel mesh grids for transmission electron microscopy (TEM) study, before and after the addition of sodium azide. The remaining portion of the compound was dried under vacuum at 60 °C and used as a catalyst for the title reaction.

Result and discussion

Mechanism for the formation of copper azide nanoparticles (CANP)

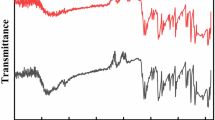

Metal salt of gold, silver and palladium mediated synthesis of polyaniline, from aniline monomer, involve the release of electrons during the reaction, where the metal salts act as an oxidizing agents. The released electrons reduce the metal ions with the formation of the corresponding nanoparticles and the oxidation of aniline forms polyaniline, act as a stabilizer for the particles32,33,34. In the current experiment, during the reaction between cupric sulphate and aniline evidenced the formation of Cu(I)-polyaniline, due to the partial reduction of Cu(II)27,28. Polyaniline have several amine and imine moieties which can act as a macro ligand35, that coordinate with the Cu(I) species. The Cu(I)-polyaniline subsequently forms polyaniline stabilized CuN3 nanoparticles by the addition of sodium azide. Figure 1 (A and B) display the TEM images of the organic–inorganic composite system before and after the addition of sodium azide, respectively. The selected area electron diffraction (SAED) image (Fig. 1, inset) indicates highly crystalline nature of CuN3-polyaniline system. Figure 1, insets, show the optical images of Cu(I)-polyaniline and CuN3-polyaniline hybrid system. The TEM image (Fig. 1B) shows the formation of copper-azide nanoparticles (dark spots) with the size distribution ranging from 5 to 12 nm.

Application of CANP for triazole synthesis

Initially, we had optimize the reaction condition and for the first set of reaction, 1.0 equivalent of each benzyl bromide (1a), 4-ethynyl-1-fluoro-2-methylbenzene (2e), CANP and tri-ethylamine were mixed together in methanol under stirring condition at 25 °C. The reaction was monitored by thin-layer chromatography technique and two distinguished spots, other than starting materials, were observed under UV-irradiation. After 3 h, the products were isolated and characterized by spectroscopic techniques. The isolated yield resulted 50% of the 1,4 disubstituted-triazole [1-benzyl-4-(4-fluoro-3-methylphenyl)-1H-1,2,3-triazole], 3ae′, and 30% of the 5-alkynyl-1,4-disubstituded-triazole [1-benzyl-4-(3-fluoro-4-methylphenyl)-5-((3-fluoro-4-methylphenyl)ethynyl)-1H-1,2,3-triazole], 3ae (supplementary information, Table S1). For a second set of reaction, 1.0 equivalent of benzyl bromide and CANP, 2.0 equivalent of alkyne and tri-ethylamine produced 3ae, with the yield of 85%, and no side product (3ae′) was obtained (Table S1, entry 7). Among the various solvents tested, methanol and ethanol showed identical efficiency and the rest of the study was performed using methanol as a sole solvent. The effect of various bases, such as, hydrazine hydrate, di-/tri-ethylamine, potassium carbonate and potassium hydroxide were tested for the reaction. The triethylamine showed the best performance and was applied for the rest of the studies.

To study the general applicability and the substrate scope of the above reaction, a series of benzyl bromide based molecules and terminal alkynes were investigated. The resultant compounds and the corresponding yield (in terms of %) are incorporated in Table 1. In the presence of CANP, benzyl bromide (1a), 2-bromo-benzyl bromide (1b) and 4-methyl-benzyl bromide (1c) reacted with phenylacetylene (2a) produced 5-alkenyl triazole products, such as, 1-benzyl-4-phenyl-5-(phenylethynyl)-1H-1,2,3-triazole (3aa), 1-(2-bromobenzyl)-4-phenyl-5-(phenylethynyl)-1H-1,2,3-triazole) (3ba) and 1-(4-methylbenzyl)-4-phenyl-5-(phenylethynyl)-1H-1,2,3-triazole (3ca), respectively. Under the above menttioned condotions, mono substituted aromatic tramninal alkyne, such as, 1-ethynyl-4-methylbenzene (2b) and 1-ethynyl-4-methoxybenzene (2c) successfully reacted with benzyl bromides (1a, 1b and 1c). The resultant products 3ab, 3bb, 3cb, 3ac and 3bc were formed in the range of 89–97% of yield. Disubstituted (o–p and m–p) aromatic terminal alkynes, 1-ethynyl-4-methoxy-2-methylbenzene (2d) and 4-ethynyl-1-fluoro-2-methylbenzene (2e), reacted with benzyl bromide (1a), 2-bromo-benzyl bromide (1b) and 4-methyl-benzyl bromide (1c) and produced 5-alkynyl-1, 4-disubstituded-triazole products, 3ad, 3bd, 3cd, 3ae, 3be and 3ce, respectively (Table 1). The single crystal structures of 1-benzyl-4-(4-methoxyphenyl)-5-((4-methoxyphenyl) ethynyl)-1H-1,2,3-triazole, 3ac, and 1-(2-bromobenzyl)-4-(3-fluoro-4-methylphenyl)-5-((3-fluoro-4-methylphenyl)ethynyl)-1H-1,2,3-triazole, 3be, are presented in Fig. 2, A and B, respectively. Ether linked terminal alkynes, [(prop-2-ynyloxy) methyl] benzene (2f) and 1-bromo-2-[(prop-2-ynyloxy) methyl] benzene (2g), have also responded on the title reaction with benzyl bromide (1a) or 2-bromo-benzyl bromide (1b) to produce 5-alkynyl-1,4-di-substituded triazole molecules such as, 1-benzyl-5-[3-(benzyloxy) prop-1-ynyl]-4-(benzyloxymethyl)-1H-1,2,3-triazole (3af), 5-[3-(benzyloxy) prop-1-ynyl]-4-(benzyloxymethyl)-1-(2-bromobenzyl)-1H-1,2,3-triazole, (3bf), 1-benzyl-4-[(2-bromobenzyloxy)methyl]-5-[3-(2-bromobenzyloxy)prop-1-ynyl]-1H-1,2,3triazole (3ag) and 1-(2-bromobenzyl)-4-[(2-bromobenzyloxy) methyl]-5-(3-(2-bromobenzyloxy) prop-1-ynyl)-1H-1,2,3-triazole (3bg), with the isolated yields ranging from 81–86%. Benzyl bromide based molecules (1a, 1b and 1c) formed 3ah, 3bh and 3ch with the isolated yield of 90, 93 and 96%, respectively, when reacted with 2-ethynyl-6-methoxynaphthalene (2h). Aliphatic terminal alkyne, hex-1-yne (2i), has also participated with 1a, 1b and 1c and resulted the expected products 1-benzyl-4-butyl-5-(hex-1-ynyl)-1H-1,2,3-triazole (3ai), 1-(2-bromobenzyl)-4-butyl-5-(hex-1-ynyl)-1H-1,2,3-triazole (3bi) and 4-butyl-5-(hex-1-ynyl)-1-(4-methylbenzyl)-1H-1,2,3-triazole (3ci) with the isolated yield of 87, 85 and 91%, respectively.

On the other hand, the reaction between terminal alkyne, attached with the electron withdrawing group, and benzyl bromide based molecules resulted 1, 4-disubstituted 1, 2, 3-triazole as the sole product (Table 2). Electron withdrawing group attached terminal alkyne, such as, 1-ethynyl-4-nitrobenzene (2j) when reacted separately with two equivalent of each benzyl bromide (1a) and 2-bromo-benzyl bromide (1b), in presence of CANP, only one equivalent of molecule has taken part in the reaction and produced 1-benzyl-4-(4-nitrophenyl)-1H-1,2,3-triazole (4aj) and 1-(2-bromobenzyl)-4-(4-nitrophenyl)-1H-1,2,3-triazole (4bj), as the sole product with 83 and 87% of isolated yield, respectively. In a similar fashion, 1-ethynylcyclohexanol (2k) and prop-2-yn-1-ol (2l) also reacted individually with 1a and 1b and formed 1, 4-disubstituted 1,2,3-triazole (4ak, 4bk, 4al and 4bl) as end product.

We also have performed the following experiments to find out the exclusivity of CANP for the title reaction. A Cu(I)-supported polyaniline (Cu-PANI), as reported earlier27, has been prepared and applied in the present reaction system under optimized condition, where, we observed only alkyne 2b and 2c yielded 5-alkynyl 1,4-disubstituded triazoles products (3) in minute amount, 4% and 7%, respectively, and 1,4-disubstituted triazole molecule (3′) formed as the major product (Table 3).

The mechanism of the above observations can be explained as follows. Initially, benzyl bromide molecule followed an aromatic nucleophilic substitution reaction and formed copper-organic azide complex, which further rearranged to its canonical conjugate form (Fig. 3, intermediate A). In presence of triethylamine, a facile deprotonating of the terminal hydrogen of the alkyne molecule allows to the formation of Cu-acetylidine complex that subsequently rearranged and produced metallacycle (Fig. 3, intermediate B). In the next step, the formation of 1,4-disubstituted triazole unit attached with copper center at 5-position (Fig. 3, intermediate C). In case of electron donating group (EDG) containing terminal alkyne, further deprotonation resulted to second Cu-acetylidine complex D (Fig. 3), which finally produced 5-alkenyl 1,4-disubstituted triazole, as an end product. On the other hand, for alkyne molecule with terminal electron withdrawing group (EWG), a strong rate limiting oxidative addition facilitate the formation of 1,4-disubstituted triazole molecule.

In all the above reactions, the ‘reagent’ (azide) counterpart of the ‘catalyst-cum-reagent’ system (CANP) was drained out to form the products. The recovered catalyst (RC), which is left with the copper component, was applied for the preparation of triazole glycoside, where the reaction between sugar azide and terminal alkyne formed the 1, 4-disubstituted triazole. Various di- and mono-substituted aromatic terminal alkynes, such as, 1-ethynyl-4-methoxy-2-methylbenzene (2d), 4-ethynyl-1-fluoro-2-methylbenzene (2e) and 1-ethynyl-4-nitrobenzene (2j) reacted with sugar azide molecules [1-azido-2,3,4,6-tetra-o-acetyl-β-D-glucopyranose (5a) and 1-azido-2,3,4,6-tetra-o-acetyl-β-D-galactopyranose (5b)] and formed 1, 4 disubstituted triazole molecules (6ad, 6bd, 6ae, 6be, 6aj and 6bj), within the range of 73–90% of product yield (Table 4).

In this communication, a facile route was adopted for the preparation of polyaniline stabilized copper-azide nanoparticle. The copper azide nanoparticle was performed as ‘catalyst-cum-reagent’ for synthesizing the triazole molecules through azide-alkyne cyclo-addition reaction using substituted benzyl bromide and terminal alkyne molecules, where copper was performed as a role of catalyst for the cyclo-addition reaction and azide was the source of triazole unit. The alkyne with electron donating group was produced 5-alkynyl 1,4-disubstituded triazoles as the sole product, whereas, alkyne molecule with terminal electron withdrawing group facilitate the formation of 1,4-disubstituted triazole molecule. The recovered catalyst (without azide counterpart) showed the catalytic performance for the reaction between sugar azide and terminal alkyne with the formation of triazole glycosides.

Methods

General procedure for the click reaction

In a 25 mL round bottom flask, substituted benzyl bromide 1 (1.0 equivalent), terminal alkyne 2 (2.0 equivalent or 1.0 equivalent for EWG attached alkyne), were mixed in 4 mL of solvent (methanol). To this reaction mixture, CANP (200 mg, 1.0 equivalent) and Et3N (240 µL, 2.0 equivalent or 140 µL, 1.0 equivalent for EWG attached alkyne) was added and allowed to stir for 3 h. The reaction mixture was monitored using a thin layer chromatography technique. After complete disappearance of starting materials, a previously reported technique23 was followed to purify the the triazole products.

General procedure for click reaction with recovered catalyst

In a 25 mL round bottom flask, sugar azide 5 (1 equivalent), terminal alkyne 2 (1 equivalent), were charged in 4 mL methanol. To this reaction mixture the dried recovered catalyst (10 mg) and Et3N (1 equivalent) was added and allowed to stir for 3 h. The reaction mixture was monitored using thin layer chromatography technique. After completion, the reaction mixture was filtered and dried under residue pressure and followed the similar procedure as above.

Single crystal analysis

Computing details

Data collection: APEX2 2014-11; cell refinement: SAINT v8.38A; data reduction: SAINT v8.38A; program used to solve structure: SHELXT 2014/5; program used to refine structure: SHELXL 2018/3; molecular graphics: Olex2; software used to prepare material for publication: Olex2, PLATON.

Crystal Data: 1-benzyl-4-(4-methoxyphenyl)-5-[(4-methoxyphenyl) ethynyl]-1H-1,2,3-triazole, 3ac, C25H21N3 (M = 363.45 g/mol): monoclinic space group P21/c (no. 14), a = 12.7083(16) Å, b = 5.5633(7) Å, c = 27.879(4) Å, V = 1934.4(4) Å3, Z = 4, T = 100.03 K, μ(MoKα) = 0.074 mm-1, Dcalc = 1.248 g/cm3, 39,612 reflections measured (2.412 ≤ Θ ≤ 28.565°), 3849 unique (Rint = 0.0699, Rsigma = 0.0462) which were used in all calculations. The final R1 was 0.0499 (I > 2σ (I)) and wR2 was 0.1323 (all data).

1-(2-Bromobenzyl)-4-(3-fluoro-4-methylphenyl)-5-[(3-fluoro-4-methylphenyl) ethynyl]-1H-1,2,3-triazole, 3be, C25H18N3BrF2 (M = 478.33 g/mol): triclinic space group P\(\stackrel{-}{1}\) (no. 2), a = 7.4264(6) Å, b = 13.0510(12) Å, c = 21.726(2) Å, V = 2075.3(3) Å3, Z = 4, T = 99.96 K, μ(MoKα) = 2.016 mm-1, Dcalc = 1.531 g/cm3, 62,912 reflections measured (2.412 ≤ Θ ≤ 28.565°), 10,501 unique (Rint = 0.0497, Rsigma = 0.0345) which were used in all calculations. The final R1 was 0.0349 (I > 2σ (I)) and wR2 was 0.0942 (all data).

References

Kolb, H. C., Finn, M. G. & Sharpless, K. B. Click chemistry: Diverse chemical function from a few good reactions. Angew. Chem. Int. Ed. 40, 2004–2021 (2001).

Holub, J. M. & Kirshenbaum, K. Tricks with clicks: Modification of peptidomimetic oligomers via copper-catalyzed azide-alkyne [3+2] cycloaddition. Chem. Soc. Rev. 39, 1325–1337 (2010).

Meldal, M. & Tornoe, C. W. Cu-catalyzed azide-alkyne cycloaddition. Chem. Rev. 108, 2952–3015 (2008).

Moorhouse, A. D. & Moses, J. E. Click chemistry and medicinal chemistry: A case of “cyclo-addiction”. ChemMedChem 3, 715–723 (2008).

Xi, W. X., Scott, T. F., Kloxin, C. J. & Bowman, C. N. Click chemistry in materials science. Adv. Funct. Mater. 24, 2572–2590 (2014).

Huisgen, R. 1,3-Dipolar cycloadditions. Past and future. Angew. Chem. Int. Ed. 2, 565–598 (1963).

Rostovtsev, V. V., Green, L. G., Fokin, V. V. & Sharpless, K. B. A stepwise huisgen cycloaddition process: Copper(I)-catalyzed regioselective “ligation” of azides and terminal alkynes. Angew. Chem. Int. Ed. 41, 2596–2599 (2002).

Tornoe, C. W., Christensen, C. & Meldal, M. Peptidotriazoles on solid phase: [1,2,3]-triazoles by regiospecific copper(I)-catalyzed 1,3-dipolar cycloadditions of terminal alkynes to azides. J. Org. Chem. 67, 3057–3064 (2002).

Krasinski, A., Fokin, V. V. & Sharpless, K. B. Direct synthesis of 1,5-disubstituted-4-magnesio-1,2,3-triazoles, revisited. Org. Lett. 6, 1237–1240 (2004).

Boren, B. C. et al. Ruthenium-catalyzed azide-alkyne cycloaddition: Scope and mechanism. J. Am. Chem. Soc. 130, 8923–8930 (2008).

Ferretti, A. M., Ponti, A. & Molteni, G. Silver(I) oxide nanoparticles as a catalyst in the azide-alkyne cycloaddition. Tetrahedron Lett. 56, 5727–5730 (2015).

McNulty, J. & Keskar, K. Discovery of a robust and efficient homogeneous silver(I) catalyst for the cycloaddition of azides onto terminal alkynes. Eur. J. Org. Chem. 2012, 5462–5470 (2012).

Boominathan, M. et al. Nanoporous titania-supported gold nanoparticle-catalyzed green synthesis of 1,2,3-triazoles in aqueous medium. ACS Sustain. Chem. Eng. 1, 1405–1411 (2013).

Fong, D., Andrews, G. & Adronov, A. Functionalization of polyfluorene-wrapped carbon nanotubes via copper-mediated azide-alkyne cycloaddition. Polym. Chem. 9, 2873–2879 (2018).

Sebest, F. et al. Ring-expanded N-heterocyclic carbenes for copper-mediated azide-alkyne click cycloaddition reactions. ChemCatChem 10, 2041–2045 (2018).

Wu, F., Zhou, W., Chen, K., Chen, W. & Liu, M. Copper mediated three-component reactions of alkynes, azides, and propargylic carbonates: Synthesis of 5-allenyl-1,2,3-triazoles. Adv. Synth. Catal. 360, 2435–2439 (2018).

Chen, Y., Liu, L., Wu, D., He, Y. & Li, A. A one-pot protocol for copper-mediated azide-alkyne cycloaddition using alkenyl triflate precursors. Chin. Chem. Lett. 30, 269–270 (2019).

Gerard, B., Ryan, J., Beeler, A. B. & Porco, J. A. Synthesis of 1,4,5-trisubstituted-1,2,3-triazoles by copper-catalyzed cycloaddition-coupling of azides and terminal alkynes. Tetrahedron 62, 6405–6411 (2006).

Li, L. J. et al. Controllable synthesis of bis(1,2,3-triazole)s and 5-alkynyl-triazoles via temperature effect on copper-catalyzed huisgen cycloaddition. Tetrahedron 69, 9939–9946 (2013).

Islam, R. U. et al. Conjugated polymer stabilized palladium nanoparticles as a versatile catalyst for suzuki cross-coupling reactions for both aryl and heteroaryl bromide systems. Catal. Sci. Technol. 1, 308–315 (2011).

Islam, R. U. et al. Palladium-poly (3-aminoquinoline) hollow-sphere composite: Application in sonogashira coupling reactions. ChemCatChem 5, 2453–2461 (2013).

Mahato, S. K. et al. Polymer-stabilized palladium nanoparticles for the chemoselective transfer hydrogenation of alpha, b-unsaturated carbonyls: Single-step bottom-up approach. ChemCatChem 6, 1419–1426 (2014).

Taher, A., Nandi, D., Choudhary, M. & Mallick, K. Suzuki coupling reaction in the presence of polymer immobilized palladium nanoparticles: A heterogeneous catalytic pathway. New J. Chem. 39, 5589–5596 (2015).

Nandi, D., Siwal, S., Choudhary, M. & Mallick, K. Carbon nitride supported palladium nanoparticles: An active system for the reduction of aromatic nitro-compounds. Appl. Catal. A Gen. 523, 31–38 (2016).

Nandi, D., Siwal, S. & Mallick, K. A carbon nitride supported copper nanoparticle composite: A heterogeneous catalyst for the n-arylation of hetero-aromatic compounds. New J. Chem. 41, 3082–3088 (2017).

Nandi, D., Siwal, S. S. & Mallick, K. Mono arylation of imidazo[1,2-a]pyridine and 1,2-dimethyl imidazole: Application of carbon nitride supported palladium catalyst. ChemistrySelect 2, 1747–1752 (2017).

Islam, R. U. et al. Polymer immobilized Cu(I) formation and azide-alkyne cycloaddition: A one pot reaction. Sci. Rep. 5, 9632 (2015).

Islam, R. et al. A polymer supported Cu(I) catalyst for the ‘click reaction’ in aqueous media. Dalton Trans. 44, 1341–1349 (2015).

Taher, A. et al. Microwave assisted azide-alkyne cycloaddition reaction using polymer supported Cu(I) as a catalytic species: A solvent-less approach. RSC Adv. 5, 47275–47283 (2015).

Nandi, D. et al. Light effect on click reaction: Role of photonic quantum dot catalyst. Sci. Rep. 6, 33025 (2016).

Nandi, D. et al. Carbon nitride supported copper nanoparticles: Light-induced electronic effect of the support for triazole synthesis. R. Soc. Open Sci. 3, 160580 (2016).

Mallick, K., Witcomb, M., Dinsmore, A. & Scurrell, M. Polymerization of aniline by auric acid: Formation of gold decorated polyaniline nanoballs. Macromol. Rapid Commun. 26, 232–235 (2005).

Choudhary, M., Siwal, S., Islam, R., Witcomb, M. & Mallick, K. Polymer stabilized silver nanoparticle: An efficient catalyst for proton-coupled electron transfer reaction and the electrochemical recognition of biomolecule. Chem. Phys. Lett. 608, 145–151 (2014).

Mallick, K., Witcomb, M., Dinsmore, A. & Scurrell, M. Fabrication of a metal nanoparticles and polymer nanofibers composite material by an in-situ chemical synthetic route. Langmuir 21, 7964–7967 (2005).

Likhar, P. R. et al. Highly efficient and reusable polyaniline-supported palladium catalysts for open-air oxidative heck reactions under base- and ligand-free conditions. Adv. Synth. Catal. 350, 1968–1974 (2008).

Acknowledgements

This study was supported by the Faculty of Science and the Global Excellence and Stature (GES) program, University of Johannesburg.

Author information

Authors and Affiliations

Contributions

D.K.N. designed the experiments and wrote the manuscript. V.K.P. and S.K.G. involved with the spectroscopic and microscopic characterization of the materials. C.A. involved with the single crystal analysis of the samples. K.M. directed the study, supervised the project and wrote the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Nandi, D., Perla, V.K., Ghosh, S.K. et al. Copper-azide nanoparticle: a ‘catalyst-cum-reagent’ for the designing of 5-alkynyl 1,4-disubstituted triazoles. Sci Rep 10, 16720 (2020). https://doi.org/10.1038/s41598-020-74018-8

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-020-74018-8

This article is cited by

-

A review on copper-based nanoparticles as a catalyst: synthesis and applications in coupling reactions

Journal of Materials Science (2024)